-

Posts

94 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Captain Shaun

-

Taking a break from wood working I made the Morse Teleflex Dual Control using a wood base covered with aluminum tape and two borrowed pins from the sewing supplies. I also made the Pot Hauler making the base the same way with wood block and aluminum tape. The pinch wheels are aluminum discs that I flared the ends of by hammering over a 1/2" dowel I had chamfered the end of.

-

The rub rails commonly install are half round metal attached to wooden rails. I couldn't locate half round but I had 24" round stock in the size needed so I used a tool that is for cutting a groove in leather to recess stitching. I cut a groove in an oversized piece of wood and then trimmed it to size with a plane and put the round brass rod in as a single piece, I was quite pleased with the result.

-

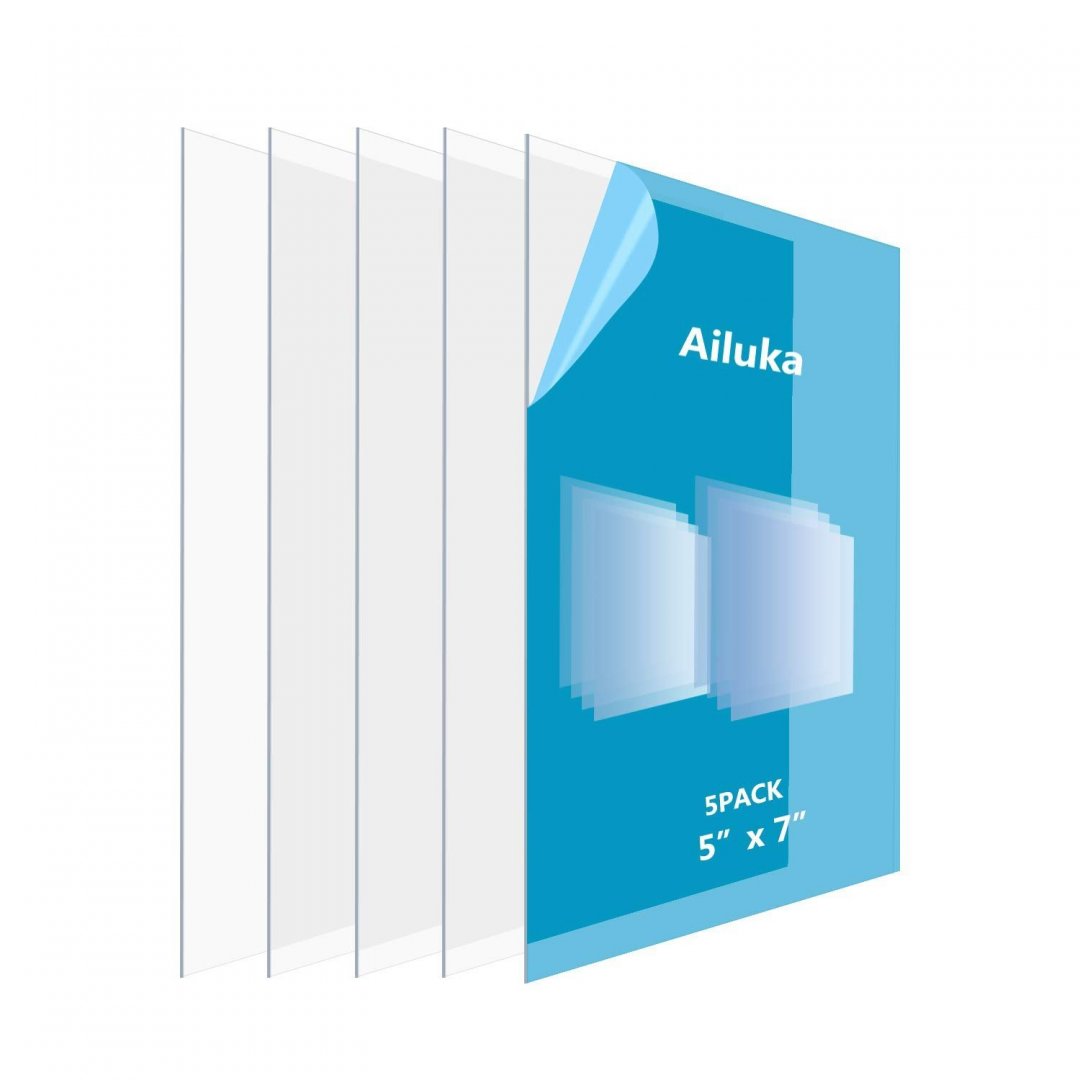

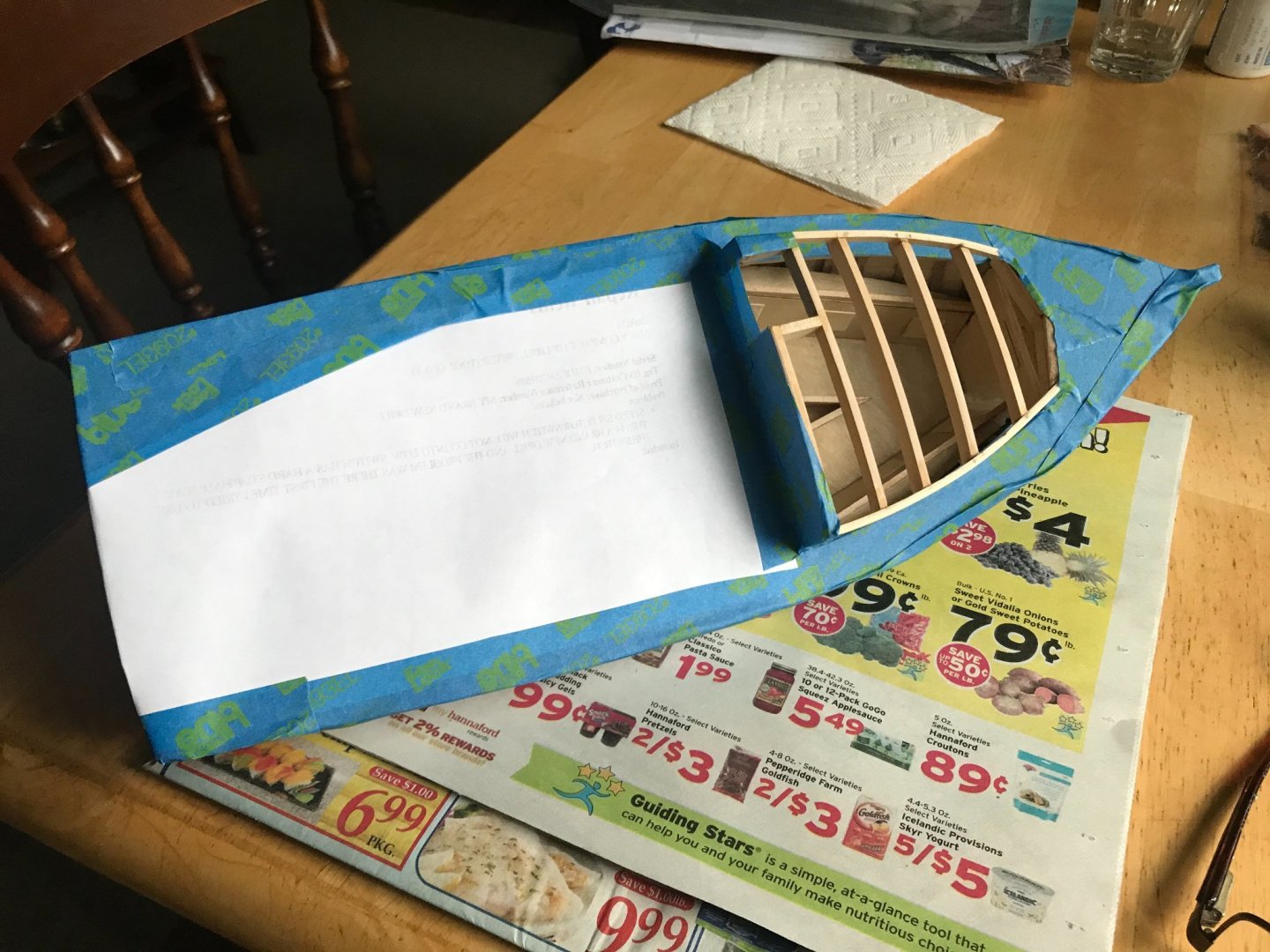

Frames for the windows are being fitted. I made a template for each one and built them on the bench. I made a LOT of templates. I had quite a bit of plastic "glass" left over that I had purchased off of Amazon to use in a Britbox phone booth I made for my daughter last Christmas. It is PET (Polyethylene Terephthalate) plastic and is very clear and soft enough to to cut with scissors. I cut it just outside the line and trim it to fit with a block plane. To simulate the aluminum frames on the windows I used aluminum tape. The starboard window is going to be the opening one in front of the wheel. I wasn't happy with this first one and remade it. Took a break from the windows and built the engine cover. Back to the windows. All of the fixed ones are done. Bow bit it in.

-

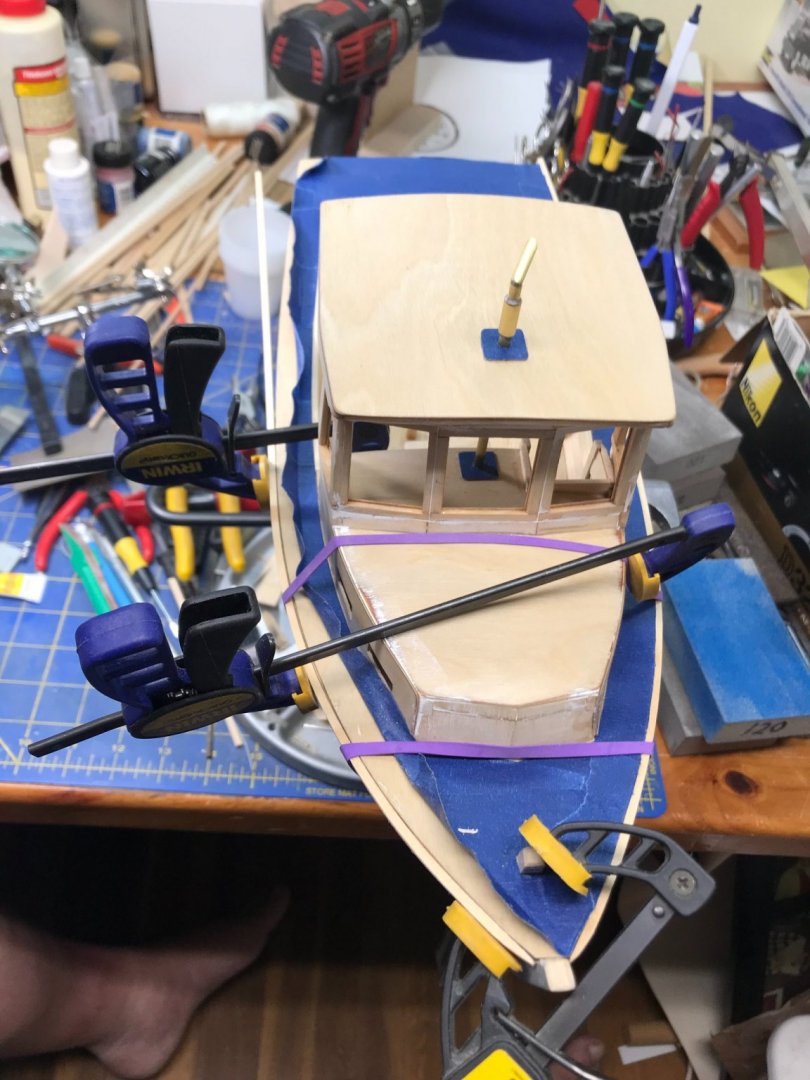

Masked off to paint the cabin interior. Painted the interior of the cabin and now the roof is being attached. Cabin door and hatch are done and the cockpit coaming has been installed. Template for the pilothouse side is being test fitted. Pilothouse side window frames have been roughed in roof installed.

-

Nice build John. Think it should list home port as Biddeford Pool Table though. I just finished a scratch built lobster boat for my daughter who lives near the NH coast and will be starting the Bluejacket Shipcrafters Bowdoin soon for my other daughter for next Christmas, She went to Bowdoin.

- 51 replies

-

- laughing whale

- maine lobster boat

-

(and 1 more)

Tagged with:

-

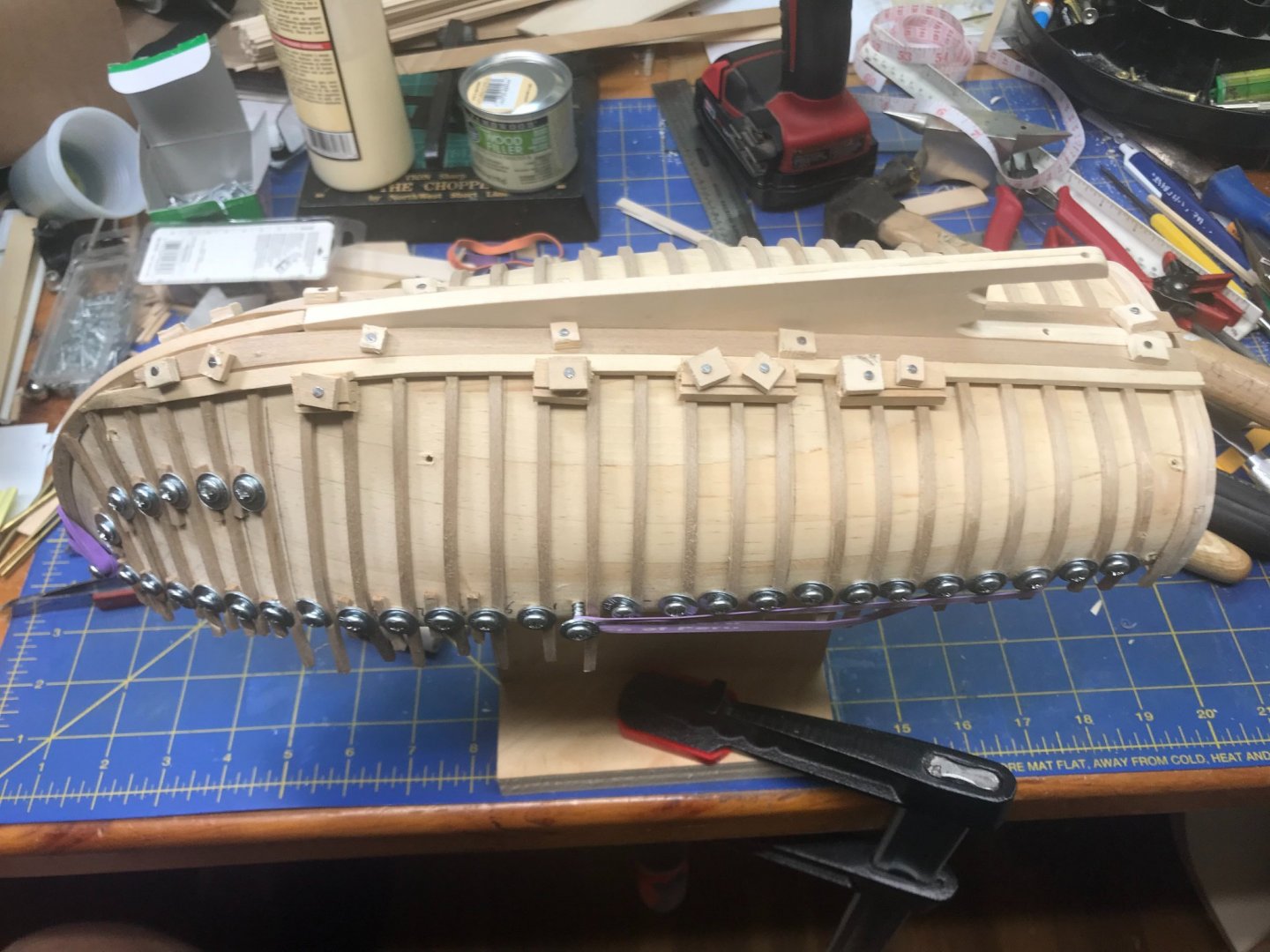

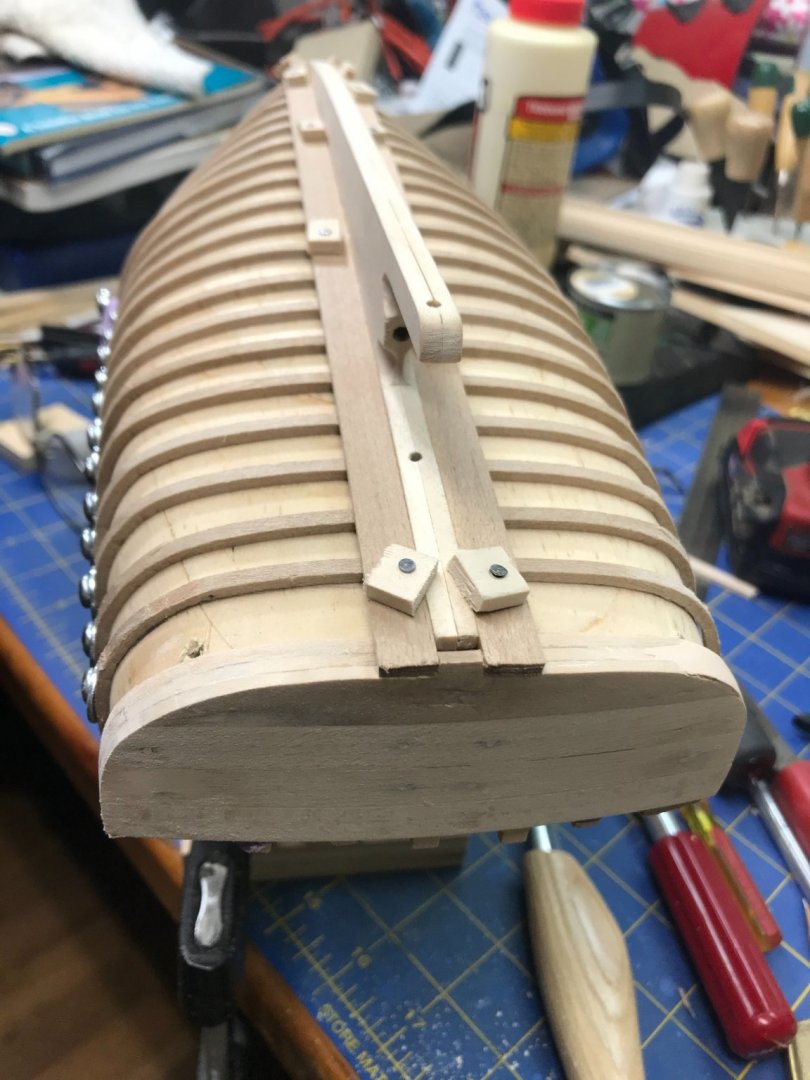

50 Yrs of tool collecting, mostly quality used but obviously some splurging now and then. Main deck sub floor install. Deck is plywood from Northeast Scale Lumber, they have excellent quality wood and top notch service. Primed the hull to show defects so I could fix them while hull was bare. Main bulkhead being fitted. Starting the V berth platforms. Cabinets are added. Put doors on cabinets. I was not going for detail here, just the illusion of the interior since it is almost impossible to see into the cabin. Framing the cabin top. The planks required some severe twisting and the adjustable wrench was just the tool for the job.

-

Thanks Keith, yes I started in 7th grade shop class (1967) and have every tool known to man it seems. I have too many interests and work with wood, metal, plastics, leather and others. I started building models around the same time in 7th grade, we had a model club. I built the Revell USS Constitution at age 12. My main interest is trains and trolleys. Feel a strong pull from the ship modeling though. My daughter went to Bowdoin College in Maine and will now start the Bluejacket Shipcrafters Bowdoin model for Christmas 2022.

-

You can buy waterslide decal paper from many places, it is available for inkjet or laser printers. The link is for the inkjet one I use. Just make your art work on whatever program works for you, I use Excel. Do a test print on paper and then print it on the decal sheet. in order to protect the ink you need to clear coat with spray can clear lacquer. I let that dry overnight and then you can use them just like any waterslide decal. https://www.amazon.com/Nova-Horizon-Waterslide-Transfer-Printable/dp/B07X7GCP46/ref=sr_1_9?keywords=nova%2Bhorizon%2Bwaterslide%2Btransfer%2Bprintable%2Bpaper&qid=1636946168&sr=8-9&th=1

-

Brass piano hinges

Captain Shaun replied to Chariots of Fire's topic in Metal Work, Soldering and Metal Fittings

I have used these piano hinges. they are nickel/silver and you need to assemble them. opened dimension is about 4mm. https://www.modelcargarage.com/eshop/pc/viewCategories.asp?idCategory=28 -

Thank you, I decided to build this for my daughter's (Shelby Lee) birthday (11/7 see the registration numbers) and started researching last February. I obtained three books that were extremely helpful. I used the hull lifts from Harold "Dynamite Payson's - Boat Modeling the Easy Way to build a 1/2" scale hull mold and combined techniques from Steve Rogers & Patricia Staby-Rogers - Model Boat Building The Lobster Boat and my favorite book Boatbuilding Down East - How LobsterboatsAre Built by Royal Lowell (1 Foot scale).

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.3e88ebbe13a2e89c1142954e0d64126e.jpg)

.thumb.jpg.0e9037eab370c33d30054e3df4009837.jpg)

.thumb.jpg.4a31170bb753142f85fbd06bc410c656.jpg)

.thumb.jpg.aca8c722af22839672e413cbd8fea641.jpg)

.thumb.jpg.e727292260a6d7e4ef51cda4ba533c30.jpg)

.thumb.jpg.db6b5f466322a2b82a7d0b28056db84a.jpg)