-

Posts

62 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bucknbarney

-

Thanks for the great compliments! Floyd, I want to have the prop in so my boy can use it when he wants to take my place as captain. Nenad, as far as placement in the home, I'm hoping (up to wife, of course!) to build a shelf for it to be placed right on the wall behind the dining room table! Wish me luck on that!

-

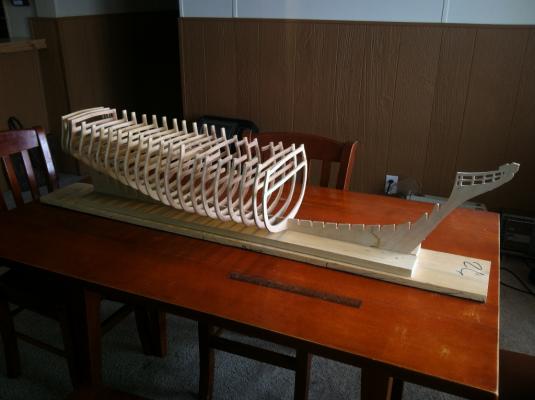

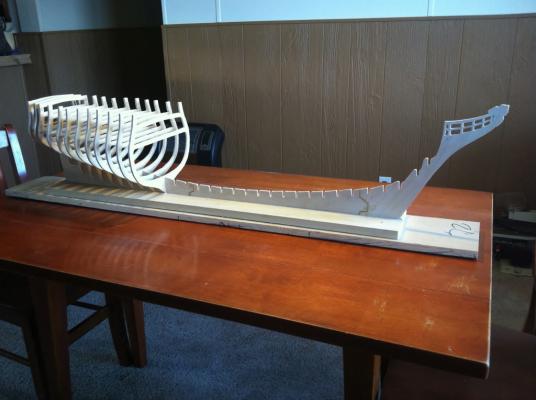

Here's my latest pic of my SLOW progress. Being a full time dad, full time husband and full time employee, I don't have a lot of time for my hobbies! lol Only 12 ribs to go! I have not glued any of the ribs down as I am also researching where I'm going to be putting my controls. Per some good advice given on this great site, I'd like to be able to work on the keel without the ribs attached when placing things like the prop and the detachable ballast plate.

-

While reading Nenad's posts on his build, he wrote about jewelry tools and supplies. It reminded me that my wife, who's from Colombia, used to hand make jewelry using native Colombian seeds (beautiful stuff). So, I dug out her equipment and supplies and found all kinds of stuff I'll be able to use (after asking of course!) in my build! So many good things on this forum! I also have to say how deeply impressed I am by all of you. I am used to working with rough, full sized building materials and you guys make things so much smaller look so much more beautiful and intricate than anything I have ever attempted. I am in awe of you all, and if I can make this build look even nearly as amazing as the models I have seen on this forum, I will be very happy!

-

Cutty Sark by NenadM

bucknbarney replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Nenad, My wife is from Colombia and she used to hand make native Colombian seed jewelry (very beautiful). I actually just re-discovered all her equipment today and I am blown away at all the goodies she used that will be useful to me (after asking, of course), from different wires, to threads and rope to small tools that will be perfect for working with all the rigging! You are so right my friend! Thanks for the great idea!- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Found some scrap soft maple at the shop and used the smaller planer to plane down some strips for planking material. Got them down to about 2mm thick. With that, I'm thinking about going 5-7mm for width of the planks. It took a couple hours to plane them all down, but I like the price... FREE. On a side note: I purchased a metric ruler and decided to try it out. Now I have one question America..... WHY THE HECK AREN'T WE USING THIS?!?!?!?!?!?!?!? It is soooooooo much easier than standard!!!! OMG!!!

-

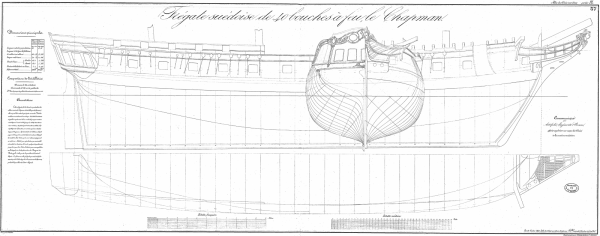

Thought I should show the pic of the plans I'm using. After a LOT of research, I'm finding that these just don't offer a ton of detail to assist me in accomplishing this build. The plans came with some PDFs that someone else had created and offered of the keel and ribs, which I am using to help get me through the framing of the main part of the hull. The rest.... must have flown out the porthole, along with a bit of my sanity, because I can find nothing else on this particular ship, which I don't even know the name of! I know I can have a little fun wit it, because this lack of info offers me the ability to explore a little artistic expression! still... just a little more info?.... lol As you'll see, it's bad enough that this is my first build, add a great lack of detail and having it be in a language I don't understand is just fun. I'm finding it a pleasurable challenge and have located some ships that were similar, like the Unicorn, that I have thought about taking ideas from. If there is anybody out there that knows what most of this plan says, or knows of similar frigates I can use for better reference, I am completely open to suggestions!

-

Thanks for the solid advice Cap'n'Bob. I have had that same thing on my mind for a bit now. After reading up on some of JerryTodd's builds, such as the Pride of Baltimore, I am actually now considering going at the hull in a similar fashion to his. Being that I am, in the end, vying for a workable R/C model, this seems to be the best route.

-

No,it is thankfully not in a u-shape! You've got a LOT of experience Jerry so if you say still use it...I'm using it! I've been considering the Hahn method as well. I have been thinking about how I'd ensure that the frames where plumb and level when I glued them and was thinking about using spacer blocks, 90 degree angle braces and clamps. Still, it appears to be a little easier, after the building base has been made, to use the Hahn method.

-

Well!! first of what I'm sure will be MANY wonderful pitfalls in this build of mine.... Noticed this morning that the keel is bowing. Being that it is 1/4 ply, I can't steam it or go any of the other routes using heat to straighten it as I will delaminate. So... This morning I attempted a fix by just moistening the outer plies on each side and placing the keel on a flat surface with weights to keep it flat while it dried during my work day. Came home and checked at it is straighter! But... alas, it is not perfect. I'm going to attempt it again tonight with the hopes that it will straighten out even more over night. Anyone have any suggestions? I even asked several of my co-workers (I'm a carpenter) and they couldn't think of anything better besides just scrapping the keel and cutting and filing another. I don't want to have to do that!!! But, I will if it comes down to it. Well, like most projects, there's always something else to do while you wait. So, back to tracing, cutting, and filing more ribs!

-

Cutty Sark by NenadM

bucknbarney replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

OMG! Nenad, this is beautiful man! I am so stoked to get where you are now! Many kudos to you!- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Thanks to all for your awesome help and encouragement! I am planning on keeping this log up as much as possible. Thought I should throw out there that I am hoping to have this model floating by summer and all the masts, yards, sails, rigging and R/C components finished by fall. This may be a bit ambitious, but that is how I am! Lol

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.