-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by builder_Nick

-

The first phase of building the mold is pretty straightforward. I decided to attach it to a board where I first put down guidelines to help keep everything straight and in proper position. I glued it down by welding corners with hot glue. I figured that gave me an easier out if I needed to remove it from the board. Pictured also is the frame materials cut to length in prep for bending to the mold. Side note, I would have left the sheer tabs off until after fairing. They get in the way and are easily added later.

-

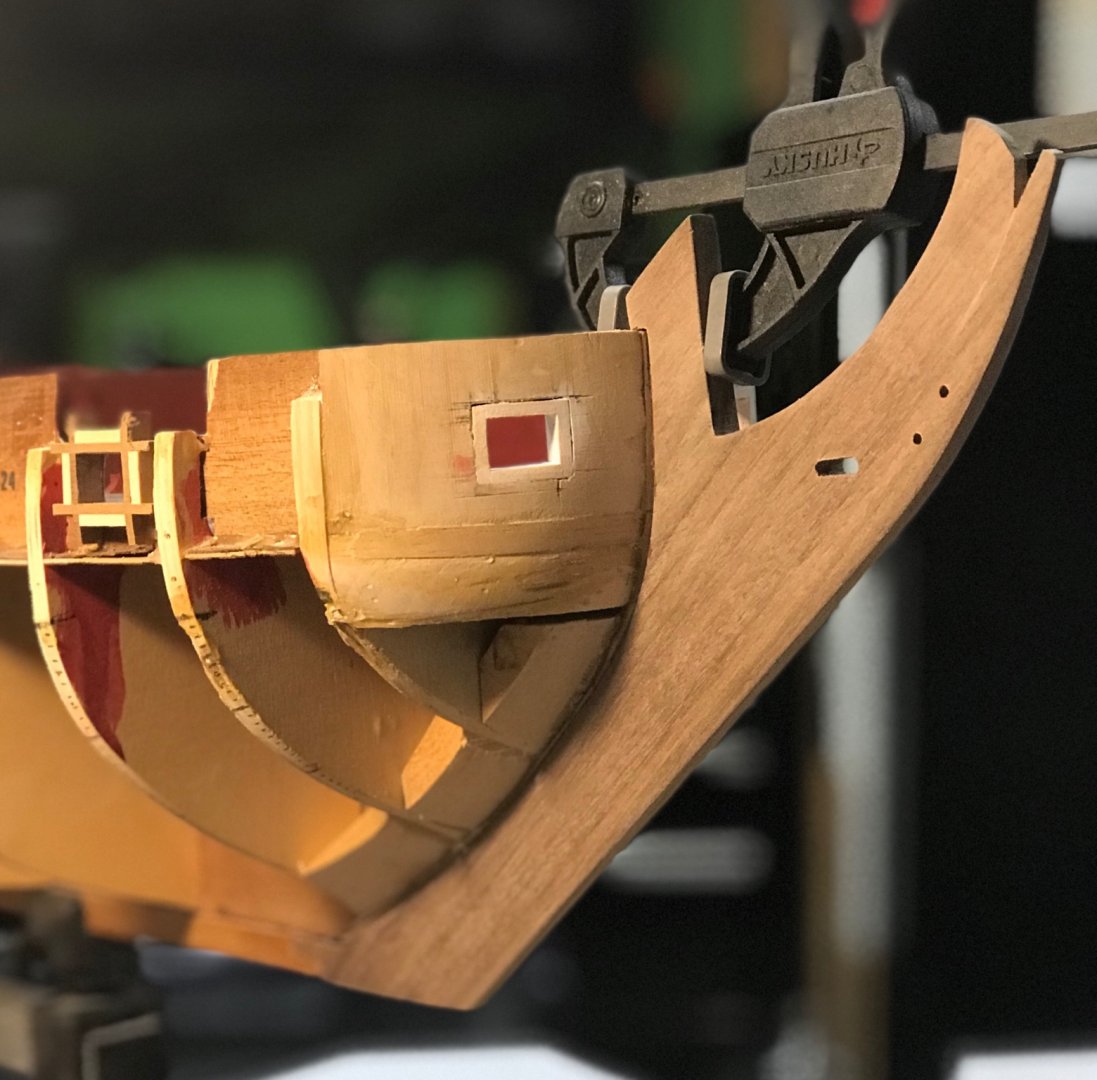

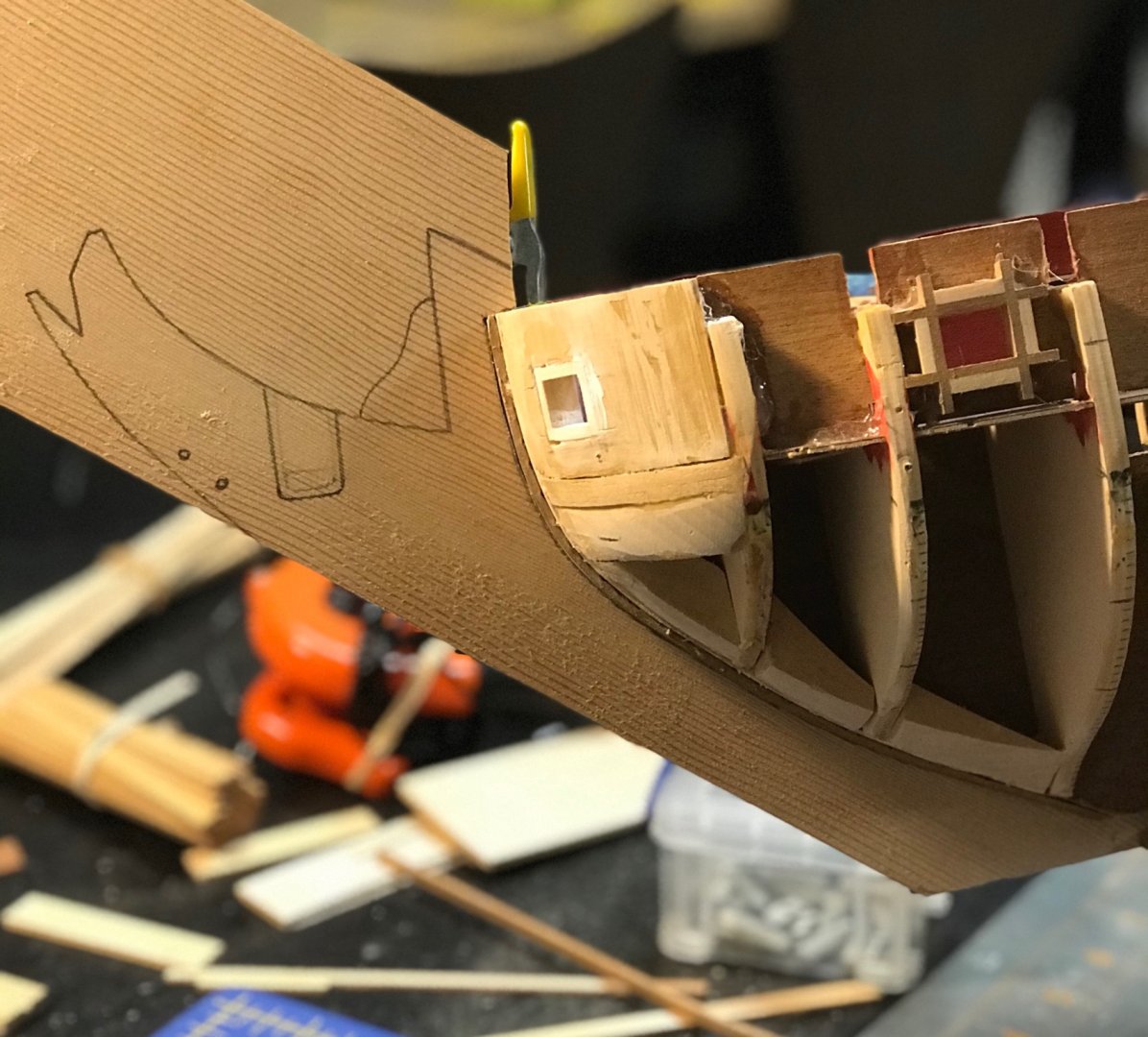

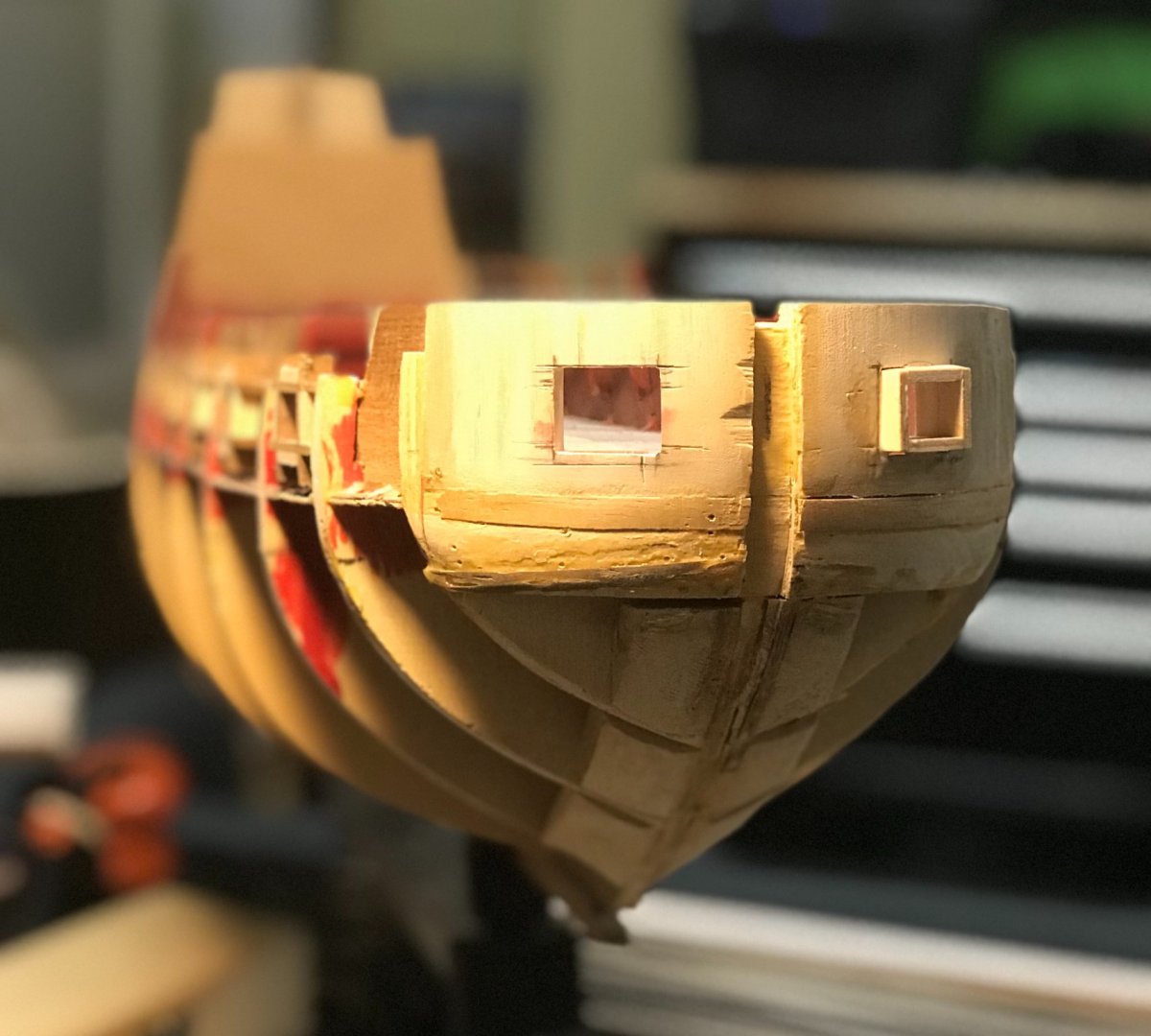

The ports on the bow are unique as they are meant to be cut in through a crescent piece of wood without frames like the others. While probably a minor detail, I was pleased with the way the other ports looked and decided to give these two a similar treatment by making the openings bigger and creating custom frames. The first picture shows the over cut opening on the left and one of the frames installed on the right. I made the frames deep enough to get the inside and outside curves. The second picture shows the frames trimmed, sanded, and installed. All ports on the gun deck are now uniform with clean, accurate, square edged frames. Now that the ports are installed, I am going to give the ship a once over to do some fairing. I need to figure out what was happening around the bow that caused some deviation from the original plan. As the pictures show, there is a slot cut in that I don't see mentioned in the instructions or any pictures of other builds I have found. I am hoping it was only for additional strength. My concern is that it will bring the stem back and interfere with future alignments. I may adjust my new stem that I am milling to accommodate the slot depth. There is also some strips of wood added and saw marks that make me think some fairing had taken place to correct the shape. I am going to do some research into fairing techniques and then get this ship a step closer to planking.

-

I was looking through the box and found the stempost. It appears to have been glued on the bow and then removed. I’m not sure if it was intentionally or accidentally removed. It suffered some damage and doesn’t seem usable. I have some walnut to mill a new one. The stempost doesn’t appear in the instructions yet, but I like the technique of leaving a rabbet to tuck planks cleanly. I’ll be doing a little more research as I plan out how to mill the stempost and incorporate the rabbet.

-

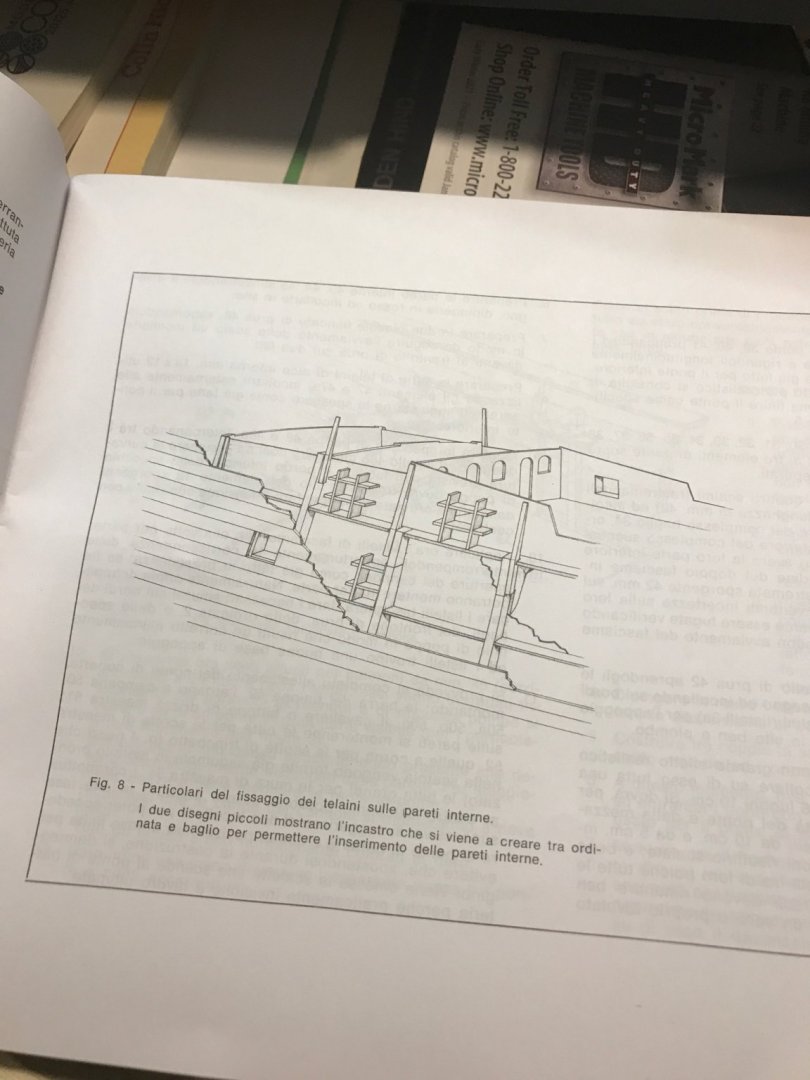

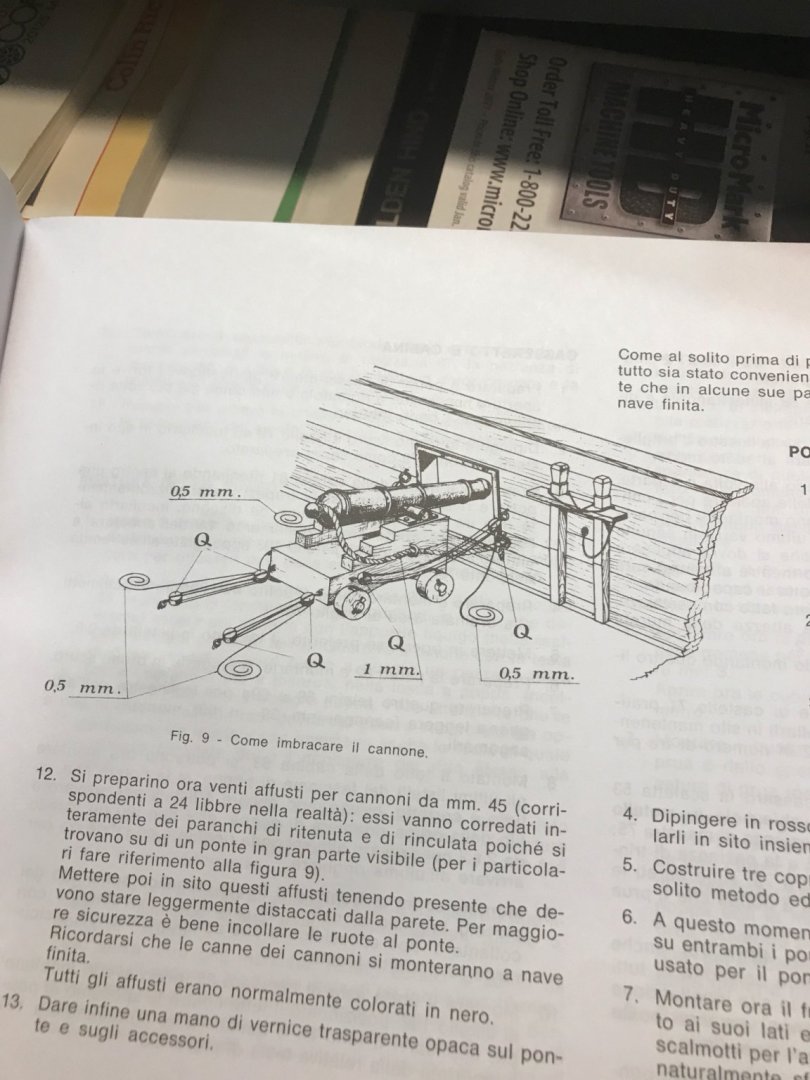

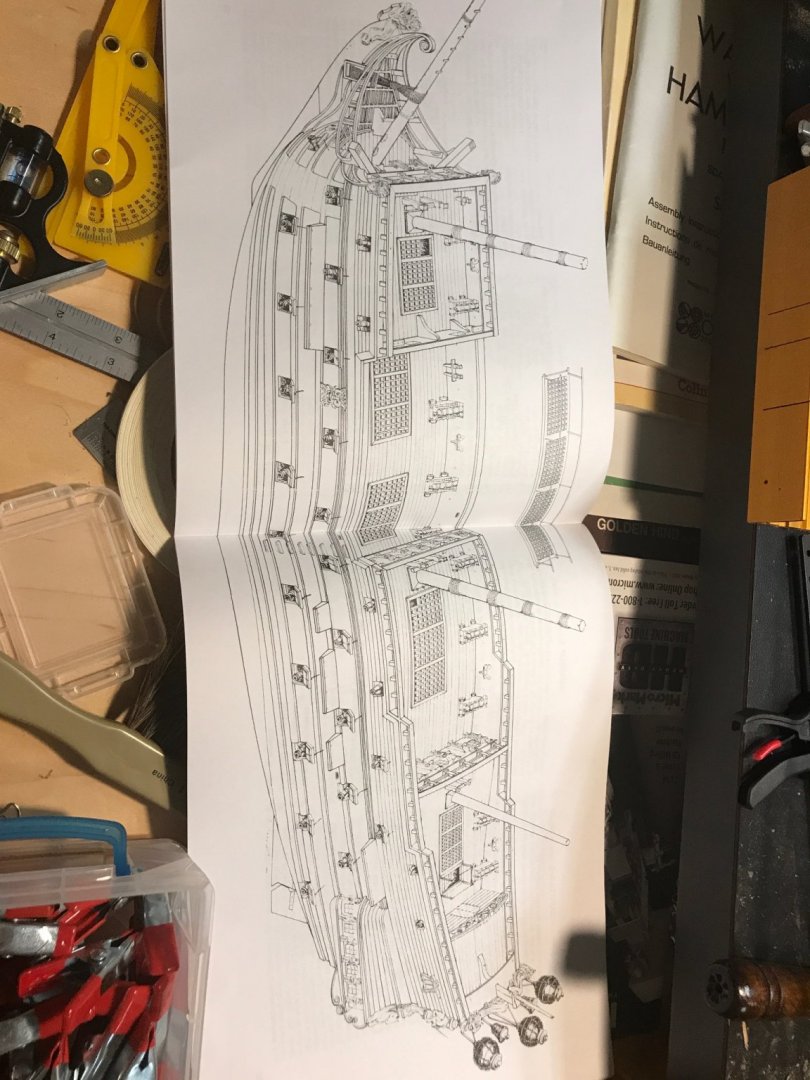

I have been comparing the instructions, drawings, and model to determine the completed steps. I’m hoping I have all the literature. The instructions refer to figure #s that I don’t see. The picture below states, “Fig. 8 shows in detail...” Is there more than the assembly instruction manual and plan drawings? Some elements have been completed out of sequence with the instructions. I know that is fine and that many builders work in different ways. I just want to make sure I understand what has been done and what I should do next.

-

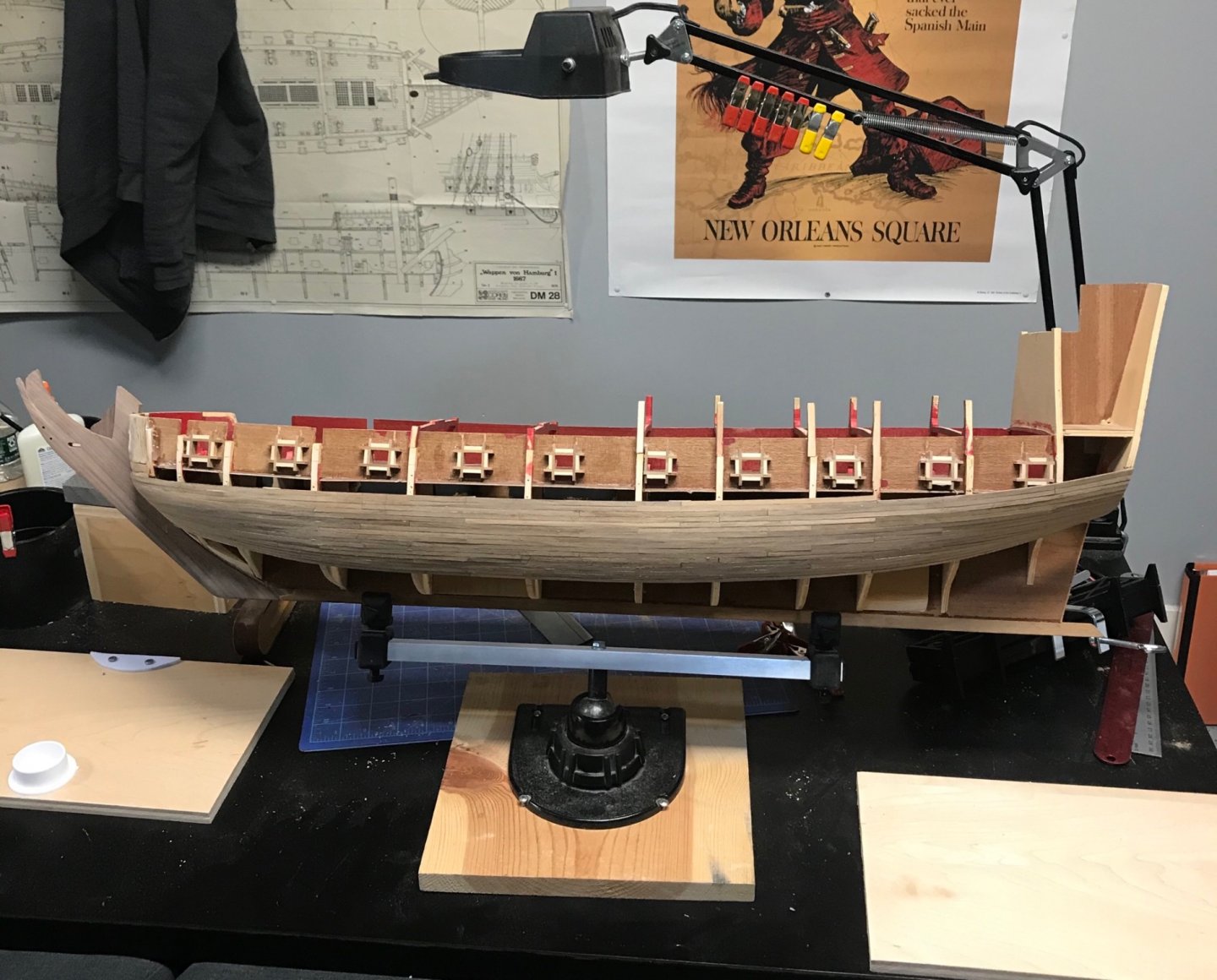

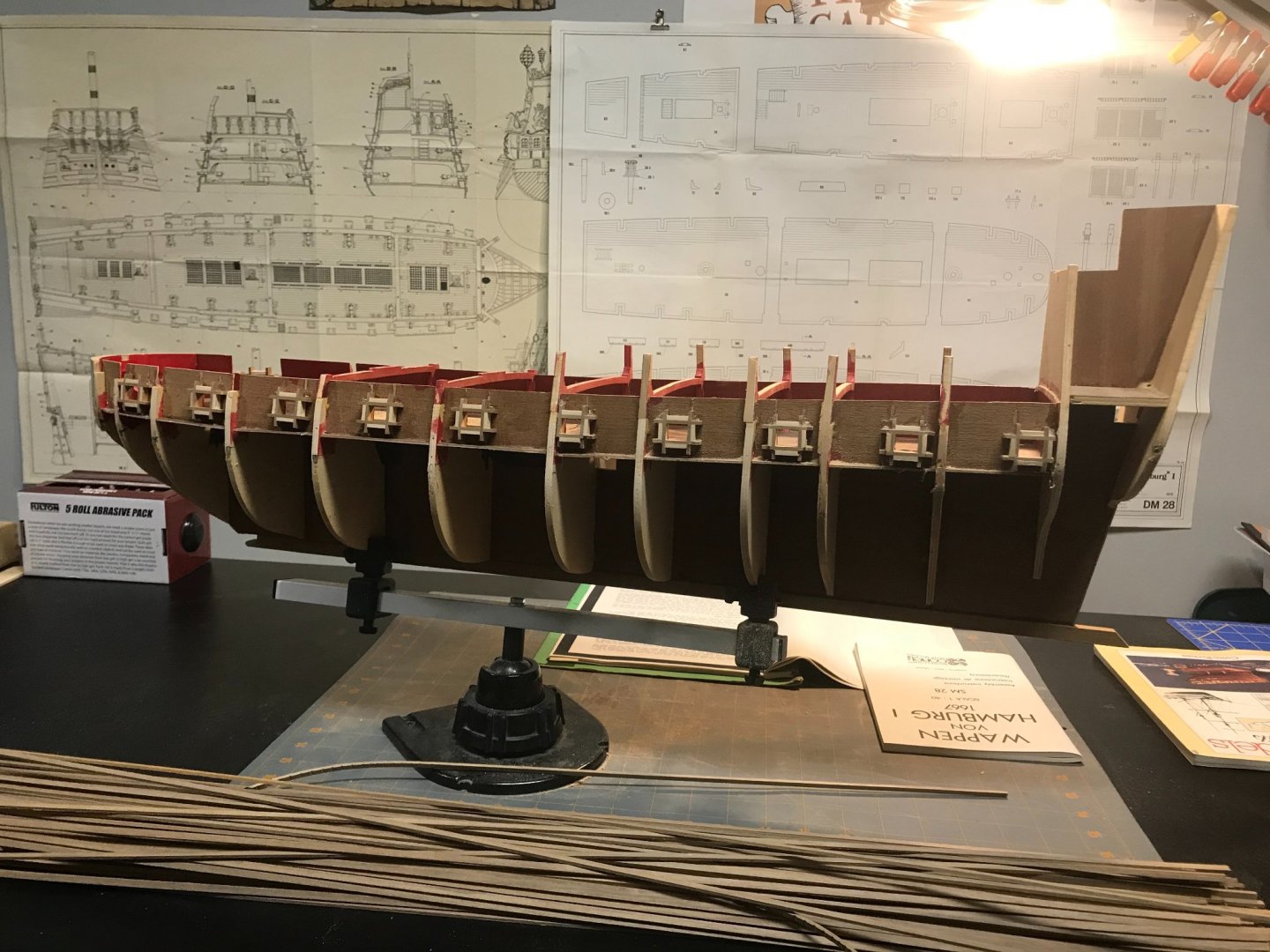

My wife’s grandpa passed away shortly after giving me the kit. It had some damage and a few elements in progress that I adjusted. He had built custom frames for the gun ports. Unfortunately, they were varied in size and location so I opted to remove them and use the frames from the kit. This allowed me to align them and know that each will be of uniform size. They are now glued and sanded to match the curvature of the ship. I also added blocking for better attachment of the planks.

-

Hello Everyone! I am starting a build log for the Wappen Von Hamburg kit from Corel. The start of my build comes with some back story as I am not the one who purchased the kit or started the build. A number of years back I was along for a family visit to my wife's grandfather. During the visit he took interest in my woodworking experience and asked if I would be willing to fix a few ships he had build years earlier that had been damaged. I enjoy models, tall ships, and a good challenge so I took them home and restored them as best I could. When returning the ships, I was presented with two kits and an assortment of tools and supplies that he felt should go to someone that would appreciate them. One of the kits was the Wappen and the other the Victory. The Wappen had been started and the Victory untouched. Life was too busy with work and family. The kits remained in storage for many years until recently. The adventure begins as I tackle what I understand to be a very complex and advanced kit as a complete novice. I look forward to documenting this journey and hopefully getting feedback and advice from those with more experience than I.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.