-

Posts

91 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by StuartC

-

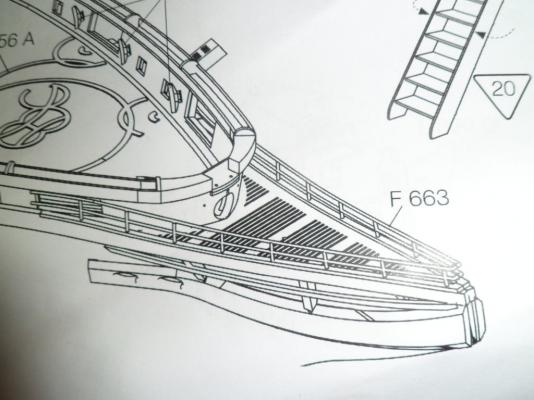

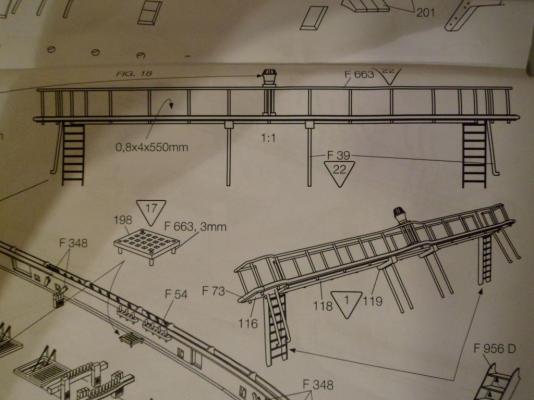

Alright people, I need to ask for help as I'm stuck. Below you will see a picture of the instructions for the guardrail (Part F663 being 0,8mm brass wire). I am trying to set up to solder the bits together, the problem I'm having is that everything I use to hold the parts in place acts as a heat sink, I have ordered a soldering board but I don't think this will resolve the issue. I am using a gas powered soldering iron with the blow torch attachment, so I have plenty of heat, it's just that it is being soaked away from where I need it. I need to resolve this issue as the Bridge structure is made the same way. All help gratefully accepted.

-

Hi Grant, If you look at the actual Warrior the brass work is inlaid, and as much as I would like to do this I've had to take a bite of reality pie, and recognize the fact that the damage I could cause to the deck far outweighs any benefit I would get from trying to inlay the brass. In short it will be stuck on top.

-

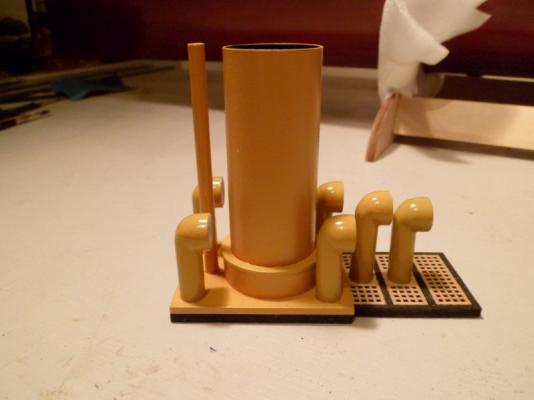

There are times I amaze myself, if you look at this photo of one of the vents, and the fact that both parts are made of brass and given the choice of joining them by either a - tape b - glue c - solder I managed in an addled state to pick b, yes b. Not only that I have stuck with choice b for an inconceivable length of time. Finally in the words of a famous man " I had a dream" that it would be great if you could join two bits of metal together using another type of metal that would melt at a low temperature. I decide to call this metal solder......wait a minute that's been around for ages. So can anyone please explain to me why the xxx I picked glue!!!

-

Hi Glyn, Yep, just measured and it is 70mm. I looked at buying a pre-made prop and trying to adapt it. The problem I found was that the examples I found were: 1. Not cheap 2. Even at 75 or 80mm, there wasn't enough material to adapt. 3. Was never sure that the hub would fit correctly. Taking all of this into account, I decided to get one cast from my assembled version. The two big advantages were that I got exactly the design and fit I wanted, and amazingly enough it worked out cheaper. Basically an all round winner. I never looked motorising it, are you going for the modern solution or the whole steam plant?, either way I can't wait to see how you get on. Cheers, Stuart.

-

Hi jbwok, If you like filler this is the model for you, the planking is purely a base. I filled and sanded for hours to get the finish I was after. If you look at a lot of the build logs with copper plated bottoms, they have a filler top coat to allow for a good finish. There is no shame in filler I came to the same solution as yourself for the gun ports, I made back boxes about 8mm deep, which I attached prior to doing the planking. Here are a few pictures I was sent

-

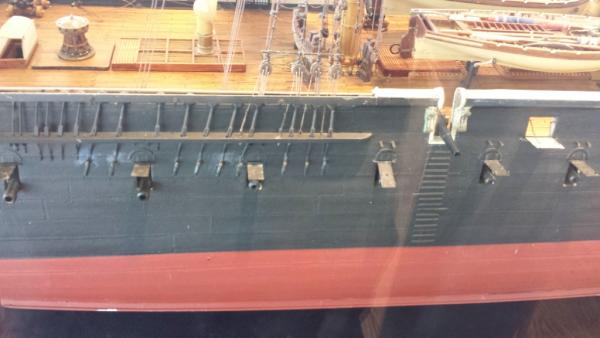

Hi jbwok, I based the protrusion of the muzzles on some photographs taken by someone who had visited Portsmouth Dockyard, and found a very early model of the Warrior in the museum . They also sent me a whole pile of pictures of the actual ship, both of which I have found to be extremely useful. If you want, I will forward them on to you, or I could just post the pictures of the museum model here. As far as the model is concerned there isn't a lot of detail that could be added. One thing that was suggested would be to simulate the plating, but I personally didn't do that, as from any distance it just wouldn't be visible, I'm finding that most things added to the hull once painted black just seem to disappear anyway. Having said that I really like the lines she has, but it is never going to be as detailed/busy as the Victory or any other model of that ilk. If there is anything I can help with let me know, but as this is only my third model I don't have the vast experience of quite a few of the members who post on here. Try starting a build log, as you can see from reading them, this crew are a really friendly bunch and will give you any pointers they can. Cheers, Stuart.

-

Hi Jase, I should really read the full post, and not just the PM before replying. I see now you are not quite based down south . My inlaws live in Portchester, and I keep promising to get down there, but life keeps on getting in the way. There's always next year. In the meantime thanks again for the offer. Cheers Stuart.

-

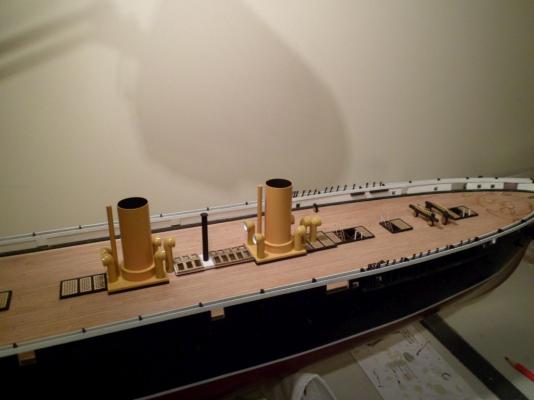

I haven't been posting any updates, because I thought I would wait until there was some noticeable progress. However I have added hundreds of bits, painted them black, and they all seem to disappear . So this is where we are, initial bow fitting complete, chain plates on and hammock stowage's in progress

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.