MeandSuzy1

Members-

Posts

82 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MeandSuzy1

-

Well part of me is back guys. I hardly even figured out how to log in. I was taken off a 21 yr string of a pill called clonazepam in early June. Put on antidepressants. Been on 4 different strings now. Each fail and my cognitive ability is worse each second. I look back and don't even remember putting the earlier pictures up. If I do anything inappropriate I apologize in advance. This is the worst thing in the world. My once not too bad of a mind is gone. I started rounding 4 some planking today. I'm gonna try something simple

-

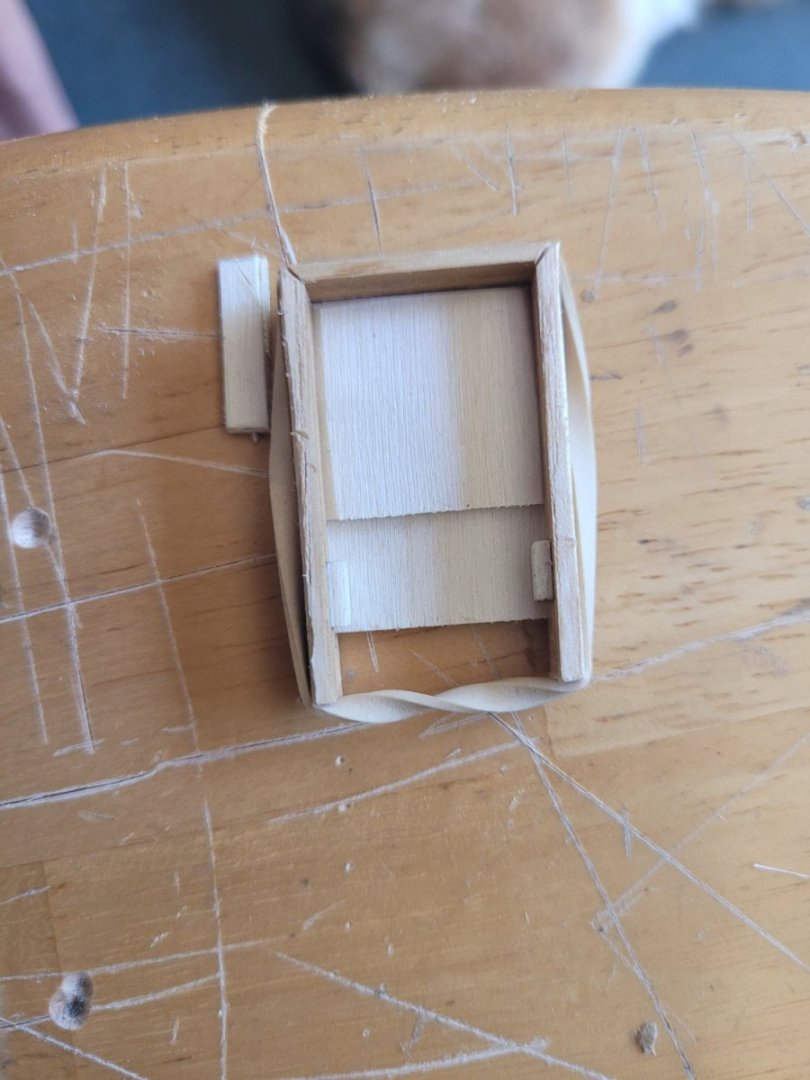

I'm back temporarily guys.. just a quick post and question.. I "think" I'm ready to plank hull. I'll have to figure out how to conceal wires as I go,but. What i think I've figured is I got to dremel radiuses on ribs so as to allow planks to form. I'm cutting guncase foam to fit in hopes of not trashing stuff inside.. any pointers appreciated

-

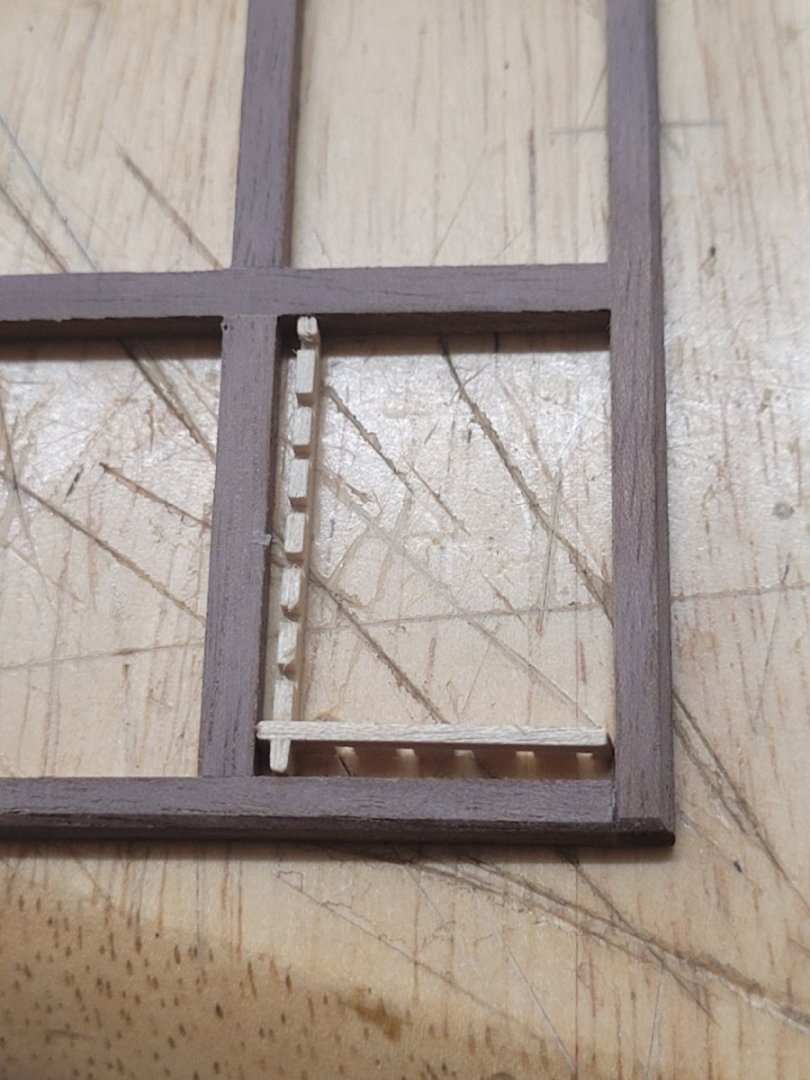

I made my upper grating a bit more robust. 4mmx4mm walnut (yes I'll probably run out of some woods) .. oh well. Squaring up the gratings to glue in.. I use one side of real sharp toe nail clippers. Clean. I put them together at approx length, then mix 50/50 white glue and water. Brush it on back side. Let dry then form to final size

-

Hi Guys I think Artesiana is trying to sabotage my build. They can't replace a broken main mast cause they say I have the wrong part #. That not withstanding ' how many things would be called "main mast" in this kit ??? OOKAY Does anyone know what the brass grommets with rope running through from top deck all the way to hold do ?? I almost blocked one off due to the AL lovelies keeping it a surprise

-

Well the deck is now stripped ,nailed, and eurothaned. I still hate the cross members I needed to bury my goof,but.. oh well. 020x3/33 nails go all the way through. Just,so I epoxy the back. Nothing will come loose anyhoo. Used the Lepage extreme glue. Gave perfect 30 min set time. The mid deck and hold each have lacquer spray but I flattened with wash. A lot in hold. Some mid,but. All gloss top. With just minor was near stairwells and main wailway

-

Ah that's okay. Hey guys I picked up the Lepage extreme I told you about Allan. We got a product here. Wow. She's a nice thick gel. I set this old saw blade on lacquered wood. I purposely put the blade on the gel pile on an angle to produce a gap and like with top deck to rib a tapered gap. I had good movement for 24 mins. Moderate for 9 more and by minute 40 a rock solid clear adhesion. I bent the blade peeling off. This is between 5 min epoxy and glue glue. Very fine prodect

-

Geez I'll do better then. Building things on these,or so I've noticed seems to be the one place common sense can still be used. As mentioned, the kits no help though. FINALLY..Think I've relief cut the back, steamed, bent n twisted the top deck that he SHOULD'NT a ton of stresses. Ya I figure it's ok to glue and clamp, but. to have all the clamping pressure that it would have taken to stay loaded in my model was not going to pay back well 20220719_172553.mp4

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.