-

Posts

225 -

Joined

-

Last visited

-

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Dan DSilva reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

dvm27 reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

dvm27 reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Cpt.Barbossa reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Cpt.Barbossa reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Jefta reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Jefta reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Stavanger reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Stavanger reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Gregor reacted to a post in a topic:

La Belle 1684 by Oliver1973 - 1/36

Gregor reacted to a post in a topic:

La Belle 1684 by Oliver1973 - 1/36

-

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

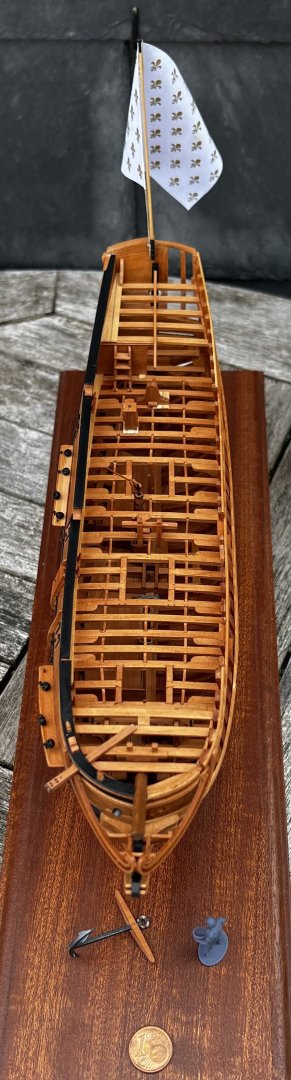

Thank you for all the likes, I'm humbled. After a good five years, my version of La Belle was launched today. For the most part, the project gave me great pleasure. Not everything turned out as I had dreamed - on the other hand, I didn't know whether such a model could be realized in a home office (but on its own desk). In any case, I learned an incredible amount. In my opinion, La Belle is ideal as an introduction to frame model building: not too big, not too complicated, but with all the exciting elements of 17th century French shipbuilding. You can also take a few liberties. Boudriot's reconstruction is juxtaposed with more recent archaeological research results. The beautiful decorations in particular are probably a little lavish. I have compensated for this with an extra-large flag. White Bourbon cloth would probably have sufficed - I simply treated myself and the little ship to the golden lilies. Cheers, Gregor

-

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

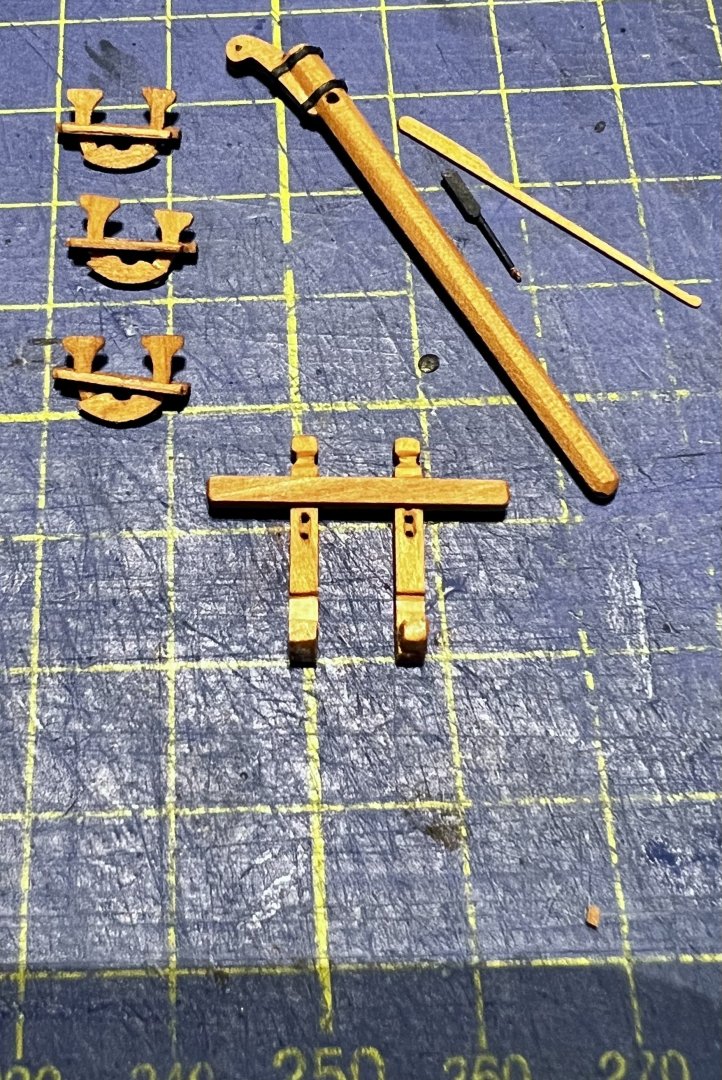

Thank you @fmartins for your kind feedback. As for craftsmanship, I'm not so sure. Look what happened recently: La Belle fell out of my hands... Luckily, all is well again. I made a small binnacle. My La Belle will now be able to find her way to her final resting place in the Gulf of Mexico. Cheers, Gregor

-

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

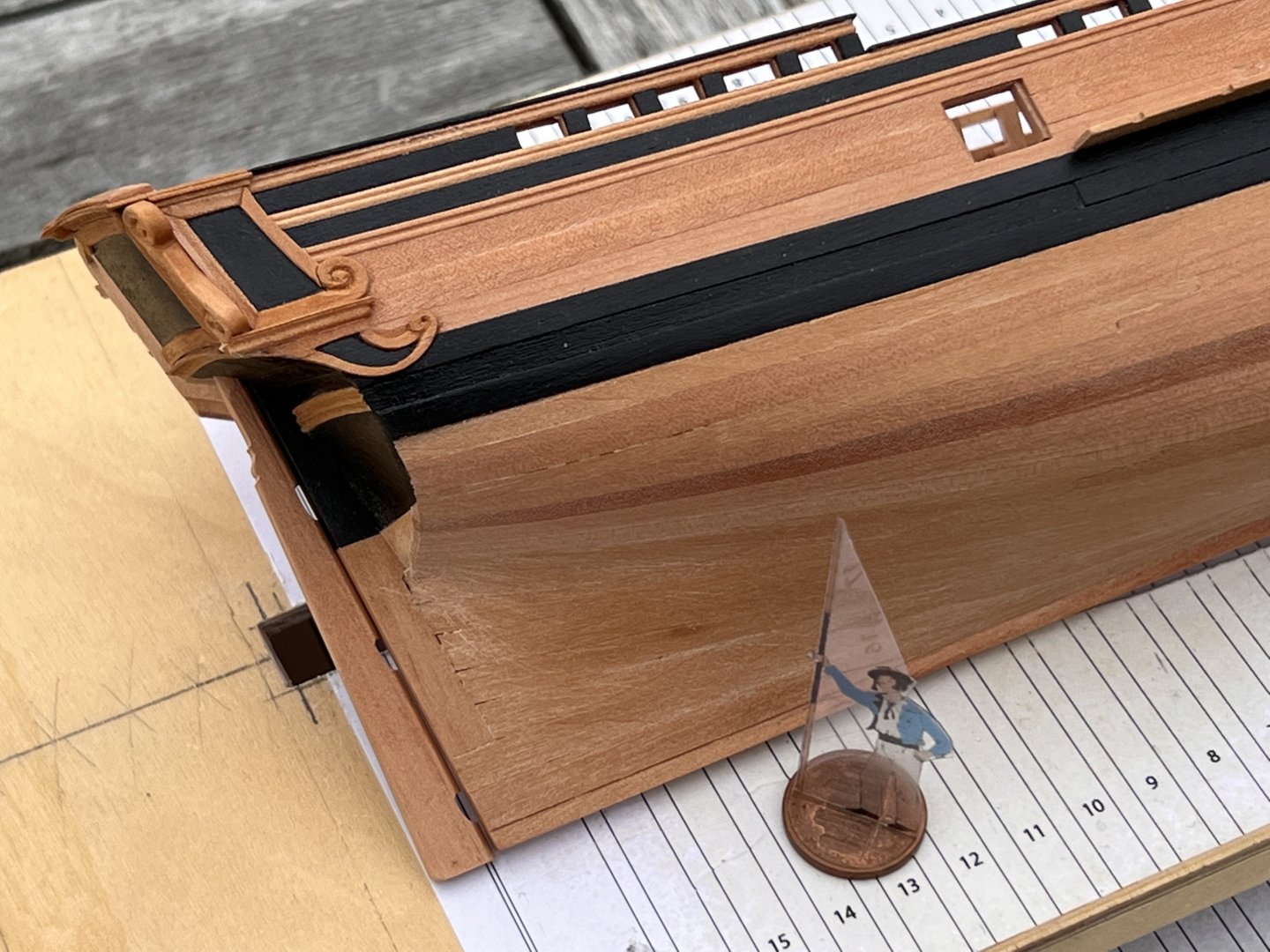

Only a small update: the galion, inspired by Boudriot and much simplified. I hope to find some time to do the deadeyes on starboard and the rudder. Cheers, Gregor

-

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

Gregor reacted to a post in a topic:

La Belle 1684 by Gregor – Finished - 1:64 scale

-

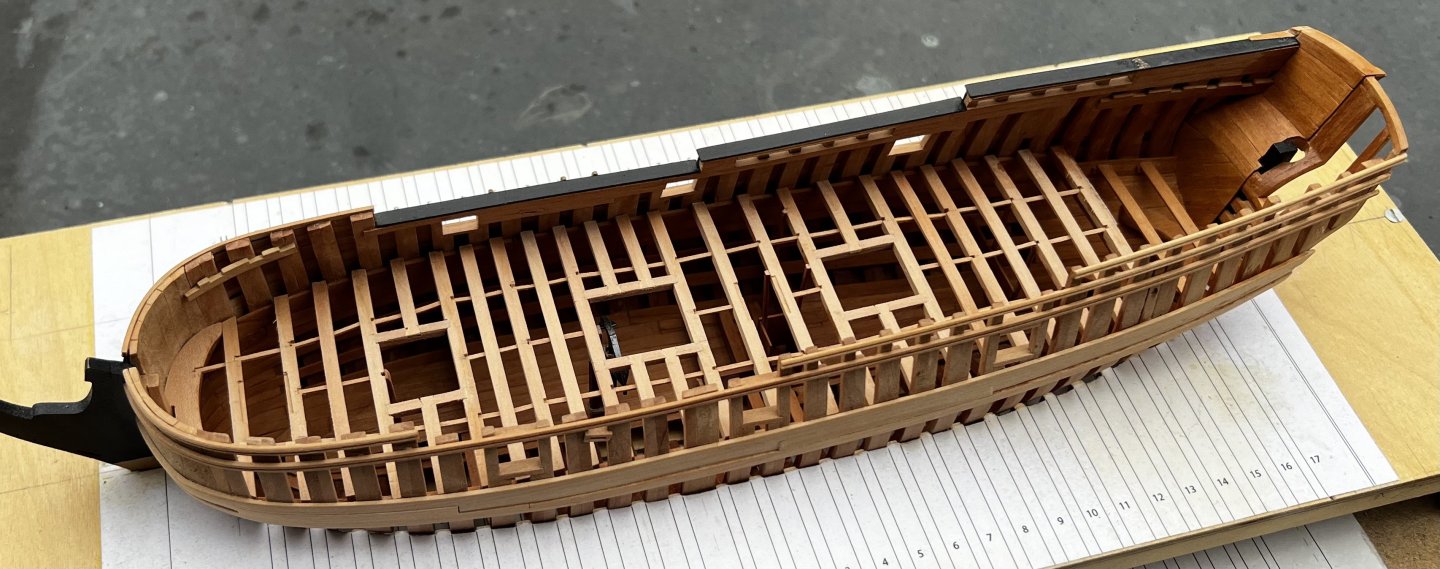

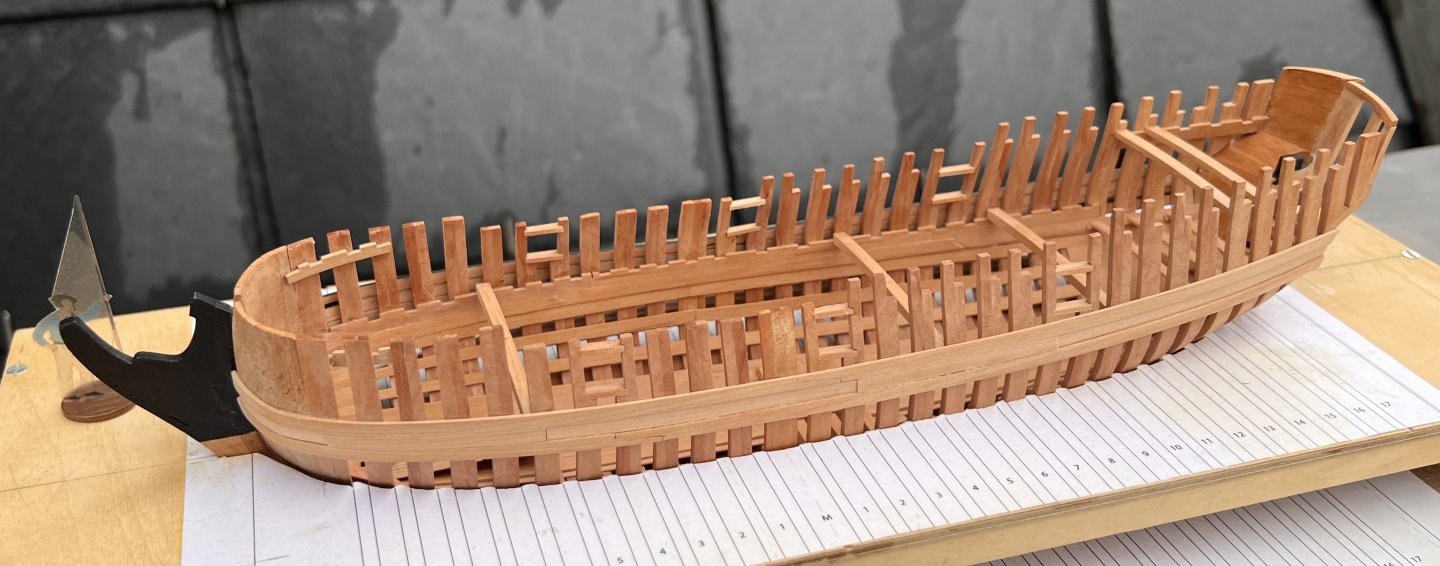

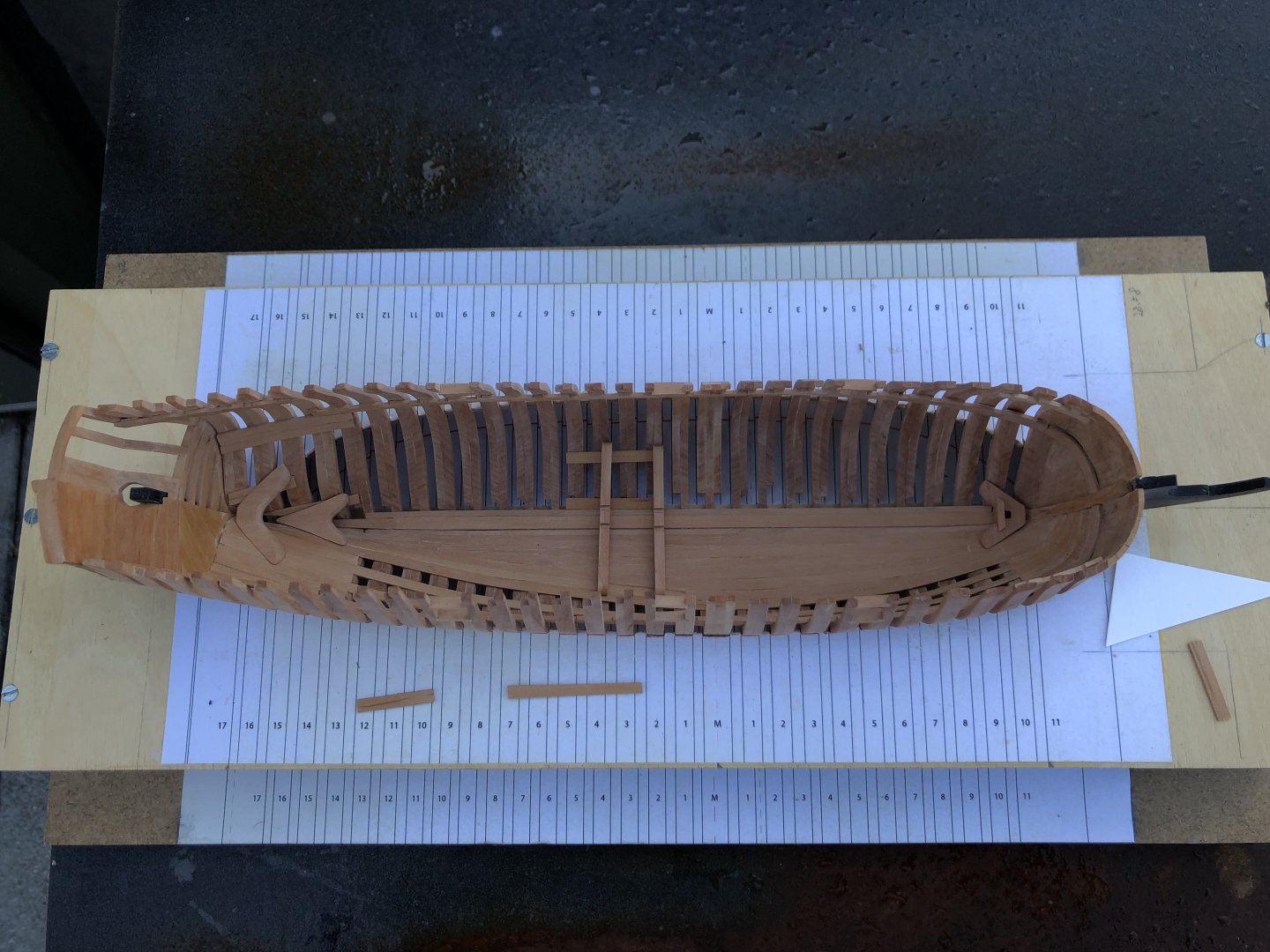

Well, I'm happy to report that I can take off my prescription glasses when I work on small details - one of the benefits of aging 🙂 @JacquesCousteau: Each regular frame consists of two parts, each 2.5 mm thick (frame M has three parts).

-

I finally found the time to add a few details, a cat head and spill, bitts, belaying cleats and a pump. Cheers, Gregor

-

Gregor reacted to a post in a topic:

La Mutine and La Topaze by Gregor – 1:64 scale - French Schooners - La Jacinthe Type

Gregor reacted to a post in a topic:

La Mutine and La Topaze by Gregor – 1:64 scale - French Schooners - La Jacinthe Type

-

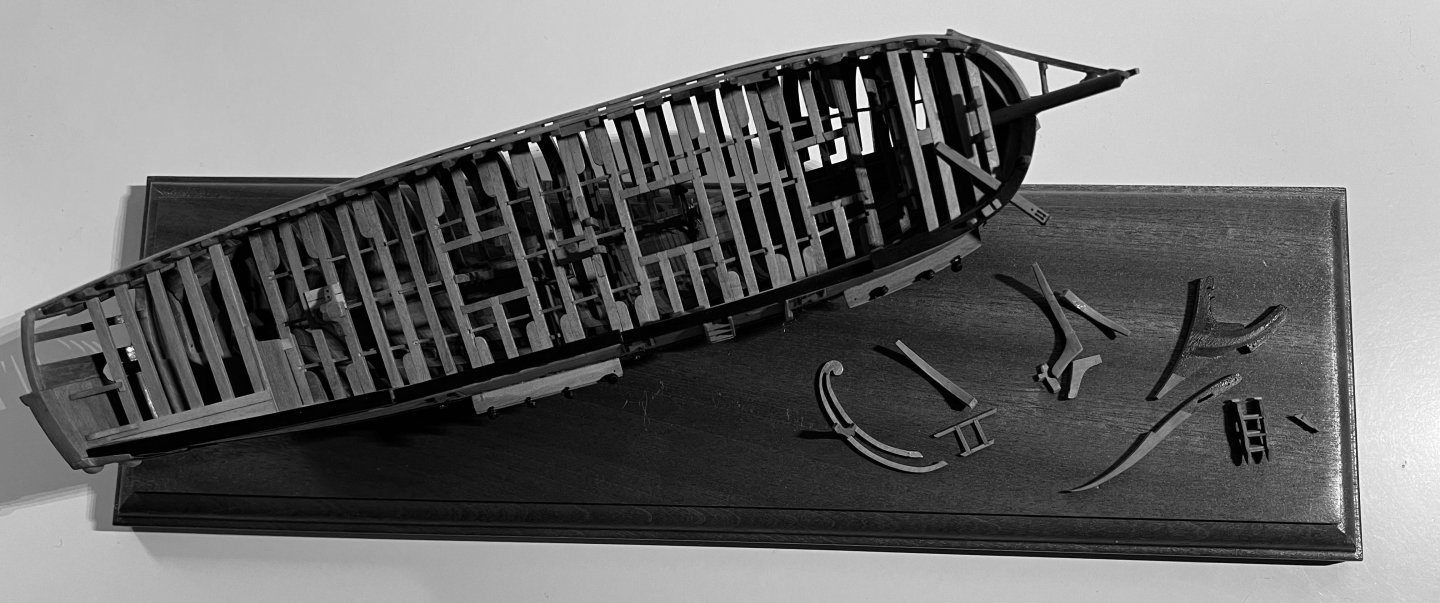

And this is the current state of the work from January to July 2024: 86 grams (I apologize for the picture quality - a summer evening on the roof).. An update will follow, sometime... Cheers, Gregor

-

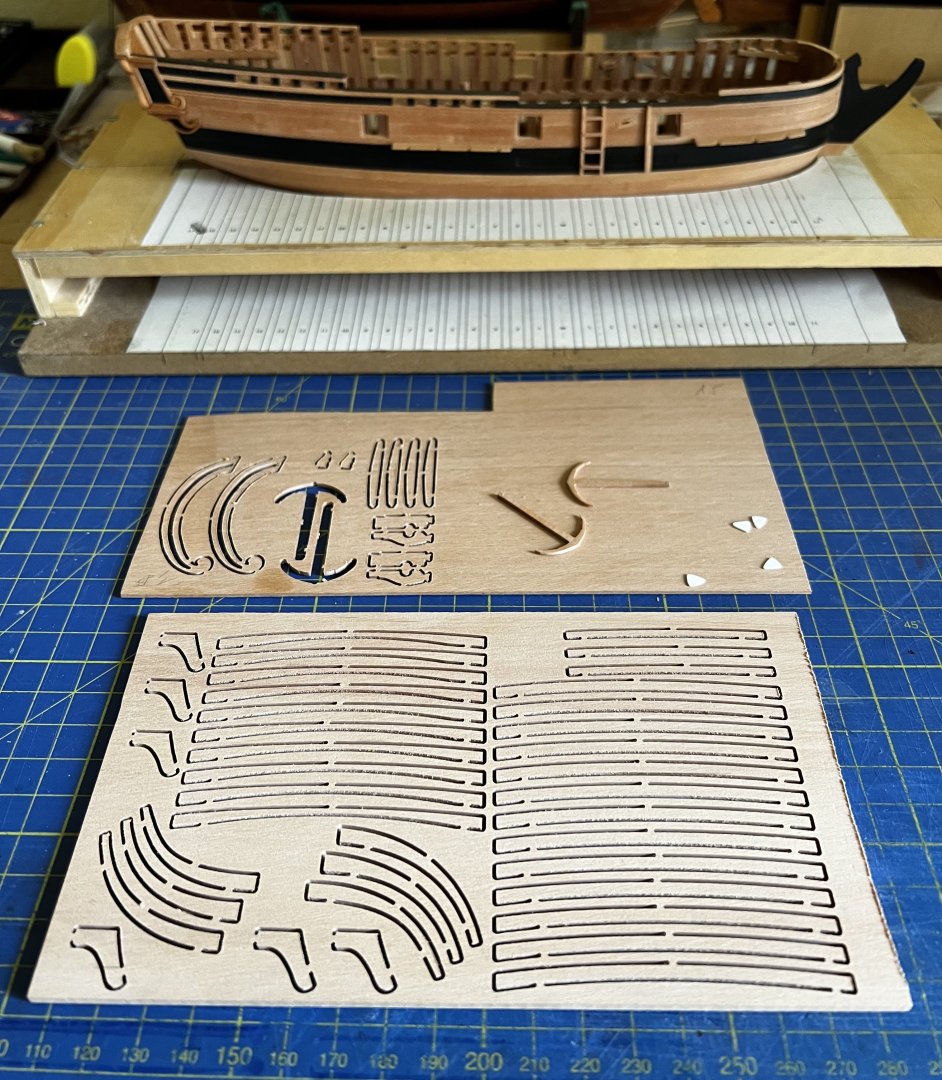

November 2022: A reserve anchor had to be provided before the deck beams could be installed. At the same time, I built up my stock for the coming winter and had more parts milled. I failed miserably at sawing through a copper sheet, so the anchors were also milled ... ... and painted.

-

Summer 2022: La Belle now weighs 71 grams. I worked on the stern decoration (with simplifications) and the starboard side. Not everything is exactly according to Boudriot - I was also inspired by alternative reconstructions (Grieco, Delacroix) and the contemporary La Volage. Here are a few impressions:

-

Two months later, I can record an additional two grams: La Belle now weighs 66 of them (the kitchen scales are obviously not a precision instrument).

-

When the sun shines, I'll get back to work on the trim strips - not everything works in the home office. The scraper blades from Amati don't take anything smaller than 2x2 mm - then the rest is milled away. It only takes a few minutes (it's December in Switzerland).

-

Templates are helping to avoid manual destruction (I guess this sounds strange, but I think you know what I mean):

-

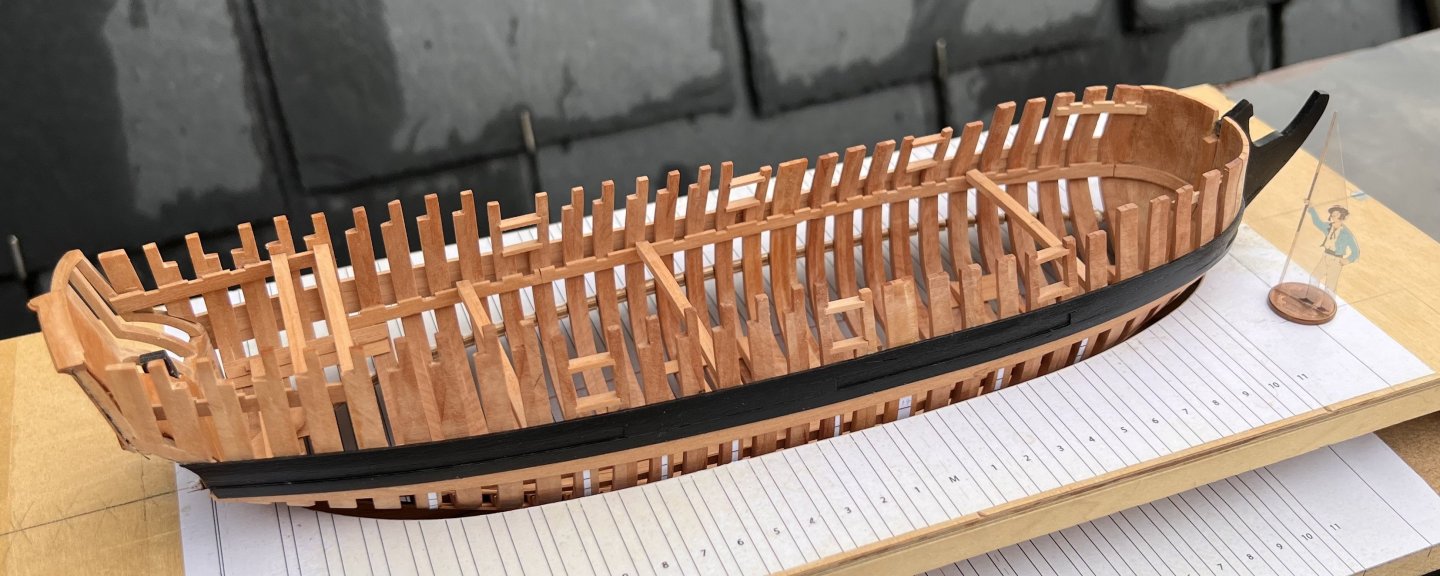

At this stage the little one weighs just 51 grams. Making the bow timbers was tricky. This is the first time I have seen the hull complete:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.