Don Case

Unsubscribed-

Posts

482 -

Joined

-

Last visited

-

Canute reacted to a post in a topic:

Boxwood and how to get it

Canute reacted to a post in a topic:

Boxwood and how to get it

-

RustyGuts 257 started following Don Case

-

sziggy8 reacted to a post in a topic:

Crack filling technique

sziggy8 reacted to a post in a topic:

Crack filling technique

-

Chuck Seiler reacted to a post in a topic:

HMS Discovery 1789 by Don Case - 1:48

Chuck Seiler reacted to a post in a topic:

HMS Discovery 1789 by Don Case - 1:48

-

Jpsteve reacted to a post in a topic:

HMS Discovery 1789 by Don Case - 1:48

Jpsteve reacted to a post in a topic:

HMS Discovery 1789 by Don Case - 1:48

-

Soaking plank

Don Case replied to zamboknee's topic in Building, Framing, Planking and plating a ships hull and deck

I've only done a few so take that into consideration. I soaked mine for about 30 min and then clamped it into position. Let it dry overnight and then refit it and glue it in place. Apparently if you glue it in place while it's still damp it can shrink and leave gaps. -

Fiberglass a boat Hull

Don Case replied to Riotvan88's topic in Building, Framing, Planking and plating a ships hull and deck

When I first started making RC sailboats I made a balsa fin keel for one and covered it with 2 oz cloth and epoxy. I guess when I was sanding it I went through the cloth a bit on the leading edge. It was subsequently painted and looked fine. I sailed it numerous times then one day it was sailing along great and then shuddered and almost came to a dead stop. I pulled the boat out and the entire leading edge of the fin looked like popcorn. Somewhere, sometime some water had gotten in and virtually exploded the leading edge. I'm not sure what the moral is other than be very careful, water will find a weak spot. -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

Before I explain why I tore it apart again I thought I should explain what I'm fighting. First thing is I dove in too deep. I didn't understand quite what I was getting into. As far as just building I'm OK. I have no problems with just building. If I had good plans I'd be golden but I don't. What I have is three sets of plans. One set set shows the body plan, internal profile(I think it's called) and deck plans. No bow or stern drawings. The other two are the same but no body plan. The Discovery was just about finished when the Navy bought her. For the trip to the Pacific Northwest she had some mods done. As near as I can see they raised the quarter deck a couple of feet and the forecastle about the same, maybe a little less. There was a set of drawings made for the 'proposed' changes. I have those. They are from 1790 probably. The next ones are from when she was converted to a bomb vessel. There are the 'proposed' in Feb 1798 set and the 'as fitted' set in May 1798. So I'm trying to build a ship for the period between the 1790 proposed and the 1798 proposed. The 1790 proposed isn't a completed drawing. It's very vague. The 1798 proposed has all of the midships except the hull erased to draw in the mortars and supporting structure. So I'm trying to build a model with info from what they might have done to what they might do next. I also have a few of John McKay's drawings of his interpretation of what she looked like but he only drew an internal and external profile and an oblique cut away. They have been a big help in trying to interpret the faded old drawings. John has experience to know what "probably was" so it fills in a lot of blanks. So when I started building I thought I had multiple copies of the same drawings. I didn't know until almost had it framed that there was an eight year gap and even longer until I realised that there was a "proposed" and "as fitted" set in the bomb conversion. Anyway this is why I'm grasping at straws trying to understand what this ship looked like. This week I was working on the forward platform and when I cutup some copies of the deck plans and held the in place I realised that I had a scuttle in the floor of the magazine. I tore up the planking and corrected that moving the scuttle out into the light room. Then I looked at the access from the lower deck down to the light room and saw that the 1790 drawing was different than both the 1798 drawings. Because the 1790 is just proposed and the 1798 drawing made much more sense I decided to use the 1798 drawing hoping that they had actually built it that way in 1790. When I cut the hatch in the lowerdeck template there was a bunch of breasthooks in the way of the stairs/ladder. I had made them too robust. So out with the IPA and carefully rip out the breastkooks and sand them all thinner. Tomorrow I will glue them back in. Even though I'm having problem after problem I'm enjoying it immensely and as long as the world doesn't run out of IPA and you guys keep helping me I'm good. No pictures this time. -

OK the Zona keyhole saws are .020 thick with relatively big teeth. I have two dull ones. The one I'm thinking of butchering is .010 thick with tiny teeth. Apparently the Xacto #15 is not available any more but Excel makes a replacement. I can't find any tooth count or kerf width on them. They look very similar to the Zona keyhole. Scroll saw blades sounds like a good idea but I just did a quick search and 28 tpi is the smallest I can find. The Zona pull saw is more than 50 I'm going to give it a try. I cut the back with a cutoff wheel and the blade with tin snips. The snips curled the blade a bit but it straightened out fine. I was afraid to use a cutoff wheel on the blade because I would lose the temper. Anyway it works great and I can make a second one from the piece I cut off. The picture looks like the blade has been overheated but it hasn't. It's fine, just the flash from the camera. Edit- It took about 2 minutes to do. Thanks for the input.

-

I have a couple of these Zona backed pull saw blades. I'm wondering if I could cut it where the red line is to make a thin keyhole type blade? They are a pull type blade so they don't have to be too stiff but I hate to ruin a good blade so I thought I would ask if anyone had tried it.

-

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I adjusted a deck plan to the right size, printed it and cut it out so I could lay it on the Platform. It looks like there is a ladder down from the lower deck(sounds weird) to the light room and then there is a square that I'm guessin' is the scuttle down to the "Bread Room". It's funny how laying that drawing in there sorts things out. -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

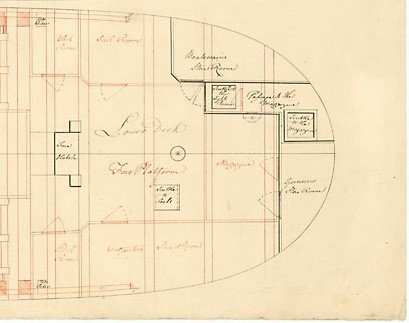

Thanks Alan I just discovered that that nice little scuttle in the forward platform is in the wrong place, if it exists at all. That is about right in the middle of the magazine. I "think" the bread room is under it and I can't imagine they would want to have to go through the magazine every time they need bread. So I've torn the decking off before the glue got too set. Here's the drawing that shows how they put the two decks on the same drawing. Makes it kind of confusing. it's a little clearer than this image shows. I thought that, since it says Forward Platform in red ink that everything in red was Forward Platform but all the Bomb modifications are in red too. I'm pretty sure that the black ink is Lower Deck -

HMS Discovery 1789 by Don Case - 1:48

Don Case replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

I decided not to treenail the interior planking I've started to glue in the interior pieces. The forward platform is in and I am planking it. The magazine sits on it. I glued in the mast steps and the aft platform. I glued in the midship platform and the next day realized I hadn't put in the carlings and ledges in it so out it came. I started the carlings and ledges and hit a shag. See- After I got that sorted, sort of, I finished up the carlings and ledges on it and now I'm ready to glue it back in. I started on the right side and worked left. You can see the line of ledges gets straighter from right to left🙂 -

Sloop of war, I just got tired of typing🙂 I was just re-reading this thread and you give some scantlings for the "Echo". If I'm reading it right and you use the lower deck carlings and ledges you end up with the carlings being bigger than the beams. That doesn't make any sense to me. Is there any place on line that I can look at any contracts. I tried the NMM and I can see where they have them but being 20-24 pages they don't show any part of them.

-

The hard thing is that a SOW doesn't show anything for a midship platform so I assumed that they didn't have one. On folio 19 a midship platform is only shown for frigates. So I just used the smallest for the beams if I remember right. The carling/ledge scantlings I got(the 4 and 3 inch ones) I'm assuming are for the aft and forward platforms. These are a lot narrower than the midship platform so I would expect the scantlings to be smaller. it is going to be planked and no one will ever see them so it's a moot point really. It's just for my own interest. I can't spend the farm on books so I guess I'll just build it as I think it should be and then correct it when you guys tell me it's wrong.😃 Thanks

-

Did you mean the two 'knees' between deck beams? If so the lack of a scarf was just laziness on my part as it will be planked. If I'm following you about the hanging knees, Alan and I had a discussion about this. Apparently these are not 'knees', they are hanging standards so they go under the beam.

-

I wondered about the dimensions too, carlings looked way to small. I got them from folio 17 for SOW. Carlings 4"x3" and ledges 3"x2".The midship platform scantlings appear to be on folio 16, at least the beams are, but I couldn't find carlings and ledges there. I turned the page and found carlings and ledges in the the aft and foreward platform sections. I assumed that if they weren't mentioned earlier that this must be them. As I have said before, I find navigating Steel rather difficult at times. Funny thing is I had made the decision that I had finished all the parts below the lower deck and glued them all in. The next day I noticed that the platform had no carlings or ledges. Dumbass. So I pried it out and started installing them. Now I find that may not have been necessary. So maybe I can just rip them all out. Thanks for all the responces

-

I'm putting the ledges in the midship platform. The space between beams is 1.25". Steel wants 1/4" between ledges so that means 4 ledges. I'm assuming that asunder means between ledges and not between centers. If I do that the ledge that comes up to the knee hits it at a very long angle. In a situation like this should I just leave out the ledge? It would mean that a portion of the space would be more than 1/4" but it would only be for maybe half the length of the ledge. I've looked around at various builds and it looks like some do just that but it's really hard to tell distances on pictures. Maybe the knees should have been skinnier.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.