OT1138

Members-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by OT1138

-

Proxxon cross cut sled + other accessories

OT1138 replied to OT1138's topic in Modeling tools and Workshop Equipment

Thanks, that's a pretty nice list. My crosscut sled is ok-ish. It gets the job done but it really suffers when cutting longer pieces and I typically have to spend a lot of time evening things out on a sander. I wonder if perhaps trying again with some new runners might do the job. -

I've seen this posted before but never with any conclusive answers. Has anyone here managed to build a GOOD crosscut sled for their Proxxon table saw? I've built one following the steps in the popular German youtube videos on the subject but I found the resulting sled to be a bit wobbly and inaccurate (despite numerous attempts to perfectly align it). I used wood runners and found that between just ordinary wear and temp/humidity changes, the angles are really inconsistent. I'd love some pointers. Also was wondering if anyone knew of any other "must-have" accessories to buy/build for the Proxxon.

-

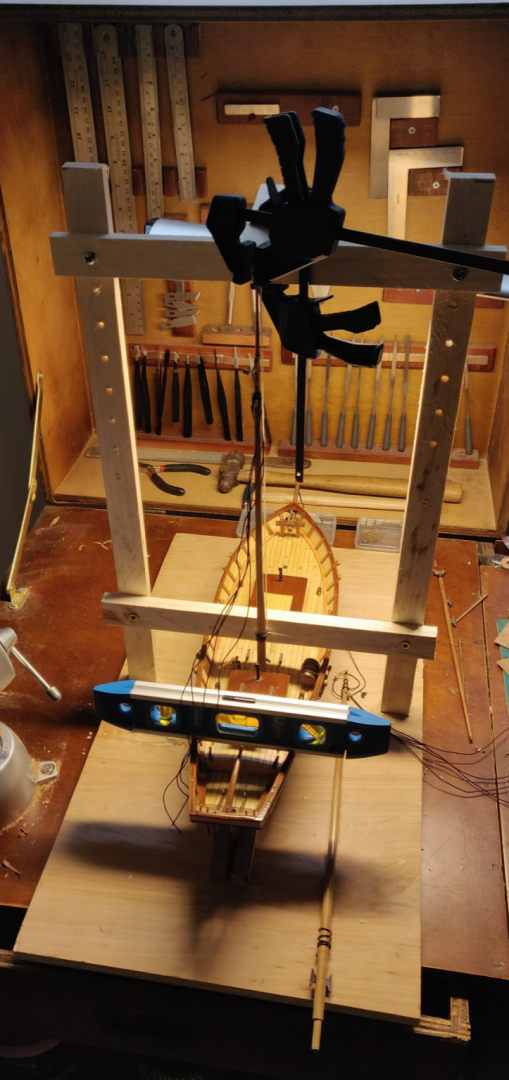

Tons of progress! I'll post more photos at some point but here's where the build currently stands. Almost finished, but still have the top sail, anchors and loose ropes to clean up. Oh yes, a flag! I've managed to billow out the sails but they don't stick out convincingly so I'm considering mounting the boat in an epoxy "sea" at an angle, like some others have done. A 15 degree angle or so gives them a dramatic look.

-

Was wondering if anyone has them? My 1982 version of the kit does not. Thank you!

-

Lots of progress though I've been slowed down because the kit is missing a gaff and two cleats. Also, my only set of sharp drill bits (purchased from Amazon) were super brittle and all the bits broke pretty quickly. I really dislike the stock brass mountings for the boom and gaffs, so I purchased some 2mm beads to make proper trucks. I also hand carved a couple of boom cleats from basswood and hope they'll be an acceptable match for the ones in the kit. While I'm busy waiting, I ordered some replacement rope and blocks from Chuck. Should give the model a nice look.

-

Dilute some wood glue and spread it into those planks. Then give it a light sanding. The sawdust will likely help to cover it up. I think you are right though, the waterways will cover up most of it... maybe all.

- 27 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

Syren Rope Rocket

OT1138 replied to DelF's topic in Rope Making/Ropewalks's Commercial sources for ropewalk machines

Hi Chuck, I was wondering when these might be available? I just purchased one of your rope serving machines, expecting it to arrive later (as just about everything else on the market has been delayed by a month). It arrived way ahead of schedule! So now I need to make some rope. 🙂- 42 replies

-

- ropewalk

- rope rocket

-

(and 1 more)

Tagged with:

-

Coming along nicely. Thinking about replacing the brass clips for the boom and gaft with parrels. Wonder what size of beads I could use for that? Ropes are another detail I'm starting to learn about as well. The kit comes with some beige twine but I'd like to have both standing and running rigging (with sails), so I may need replacements.

-

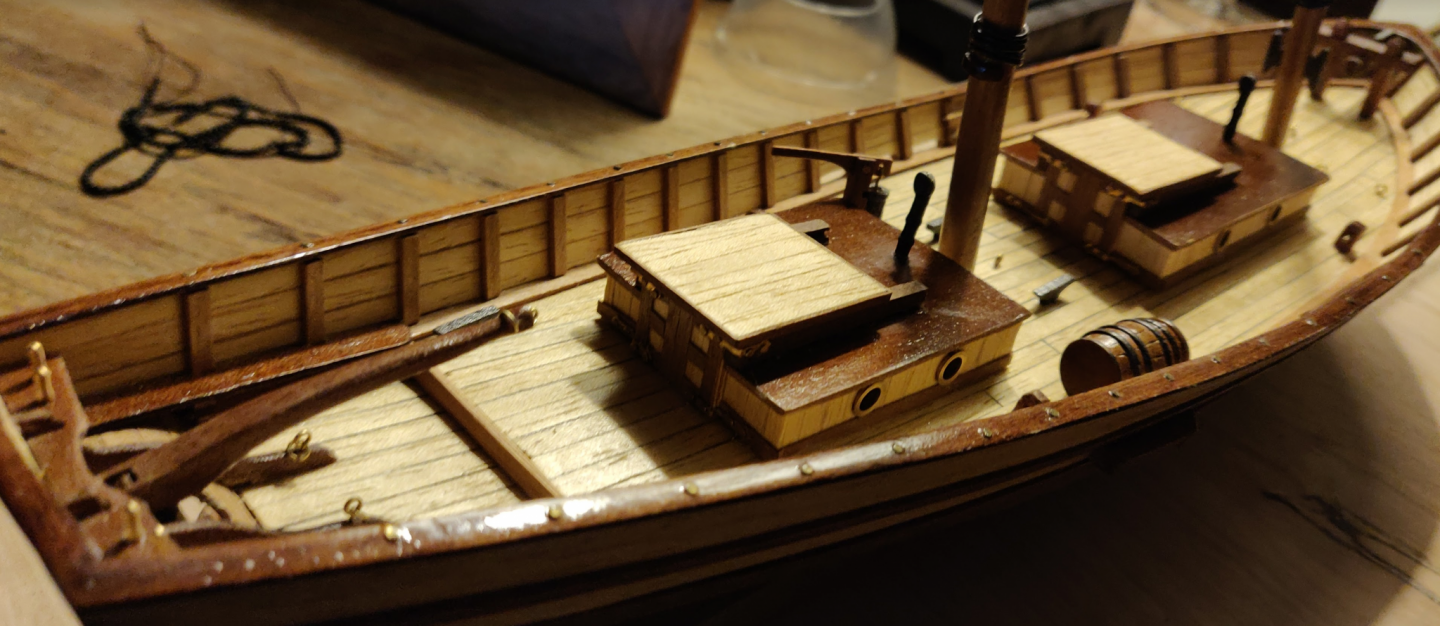

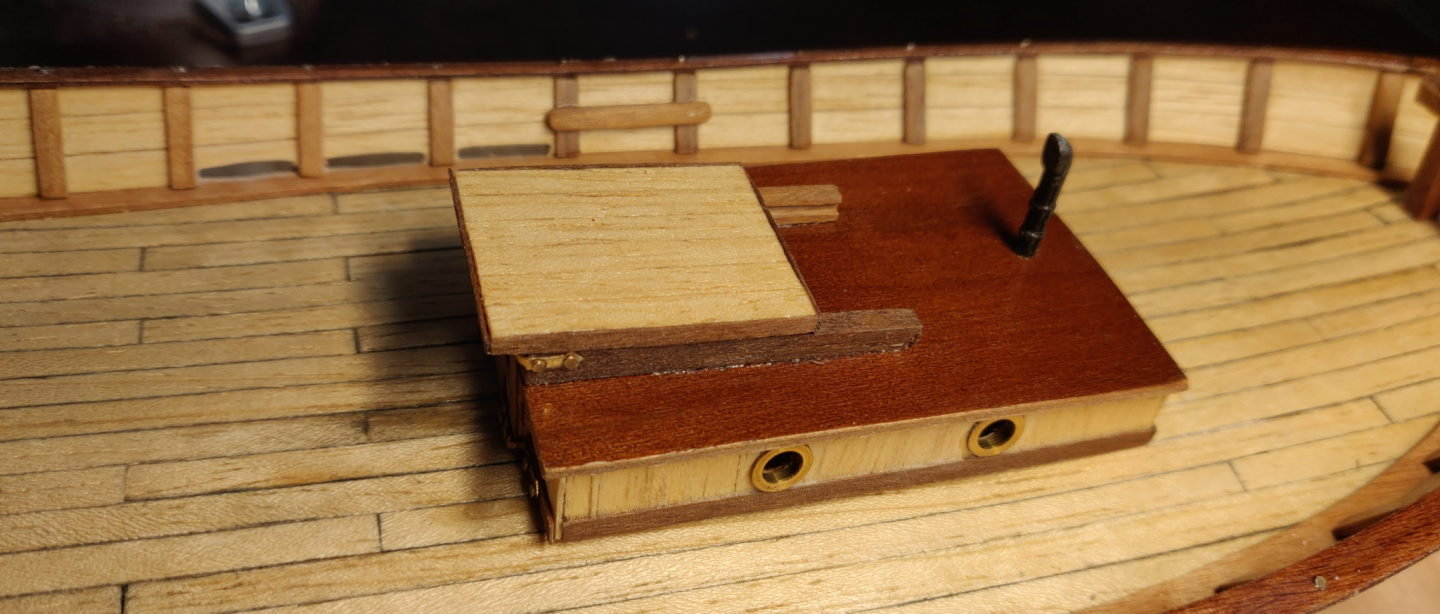

The cabins were a lot of work, mainly due to having to make the hatches and doors twice to get things to fit right. The kit provided parts were nowhere near the right size and the rails for the sliding hatch were not pre-cut, so this took a lot of work as well. The air/smoke/ventilation pipes were made from old lead and required brittle flashing to be sanded off. Finally, I found some 7mm brass portholes on eBay, so added two on each side. I found it interesting that the plan indicates that doors were only about 3' tall.

-

I soaked the bulwarks for a couple of hours, then held them in place overnight using rubber bands. They kept jumping out of place, so I ended up using a short piece of scrap wood on the bow to hold them in place (otherwise they would slip downwards). After drying, they held their shape readily and were not far from where they eventually needed to go.

- 27 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

So this part ended up being kind of a mess. I still didn't like how dark it was, so I brought it down almost to bare wood. I left a bit of the toner in place to give the wood some depth. But that was far too light. The rails were already glued in place so I attempted to brush more toner on and it came out blotchy. So I relented, stripped it down again and masked her off before giving a light spray of Perfect Brown. Finally, a color I liked! I then ended up having to fabricate new parts for the stern as none of the premade ones fit. These were sprayed with 90% Perfect Brown and 10% Red Mahogany. They came out pretty good, I say! A little thing that tripped me up were some builds that put the benches half way up the bulwarks. The 1982 instructions clearly show that they should lay flat, supported by the counter and the main deck. I presume these were provided for seating and if you think about it, placing them halfway up the bulwarks would be far from comfortable!

-

I think I'm confused about the term "stringers". If you look at Fig 5 in the plans, part 19 is the waterways (I think that's what they are usually called but I could be wrong). There is a die cut part for this on the plywood. The walnut strips might submit being bent this far laterally but I would be surprised if they lay flat without a lot of persuasion. I was referring earlier to the rails and caprail, which sit on top of the bulwarks.

- 27 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.