-

Posts

477 -

Joined

-

Last visited

About BenD

- Birthday 01/09/1990

Contact Methods

-

Website URL

https://ropesofscale.com/

Profile Information

-

Gender

Male

-

Location

Toronto Ontario Canada

Recent Profile Visitors

-

CiscoH reacted to a post in a topic:

Ropes of Scale developments and updates

CiscoH reacted to a post in a topic:

Ropes of Scale developments and updates

-

Thukydides reacted to a post in a topic:

Ropes of Scale developments and updates

Thukydides reacted to a post in a topic:

Ropes of Scale developments and updates

-

Archi reacted to a post in a topic:

Ropes of Scale developments and updates

Archi reacted to a post in a topic:

Ropes of Scale developments and updates

-

GGibson reacted to a post in a topic:

Ropes of Scale developments and updates

GGibson reacted to a post in a topic:

Ropes of Scale developments and updates

-

Paul Le Wol reacted to a post in a topic:

Ropes of Scale developments and updates

Paul Le Wol reacted to a post in a topic:

Ropes of Scale developments and updates

-

Hi EspenT, Higher counts per strand make nicer ropes with this particular thread. Of course, it takes more time to make ropes as you are spending a lot more time walking back and forth. On a small size, such as 0.45mm, it's hard to tell the difference without magnification. I use the E121 for 0.45mm rope production. 3 threads per strand. It just looks better to me.

-

BenD reacted to a post in a topic:

PHOENIX 1787 by ccoyle - Master Korabel - 1/72 - Russian brigantine of the Black Sea Fleet

BenD reacted to a post in a topic:

PHOENIX 1787 by ccoyle - Master Korabel - 1/72 - Russian brigantine of the Black Sea Fleet

-

BenD reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

BenD reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

BenD reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

BenD reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

BenD reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

BenD reacted to a post in a topic:

Syren Ship Model Company News, Updates and Info.....(part 2)

-

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

BenD reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

BenD reacted to a post in a topic:

Big changes at Syren Ship Model Company...

BenD reacted to a post in a topic:

Big changes at Syren Ship Model Company...

-

hollowneck reacted to a post in a topic:

shiny rope

hollowneck reacted to a post in a topic:

shiny rope

-

Ryland Craze reacted to a post in a topic:

shiny rope

Ryland Craze reacted to a post in a topic:

shiny rope

-

grsjax reacted to a post in a topic:

shiny rope

grsjax reacted to a post in a topic:

shiny rope

-

Desertanimal reacted to a post in a topic:

shiny rope

Desertanimal reacted to a post in a topic:

shiny rope

-

druxey reacted to a post in a topic:

shiny rope

druxey reacted to a post in a topic:

shiny rope

-

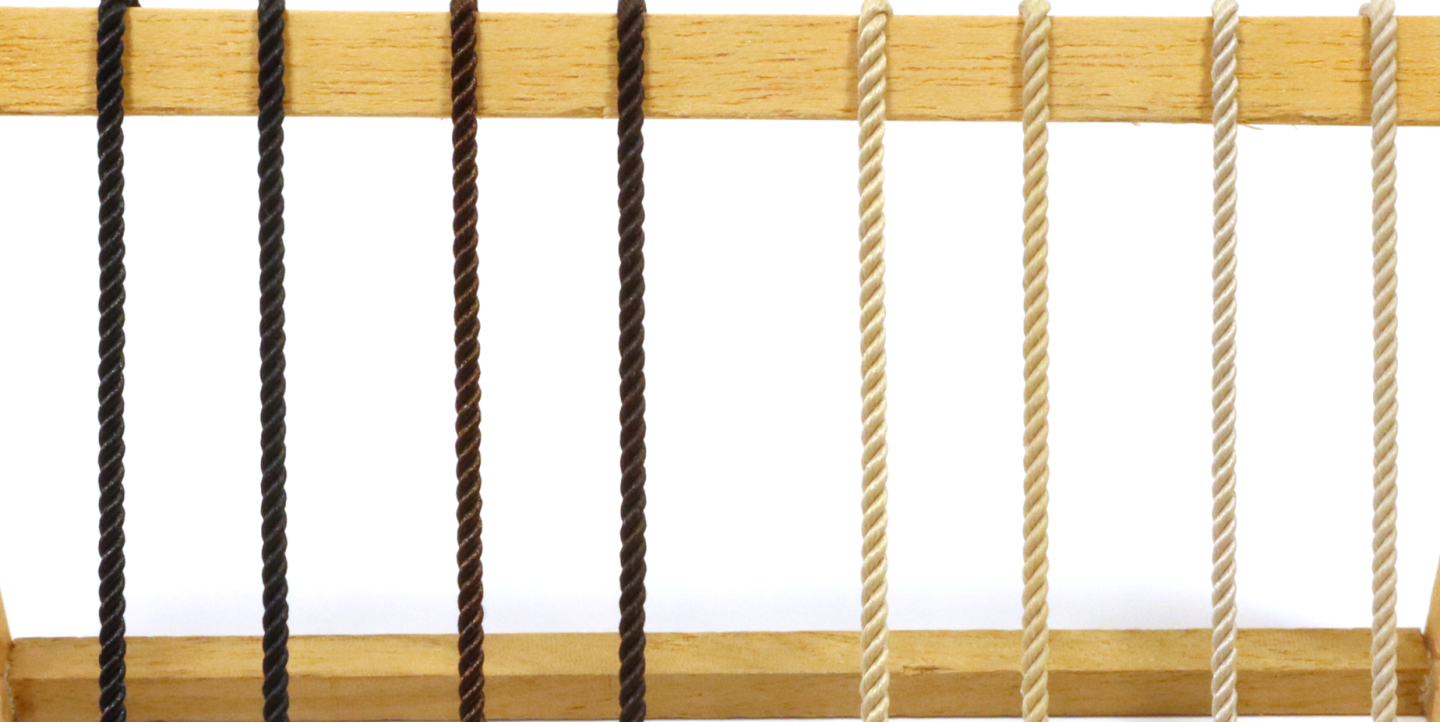

The polyester ropes I make at Ropes of Scale are a bit shiny. It's only really noticeable on the black and dark brown ropes. I've noticed that it helps make the details pop even in low lighting, so I'd personally leave them as is. Brushing the ropes down with matt varnish after rigging is an option. In the picture, you see unvarnished ropes on the right and varnished ones on the left.

-

I approve. I just got an airbrush and spray booth. Right now, the booth sits on one end of my crafting desk, taking up about one-third of the space. It's not great if you are building ships...

-

Hello Everyone, The Canada Post strike ends tomorrow, Tuesday the 17th. That means my usual shipping prices will return. They are much cheaper than FedEx or other couriers. I'm hoping that all of the orders that were stuck in the system get sent out quickly. Canadian customers. Oversize letter mail rates will return. You can't beat $2 stamps! US Customers. $7 USD tracked parcel rates will be available once again. For the rest of you around the world, there should be much more affordable rates. I wish everyone a happy holiday season.

-

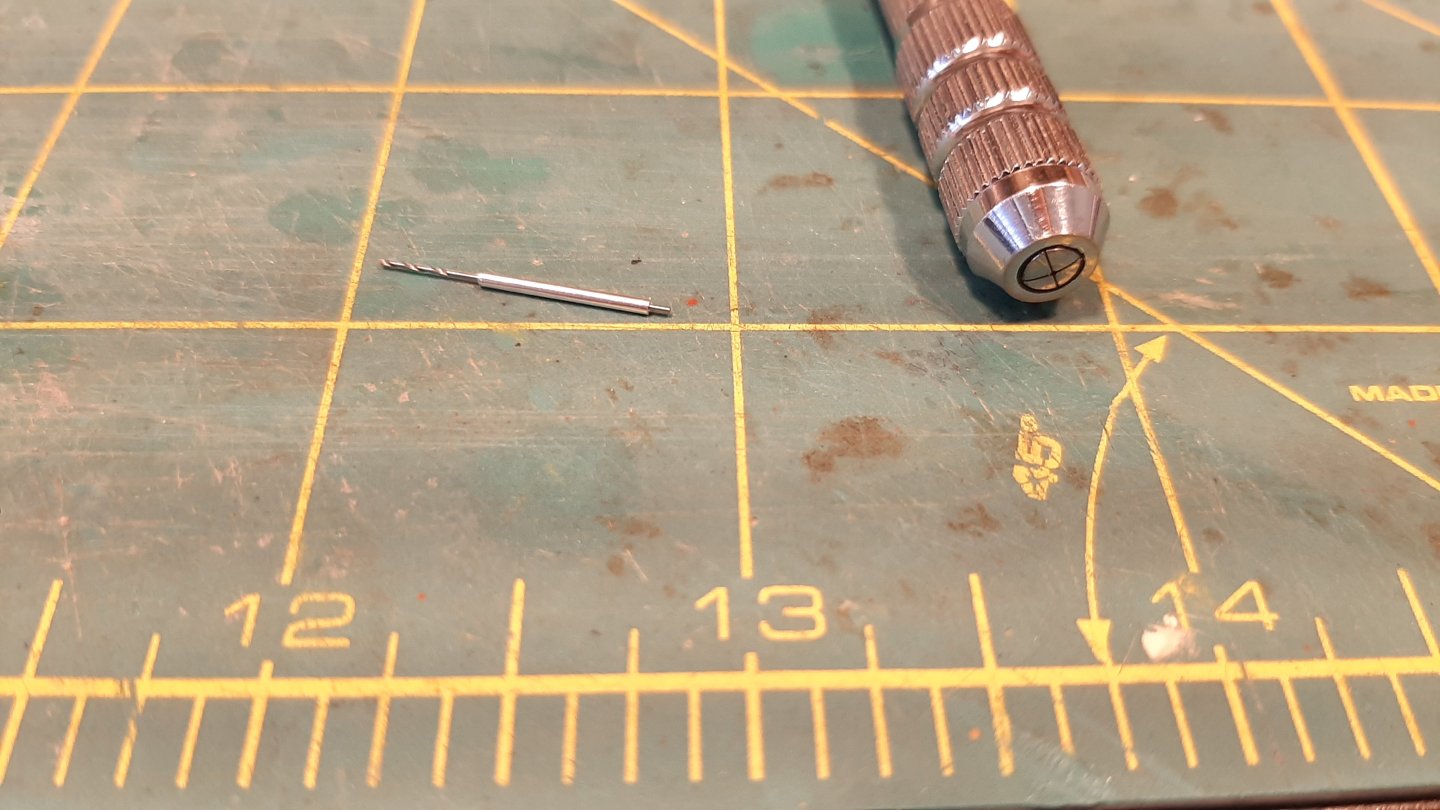

Are there better tools for drilling tiny holes?

BenD replied to Dan Poirier's topic in Modeling tools and Workshop Equipment

Getting a set of drill bits with a large shank will help. Another solution that worked for me was to use some aluminum foil. The pictures below will demonstrate. The bit never moved when being used. -

@Thukydides your Alert build is just fantastic. It is a great example of what kind of detail can be added with after-market parts... and a lot of talent! I might just do that. However, I will need to add all the smaller sizes of cable to the collection first. I'll get around to that in the next few months. I will keep the cotton ropes in production so don't worry. You are not the only one who is worried that I would discontinue them. In fact, I was going to add some more sizes of ropes and cables to the cotton lineup this summer or fall. I've also found a nice light brown color to add to the mix. So look out for that. - A big thanks to everyone for the likes and support! I hope now that I'm working on this full time I can add new products. The next possibilities are adding linen ropes or making more affordable/longer ropes with a modern machine.

-

Hello Everyone, It's been a while since I last posted. Ropes of scale has been keeping me busy, so busy in fact I had to quit my day job. Thank you guys/gals for all of your support! I've finally added sample cards to the website after years of people asking at least once a month. This product has gone through a few iterations over the past year or two. These are simple, affordable, and hopefully useful. Sold separately or together. Size Card contains every size of polyester rope sold from 0.25mm - 1.8mm. Color Card has one length of each color sold from the Ropes of Scale lineup. https://ropesofscale.com/products/sample-cards

-

New member and brand new (Paper) modeller!

BenD replied to Marcel1981's topic in New member Introductions

Hey Marcel, What ships have you been building? Welcome to MSW. I just got into card modeling. I just butchered the seahorse Armed Virginia Sloop -1776. I was rushing and messed up some of the alignment... mistakes were made, and lessons were learned. Anyway, I've just got my hands on the Shipyard HMS Alert -1777 and have put all the frames together. Look's promising. -

The Seahorse 3D-printed ones look really good. The only problem is they are slightly translucent at that size. Shipyards card blocks are actually pretty decent. They do need a lick of brown paint to look better, and of course, they need to be carefully assembled. The HIS new rounded blocks look great. They only make the rounded ones from 3mm and up. If you have the money these might be the best option. If Syren made smaller blocks I would tell you to go all in on their CNC blocks. The Caldercraft ones are the typical European blocks that most kits use. They are not great-looking and need sanding, shaping, and re-drilling. Some day I plan on getting a CNC machine and making blocks to sell, but that is a few years down the road.

-

For brush painting, it really comes down to how much thinning is needed. I've found the Vallejo paints made for air-brush are really nice out of the bottle for hand brushing. I was looking at some Citadel paints at a hobby shop a few days ago. I should have bought some to try them out. The Vallejo model color ones I have need quite a lot of thinner to make the brush strokes disappear. As for mixing paints on models, I've personally had no issues. I only use acrylics. I also bought some mixing balls a few months ago. They are really amazing at getting a bottle mixed up and ready to go. I highly recommend them to anyone.

-

Which one is the best ropewalk machine?

BenD replied to modeller_masa's topic in Modeling tools and Workshop Equipment

People get confused about cable-laid ropes quite a lot. That 3.8mm cable-laid is three 1.8mm ropes laid together. Each 1.8mm rope has 39 yarns, which means the cable has 117 yarns. -

Back at it! I like how the ship's wheel turned out. You'll be done with your Wolf before I even take mine off the shelf.

-

This is totally how polyester behaves. One thing I've found about rope made with Gutermann E thread is it takes CA glue really well. Some polyester threads I've tried end up weak and crusty after being glued with CA but this stuff gets super strong. Another way to shape this rope is to use "super thin" CA, it goes right into the rope and then holds whatever shape you want. You will need a good applicator to pull this off. Every type of thread I've used for making rope has problems. I'm always looking for new threads to try.

- 560 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Absolutely beautiful ship. Estimating 2,500 hours of work involved... sounds about right for this level of kit bashing. Looking forward to the photo shoot. What's next up in the shipyard?

- 208 replies

-

- kitbashing

- Woodcarving

-

(and 4 more)

Tagged with:

-

I have an article about pine tar that might interest you https://maritime.org/conf/conf-kaye-tar.php It states that the production went on well into the 1900s. I'm pretty certain the industrial process for coal tar didn't pick up until the 1850s (Can't seem to find my article on it). The Grecian being an American vessel I'm not sure about what tar would be used. The Royal Navy would have used Pine tar to the bitter end no doubt. On tall ships today they use pine tar and coal tar mixed together from what I've read.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.