-

Posts

170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SaturnV

-

Hello folks, I had some warmer weather over the weekend and so made the wing transon part. The part has basically square ends and is not like the other wings below it. I am curious as to how this is to attach to frame 28. It does not meet the frame flush but rather buts against it on one corner of the wing. Have others made this part and how did they attach it to frame 28? The TFFM shows it blending right into the frame (as I think it should) but this is not the shape shown on the individual drawing of this piece. Any help with this would be appreciated. Richard

-

Thanks Guy! To be honest folks, I have been slacking on the model lately. I have been caught up in the Olympics the last couple of weeks and I have many many recorded hours of it to go. I did put spacers inbetween the bow cant frames over the weekend but that was all. Its probably going to be that way for the next couple of weeks as I finish out my backlog but I will get back into the model right after that. I promise.... Richard

-

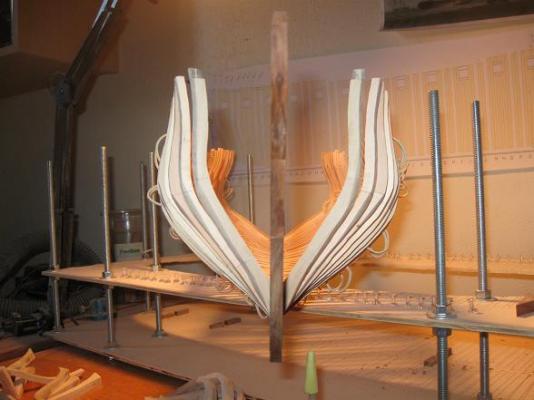

Hi all, Made some more progress over the weekend. Got tired of watching Olympic Curling so I proceeded with the glueing up of the other hawse timbers. I got a little off track on the top of these but I can add and subtract materials as needed here because it will be planked both inside and out - no worries.

-

Thank you all for the nice comments. Lots of sanding and smoothing to go but it does have the basic shape. Randall, after reviewing many documents, books, and websites I ended up using a long metal rod with sand paper around it to sand in the semicircle on the stem. I used one of the side profile drawings for the Triton and extended the line of the boom down to the keel (about 1/3 of the way back from the stem). At that point I knew where to place the metal rod tip on which frame so that when the rod rested on that frame and also on the stem I had the correct angle. I also did my best to check it with a protractor but that is difficult on the inside of the hull. After getting the angle correct on the metal rod I slid the sand paper back and forth along the rod and the stem to sand in the curve. The bollards I just held up to the curve on each side and marked the bottom of the curve onto the bollard so that they would match. There was still some fudging to do because when you start the sanding the metal rod is too high. As you sand the rod moves down and so adjustments have to be made. The hole is really still too small but this is on purpose so that the final installation of the boom can have some play in it in case of errors on my part. make sense?? Richard

-

Hello all, Had a warm stint over the past weekend and so managed to do some rotary work on the hawse timbers which in turn allowed me to glue them in on the one side of the bow. They are only roughed in at the moment and still require quite a bit of sanding to finish them off. It is good to finally see some progress. Richard

-

No skecth or pic available. I did find a definition online: A compass breast timber that crosses the hawse timbers above the edge of the ends of the upper deck planking and over the hawse holes. I think it will look just like the other hooks in that area. I will try and take the shape from the deck framing plans and side view plans. Not a big deal. Just thought it would be easier and possibly more accurate if the actual drawing existed. Thanks for your offers of help guys. Richard

-

Welcome to the Triton build Eric. I'm part Irish and I don't mind you being here. Or maybe my ancestors weren't wanted either! Either way, we don't care where your from, we just love to have new members to the Triton build. We also like lots of pictures and it appears you have that part down pat. Best of luck with your build and keep the pictures coming. Richard

-

You are progressing rapidly Daniel! Nice work. I will be doing as you said - finish the hull before moving into the interior. The construction of the hawse pieces creates a lot of flying sawdust so I have to do the sanding outside. However, it is going to be cold this weekend here in Colorado so I may put the Triton aside and build something else. I have a couple of small models that need building and this might be the time to do them. If not, I will work on the aft cant frames. They are sanded and ready to glue in place. Decisions, decisions..... Richard

-

Hi all, Worked on the first set of hawse timbers yesterday to close up the the remaining hole at the bow on the port side. I had trepidations about making these parts so I put it off until there was nothing else I could do. Turned out, it was not that difficult. I used Daniels picture tutorial when needed to confirm I was doing the correct thing - thanks for posting the pictures Daniel. I used rubber cement to glue the pieces togther so as to get an overall view of how the wood should be sanded. After a while the glue gave way but I had sanded off enough to get a good basic shape to the parts so now I will do each timber individually to finish them up. All in all not difficult and looks pretty good. I'll post pictures when they are done. Richard

-

Thanks Daniel, that is what I was looking for - folks opinion on what to use and how to apply it. I will do some tests on scrap wood to see what it looks like before I go applying it to the real parts that I will use on the model. And yes Mark, my hopes are to make some fiber optic lamps down in the holds to make everything visable. thanks for the help, Richard

-

I built the Pinco Genovese and it was a very nice kit. I got it off of ebay and it was missing quite a few pieces of the wood but it built up into a really nice model. The plans are very good and give you lots of options to improve the final product. I'm afraid though that if you don't like scratch building parts you may want to steer clear of these kits. Richard

-

Listing a very high "retail" price and then having a "sale" price of a lot less makes the deal seem so much better, in turn getting people to buy the kit - "hey, I'm saving $2000 on this kit!" sort of thing. With that said though, the MS price is a really good price for this kit. The model is huge compared to others so in just the materials it would be worth the sale price. Richard

-

I just found your build log Tom. Stupendous job! Funny, all of the problems you had with the kit I had also. They are "erros in engineering" that sure wish MS would fix instead of continuing to sell the kits this way. I would give them a 5 star rating on this kit if it were not for the problems. But like most of us, you overcame and produced a wonderfull boat model. Congrats! Richard

- 153 replies

-

- model shipways

- bounty launch

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.