-

Posts

32 -

Joined

-

Last visited

Profile Information

-

Location

Seattle, WA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

BenD reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

BenD reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

kuya reacted to a post in a topic:

Muscongus Bay Lobster Smack by cbeckenb - Model Shipways - 1:24 Scale

kuya reacted to a post in a topic:

Muscongus Bay Lobster Smack by cbeckenb - Model Shipways - 1:24 Scale

-

kuya reacted to a post in a topic:

Muscongus Bay Lobster Smack by cbeckenb - Model Shipways - 1:24 Scale

kuya reacted to a post in a topic:

Muscongus Bay Lobster Smack by cbeckenb - Model Shipways - 1:24 Scale

-

SUBaron reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

SUBaron reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

GrandpaPhil reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

Dave_E reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

Dave_E reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

Dave_E reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

Dave_E reacted to a post in a topic:

Corsair by cbeckenb - Occre - 1:80 Scale

-

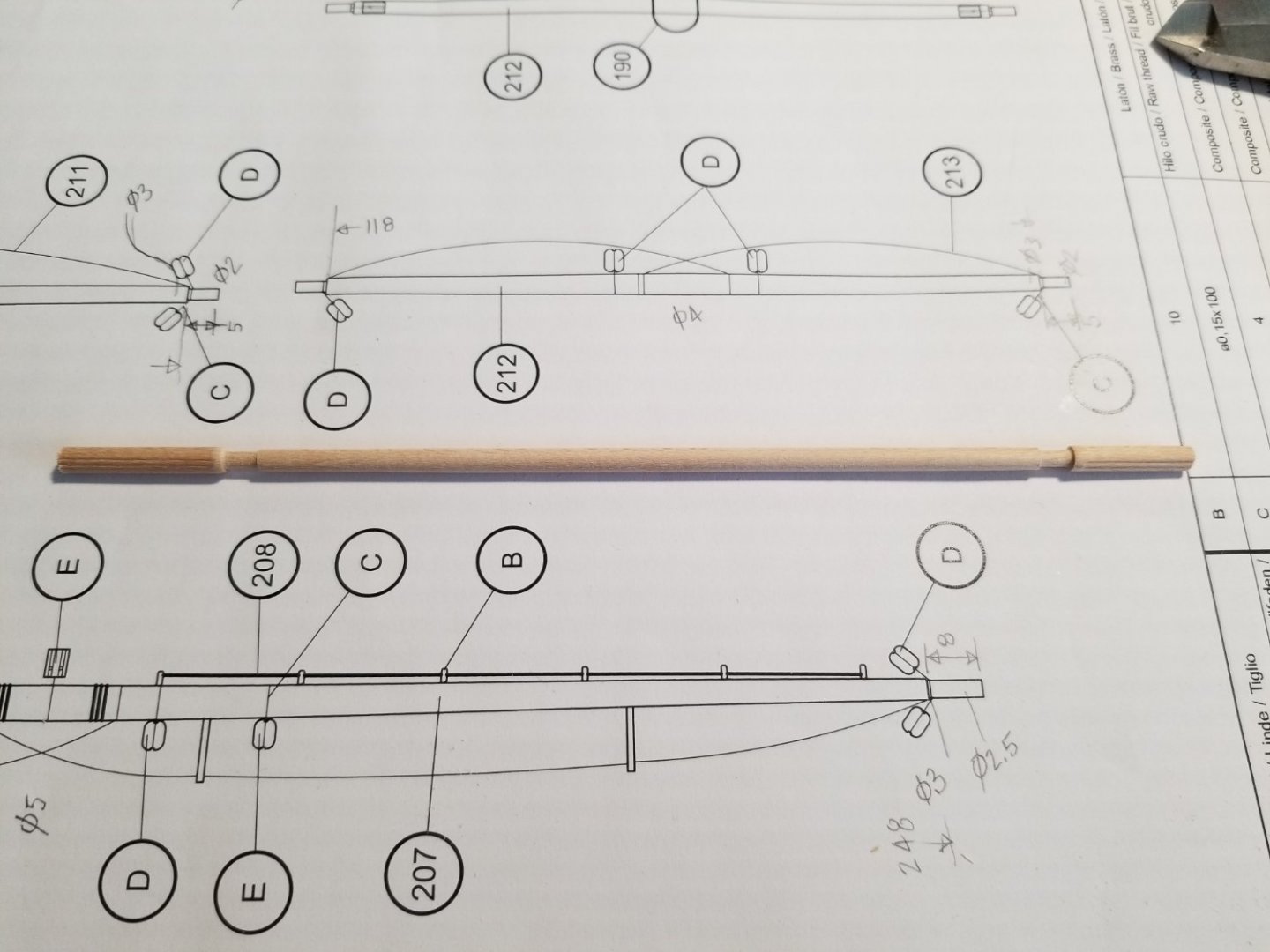

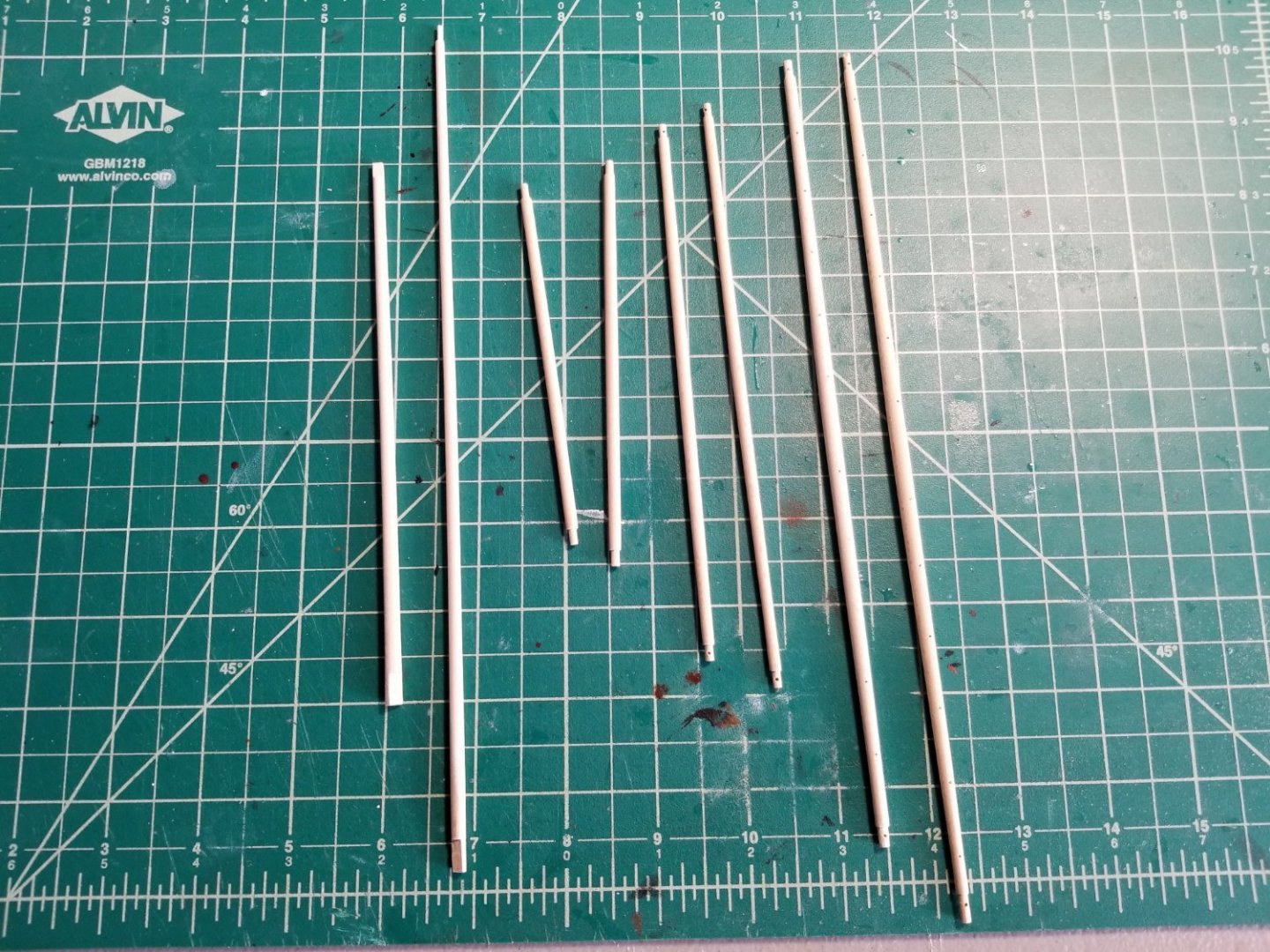

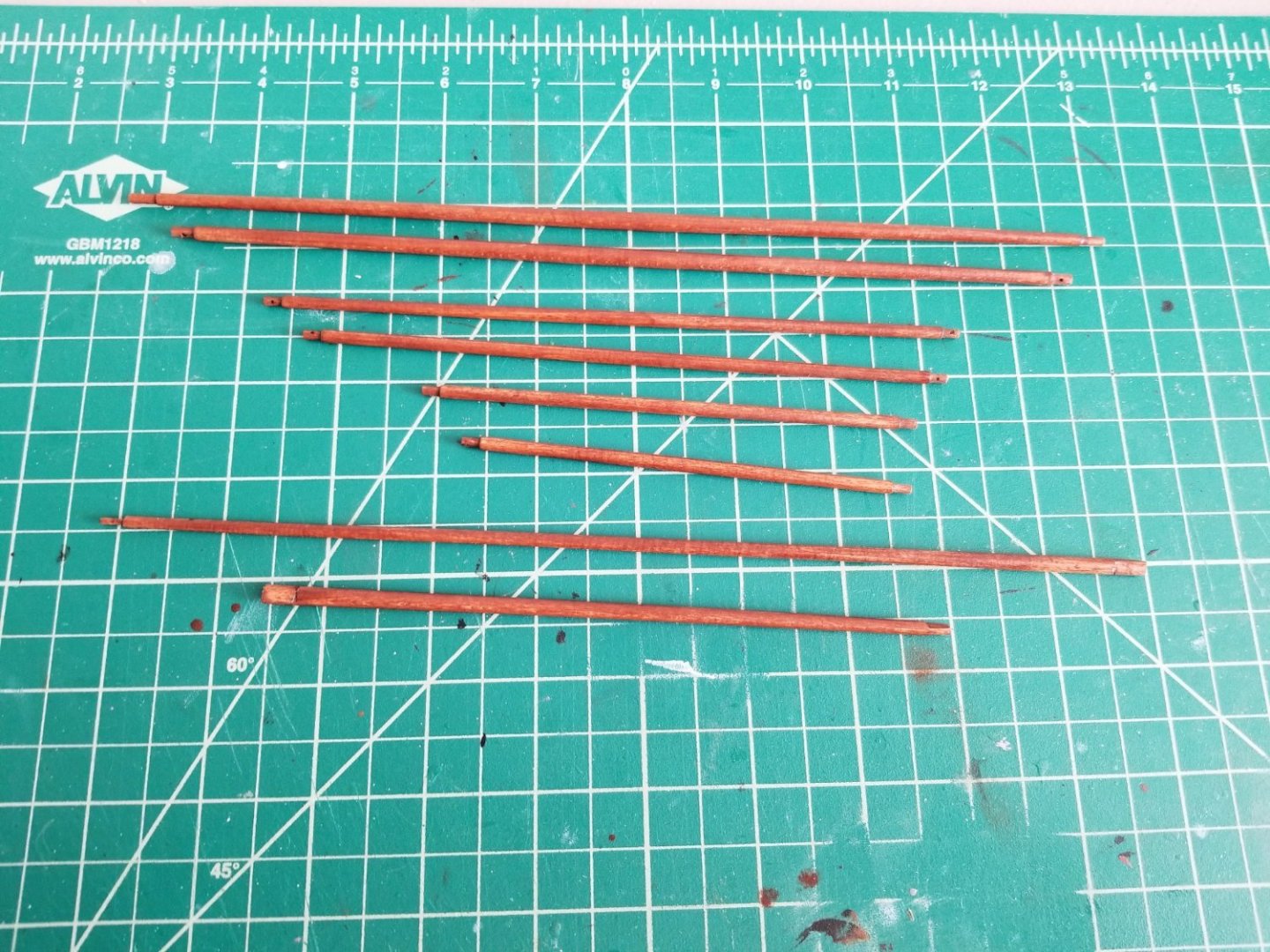

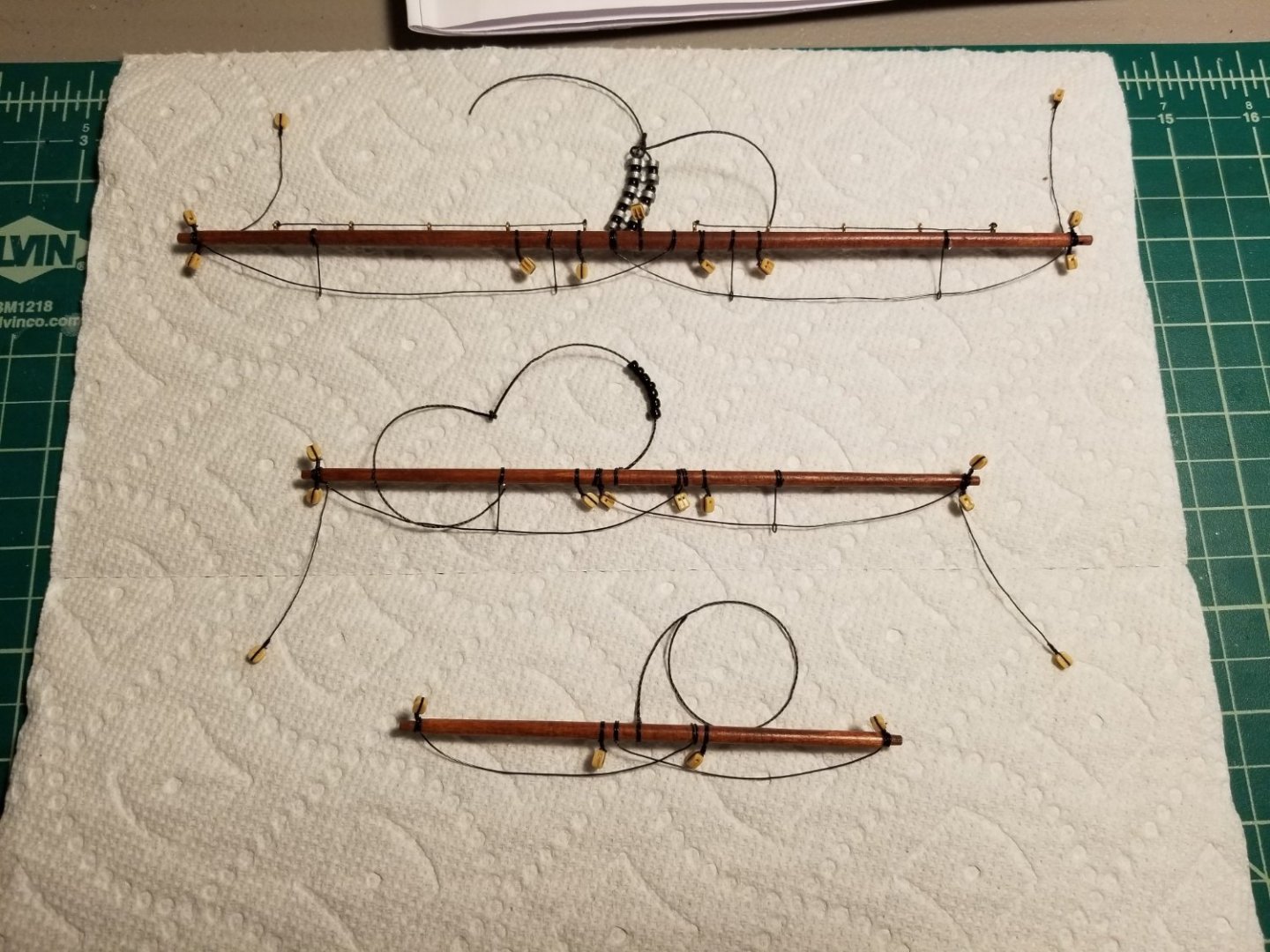

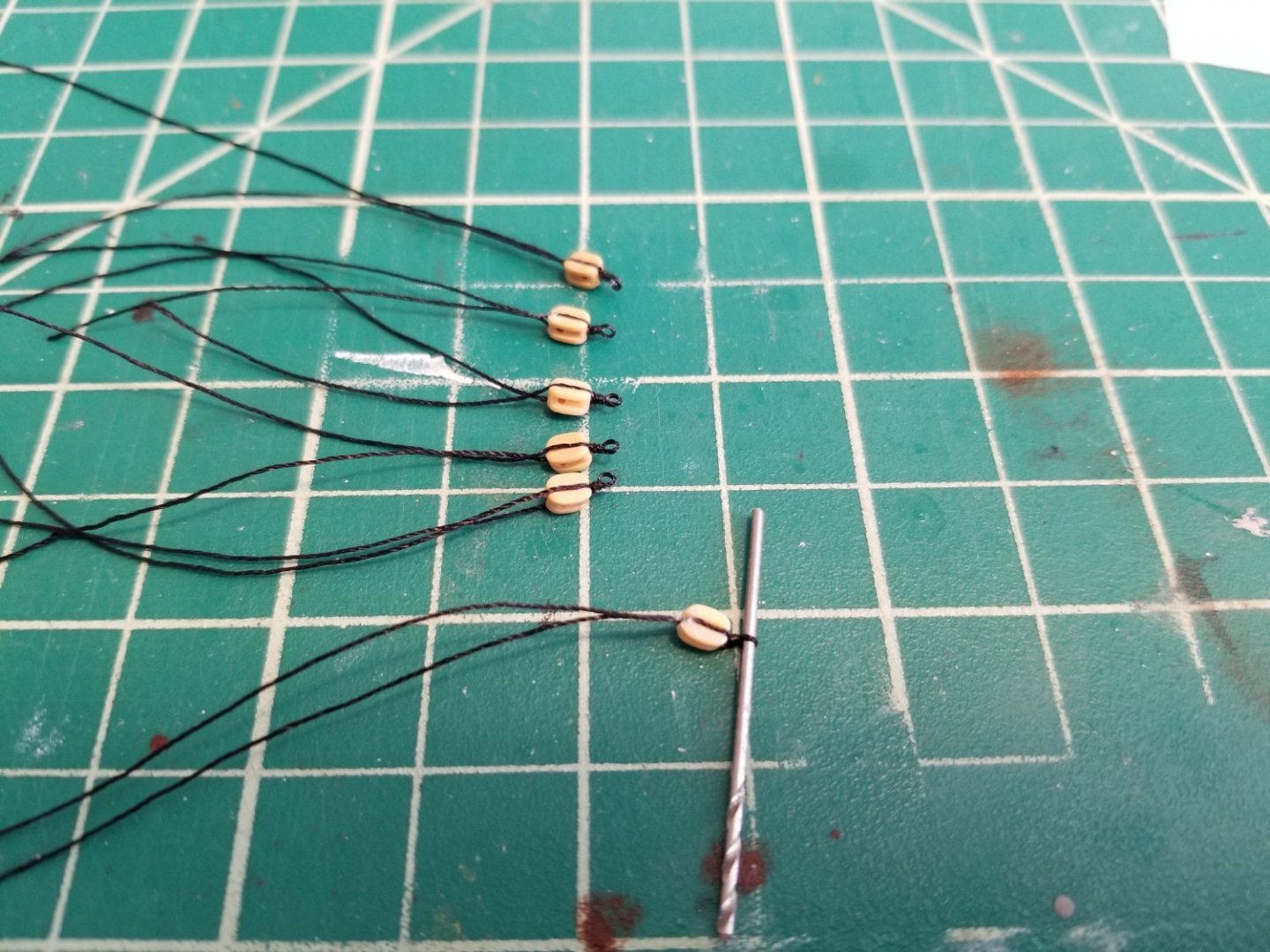

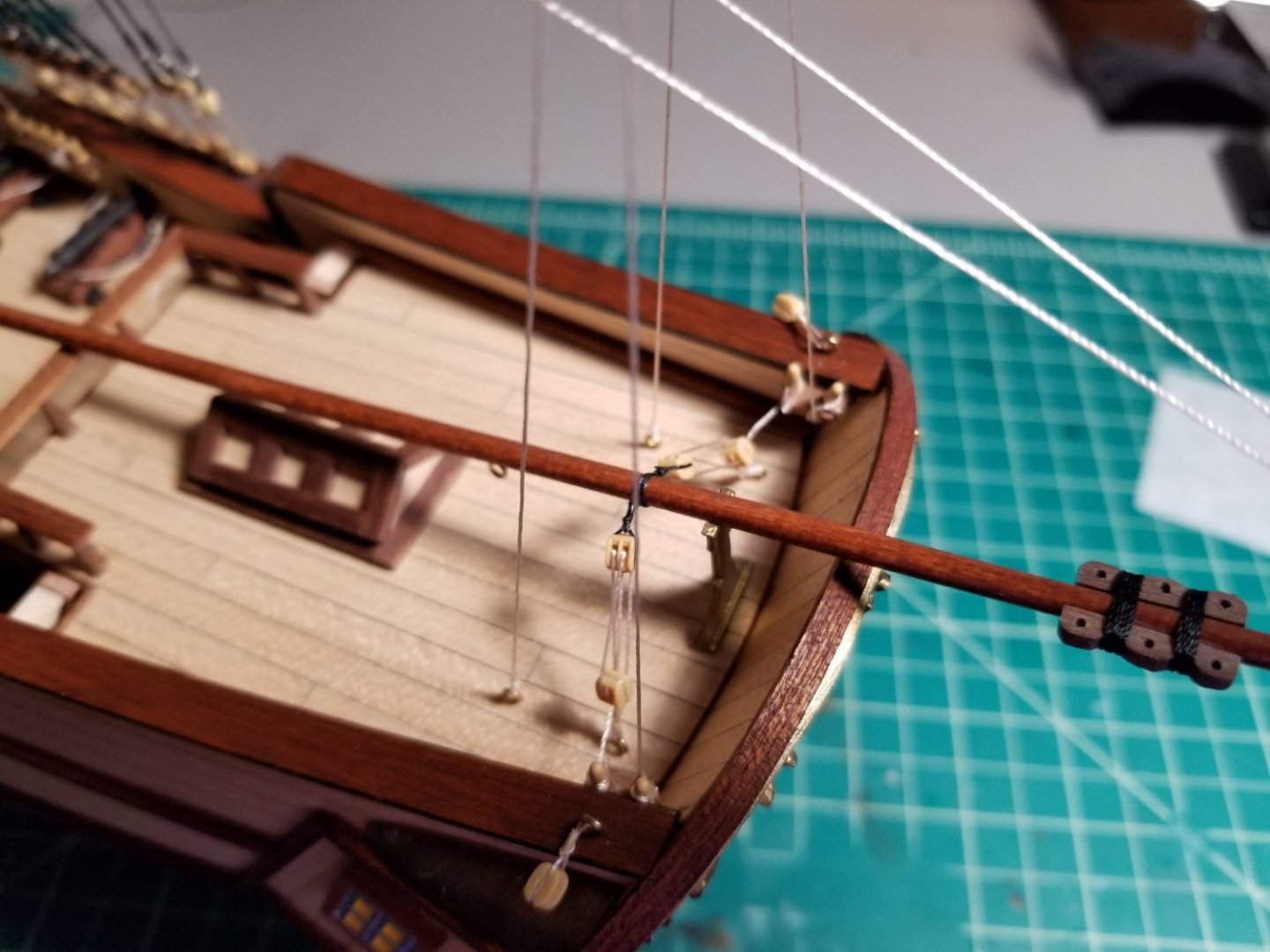

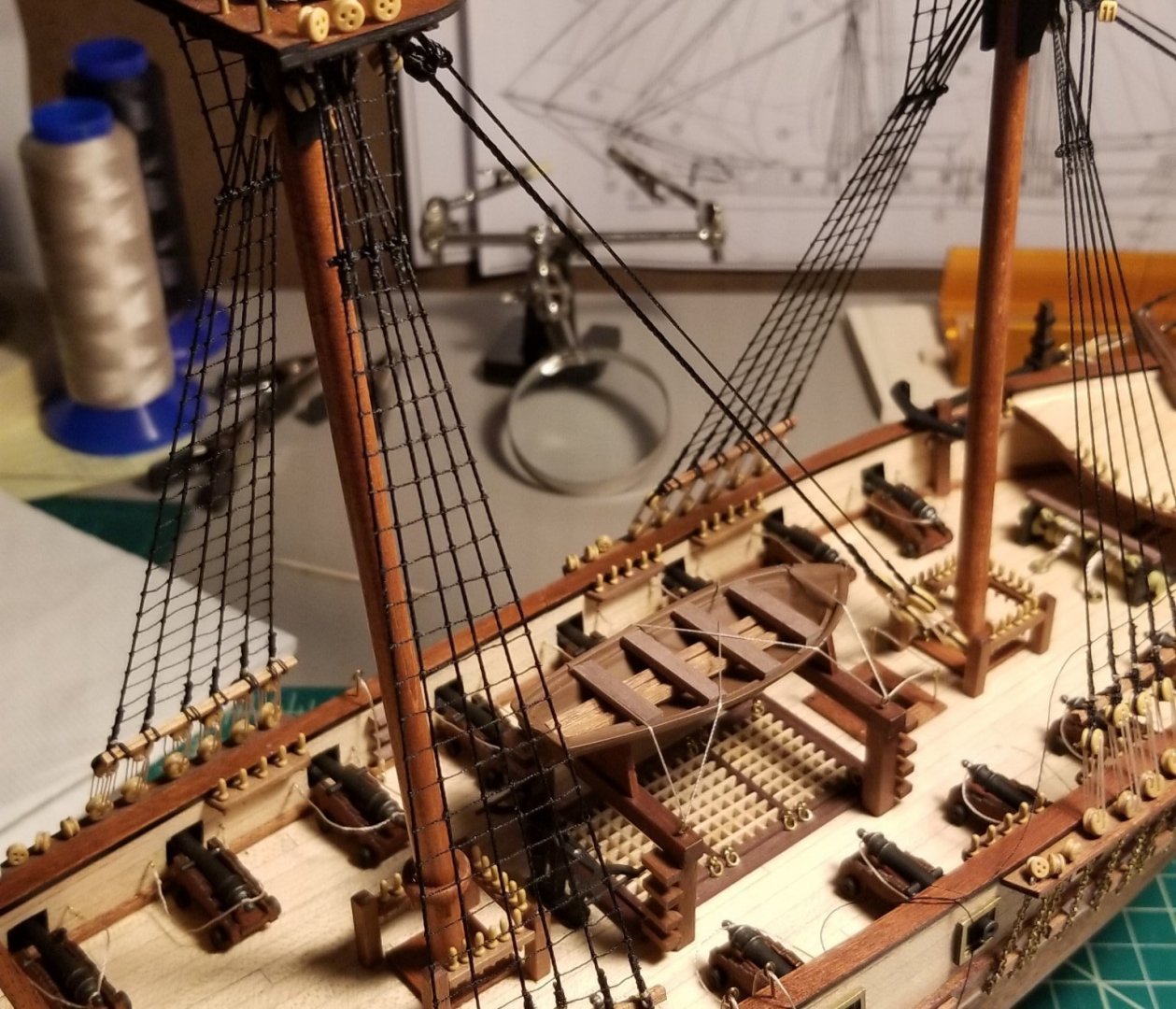

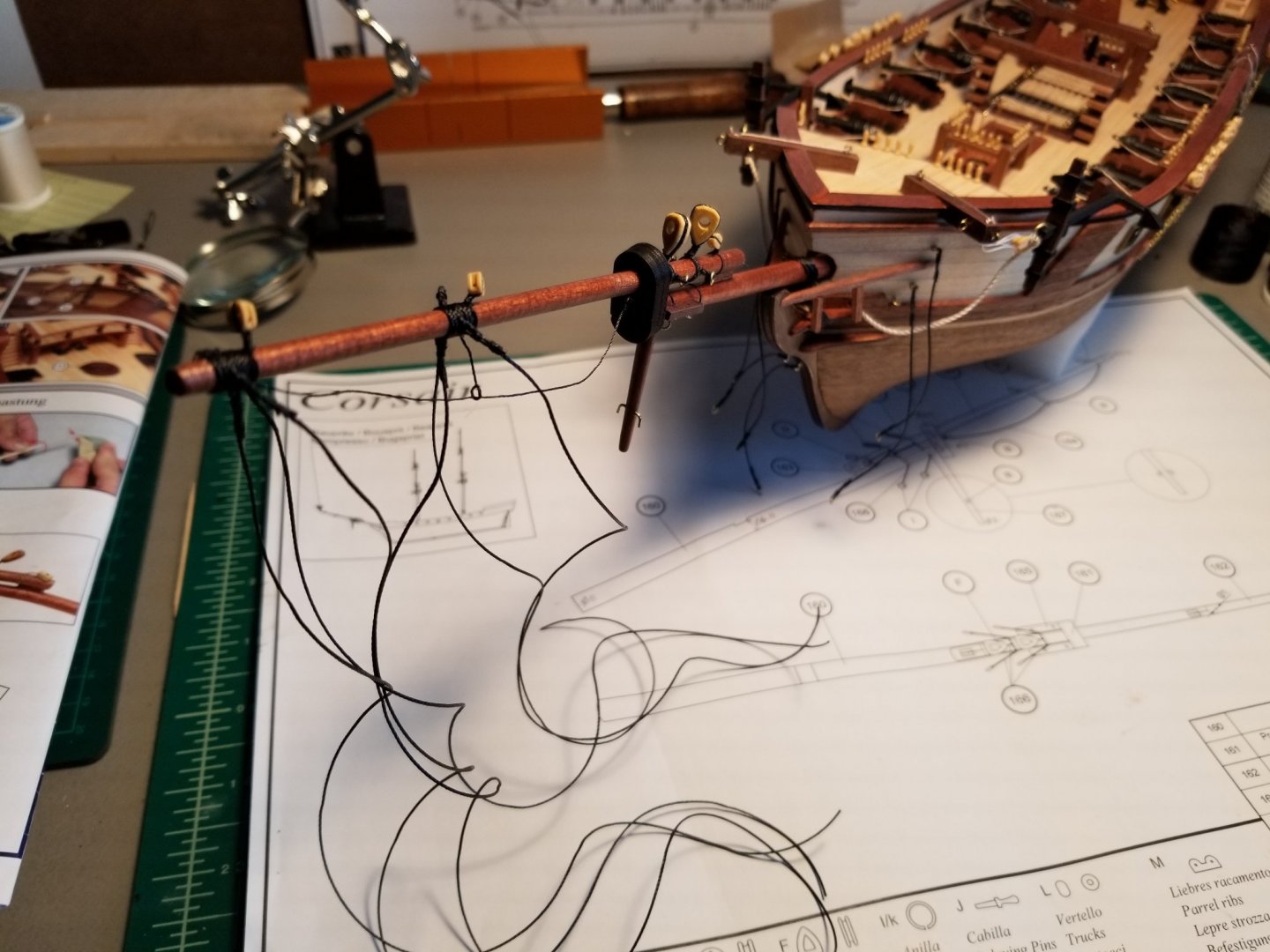

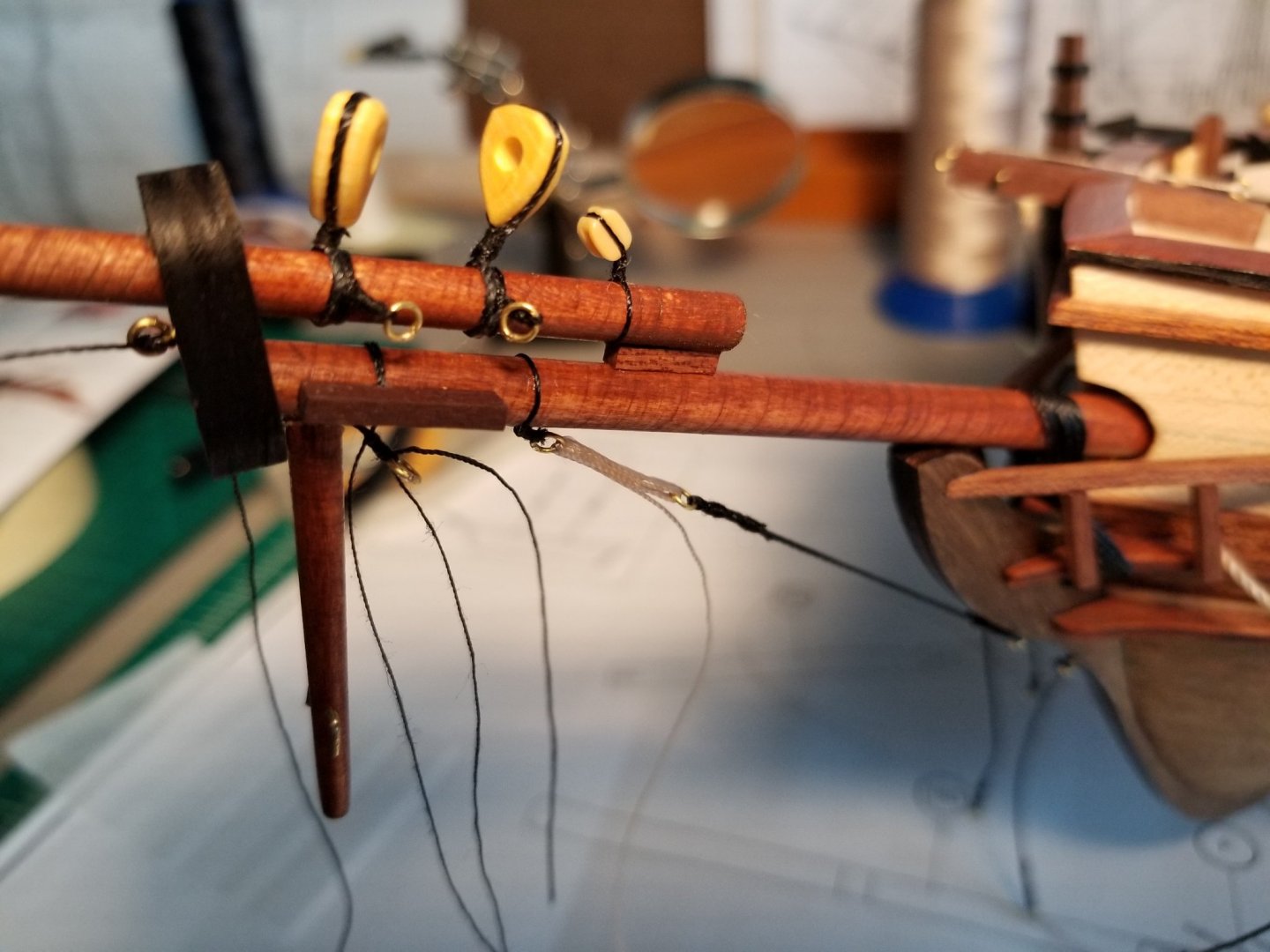

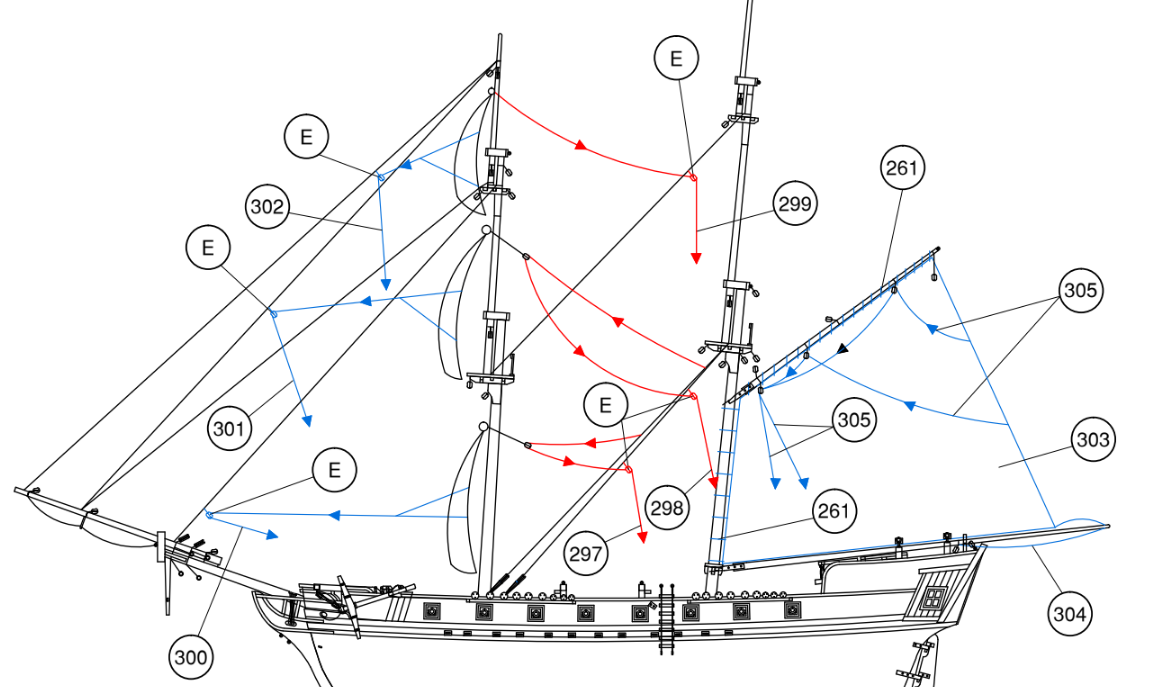

Another very productive week. Had the whole week off from work so I had plenty of time to kill... I made the yards, gaff, and boom using the same method I did for the masts/bowsprit, using a handheld drill and sandpaper. For the yards that have to taper at both ends I left a decent amount of extra to go in the chuck, like this. I had one break when I wasn't careful enough while making those notches on either end but fortunately I had enough dowels not to run out. Here is all the spars ready for stain: They were then stained with the same stuff I used for the masts and a coat of Wipe-On Poly was applied. Naturally the next step was getting all the blocks and so on rigged. Here's the gaff and boom: And yards for one of the masts: For the footropes I used 26 gauge black wire. It's easy to accidentally bend them while moving the pieces around but the stuff is very malleable, so fixes are easy. The last thing to do before starting the standing rigging was some rework on a few blocks that should have had beckets on them. Occre's method (as shown in their YouTube videos) for blocks that should have a rope seized to them is to just tie it on the end with the sheave and call it good. I don't like the way that looks, so I just decided to re-strop the blocks with beckets... And so the running rigging has begun! Starting at the stern, with the gaff and boom: I belayed the boom sheets to the nearby belaying pins since there is nothing in any of the drawings showing where those should be tied off.. With the stern rigged, next up was the lower main yard: After getting the lower yards on, I got into the zone and got both fore and main topsail yards on and rigged, though I neglected to take pics as I went.. I pinned the topsail yards to the masts for peace of mind, though I think the rigging alone keeps everything quite robust. Not having built a square-rigged ship before, I had expected that the yards would swing around a lot, but to my surprise the opposing tension of the various lines keeps it all in place very well even though I did not make them as tight as I did the standing rigging. The belaying pin racks are getting crowded! With every line that gets added, it gets harder and harder to get tweezers in there. The belaying pin diagram does not make much sense to me. It's not symmetrical and there are a few pins that are doubled up. Up next is rigging up the topgallants, and then finishing up the lower course braces, sheets, and so on. The flag(s) need to be rigged too. The kit came with sails but I decided against putting them on since they hide all the details (plus I just don't like the way they look, and they're heavy and thick which ruins the scale effect). Unless I am forgetting something, which I usually am, I think that is all that is left for this one!

-

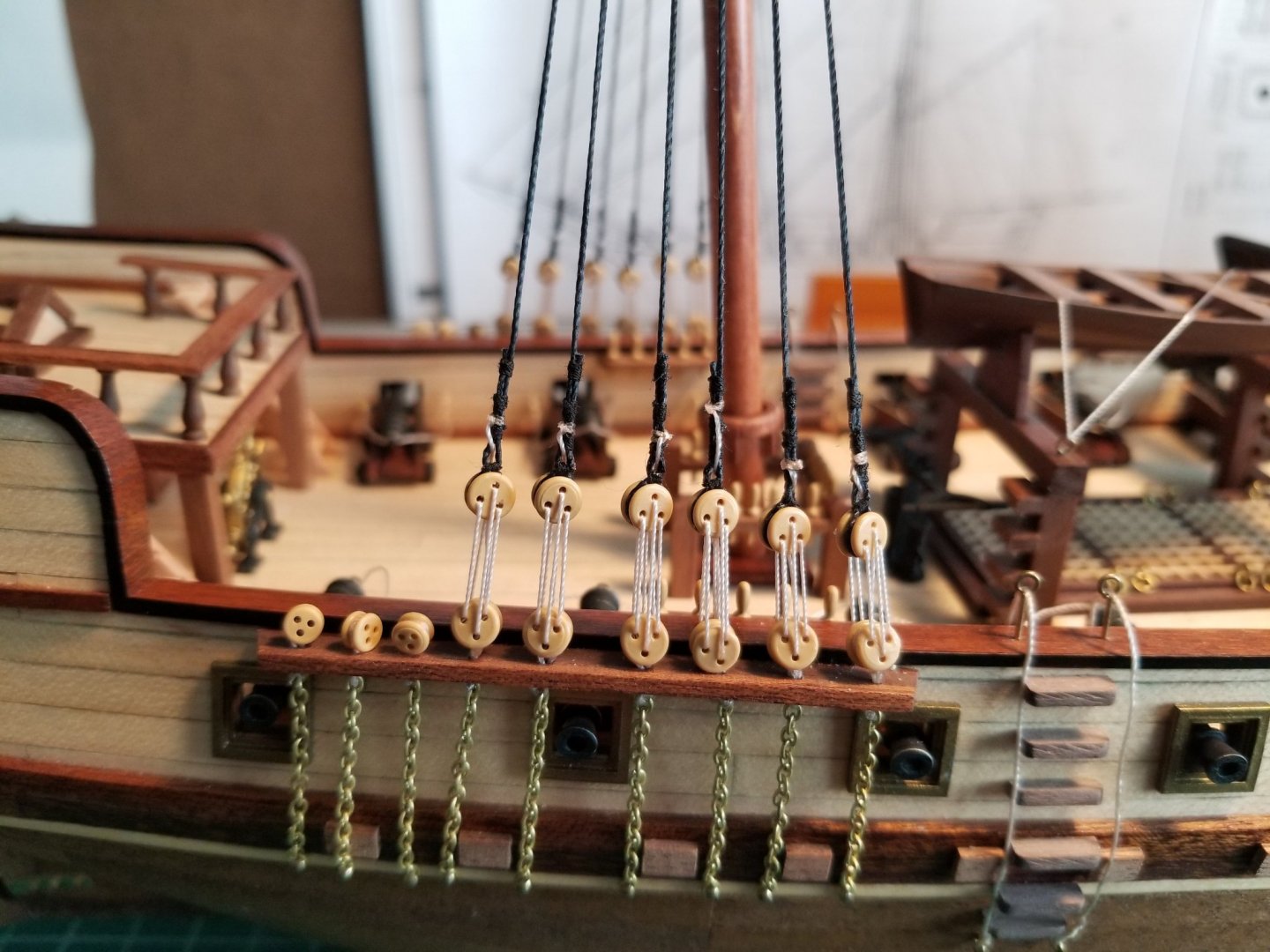

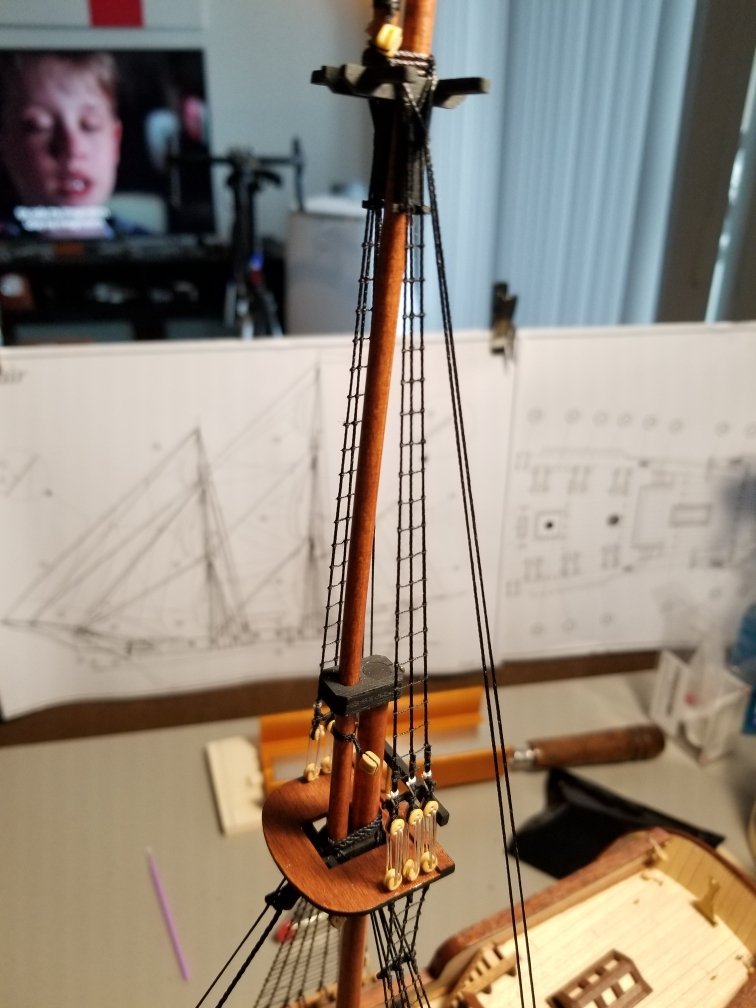

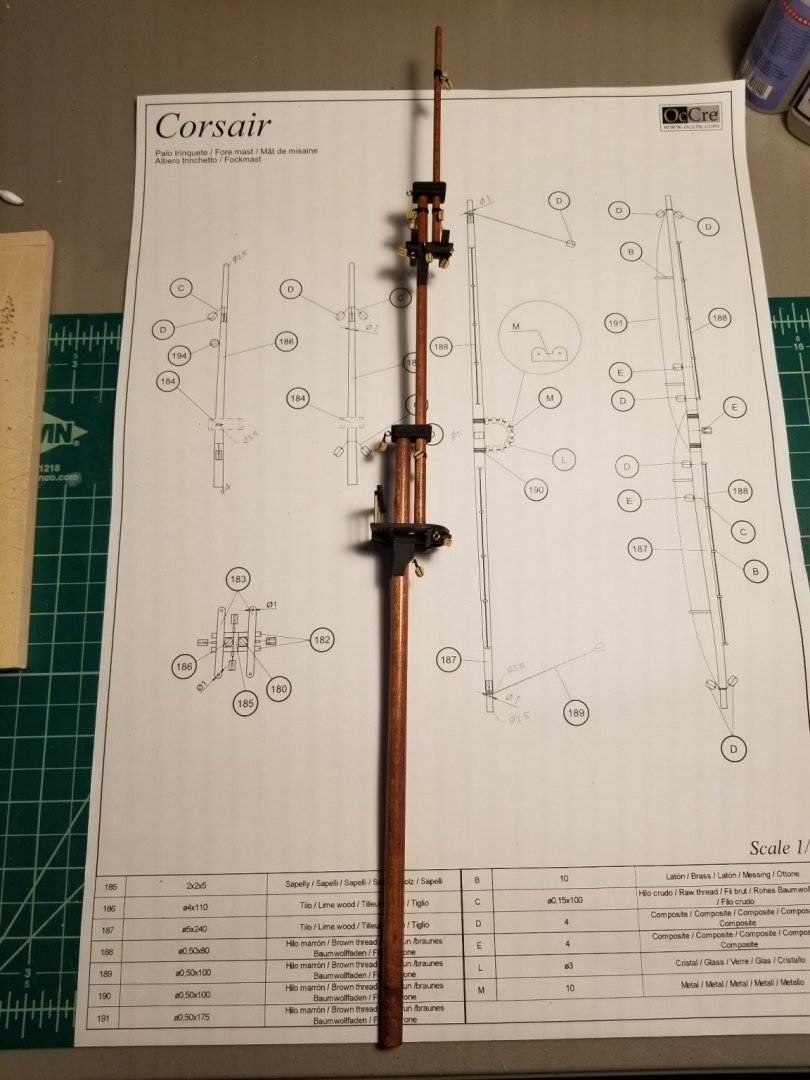

Now for the standing rigging. I used Chuck's Syren practicum and instructions from the Fair American as guides for the rigging, since the Corsair instructions really don't tell you much. Started off with the shrouds: I am reasonably happy with the deadeyes and lanyards, though they could be more even. A note to anyone using this build log as a reference for this model: Make sure your knots and string tying the deadeyes to the chains are VERY strong! I had to redo at least 5 or 6 that broke while I was tightening the lanyards. And I'm not entirely sure that all will stand the test of time, though so far they're holding. Next was the main and preventer stays. I used 1mm cord for the main stays and 0.5mm for the preventers. Again, the eyebolts pulled out of the deck a couple times while tightening these up... Consequences of making everything taut, as I like to do. Next up, the sheer poles and futtock staves were lashed and glued: Now for my first attempt at doing ratlines: I used thin thread and a curved needle, clove hitching every knot. I used some very thin superglue to hold it all together. They could do with some sag in between the shrouds, but I'm happy with the way they look. After my ~4 month hiatus, I picked up this weekend with the topmast shrouds: These deadeyes turned out more even than the lower shrouds and I'm happy with the way they look. Next were the ratlines for the topmast shrouds. After that, I got the backstays on followed by the main and preventer stays. I had to be a little creative on where to attach these on the foremast... it seems that the proper way to do topmast stays is to reeve them through blocks and down to the deck. But, for this model, it seems the intent is just to seize them on the foremast, so that's what I did. Topgallant shrouds, backstays, and other stays were then put on. Once all that was done for the mainmast, it was all repeated for the foremast. The masthead looks pretty busy with all those stays and shrouds. The final pieces were the fore topmast/topgallant stays and jib stay. Here we are, standing rigging all in place! (At least I think so! I may have missed something...) I'm very pleased with the rigging so far. All the lines are tight and none of them are slack; I managed to get the tensions balanced very evenly. Everything is very robust and stiff now. Now the next things I need to do are to shape and rig the yards, boom, and gaff. Then it's the standing rigging, and I think that's just about it.

-

After getting all the deck furniture in place, finally it was on to masting and rigging. I did not take many pictures of the masting process, but the way I shaped the dowels was using the drill and sandpaper method, using calipers to get the diameters correct. A lesson learned is to make sure that if you use very coarse sandpaper, make sure you use finer paper for long enough to really get out all the gouges. On the bowsprit, I just ran the finer grits over it until it felt smooth. The stain, though, reveals the spirals of where there were some deeper cuts I did not get smoothed out. I was more careful with the masts. After the masts and bowsprit were all put together, first up was to step the bowsprit and start getting it rigged. The gammoning turned out well for a first try: The bobstays, martingale stays, shrouds... I'm not crazy about Occre's way of doing lanyards with brass rings.. there is a high potential for them to split open while reeving the lanyard if you're not careful. After only a couple of redo's, it all came together. So here it is with the masts stepped:

-

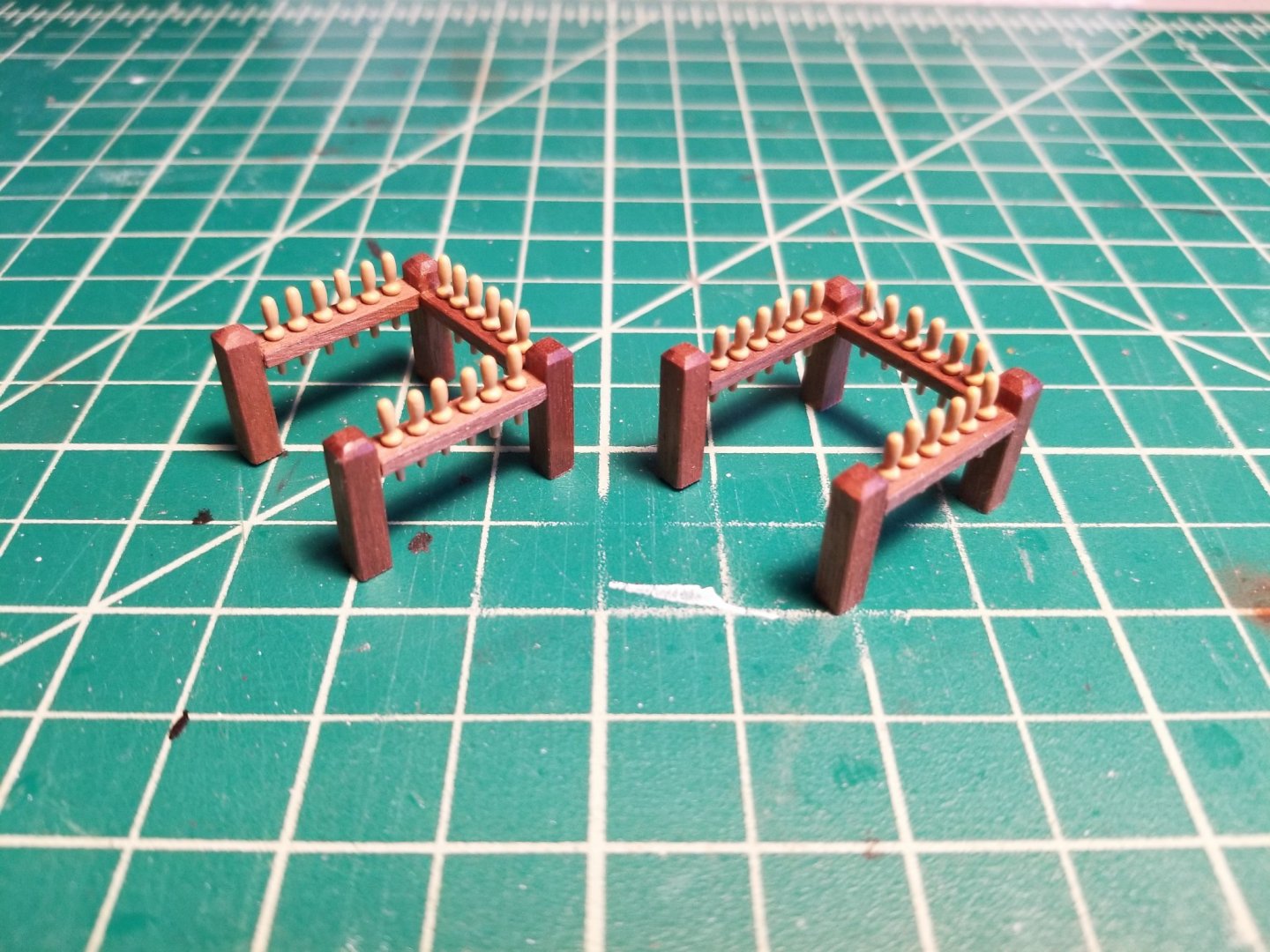

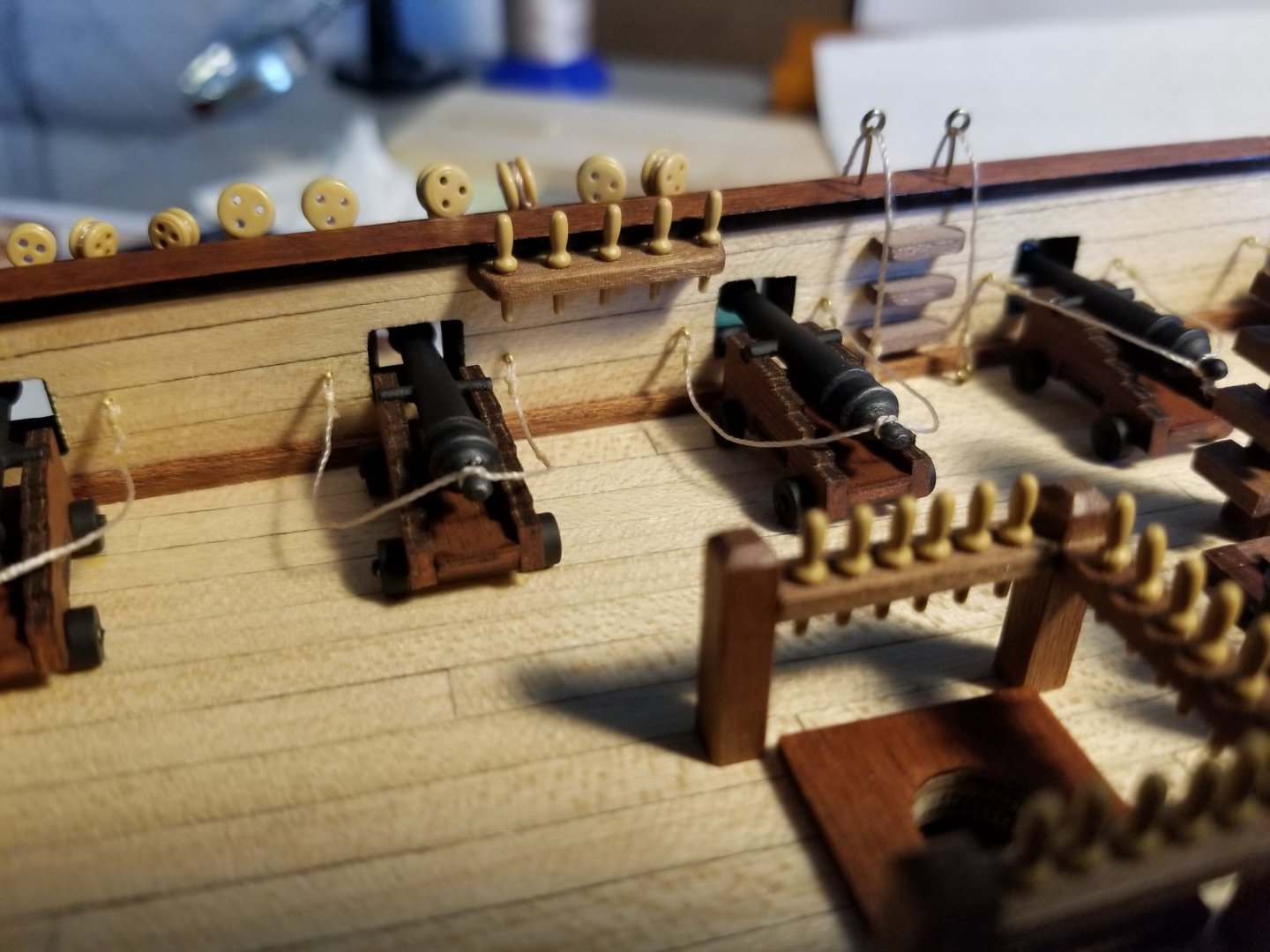

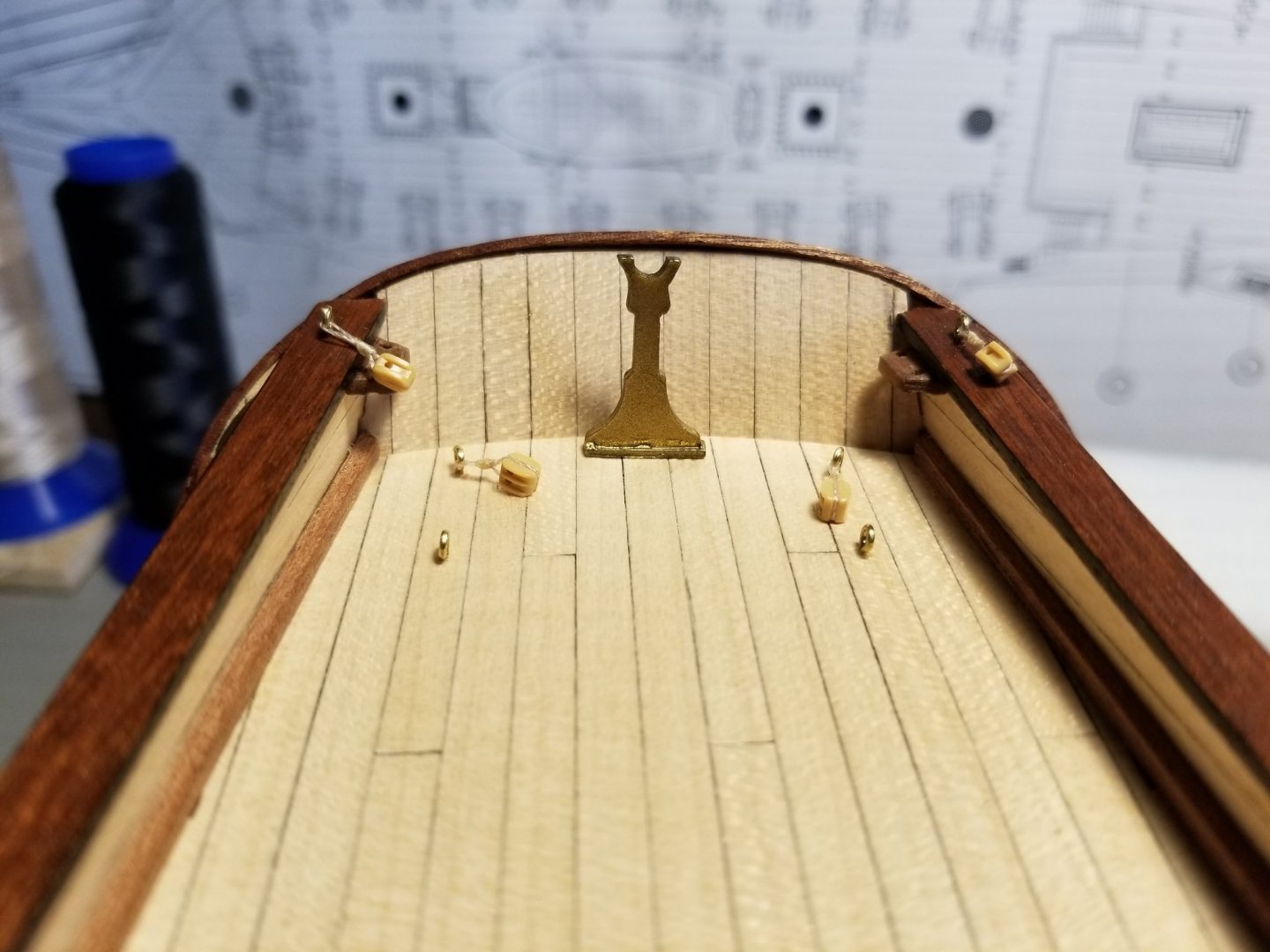

Time for a LONG overdue update! I have not built for a few months, first due to some mental health stuff, then due to some COVID stuff... Anyways, I pulled everything back out this weekend to get some rigging done. I have lots of photos of the progress I've made between the last post and now, so I'll break it up into a couple posts. To start with, after that last post, some deck items had to be fabricated, like the pin racks, wheel, cannons, etc. I decided to do some very minor rigging for the cannons, rather than just gluing them in place. I would do all the tackles and so on if I had the patience, but I don't. I got the anchors on as well..

-

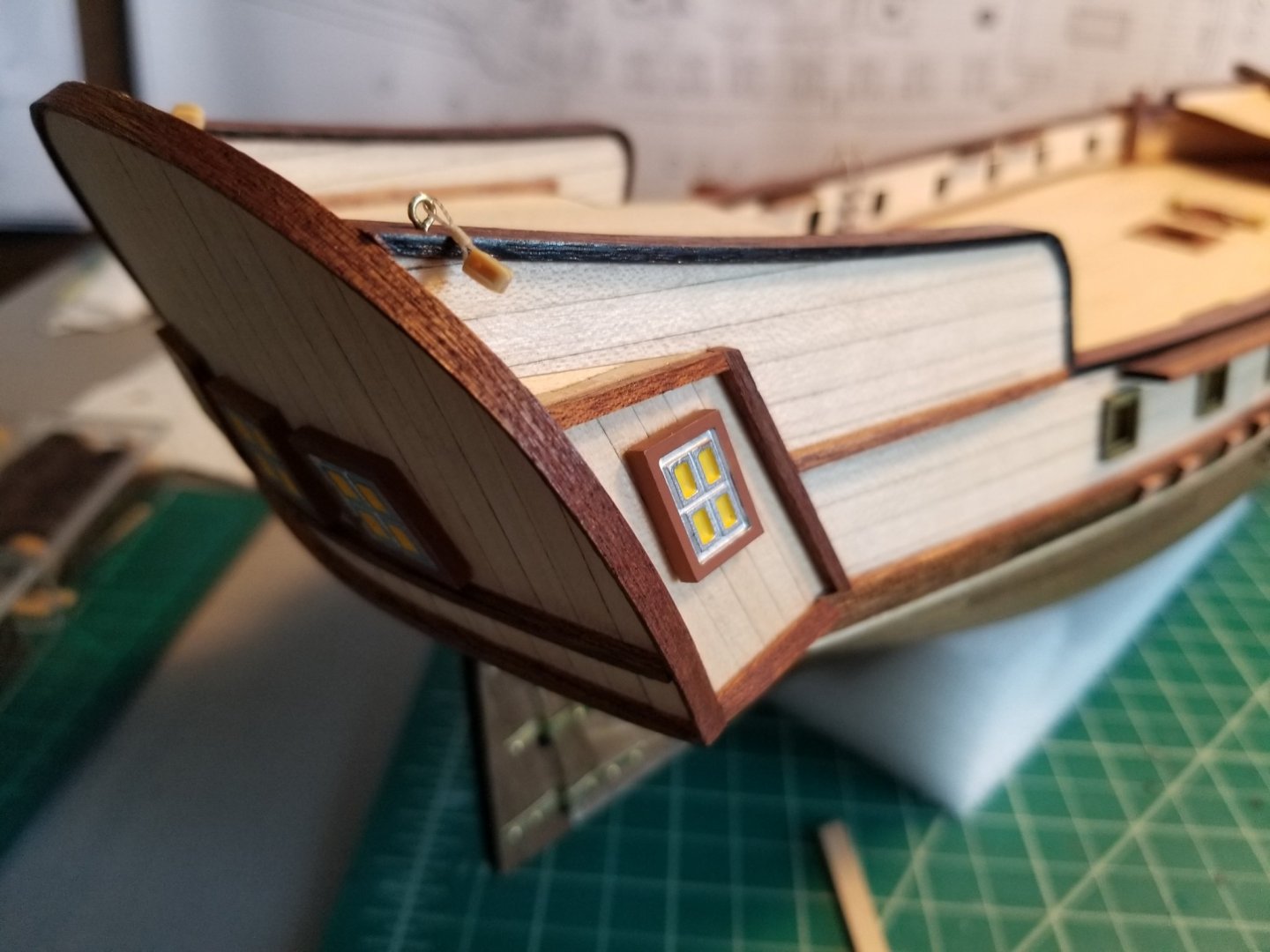

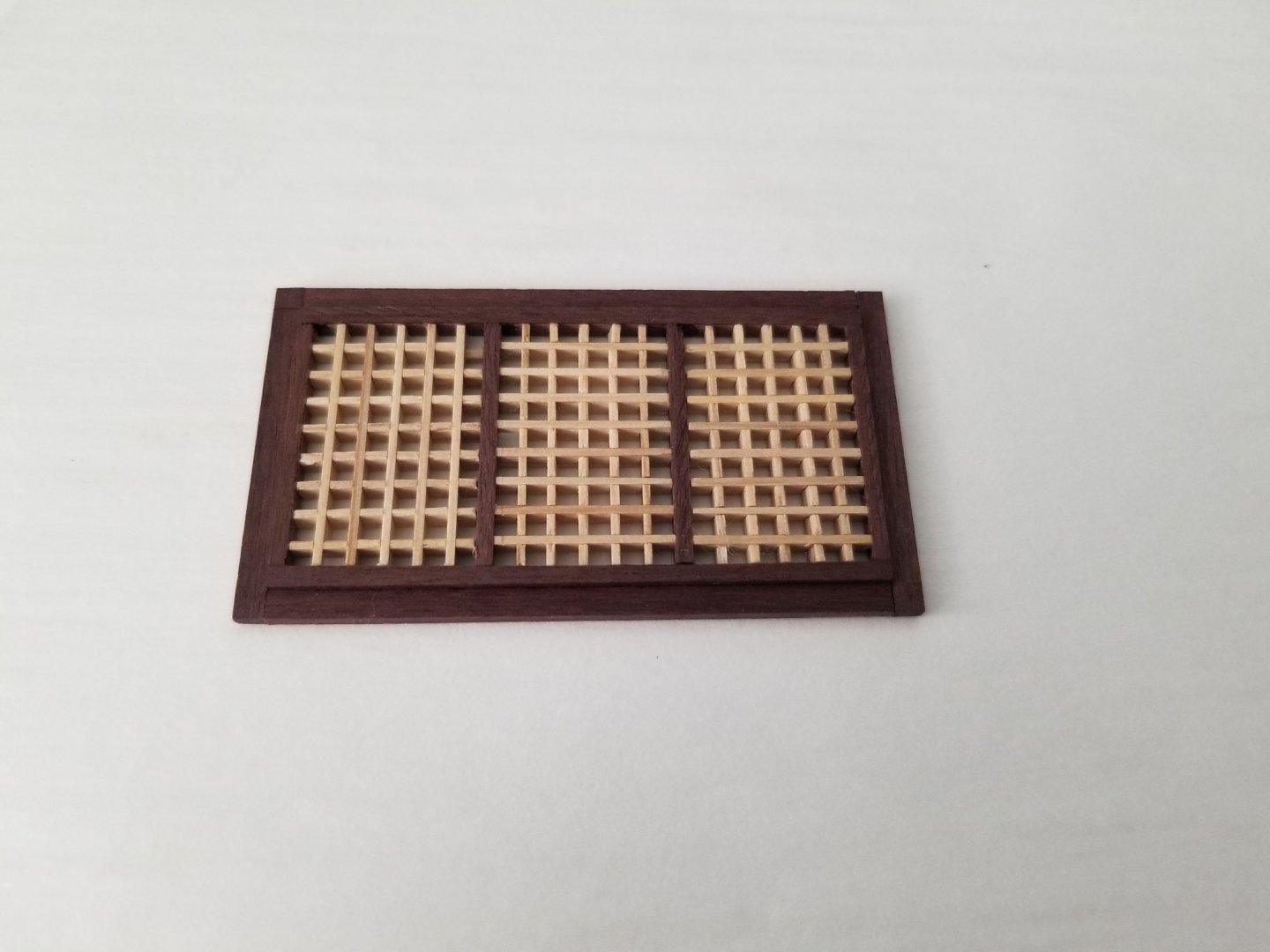

More good progress this week. Started off getting the gudgeons and pintles nailed on and the rudder attached. Took a while longer than I thought to cut the hole in the stern for the top of the rudder but managed to get it all done. Then I made pinracks and cat davits, and started on the beakhead. I stained the laser-cut parts to get closer to the color of the kit wood. Other various details were added on, like ladders, windows, and the decorative sternpiece. I experimented with making my own windows but after spending an hour on one of them and then messing it up, I decided it wasn't worth the time investment.. The first rigging is on the model, which is just some blocks and hearts attached to the deck: Other major item this week is getting the deadeyes installed: Took a few tries to get the process down for these, but it went somewhat quickly once I had it figured out. I'm not entirely confident in the ability of those chains to take very much tension since the links come undone pretty easily, so I will have to be careful when tensioning the shrouds later on. The spacing of the chains bothers me too, but between trying to stay in line with the shrouds and avoiding the gunports, I guess that's the way it has to be.. A couple other details, I managed to get the railing on the upper deck last night and got the grating made. The ship is really coming together! Masting and rigging is not far away.

-

Hmm good point. The Occre Corsair is fictional and does not really have a time period established anywhere that I can find so I am not too concerned about being period-correct. Only hint is that it's supposed to be a merchant vessel converted for privateering, but that doesn't really tell me anything. "This originally merchant brigantine was transformed when it got into the hands of the corsairs, and fitted out with 16 cannons and 4 falconets, which all helped them to carry out their misdeeds with better chances of success."

-

Thank you for the advice, everyone! I am examining some photos of brigs in the RMG collection trying to get an idea of what lines are included. Not being familiar with them all, it is taking some research to figure out what line is what. Lennarth Petersson's book is a great resource while I figure this out. I like the idea of leaving on as much as possible (where it makes sense) since I think rigging is one of the most impressive features of model ships (and it's my favorite part of the build). So the strategy will be to leave the blocks and such on the model, and as I get closer to the rigging stage I think I will get a better understanding of how it will all go. If it turns out too busy I might end up leaving some out.

-

Progress update. Since varnishing the lower hull, I have made some decent progress this week. I started off getting the railings on and some other decorative strips along the bow and stern. I am rather proud of the way the curved pieces at the top of the poop deck worked out. Per the instructions, they were made out of some little 2x4mm pieces. All sanded down and stained they look pretty good on the ship. A coat of poly was then applied to the hull above the wales once all those pieces were on. While waiting for that to dry, I decided to get started on painting the castings since they'll be going on the model pretty soon. I airbrushed the stern decorative thing and the gunports gold over black primer, which turned out pretty well. Cannons and anchors painted with black primer, with some drybrushing to add a little depth. I spent way too much time mixing the brown to go on the anchors, since I can't seem to find an appropriate shade ready made. I also built and stained all the cannon carriages: The little wheels provided are plastic and a kind of light tan, which I think makes the assembly look like a toy. Since I can't seem to find a brown paint I'm happy with, I'm thinking I will just paint the wheels/axles black.. any thoughts? The gunports are now on the hull along with a couple small additions, which sums up the progress this week. I am reaching the point where I need to cut into the railing on the forward deck for the cat davits. I realized that I had installed the fore deck much too low for the cat davits to end up flush with the railing so I also pulled that off and reworked it a bit to install it at the right height.

-

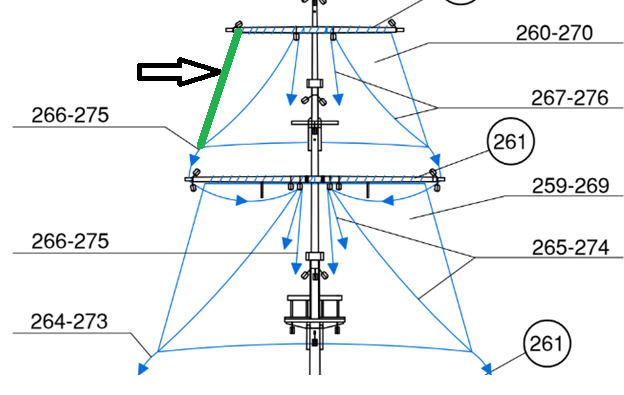

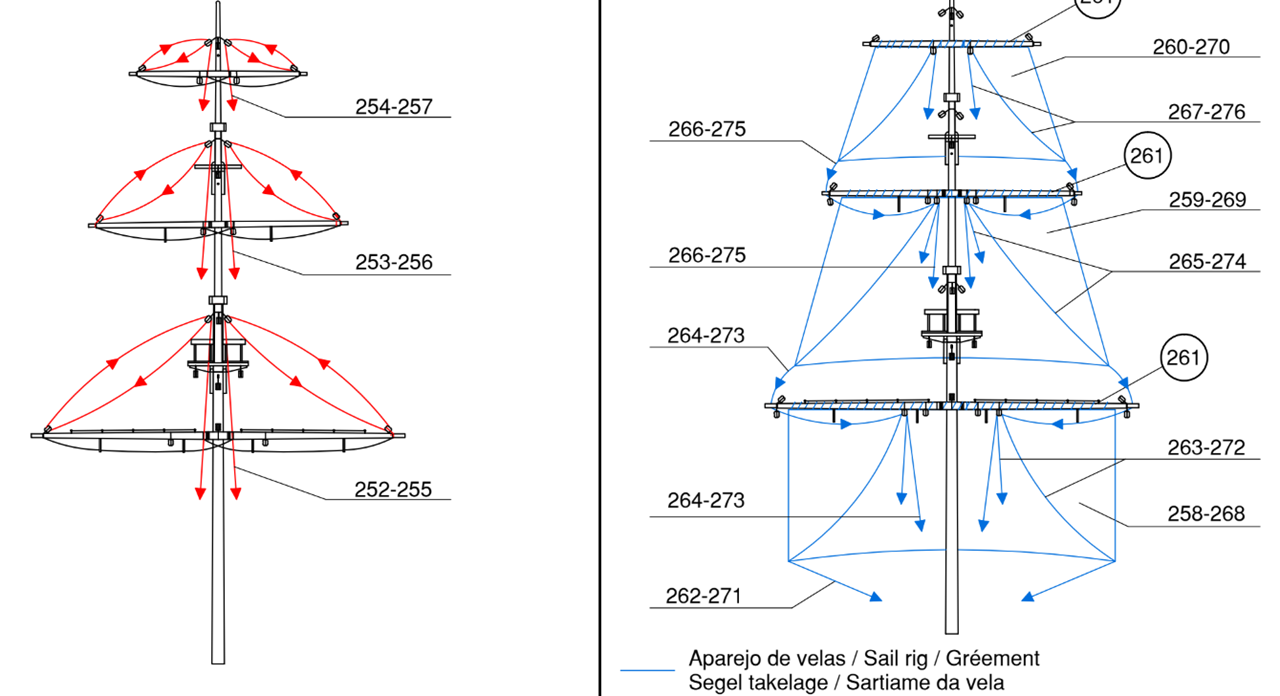

Hi all, I am working on the Occre Corsair, which comes with sails and the instructions assume you will use them. I do not want to put on sails, but I am not sure what things I should leave off or not. The instructions are pretty good about showing what rigging belongs to the sails: But there are things like the blocks next to the mast on the yards that don't appear to be used except for sails.. do I just leave those off then? Or in this diagram there are obviously lots of lines for sails, but should I just leave those out entirely? Would some of these things be left on the ship even without sails? (there are 8 sheets of similar diagrams) Any of you more experienced folks and ship experts have advice on what I should do?

-

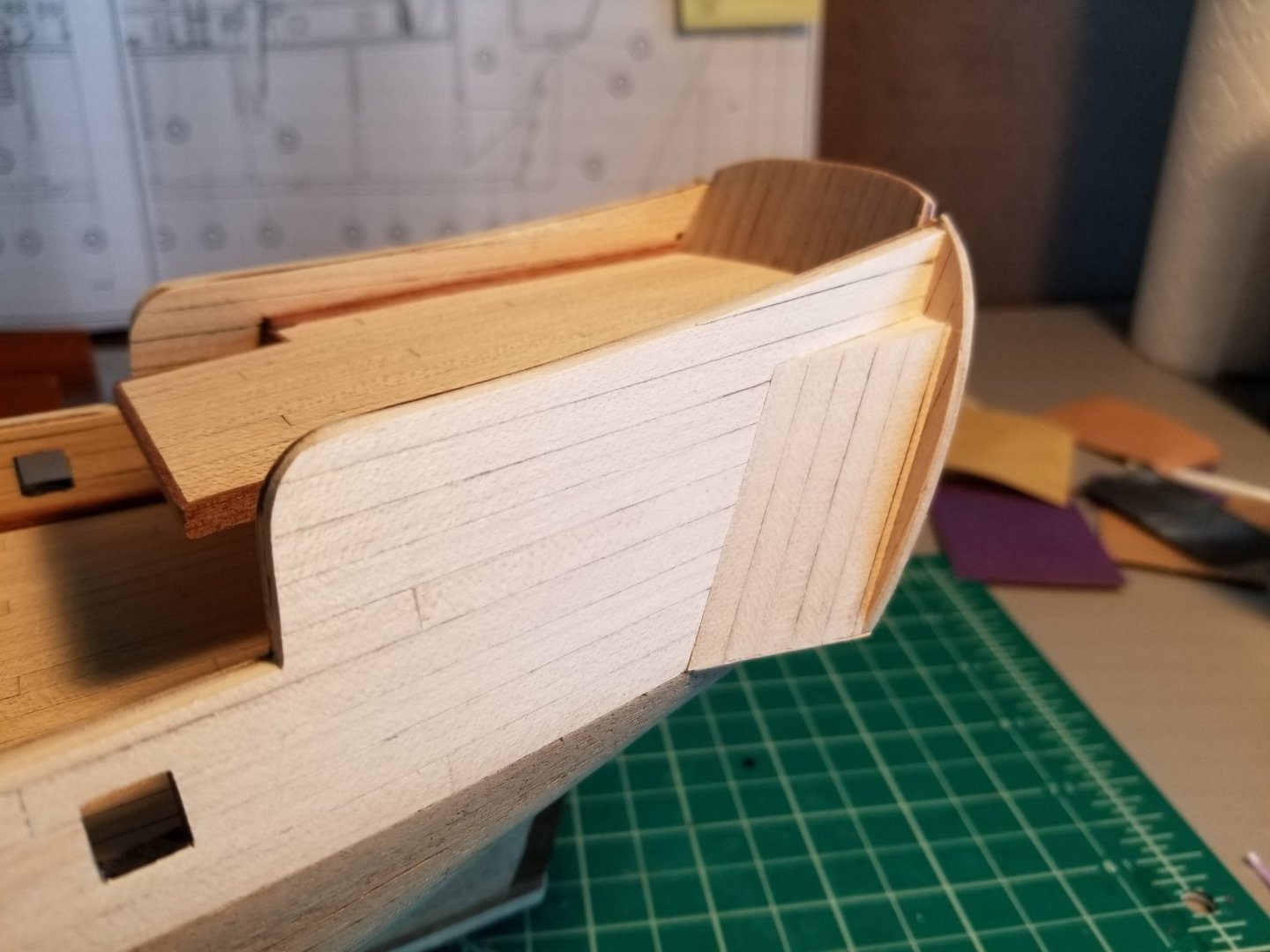

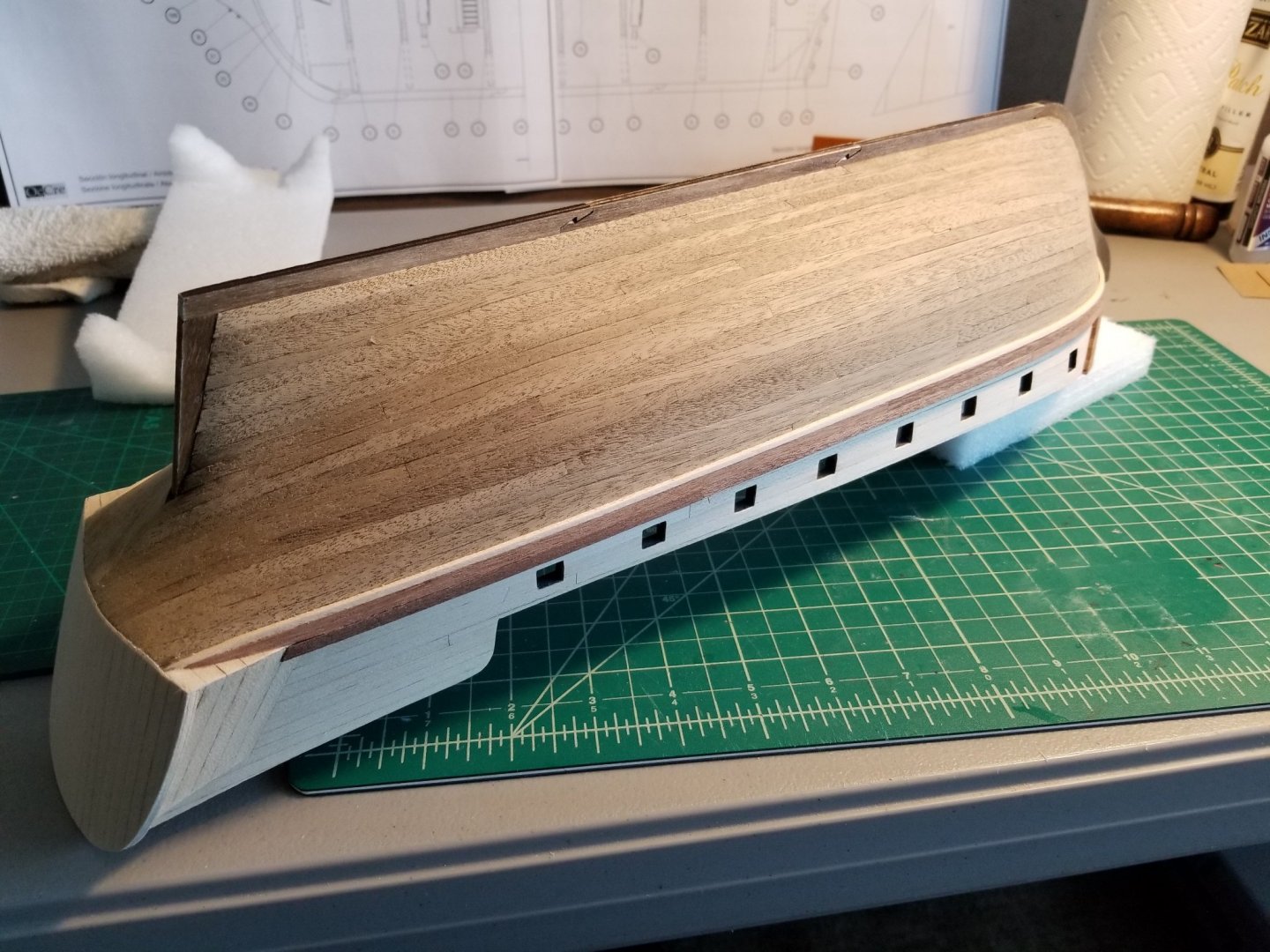

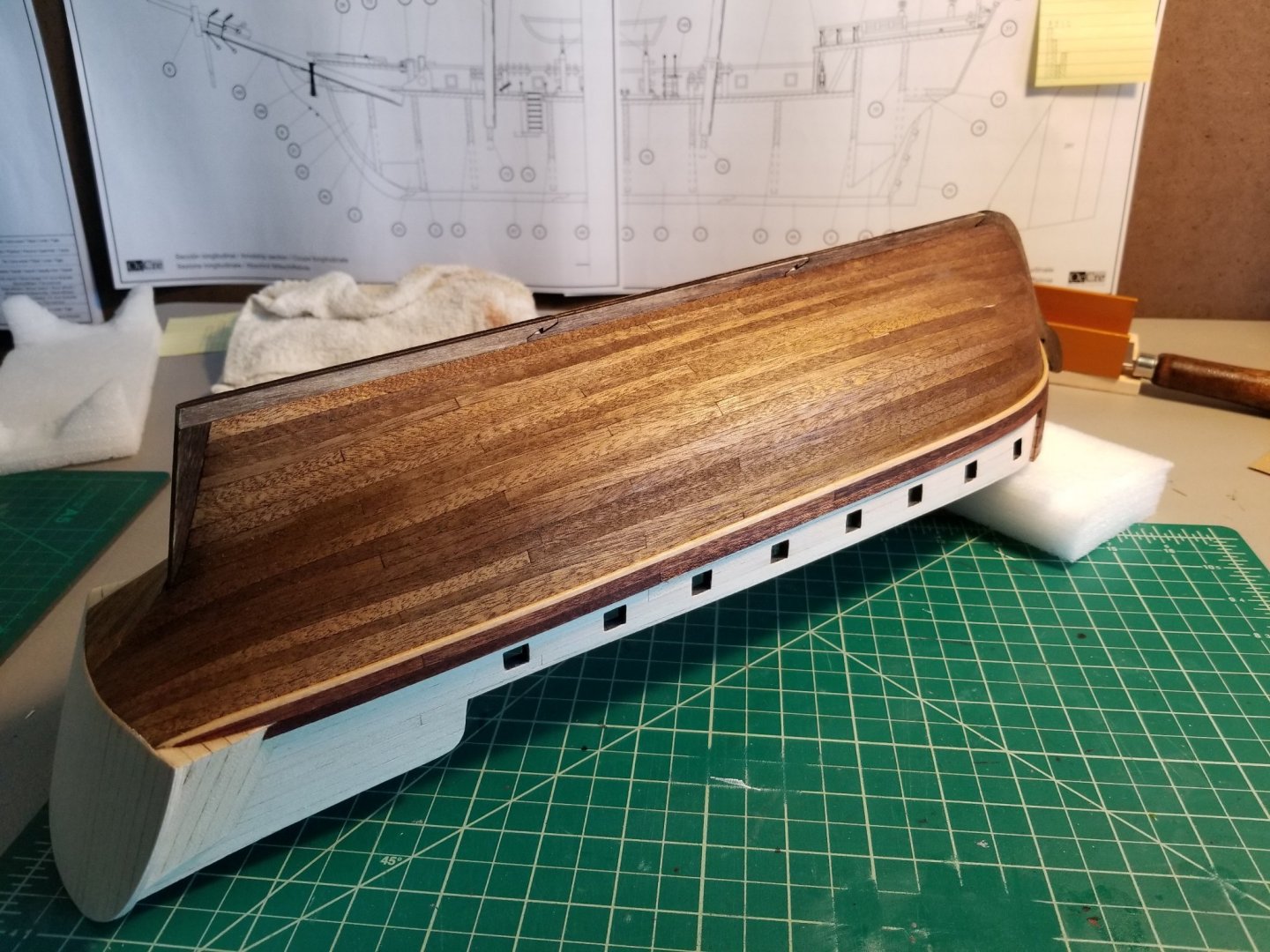

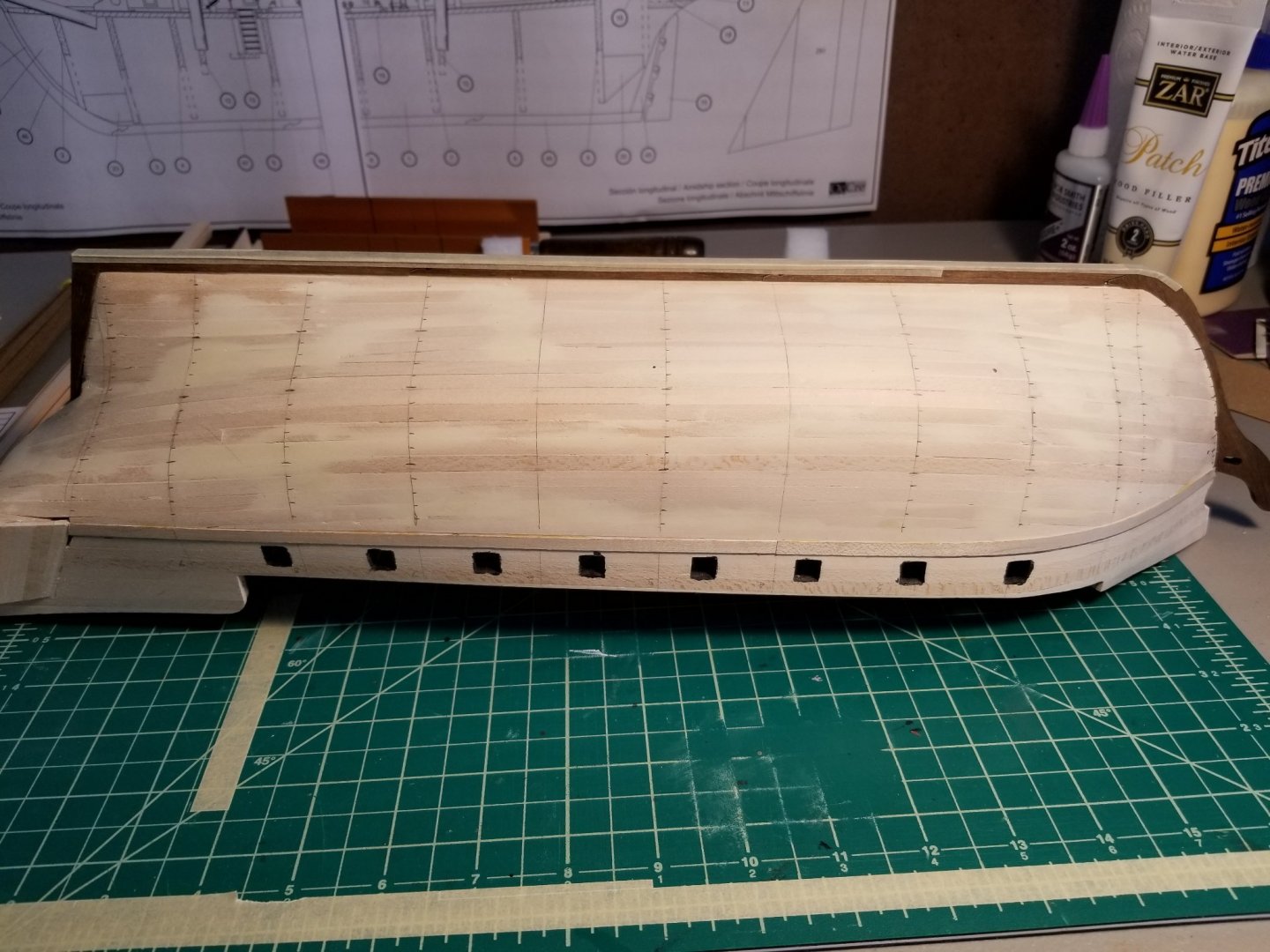

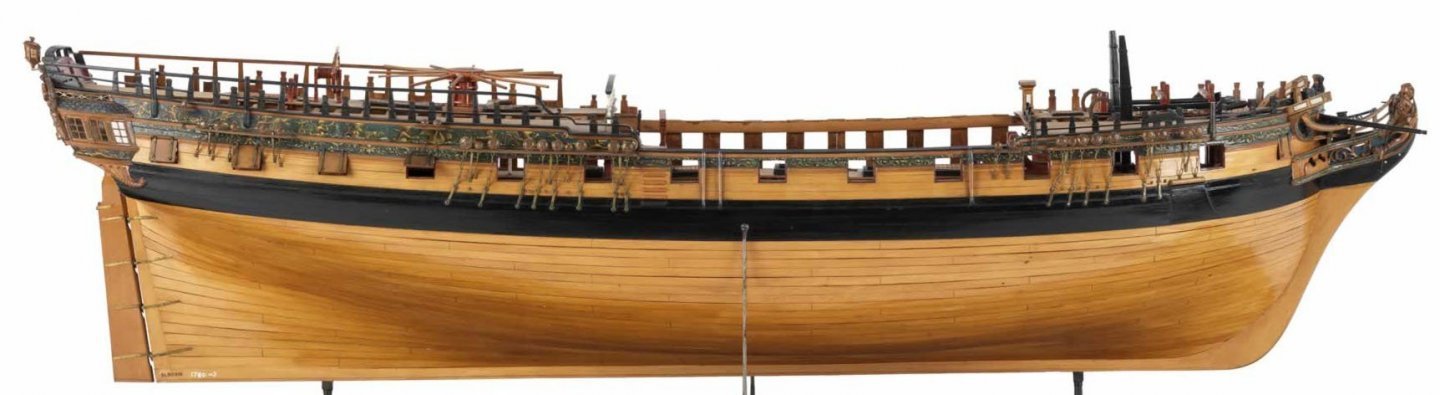

Great progress this week. I have finished the second layer of planking. Despite the roughness of the wood the lower hull turned out great. Yesterday I got the upper hull planking finished up which was significantly easier, not needing to spile every single plank. Stern galleries planked over: And then today I got the rubbing strakes put on and the upper stern planked over. The strips provided for the rubbing strakes aren't quite long enough to run the full length, so I ended up cutting them into 16cm lengths which split the strakes into three pieces, which I think turned out to look better. So after getting all these pieces on, I figured it was time to put a coat of poly on the lower hull to protect it while I move the thing around getting the other decorative pieces on the wales. Quite a large contrast! I think it looks fantastic, much better than I anticipated to be honest. I'm really glad I went with splitting up each plank into ~20cm lengths, I think the variation makes it much more interesting to look at. We'll see what it looks like after the poly has all soaked in and dried overnight; I don't think it will be as glossy but hopefully still keeps the color. There are a few little gaps where the wood splintered at some point and you can see through to the first layer of planking.. had I seen those earlier I would have tried to fill them in. As it is, though, you can't seem them when the ship is sitting upright so I'm not too bothered.

-

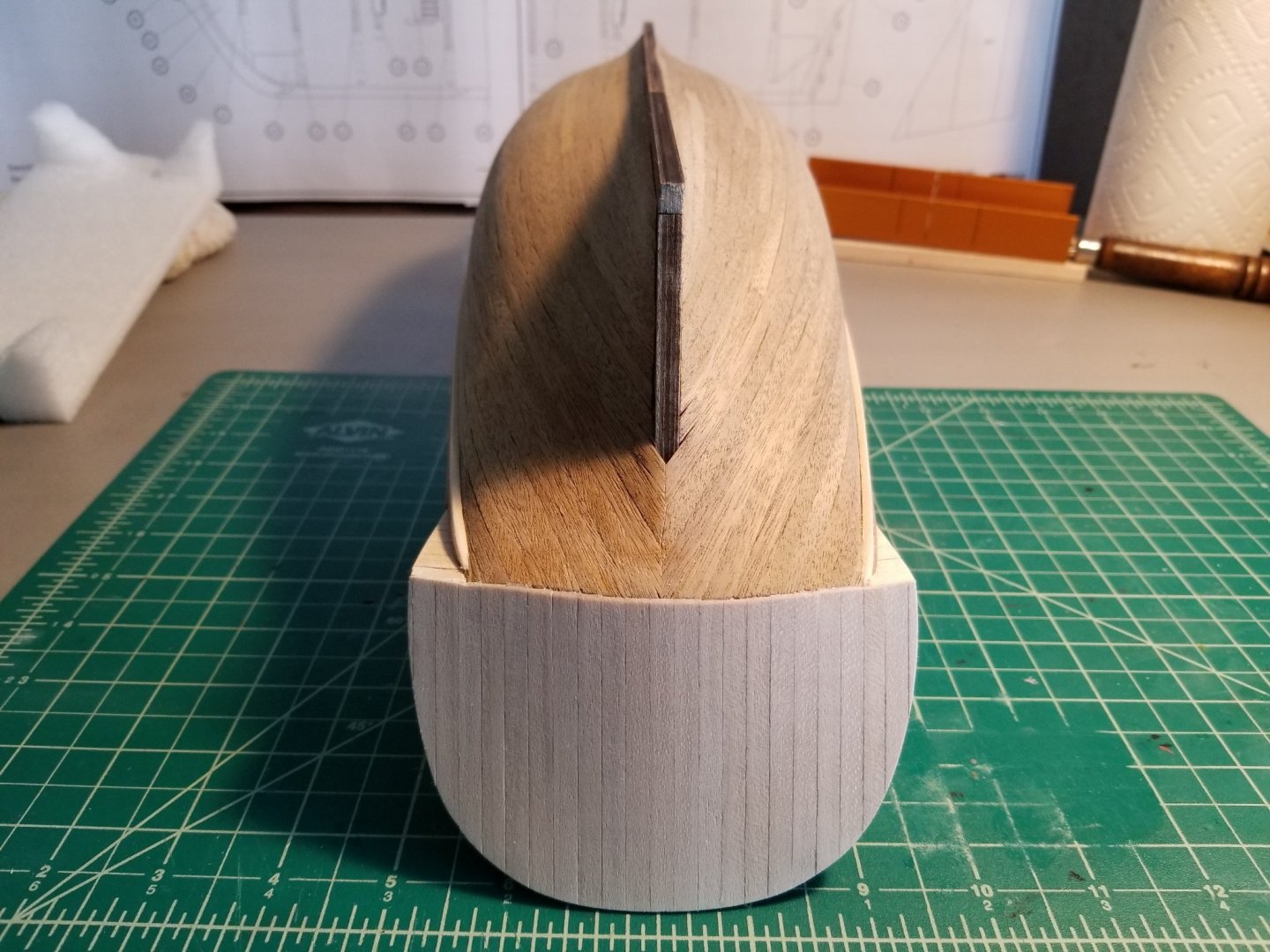

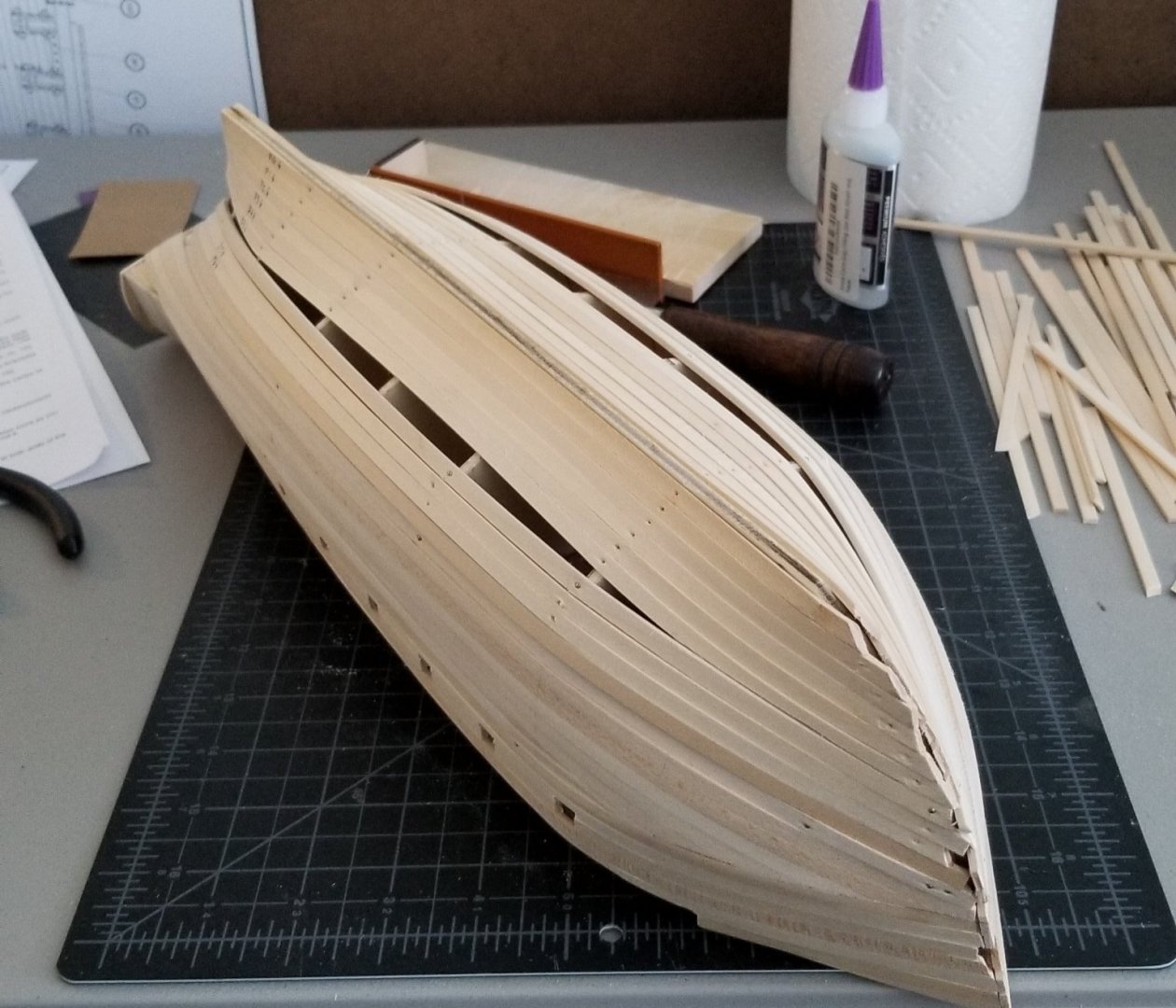

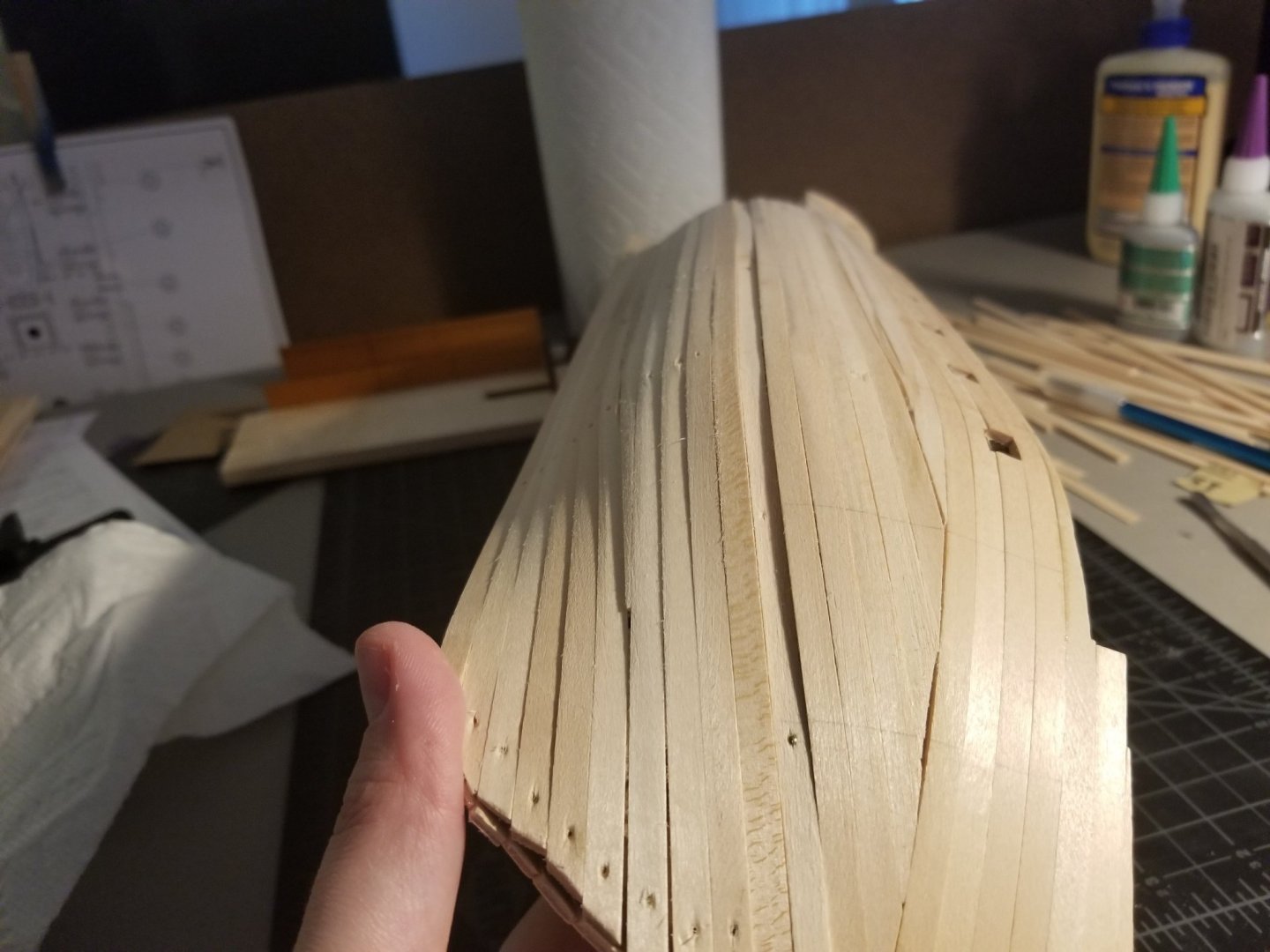

Planking update! The first layer of planking is all filled and sanded and I have done about a third of the second layer. Sanding and filling took a good several hours this weekend but turned out much smoother than I anticipated. (I did a little cleanup at the stern after taking these pics) The hull has quite a nice shape to it and should look pretty good in the end, I think. Once that was all cleaned up, I glued on the keel and stem parts. It took some sanding and cutting away bit by bit at the upper bow to get the stem in place but ultimately it fits pretty well. Next I spent a few hours planning out the second layer, including measuring and lining off the hull. I may have gone overboard but this is my first shot at doing it this way, with spiling all the planks at the bow and stern. So far so good. You'll notice I put some masking tape over the keel to stop it from getting scraped up as I move the thing around. Turns out those pieces are just regular plywood dyed that dark color, so any marring of the surface really shows.. Next is the second layer of planking, which is this nice looking walnut: I'm not sure if it's actually walnut or something else dyed this color. Anyway, it's paper thin and easy to bend and twist. However, it is really fragile. it will splinter and fall apart really really easily. Dampening each strip with my finger before working with it seems to help. I decided to go with a 3-butt shift, my first time attempting it. It's actually pretty quick using Chuck's method found in some YouTube videos in the Planking section of the forums. About 20 minutes per strake so far, though I'm getting quicker. I think it is going to be a handsome looking ship, I like the wood color. I will leave it natural like this and just put on a few coats of Wipe On Poly. I've learned it is best to cover one side of the ship with masking tape while I'm planking the other side.. otherwise these planking strips will catch on anything cloth and start to splinter.. I'm not sure if that is typical of this kit, but the wood is so fragile that I'm kind of worried I'll run out if I'm not really careful. All said, I think I'll be done with the second layer this week if all goes well!

-

I couldn't figure out how the outermost planks were supposed to sit at the stern so I decided to build up the stern galleries first.. this is out of sequence with the instructions but it made it easier for me to figure out how planks are supposed to sit back there. Once the top was done, I started from the garboard up and the master strake down to meet in the middle. I was more intelligent about the bottom planks and soaked one end in water, nailed it in place and let it dry to get the twist at the stern easier to deal with. Then took it off, soaked the other end, and nailed it in place at the bow, and let that dry. Once that was done I took all the nails out and glued them into place. This of course led to some weird shaped planks needed to fill in the gaps but that was not too hard a chore. So the next problem to solve was the aforementioned depth of the master strake: The discrepancy is almost 2mm at the curves at the bow and stern and clearly can't be managed with just filler. So I decided to stack up some 0.5mm strips to fill it in. I'm not sure how well this is going to hold up during sanding but we'll see... So there we go! First layer of planking done. Thank goodness there is a second layer because this looks terrible. I don't like the way Occre wants you to plank the hull. Instead of doing it properly and having a consistent number of planks that taper at the bow and stern, they have you do it this way where the planks are attached as they would be if you just lay it on the side and bend it into place without any tapering or spiling. Look at the way the planks curve upwards at the bow vs. what the correct way would be: I know they do this to make it easier, but to me it makes it more difficult to figure out whether they are twisting or bending the right way as you go. I will definitely do it the right way for the second layer of planking, as the way the first layer is done just looks very unnatural to me. Unfortunately, if you attach the master strake in the notches on the bulkheads you have no choice. It may have taken less time but I feel like it will make it more difficult to do the second layer properly. I also wish the strips for the first layer were thinner, as that would have made it easier to twist and bend them and get them to lie more correctly. Well, in any case, next up is a few hours of sanding and putty to get a decent foundation for the second layer of planking.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.