-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by builder_Nick

-

In thinking ahead, I need to do some research on how to handle the rigging. I didn't drill holes in my thwarts to add belaying pins because I thought I had read somewhere that this would not have been used on the real boat. Am I correct or not? And if so, would anyone be able to point me in the right direction for proper rigging attachment points?

-

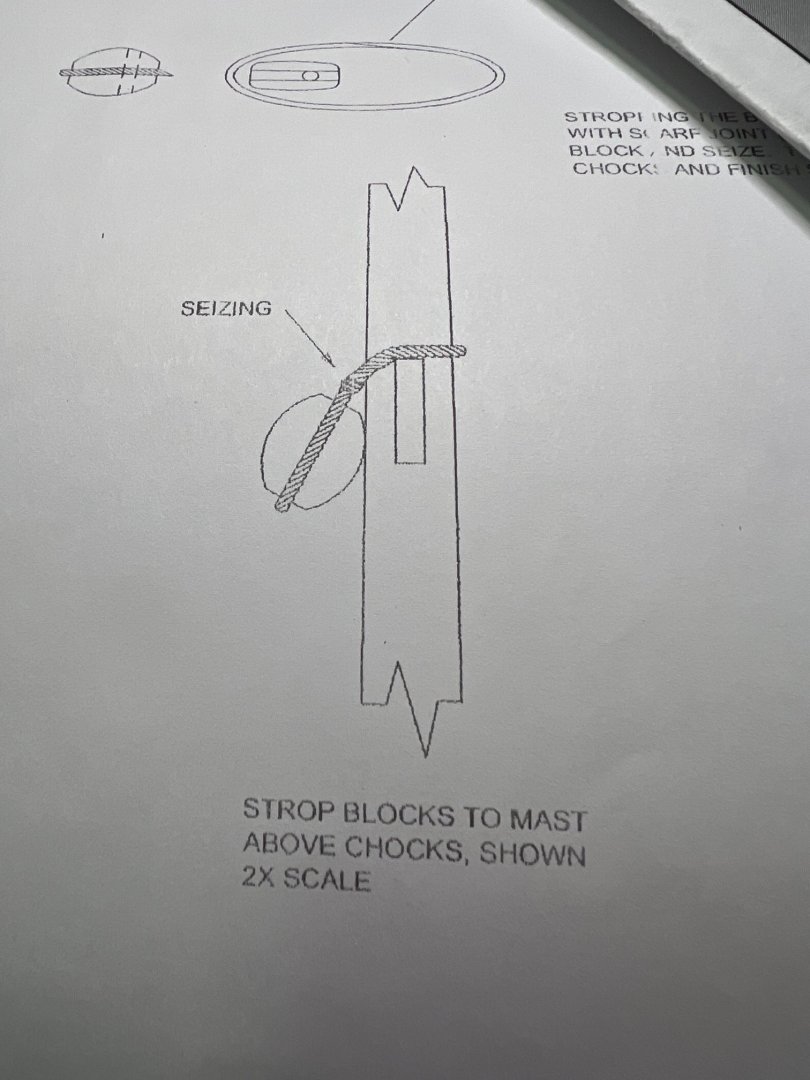

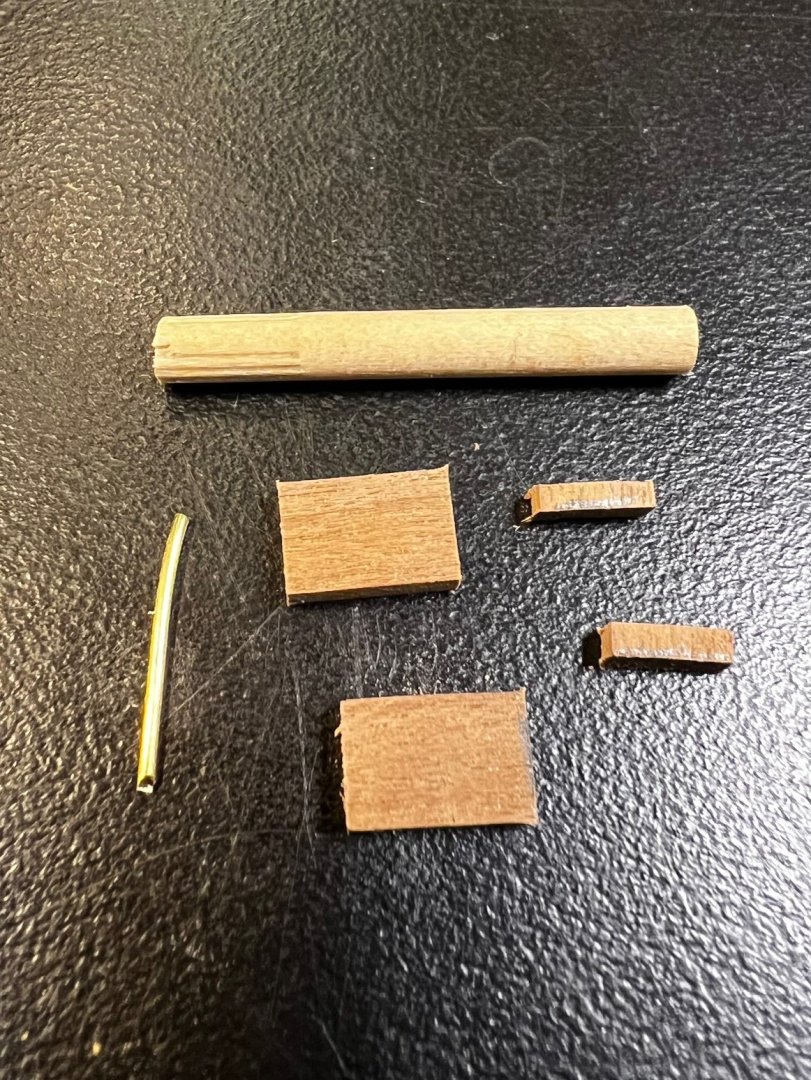

Masts are cut to length and tapered. I put the mast into a long clamp that would hold it at an angle with one end flush and the other protruding above the surface. This made it easy to sand down to the surface of the clamp creating a tapered faceting of the mast. I did this multiple times rotating after each facet was sanded. Final sanding was done by hand to remove the transitions from facet to facet rounding the surface. I tried to take pictures of the process, but they didn't seem clear enough to be helpful.

-

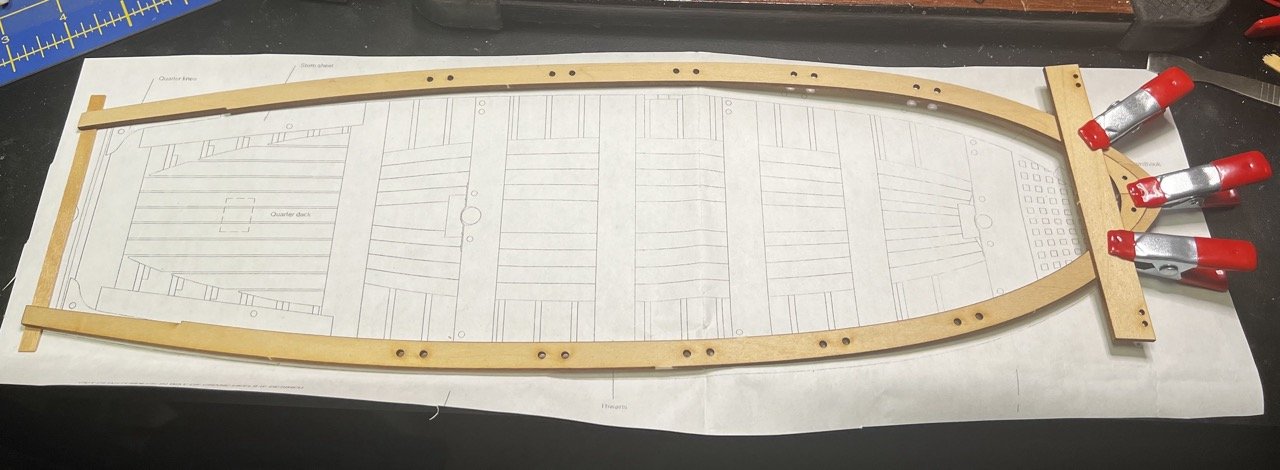

The instructions leave out any mention of the quarter deck. This step requires use of the plans for a general idea of what to produce. I made slight adjustments to keep the supports at a proper height and level. I also installed the rear thwart area. It was nice to complete this area as it was the last unfinished area of the hull. Stain and a coat of poly was applied to the newly installed parts.

-

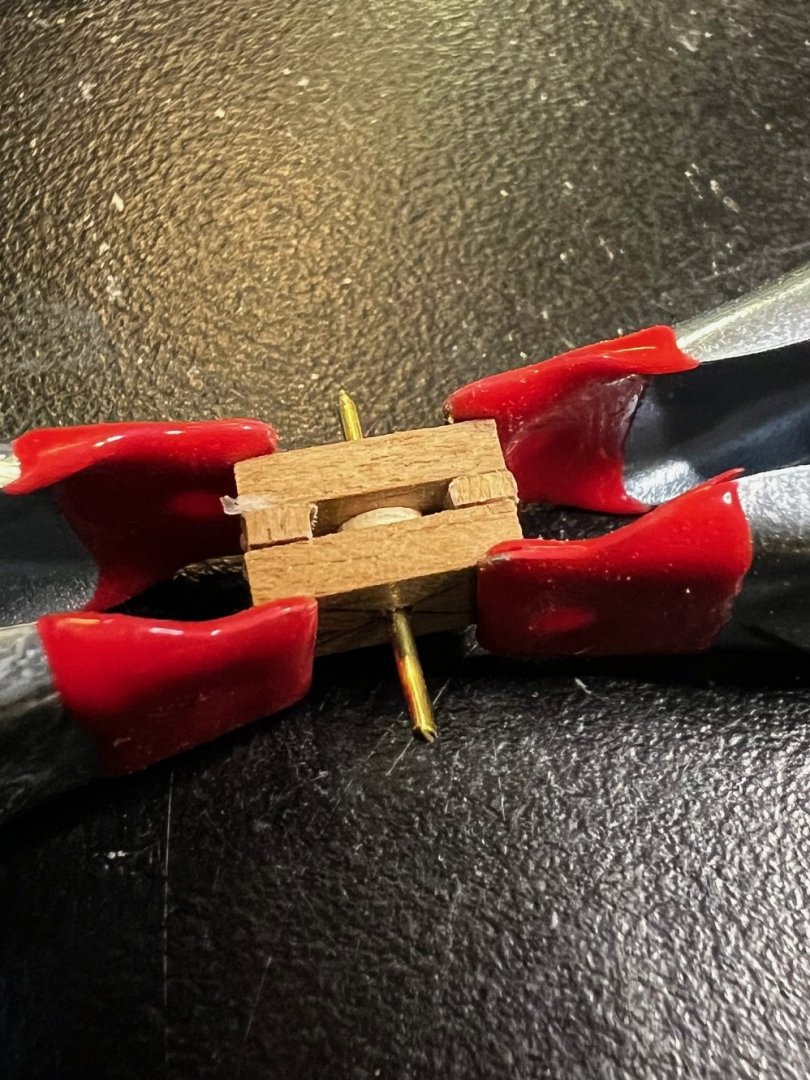

Progress continues on the launch. The interior staining involved some experiments and adjustments. It's like a dance, one step forward and two steps back. Stain was applied, sanded, and then corrected. The result is better, but lessons were definitely learned. The stain also added more gloss than expected, which was also compounded with a clear coat. I'm planning on addressing the sheen later down the road. I also started adding interior components. Creative engineering was used in the moment to hold everything down.

-

I decided to add trunnels to the boat. The 1:16 scale seemed big enough to warrant the extra work. I used a draw plate and basswood (same material as the planks) to create the treenails. The size ended up a little big (1mm) but it was as small as I could go without the material falling apart as it was pulled through the plate.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.