-

Posts

1,430 -

Joined

-

Last visited

About Mike Y

- Birthday 08/04/1988

Profile Information

-

Gender

Male

-

Location

Stockholm, Sweden

Contact Methods

-

Skype

michael.yalov

Recent Profile Visitors

-

archjofo reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

archjofo reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

-

Mike Y reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

Mike Y reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

-

Mike Y reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Mike Y reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Mike Y reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

Mike Y reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

Mike Y reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

Mike Y reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

Mike Y reacted to a post in a topic:

Bending hard brass.

Mike Y reacted to a post in a topic:

Bending hard brass.

-

Gregory reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

Gregory reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

Mike Y reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

Mike Y reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

Mike Y reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

Mike Y reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

mtaylor reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

mtaylor reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

mtaylor reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

mtaylor reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

dvm27 reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

dvm27 reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

Hi Michel, No, your model is quite awesome! You should really start the log and post more. There is always some other log that looks better, that is not an excuse And we all are masters of finding flaws in our models, so it's never perfect... Have you built yours out of the Lumberyard "timbering package" or entirely from scratch (plans only)? Haven't seen any Lumberyard based build logs, frankly... Would be very interesting to see! The scrolls under your quarter gallery look laser cut, so that's why I thought about a package

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

hollowneck reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

hollowneck reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

Curieux, so nice to see another Beaver's Prize build! Hope you can start a build log and share your progress (even retroactively, it is interesting to follow the old build steps even if it you are much further into the build by now). I see you are building the pre-modification version? Yes, Hahn frame is a styling choice and does not follow the real practice, so both of our cant frames are incorrect We can refer to the same period Swan class that is greatly documented in the TFFM book series to see the proper practice. Would like to see more photos, hopefully not only the finished model. Really like your unpainted railings, but hard to see anything else from this angle.

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Keith Black reacted to a post in a topic:

Hello from Sweden

Keith Black reacted to a post in a topic:

Hello from Sweden

-

Nirvana reacted to a post in a topic:

Hello from Sweden

Nirvana reacted to a post in a topic:

Hello from Sweden

-

Välkommen! 😊

-

Adding a cheap DRO to a Proxxon XY-table

Mike Y replied to Kris Avonts's topic in Modeling tools and Workshop Equipment

Very interesting mod! Have you considered decoupling the screen from the rest of the measurement device? Since you have pretty much disassembled it anyway, and I assume the screen is just attached with some connector and can be soldered with a longer wires, creating a convenient "DRO panel" on the front of the mill. Though it might be just integrated to the rest of the circuit entirely... Is it actually possible to crank the Y axis wheel with the caliper being that close, or is it designed for a left handed user? From the pictures it looks to be right in the way. Pardon if I am just overthinking it -

Found my rhythm and finally produced first parts! Admittedly got carried away with the shape of these mast posts, they are supposed to be much more boxy-looking and utilitarian. I was inspired by a few other models with very elegant posts For the same aesthetic reasons iron bolts are omitted and edges are aligned with the run of the planking. I really love the look of curvy pear parts, big fat black dots would spoil it a bit. And after all these parts would be hidden deep in the hold. It is more labor intense without a disk sander, so shaping and beveling involved a lot of chiseling. Though it is a pleasure with a nice and honed chisel. The most pleasuring moment was chamfering these edges with some relaxing background music Super happy, the joy is back! Finished with my new go-to finish Osmo Polyx 3062. Contemplating leaving smaller parts unfinished later during the build, but these are right next to the dark shiny pear frames, would be too much of a contrast. Before and after the finishing, side by side: In the hull (dry fitted). Quite ashamed with the quality of planking at the bow, who left all these giant gaps? 🫣 Did not look that bad on photos from 2021... No big deal, it only means I should be more careful next time. Also spotted an obvious misplacement of the top breast hook notch, it was the same guys fault. I was too young back then

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Self cleaning sand paper

Mike Y replied to woodartist's topic in Modeling tools and Workshop Equipment

Interesting, thank you! Was not aware of the "mesh" type of the sandpaper. And it even goes up to pretty high grits (800 grit for square version and 1000 grit for the round one). Will definitely try! -

Erik, thank you! Your build is one of my inspirations too Greg, thanks, that is a clean shot! Though so far it was actually easy to sneak on a good fit, since with wide Hahn spacing and no chocks it is easy to put a part to the edge of the next frame and mark a clear line. But time will tell

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

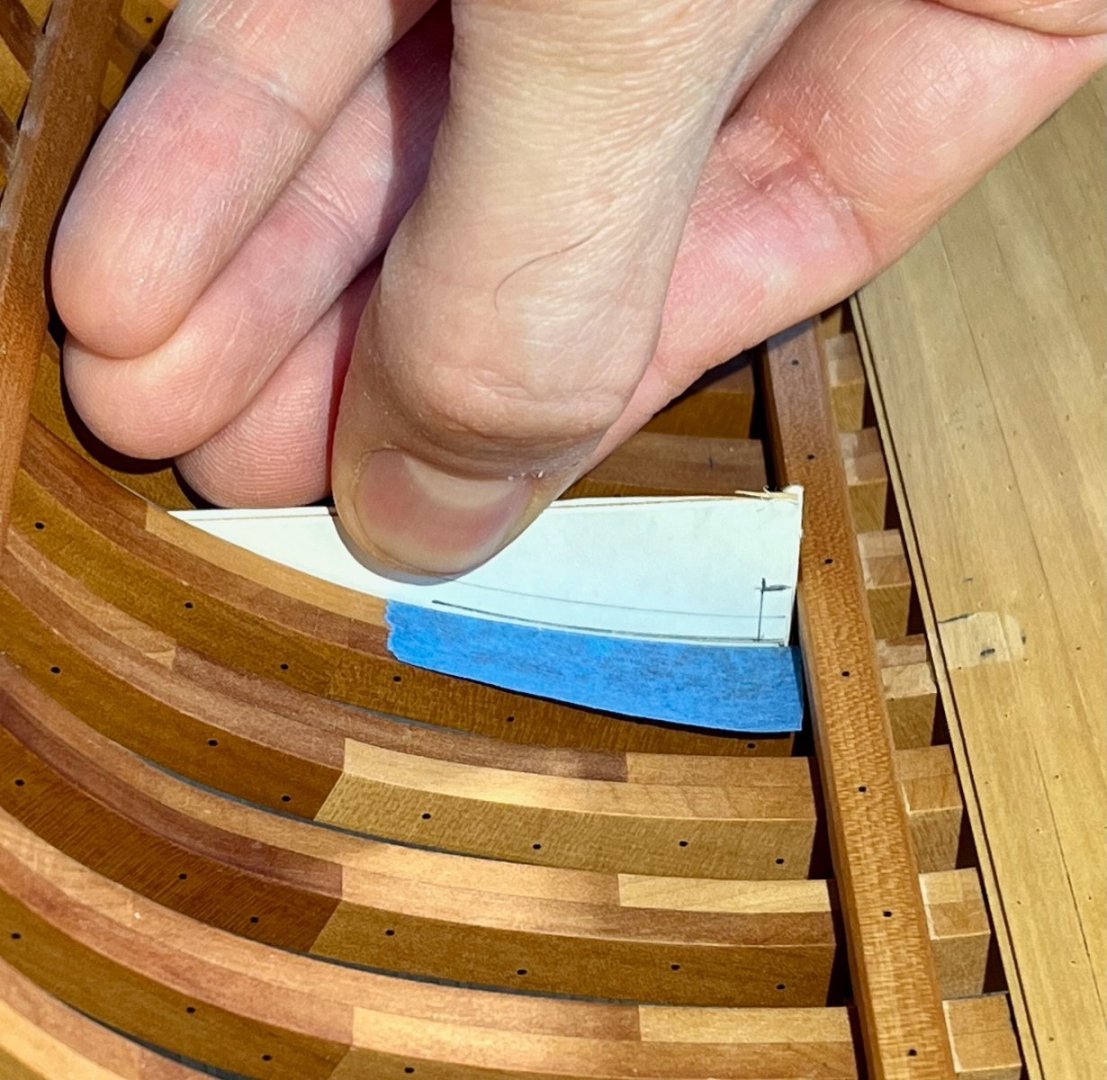

Thanks everyone for your support! Ron, can definitely recognise that Toni, thanks, will try that approach too. Inserting a pattern between the frames is a nice benefit of keeping one side unplanked, but haven't tried taping smaller pieces together.

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

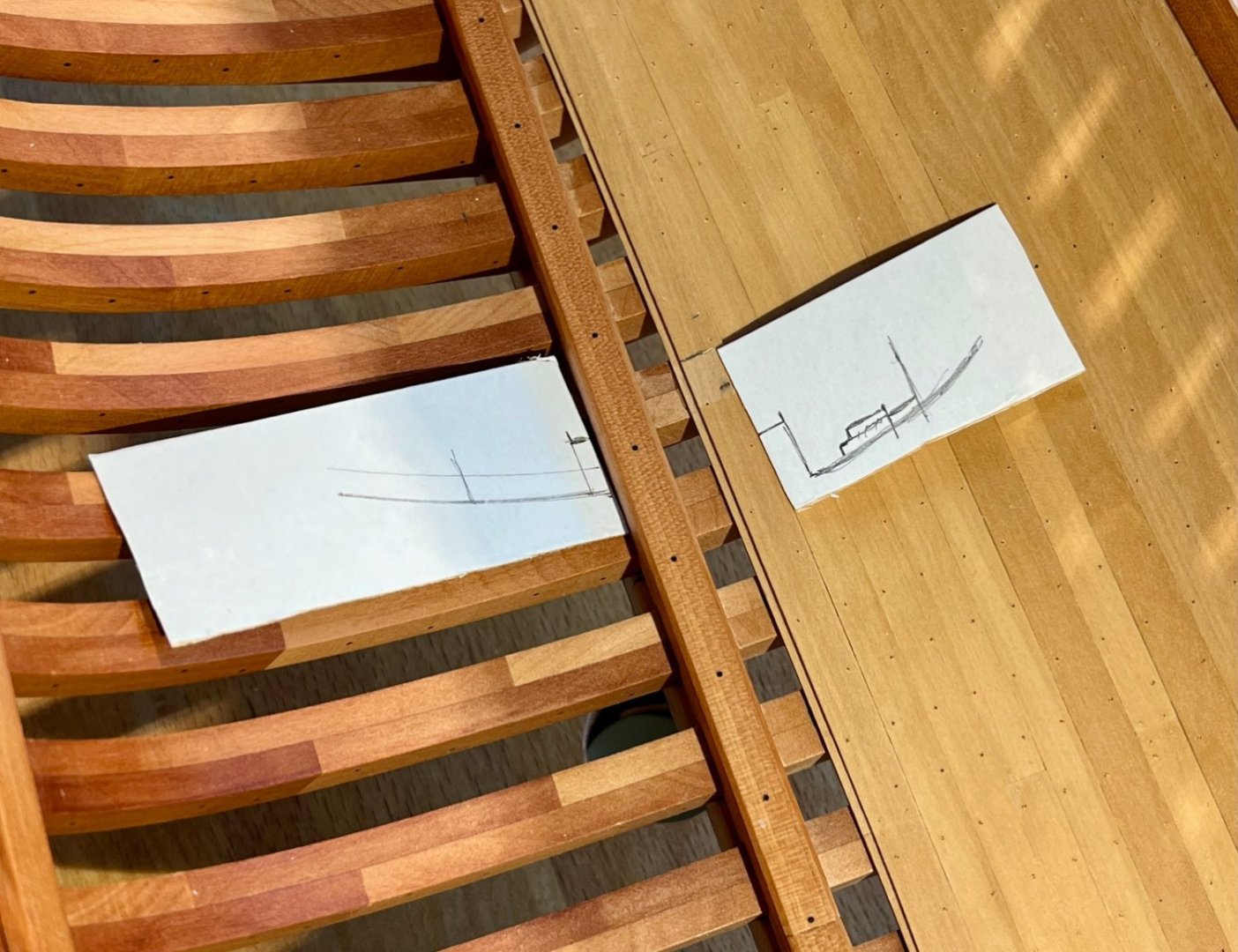

Mast steps are not complicated, but struggling with pattern transfer. Feeling like I miss some obvious tricks? Even thought about making a miniature duplicator tool with toothpicks instead of metal pins Would appreciate your advice! First I tried to make patterns like on a full scale - by gluing small rectangles on a piece of card. That way works great for real boats, but is very awkward and potentially messy on a small scale. But I like that tiny plastic vernier gauge! Got a few of those to measure spacing inside the hull without scratching it. Then I just traced a frame pattern on a piece of card and eyeballed the other side. That is less complicated than I thought, but takes a lot of fine tuning (counter light helps too). But feels like an art rather than a reliable and repeatable method. Though should admit - trimming and cutting card is quite satisfying! Is that how everyone is doing it or is there is an easy way? Practicing the quiet modelling (in preparation for the evening sessions) - tried a coping saw instead of a bandsaw. The dust extraction problem solved itself, vacuum hose fits perfectly between the clamps: Finally - the rough pear blanks are cut and I hope to shape them into beautiful parts in the upcoming days! I really aint much, but a little symbolic step towards the healthy hobby routine

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

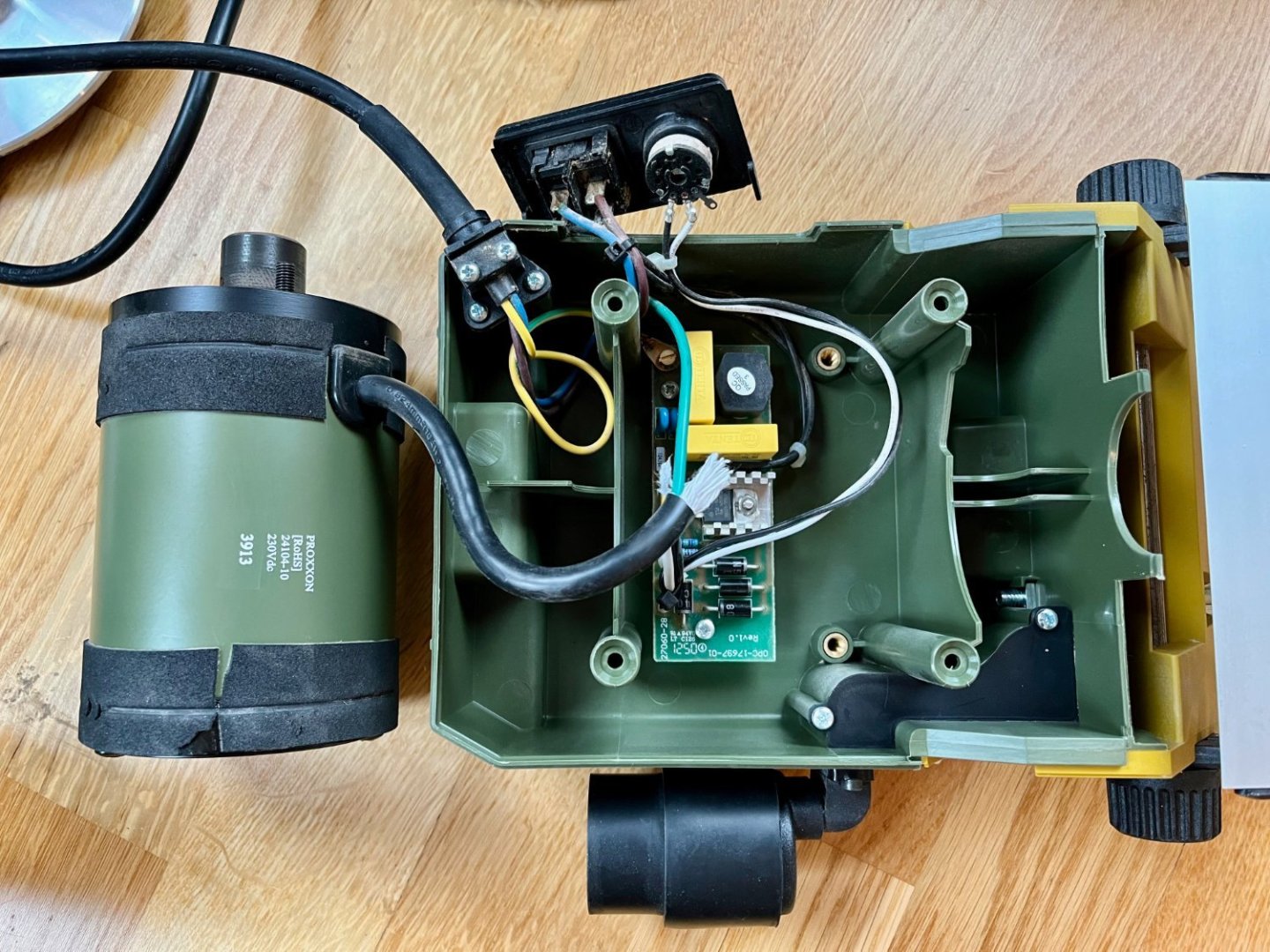

Hmm, where was I? What is this thing? With an active family life and outdoor activities I barely had energy in the evening to plan the next step of the build. And while kids even nudged me to make some sawdust - the main problem was the planning. Planking does not take much brainpower once the markup is done, but now I need to make mast steps, breast hooks and so on - need to analyse plans, mark out locations, get the necessary dimensions, etc. These details are omitted in the Hahn plans, and I wanted to build the model after the British modifications (including the fore mast that was moved ahead two feet). Just imagine - once everyone is asleep you open up books and plans, mark and measure and scratch your head, and in no time the brain just says "nah, lets watch some movie and go to sleep" 😇 Next day you are really worried about mistakes the tired brain might have done, and so you get a mental block and put it on hold. But now I am trying to break that barrier and spend some quality hobby time while family is away for Easter. Feeling very rusty, forgot a lot of things (including the location of some tools) and everything is slower than it was before. Also discovered that my Proxxon disk sander broke entirely (motor is humming, but not moving). It was slow to start before and was a bit unstable (I think I bumped it during an apartment move), but after a couple of years of downtime it failed entirely. Could not find any obvious failure once opened it up, so really hope Byrnes shop would eventually reopen and I can upgrade to the sander I was dreaming about. Shaping thick parts without it would be quite a challenge...

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Volume 2 is released now and is available in the museum shop! You can also find it on Amazon: https://www.amazon.com/Vasa-II-Rigging-material-archaeological/dp/9188909115 However volume 1 is sold out everywhere is available in a second hand market for ridiculous collectible prices (3-5k USD, sky is the limit)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.