-

Posts

441 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael101

-

hello everyone thank god i start to work on the rattlesnake (model shipways) now i need to make the rabbet/bearding line and is my first time to do it (my privius ship its of mamoli and ther is not bearding line ) with the rattlesnake model its recomanded to glue the keel with the center keel befor cuting the rabbet line so i did it like it says on the constraction i have all the tools from hobby knife til dremel... but i not have a chisel and i cant find smal chisel in my cantry only from ebay but it will take a while until i will recive the order from the ebay please help best regards Michael.

-

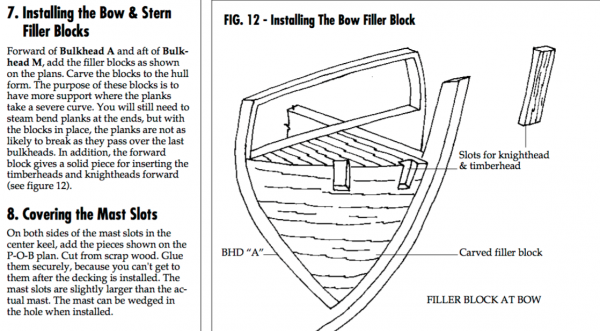

Thank you all ! I'm going to work on the rattlesnake of model shipways And now I'm checking the plans ... Hornet The block filler is to smal so I can't do as the tutorial it's will be very smal pices to work with... CaptainSteve can you explain me the steps again my English is not very well but it sounds interesting the guide that you wrote Also I didn't understand what you wrote about the levels (what levels mean?) Thank you Michael.

-

HELLO EVERYONE i see this tutorial on the internet perfect and easy to build !!!! but im just need the Measurement for our hobby i guess 20 cm long , 7 cm wide , 4 CM Thickness . but correct me if im wrong here is the link :http://forums.toymakingplans.com/post/udies-diy-block-plane-sander-7226203 best regards Michael.

-

fairing technique

michael101 replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

hello Jan the frames are very bad cut even the drawing are not Symmetric Nigel but how can i know if the first and the last one are ok maybe they are too high and the rest are ok? i don't know where to start , i was thinking to start from the middle I mean to work on 4-5 frames from the middle to Fill the frames with lime strip and than to go forward and backward is it sounds ok? thank you Michael. -

fairing technique

michael101 replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

here is example: (i tried to do like Antony advice but i don't know where to start...) side: down the frames: -

fairing technique

michael101 replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

thank you Antony and Nigel Nigel its not going to help me .... like you Sade even the plans are not symmetrical for example frame 9 has 20 cm wide frame 10 has 19.8 wide and frame 11 has 20 cm wide so the solution is or to fill up frame 10 with 2 mm or to sand frames 9 and 11 and to be honest if one side will be a bit fat from the other side even with 3-4 mm of different no buddy can see that in our case that the frames has 20 cm wide my problem is only to make the frames level with the other frames at the same side then i will do the other side thank you Michael. -

fairing technique

michael101 replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

Hi thank you for the answer But I'm not worry about the center the different May be 1-2 mm for frame(and the frame have 20cm wide ) My problem is only to level the frame with the other frames i know how to do the basic fairing but im Afraid to make an error if someone have pictures of the steps its will be grate thank you Michael. -

fairing technique

michael101 replied to michael101's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Antony thank you I have no problem with the keel Like i sade they dident cut properly the frames at the factory about your way to firing its nice i did the same with my first kit but now im working on a very large ship may be i need to Divide the ship to 3 sections and to work part part.... but im sure that there is a way to do it .. thank you Michael. -

hello i just start to work on the royal louis of mamoli and there is a lotttttt of problems with the frames... so i glue them on 90 deg but they Still uneven so far i got the deck leveled and 90 Degrees on the frame Against the kill now i got left(to make level )the Bottom and the sides of the frames (they dident cut the frames properly in the factory !!!!!!!!! ) for that i have to learn how to do the firing properly because i dont want to lose the forma of the ship i know that i will have to fill some frames also (because some of them they are out of the line and some of them not geting the line... ) i dont know where to start and where to finish ... so if you can Explain here in the forum or if you can give me a link for a tutorial i will be more than happy thank you, Micharl.

-

thank you all !!! tomorrow i will get quote from Jim i hope the price of the shipping is not going to be expensive because in Israel we paying 18 precent tax for import i hope to to write you tomorrow that I'm buying the byrnes table saw but if not i will go on the proxxon thank you for all your comments Michael.

-

thank you all!!! Jim i send you email back thank you! Michael.

-

hey Ron thank you for your comment about the thickest i don't know but i need something to serve our hobby about the proxxon is it made of plastic? (the base)

-

hello I have a few questions before I buy a table saw 1 . can i cut strips from sheets by Proxxon (fet) 2 . do i need to buy only mini saw for that work or maybe can i buy real table saw like bosch , makita , dewalt ect. i can't buy the byrnes table saw because I'm from israel and i tried lot of time to send email to hem but never received answer.... anyway in my country i can Choose between proxxon the fet model or to buy "real" table saw i mean the big one... By the way the price of the proxxon its expensive i can bay kind regards Michael.

-

Thank you all !! I love this forum !!!

-

Thank you for the answer But to be honest I don't want to use any kind of paper it's my first build and I'm working on that mor than one year and I never used other alternative than wood or metal So I don't want to start using that alternative in the last part of my model In the official pic of mamoli they post that pic http://ecx.images-amazon.com/images/I/716Uq29HV4L._SL1196_.jpg And you can see that they used ropes on that part of wood the question is for what is used for , is it for making the wood stronger like the ropes on the masts or to making that heavier , and if it's for making that stronger I guess that it's ok to use rope like in the official model of mamoli Michael.

-

hello please someone know how to tie the rope on the anchor on the wood part? thank you Michael.

-

thank you Danny !!!!!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.