-

Posts

150 -

Joined

-

Last visited

About closehaul

- Birthday 08/31/1952

Profile Information

-

Gender

Male

-

Location

Flat Rock Alabama

-

Interests

hiking and kayaking and sailing.

Recent Profile Visitors

-

halvoric reacted to a post in a topic:

Atlantic by closehaul - FINISHED - BlueJacket Shipcrafters - 1:96 Scale

halvoric reacted to a post in a topic:

Atlantic by closehaul - FINISHED - BlueJacket Shipcrafters - 1:96 Scale

-

catopower reacted to a post in a topic:

ALFRED by schooner - FINISHED - BlueJacket Shipcrafters - 1:96 - Continental Navy Frigate

catopower reacted to a post in a topic:

ALFRED by schooner - FINISHED - BlueJacket Shipcrafters - 1:96 - Continental Navy Frigate

-

Thank you Nirvana, I look forward to improving on my builds with each successive vessel.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

Me too Bob. The steel construction of Atlantic may account for the size difference over the wooden schooner yacht America.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

Thank you gsdpic. This was a must build when I first saw it.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

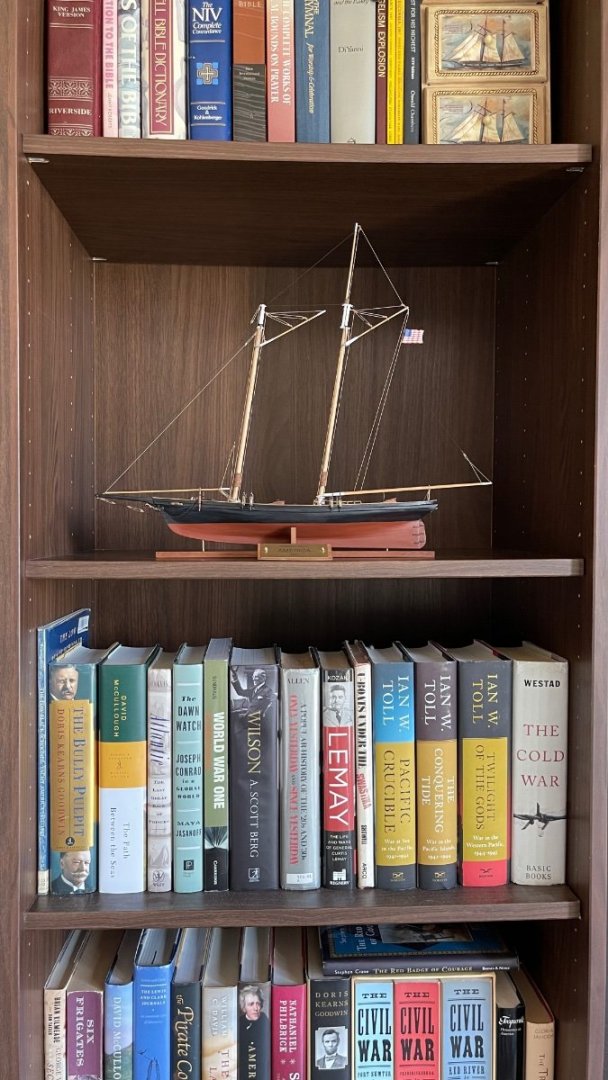

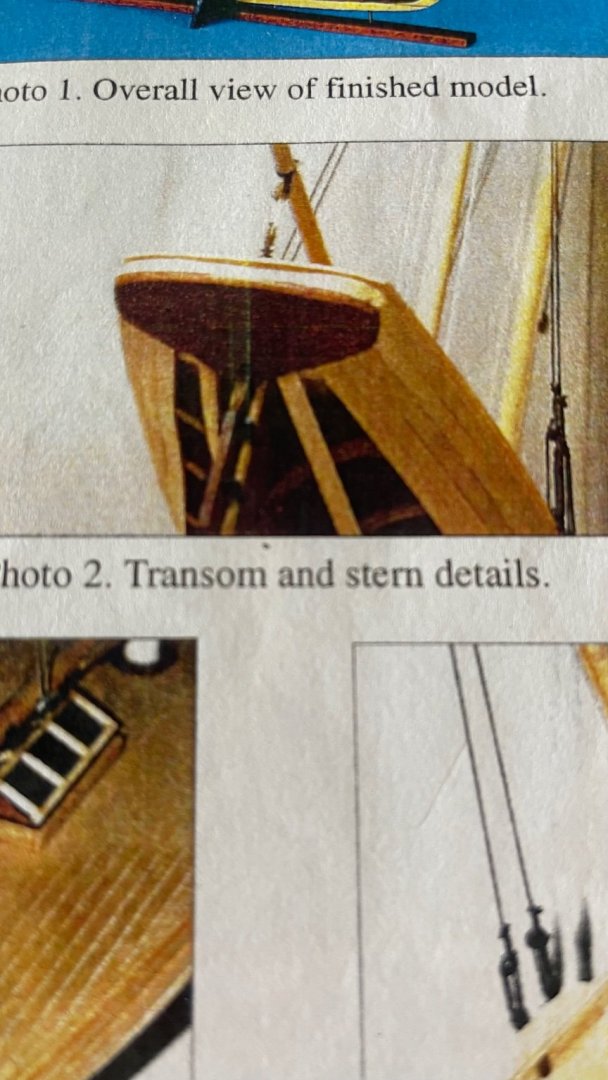

The last of America’s details have been added about the decks,hull and rigging. Anchors and chains set in place, the eagle mounted to the transom, flag hoisted, rope coils hung on belaying pins and the sheets flemished down on the deck. I used the whole 5 yards of .006 line provided in the kit to make the rope coils which surprisingly came off better than my last build, but the Flemish coils on deck kept separating and had to be done over or scrapped. The last items attached were the gudgeons and pintles on the sternpost and rudder. CA glue was used on all these above items except for the flag and rope coils which were brushed over with a 50/50 white glue/water mix. The bottom photo is of America snug in her new berth. Having completed this Bluejacket kit I was quite pleased especially with the deck furniture and rigging coming off clean for me. The kit is rated intermediate so this being my first POF build it was inevitable I wouldn’t pull off a properly faired hull. To compensate on the next build I’ll be using a Model Shipways fair-a-frame building slip and using Titebond II wood glue instead of CA glue and study the various fairing techniques in MSW. Ciao everyone! Ange

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

At this point of the build I thought I’d do a size comparison of America with my previous build of Atlantic. Both vessels share the same 1/8” scale.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

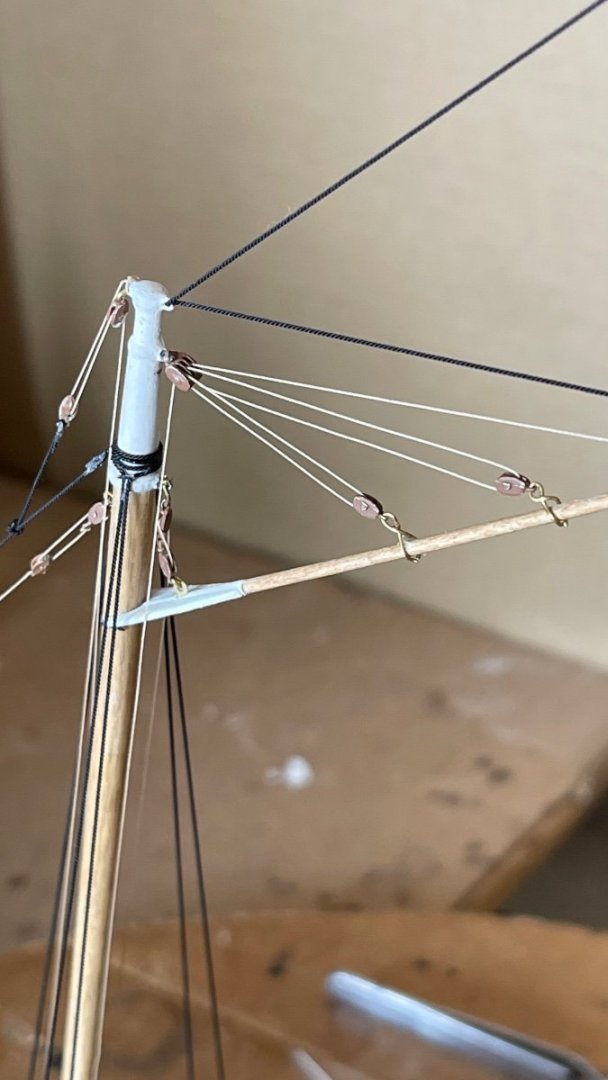

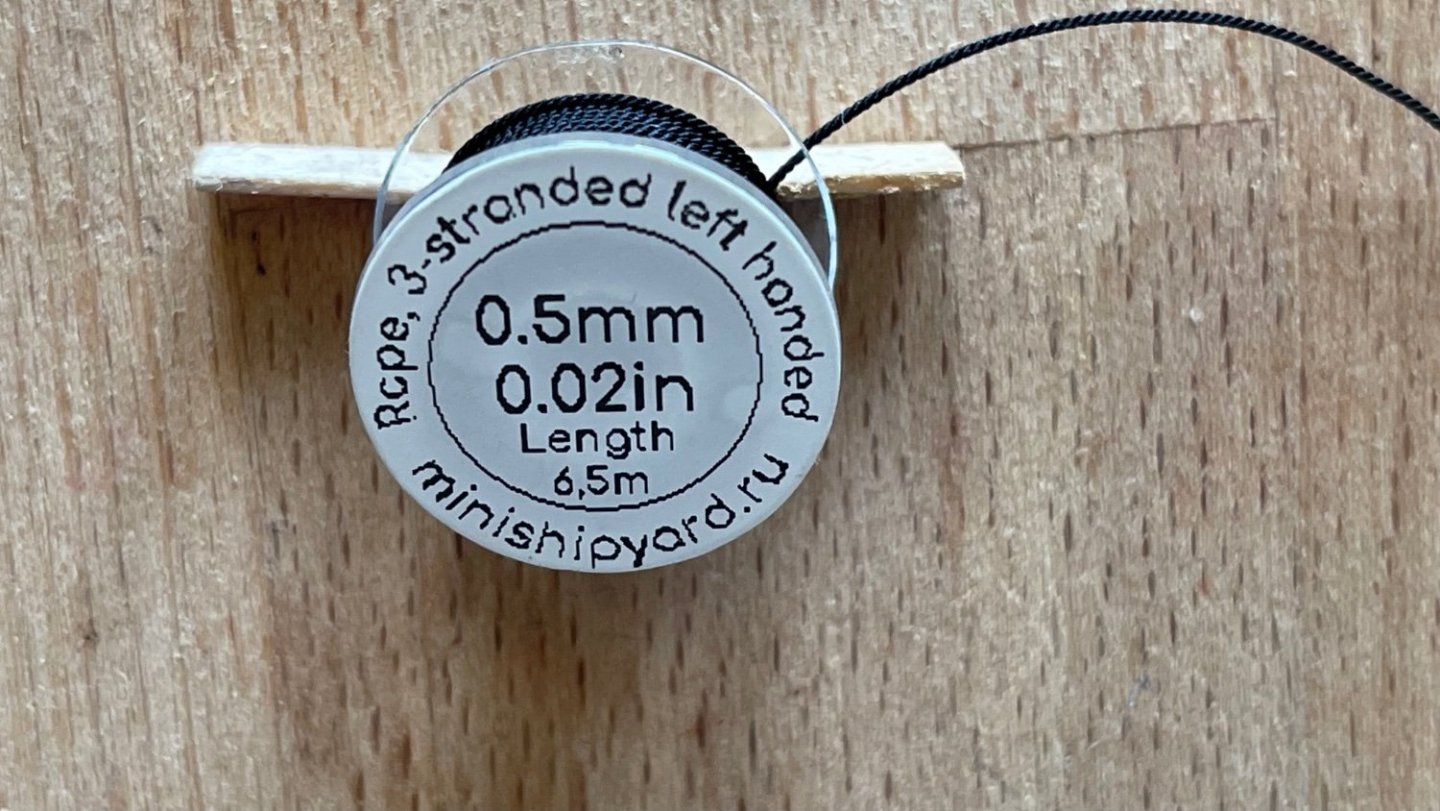

The running rigging has been rove through all blocks using .010” 3 braided polyester line (top photo). The second photo down shows all running gear lines have been made fast to belaying pins and cleats about the spars and decks. The details of the belaying pins and some of the foremast gaff rigging lines are the 3rd and 4th photos. The bottom shot is the entire rigging having now been trimmed of excess line from the cleats and pins.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

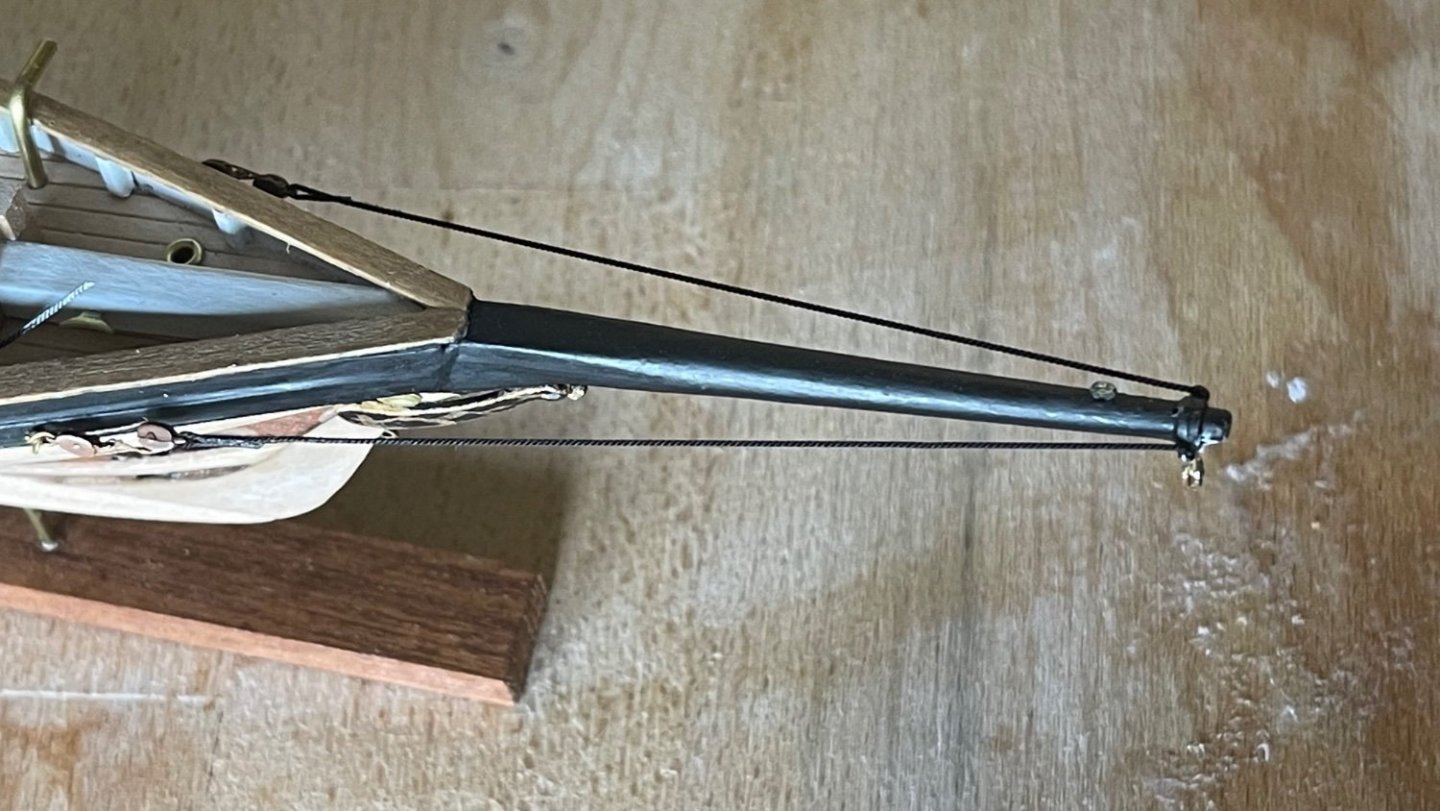

In the top photo all of the rigging shrouds have had the lanyards rove through the deadeyes and left slack. The forestay at one end, having been made fast on the lower mast cap ring is lead down through the hole at the tip of the bowsprit and rove through secured to the eyepin just above the waterline at the bow. Also the bobstay is run from the same eyepin up to the end of the bowsprit’s eye ring. The bobstay and forestay each have a pair of blocks with a lanyard rove to trim them. The main topsail stay and the mainmast spring stay (one length of cord for both) were rove starting at the upper end of the main topsail downward through the upper eyeband ring and back to the eye on the fore of the lower main mastcap. The last lines to complete the standing rigging are the jib club topping lift pendant and the main boom topping lift pendant. The bottom photo shows all standing rigging trimmed and ready now for the running rigging.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

I applied 1/16” gold block letters to the transom for “America”. They will soon be brushed over with a flat topcoat (Minwax polycrylic). While paging through my copy of “The low black schooner” I couldn’t find any image of the ship’s namesake affixed on the bow planking so It remains it’s black base coat. I’m still working on painting the transom eagle figure. Painting the red and white striping on the Union shield is proving to be a challenge but it’s very easy to wipe it clean and try again. In between the painting attempts I started the standing rigging with the guys and moved onto the foremast shrouds using .020 black polyester thread. The deadeyes having been made fast to the shroud ends and chainplates (portside) are to be reeved next.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

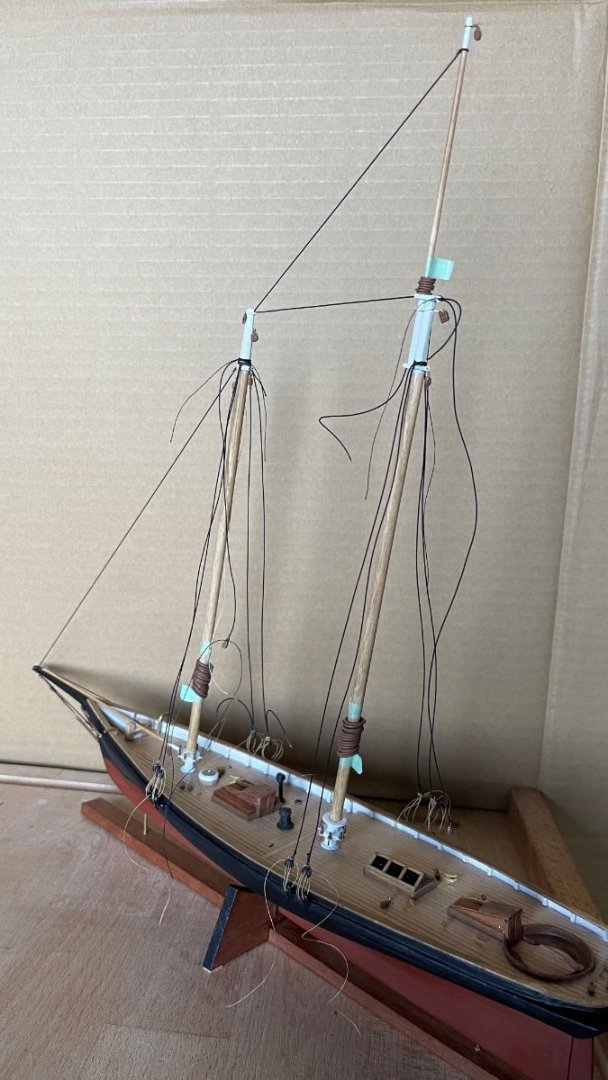

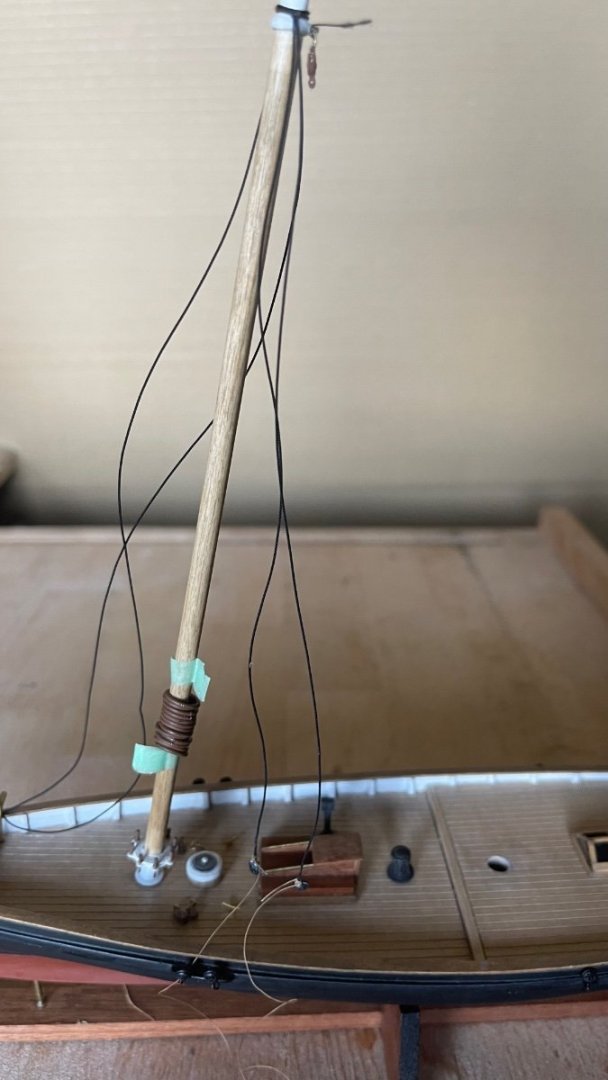

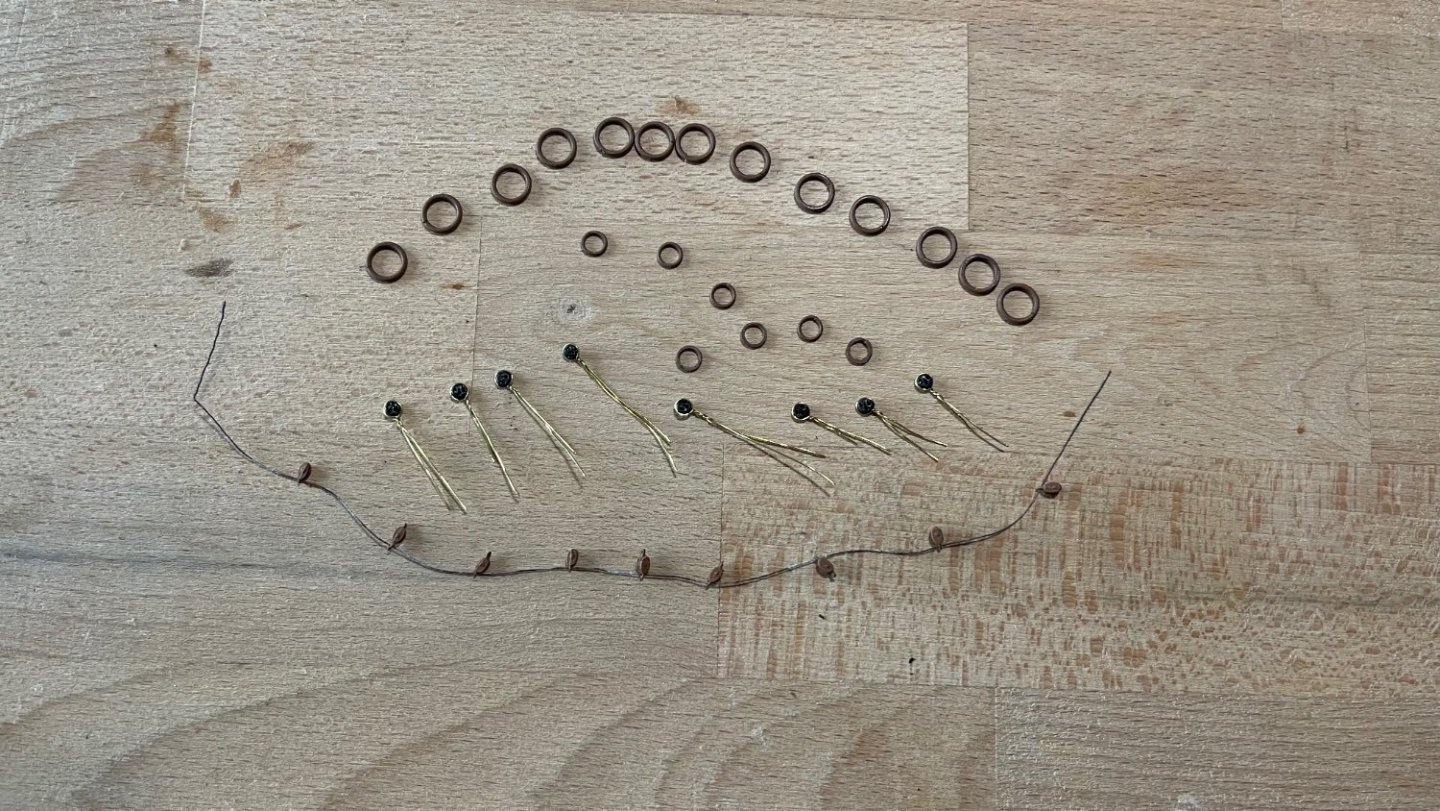

Blocks, cleats, belaying pins, mast hoops and mast boots have been affixed to the spars. The masts have beeb temporarily stepped for the photo only. Once they are removed I will attempt applying 1/16” block letters for the name on the bow and transom. (Lord willing) along with the eagle emblem. Note: the mast hoops (1/4" ID split rings) and boots (3/16" ID britannia metal) were additional parts I purchased from Bluejacket Shipcrafters in leu of scratch building them from the brass wire and basswood provided in the kit.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

The spars having been shaped were then painted at their spar tips, bases and mastheads. Eight eyepins were inlayed into each of the spiderbands on the fore and main masts and their accompanying belaying pins then glued into the eyes. One note of caution, if you plan on using eyepins for the bands as the instructions direct then you will need more eyepins than the thirty the kit provides. (I had extra eyepins I ordered on my previous build of Atlantic.) One alternative would be to just drill eight vertical holes through the bands to secure the belaying pins. The jaws rest for the main boom was then affixed just above the spiderband. The remaining blocks and mast hoops were then painted with modelmasters flat military brown enamel.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

This quote is a remedial post of the transom correction I’ve been working on the last six weeks. A new transom has been fashioned according to scale from the sail plan. After having pressed the curve into the new transom, a 1/32” thick wood insert was glued to widen the stern section along the top of the transom and puttied to plan. My error in the first attempt was not taking time to properly interpret the sail plan and to stop the build until the plan was fully comprehended.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

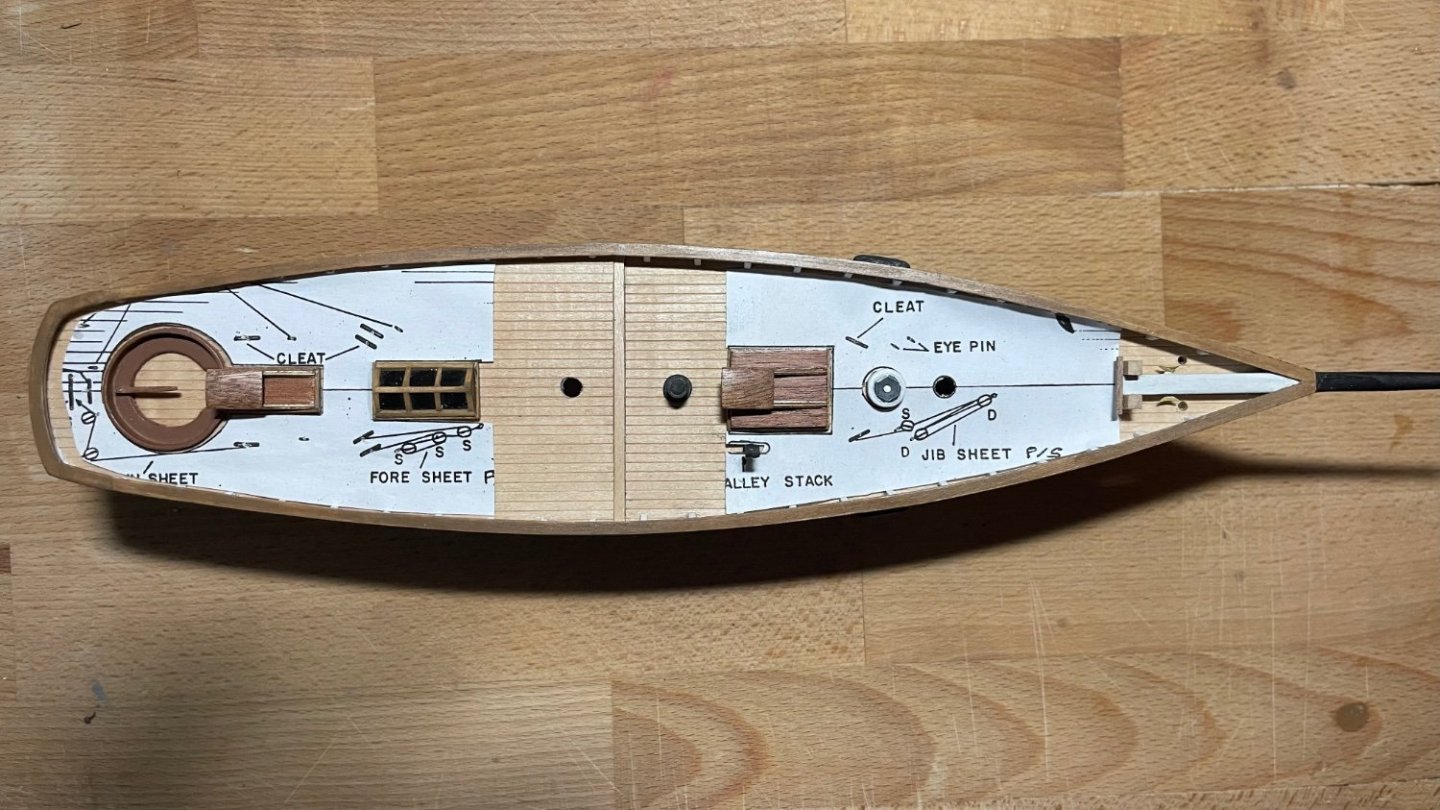

All deck hardware has been installed minus the blocks for the eyes and horse. The blocks were drilled clean with a #75 bit and had burrs smoothed down with an Emory board. Then they were pre-cleaned, rinsed and dried before being coated with a thinned half and half coat of True North grey primer.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

So now I’m drilling #75 bit holes for the eye and cleat positions about the decks. The furniture is set according to the deck layouts but at this point in the build I have to point out a major inconsistency in the build. The actual deck aft of the cockpit extends well beyond the plan about 3/16” further to the stern bulwark. The position of the cockpit was built on the laser precut hole in the sub quarterdeck that lies beneath the scribed decking cut out for it but the main mast hole of the same subdeck was in line perfectly to accommodate the mast. At this point I’m at a loss to pinpoint how I could have rectified this after rolling it around my head for the last couple of days but will simply contribute it to operator error. Otherwise America is coming along swimmingly.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

I was just browsing and ran across your latest build log Bob. Your detailed building techniques especially concerning the fairing of Flirt’s frame and hull are the skills needed for me to properly assemble a planked vessel after I’ve finished the Bluejacket 1/8” scale America. I’ll be studying your log closely to avoid the pitfalls I experienced in fairing America’s hull which were naturally to be expected in my learning process. It’s quite admirable how quickly and accurately you built Flirt’s frame and faired the bulkheads to lay the planking flush against them, just one of many techniques I intend on mastering in my own future builds.

Ciao! Angelo -

It’s been a few weeks since the last post. I was fussing on the deck furniture getting them straight and plumb. The quarterdeck skylight was particularly troblsome having to do it over twice but satisfactory result upon completion.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.