-

Posts

66 -

Joined

-

Last visited

About Philthy

- Birthday 09/18/1985

Profile Information

-

Gender

Not Telling

-

Location

Ft. Lauderdale Florida

Recent Profile Visitors

-

grsjax reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

grsjax reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

-

grsjax reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

grsjax reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

-

GrandpaPhil reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

GrandpaPhil reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

-

aviaamator reacted to a post in a topic:

hms bounty anchor

aviaamator reacted to a post in a topic:

hms bounty anchor

-

Mirabell61 reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

Mirabell61 reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

MarisStella.hr reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

MarisStella.hr reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

MarisStella.hr reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

MarisStella.hr reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

CaptainSteve reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

CaptainSteve reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

dgbot reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

dgbot reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

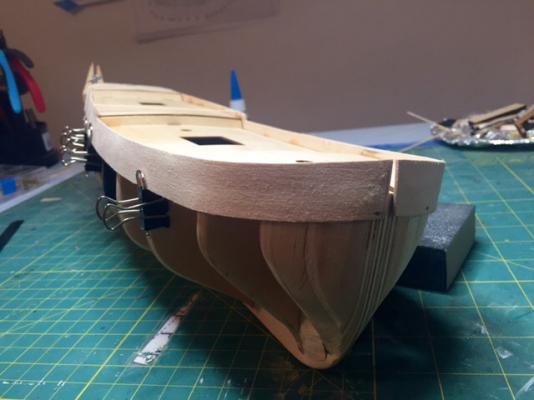

First off YIKES! I really need to clean up my work station. It just goes to show you how crazy the past week has been. I am starting the first layer of planking. After reading and rereading a bunch of different methods on planking I have decided to got with the "just wing it method". The first plank is bending to shape right now and as you can see by the photos I am going to have a interesting time getting all the planks to line up just right. I decided to let the first plank lay naturally since it seems like all the planking methods call for this. Hopefully this will prevent the planks from bunching up too much at the bow.

-

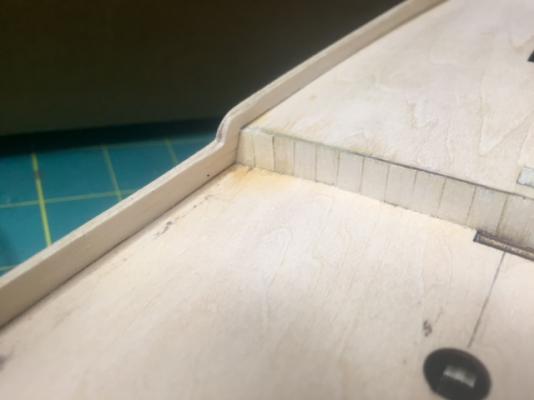

Welcome back sports fans! I haven't posted any updates in awhile because work has been crazy busy the past couple of weeks. During this time I finished up the inner bulwark. Im very pleased how this section turned out after a few days of scratching my head on how to go about this step. The funny thing about this step is I found an alternative source of scrap wood to use on the model. Coffee stirrers found at the coffee shop! I measured out the scale length of about 20 feet or under. Same length I am going to use for planks when it comes time to deck. So I glued and trim to fit my converted coffee stirrers, cut to shape with my exacto blade, then sanded down. Presto-change-o the inner bulwarks are set.

-

Hi John, Good call with test fitting the bow sprit before moving along. I decided not to cut out the half circles on the scratch made bulwarks as seen on the original ply wood pieces. I figured they wouldn't line up (nothing else has) and decided to wait until the bulwarks are set then cutting out the guid holes. As for the scuppers I also decided to wait since they were not lining up with the deck properly. I am still planning on doing both waterways and scuppers to add some details to a rather vanilla kit. I am currently installing the inner bulwarks and when this is set I can add the waterways and scuppers. This seems like a logical sequence the make things easier.

-

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

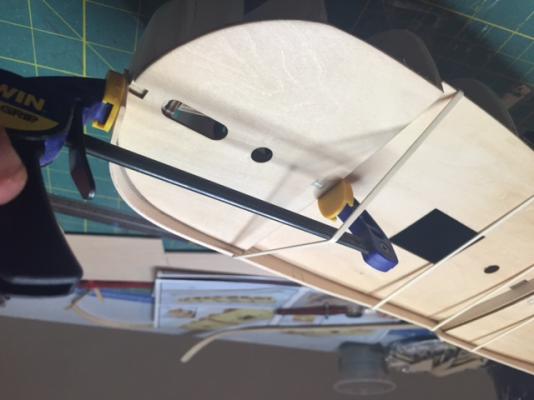

Made a little progress last night with installing the second bulwark and am pretty happy with the results. One side is a little higher than the other by about 2 mm but I should be able to even this out with some sanding to make it hardly noticeable. I am really glad I decided to ditch the stock bulwarks in favor of basswood pieces I made. They simply look and fit better which should improve the over all finished look. I wanted to mention the CA glue I have been using from Model Expo. This product is top notch in my opinion. Your probably saying so what it's just CA glue. I get it, but what I like about it is how thin the viscosity is. Just a touch on a seam and it spreads on out and gives a solid bond in a few seconds. This really helped out in giving me the initial tight bond to the sub decks while I added PVA glue on the insides for more strength. Up next installing the stern post. I want this piece on before I start working on the transom so I can get a better idea of the overall look. Since this is more or less a imaginary kit I'm going to explore some transom photos of schooners from the period.

-

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

I live just down the road from model expos office. Took the grand tour and sadly they are in the process of moving from Hollywood down the road to Miami if I'm not mistaken. Long story short my back ordered fair American took about 2-3 weeks to arrive due to a tool issue that delayed the order. I was not upset in the least since I am busy with my Independence build.

-

Philthy reacted to a post in a topic:

Armed Virginia Sloop by GuntherMT - FINISHED - Model Shipways - scale 1:48

Philthy reacted to a post in a topic:

Armed Virginia Sloop by GuntherMT - FINISHED - Model Shipways - scale 1:48

-

Hi Gunther, After thinking about it I am planning on making a waterway for only the main deck with an edge plank as shown on your AVS. The other decks will have an edge plank as well with nibbing. I realized that prepping for working on the deck is a little premature at this time since I have other tasks I would like to finish up before moving on. The plan for this week is to install the starboard bulwark piece and start work on the transom. The kit provides a metal cast transom piece that looks plain awful in my opinion. So it looks like I get to learn how to make a transom, windows, and decorative trim! I will be sure to post some pictures when I get both of the bulwarks glued on if free time allows in a day or two.

-

Ok so I have a question for the forum. Should I do any decking work i.e. waterways before I install the bulwarks? I have been snooping around some other build logs and it doesn't look like waterways are found on decks other than the main deck. This kit does not provide parts for this so it would have to be scratch made. Unfortunately the plans and instructions only call for a basic deck planking layout and I am tempted to add upon this in the form of waterways, hook and scarph at the bow, and staggered planking with treenails. I am a little hesitant about doing the extra deck detailing since this would be my first attempt at this, there is no clear how to for this kit, and all the parts would have to be custom made. Here is my thought process on this. Before I install the bulwarks I would use a template to cut out the waterways from a sheet of basswood. I can then sand them down to reduce the thickness since my deck planking is very thin strips about 1mm thick. By installing the waterways and perimeter deck planking I can ensure there is minimal gaps when its time to install the bulwarks.

-

Philthy reacted to a post in a topic:

Armed Virginia Sloop by GuntherMT - FINISHED - Model Shipways - scale 1:48

Philthy reacted to a post in a topic:

Armed Virginia Sloop by GuntherMT - FINISHED - Model Shipways - scale 1:48

-

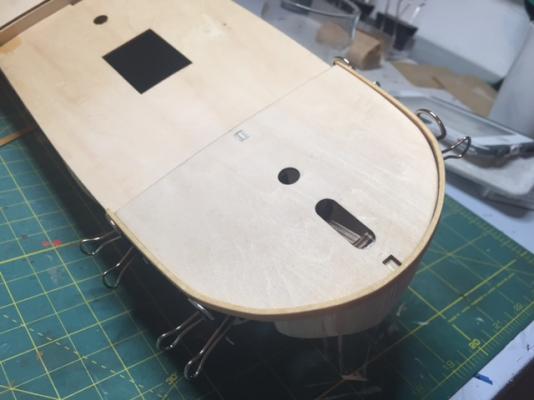

Woohoo I figured out how to make the deck walls That single piece of basswood worked out pretty well and looks a lot better than the ply wood. Now that I have figured this out I am starting to do some research on waterways. I think it would be a lot easier and look better if I can get the waterways installed before I attach the deck walls. lionfish: about your question on how I bent the wood a few posts ago. Its a bit complicated and scientific lol I soaked the strip in a wine bottle with hot water for about 5 minutes. I then clamped down the piece and held it in place with some modified binder clips till dried and its shape can be retained.

-

I think it was the camera playing tricks as well as how I holding the wood strips. I checked and rechecked a bunch of different angles and the strip seems to have good coverage on the last and second to last bulkheads. When I did the final shaping of the blocks I used one of my little flat files so I shouldn't have and bumps in the back.

-

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

Philthy reacted to a post in a topic:

USS Independence by Philthy - Artesania Latina

-

Philthy reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

Philthy reacted to a post in a topic:

Bon Retour By Philthy - Artesania Latina

-

Philthy reacted to a post in a topic:

USF Confederacy by Augie & Moonbug - FINISHED - Model Shipways - 1:64

Philthy reacted to a post in a topic:

USF Confederacy by Augie & Moonbug - FINISHED - Model Shipways - 1:64

-

I wanted to do a separate posting for this part to keep things in order. For the past week or so I have had in the back of my head the problem of how to approach the top section of planking that makes up the deck walls (not sure of the name). As posted earlier in this build log I have the kit provided piece of ply wood that is meant to be the wall for all sections of the deck (except for the poop deck). I am not entirely thrilled at how this piece fits though. The top most angles of this piece is off that will mess up pretty much everything i.e. wall hight at each deck, scuppers height, and height of the gun ports. Im still not sure the best approach to this so I am doing a little experimentation. In the photos I have a piece of scrap planking forming the bend around the forecastle. The plan is to build upon this bent piece until the deck wall height is reached as well as the angle. I feel this will make achieving the correct angle that goes the entire length of the ship difficult. Maybe if I install the wall support pieces cut to length will help? The other option I am kicking around in using one solid piece of basswood instead. I am thinking of cutting out a piece about 1 inch thick that runs the length of the ship. I can then draw the deck levels on this piece based on the 1:1 plans and finally cut to size. One way or another I am going to focus on resolving this little issue tomorrow. If you guys have experience with something like this please feel free to chime in. Im sure both options are feasible but maybe there is a better way. As a side note thank you all for the likes and comments as well as following the build log It has been a real pleasure keeping it up to date with the progress being made

-

I believe the stern filler blocks are all set and were a success. This is my first experience using filler blocks at the bow and stern and used scrap wood that I had laying about to boot This is just one of those little problems I had to figure out that will get better in time with following kits in the future. I also fixed the little issue I had with the deck heights being a little off. This was actually a lot easier to fix than I initially thought. I cut out about an in or so on the high or low side of the deck, adjusted accordingly, then secured with fast drying CA glue. Easy peasy. I still want to do a little bit more sanding on the false decks but I will leave that for tomorrow. The poop deck in particular looks a bit screwy but I am hoping some attention with a sanding block will do the trick.

-

Made some progress today on the stern section by adding some filler blocks. This is already helping me out in visualizing how the transom will go together as well as the ending points for planking. No real issues in making or shaping the stern blocks after cutting my teeth on the ones made for the bow. I also installed all the false decking and sanded the sides down so the are inline from the bow and back. I did mess up the "leveling" of the decks. I under stand there needs to be a slight curve outboard however on some of the decks, one side is higher than the other side. I am hoping a sanding block on the high side will correct this. The difference is maybe a millimeter or two and the plywood should be thick enough. Im really glad I went overboard with the bracings since I have been putting some stress on the hull during the standing and filling steps.

-

Philthy reacted to a post in a topic:

Fair American 1778 by jdbradford - Model Shipways - scale 1:48 - 14-gun Privateer

Philthy reacted to a post in a topic:

Fair American 1778 by jdbradford - Model Shipways - scale 1:48 - 14-gun Privateer

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.