-

Posts

125 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Organ tech

-

"Material posted on MSW shall not be shared with other forums in any manner. This includes but is not limited to the information being made visible to members of another forum or to the public on another forum or to the staff of another forum by any means." Does this mean that I cannot share my own model building process on a forum such as Facebook, in addition to here on Model Ship World? If so, I will comply.

-

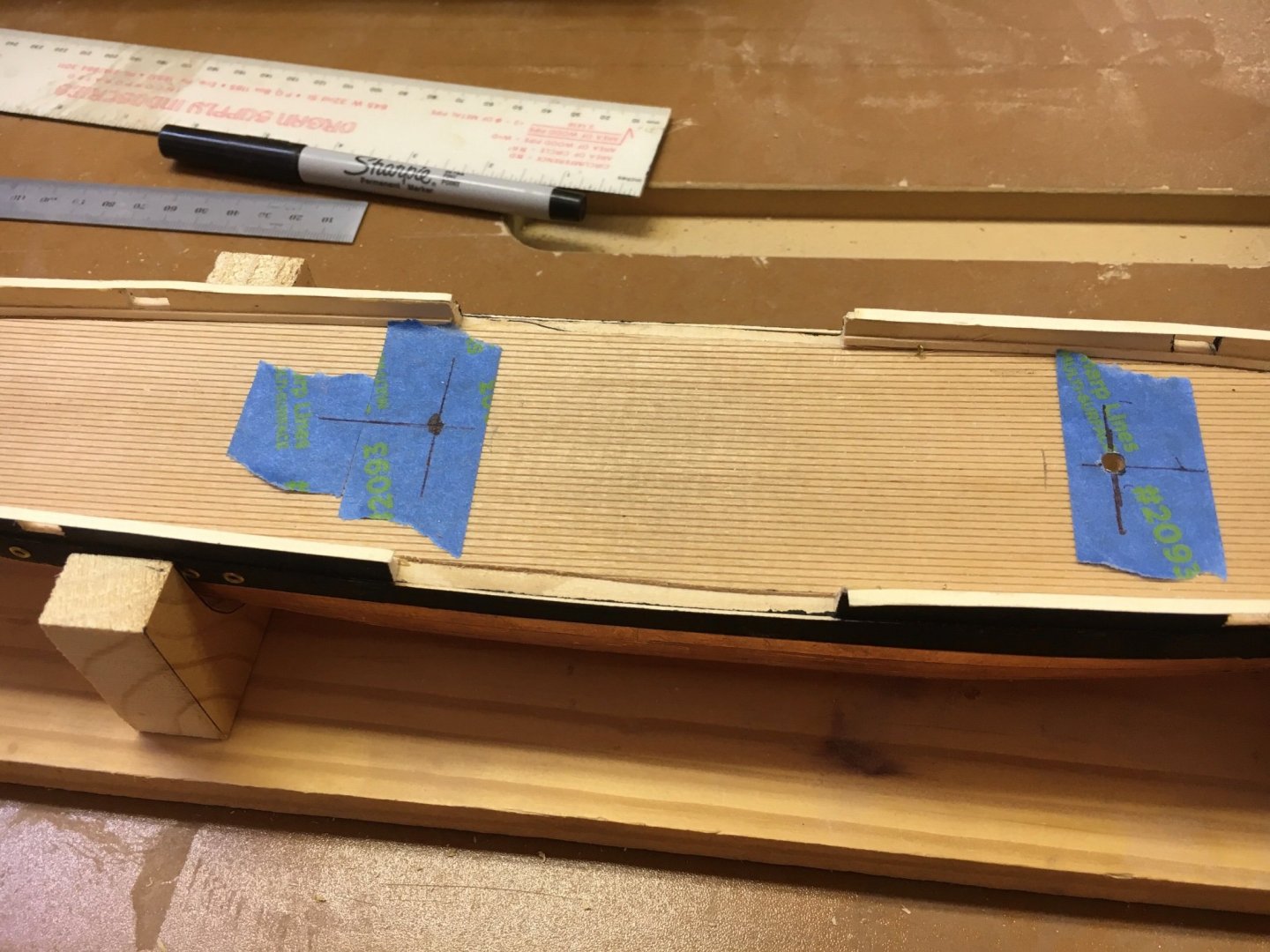

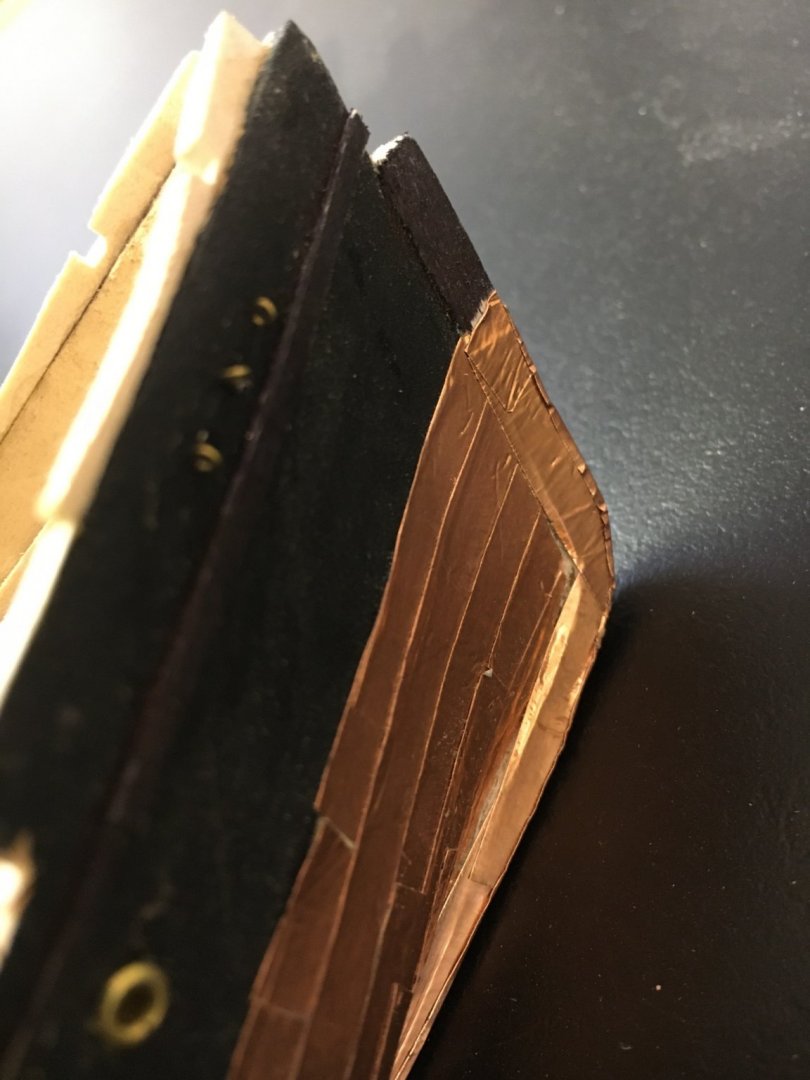

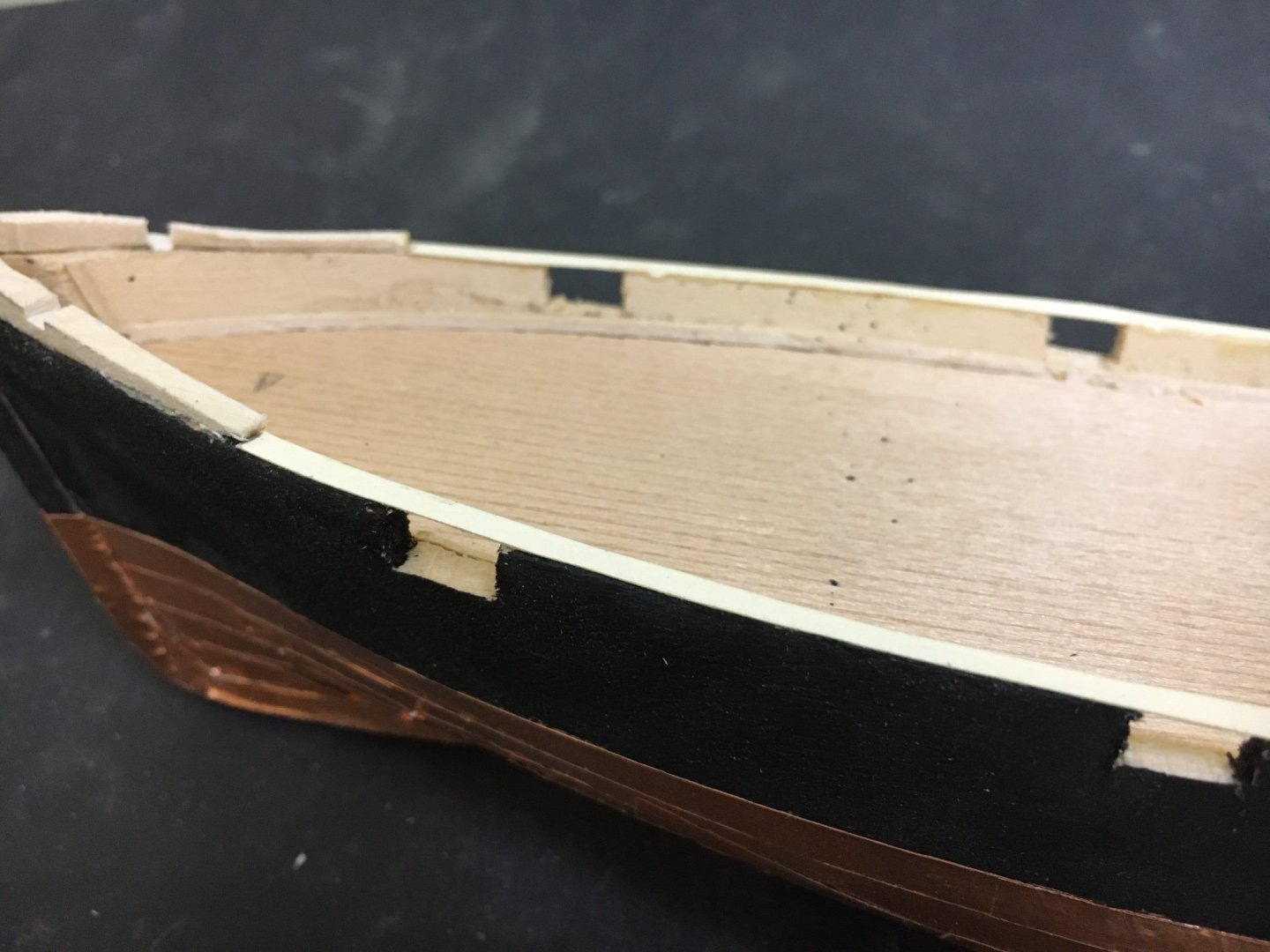

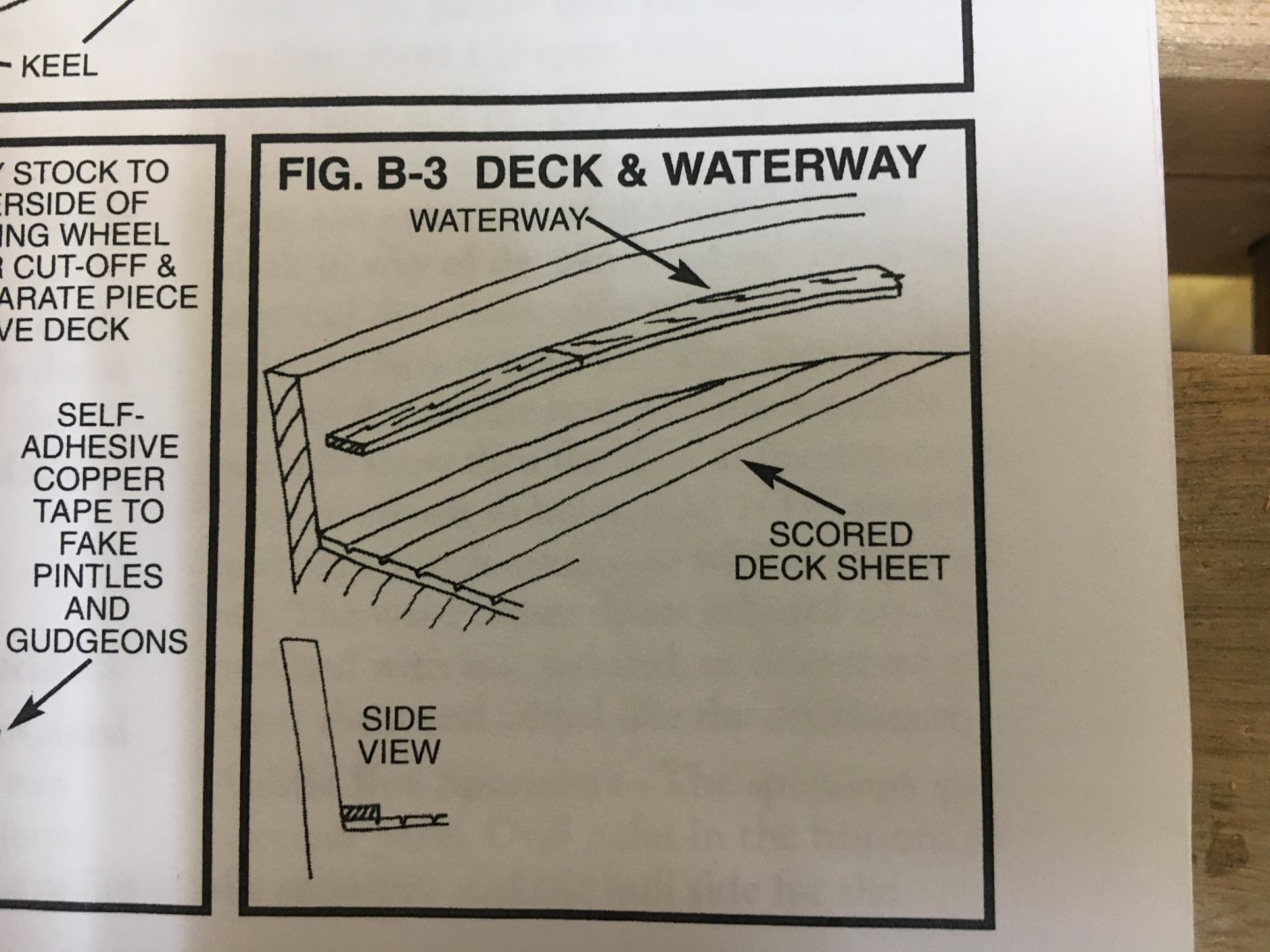

When satisfied with the pattern, I anchored it to the basswood deck sheet with a couple dabs of rubber cement, and cut it out with a razor knife. The deck sheet was barley large enough, but adequate. I used contact cement to glue it into the hull. My fit is good enough where the waterline "moldings" shown in the instructions, will cover any gaps between the bulwarks and deck. small pieces will need to be glued between the sponsions and deck. Coming up---gun cutouts, outside hull painting, and copper sheeting, as well as keel and rudder.

-

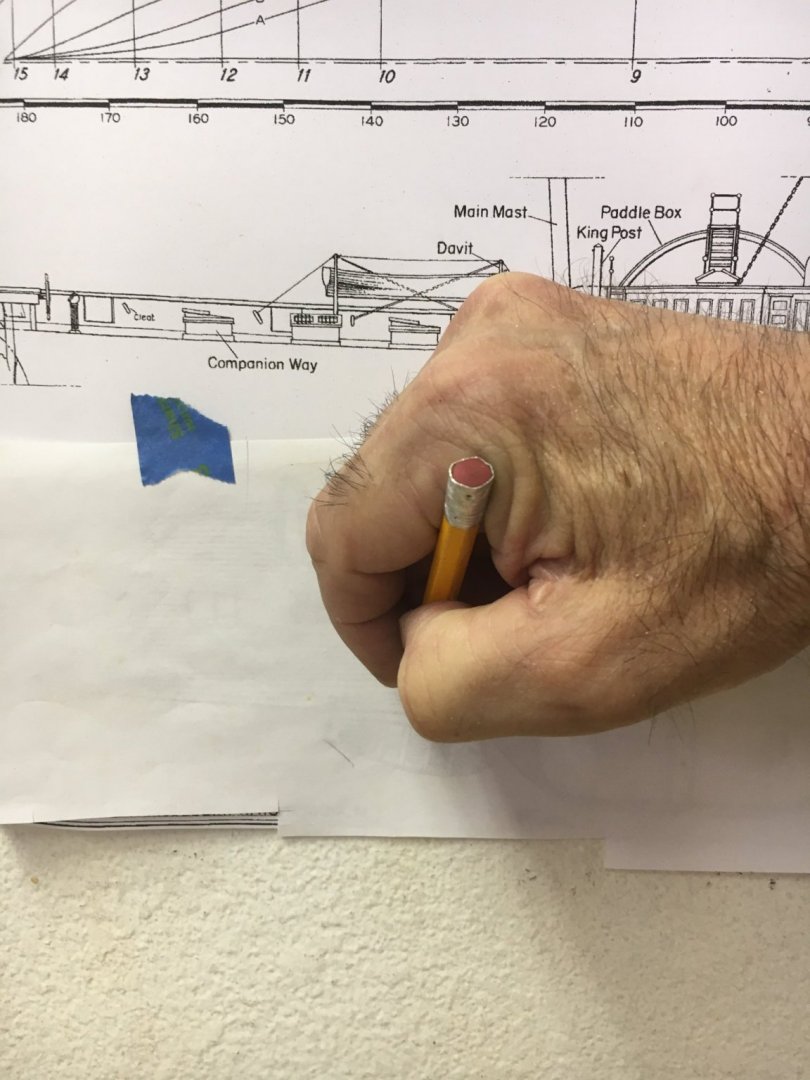

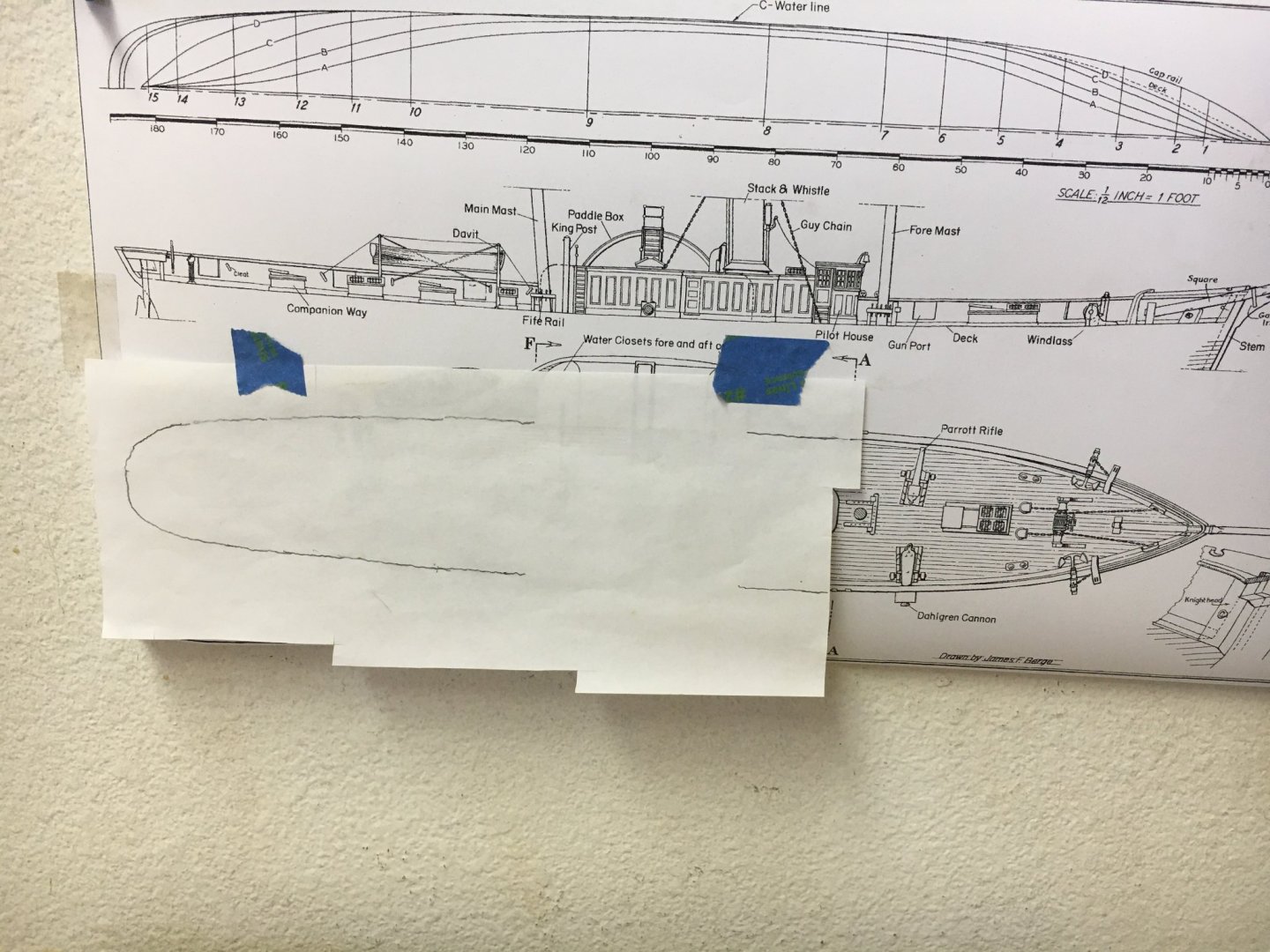

Next, I traced the paper patterns for the deck, a thin basswood piece, suppled with the kit, scored with lines to be the planking. For logical reasons, this pattern will only be approximate, and need to be corrected, with paper "shims" to accurately conform to my actual bulwark outlines. Reasons for correction---paper and wood both change size slightly with humidity, micro-deviation of my my bulwark carving from the paper pattern, to name a couple. Pics show the tracing, paper inserted in the hull with a "shim" at the stern. My pattern was pretty close.

-

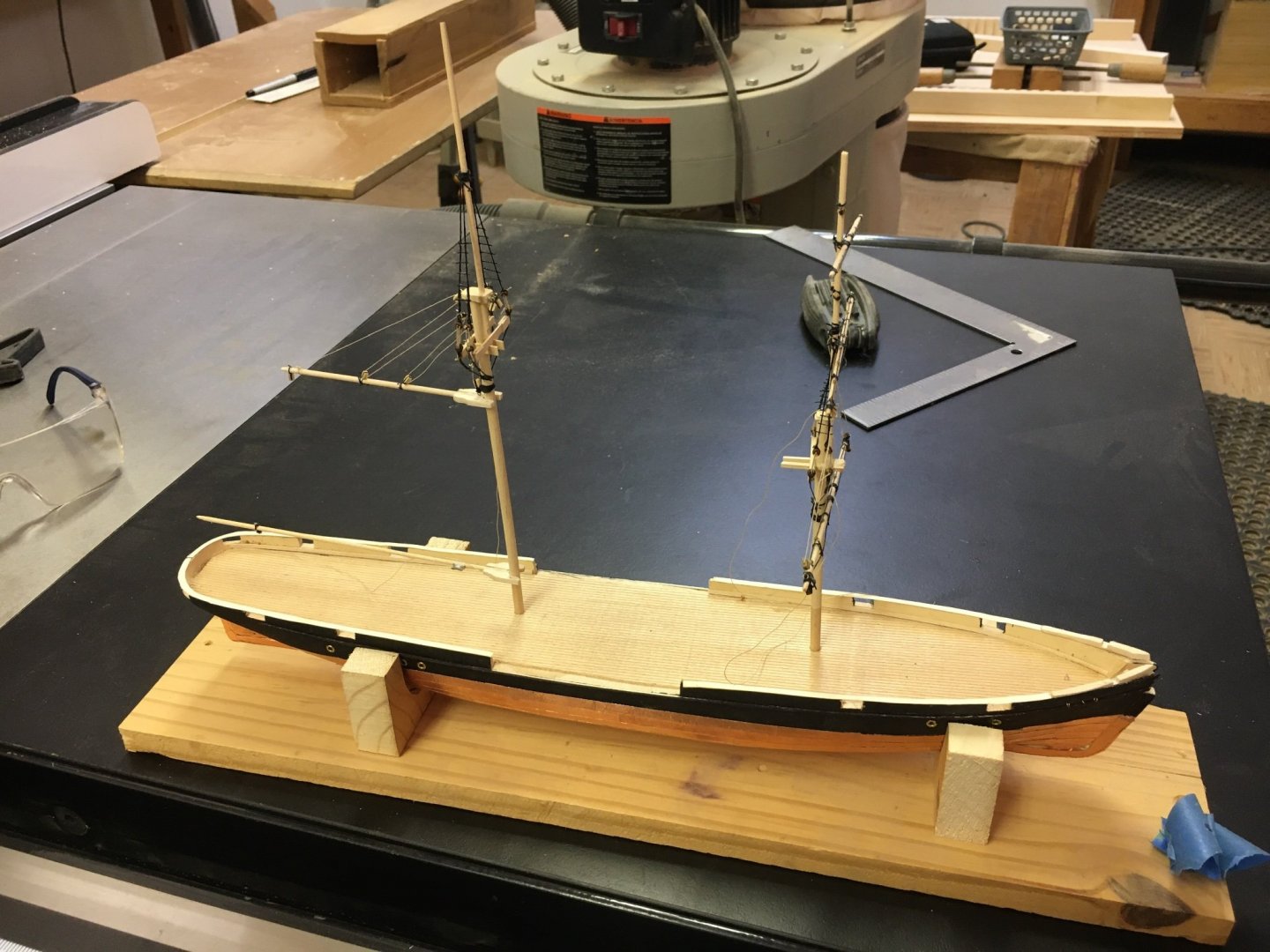

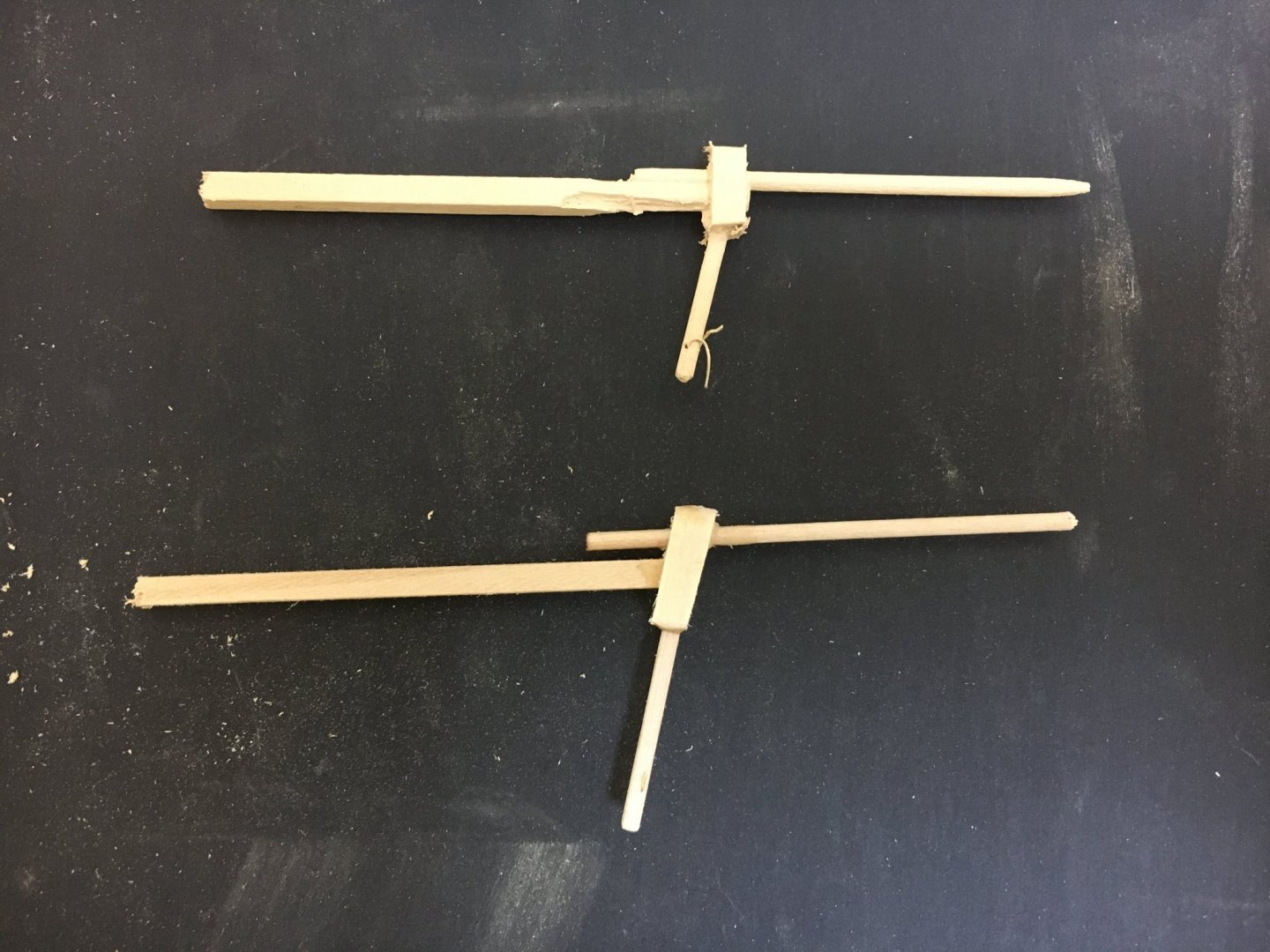

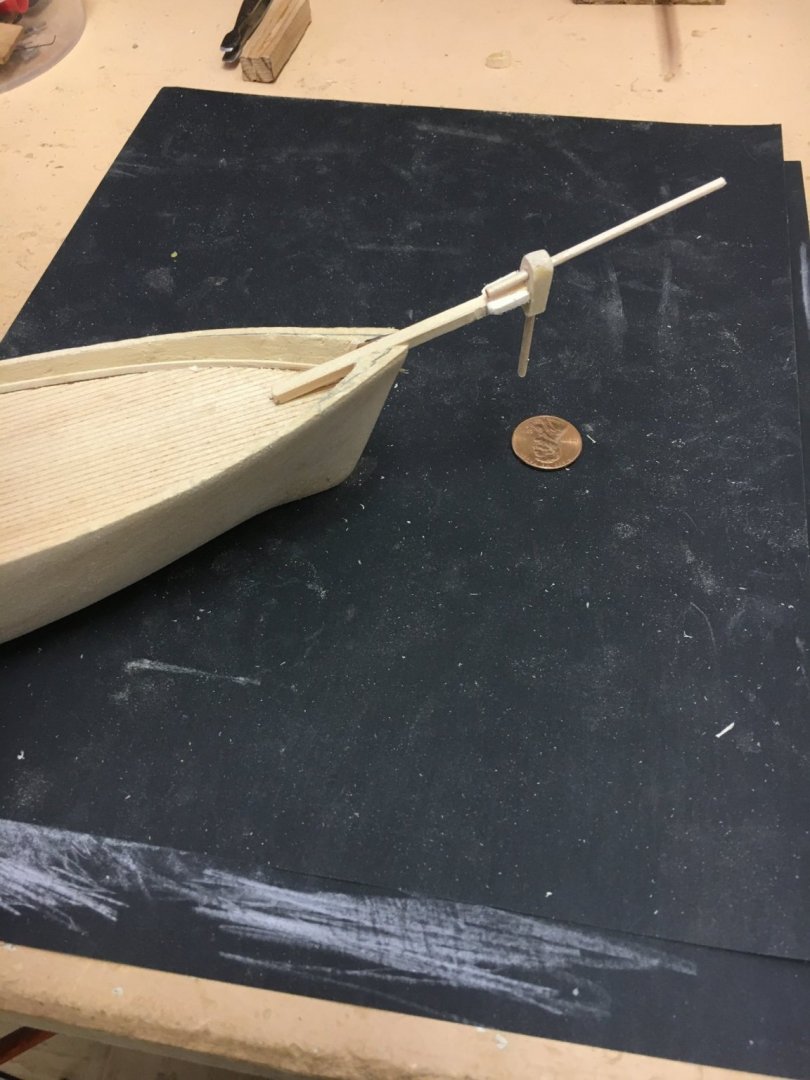

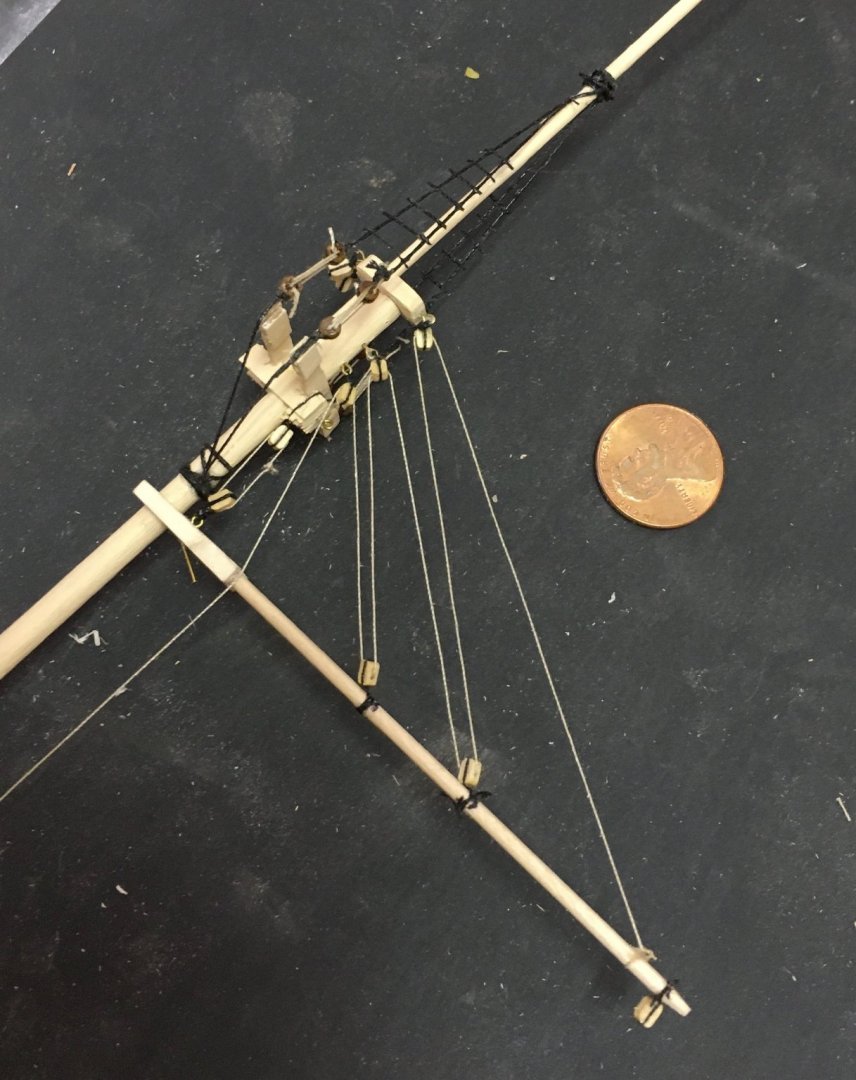

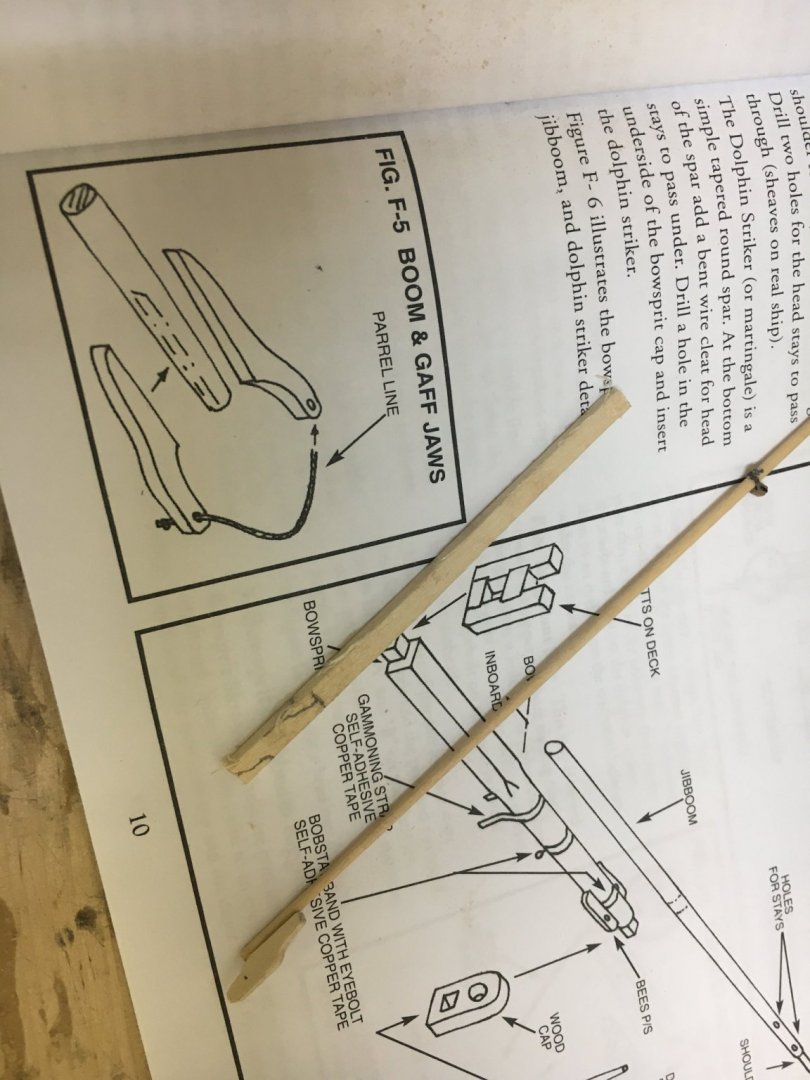

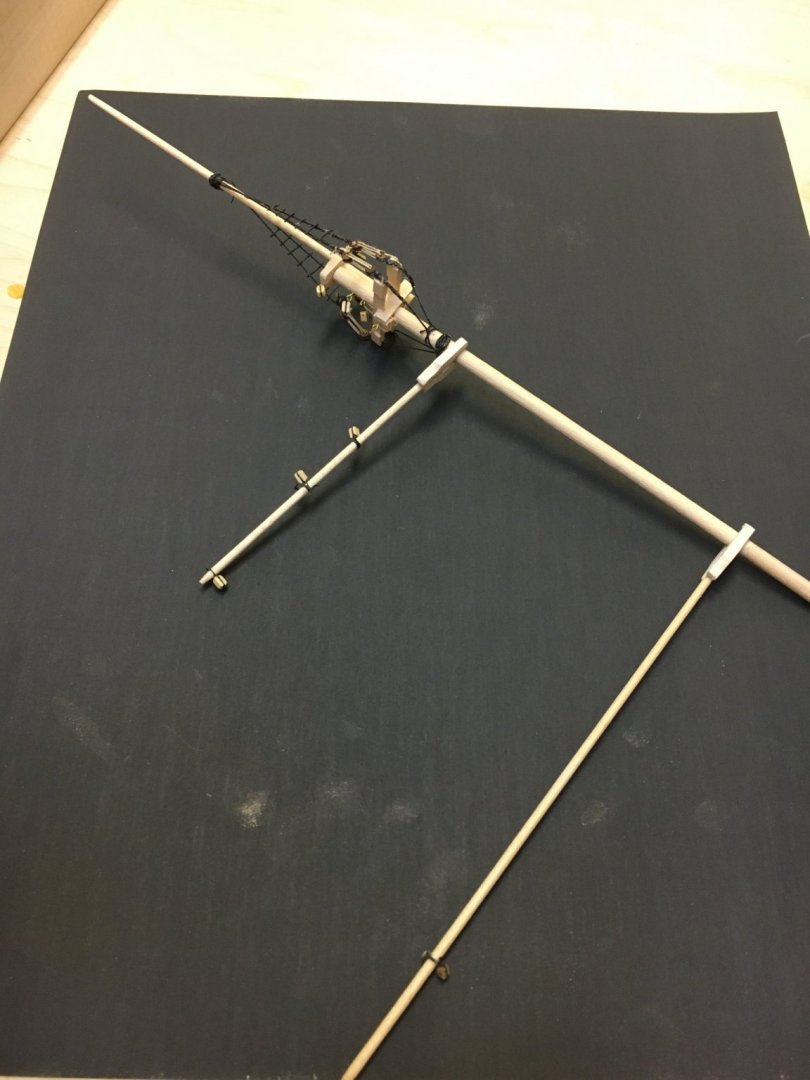

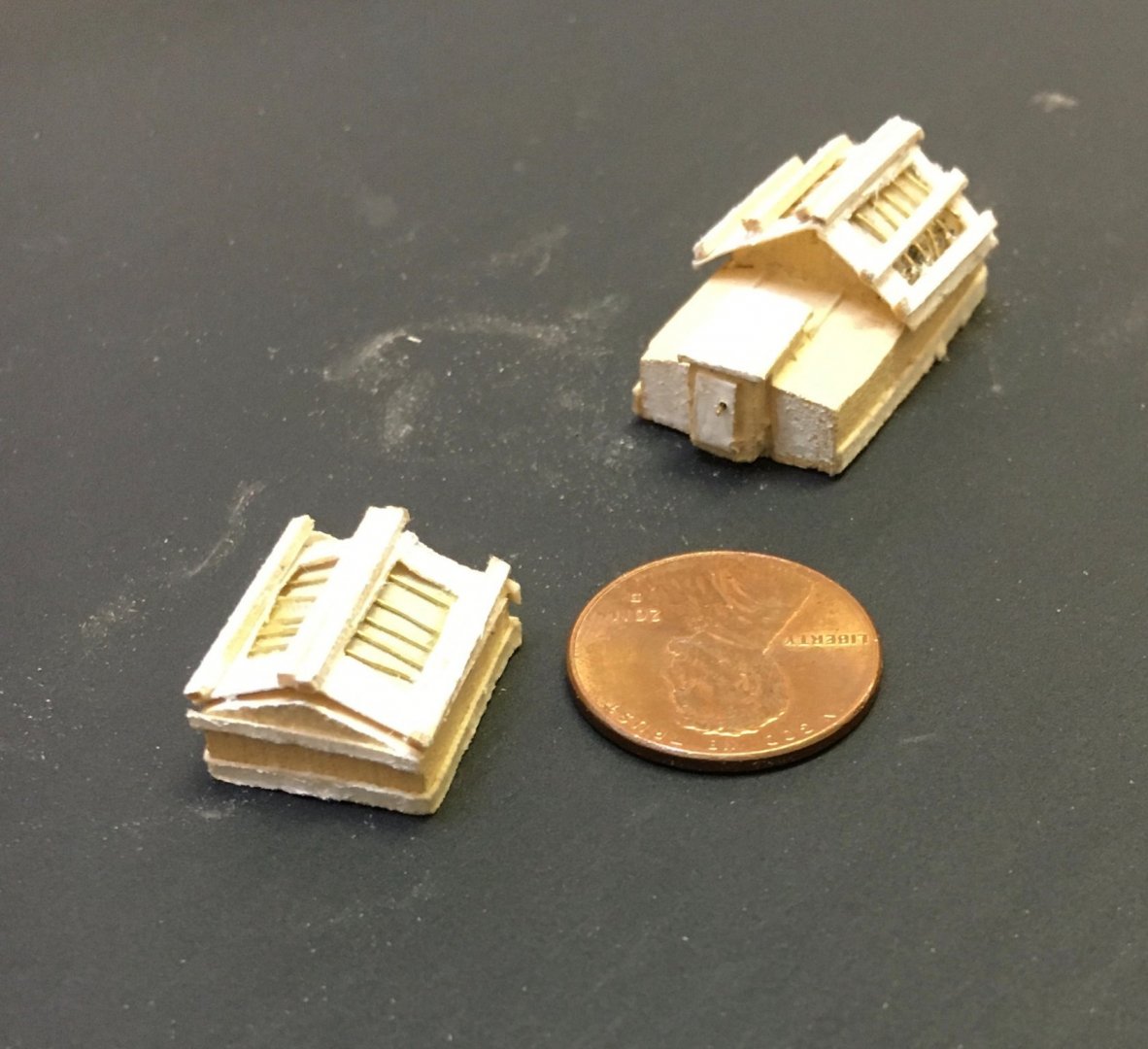

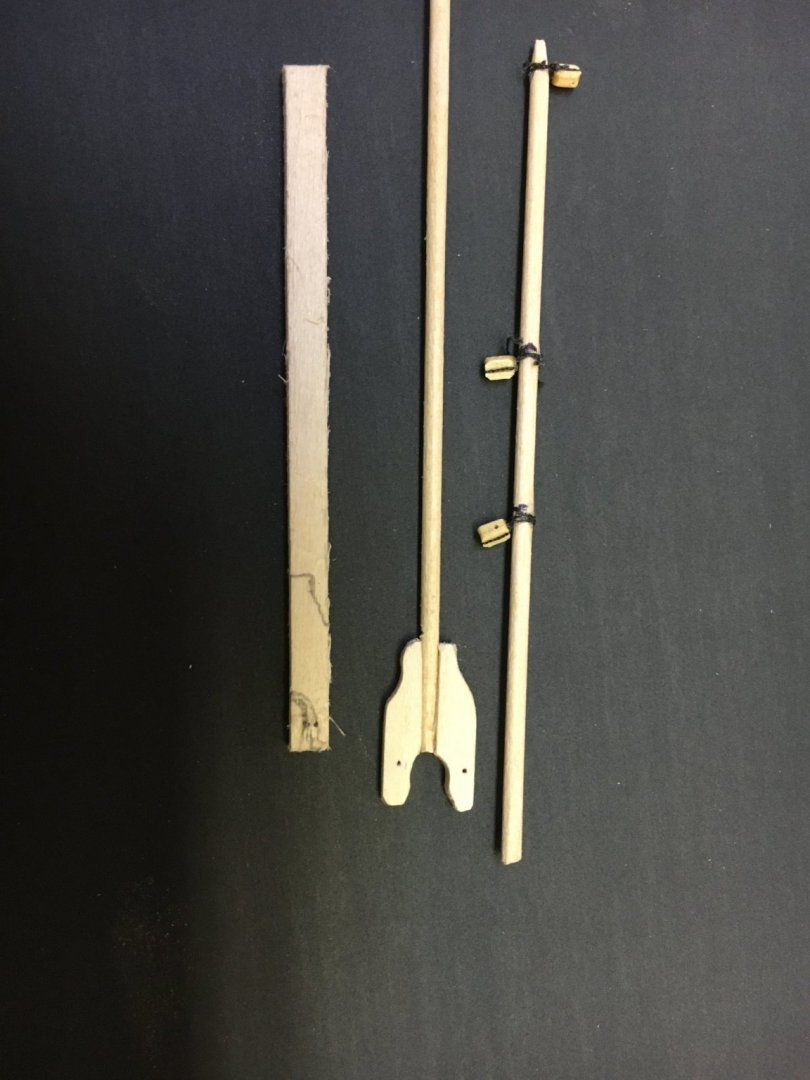

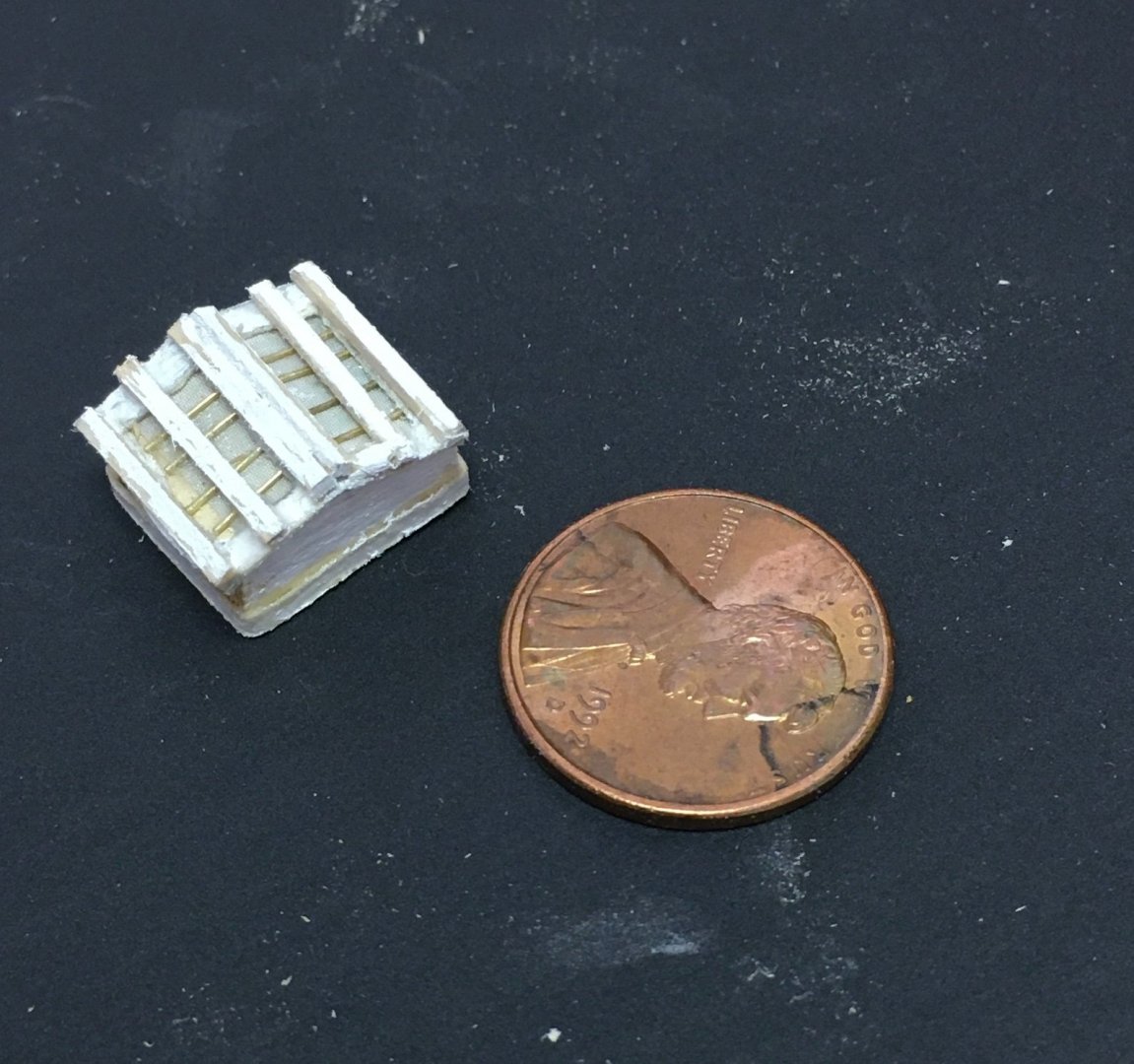

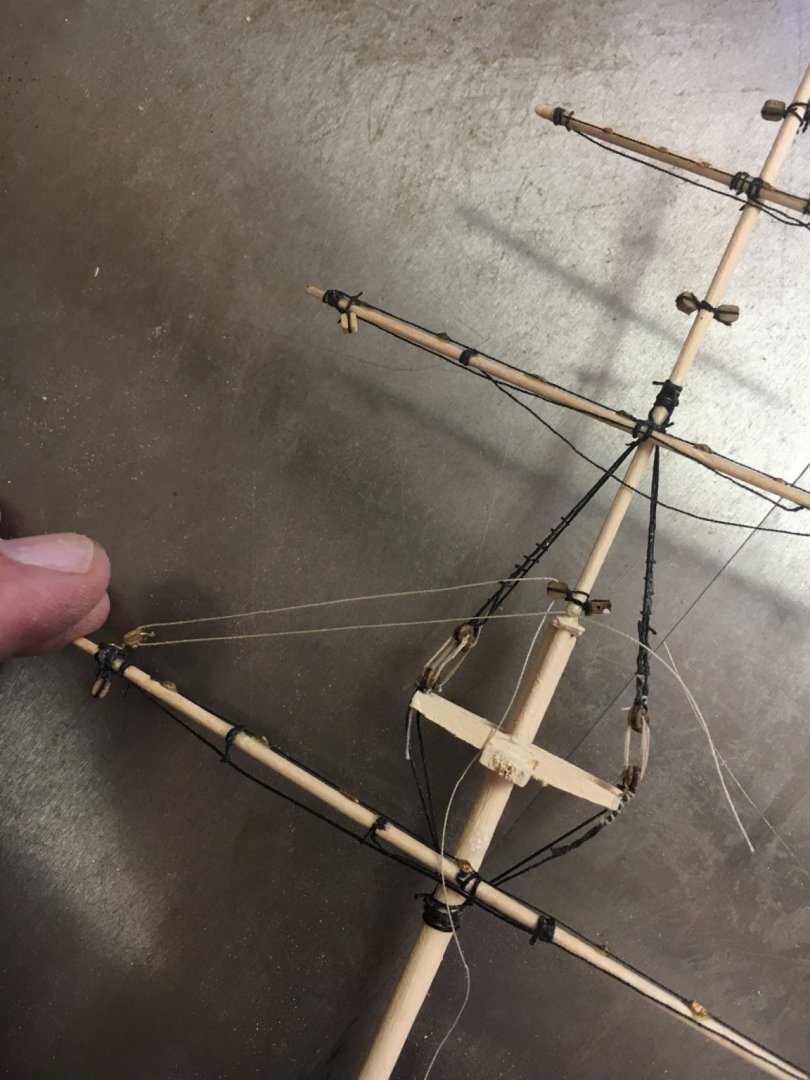

I bought some wood dough to help smooth the inside of the bulwarks before I paint the inside of them, then add the prepared decking, suppled with the kit. Meanwhile, I made an fitted the jaws for the mainmast boom and jib. They fit the mast snugly. I worked more on the forward companionway and one of the deck skylights. These look OK, viewed with the naked eye, fuzzy and rough in the picture.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.