-

Posts

170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SaturnV

-

The DB250 is very good for small stuff. For spars and masts it has a through bore in the chuck so length is not an issue. It will not pass large diameter dowels though so there is a limit. The motor is strong and variable for its size. I have one with attachments and am quite satisfied with it for turning tiny parts. You will need tiny chisels for it. Richard

-

Daniel, the wife has already banished the jig to my work desk and the work desk doesn't fret the scratches. I would say that you could put several things on the bottom bolts to make them softer but the nuts on the hardwood desk is the most stable. I'm happy withit as is. :-) Minnie me just stares at me while I work. Doesn't seem to want to help... Working on the frames now. Decided to start with the easiest first, frame 0. I'm using applewood and it is coming out well with clean straight joints and really smooth finish. Several folks have suggested doing the whole ship in applewood so I am reconsidering remaking the keel. I'm not real happy with the way the rabbit came out so a remake might be in order.

-

Thanks for stopping by Daniel. The threaded rod goes all the way through the board and there are 3/8" nuts and washers on the bottom - the threaded rod does not protrude out of those nuts on the bottom. The nuts, being of uniform thickness, give a nice level surface on the bottom board. This setup is not recommended for use on top of nice furniture because it will scratch whatever surface it touches. I left the threaded rods long so they can be used for other things in the future after I am done with this project. Richard

-

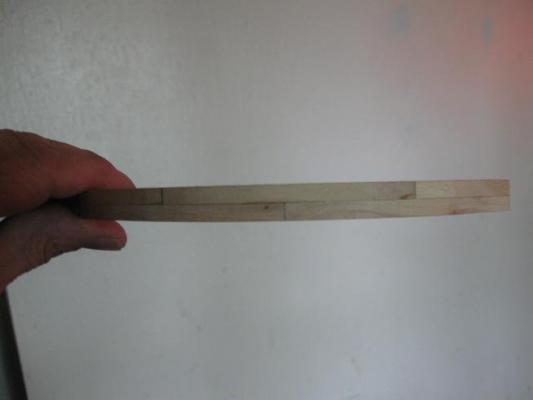

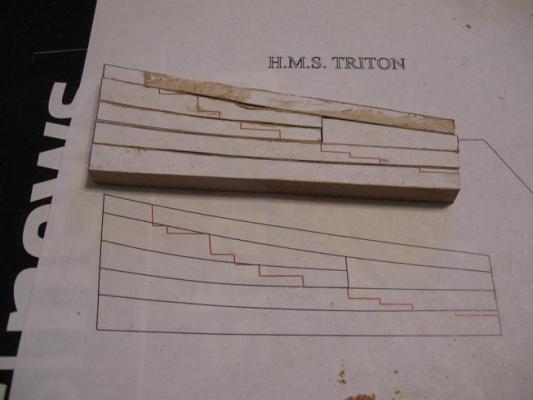

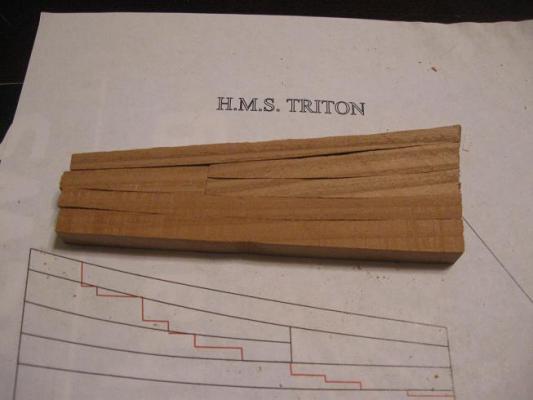

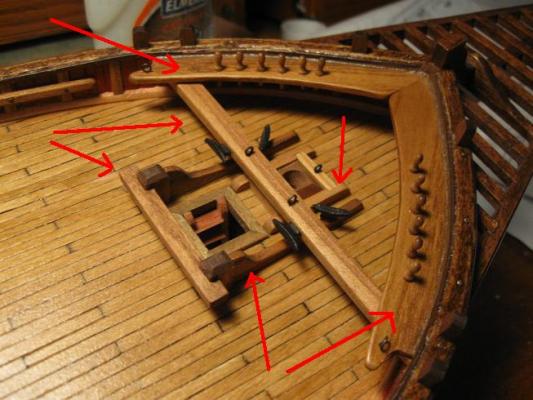

I have completed the bow portion of the keel and also all of the way back to the stern deadwood. I want to install the false keel before proceeding with the installation of the stern section so I am concentrating on that at the moment. The false keel is rather thin and I have to sand in the interlocking joints (term for this?) on them prior to installing. Should prove to be a learning experience. The false keel will be made from some walnut I collected from a friends house. He cut down the tree 10 years ago so that now the logs are perfect for modeling.

-

Thank you Matrim. That is a good idea. I will go home to tonight and try to get an appropriate picture of myself. I have another question, on the frame drawings for frames 28 through 19 there are degree numbers - i.e. frame 28 says 29 degrees. Is this the amount of twist in the frame from top to bottom? Richard

-

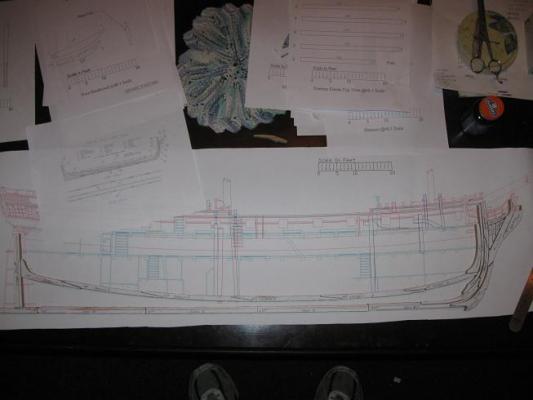

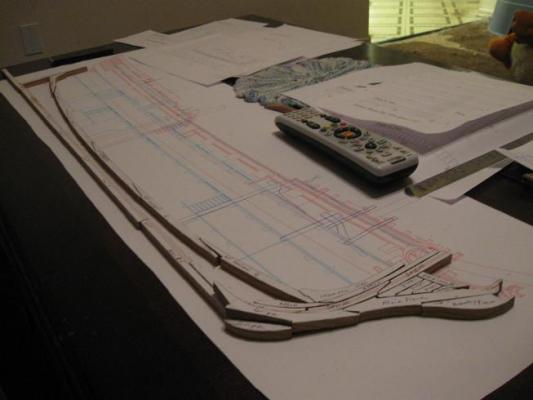

All, A couple of questions: 1) On the Jig Plan, is the "support post template" the height at which the plan should be placed above the the building surface? I think it is, but wanted to be sure. 2) Where do you all get the picture of the scale sized little man holding the stick? =) I see this guy in several posts and wanted one for myself. Thanks ahead of time for any responses, Richard

-

Hello all, I have made some progress on the deadwood over the weekend. This is much better than the last attempt and I feel confident that I can move on to the fore deadwood now. It is difficult to take a picture of a taper but with the right shadows it kind of stands out. Here is a picture of my work in progress on one side of the deadwood. I think I will save the final sanding of the taper until I get some frames made up for that area so I can get the taper to blend well with the frames:

-

Hi All, Started the aft deadwood section. I cut out the pieces and have begun sanding them to fit each other. Used my new Jet 14" with a 1/8" blade - works very well. I just need a steadier hand and some practice but what I have done so far is acceptable. Once sanded completely I will post more pics. Looked into those books you all mention. Pricey stuff! It will have to wait for a while before I can gather the money to buy them. Maybe the begining of June I can get the first volume. Richard

-

Heres is an article from a newspaper in Montana about their problem with this tree. They should let me go in and cut it all down for my own use! =) Of course I just want the trunks. They can keep the small branches and the thorns. http://billingsgazette.com/news/state-and-regional/montana/non-native-russian-olive-trees-a-nuisance-to-some-savior/article_57cef300-7f09-11de-bffd-001cc4c03286.html Richard

-

Thank you all for the welcome - you guys are the best! Russian Olive is a local tree in the Denver, Colorado area. It grows wild but is not native. The state considers it an invasive weed however I consider it good fortune. There are lots of them that are cut down or are dead so the there is a plentiful supply of already dry wood to collect. It takes a nice edge, can be cut small yet remain strong and I like the color. I am trying to figure out how to post a picture on the new MSW 2.0 Twas'nt hard on 1.0 but I will need some time to figure this one out. I can't do URL's...... Richard

-

Hello all, So it begins. I spent Saturday looking for logs to use for my build. I have a decent pile of Russian Olive to work with on this build. Tonight I will get a tally of what size wood I need to build the keel. Once I have that I will go to the bandsaw and tablesaw, cut the rough size boards, and then run them through the thickness sander to obtain the pieces needed to make the keel parts. I have high expectations for this model - it is grander than anything I have tried in the past but I do so like a challange! I will take pictures and post them as soon as I have something besides a pile of logs to show you. Thanks for having me. Richard

-

Hey, I found you Bob! Nice looking work on the cross-section. You jumped ahead of me on scratch building as I am still trying to finish the Pinco kit. As soon as that project is done I will join you in the scratch building world. So far you seem to be doing quite well with it. Did you get anything from the wood working store on Saturday? Maybe a bandsaw? I picked up a Jet 1220vs lathe so the wife could join me in the woodworking hobby (getting her to build model ships is next). Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.