Peter Joyce

Members-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Peter Joyce

-

Plate 2, Part 14: Belaying Pin Rack Another easy one -- this one is "cut out form laser cut sheet and glue to board." I considered fabricating these but didn't have the wood on hand. I opted to stain these as they looked a bit plain. These are then mounted to the stern. I needed to do a bit of filing and sanding to match the angle of the transom, but other than that, it was just a matter of gluing them on. I opted to make and mouth the midship set as well. listed as part 17. I hope nobody turns me in for cheating.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, part 13: Tiller (Stock) Again straightforward, though differs from the instructions. The instruction say to shape from 7 x5 x50 Beechwood plank, but the pieces are included in the 5mm Laser-cut sheet. There are two parts, a swept part and the hole for the attachment. Putting one in the other gives you the rough tiller shape: This is then glued and sanded down to the correct shape. And finally, mounted to the top of the recently placed rudder, I will end up painting this. In this case I don't like the raw wood look of the plywood, so likely painting it brown.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

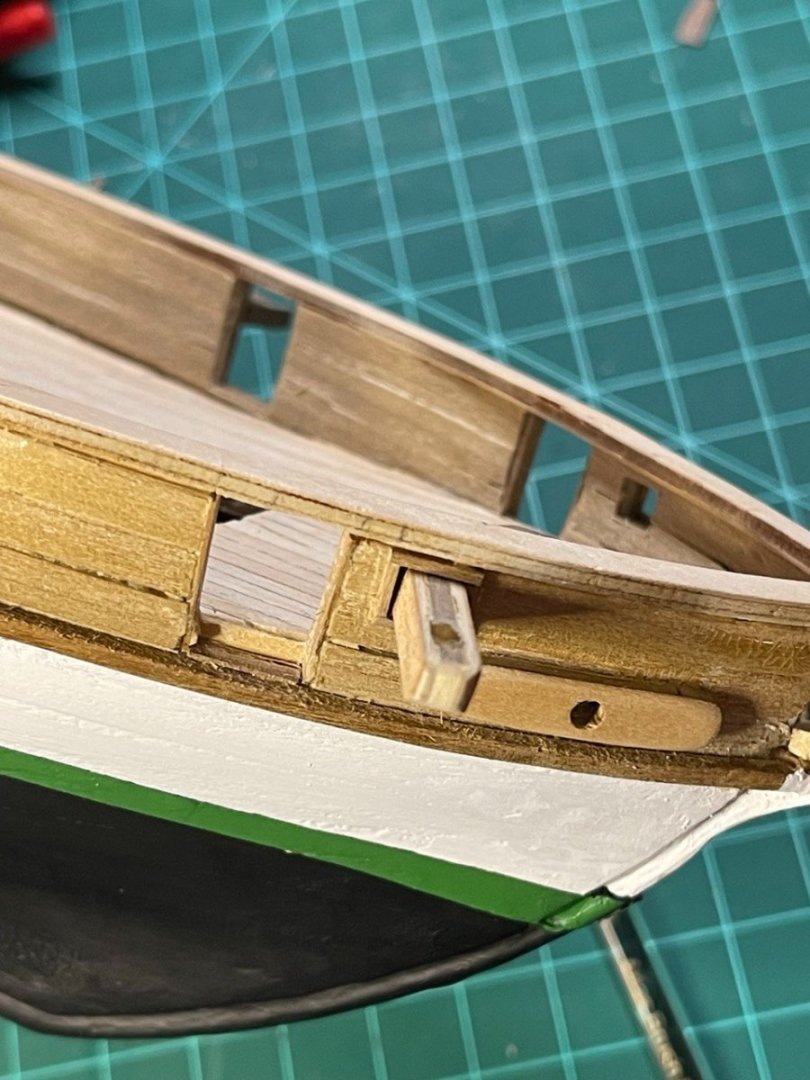

Plate 2, Part 12: Rudder The rudder was fairly straightforward. It is included on the 5mm laser-cut sheet and must be shaped to have a rounded edge to allow for rotation. It took me a minute to realize that I had to drill/carve a hole to allow the tiller portion to extrude through the deck. I had assumed the rudder would be decorative only and the tiller would just be adhered to the deck, but when trying to figure out how it went on I figured out that the top part attached to the tiller. To do this, I laid the rudder/tiller on the stem and marked the middle, then used a pin vice to drill a hole up to 1/8". It was a bit too tight to get a good angle and my first hole was a bit off, which I'll have to fix on the deck. To get the right angle and size, I filed out the hole until everything fit and there was some range of motion. This is where experience comes it, I had taken great care to shape and paint the planks which I ended up basically filing away. Unfortunately no picture of the process. The instructions say to affix the rudder braces with the pins inserted, but I found no pin. Instead, I used 1mm brass rod and drilled a hole. Because of the angle of he pin-vise I had to insert the rod and then bend it straight, which wasn't difficult with the soft brass. I then affixed the braces to the rudder by drilling holes and inserting brass brads. I repeated that process with the ones attached to the hull, with a bit of finagling. I was at about a 60% decision to remove and re-place the top bracket to align it with the others, not sure what happened there. Now looking at the picture, I think that has increased to 100% chance. The below shows the portion of the rudder on the deck to which the tiller will attach. I will need to put something around it to neaten it up and cover the hole, I believe a circle of wood is the traditional thing to put there, so I will likely cut a dowel and drill out the center, then file and sand to shape.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

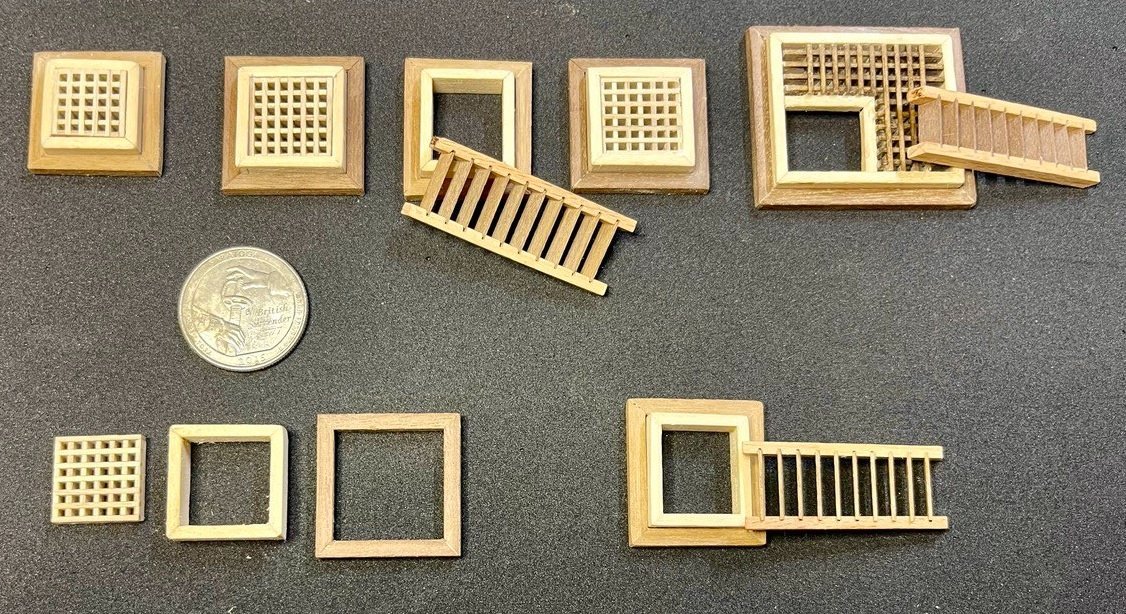

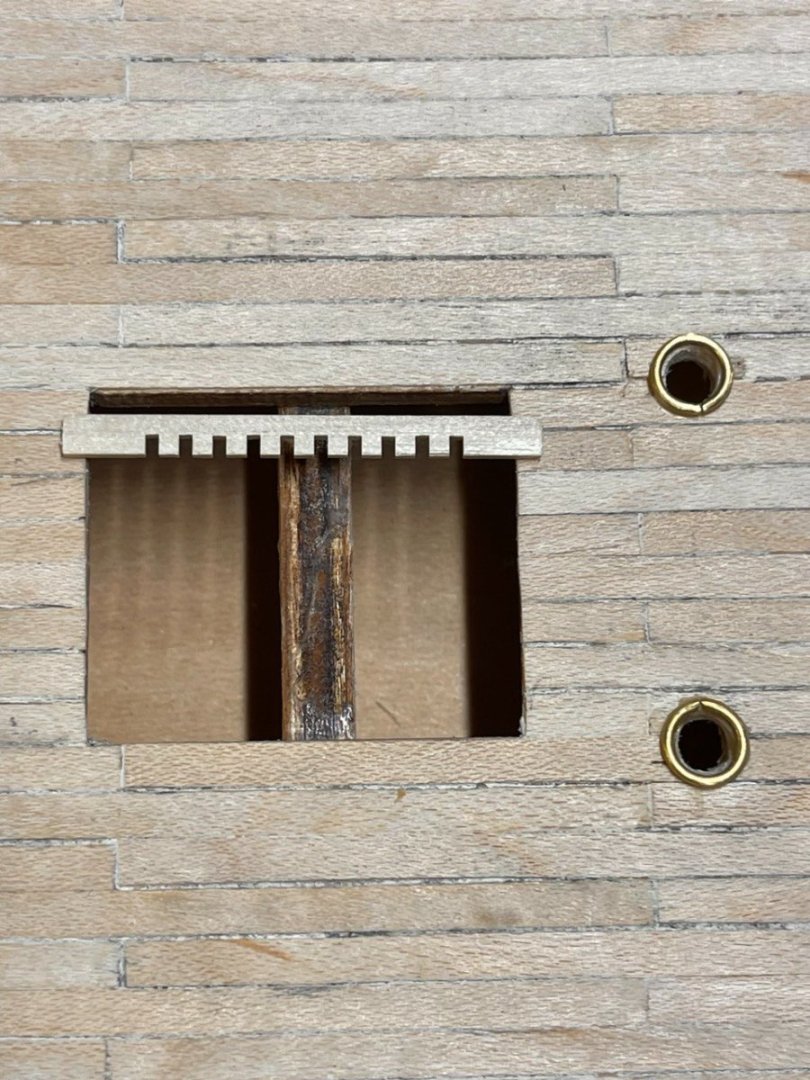

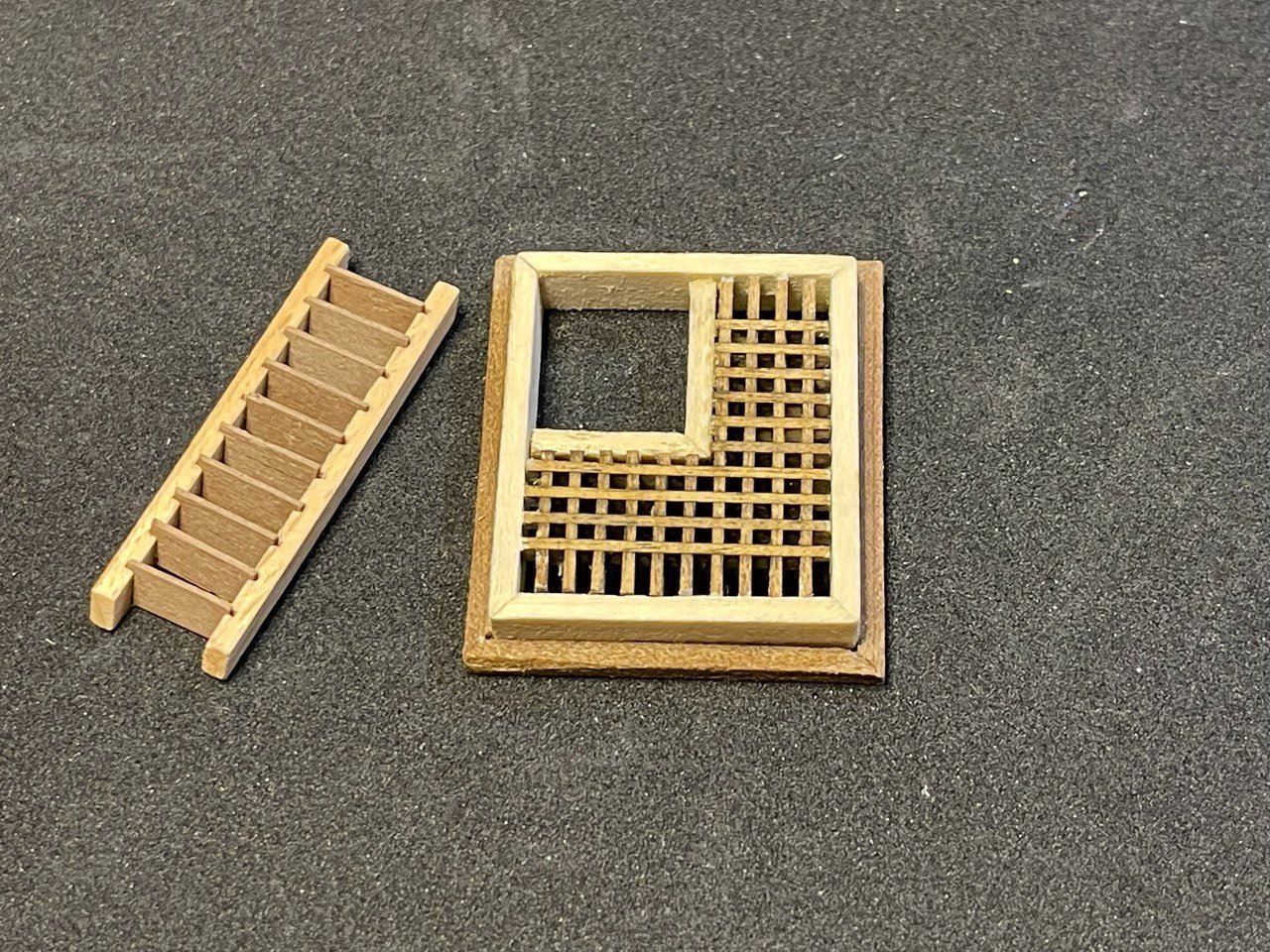

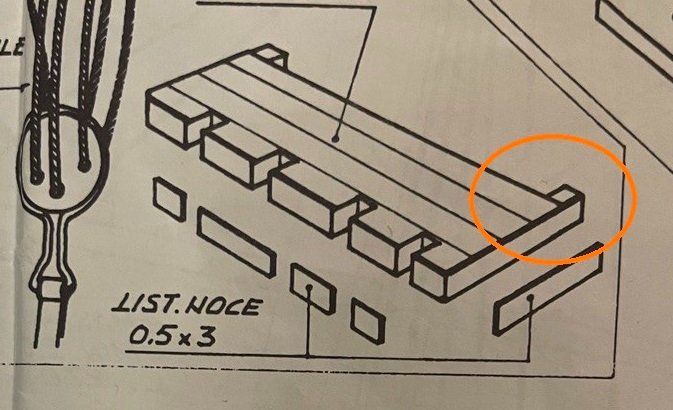

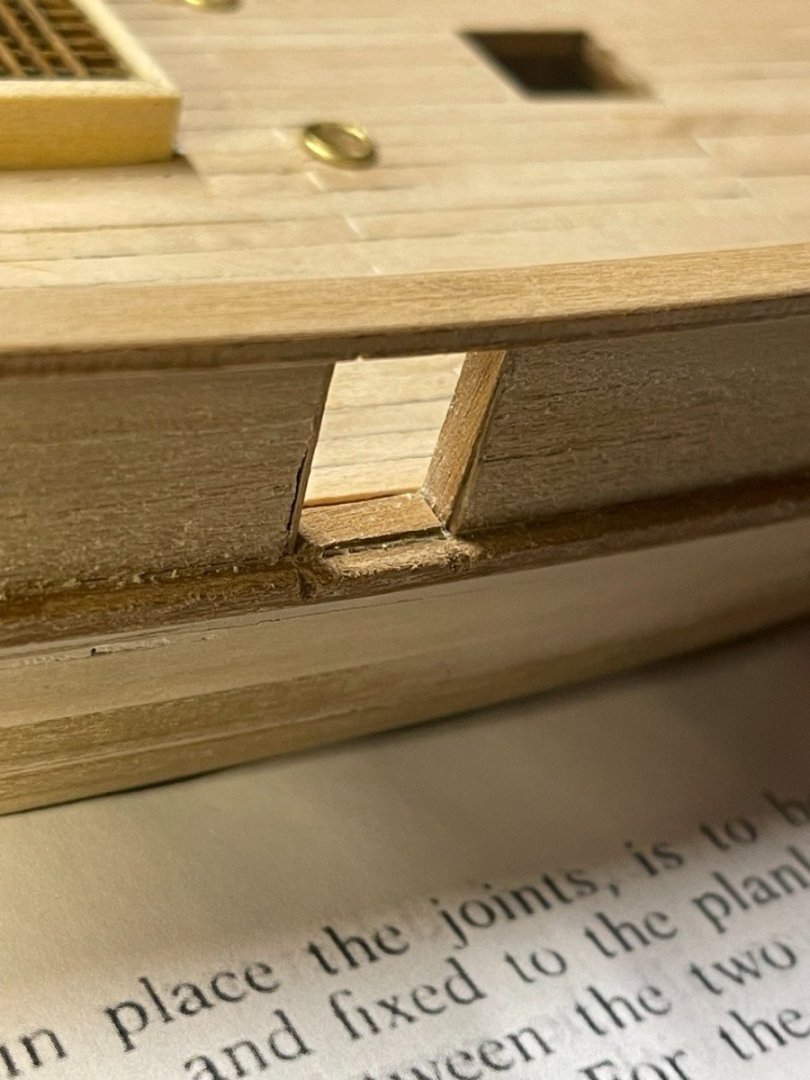

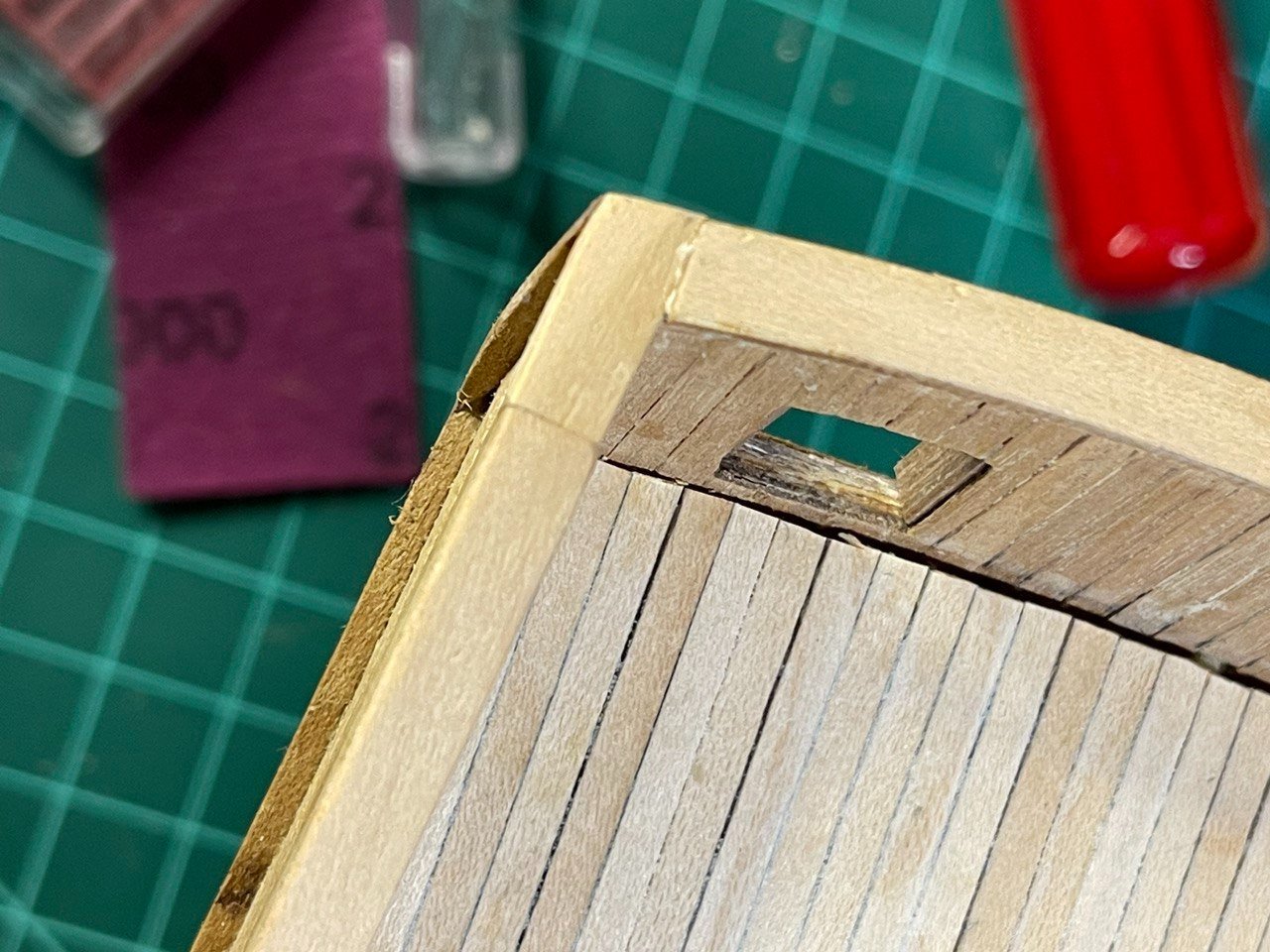

Plate2, Part 11: Grates and Ladders The instructions for this are "Follow the methods and materials (not for dimensions and geometries) which have already been explained in Part 9." So basically "Build the grates and ladders." Because I am insane I opted to miter the joins on part 9. To be consistent I had to miter the rest of the grate openings and surrounding trim. For the grates themselves I had ordered additional grates, but it wasn't exactly the size that came with the kit, so I ended up just using the kit ones. As PChem noted in his build, the materials were tight and I needed to use some scrap from the big central grate in #9 to complete the grates. I had initially planned to trim them down and have the last "Grate" portion abut the frame, but after making the central grate it didn't look finished enough for me. So my process ended up being: Build grate to closest size of opening, ensuring it made an enclosed square of grating Miter cut the 2x5mm wood to fit the grate Miter cut the external walnut ring to fit that. Sounds like much less work when I put it like that. But there are 4 more grates and two more ladders openings so it took a bit of careful detail work. In addition, I had to construct the ladders and as noted again by PChem, I will have to trim those. I used 0.4x4mm walnut that did NOT come with the kit. The instructions specify 0.5x3mm walnut but I found I did not have enough. Below is the result with an appropriate quarter for scale. I have not yet glued anything together except the center one and the ladders. This is because I am still trying to decide if I will stain the grates. I'm leaning towards yes, because the center one is stained and I would want them to match, but not sure how much I like that now. But I also don't have the materials to rebuild it. Below is how they look on the deck. I have put two treatments of Tung oil on the deck and rails and it will likely get a few more. Initially I intended to just use Polyurethane on the deck, but after following along here I will likely stick to Tung oil and perhaps wax. I have painted as well and will show that in a subsequent post.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

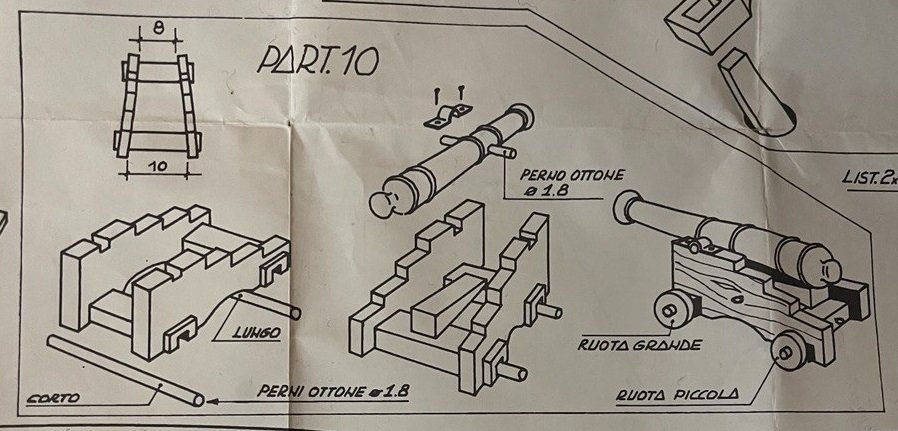

Plate 2, Part 10: Cannons I'm not sure why the instructions have this part before the rest of the grates. I suspect because that's just how the drafting was best laid out. It worked out well as I am waiting for more grating to be delivered and I'd like to see if it works a bit better than the kit-supplied grating. The parts and process for the cannons differs significantly from what the instructions say. The drawing shows two pieces of wood with axles and separate wheels as well as an elevating wedge. the kit contains pre-built wheel and axle assembly and the instruction "The big wheels must be used for the front and the smaller for the back," confused me because there are two lengths axle/wheel assembly and the longer on goes in back with the shorter in front.. I figured out they were referring to the diameter of the wheel, not the length of the axles. My first attempt was to cut scrap wood to what was shown in the plan, but while it looked OK, it just didn't have a good, finished look. I then recalled some parallelogram-shaped parts of the laser-cut 2mm sheet and measured. There were 8 total and they all measured appropriately for the cannons. Scouring the plans, I didn't see where else they might be used, so I took a chance. This is likely where experience would have paid off, I imagine this is a common assembly for cannons, though looking it up didn't get me many results. I also found small pieces that I had been wondering about. I surmised that they took the place of the wedge and provided a cradle for the cannon. I did a couple of tests and dry-fit everything together and it worked. Additionally, included with the cannons were 24 (3 ea) black things that looked like cotter pins and 16 brass rings (2 ea). After doing some research, I decided are for the breech and tackle lines, with the brass rings attached for the breech lines. it remains to be seen if I will rig the lines to the carriages, there's no hardware I can find in the kit for that, I may have to order it. So the pieces for a single gun are below as best I could figure: To mount the brackets, I drilled pilot holes for my nails and then pushed the nail in the rest of the way. The same for the pins for the breech lines, which get misshapen very easily, so I had to take care. For assembly, I first stained all the pieces, then mounted the brackets. I glued the bottom to one side of the carriage just above the cutouts for the axels and then put in the pin and mounted the cannon. I then applied glue to the edge of the bottom and slid the side of the carriage into place. This allowed me to align the cannon properly. Building it first and then mounting the cannon, while it makes sense, wasn't working for me and it seemed simpler to line it up as the glue dried. Below is the finished product: This plywood does not seem to take stain well. The stain tends to gray (I may need to try a second application) and the above is after adding tung oil. I may end up painting these, so any suggestions on appropriate colors would be appreciated. One interesting research item is that Lynx is described as a six-gun boat during her capture in 1813 but the kit includes 8 guns. It would be interesting to know which is correct.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Gorgeous! I hope mine turns out 1/4 as good as this one. Thanks so much for posting this. This seems to be a not uncommon kit, but other than the one on the front of the box, this is the first completed one I've seen. I searched for pictures so that I could have a reference in the past and haven't been able to find much. Lots of folks seem to start this model but few complete it.

-

Thanks! I had test fit the ladder and the grate and saw it was too long. Good to know it isn't just me, just that reassurance helps! So it looks like I'll be cutting the ladder, thanks for the tip. I considered having it stick up above the opening, but looking at yours flush, it looks great so that's the route I'll be taking. I'm waiting until I have all the pieces constructed before I start affixing things, just so I can dry-fit and handle and oddities that come up. Thanks for posting yours so I can cheat off of your homework.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

I'm so happy to be able to see your progress as I slough along behind you. It looks fantastic, and I have to keep stopping myself from comparing. I remind myself it's a first time for me and I will (hopefully) improve. It's great to have yours as a refence though. I love your paint, and am considering following something like your example. I have started, and was planning on following the plan's scheme of black, green waterline and white up to the fender rail. I have looked at many pictures of Baltimore Clippers and the vast majority look like yours does, with white paint between the gunnels and the fender rail. Also, a little paint and wood filler would cover a number of my sins. I don't know how I messed up the portholes still. I measured carefully, but the standoff for the chain-wales didn't fit on mine and I ended up having to trim them down. It looks OK, but yours look much better. I like what you did with the holes for the tabs, but that wasn't an option for me. Anyway, thanks again for posting all this, it looks fantastic!

-

Plate 2, Part 9: Midships Grate and Ladder My first grate and it was pretty complicated. Fearing that I would run out of grating, I also pre-assembled the pieces for the other grates to figure out how many pieces would be required for each one. The instructions are very specific about the supporting frame aligning with the cutout in the deck. However, the grating supplied is not large enough to cover the opening with full grating. See below: I decided I would live with it and just have some extra on the sides. I think that was a bad idea and I should have simply moved the frame in so that the outside of the frame aligned with the inside of the opening. But being a first-time builder I opted to follow what instructions I had and build the frame to the outside. I have since ordered more grating, but that will not arrive for a week or so. At that point I will consider either knocking out the grate and re-doing it, or rebuilding it. Or leaving it alone if the new grate doesn't look right. Because I was following the specification that the frame should match the opening, I decided to build that first and match the grate to that. I then carefully measured and cut out the section for the ladder. I then put 2x2 around that opening as specified. I aligned that with the bottom of the grate as I liked the added depth and texture that gave. Though I've recently seen PChem's grate and am a bit jealous of how seamless it is, so that also may have been a bad decision. Live and learn! Finally, I stained the grate walnut as it breaks up all the blond wood. The ladder was annoying but straightforward. For this I used my purchased 0.5 x 4mm instead of the 0.5x3mm included with the kit as I am pretty sure I will run out of it and I want the ladders to match. Below is the final result of it all. In all, I'm pleased but as stated, there are some thing I would do differently. The problem is that with the extra on the side, it looks less like grating and more like lattice. I'm not sure the staining doesn't contribute to that. Oh, and one thing I'm proud of is that the ladder fits perfectly in the space provided!

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, Part 8: Anchor Line Holes Again a simple part. This is simply two holes in the deck with brass rings around them. To find the centerline, I put the compass on either corner of a few of the openings and drew a short arc roughly at center from each side. I then lightly drew a line connecting the places where the arcs intersected and measured from center to match the plan. (I remember my old drafting classes. ) I drilled the two 4mm holes and then used a round files to file them out a bit more, the 6mm dia rings were just a touch too big. I considered filing down and removing some of the decking to inset the brass rings, but wasn't confident I could do a good job of that, so I glued them in place. When the anchors and anchor lines are attached, those will end at these holes.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, Part 7: Smokestack Another straightforward piece. The 6mm dowel is included in the first parts bag mentioned above in Plate 2, Part 1. I cut a 45 degree angle using the Xacto saw and miter, then flipped it. I trimmed the piece to the correct size and glued the pieces together as shown on the plan. I used (I believe) a 1/8: drill bit to drill out the center and then a circular file to carve out the inside. The base for this piece was included on the 2mm thick laser cut and was one of the ones that was cut from one of the holes in the deck. I sanded the edges of that a bit and finally painted the smokestack flat black.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, Part 6: Chain Wales This part had some issues and I wish I had asked here before moving on, but perhaps I can get some confirmation. The chain wales go between the second and third portholes. I cut the pieces out of the laser-cut board to find that they did not fit between the two portholes, the chain wales were bigger than the space there. I pulled out my compass and checked the plan against what I had cut out and it turned out to be exactly right. in addition, there were extended pieces on the ends that I wasn't sure what to do with. These extended about 1/2 way to the edge of each porthole, and I thought about carving out notches for them and having them stick partway into the portholes, but there was nothing on the instructions about that. So if anyone knows what I should have done, please leave a comment. Having them extend over the portholes didn't look right or good to me, so I ended up trimming off the excess on the sides of the chain wales which left only a sliver of those pieces which I trimmed off. I then planked it as shown with 0.5x3 walnut and glued directly on the hull. My theory is that the actual tension from the rigging will be on the brackets on the hull, with this just acting as a stand-off. Wish me luck! The instructions for this part also include affixing the brackets, but I am deferring that until later when the paint is finalized. Look for a follow-up for that, I've only started paining the hull.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Thanks so much, I'll see what I can scrounge up!

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, Part 5: Bollards Another fairly simple pair of parts. The bollards are to be cut and carved from 4x4mm Walnut. This is included in the lumber in the kit and the bollards are cut to 10mm and have chamfers/notches 1mm apart starting at the top. These are indicated on the plans. The carving was a bit difficult as they are very small pieces and I had to be careful not to carve away too much material. I used a square file at 45 degrees to cut out the notch, which worked out well. I made sure to carefully mark it so that the sides would line up properly. The instructions and diagram show that it is attached by a 1mm brass pin, however I have not found that pin so I may just end up gluing it on. I haven't put may of the deck fittings on yet, my plan is to complete the pieces and then assemble them on the deck. I want to ensure the placement is correct and I haven't messed up something that needs to be adjusted.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, Part 4: Anchors The anchors are included in a separate bag containing the two anchors and two brass rings. The anchor stock is on the 5mm laser-cut board. The assembly was quite straightforward for these. I cut out the anchor stock and files/sanded to the shape indicated on plans. This entailed shaping just the top and bottom to match the angle of the two sides. I pushed the included anchor into the hole in the stock and placed the brass ring by bending it with needle-nose pliers and putting it through the hole, pretty standard. Before wrapping the lines around the stocks, I gave them a coat of clear polyurethane. After that dried, I wrapped the lines and held them in place with a drop of glue. I made sure to wrap the outside around the area where the wood from the plywood transitioned from the exterior walnut to the interior (poplar?) to make the transition look more intentional.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, Part 3: Cat-Davits The cat-davits themselves are included on the laser-cut 5mm sheet and do not need to be carved as the instructions say. In some cases I think carving from wood would have been a better choice, but the cat-davits work well with plywood as it looks assembled from separate boards. In the blister pack, there is also a bag containing 2 pulleys, 2 brass rings, a copper band 24 small eyelets and two sizes for brass wire (this is from memory, your results may vary). There is a similar bag listed in the manifest, but the contents differ slightly. In any event, if you're making this model, look for the bag with the 2 pulleys. I drilled a hole in the top of the cat-davit and then widened it with a file to allow room for the pulley and some movement room. The pulley is affixed with a brass nail through the center. I did not pre-drill a hole as I thought it might be too big and allow the nail to move, so I very carefully pushed it through making sure it aligned with the center of the brass pulley. Once the nail was well-set, I filed the ends of it flush with the board. The plans show the ends of the davits chamfered, so I used a file to chamfer the ends. To create the hole in the hull, I located the placement on the plans and measured from the porthole astern of the hole. I cut and filed, test-measuring with the constructed cat-davit. Once both holes were cut, I put the 1x1mm walnut from the package in Plate 2 Part 1 above around the outside of the hole. Finally, I trimmed the base of the cat-davit that goes on the deck to the proper height to sit flush on the deck. This may have been a symptom of my deck sweeping upwards at the bow.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Plate 2, Part 2: Hawse-Holes The hawse holes are fairly straightforward, however there are a couple of considerations. On the plans as well as the original drawing in Chapelle, the hawse-holes break the plane of the fender rail. However, for whatever reason the deck on my model rakes up slightly at the bow and the anchor lines must go on the deck. I don't know if I did something wrong in putting in the deck, but the time has passed to correct it if I have. I did notice in the photo on the front of the box, the hawse-holes appear above the fender rail, so that may be a compromise and in my model it is. The plates are on the 2mm laser-cut board and do not need to be carved as indicated in the instructions. To place them in the correct location, I measured from the plans and drilled from the deck side as low as possible and then placed the plate over the hole.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

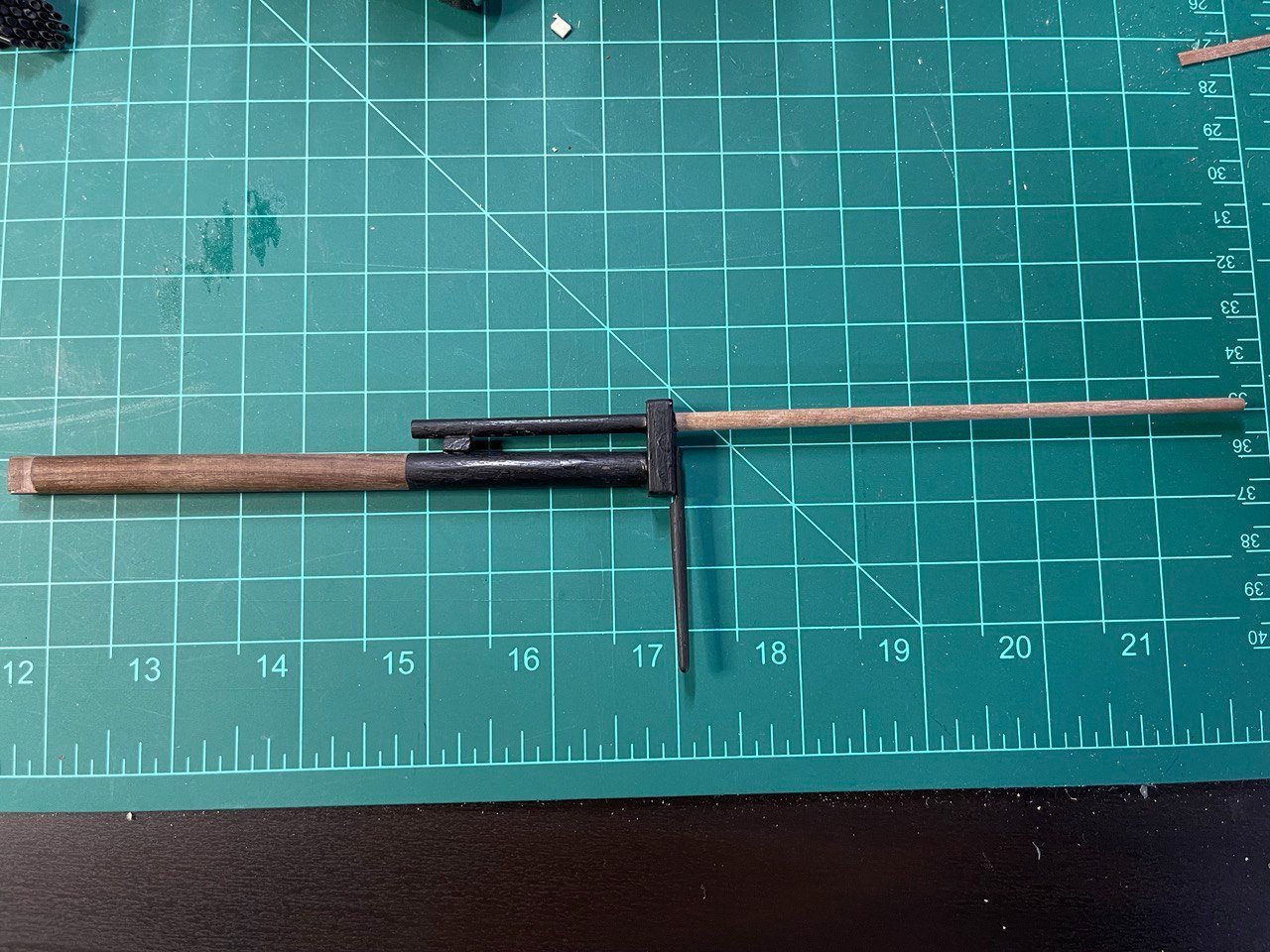

Plate 2, Part 1: Bowsprit I'll be changing the nomenclature for my posts for a bit. The instructions and plans each have numbered parts and I will be using that to title the posts, using one reply for each part listed on the instructions. The first is the bowsprit. This is also where a great deal of guess/investigation work happens for the parts. The first segment of the bowsprit is made from 8mm dowel and attaches via an 8x8x15mm block on the deck. The kit include 2@8mm dia. dowels from which the masts and that bowsprit are made. Laying out the masts I determined that the shorter of the two dowels will be the larger of the two masts and the longer dowel will be the shorter mast and the bowsprit. The kit also includes in the blister pack a small bag containing an 8x8x15 walnut block, a 6mm dia. short dowel of white wood (For part 7) and a piece of 1x1mm walnut strip (for part 3). This bag does not appear on the instructions nor in the manifest of parts, but I scoured over the instructions and didn't see any other uses for the items in the bag. The bowsprit attaches via a tongue and groove which you carve into the bowsprit and the block. I opted to cut the groove into the block first so that I could mark and cut the tongue in the bowsprit. To accomplish this, I drilled a 1/8" hole 7mm back from the forward part of the block and carved from that hole to the front of the block with an Xacto. I then filed that down to expand it a bit and smooth it. I then field down the sides of the bowsprit to fit into the groove with lots of trial fittings along the way. To attach the next section of the bowsprit, the first segment mush be tapered down to 7mm dia. I dry-fit the assembly to the hull and marked where the bowsprit piece emerged from the bow. I wanted the taper to start there and not at the portion that was inside the deck. I wrapped that part with blue painters tape (a lot of blue painter's tape) and used the Scary Drill (Electric) as a lathe and narrowed it down with sandpaper to 7mm, dry-fitting it to the fitting. Note that the fitting is one of the square pieces with two dissimilarly-sized holes cut from the 5mm thick sheet that held the spine. The next segment is created from 4mm dowel, cute to 170mm and tapered down to 3mm. I used the same method for tapering, ensuring that only the portion of if that extends past the fitting is tapered. This is affixed with a small piece of wood, noted as 2x3 walnut. I did not find this piece and used a bit of scrap and glued them together. Finally, the dolphin striker (not mentioned in the instructions, but included in the detail diagram) which is made form 3mm walnut dowel and tapered to 2mm. It also gets filed down to have a tongue and is affixed with two brass nails. I pre-drilled holes in the piece, but not in the dowel. Unfortunately while trying to drive the nail, I bent the first one (you'd think I'd know by now) and split to wood slightly. It is like that now, with only 1 nail because it covered both hole when it bent, so I may re-build this piece if I have some dowel left to do so. Below pictured is the completed (for now, there's another part detailed in a later step) bowsprit without the wrapped thread to show the joining piece.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Part IV: Bowsprit Passage The next and final step for this plate before moving onto specific parts was the passage hole for the bowsprit. I procrastinated on this and did a lot of sanding of the hull in the meantime. I was intimidated by drilling a hole in the bow and had visions of the drill smashing up all the hard work I had done. The instructions say simply "Make a hole for the passage of the bowsprit with a 6mm bit. Then, use a round file to enlarge the diameter to 8mm." There accompanies a diagram, but it's just a drill bit going through the bow so I won't include it here. Eventually I had to stop procrastinating and just drill the damn hole. I opted to carve away a bit of the outer planking to give myself a surface to place the drill bit and then I built up, starting with a 1/16" (1.6mm) hole using a pin vise. To find the location of that, I measured up 4mm from the bobstay piece where it meets the hull and marked that. I worked my way up to 1/8" (3mm) using the pin vise, but that was as far as I could get with that tool and I had to switch to the Scary Drill. I used that up to 1/4" (6.35 mm) at low speed. It turned out much less scary than the vision in my head of the bit catching an edge and smashing my hull to pieces. As per the instructions, I then expanded the hole to 8mm using the dowel as a guide. Below is the end result.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Yep Chris, that is absolutely true. As I’m discovering, there are a bunch of laser-cut parts that don’t appear on the plans and I’ve had to figure out what goes with what in my own little mystery novel. It boggles my mind that they haven’t added “(note: lumber for this step not included, please see wood sheet #3)”. As a first-time builder it’s a bit disconcerting. They took all that time to create the pieces but didn’t update the xeroxed instructions? Thanks for reading!

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Part III: Transom, Deck and Portholes Planking completed, I moved on to the deck. One item I neglected to mention was that after removing the upper portion of the ribs, the instructions had me add three of the walnut planks on the inner portion of the ship up against the first, limewood planks. That also helped to hide my sanded glue marks from gluing the first planking on. Then the railing went on. Transom As I mentioned, I had to build out the stern portion of the rail. After doing that, I covered the inner part of the transom with 0.5x3 walnut strips vertically. I did this and then from the exterior cut out the portholes in the back. The instructions again told me to bend a piece of 2x6 for atop the transom, but again, I found that piece in the laser-cut plywood. (No mention in the instructions) Now, this plywood loves to delaminate, which I had already experienced. I don't know if it's in the original gluing or a product of having sat in a box for too long, but I knew soaking it would not be the right choice so I used the evil crimping-type plank bender very carefully. I applied that and clamped it in place. Below is the completed transom The instructions say to use 0.5x4 walnut laths horizontally for the stern of the transom, but I didn't have those. Not sure if that was neglected in the kit, there is a remote possibility that I misplaced those or used the wrong wood somewhere (not sure where I would have and I was meticulous in keeping the part together so doubt I lost it) but I didn't have it and taking stock of what I had left to do, the amount of 0.5x3 walnut lath was not going to be sufficient to complete it. I also dry-fit it and it didn't look right so I opted to order 0.5x4 walnut lath which it turns out was a spectacular idea. The wood itself is a much nicer quality than what is included in the kit. Unfortunately I ordered it from Model Shipways out of Australia and I am in the US so shipping was a bit expensive and took a while. While I waited for that, I moved on. The Deck Next is the deck. The instructions said to glue the deck piece on and then apply the lath. I had seen several videos and posts of people building the decks of their ships and every single one showed the deck being planked before being fitted to the model. Nevertheless I opted to follow the instructions and glue the deck in first. The deck has a sweep and a rake to the sides, so I rationalized that the reason for the decking going on after was to allow for that. Now, here comes the big mistake. I put the dowels to be used for the masts into the holes on the deck to line the them up. Looking at the plans and Chapelle's book (Strange coincidence, I happened upon a copy of if when I wandered randomly into a used bookstore and of course had to buy it) the masts rake back about 15 degrees. User PChem530 documents this in his build log, but unfortunately I did not see any of that until later. I glued the deck down being careful to ensure the very slight rake of the deck was reflected and then moved on to the deck planking, which you can see in-progress in the glam shot I took for social media below: A couple of things to note about this -- First, there is a gap (as PChem530 noted) between the deck and the bow, I built the jig as suggested in the instructions, and I used pins to mark the centerline of the planks. With pins placed less than 80mm apart it makes it easy to line up the planks on center to glue them down. I meticulously glued each one down rather than slop glue on the deck and place them. I didn't have the confidence to be able to do the planking in time and didn't want a crust of dried glue under my planks. The gap I filled with scrap (not pictured) but did a poor job of it and some of the planks are still "floating." We'll see how that works out. The Portholes I knew I had to carefully measure porthole placement against the plans because a lot of the exterior hardware depend on that placement. There is one issue, however. The chain-wales (part 6 in plate 2) do not fit between the portholes. I ended up trimming them a bit and I will get to that in the post about that part, but keep that in mind if you are following along. The chain-wales included in the laser-cut kit do not match the plans.I don't know if that's intentional to give you more material, but that's how it ended up for me. Your mileage may vary. Finally, the instructions say to line the portholes with the 0.5x3 walnut lath. Astute readers will realize that that area consists of planking width of 1.5mm and 2@1mm for a total of 3.5mm. 3.5 >3... so that means the lath does not quite fill up the inner part of the portholes At this point I did not have my 0.5X4mm lath from down under, so I went ahead and did it. I may end up ripping it out and redoing it. Below shows the best I could do with that gap, as well as a teaser for how it looks today:

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Thanks, I’m past that point and didn’t think to check it against the plans. One of those learning things I suppose. What I did was drop the masts into the holes and make sure both sets lined up, I poured over the plans but somehow it just didn’t occur to me until later as those two sets just lined up so nicely.

-

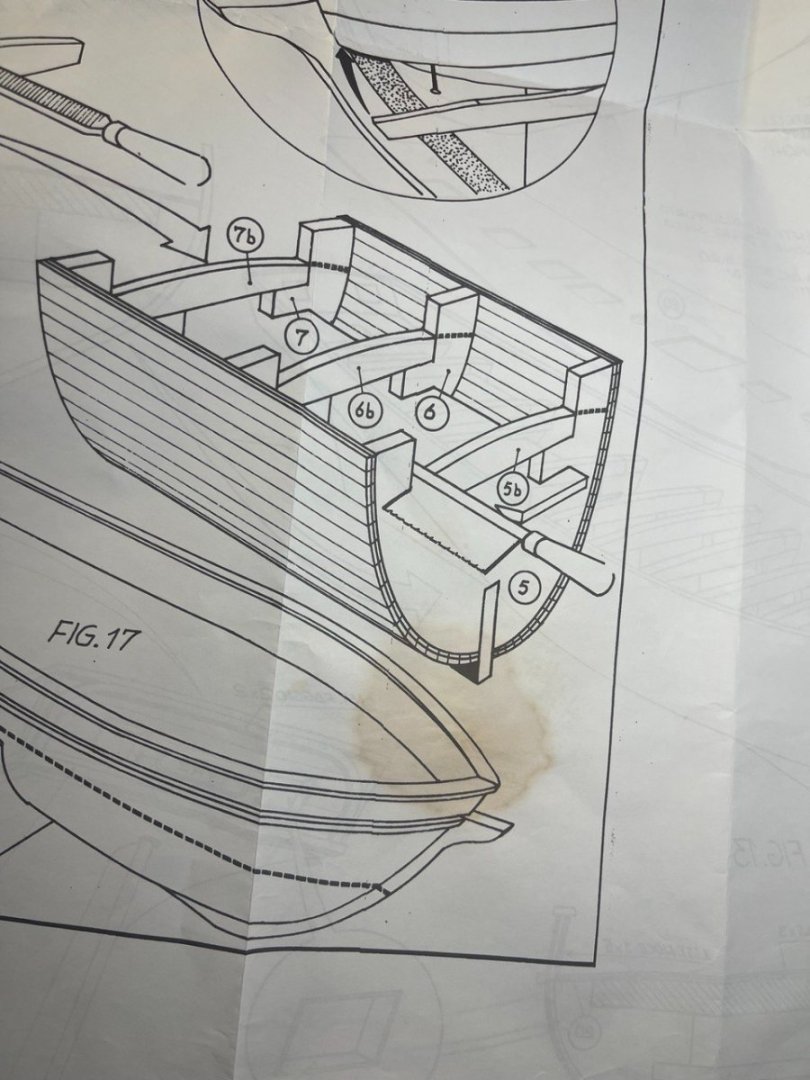

Part II part 2: The Return of the Plankening Having completed the first planking, I then spent a lot of time sanding and filling. Alas, I don't have photos of that, but my goal was to get it as smooth as possible. I felt that any imperfections in the first planking would be accentuated in the second planking. It also gave me an opportunity to hide some of the issues I had with the first planking, such as the aforementioned cracked boards and odd bends. This time I used the proper tools and was able to bend the planks more smoothly. This is aided by the fact that the second planking is done with 1x5mm walnut which bends a lot more easily. Some of the planks ended up needing a bit of a twist and it was difficult to coerce them into the right shape. I think a proper planking plan would have prevented poor planking, but in all it worked out well. I was more or less following the "Template" I had created by doing the first planking. The below image was taken recently but shows the end result. I also went too far down on the keel with the planking, so I don't have enough keel showing. I may need to build that up a bit. In any event, the planking completed I moved on to the rest of the vessel. The next step is to cut away the upper portion of the hull framing after inserting the beams across them. The helpful diagram shows how to do that in an impossible way because you can't get the correct angle if the saw has a handle. If I had coping saw, I could have done it easily but I just laid the Xacto saw blade flat against it and managed to get it done slowly but not painlessly. I don't have photos of that process, but below is the diagram of the impossible task. Oh, remember how I said I glued the planking on? So now I had to remove the upper part of the planking which is why you might want to avoid gluing. I knew that I would have to do that when I got to this step, so I had done a bit of prep in loosening the glue and had glued only lightly with wood glue. As it turned out, the pieces snapped off easily, though it was a step I was apprehensive about. Then came the railing. This is where the instructions begin to deviate almost immediately, a theme that is continuing and worsening. The instructions tell you to build the railings from 2x6mm walnut. My kit does not contains 2x6 walnut but does contain a laser-cut railing which I surmised to be the proper part for the job. Those are included on the sheet with the deck and a number of other pieces. I glued those on but they did not quite fit. I ended up fashioning a bit extra from the same board and attaching that. I'm not sure what, if anything, I did wrong. Below shows the addition, though this is after a few more steps I consider three possibilities of what may have caused the shortage: What I thought are the railings are not, but they are not noted anywhere else in the instructions or diagram I assembled the frame incorrectly. I don't know how I could have, it snaps together. The pieces are cut incorrectly. I am still unsure that this is the case, but it's all I have to go on. The interesting thing is that if the rails and deck move further towards the stern, it would help with the rake that is missing from my masts, which is a bridge I'll have to cross later.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

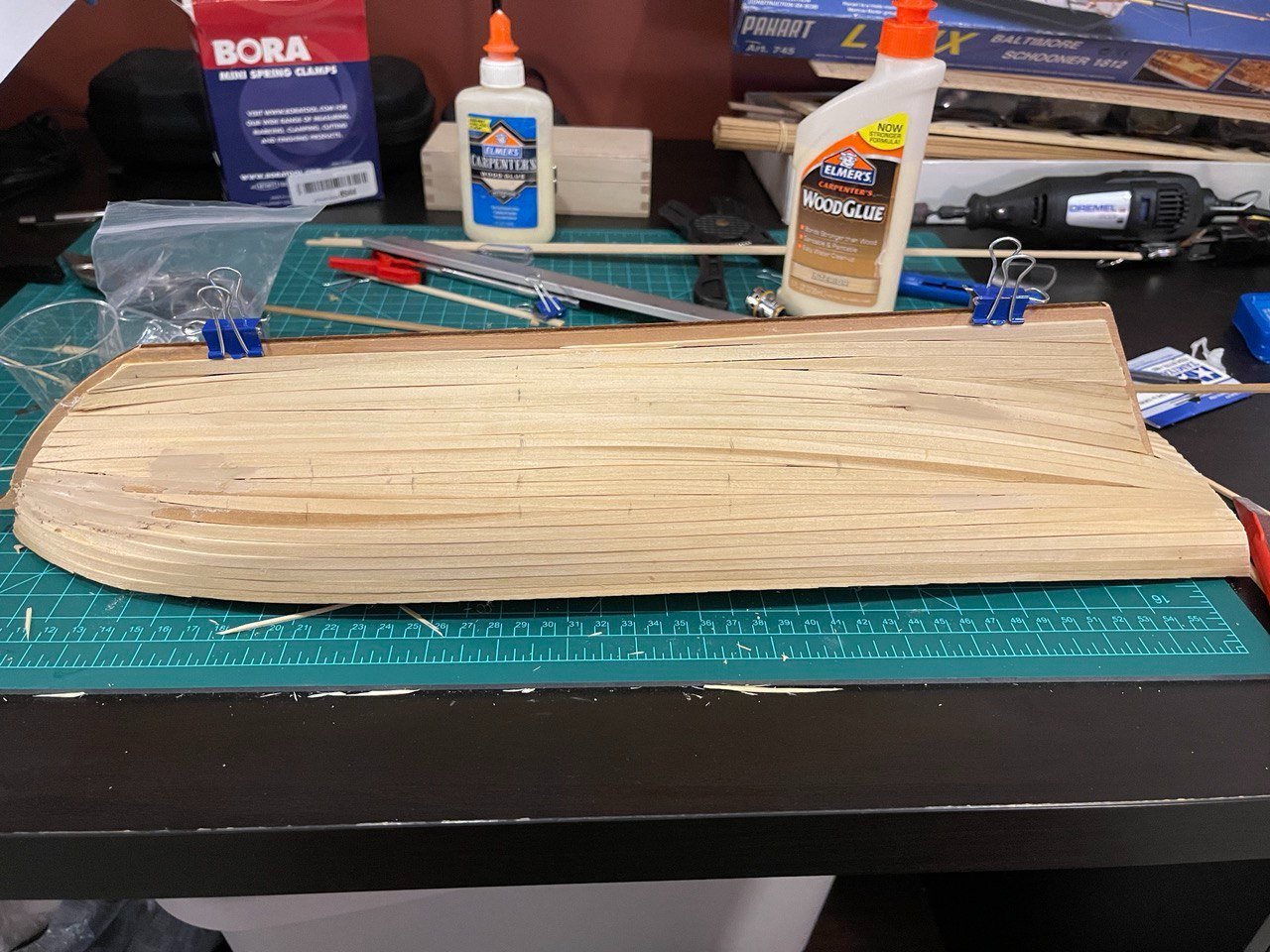

Part II: The Plankening Never having done planking before, I turned to YouTube and found a number of videos instructing me in about as many ways as there were videos. I looked for a planking plan, but didn't find anything so I decided to just wing it. I will say, the instructions come with a nice illustration showing about where planks bend and where to trim, so I had an idea of what it should look like. The most important part was that the top four planks must be lined up and even as they will be above the deck. So I did those four on each side. The instructions said to put the planks in with brass nails, which will later be removed. I see that on this forum a lot, but I had no success with that. I tried with a hammer and the nail bent, I tried with a nail pusher thingy and the nail bent and the few I was able to get on took a lot of coercion and pain. I ended up abandoning the brass nails and went with gluing the planks on and holding them in place using the binder-clip trick. I'm not 100% sure I was supposed to glue them, and in fact further steps indicate that maybe I shouldn't have, but I did it and it worked. Another mistake was the plank bender. I used the grippy one. I ended up cracking some of the boards and with some pretty harsh bends. I wish I had discovered the soldering-iron type which in later bendings worked much better. But my progress slowed considerably at this point. I would take out the model, bend a plank, glue and place it and then let it dry and then only when I was bored and had some time. So my first planking took a few of years with on and off modeling. Partly this was due to not having dedicated place to work. I'd pull my rubbermaid container out, pull out my tools, bend a plank, and then put it away for a month or longer. Then 2020 and the pandemic came along with telework, the result of which was much home renovation. The last of the renovations included an office/hobby room for me and we were off to the races! I managed to complete my first planking a mere 5 years and 7 months after starting the model.

- 25 replies

-

- Baltimoe Clipper

- baltimore schooner

-

(and 2 more)

Tagged with:

-

Yeah... I am building the same and I did not adjust the deck, I was wondering how I was going to get the rake, but assumed that it would become evident as I built it since it was clear in the plans and in Chapelle's book. This will be interesting for me.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.