-

Posts

128 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Matsudo, Chiba, Japan

Recent Profile Visitors

-

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

fake johnbull reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

fake johnbull reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

fake johnbull reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

fake johnbull reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

fake johnbull reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

fake johnbull reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

fake johnbull reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

fake johnbull reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

fake johnbull reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

fake johnbull reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

fake johnbull reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

fake johnbull reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

fake johnbull reacted to a post in a topic:

Sovereign of the Seas by 72Nova - Airfix - PLASTIC

-

Mr Whippy reacted to a post in a topic:

HMS Bellerophon 1786 by fake johnbull - Amati/Victory Models - 1/72

Mr Whippy reacted to a post in a topic:

HMS Bellerophon 1786 by fake johnbull - Amati/Victory Models - 1/72

-

Massimo59 reacted to a post in a topic:

HMS Bellerophon 1786 by fake johnbull - Amati/Victory Models - 1/72

Massimo59 reacted to a post in a topic:

HMS Bellerophon 1786 by fake johnbull - Amati/Victory Models - 1/72

-

Massimo59 reacted to a post in a topic:

HMS Bellerophon 1786 by fake johnbull - Amati/Victory Models - 1/72

Massimo59 reacted to a post in a topic:

HMS Bellerophon 1786 by fake johnbull - Amati/Victory Models - 1/72

-

Jaager, Gary and Mike, Thank you for your useful discussion while I was sleeping and going to work. I re-recognized the risk of referring to surviving preserved ship. Gary, Thank you for detailed explanation of processes of restoring Victory to Trafalgar appearance. I’ve recognized Wyllie only as painter of Victory under restoration and Laughton only as author of “Old Ships Figureheads and Sterns”. It is great pressure for me to learn theses facts I didn’t know. Thanks again all members on discussion. Kindest regards, Mitsuaki

-

Jaager, Firstly I'm sorry if my term "round stern" mislead you. You maybe refer to sterns of ships like Gannet or ironclad Achilles. Gannet photo by myself Achilles from NMM (https://www.rmg.co.uk/collections/objects/rmgc-object-66902) I I intended to refer to round stern introduced by Robert Seppings but unpopular amongst officers as ugly and uncomfortable. Queen Charlotte from NMM (https://www.rmg.co.uk/collections/objects/rmgc-object-68226) My appology again. BTW, your mentioning on Leda class frigates reminds me of two survivors amongst them. Trincomalee from wikipedia (https://commons.wikimedia.org/wiki/File:H.M.S._Trincomalee,_Hartlepool_Maritime_Experience_-_geograph.org.uk_-_1604022.jpg) Unicorn from wikipedia (https://commons.wikimedia.org/wiki/File:HM_Frigate_Unicorn,_from_the_stern_-_geograph.org.uk_-_1316939.jpg) Unicorn has upper cabin as hulk and Trincomalee also once had upper cabin in her training ship era, so there would be some changes from their original appearance. But variations of stern shape in one class are shown in them and we are very fortunate to have these two existing examples. Kindest regards, Mitsuaki

-

Jaager, Thank you for your explanation. I don’t know if this is suitable for example of anachronism, we often see mid-18th century French ship with tricolor flag or 17th century English ship with Union flag containing St. Patrick Red X Cross. Also I don’t know if this is suitable for example of sentiment to old days, elliptical stern would be one of revival of old stern appearance against unpopular round stern. Kindest regards, Mitsuaki

-

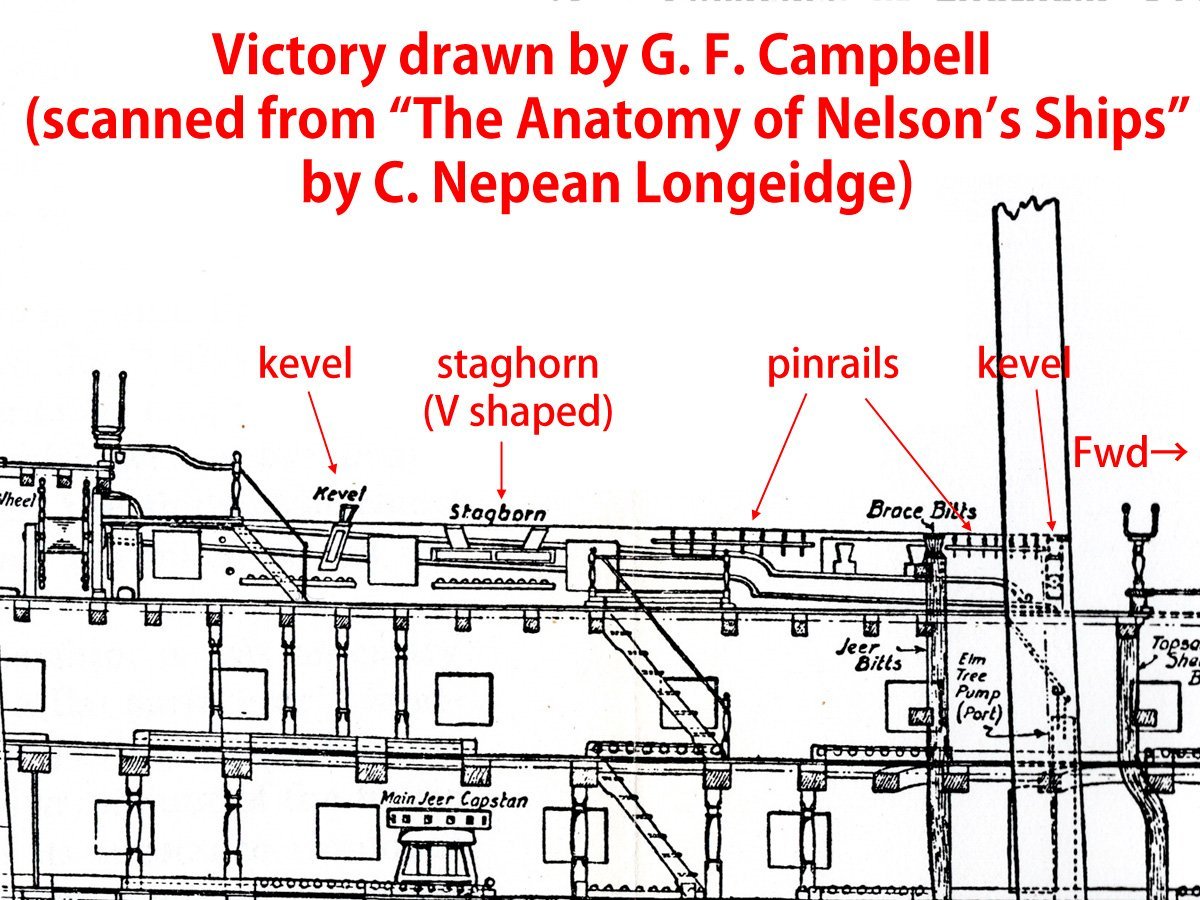

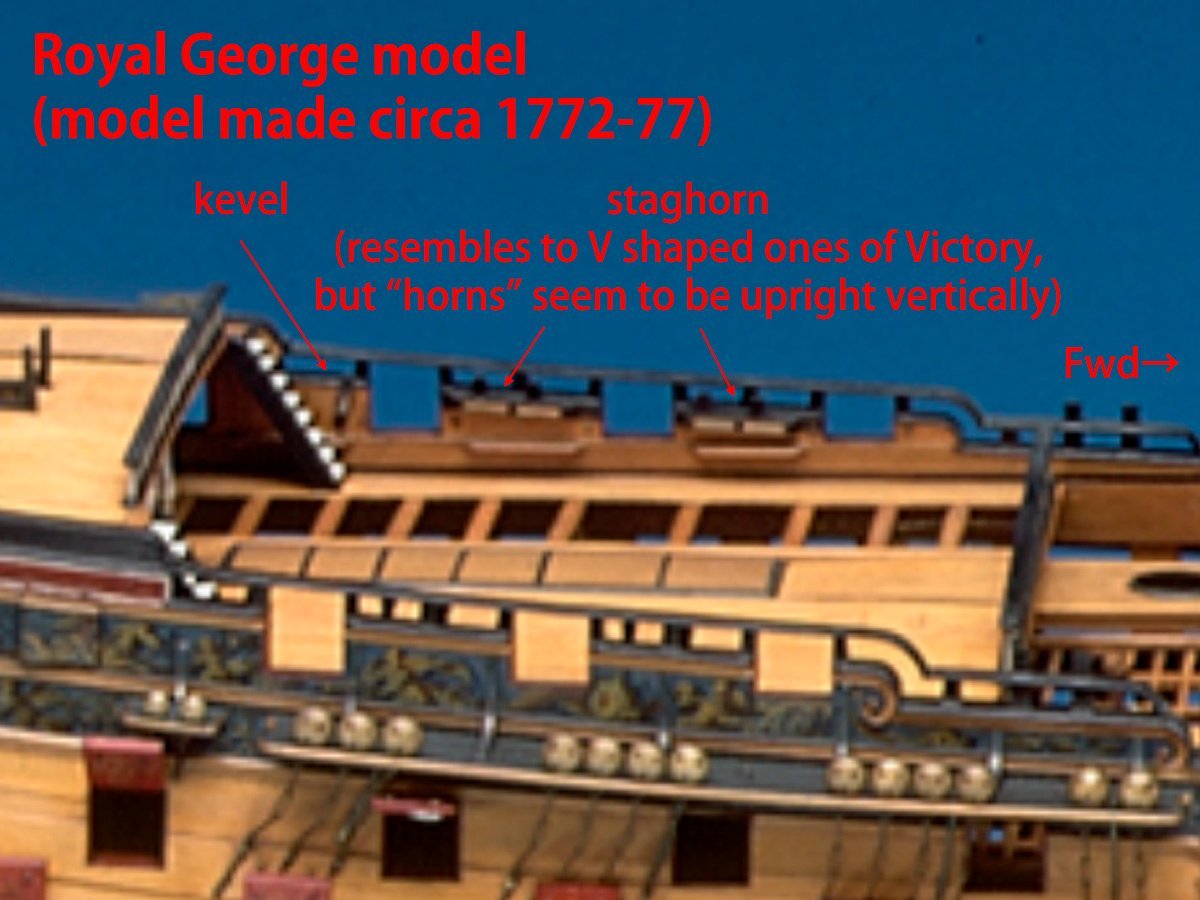

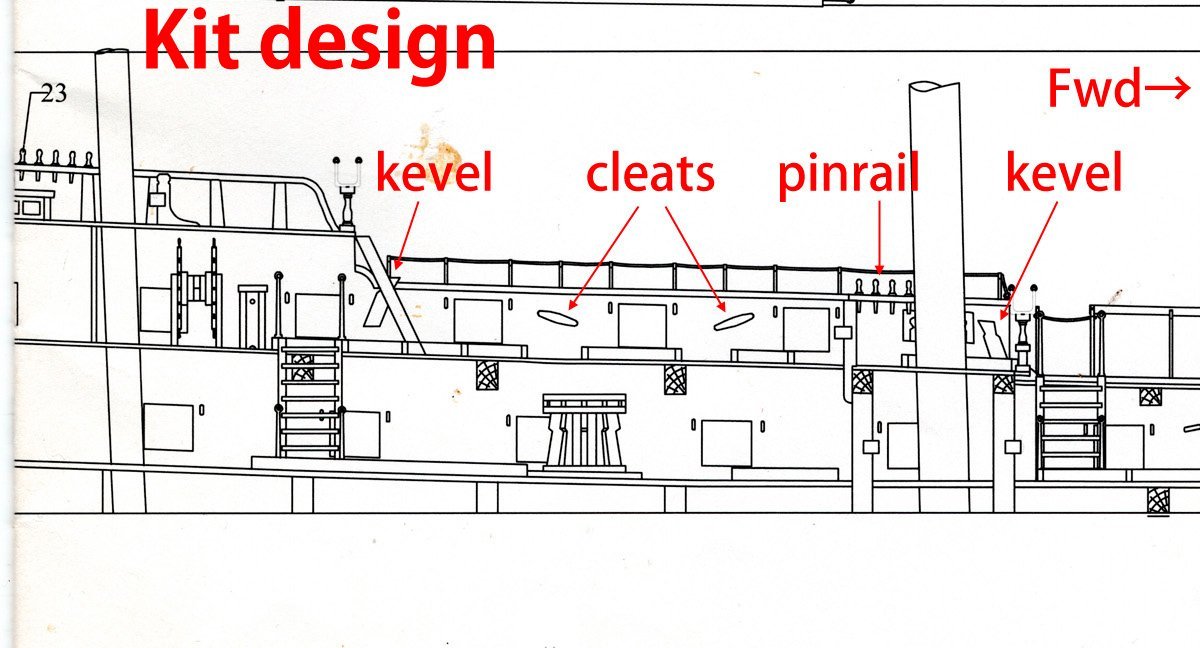

jaager, Allan, Gregory and Mike, Thank you for your reply. I agree these fittings are subjects of changes by preference of Captain, Sailing Master or boatswain. jaager suggested the importance of “avoid anachronism“. In this sense, I believe U shaped staghorns had became old-fashioned till Trafalgar days. (I’m sorry if I misunderstand jaager’s intention.) jaager and Allan, Pinrails are kit laser-cut parts. Maybe large holes are results of belaying pins from Amaty’s stock parts. I agree finer pins and holes are much better. Gregory, I agree that there is a possibility of difference of angles are result of incorrect repair of later days. Kindist regards, Mitsuaki

-

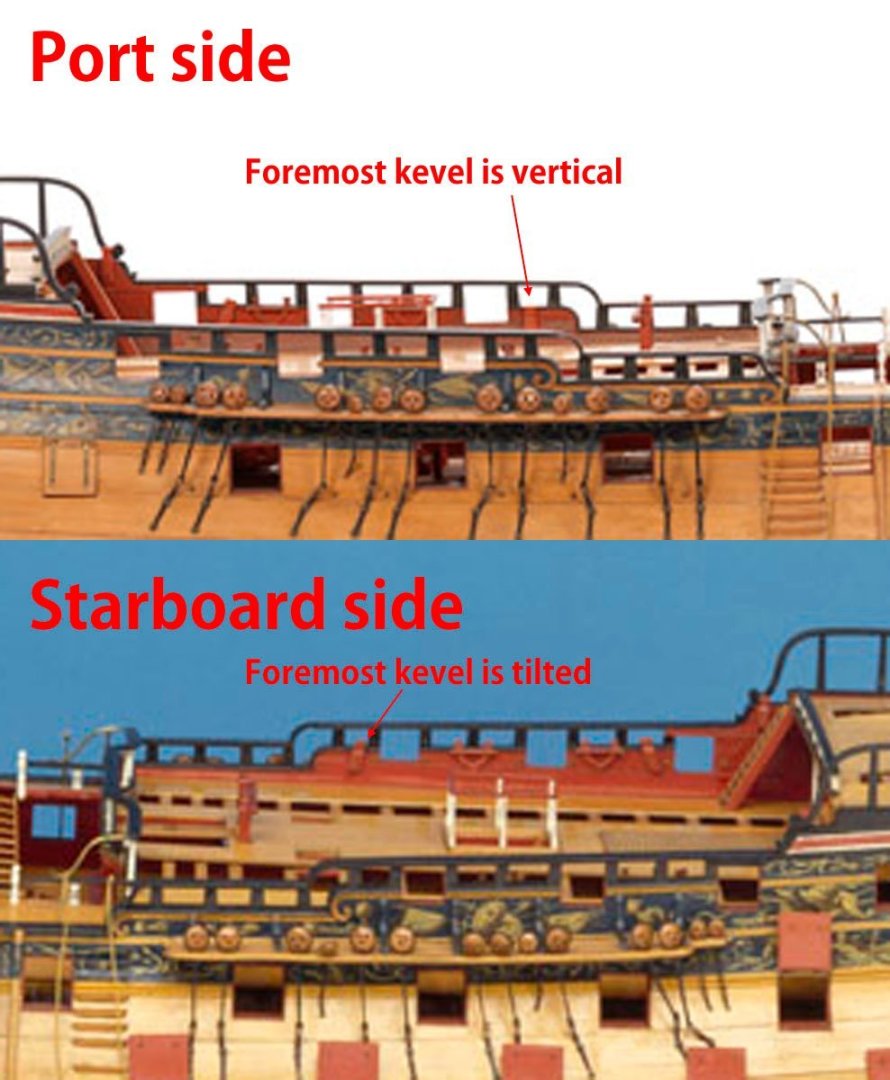

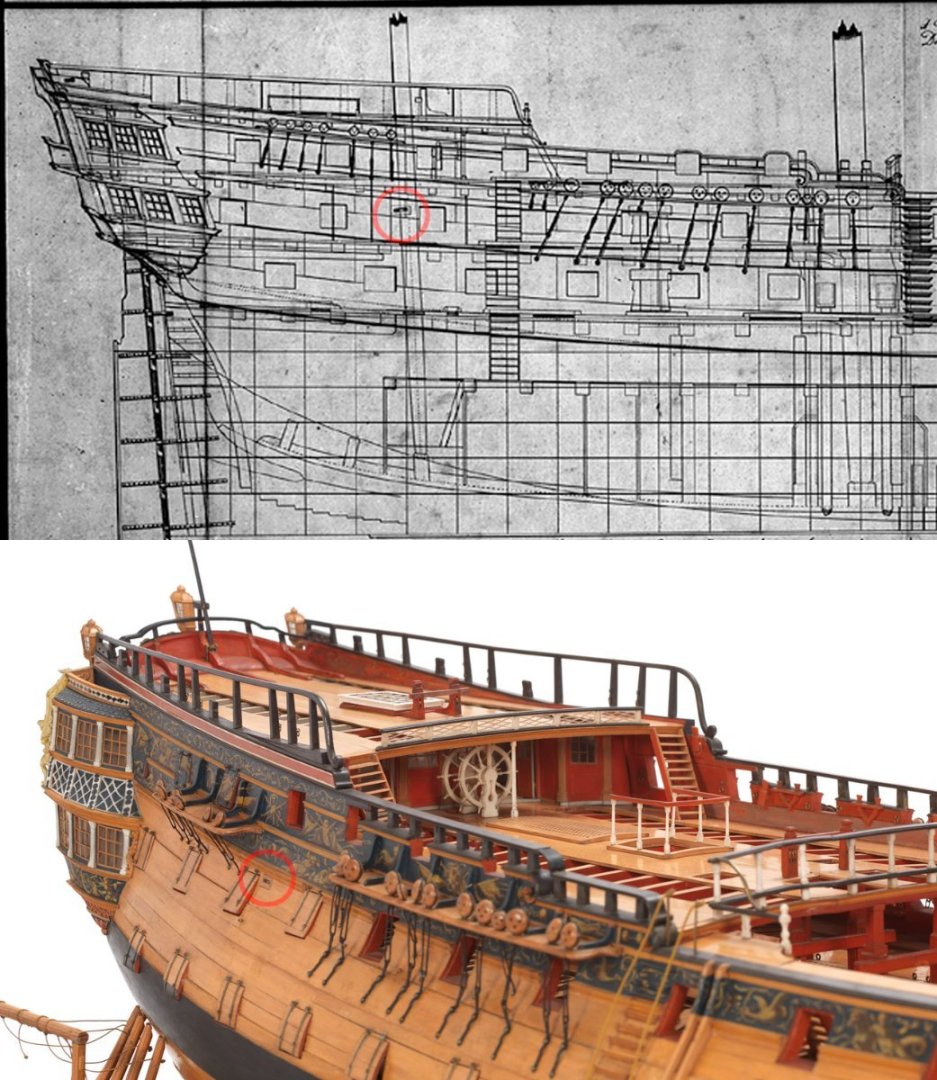

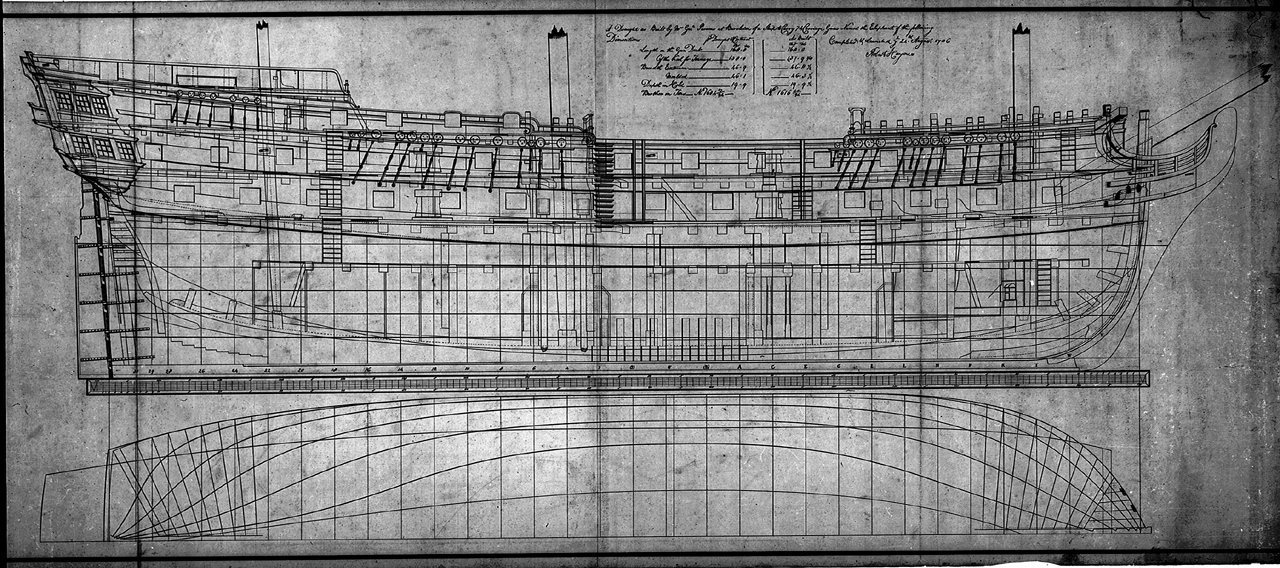

After some consideration, I've determined to adopt mixture of (or compromise between) Bellona coppered model and Victory. Three kevels are referred to Bellona coppered model and staghorn and pinrails are referred to Victory. I only hope my interpretation is not far from original😅 Of course this is only my assumption and any suggestion or opinion from other aspect are welcome. BTW. I noticed some interesting (or annoying) fact while researching belaying positions of this era. 1. Quarterdeck gunports of Bellona coppered model are positioned aft than plan shows. This difference of gunports positions also gave influence to deadeye positions of main channel. I don't know precise reason why, but I assume that this model was made for examination of new gunport arrangement including Carronades as well as promotion of coppering to the King. 2. The angle of foremost kevels of quarterdeck of Bellona coppered model are different from port to starboard. Port one is vertical and starboard one tilted to aft. I have no idea the reason why, but if main lower lifts are belayed here, vertical ones seems to be more natural. 3. Main course sheet sheave-hole position are defferent between Bellona copperd model and Elephant plan. While that of Bellona model is positioned forward of the third gunport to last, that of Elephant plan is aft of the third gunport to last. I once wrote identical plan maybe used for construction of Bellerophon, but I noticed that this sheave-hole position is somewhat unnatural considering sheet lead to this position is interfering gunnery. Again I have no idea why, but there would be some possibility that draughtsman who wasn't familiar with rigging draw sheave-hole to this positon. Kindest regards,

-

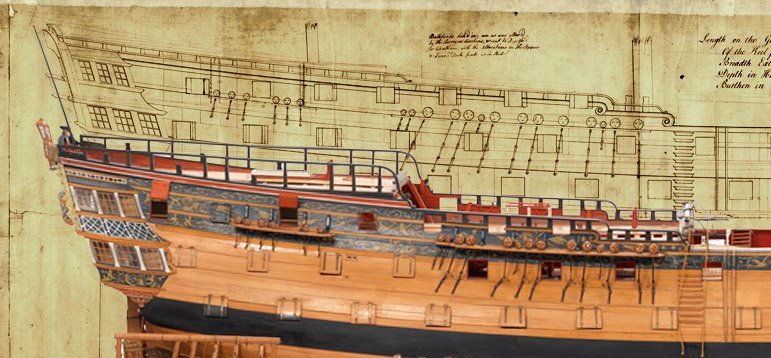

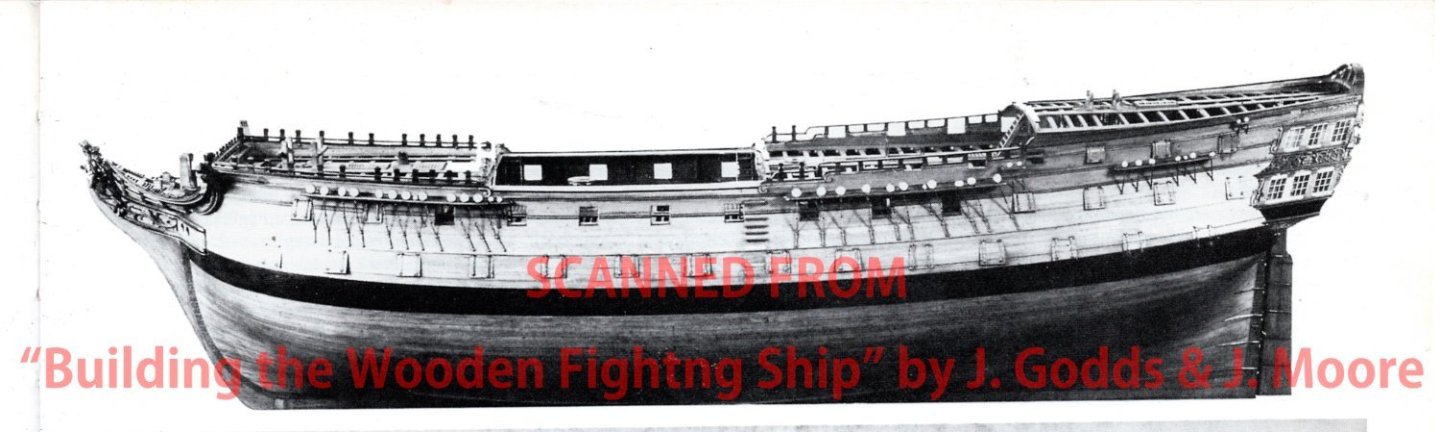

Allan, thank you for your suggestion. Hercules or Thunderer model is important and beautiful one and also appeared on jacket cover of Lees's "Masting and Rigging". But I gave up to refer this model because of reasons below. 1. Masting and rigging of this model is modern addition. Of course, rigging of this model had might been done by expert of the museum, so it is thought to be almost accurate. Image below is scanned from "Building the Wooden Fighting Ship" by J. Dodds and J. Moore, and I believe this is same model before addition of rigging. But this photo seems to be having no sheave-hole on side as well as chestree or fenders. Photos of this model after addition of rigging are showing sheave-holes for main course tack and fore course sheet, but any kind of hole for main course sheet isn't added. Instead main course sheet is lead through gun port under main channel, but I think this is expedient way to add main course sheet. 2. Photo of above seems to be having no belaying points on inside of quarterdeck bulwark. Photos of members only page of this model is also suggest it. https://modelshipworld.com/gallery/image/9197-dsc01392/?browse=1 But anyhow, this model can be safely said as one of masterpiece of contemporary works and many finding can be found. Kindest regards,

-

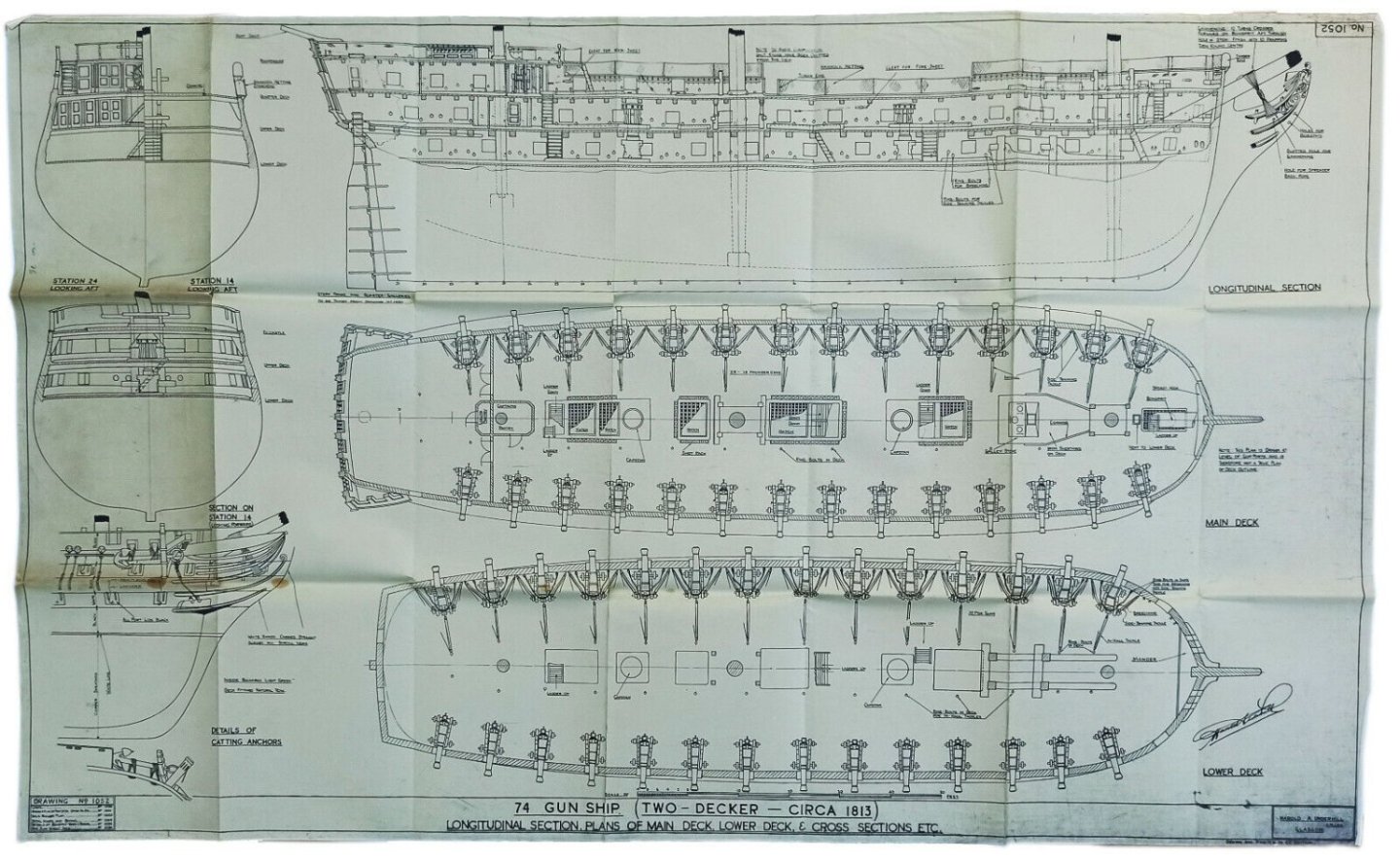

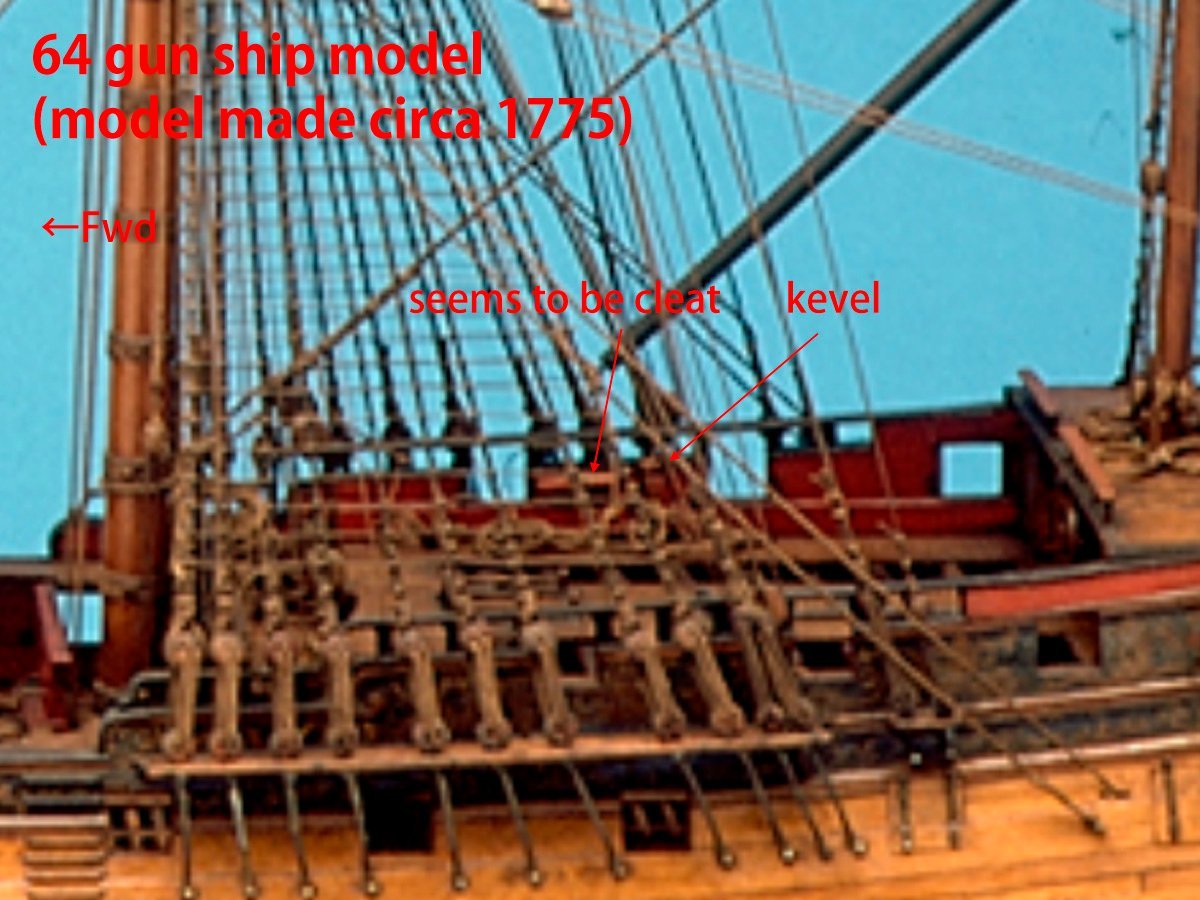

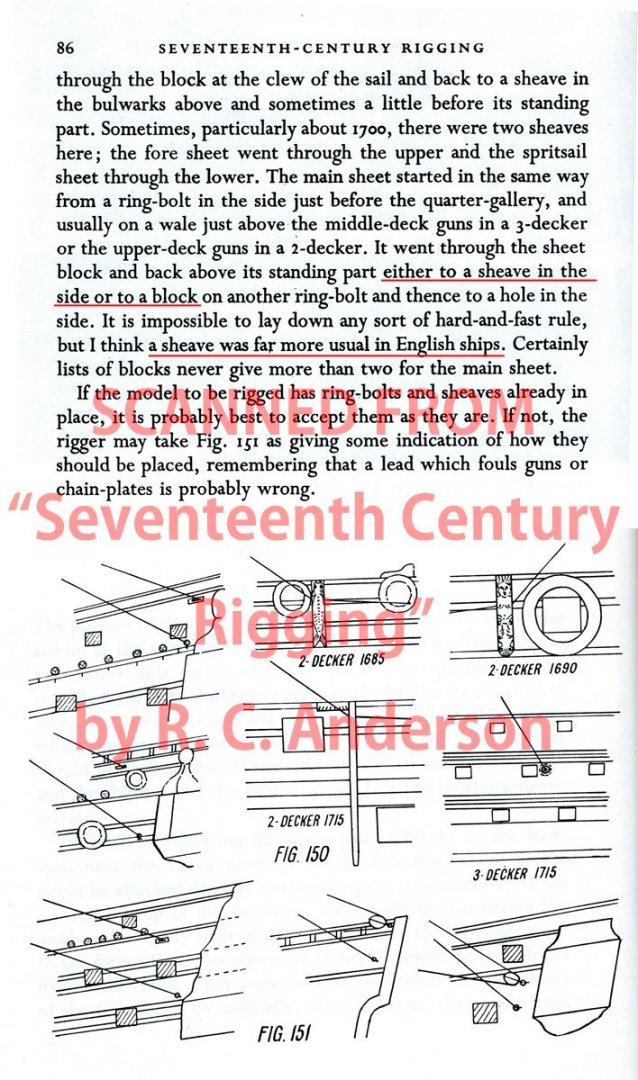

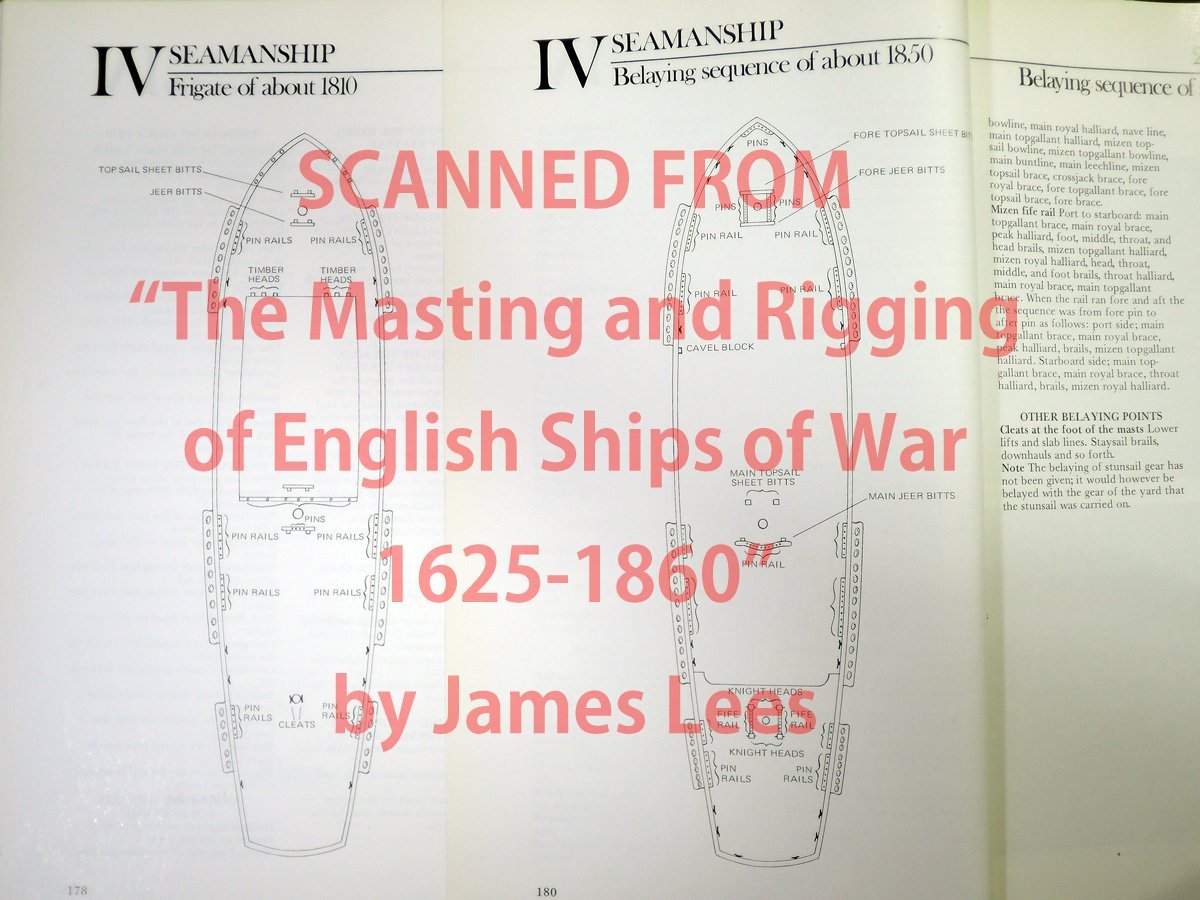

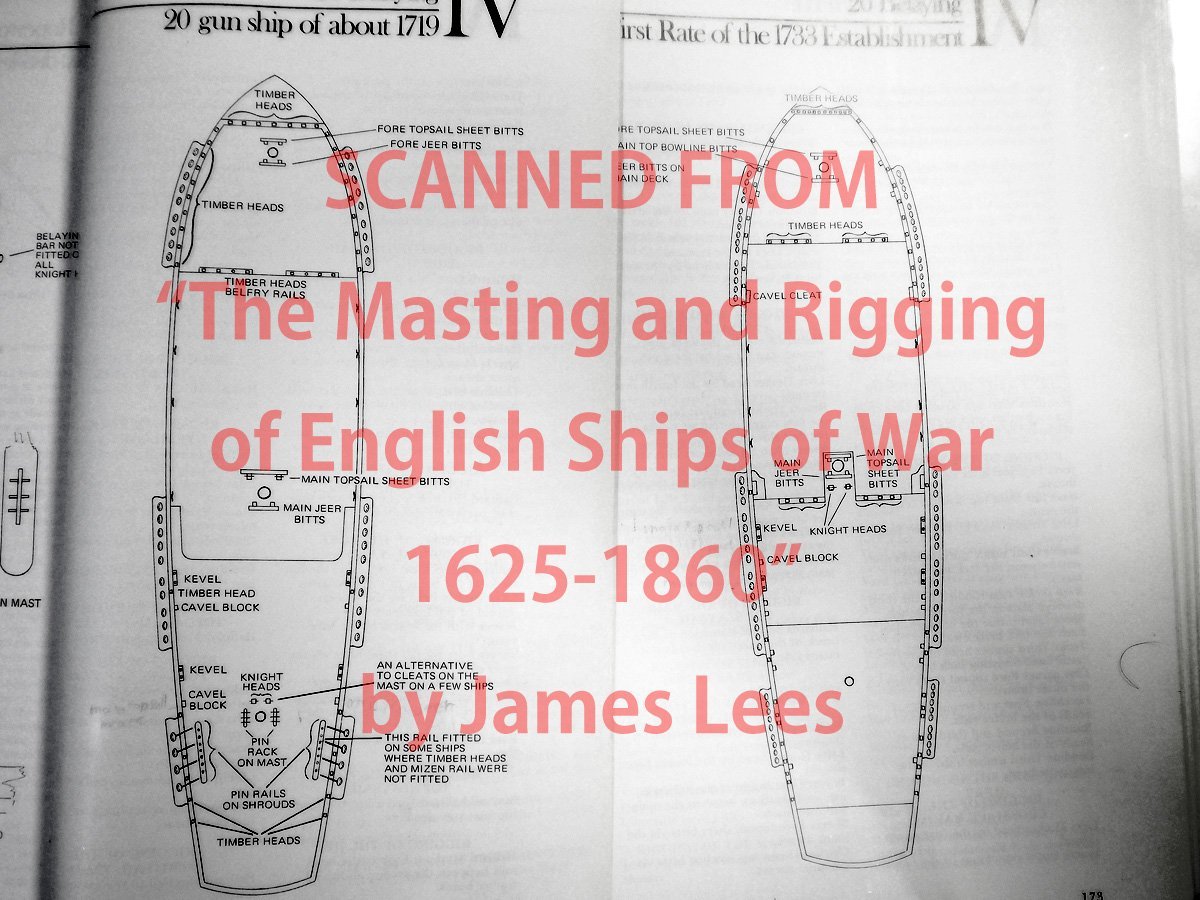

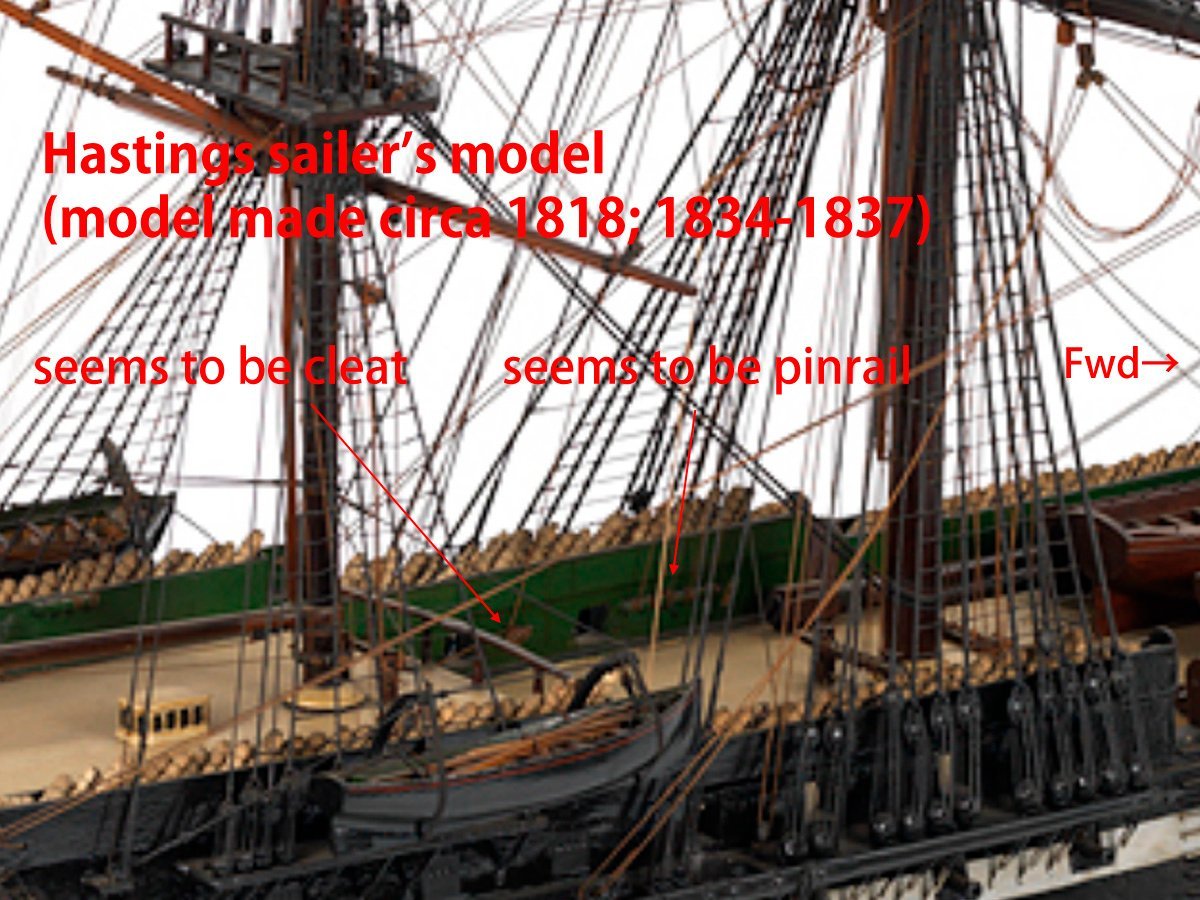

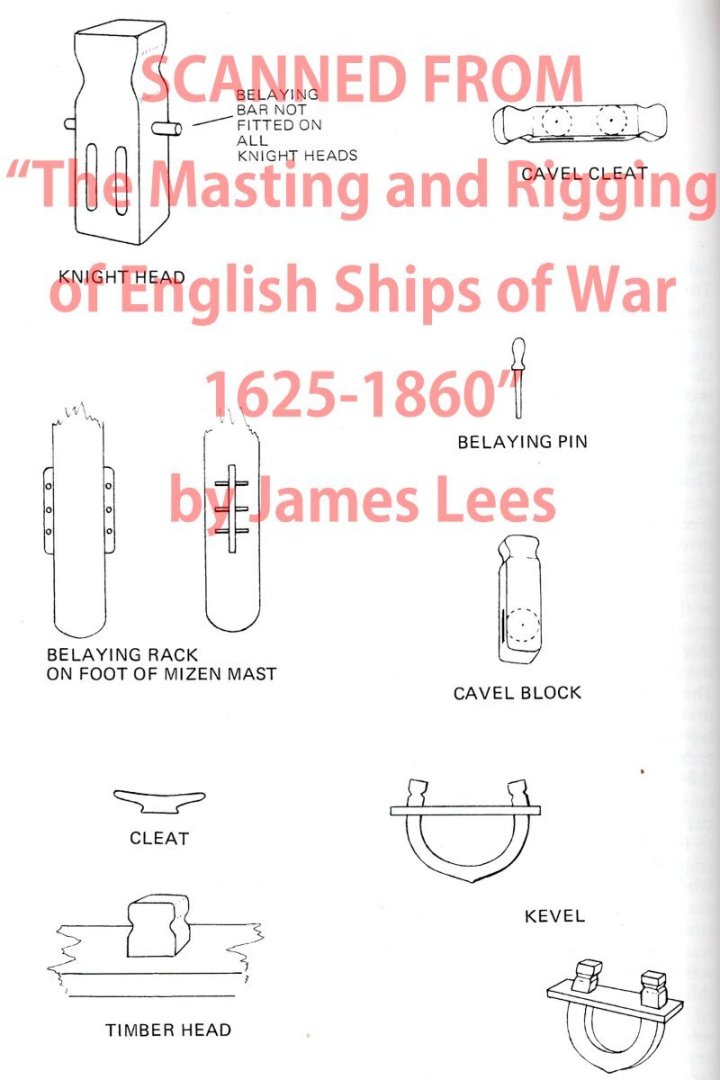

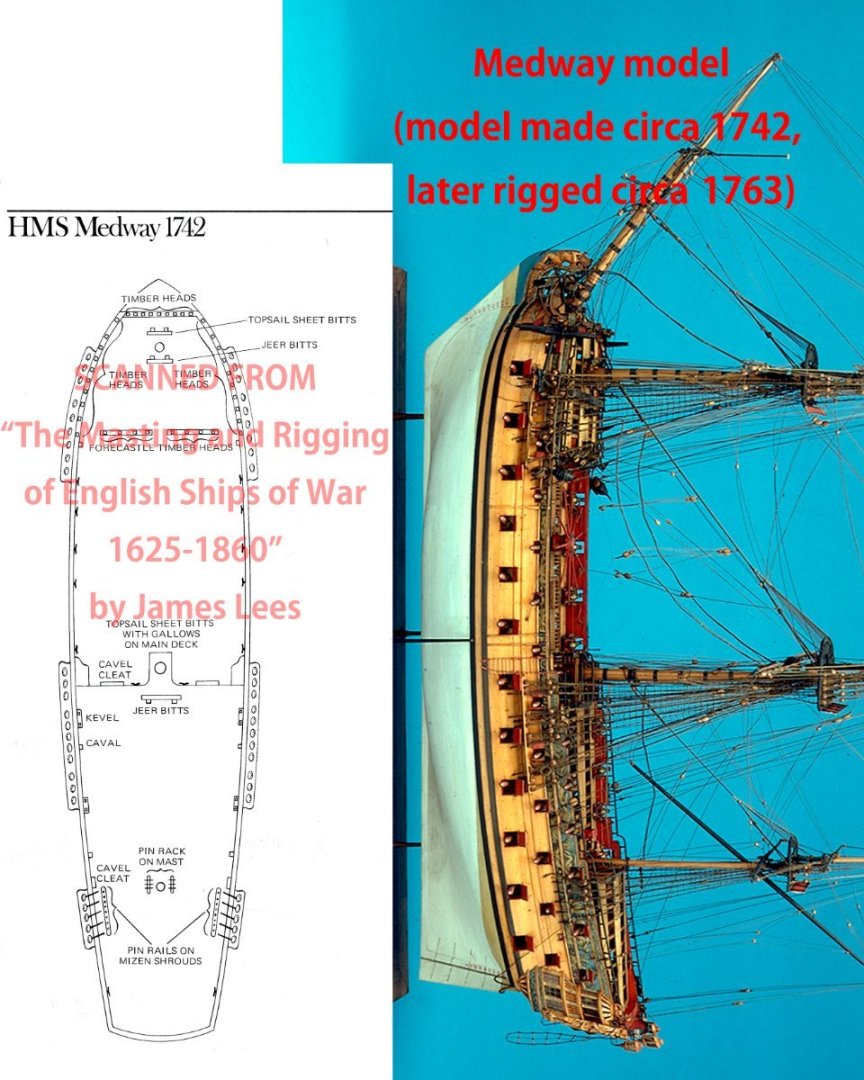

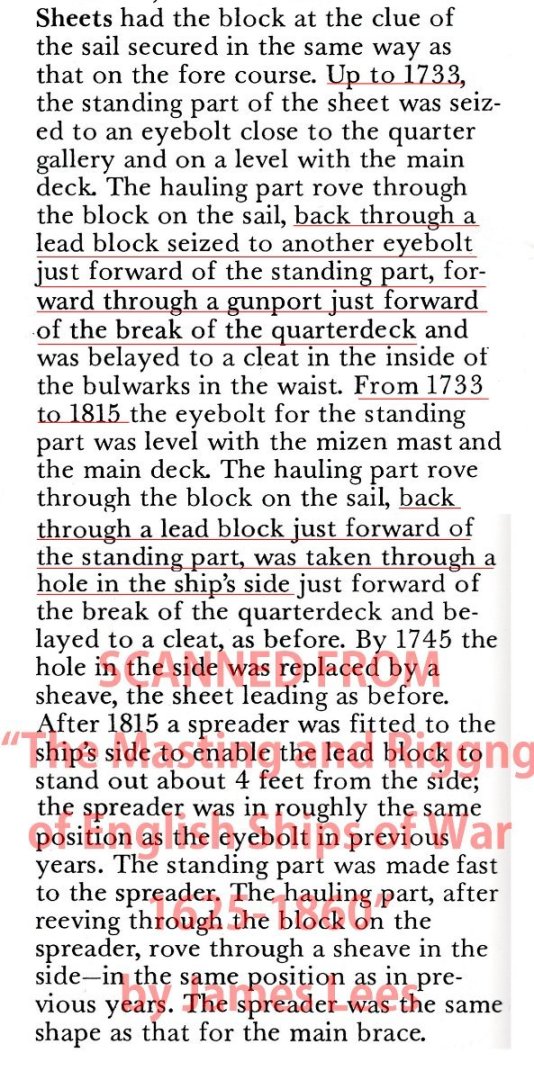

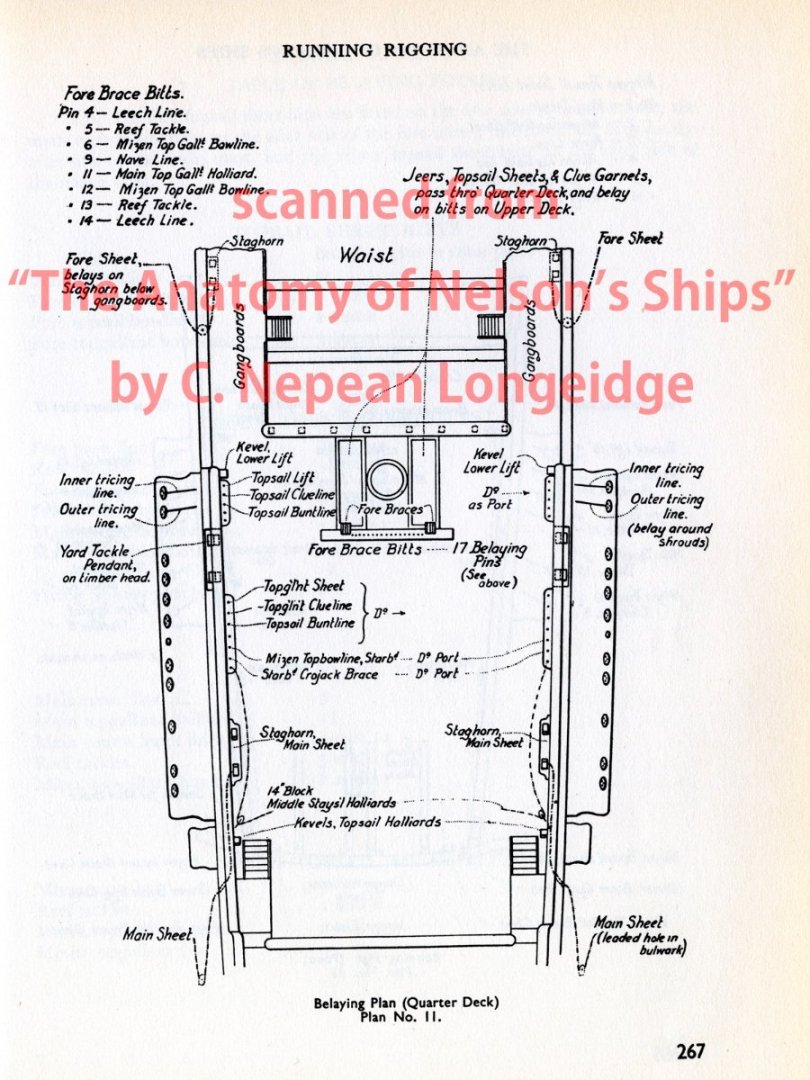

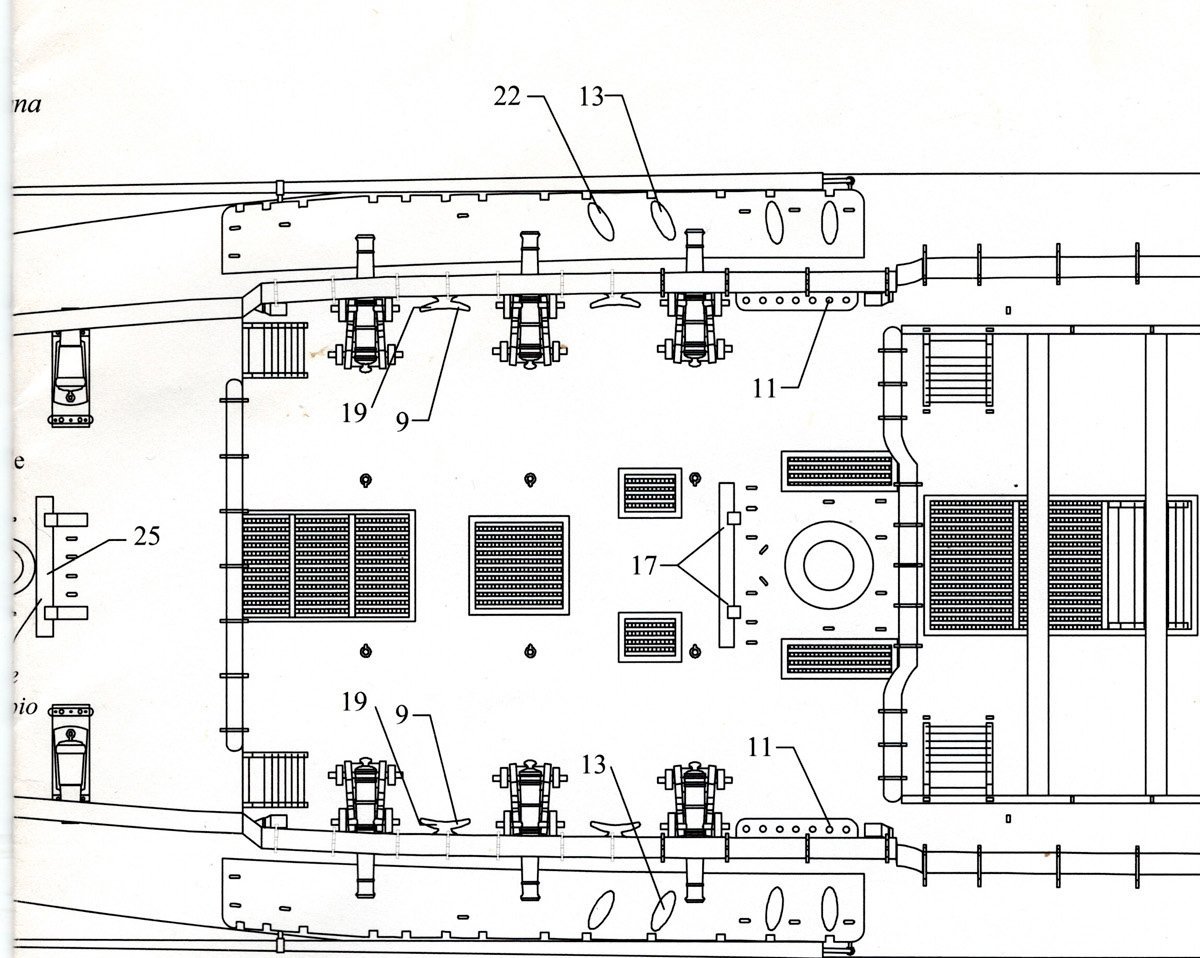

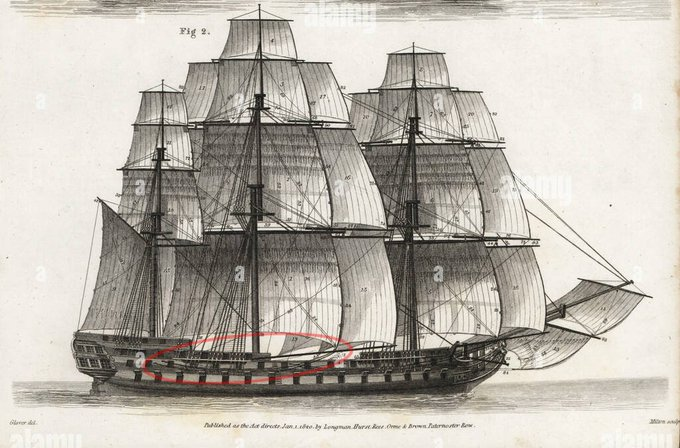

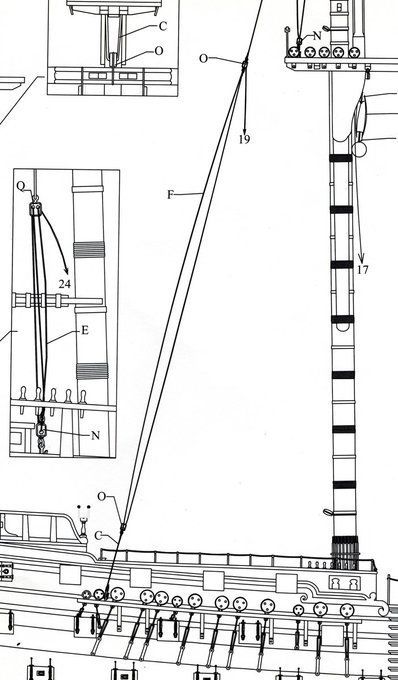

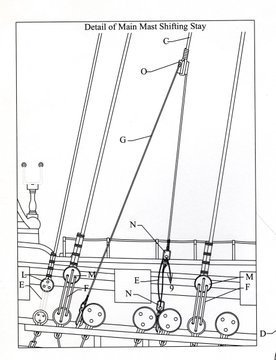

I’ve recentry re-started building of Bellerophon after I finished other modelling project, but two concerns on rigging prevent me from further progress of building. One is what most likely arrangement of her belaying points on inside of quarterdeck bulwark is, and another is what most likely method to lead main course sheet is. Firstly, question on belaying point. Kit design shows two cleats here. But belaying plan of 18th century ships appeared on Lees show no cleats here, although belaying plan of frigate of 1810 and 1850 ships show cleats here. Also some of contemporary models or Victory today have staghorns here instead of cleats. Lees "Masting and Rigging" Meway model https://www.rmg.co.uk/collections/objects/rmgc-object-66289 Bellona https://www.rmg.co.uk/collections/objects/rmgc-object-66299 Royal George https://www.rmg.co.uk/collections/objects/rmgc-object-66297 Victory has V shaped staghorn. Photo by myself. ONTH Model of 64 gun ship of 1775 seems to be having cleats here. https://www.rmg.co.uk/collections/objects/rmgc-object-66274 Images of this same model on members only page of this site suggests that rope is passing through sheave of angled kevel then belayed this cleat-like fitting. But I assume that cleats on this place are rare in 18th century ships of the line. https://modelshipworld.com/gallery/image/5205-london-525/ Plans of 74 gun ship of 1813 drawn by Underhill shows cleat to belay main course sheet. https://www.ebay.it/itm/384243693162?mkevt=1&mkcid=1&mkrid=724-53478-19255-0&campid=5338722076&customid=&toolid=10050 Model of Hastings of 1818 also seems to have cleats. This is sailor’s made model, so fittings must be authentic. https://www.rmg.co.uk/collections/objects/rmgc-object-66653 From these examples, my best guess is that staghorns had been used with change of appearances from U shaped to V shaped around some date of late 18th century, then sometime after Trafalgar cleats replaced staghorns. But I’m still anxious for my guess. Then second question, how to lead main course sheets. Steel depicts that sheet is lead backward from clew, then passing through sheave-hole of ship’s side and belayed to a range-cleat in the waist. https://maritime.org/doc/steel/part7.php#pg211 This image is I found on google image search and I believe this is taken from “Rees’s Naval Architecture”. 64 gun ship model of 1775 also shows sheave-hole to lead sheet into hull. ONTH Lees depicts that sheet is lead backward from clew , then turned forward through block and hauled into hull. This method can be seen on Victory today (photo by myself). Some of contemporary models is also showing this method. https://www.rmg.co.uk/collections/objects/rmgc-object-66407 Although this is depiction on 17th century ships, Dr. Anderson depicts both methods were used on English ships, though sheave-hole method were mainly used. My best guess is Bellerophon had sheave-hole on her side. Internal profile plan of her sister ship Elephant which Chris Watton based on for his Vanguard/Elephant/Bellerophon kit design is clearly showing it at mizzen mast position. Both of Bellerophon and Elephant were ordered from private shipyards and launched almost same time, so both ships must had been constructed on identical plans manually copied. https://images.rmg.co.uk/asset/12418/ But in the case of sheave-hole method, belaying points on the inside of quarterdeck become useless. Kit rigging plan shows main topsail halyard and shifting backstay fall is belayed to cleat, but Victory shows the former belayed to angled kevel and latter tied to hook of lower block of tackle. I’m now inclining to the idea to fit my Bellerophon with belaying points based on those of Victory today except staghorn left unused for alternative belaying point for main course sheet. But again I’m anxious for my idea and it is very appreciated to hear other possible method from members here. Kindest regards Mitsuaki Kubota Note on glossary Sometimes the usages of maritime terms are deferent from one author to another. Lees or other authors use the term “kevel” for U shaped belaying point and “cavel block” for timberhead like fitting with sheave. ONTH Longridge or Lavery use the staghorn for U or V shaped belaying point and kevel for timberhead like fitting with sheave. For convenience I followed usage of Longridge or Lavery.

-

Thank you for your word! I’m appreciated if my work will be source of inspiration for your fo’c’sle deck and quarterdeck planking. By the way, your coaming work hiding edge of baseboard is very realistic. This is I didn’t include in my work!

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

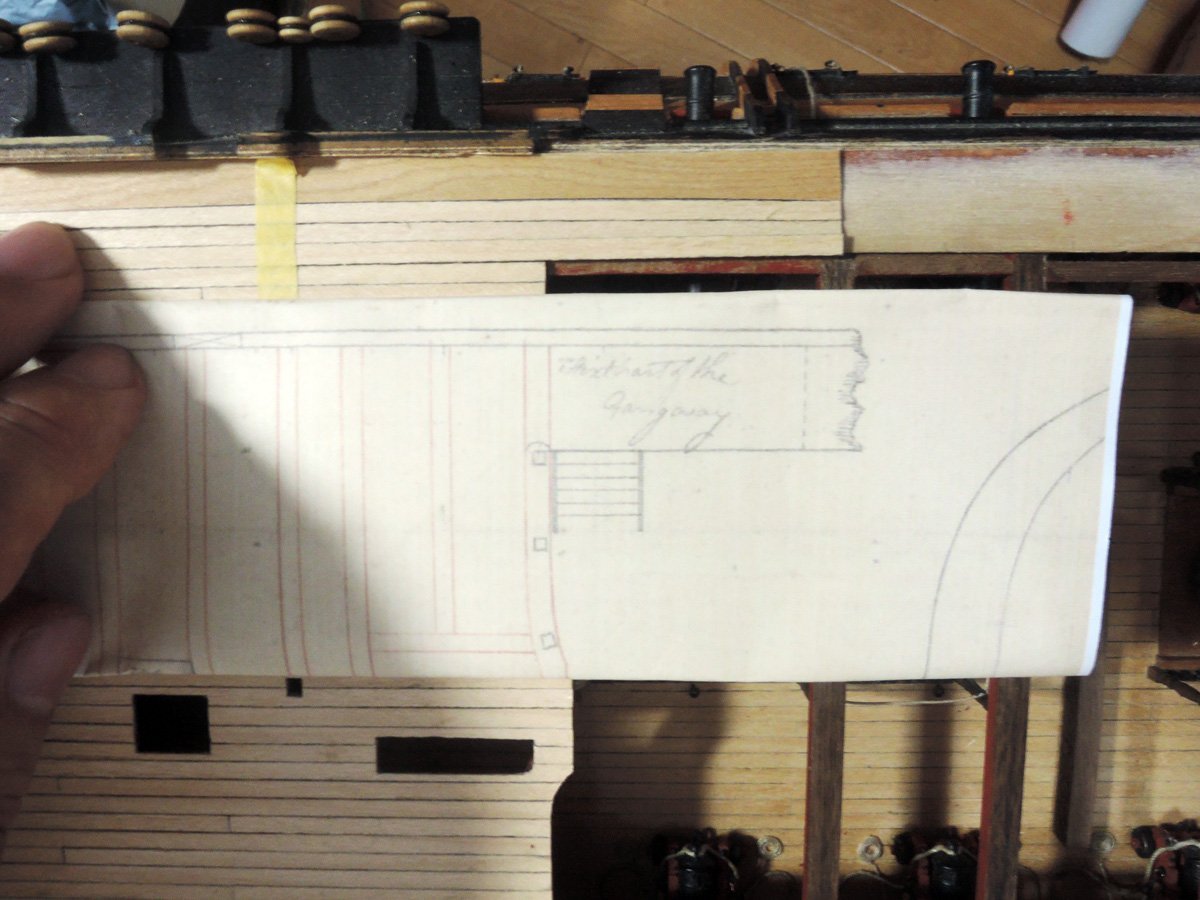

Peter, Thanks for your reply. Deck planking method is one of aspects which are often neglected, but really interesting topic. Judging from two models of Diana held by NMM, gangway is separated structure from fo'c'sle deck and quarterdeck circa 1790s, although these examples are of frigates, not ships of the line. https://collections.rmg.co.uk/collections/objects/66533.html https://collections.rmg.co.uk/collections/objects/66303.html BTW, I'm delightful to see your Bellerophon is showing common improvement with me including anchor lining👍

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

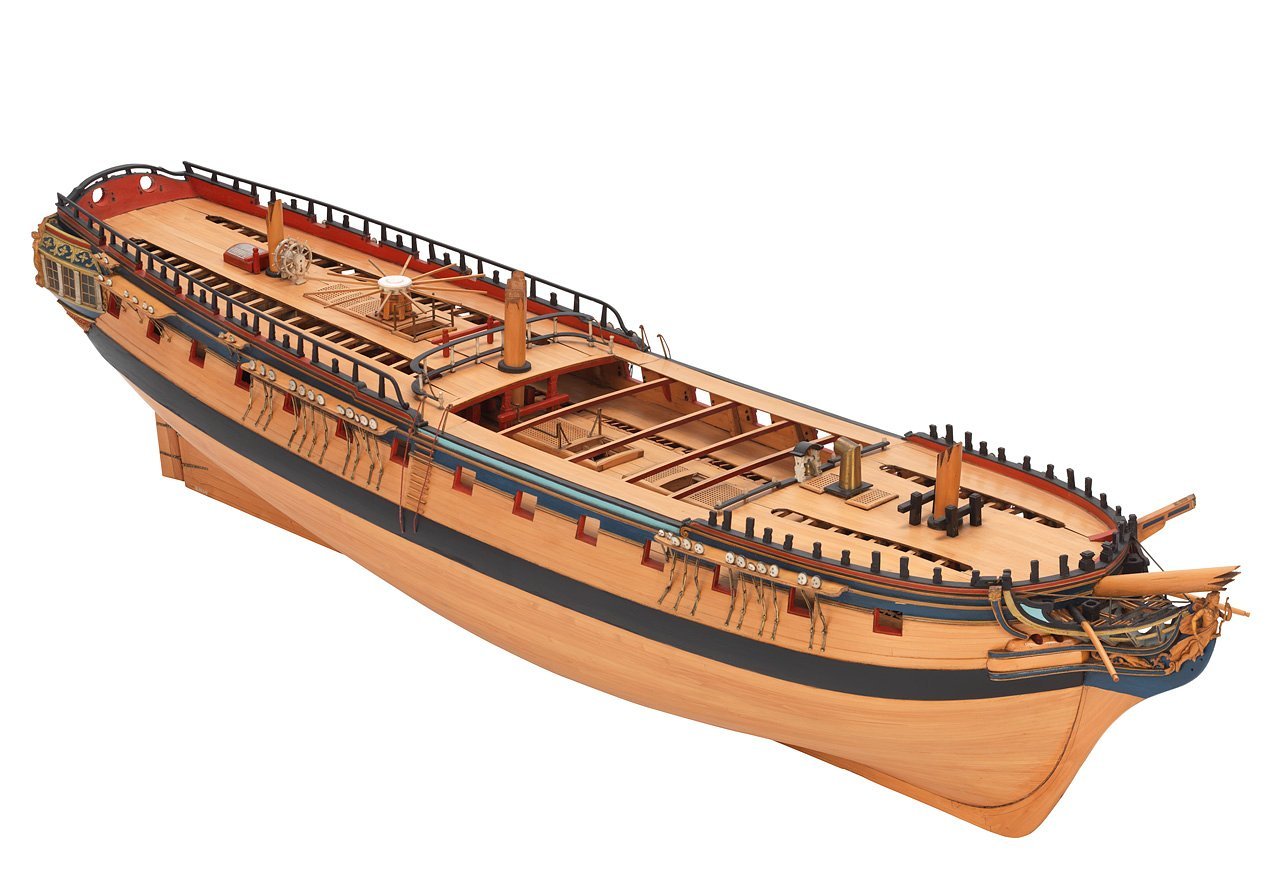

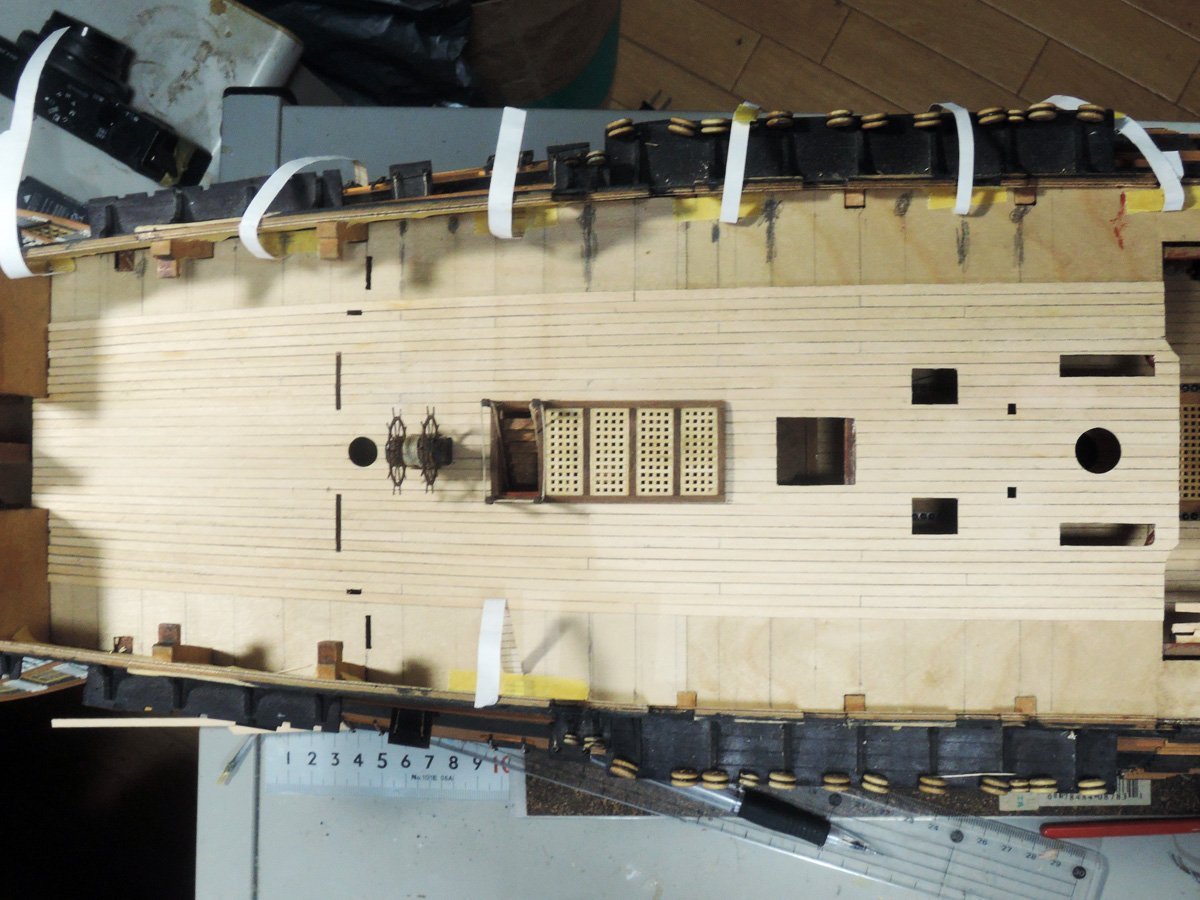

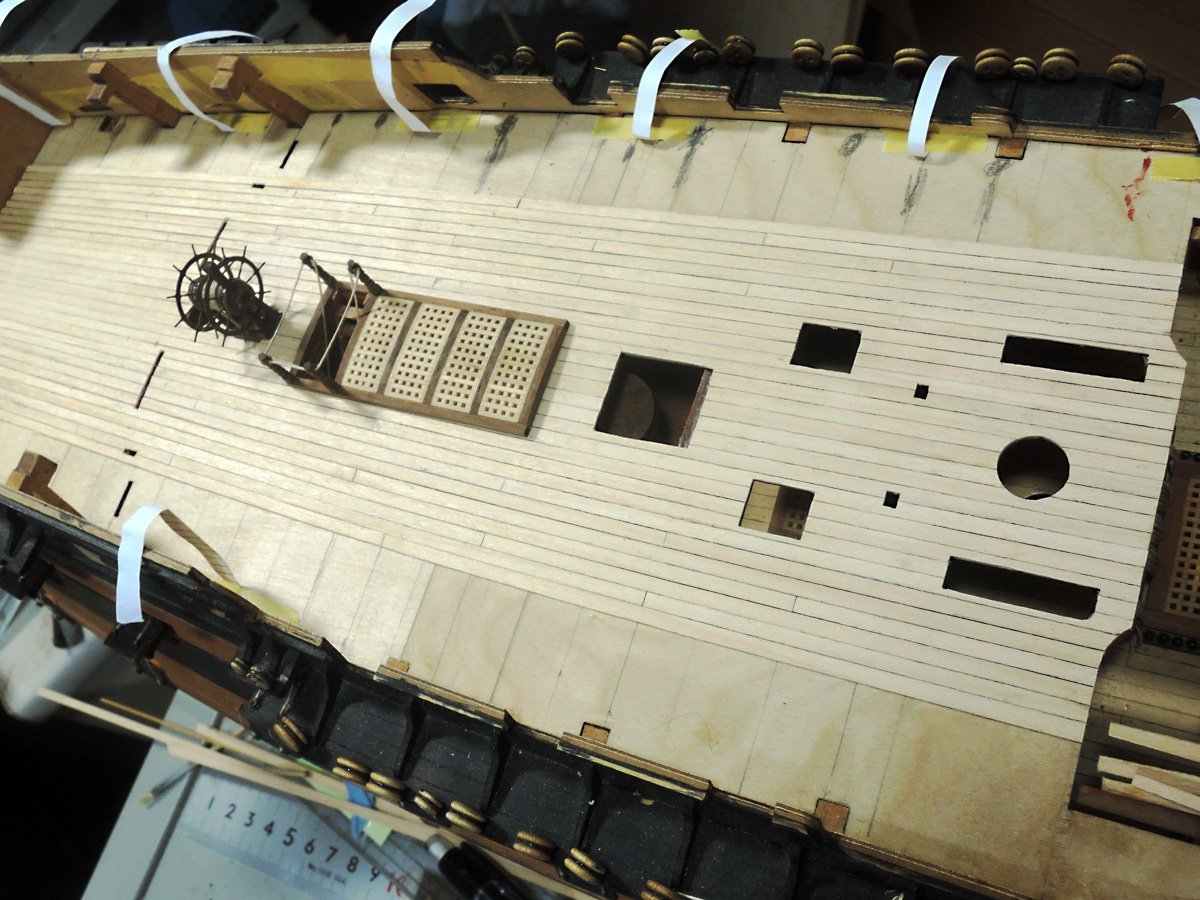

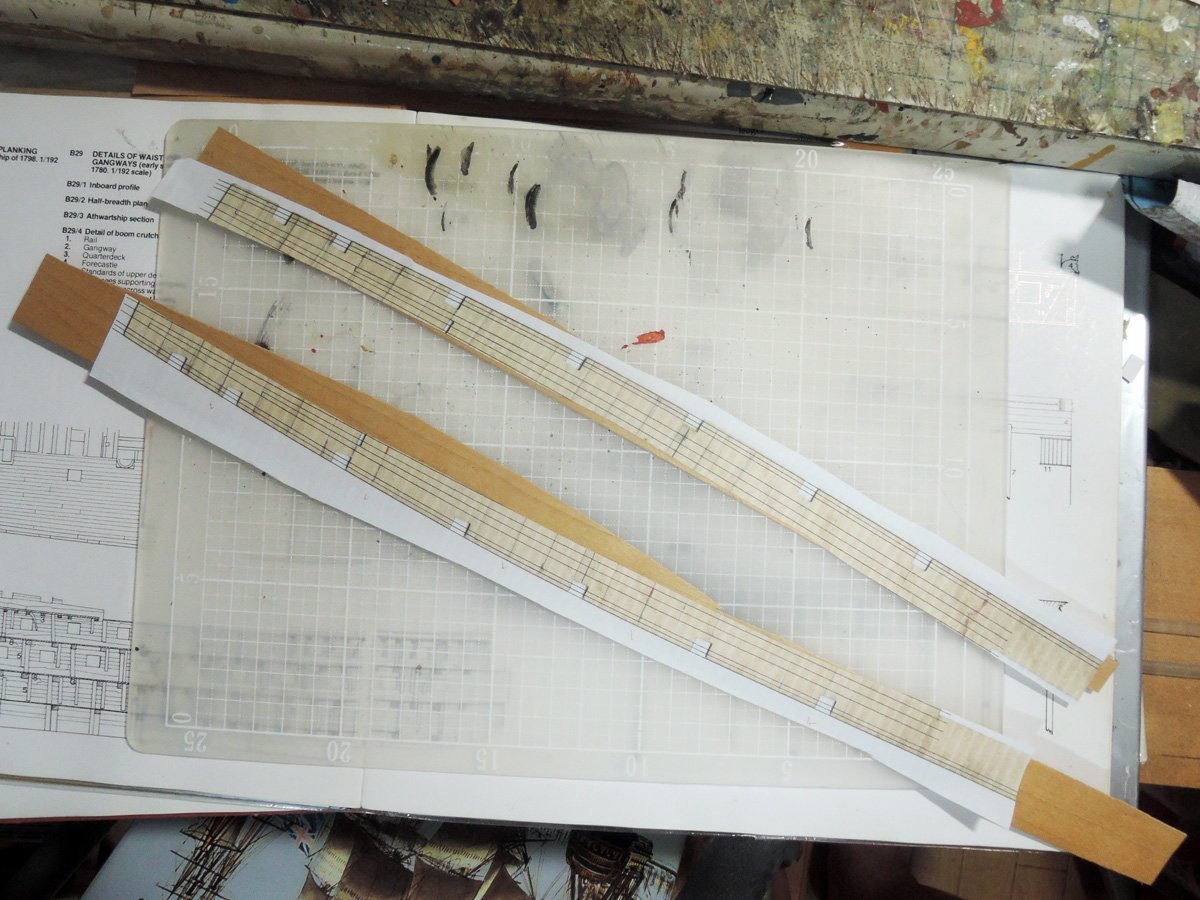

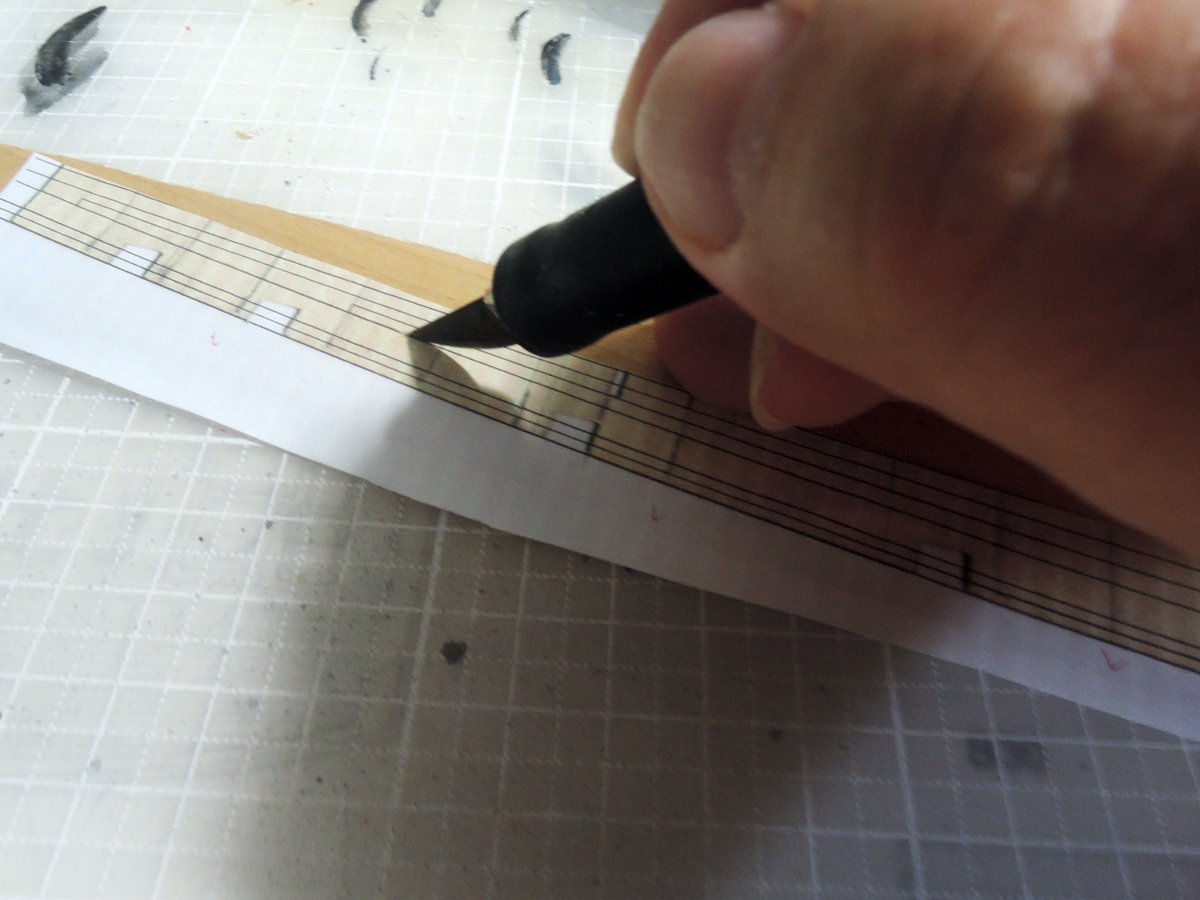

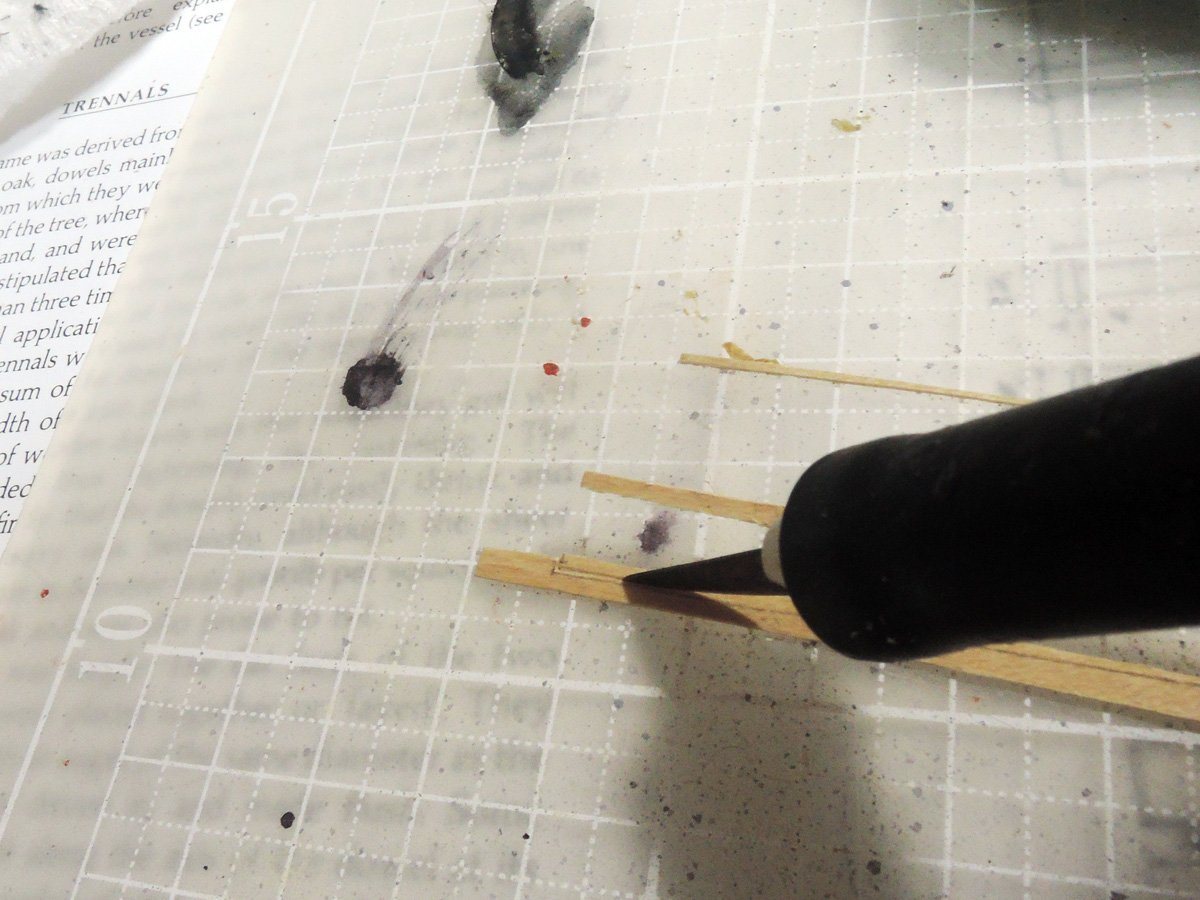

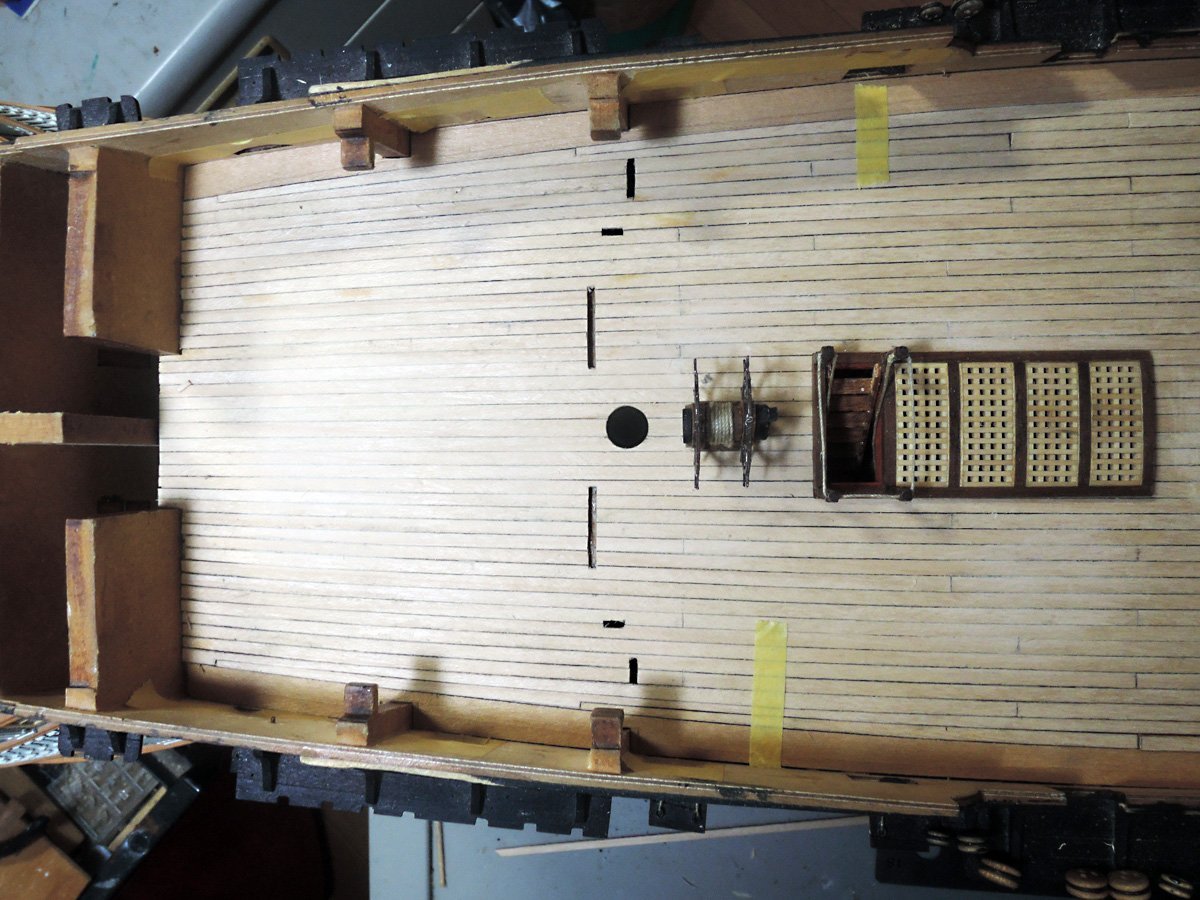

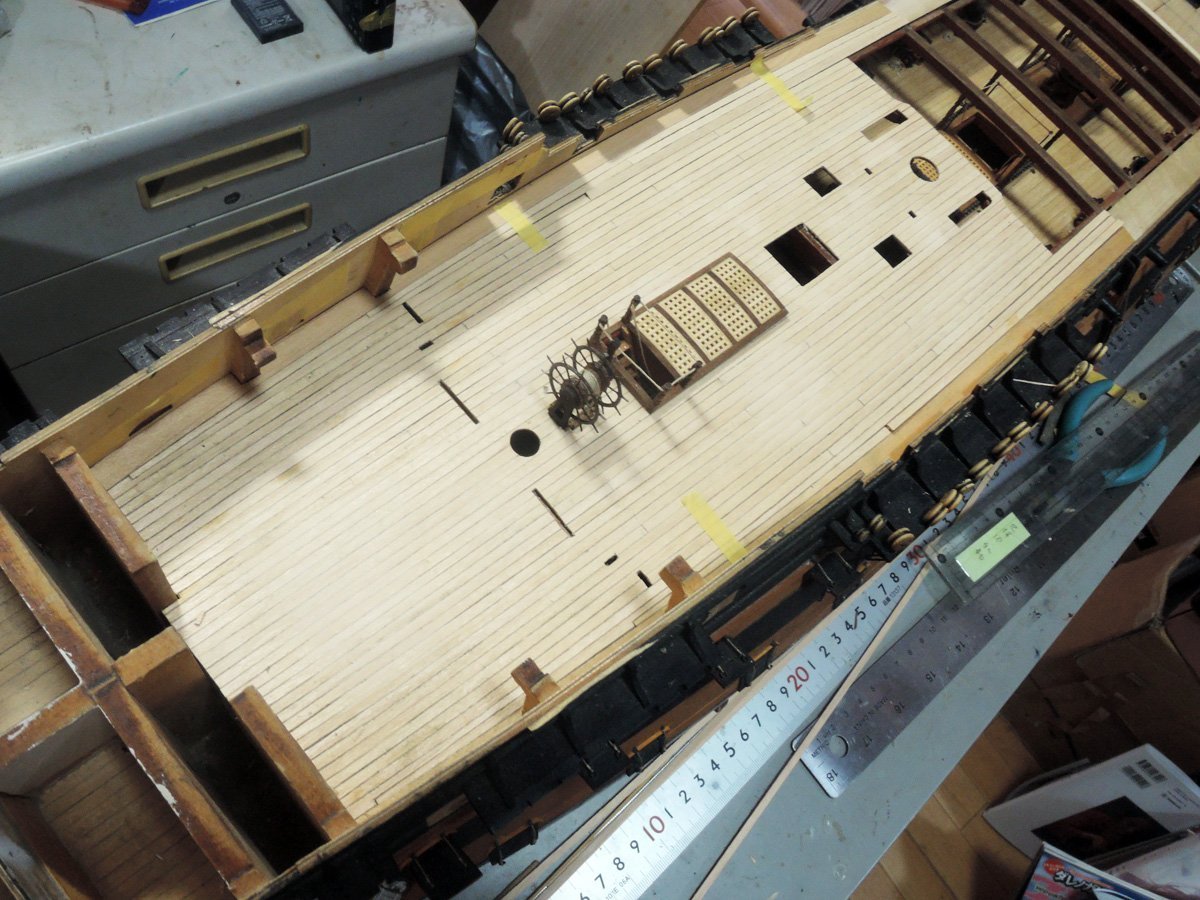

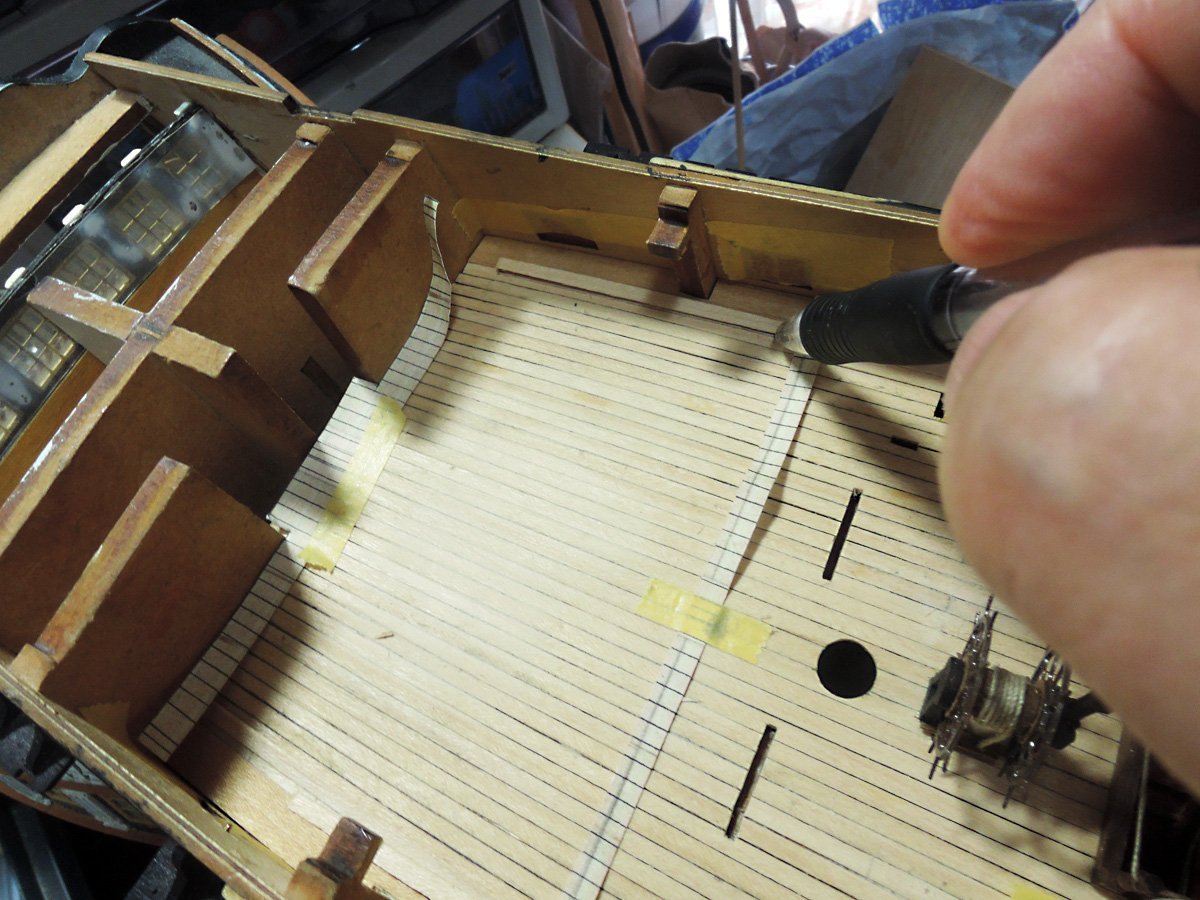

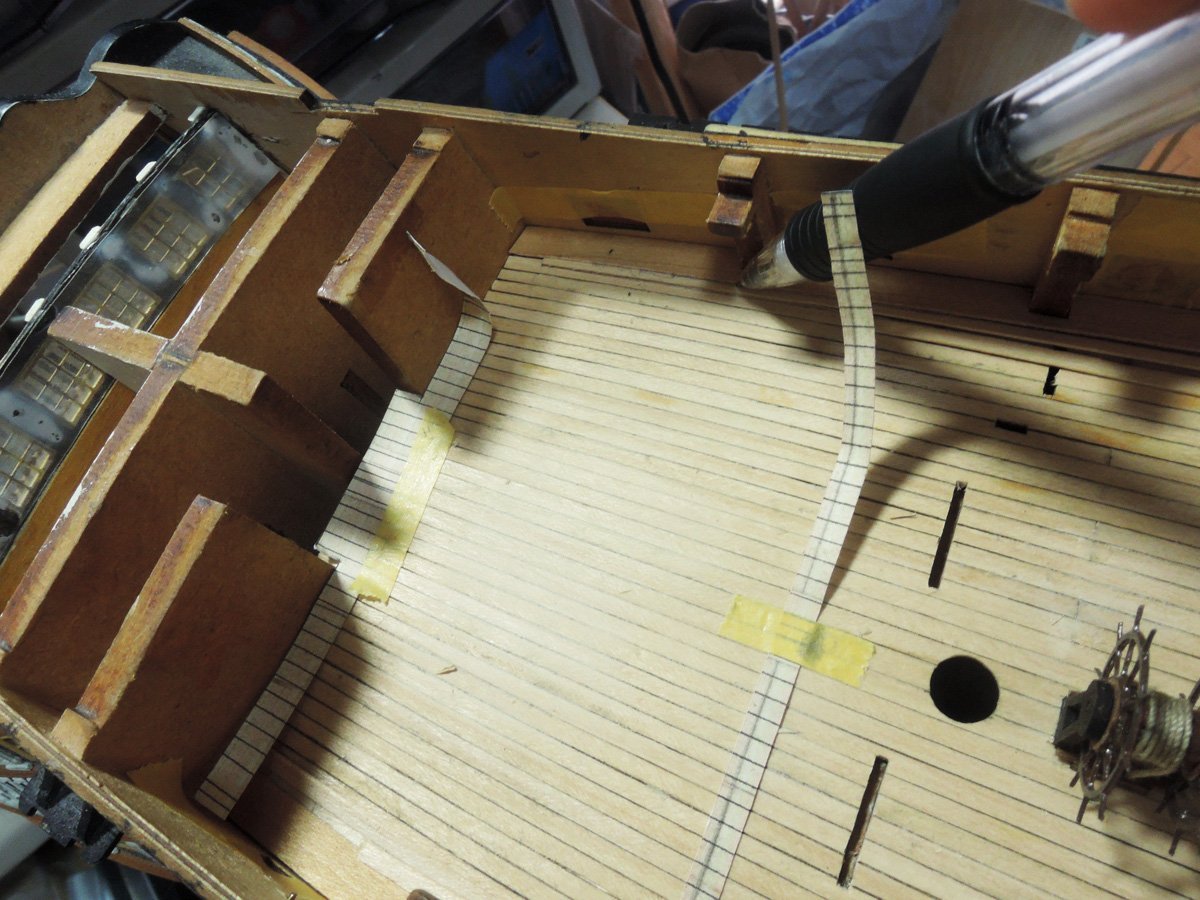

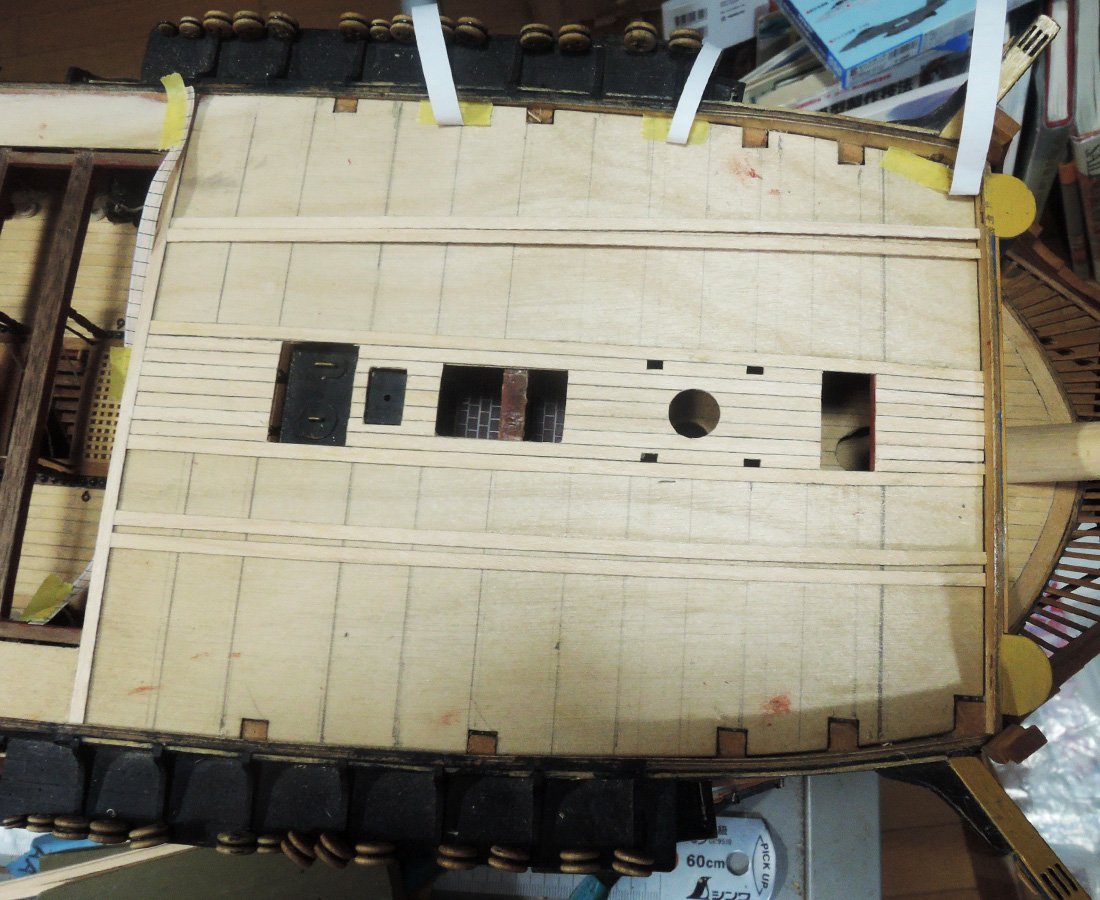

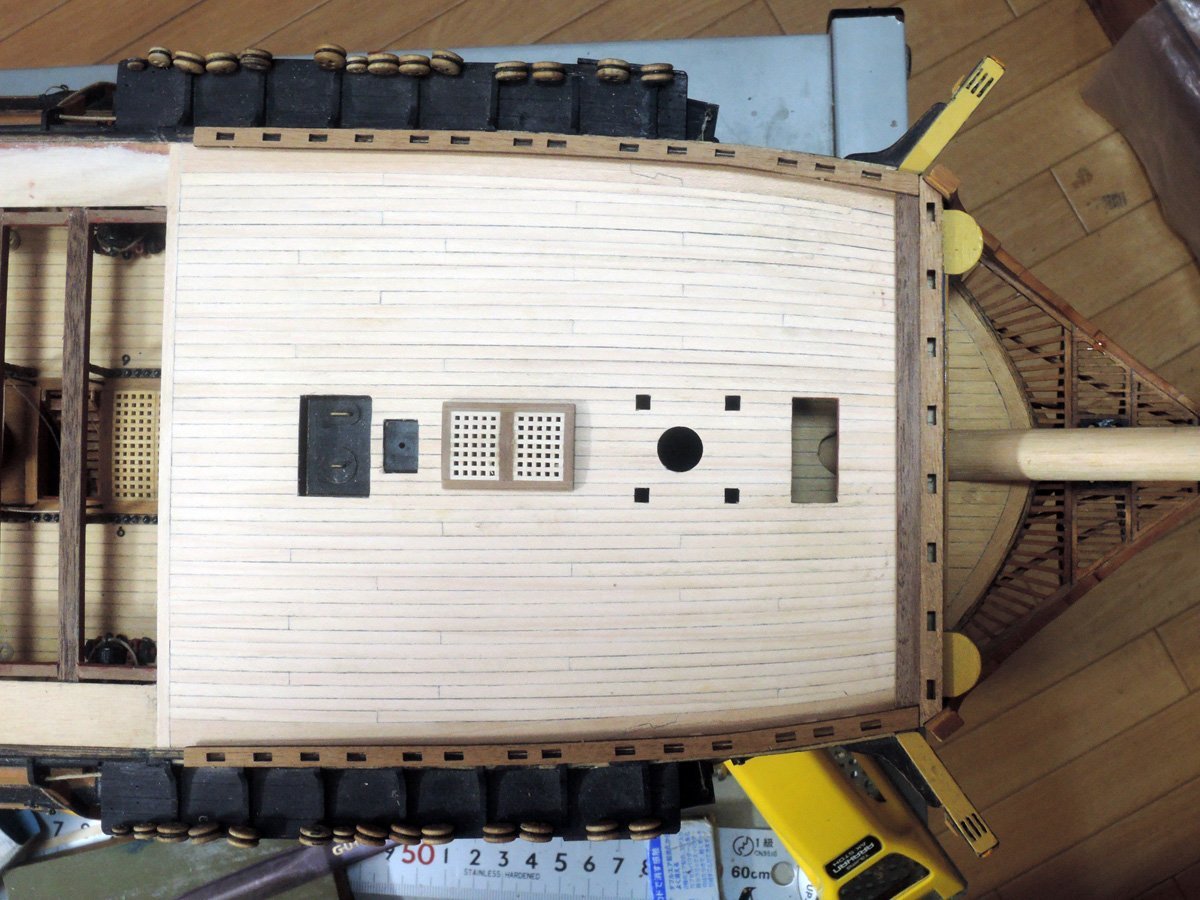

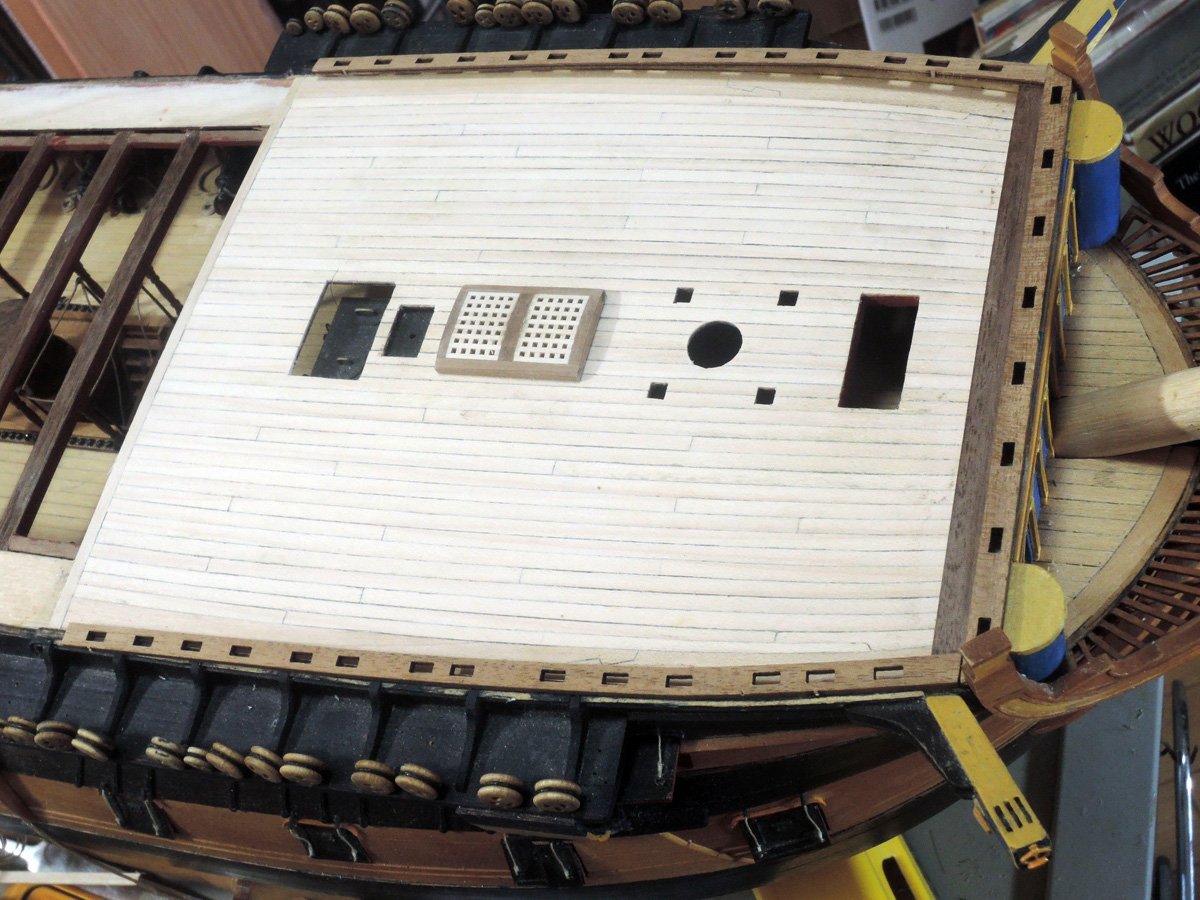

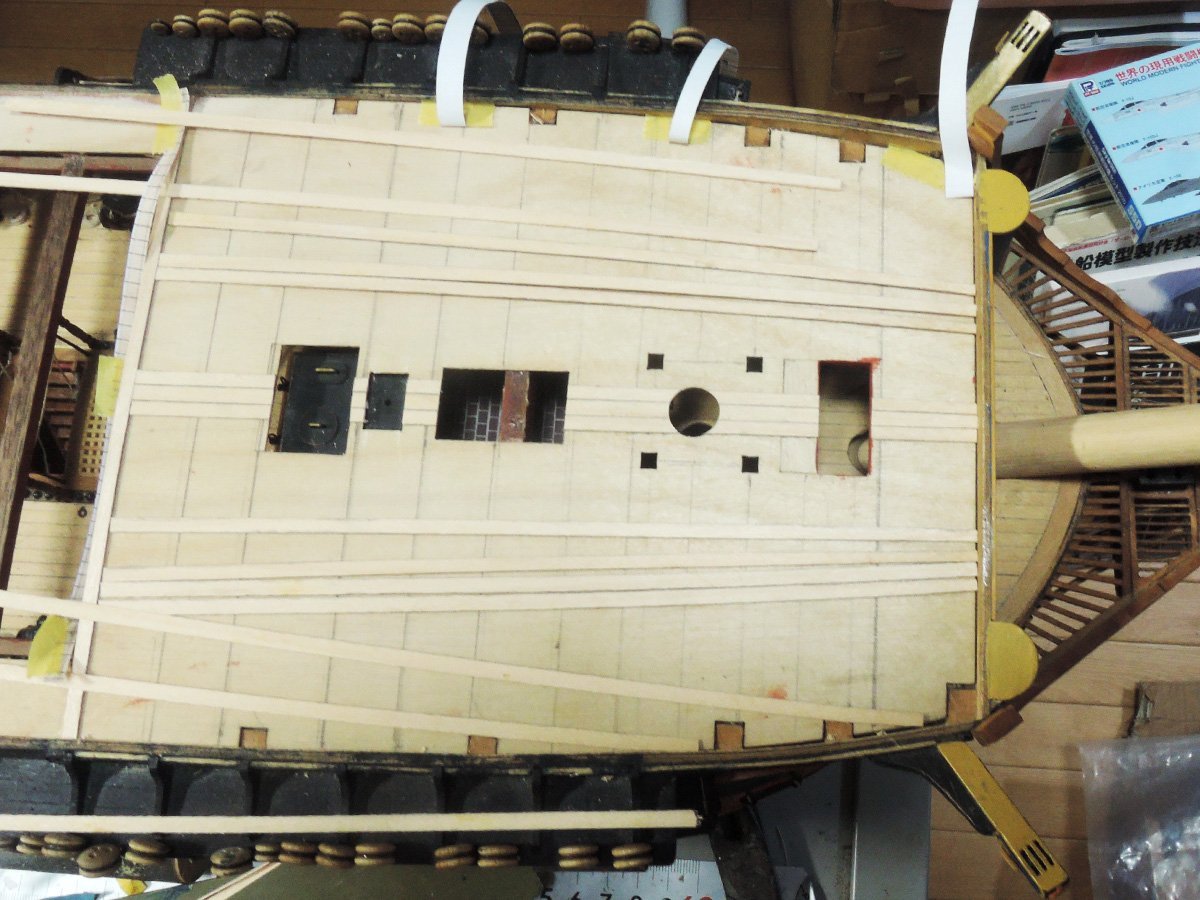

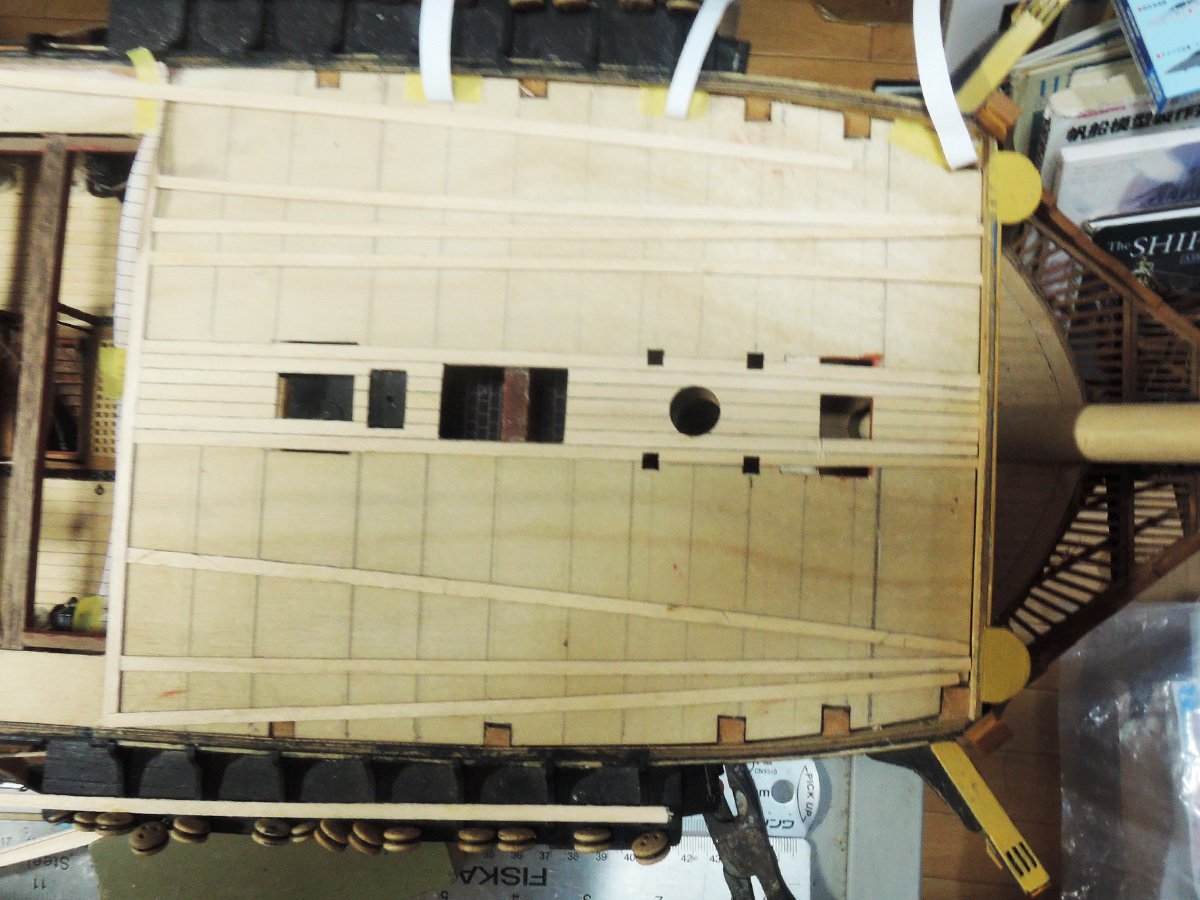

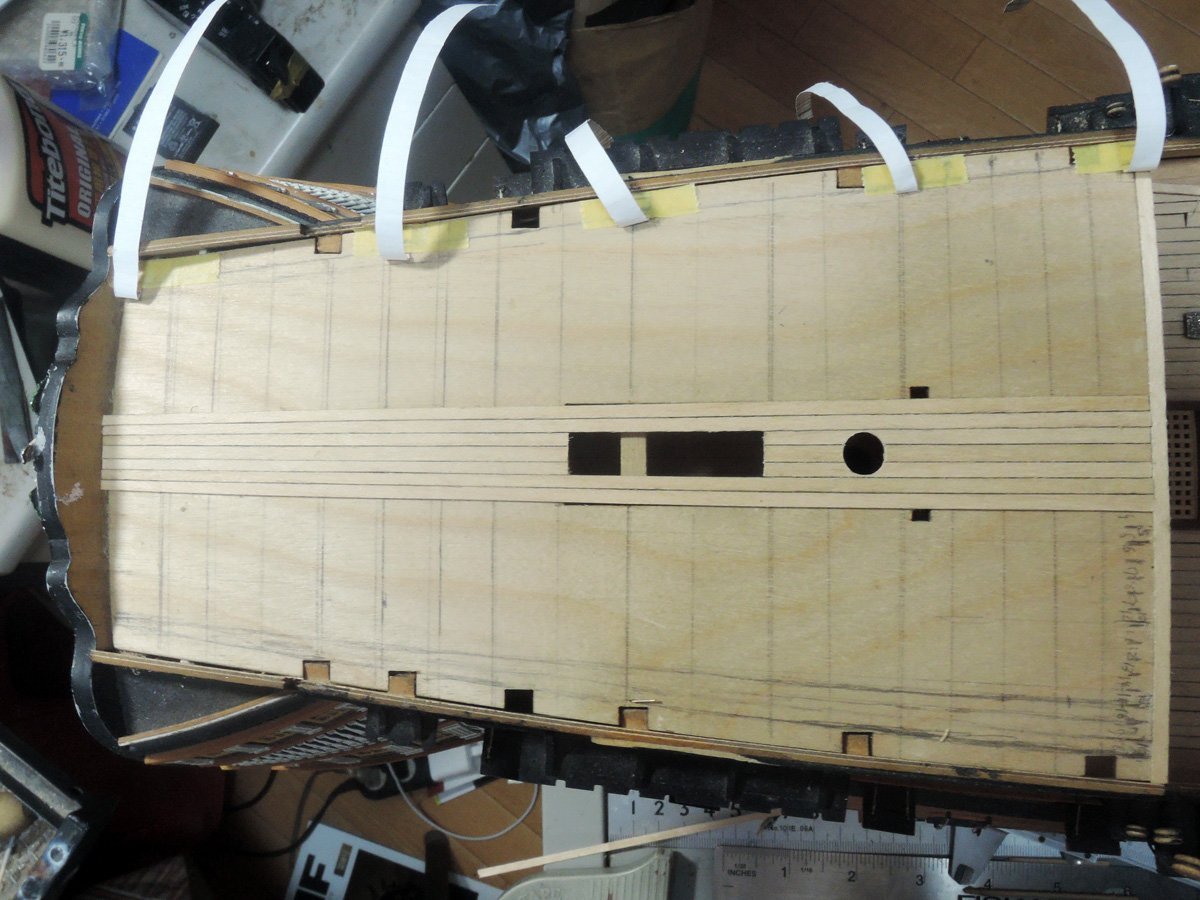

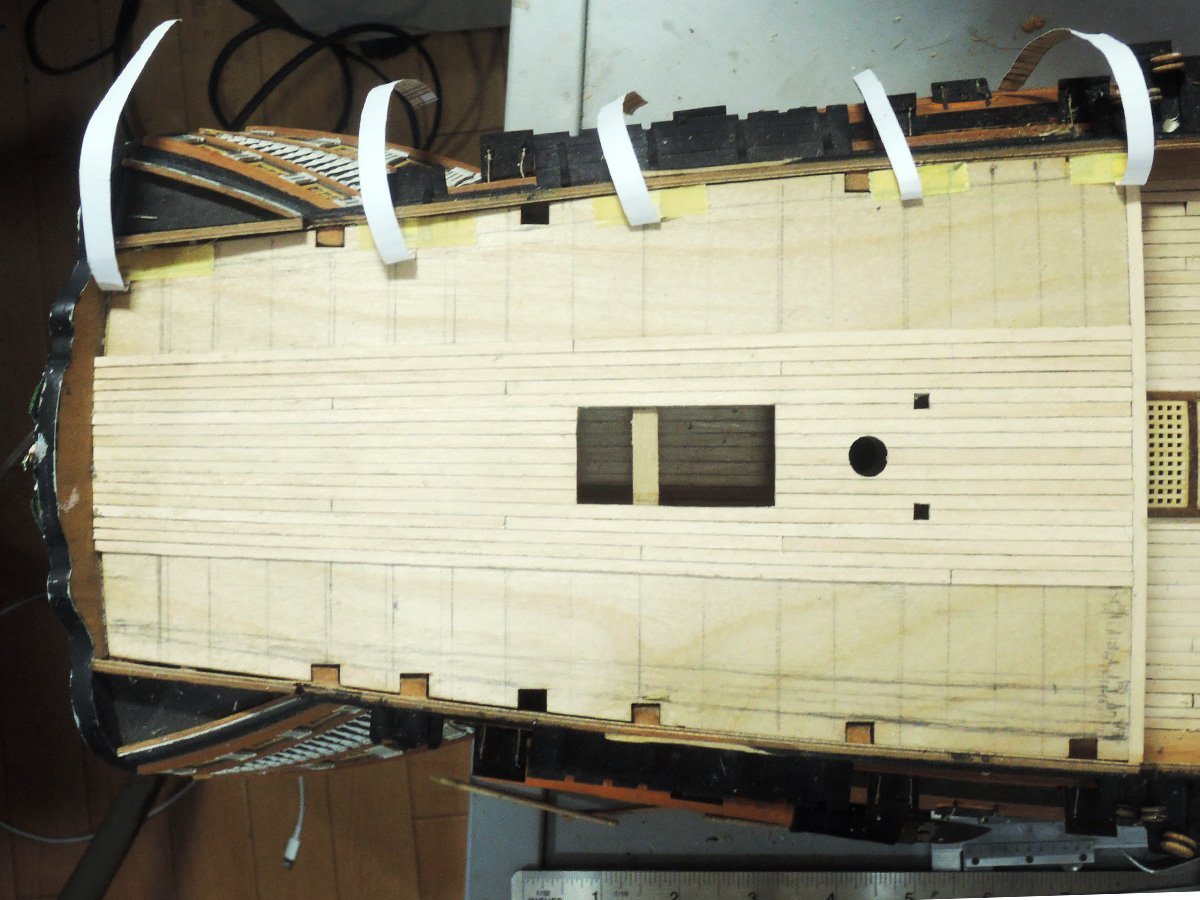

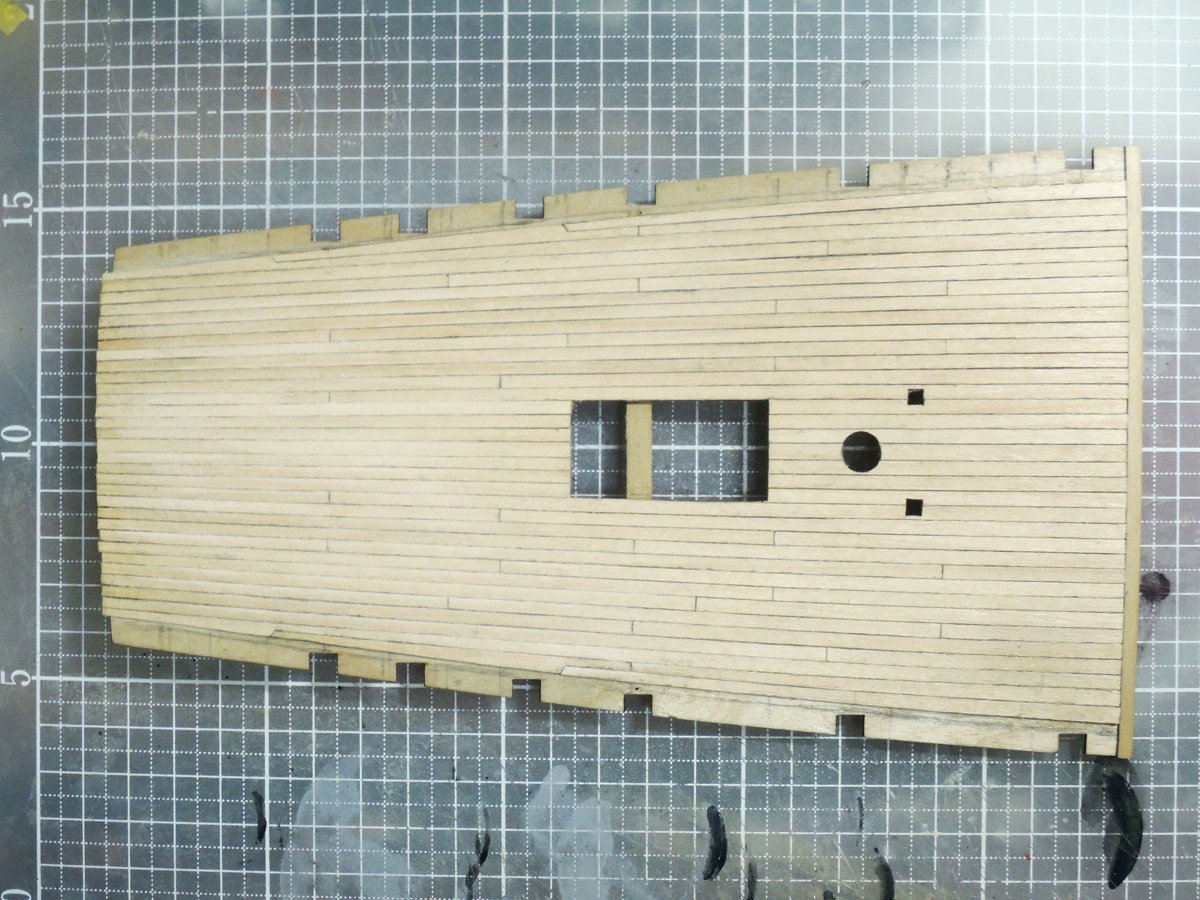

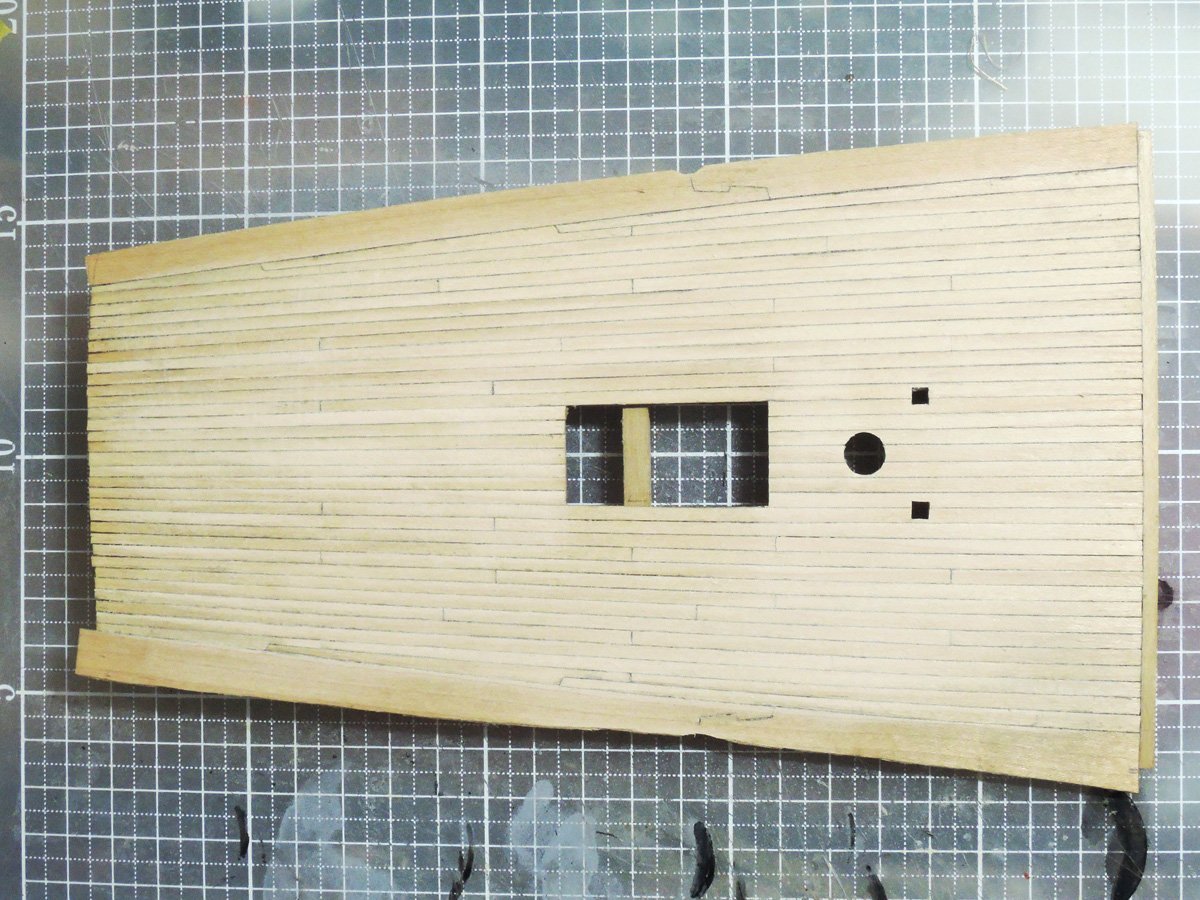

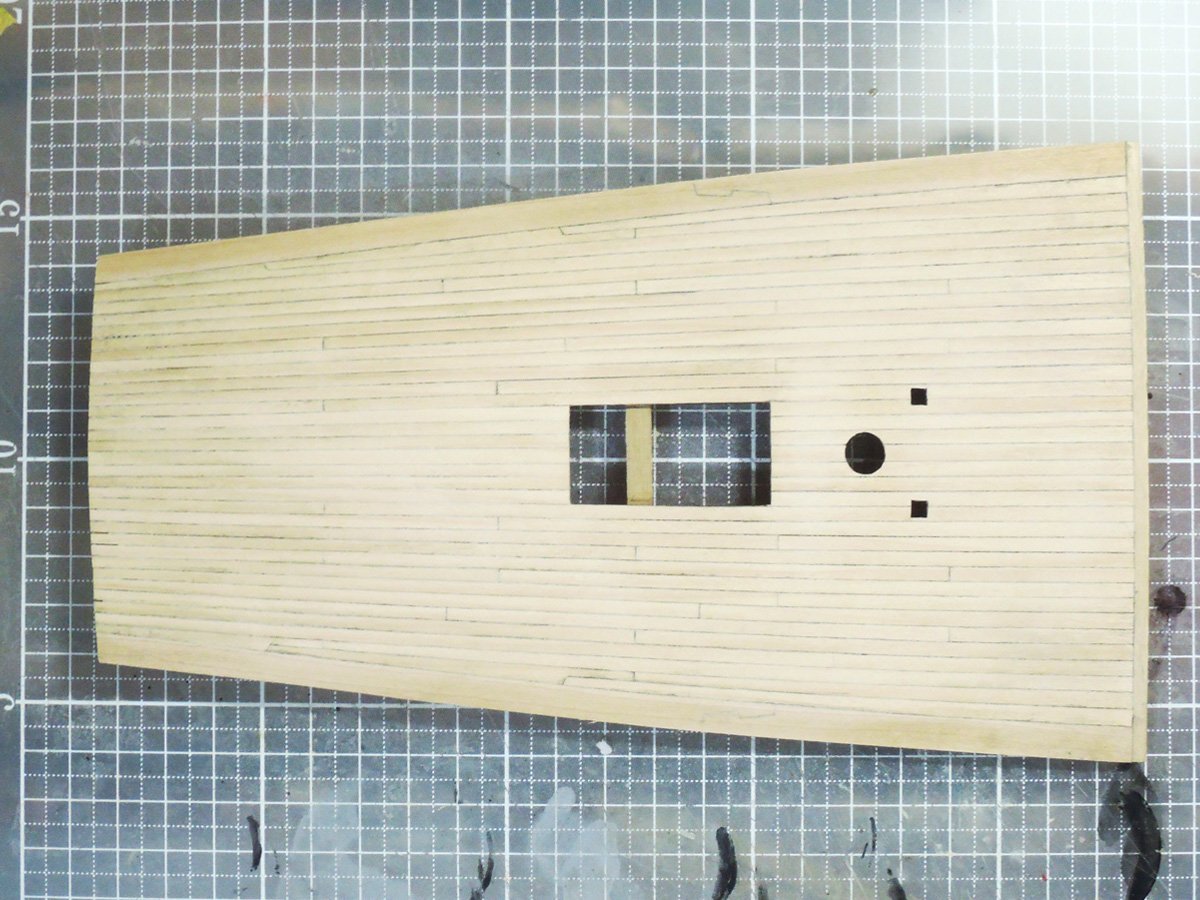

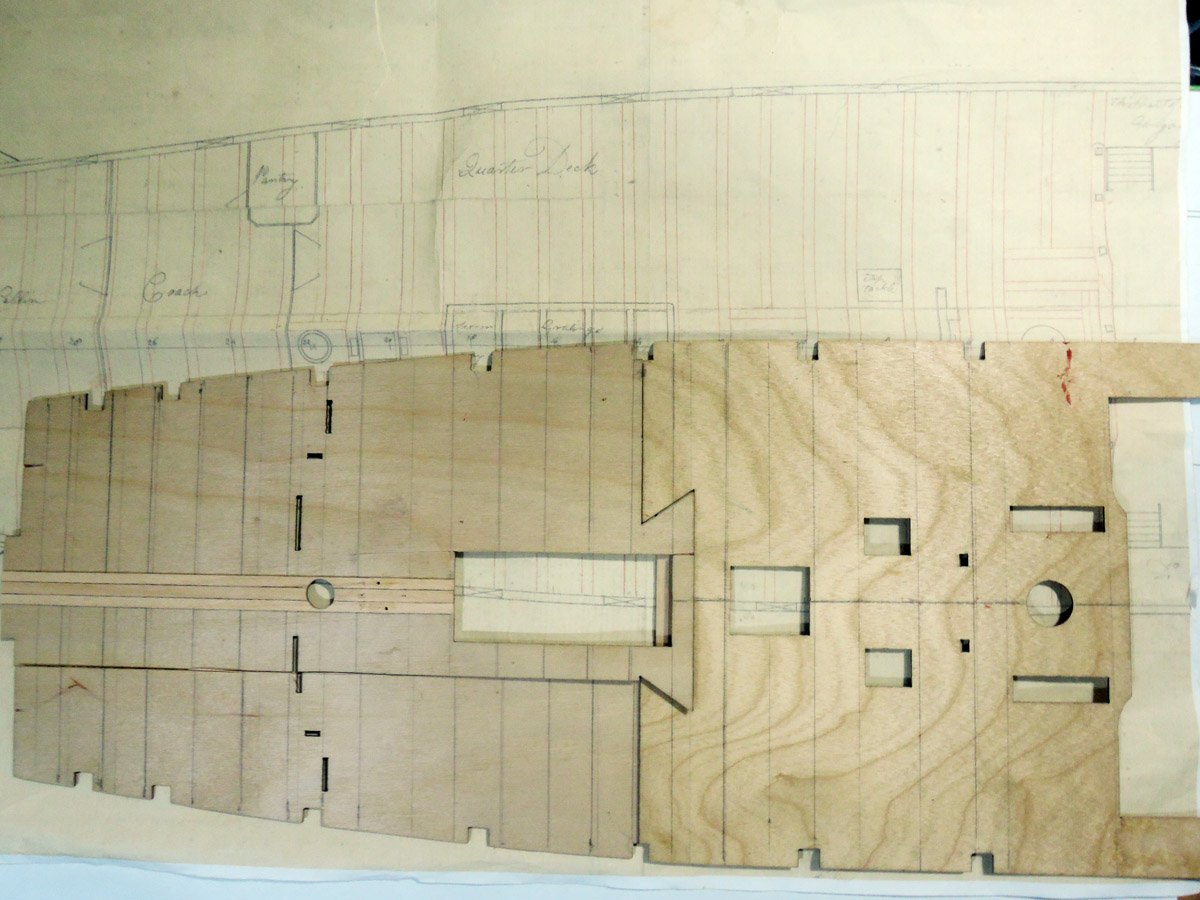

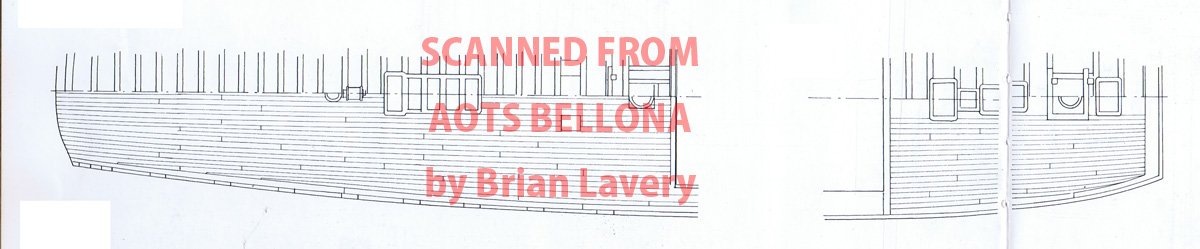

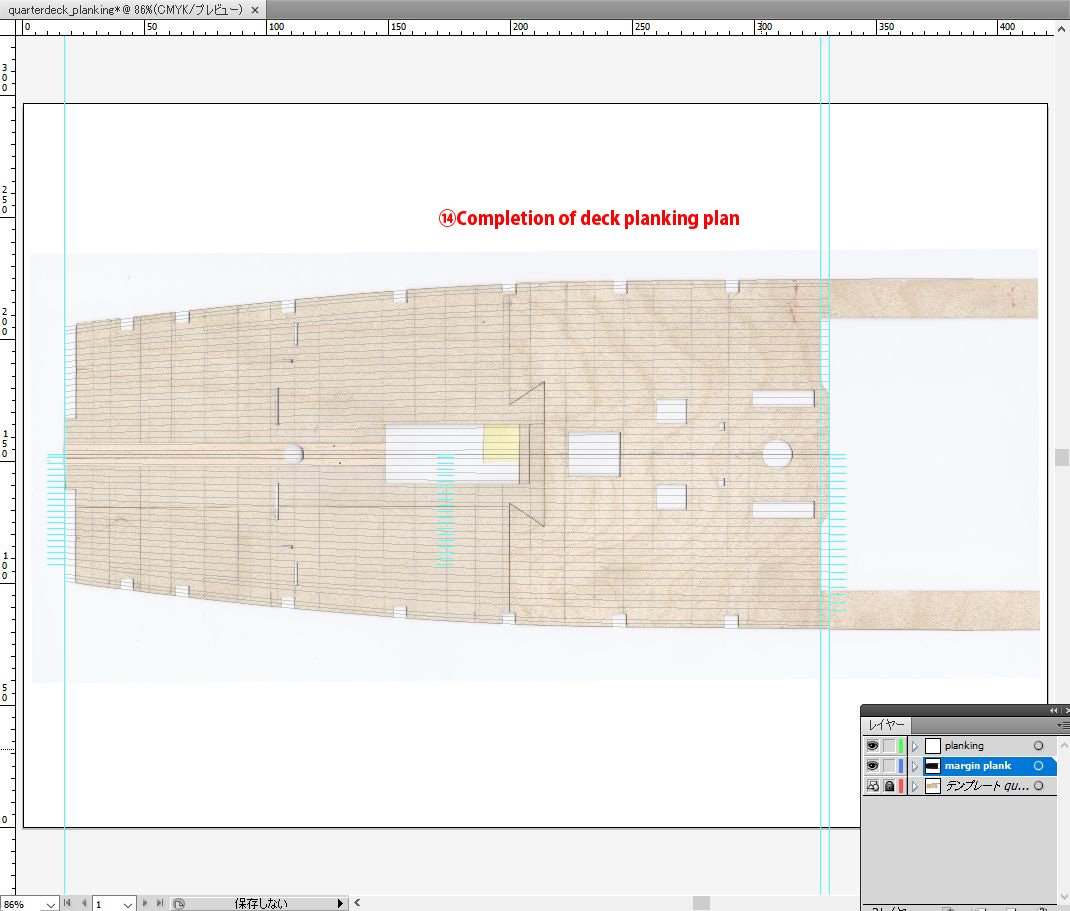

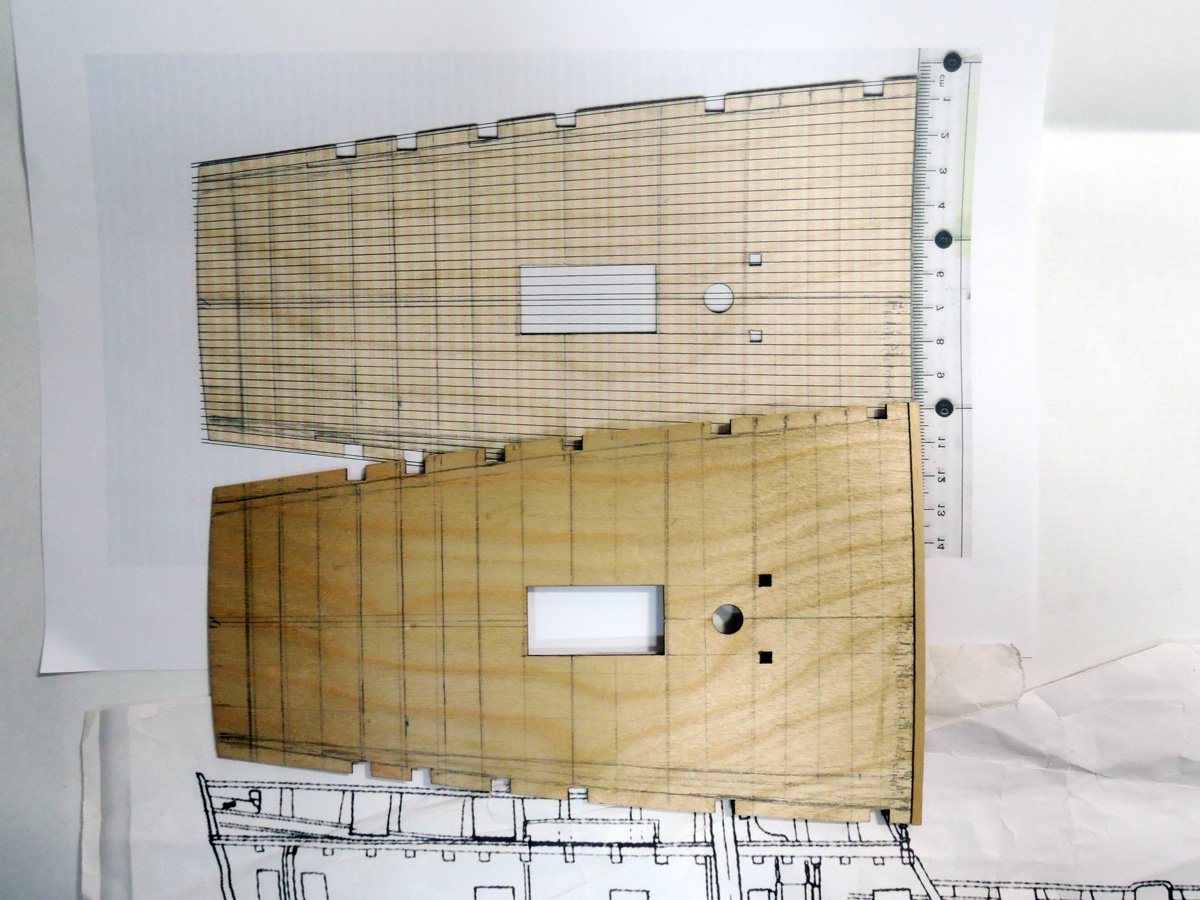

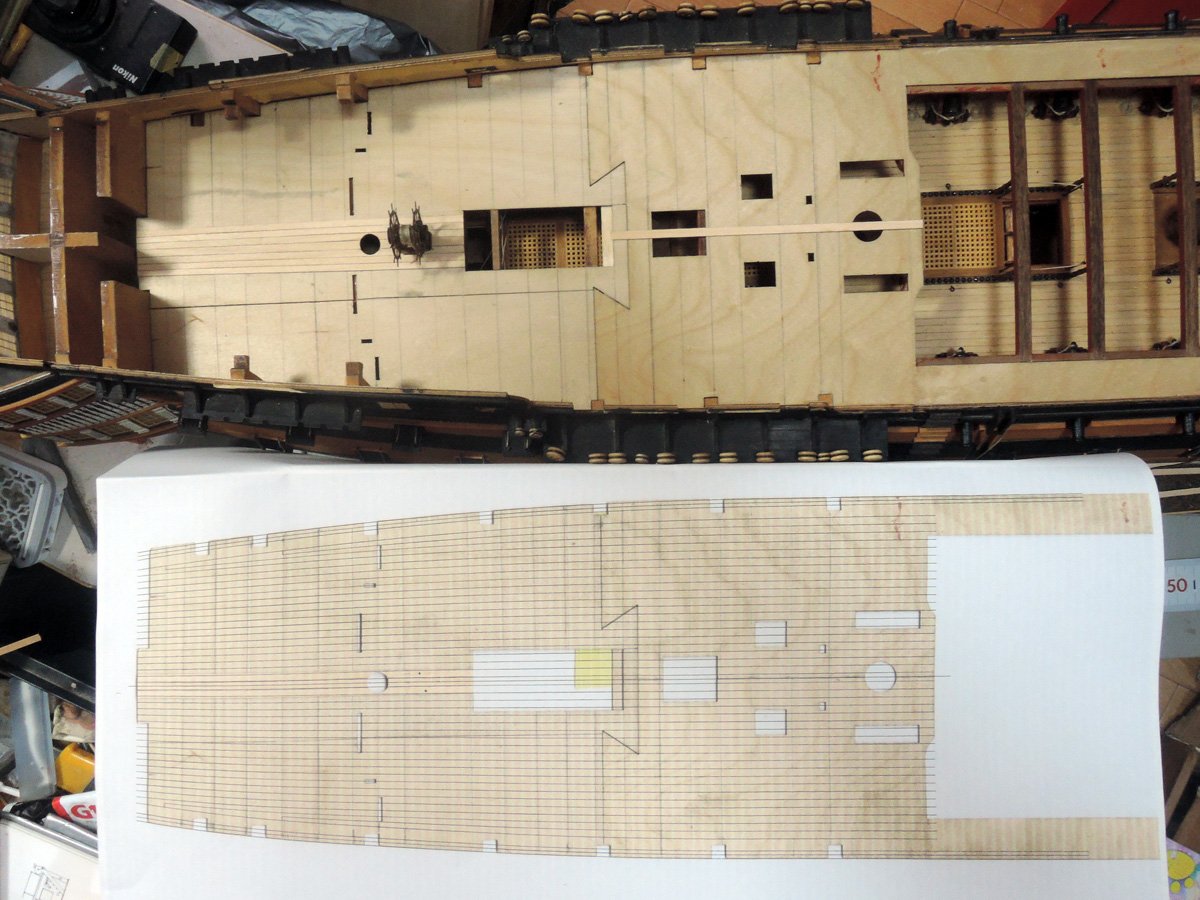

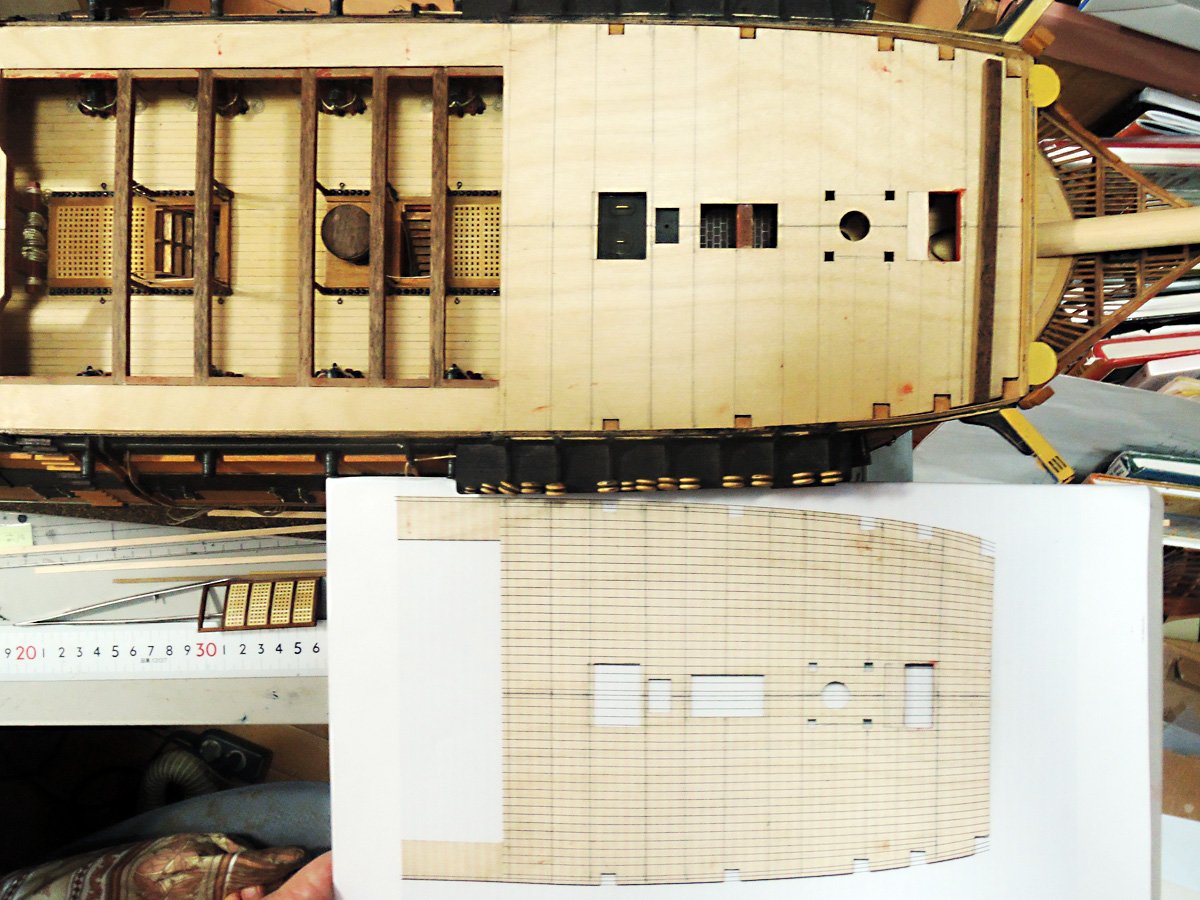

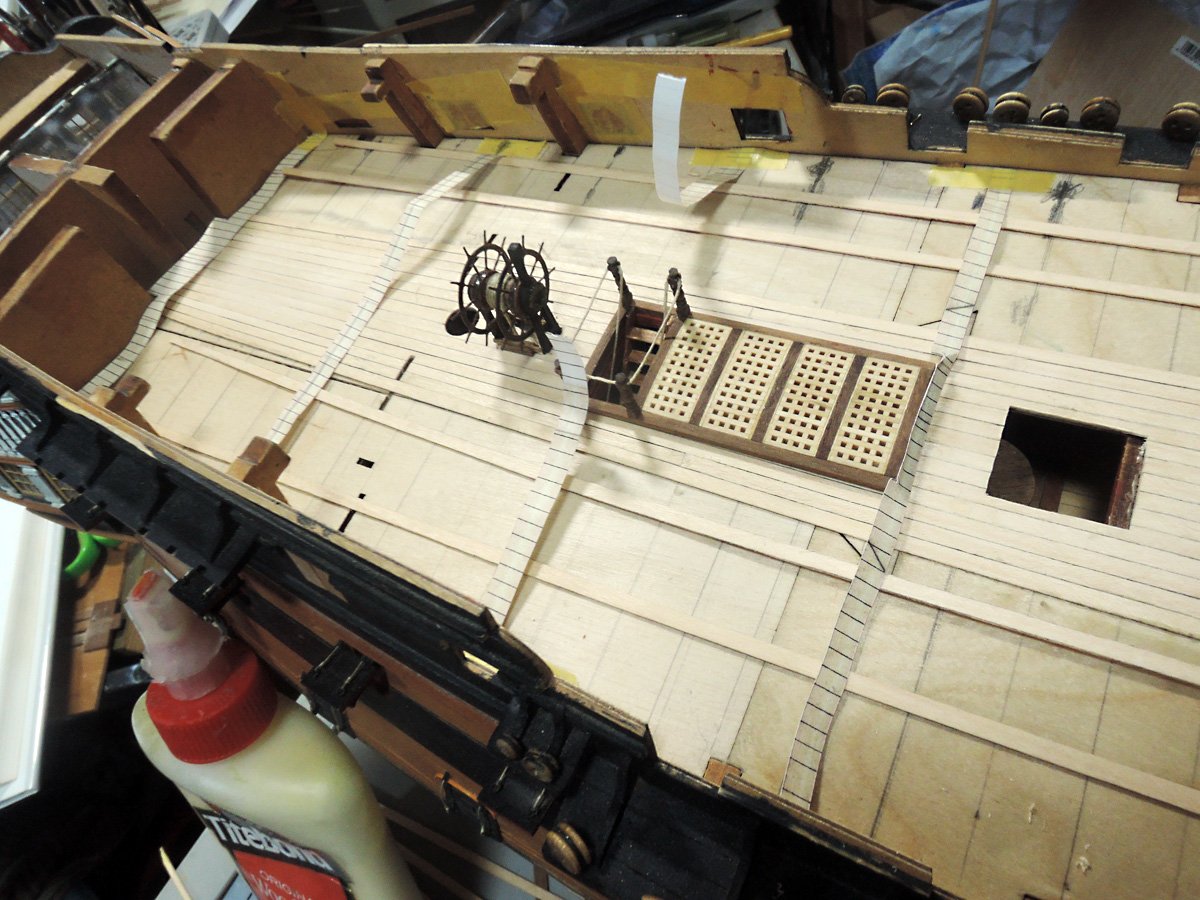

Weatherdecks planking As I wrote previously, deck planking tapering and curving toward both ends is what I want to represent. It was very tedious work to decrease widths of each plank at various stations, but patience and time solve it. Planking material is 0.5 x 3 mm maple strips I bought from Cornwall Model Boats long ago. Although maple strips aren’t necessary supreme materials for deck planking, they are easily available, and their bright colours are quite acceptable to my eyes. Their widths are varying one by one, but I can select widest one as king’s plank, although its width isn't so obvious to eyes. Also their edges are sometimes coarse but it can be resolved by careful sanding. Anyhow I prefer maple than tanganica for deck planking. I planked according to method of 3 butt system basically. Peter Goodwin wrote 4 butt method was used for quarterdeck, but deck planking drawing on pp 46 to 47 of AOTS Bellona shows 3 butt basically and are some of butt positions are shifted against regular rule of butt system at various points. Perhaps regular 3 butt or 4 butt system is aesthetically appropriate as model, I tried representing butt system which is out of regular rule. When planking is closing outer edge of deck, I cut margin plank from maple sheet. My maple sheet show sign of times comparing maple strips, but I accept it as contrast between normal planks and margin plank. Another set of deck planking plan are printed, then temporary stack to maple sheet and cut alongside of lines of planking plan. Then I engraved dummy scarf at some point. Scarf joint positions are determined to not hidden by guns. After glued margin planks onto deck edge, I filled rest of area with representation of hooked planking. They were shaped little by little repeating dry fitting on their positions. Fo'c'sle deck is also planked in same way. Method of gangway planking is also source of trouble of determination. Victory today shows continuous gangway planking from fo’c’sle deck to quarterdeck, but I believe this is later method. Finally I decided to represent gangway as separate structure between fo’c’sle deck and quarterdeck. I positioned forward end of “Fixed part of the gangway” at slightly forward than Elephant plan to adjust it on aftermost skid beam I previously fitted. This was also questionable point, but NMM model of 74 gun ship which is related to Turkey around 1800 shows fairly long fixed part of the gangway. https://collections.rmg.co.uk/collections/objects/66611.html I was encouraged by this model and adjusted forward end of fixed part slightly longer forward than Elephant plan. Also I slightly enlarged inner edge of gangway according to depiction of Goodwin. Maybe widened gangway is matching to permanent skid beams. I also planked poop deck at this point while I’m remembering experience of quarterdeck and fo’c’sle deck. Major difference is that poop deck baseboard is temporary dry fitted, not glued to its position because I wanted to plank poop deck at the situation baseboard is cambered. When planking is closing to deck edge, I removed poop deck and glues last of hooked planks and margin plank. This time margin plank is glued at last stage. Inner edge of poop deck margin plank is cut according to planking plan, but outer edge is roughly cut, and cut to correct shape after glued deck edge. Although treenailing is not yet started, weatherdeck planking is completed at last. Widths of caulking between planks are varied because of my imperfect work, but I’m satisfied to see representation of tapering and curving of planks are fairly well done.

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

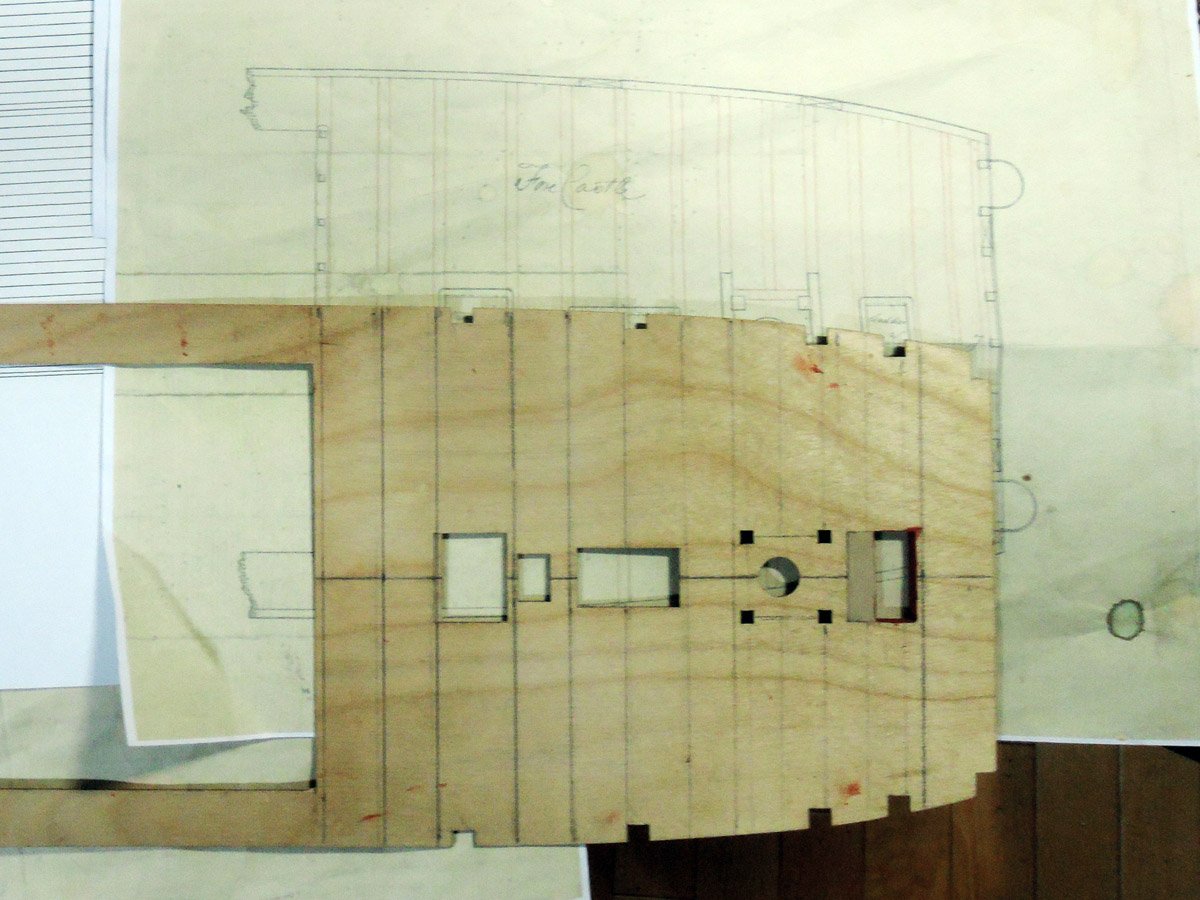

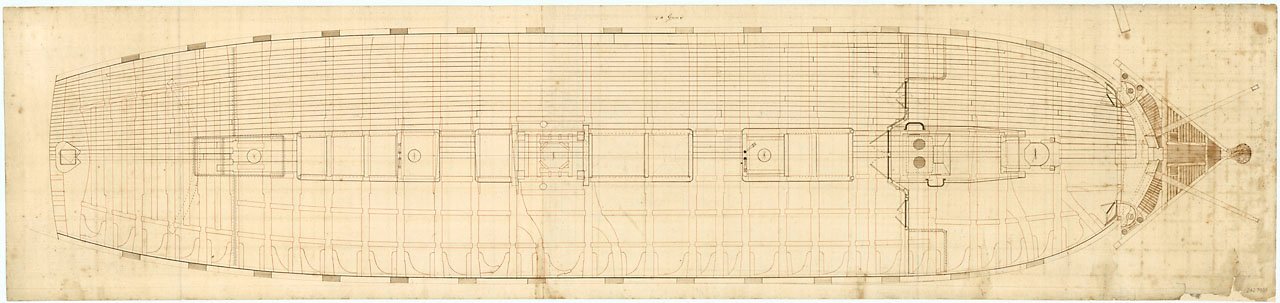

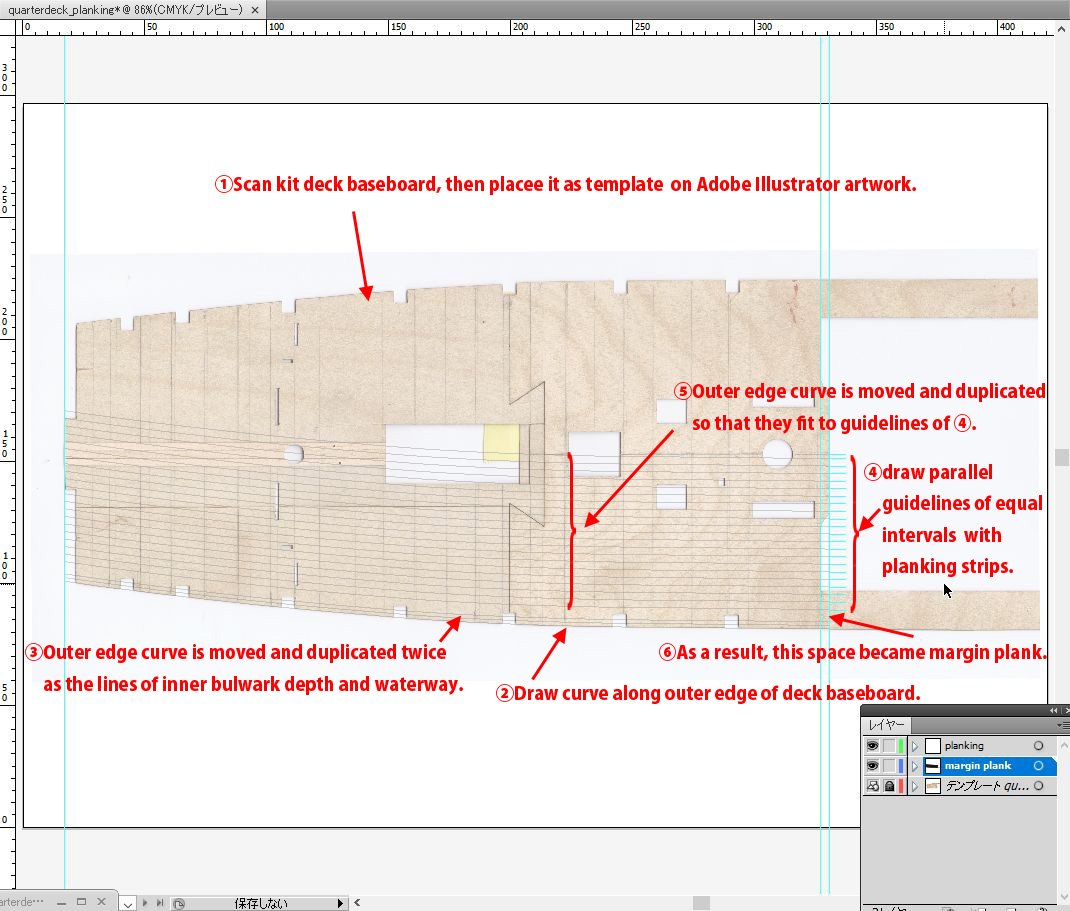

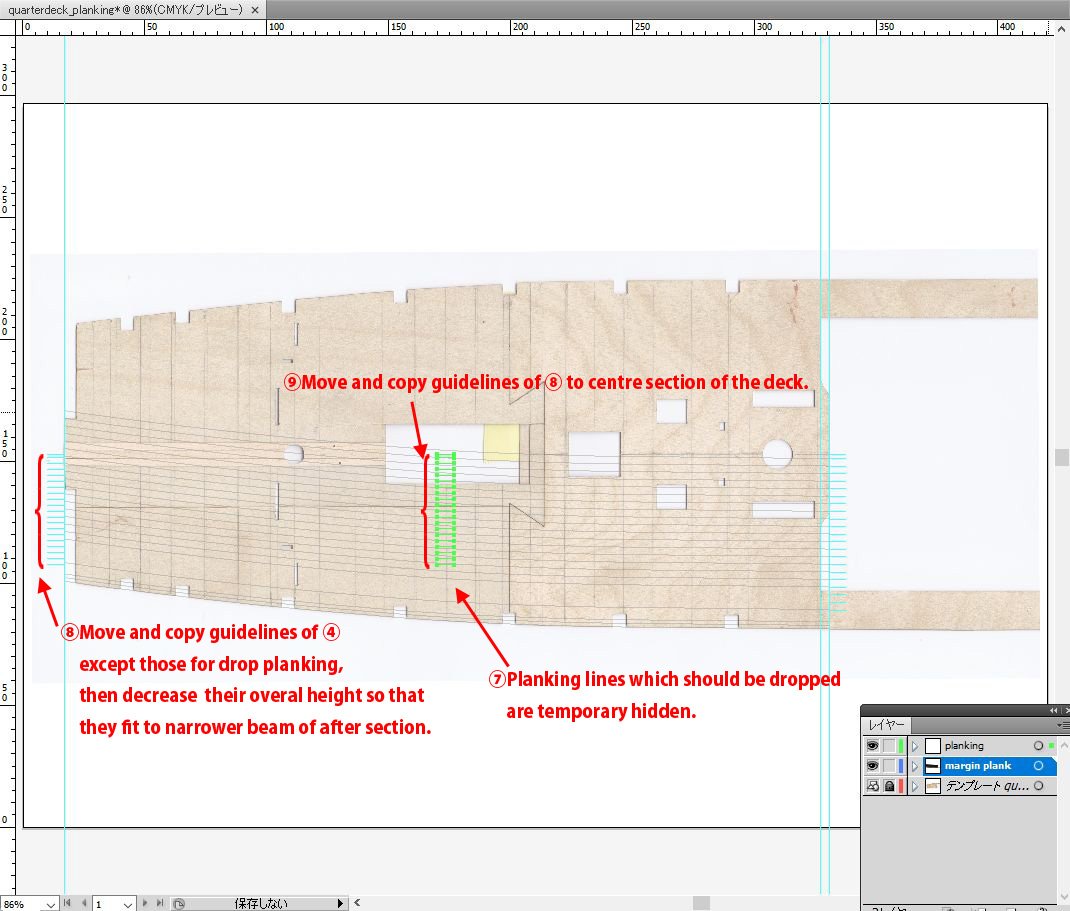

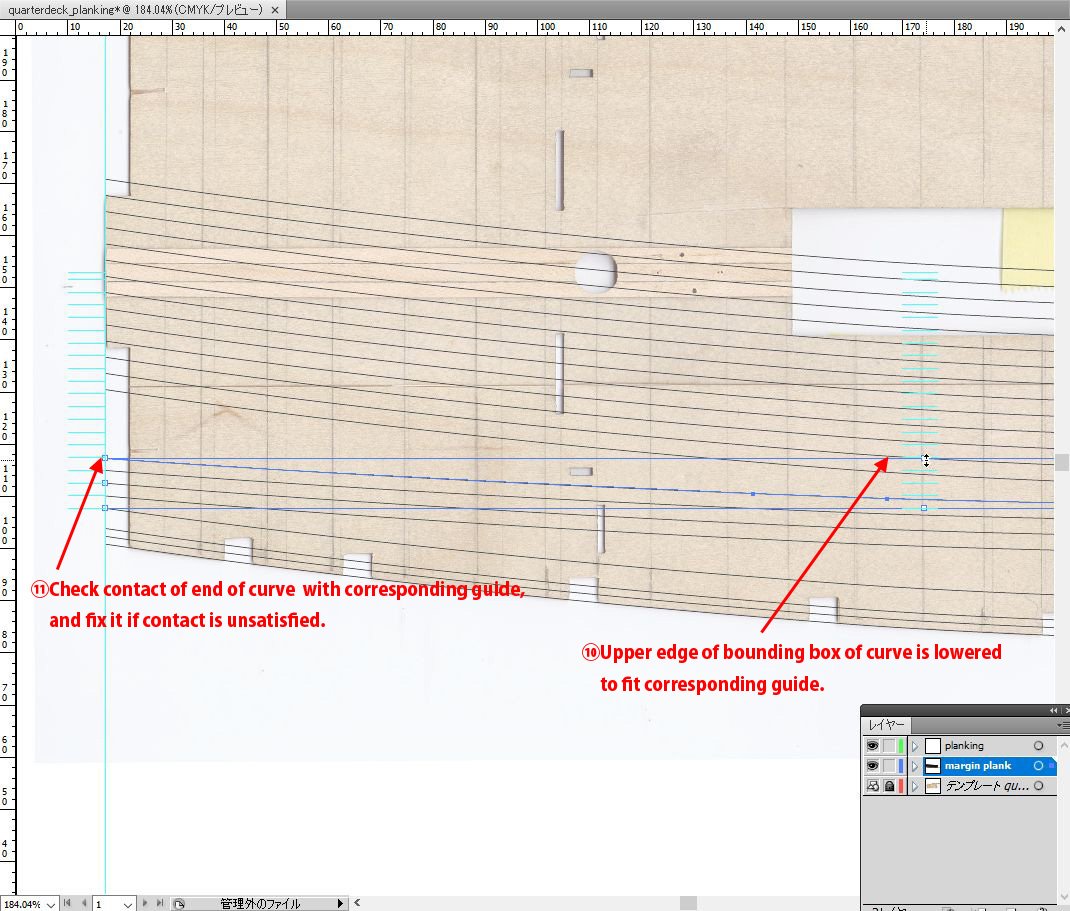

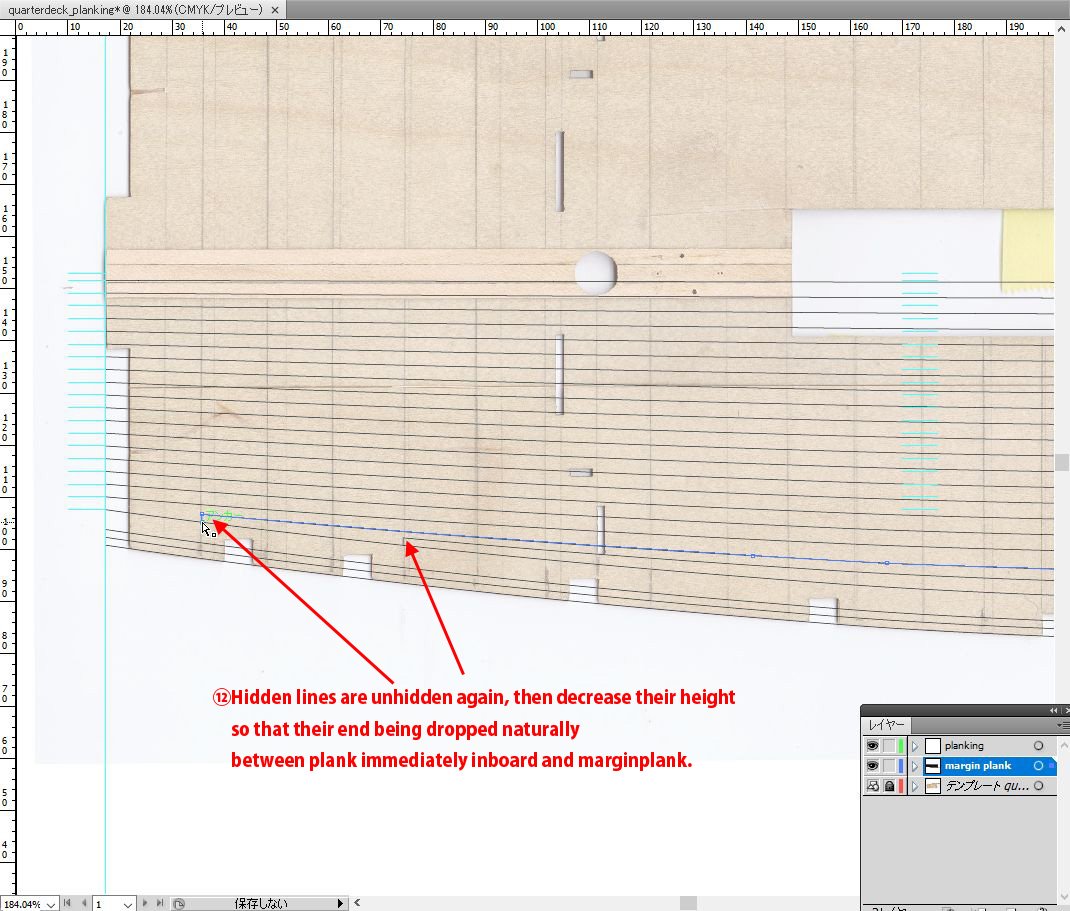

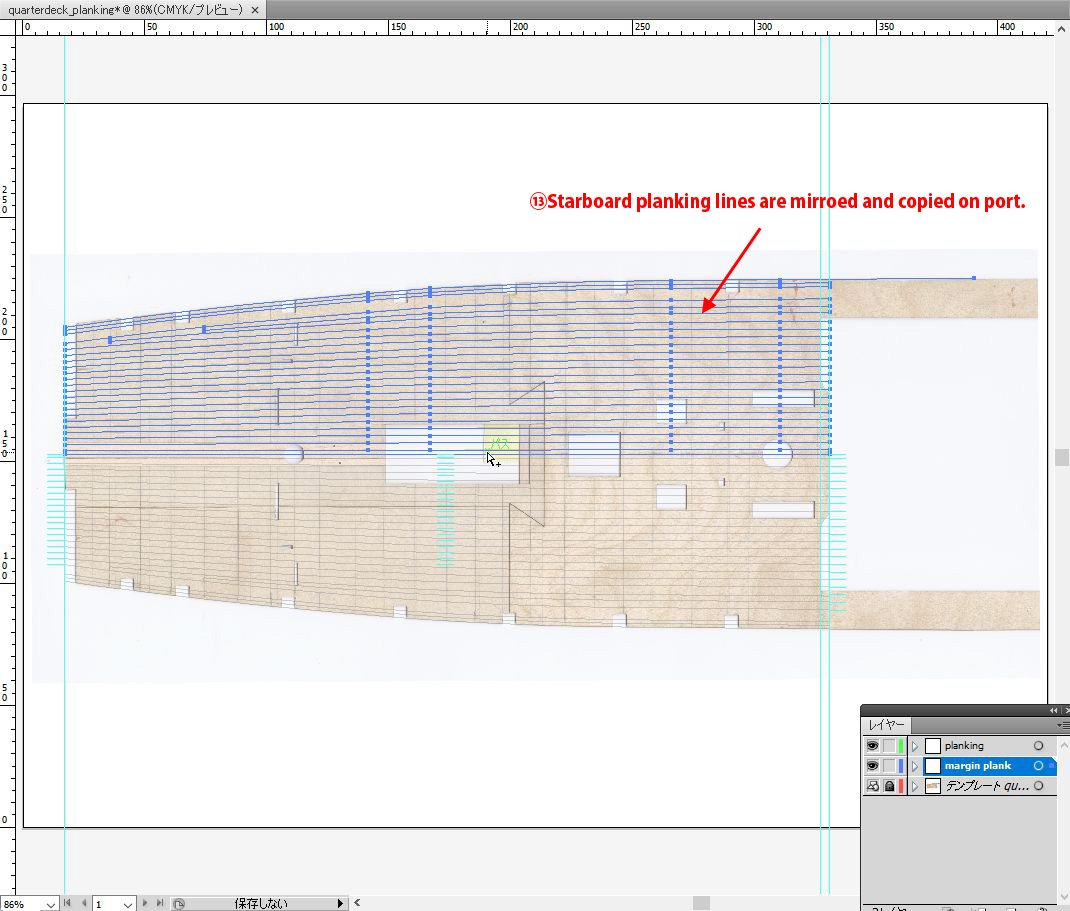

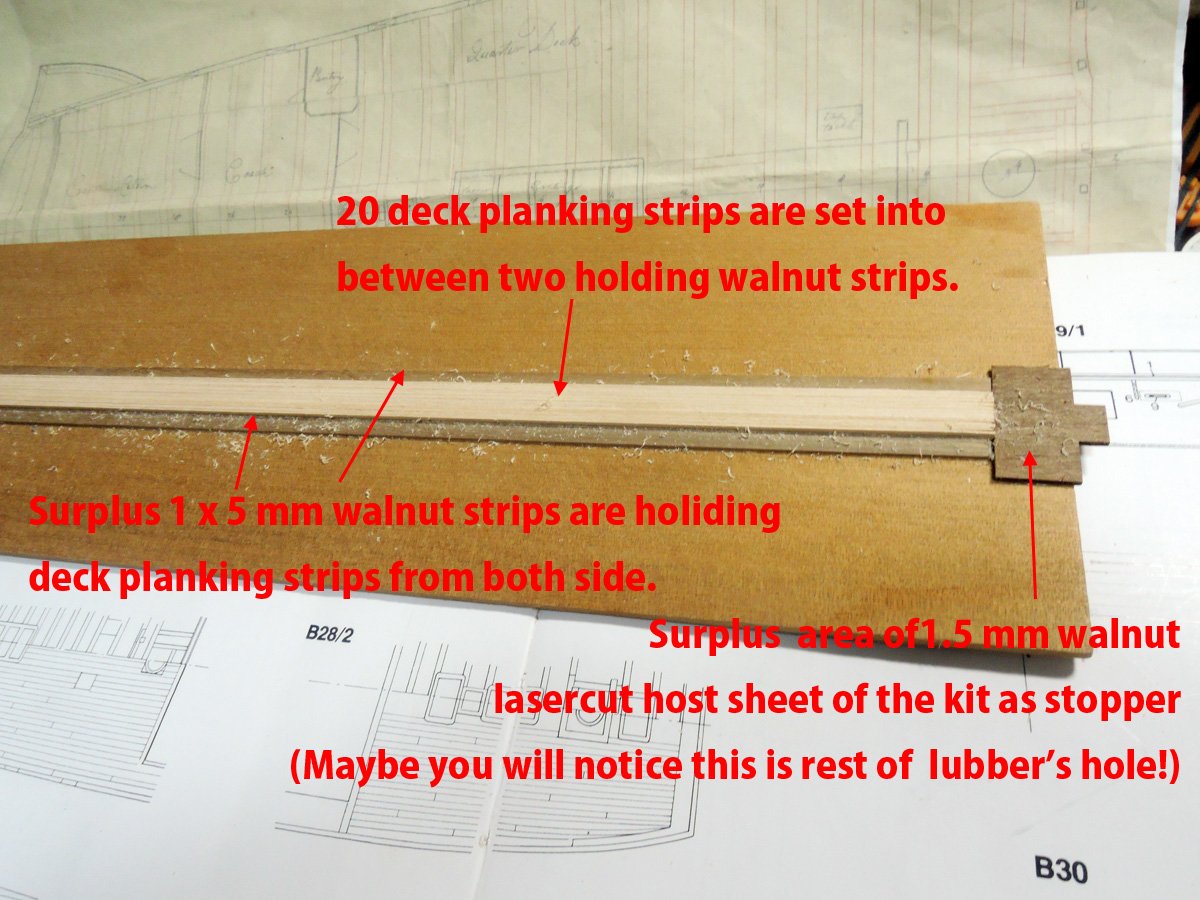

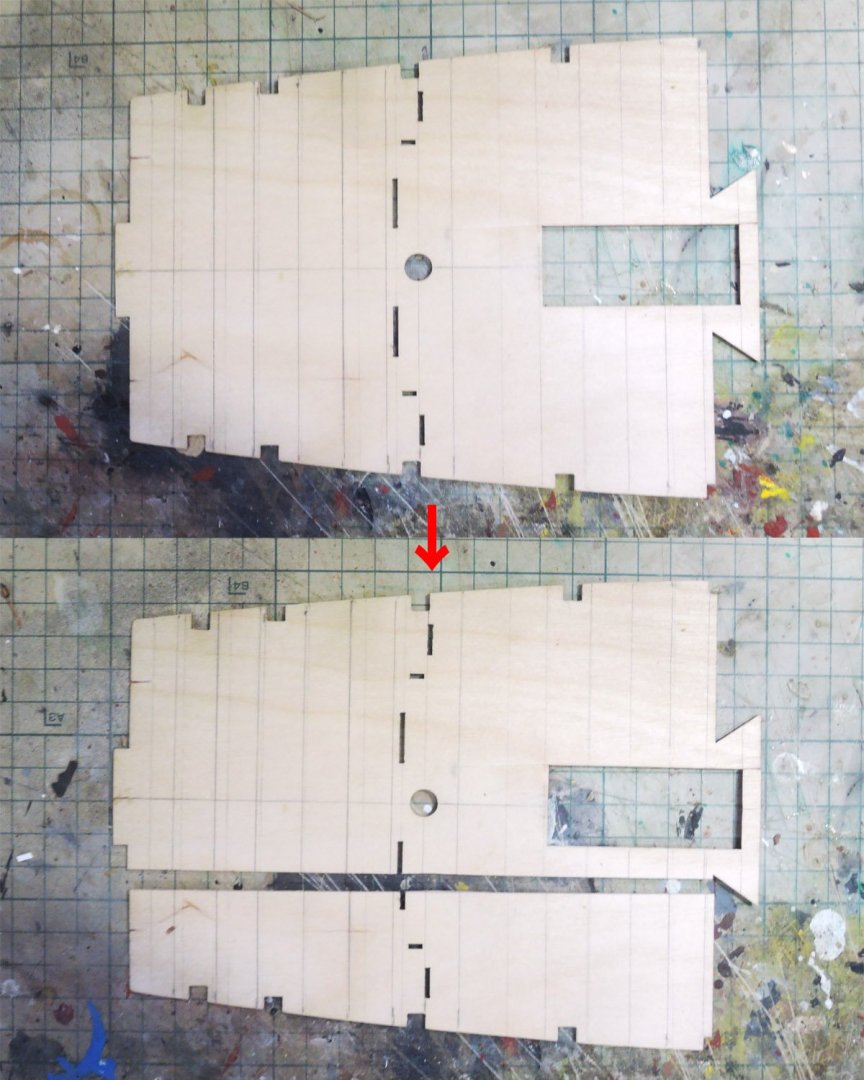

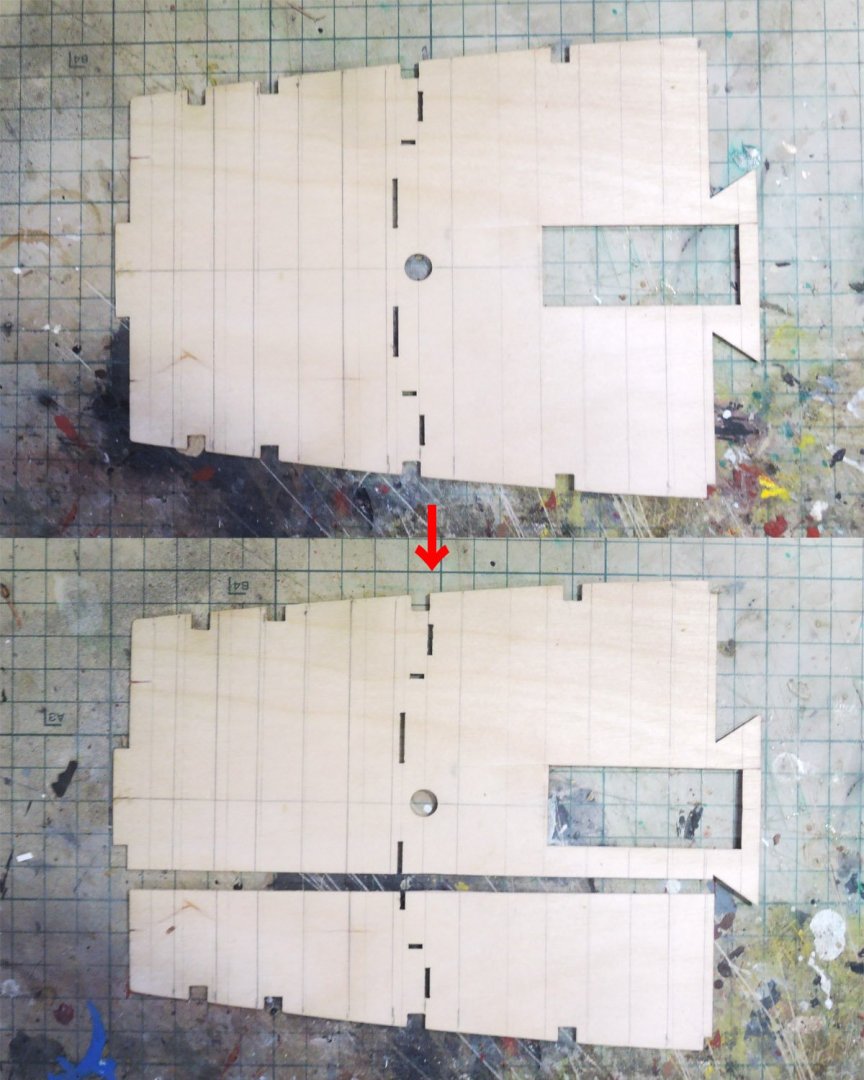

Preparation of weather decks planking Though some of these treatments were done before, I want to tell about them here. I marked beam positions onto baseboards of fo’c’sle deck and quarterdeck referring deck beam plans of Elephant. These marks will show the points where deck planks should be butted. Next is preparation of weather deck planking plan. There is fo’c’sle and quarterdeck planking plan of anonymous 74 gun ship of 1798 on pp.46 to 47 of AOTS Bellona. This plan is showing each plank is tapered and curved towards both ends. Also outboard plank is blended into next inboard plank like drop strake of hull, instead of joggled into margin plank. Although it isn't showing those for fo'c'sle deck or quarterdeck but upper deck, plan of another anonymous 74 gun ship also shows same feature. https://collections.rmg.co.uk/collections/objects/382650.html I didn’t represent these features on upper deck planking because planks of both ends will be hidden by fo’c’sle deck or quarterdeck. But most of planks of weather decks can be visible except aft part of quarterdeck which is hidden by poop deck. So I prepared deck planking plan with Adobe Illustrator. Below images are sequence how I draw planking line of quarterdeck. Plan for fo’c’sle deck is also drawn in same way. I only hope images below will be help for readers to understand how I drew these lines. Poop deck is also treated as I did for fo’c’sle deck and quarterdeck except beam positions are referred to inboard profile of Elephant because Elephant deck beam plan isn’t containing that for poop deck. Finished planking plan are then printed. I printed two sheets of each deck planking plan. One sheet will be used for general reference when I plank each deck. Another sheet is cut into several sections at beam positions and temporary stuck on deck baseboard edge as guide for checking each plank width. Planks are set into simple holder I made from surplus woods. I tapered 20 planks at once with help of this holder. Actually planks should be bent sideways as they are going to outboard. They will be bent with help of heat and steam from kettle. After these preparations were done, I started planking of quarterdeck. As posted before I split quarterdeck baseboard at slightly starboard area of hatch opening. https://modelshipworld.com/topic/2926-hms-bellerophon-1786-by-fake-johnbull-amativictory-models-172-vanguard-kit/page/4/?tab=comments#comment-822079 Firstly I only glued port baseboard and starboard baseboard wasn’t glued at this point. I firstly planked fore and aft centre area of quarterdeck because I had to finish tiller rope from wheel and rudder as well as its associating balusters and rail rope. These fittings are last parts to be fitted onto upper deck except heals of other rudders down from gangways or fo’c’sle deck which will be less troublesome. Tiller ropes and rudder rail rope are finally set using tweezers operated from starboard aperture of quarterdeck. Before gluing rest of quarterdeck baseboard, I photographed these areas with poop deck baseboard and stump mizzen mast dry fitted to their places. Although these areas will become can’t be seen as building proceeds, positional relationship of these fittings connecting several deck levels are quite understandable from this picture. Rest of quarterdeck baseboard was finally glued. Although they can’t be seen clearly, tiller ropes are barely visible through rudderway opening by illuminating these areas carefully. I understand this is only my self-satisfaction, but at same time, I’m delightful to see representation of tiller ropes show their value.

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

Allan, Thank you for your comment and sharing info on program by Adam Preston👍 Honestly saying I'm not good at English hearing, but Adam's broadcasting and pronunciation is very clear. I hope progress of the whole project✌️

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

Bruce, Thank you for your kind word. Although some of items I had added may be hidden by other items, I myself am satisfied something is surely there behind other items. It is value of building log to record these hidden details, and this is one of reason we modellers record building process.

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

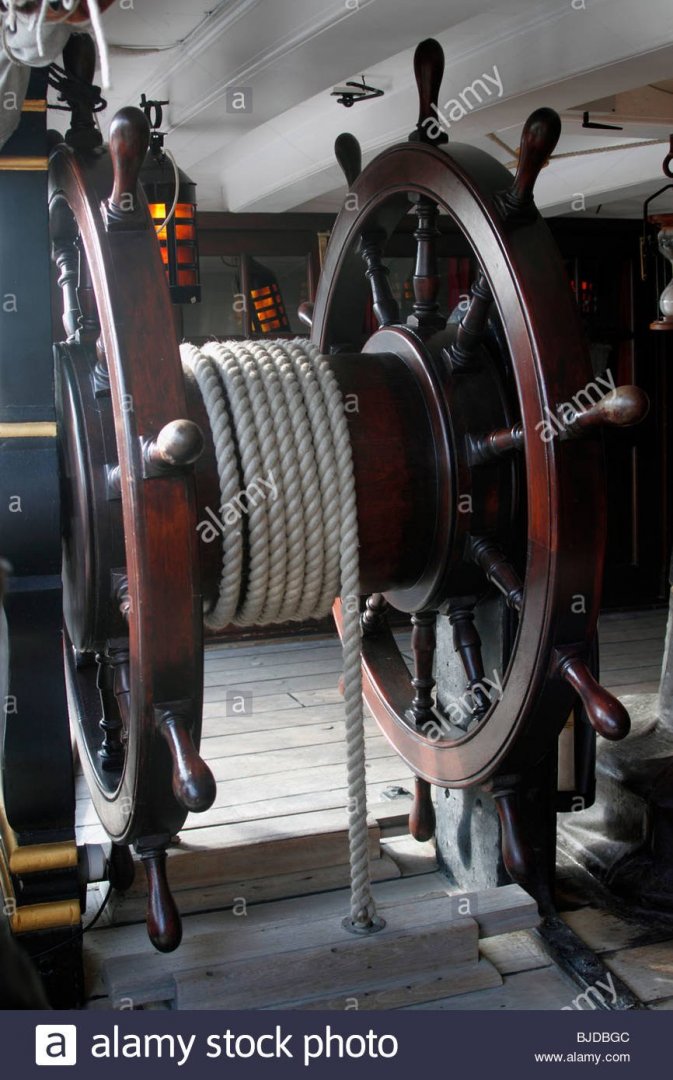

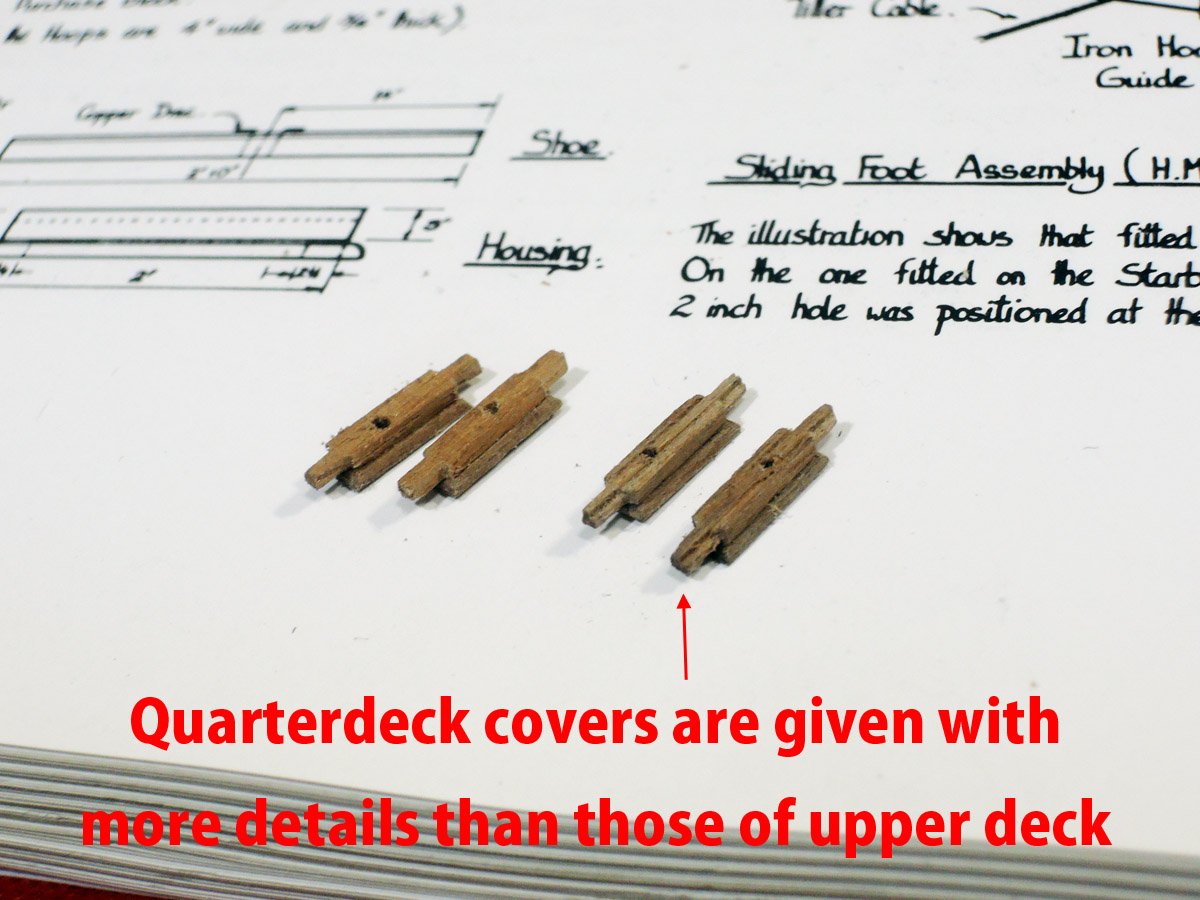

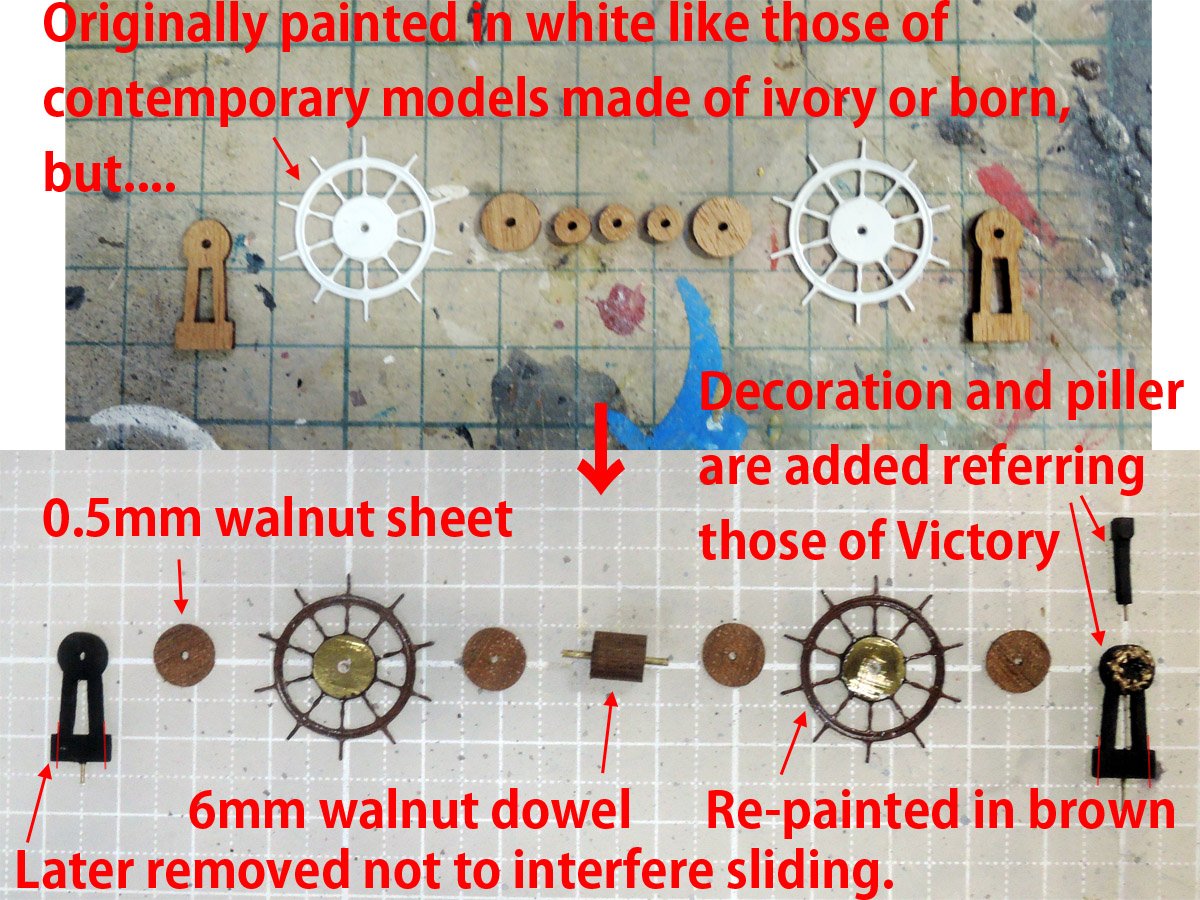

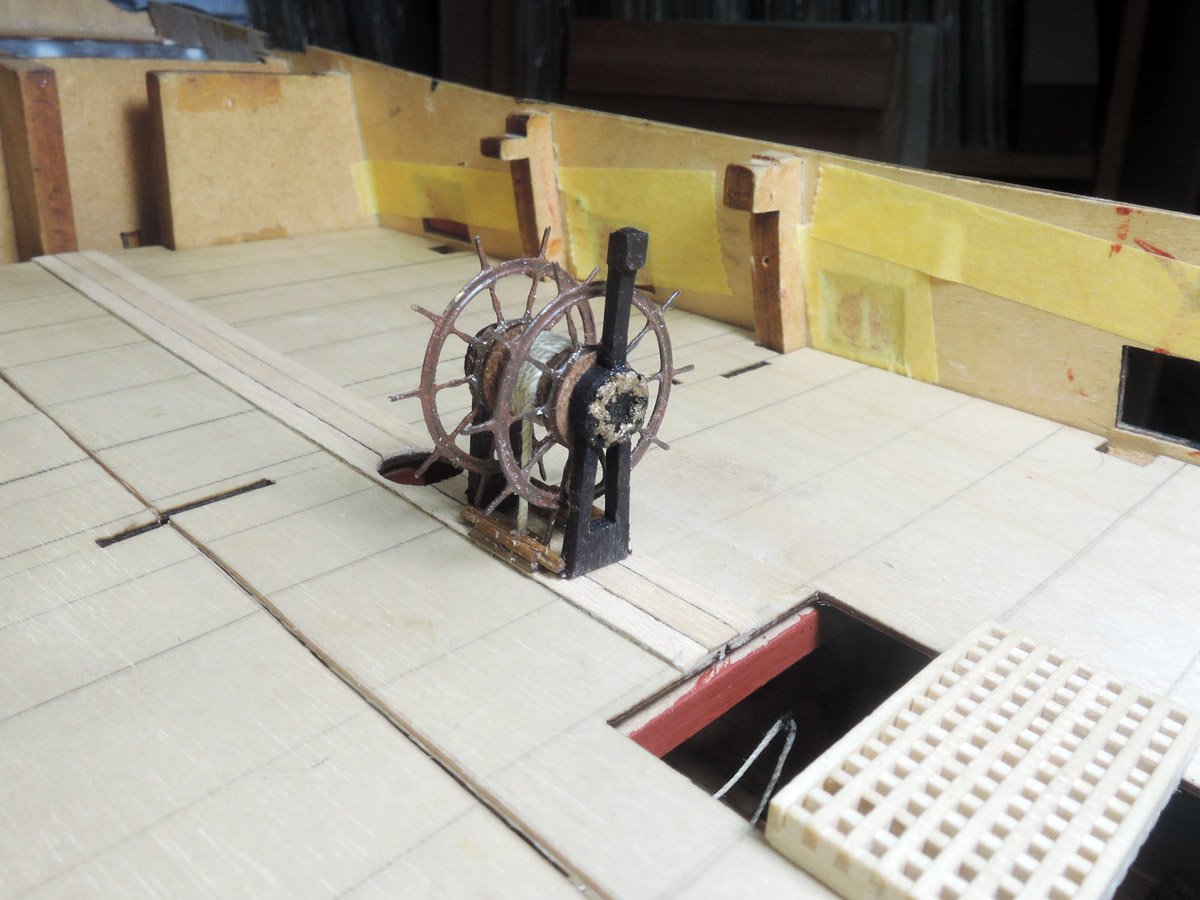

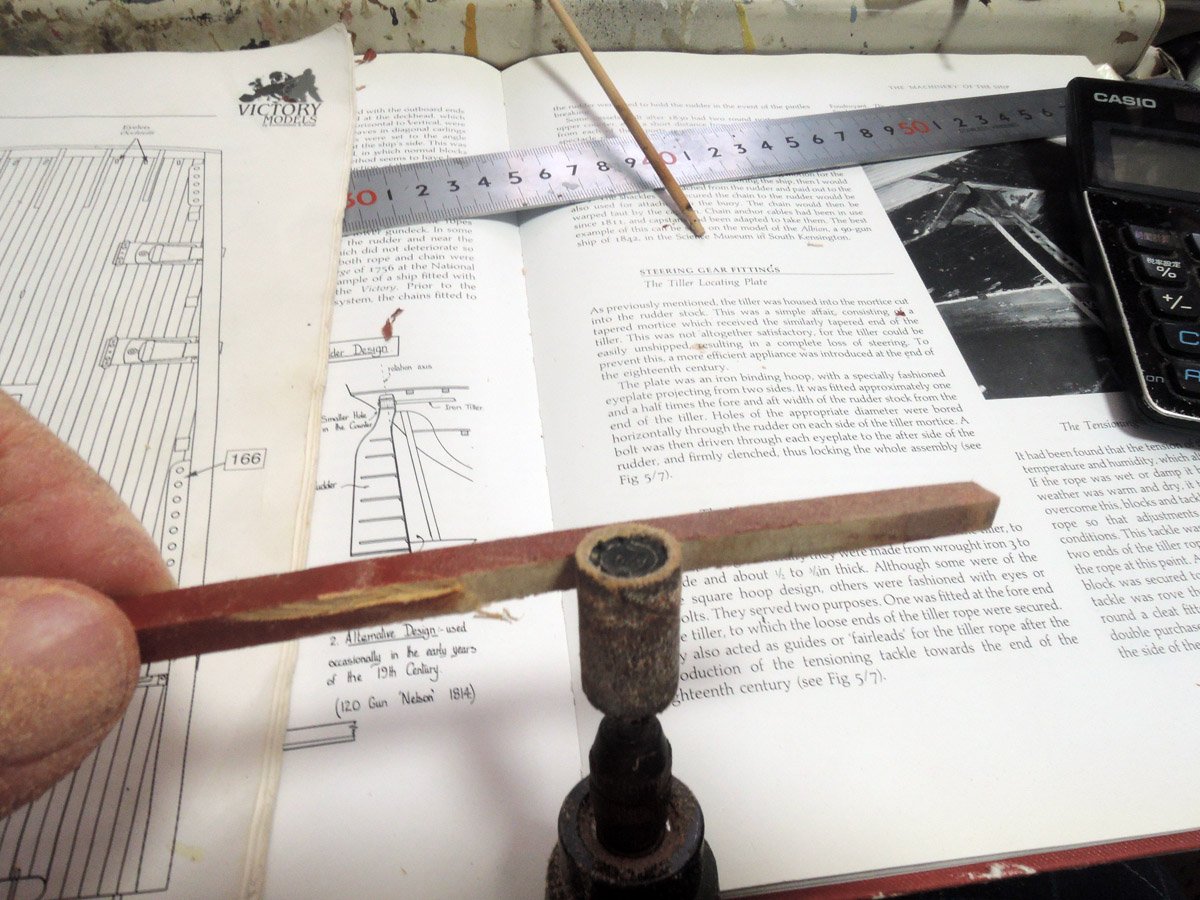

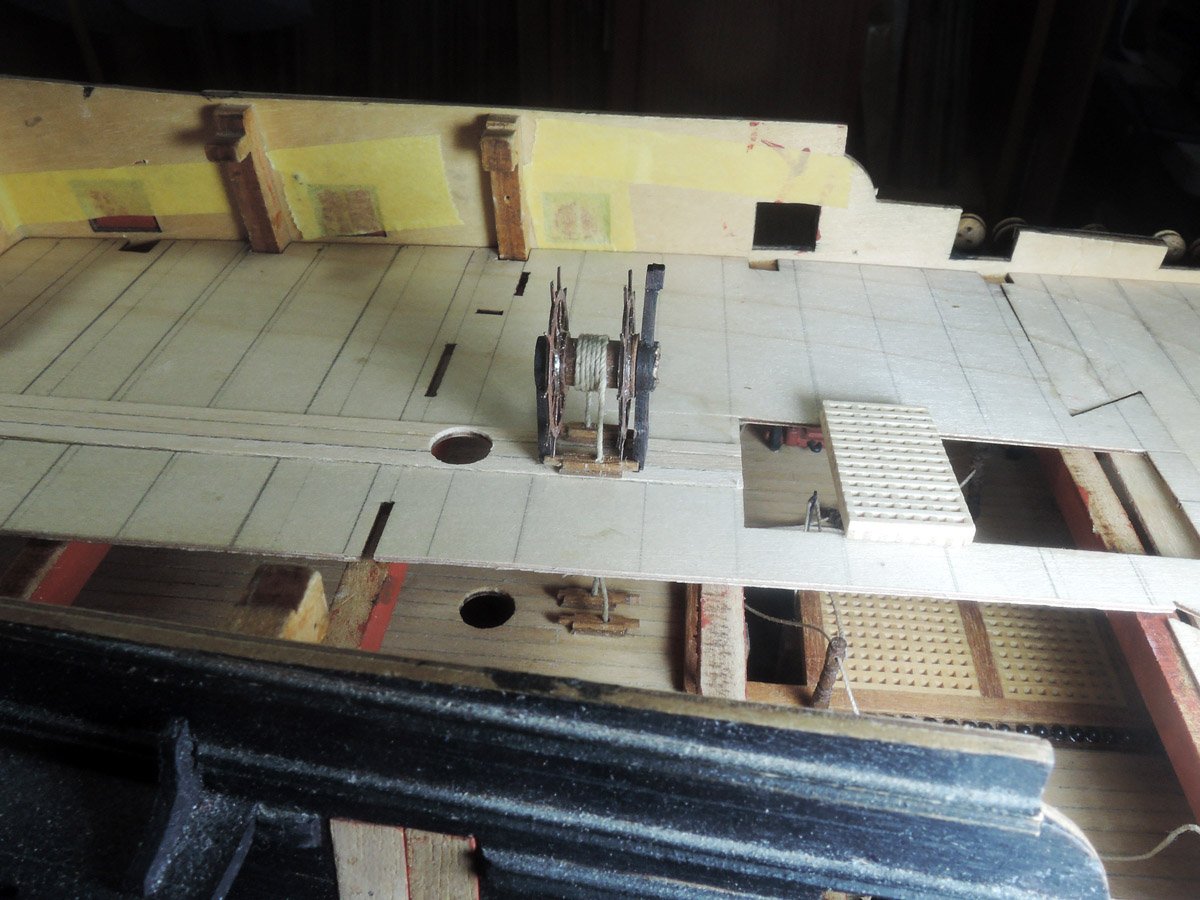

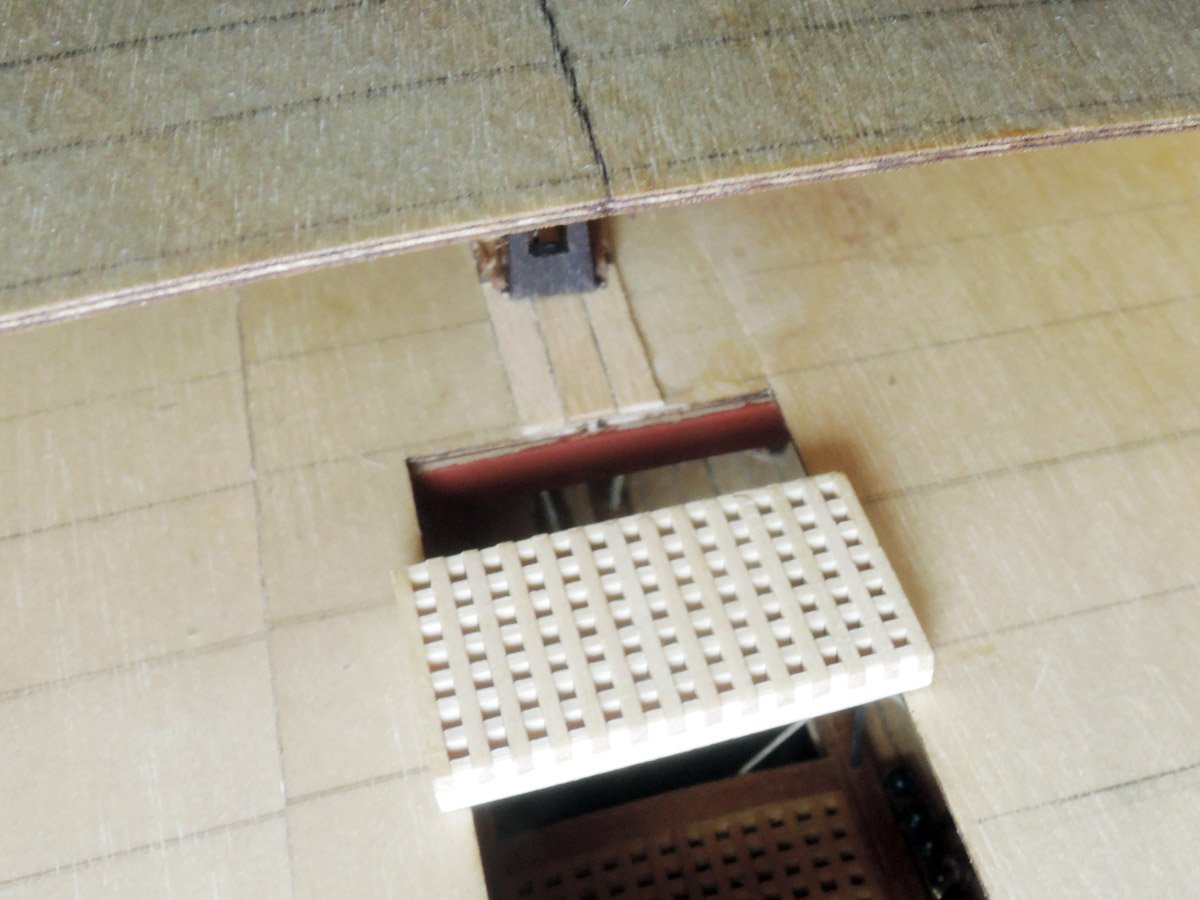

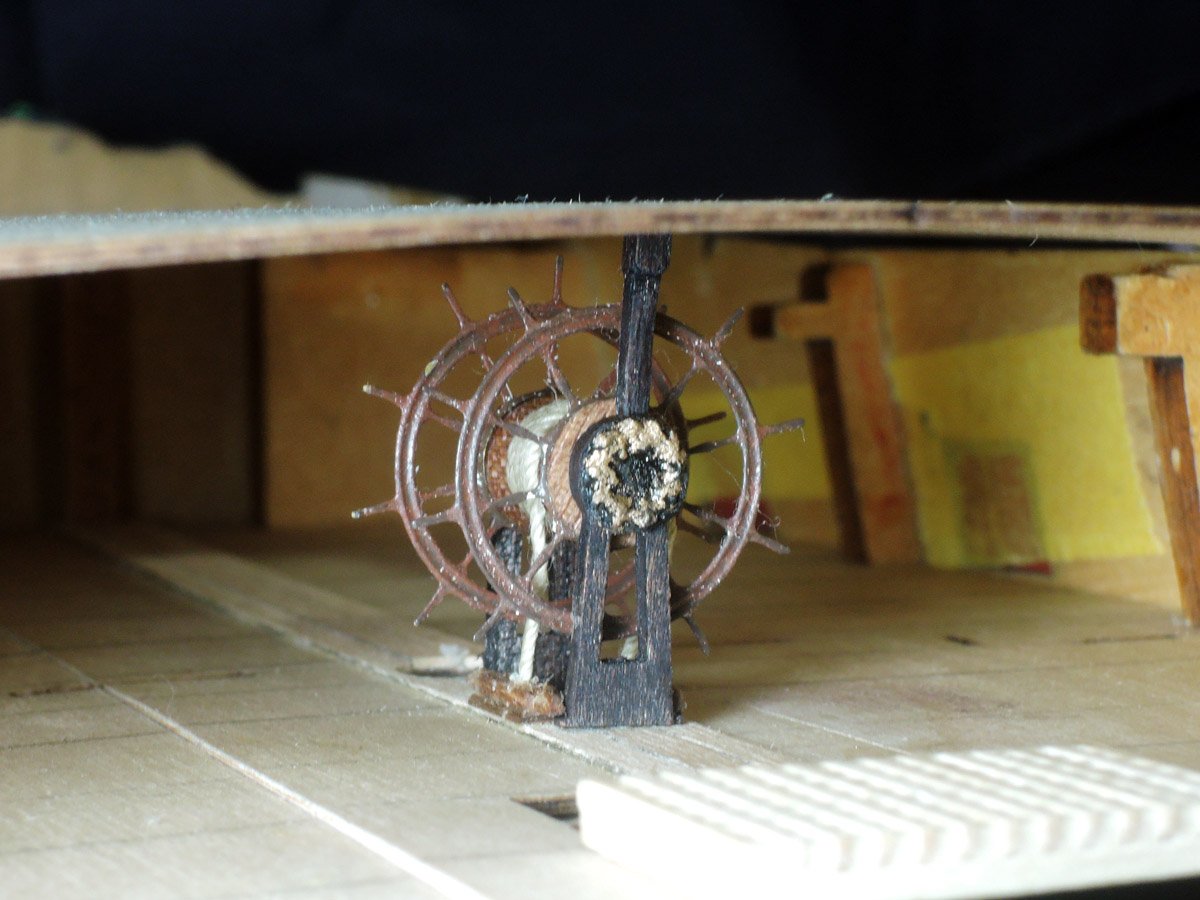

Steering gear Though steering wheel is itself fitting of quarterdeck, I made it at this moment because I want to confirm tension of tiller rope down from quarterdeck to upper deck and point of upper deck sliding foots. Sliding foots are clearly can be seen on Victory today. https://www.alamy.com/stock-photo-ships-wheel-on-hms-victory-at-the-portsmouth-historic-dockyard-28568636.html https://andyandjudi.com/2017/07/10/hms-victory-portsmouth-historic-naval-dockyard/ AOTS Victory shows sliding foots are also fitted onto upper deck. Except heels of ladders down from fo’c’sle deck, quarterdeck and gangways, they will be last parts to be fitted onto upper deck in my building. Base of sliding foot is 0.7 x 3 x 8.5 mm walnut and I rounded each edge. Sliding cover and rails of both sides are shaped as one part from 2 mm square walnut dowel and their lengths are 12 mm. These figures are referred to Goodwin’s “The Construction and Fitting”. Those of upper deck are simplified shape, but for those of quarterdeck I add some details including rabbets of sliding cover to be hold into side rails、grooves between sliding cover and rails. Wheels and their supports are upgraded. Decoration of forward support is made of 0.3 mm brass rod and Liquitex super heavy gel medium. Though it is apparently bigger than real one, I accept it considering my skill😅😅😅. After constructions of these parts are finished, I dry fitted them into their places. I split quarterdeck baseboard into two parts at slightly starboard position of hatch opening. Tiller rope is spread with tweezers and passed through sliding foot on upper deck from starboard. Depth of upper deck beam immediately aft of opening is thick because of rigidity, but I thinned it to show tiller rope more clearly. After finishing dry fitting including rest of quarterdeck baseboard, poop deck baseboard and grating just before of ladderway opening,-I shed light there. Happily tiller rope and sliding foot are can be seen through opening. They may be able to seen well after fitting of ladder of this area. Next, I want to start construction of fo’c’sle deck, quarterdeck and gangways.

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

James, Thank you for your comment. Sometimes, it is very difficult to guess details of specific ship of specific date, so we have to seek infos of other ships of same era. While I'm still unconfident of authenticity of my skid beams construction, I satisfy that they themselves seem to be rigid with pillars and hanging knees😅

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.