Don Quixote

Banned-

Posts

1,689 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Don Quixote

-

Okay, so I tossed the first attempt. This photo is from the 2nd hull. I still have one more keel and bulk heads after this one. The bulk heads are only fit in for a dry run. I broke of the aft part of the keel. I think it'll be okay, it's right where bulk head N goes so the bulk heads should be sturdy. I have one biulk head that's warped. I put weight on it for 48 hours to no avail. Suggestions?

-

Hello, fnkershner. First of all, this plank job is 100% practice. Using one planks means twisting this way AND that. I'd rather break it down to what *I* feel is a manageable plank. I've tried beveling the whole plank, then bending and twisting. For me it's not practical. Like I said, the bulkheads are so screwed up that the very 1st plank didn't lay straight. Now I have the dip, or curve I mentioned in my last message.

-

Because the bulkheads are so far outta whack, the first plank could not follow correctly. That is now causing me to ever so slightly push up on the plank being installed. See the gap? At this rate I'm going to have a problem. I can either continue and hope the garboard plank fills it on, or I can let the plank lay naturally and fill the gap in with wood filler. Which would you do? Also, I have a FEW planks staggered but towards the bow there's not much staggering.

-

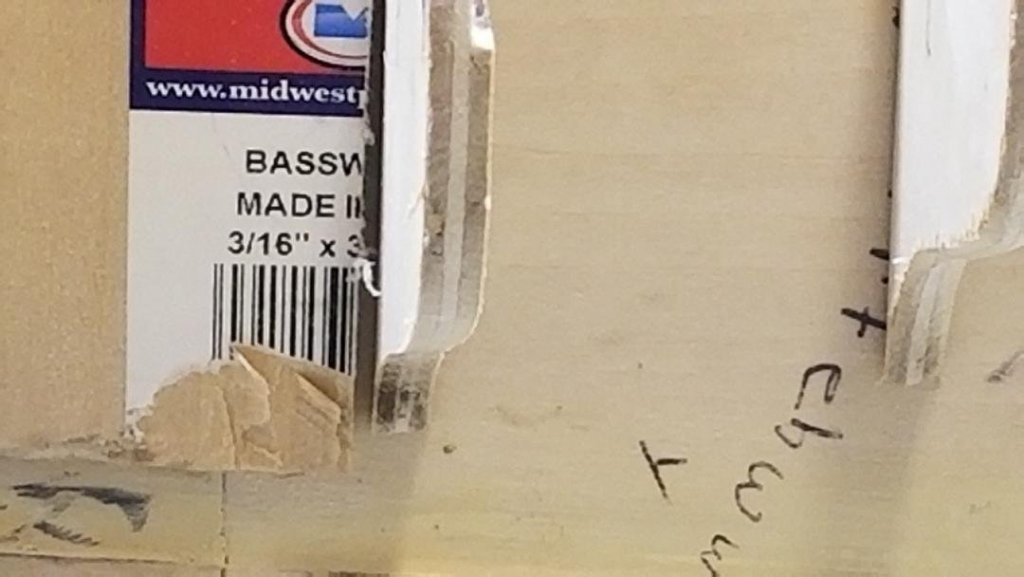

First of all, the planks that come with the kit are long enough to cover the entire length of the ship. I don't want to do it that way. I want to stagger the planks. How does one go about planning the length needed? 15 bulkheads. And I am one LUCKY ducky. Model-expo sent me 2 sets of keel and bulkheads. Since I already have 2 ships, and I bought better wood for the planking so I should have enough to practice on 2 hulls and use the good wood on the last that I'll complete.

-

Amateur, You were of course right. Lots of wood filler. I call it bondo. Some sanding down but not too bad. I'm just going to play around with the planking, but I also have another problem I didn't catch. There are 2 blocks I used to square the bulkheads that extend too far down. I won't be able to planks the entire bottom 1/4 of the ship.

-

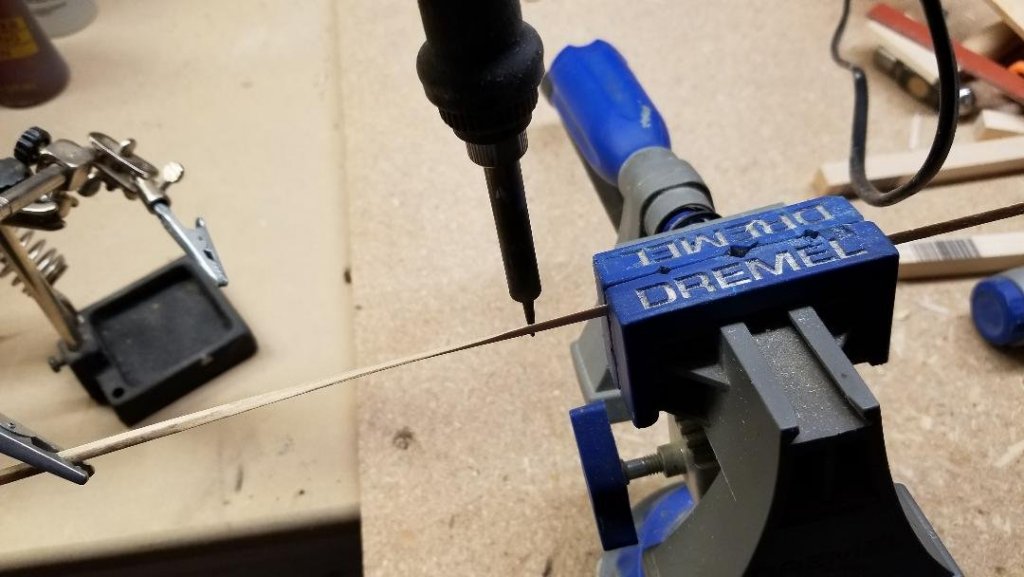

Contacted model shipway's, they said they don't care why I need the parts, they'll send them to me. So, I broke the keel at the bearding line. To make the line, I took a #11 x-acto and cut the bottom line, then using a curved blade (I don't know the number) and carved out the beard. Any better ideas?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.