-

Posts

69 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Capt.Bob

-

Ed, A very creative process, as usual. Can I assume that the boat drawings will be included in Volume II? Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ed, Question about pin (iron pin) locations. Some of the pin locations in the 5th futtocks of the last few forward square frames actually exceed the outer edge of the opposite face, (starting about P). I wouldn't imagine a shipwright would place the 1" iron bars that close to an outer edge. Should they be more closely centered ? Also, some of the pin holes are located very close to the end of some futtocks. Many are closer than the thickness of the futtock. Are those really scale locations? While I'm here, Pattern Ra has all the segments marked Rf. Just about finished with all the square frames. Can't wait to get to something different. Bob

-

Hi Ed, Here are a few items for the revision file. 1. Page 57 First paragraph. Is: "...and pushed through the hole; See Figure 5-26..." Should be: "See Figure 5-27" 2. Pattern Af: No siding reference. Missing 2 holes in Floor (both f & a) 3. Pattern Aa: 5th Futtocks "110" Should that be 11 or 10? 4. Pattern 27a: Missing top hole in 5th Futtock 5. Pattern Ea: No parting line in the floor timber 6. Patterns Ea/f, Fa/f, Ga/f, Hf, Jf : No siding or futtock data Bob

-

HI Aviaamator, How is your new model milling machine coming? Anything new? Did you rebuild the lath in the picture? What is the story? How is life in Petrozavodsk? I took a tour of your city on Google Earth. There are many photos of the city and the lake. Lake Onega must be very nice in the summer time, but lots of photos of ice in the winter. Also, I read some history about Peter The Great and the original iron foundry that started the city in 1703. I have only practiced a few things on my new milling machine. Milling is easy, Setup is everything!! Bob

-

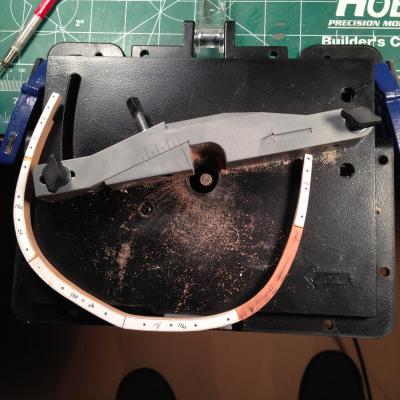

Ed, Thanks, Ordered a life time supply, which really isn't that much. After reading your section on paring the fetlocks down, I tried using the small Dremel router table. Since the amount of material to be removed is so small, it is very difficult to control the depth of cut. With the router table accurate cut depth is easy to establish and maintain. A little paring to square off the ends and you're done. Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Getting ready to add the iron bars to the fetlocks, but can't find any black mono that thick. I've been to all the fishing shops but no one has anything close. Point me in the right direction Obi Wan. The Force is with you. Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Well worth the wait. Well done. Just bought a 12 piece set of Grobet 4.5" #2 files. Now I know where to use them. There're pretty pricey, but that first stroke will tell you where your money went. Still make square frames. I'm up to 25 and almost ready for mounting. I haven't figured out any real improvements on the pin process except being more precise. Always concerned with pattern alignment on opposing faces. I certainly understand your desire to move on. Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Can't wait to see the hand wheels. BTW where did Santa find your new toy?? Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

New mini-mill... CNC and impressive

Capt.Bob replied to mtaylor's topic in Modeling tools and Workshop Equipment

Extravagance in the pursuit of excellence is no vice. -

Hi Ed, Thanks for the explanation. I don't have CNC on my milling machine, so making the fixture manually will be a significant challenge. I have been toying with some ideas about mass producing the hundreds of knees that will be required. The idea would be to make a generic form similar to molding strips that are cut to size and individually sanded angles to fit each application. The redundancy of frame fabrication has got me looking ahead. HI druxey, Nice alternative solution. Thanks, Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Interesting process. A couple of questions. It appears that the 1/32 stock wire is "inserted" into the fixture and is restrained at the handle butt and the end of the pin shank. Otherwise, the file pressure would risk bending the pin. Its a little hard to determine from the photos. True? At what speed are you turning the stock? With such close tolerances, alignment seem quite critical. What cutters did you use to cut the handle profile on the mill? The 0.021" shank of brass is obviously very thin and fragile. Any problem with the pins bending? I'm not familiar with iron pins. Your prototypes seem to have a very long shank compared with the handle. Is that typical of iron pins? Will these be trimmed to a different length? Always looking forward to your posts, Bob P.S. My YA is progressing, I've been making frames, and frames, and frames, etc.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Thanks, no need for lengthy explanations. Like you, I spent my career reading and writing technical documentation and contracts. Never found a perfect document. I lost this site or I would have posted here. Take care, Bob P.S. Found a copy of William Crothers "Freighters & Packets". My library is getting expansive as well as expensive.

-

Hi Mick, It's 3:30AM. Can't sleep. I found Dieter "Schmid" Fine Tools. (www.fine-tools.com) They have a lot of variety. Thanks Time for coffee and saw dust. Bob

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Mick, I'm saving your thumbnails of the hawser frames for future reference when I get to the bow of YA. Very nicely done. Have you got a web address for Dieter Smith Tools in Berlin?? I'm always looking for unique tools. Also, I noted your Lie-Nielsen Model plane. I've had one for years and wouldn't do without it. The A2 tempered steel blade stays sharp forever. I can't recall the last time I had to sharpen it. I also have the Violin Maker Plane. Both are great for modeling. I have been collecting their tools for over thirty years. My son wants to make sure they are in my will. Take care, Bob

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Ed, The top piece of the 1:72 Deadwood pattern. Check it against the assembly template. Seems to be cut short. Just got a new milling machine. I've stated a new folder with your machining thumbnails. So much to learn, so little time. Something about a man's reach exceeding his grasp. Take care, Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Mick, I was seriously thinking of up grading to 1:48, but that was a bit over the top. So, its 1:72. I've just gotten the new shipway built and started on the keel/stem assembly. Like all good modelers, new projects are an excuse for new toys. I'm in the process of setting up a new Sherline lathe. Thanks for sharing. Always looking forward to learning something new Bob

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Mick, Just found the forum. Particularly interested in the acrylic jigs. Too often the lighting is on the opposite side of a fixture and makes things frustrating. I'm starting on an extreme clipper "Young American". I can use all the good ideas I can find. Looking forward to your work, Bob

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Thanks, Ed Should I post any further documentation comments under the book topic rather then here? Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, I have been making some progress on building the keel, stem, & stern. I did notice a discrepancy between the Stern Assembly Template and the Sternpost-Deadwood Patterns drawing. The pattern for the forward sternpost timber (between the sternpost and the sternpost knee) do not match the Sternpost Template drawing. The pattern appears to be incorrect. It is too short and lacks the tenon to mate with the keel. Meanwhile, my scarf joints are improving, You were right to warn about closely matching the stem and stern template drawing. The slightest variation in the scarf joints throws everything out of alignment. Take care, Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Thanks David If others have some recommendations, please send them by PM. I don't want to contaminate Ed's great forum with peripheral stuff. Thanks, Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Thanks for the excellent explanation of the wheel machining process. I have to admit that I would not of had the confidence to wait to finish the spoke handles until the end. I would have done them before final assembly in case a spoke broke it would be easier to replace then the entire assembly. While on the subject of lath work, a small lath has been on my wish list for years. I could use some advice from the experienced population. What would be the first choice regardless of cost? Take care, Bob P.S. BTW I just received my new Jim Byrnes table saw today. I think I'm in love.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Thanks for the clarification. Guess I have to bone up on the proper period grammar. I am slowly getting oriented. I have managed to screw up almost everything from the false keel upward and had to repeat many operations. I've learned to be very careful about sorting stock material and keeping it clearly identified. I've picked up the wrong piece more than once. However, my efforts at making acceptable scarf joints is improving. The devil is in the details. Bob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.