-

Posts

632 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hank

-

I am looking for any detailed drawings (scaled plans w/dimensions, etc.) for deck handling equipment used on U.S. Navy Fleet Oilers (Cimarron/Ashtabula Class) during the late 1930s - 1940s. Specifically T-3 Tankers. Parts would include: Deck Winches Anchor Windless Stern Windless Cargo Winches Fairleads Any other misc. fittings (pulleys/blocks/etc.) Thanks, Hank

-

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Ken, Yes, old copiers can provide various parts for the modeler - motors, gears, glass plates, rods, etc. You just have to be VERY careful when working around the various color tanks so that you don't end up looking like The Joker!!! -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Roger, I appreciate your input on this. Actually, I have (2) 6" sq. pieces of 1" thk. granite countertop - one which matches our kitchen countertops and was in one of the drawers when we bought this house; the other was given to us at the showroom in Winston-Salem where the countertop was originally cut and purchased by a prior owner. We got the 2nd square as a possible consideration for an island countertop that I was going to build (2018). I did build a fairly large island from my own designs, but used a Norwegian Spruce Butcher block C'top instead (much, MUCH less expensive, and....it came out extremely well!). We use those 2 granite squares (I put "feet" on both of them) as cheese boards on the island - So, they are now part of The Admiral's collection, as it were and, more importantly....under the protection of (need I say it?)....... The Cat I may have a few pieces of spare glass plate somewhere in the "dammit" room upstairs amongst all the "stuff". I'll just have to look! If not, I'm inclined to go to one of the glass stores in town and get them to cut me a "12x12"x 1/4" plate and have them dress the edges. By evening I was running out of steam after removing some of the constructions tools, etc. from the inside of the shop. So, I'll be back at it tomorrow perhaps. I would like to get the back workbench surface cleared, cleaned, and ready to use. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

The drafting chair that came w/my table is adjusted for the table - but also works for the workbench - I don't need to adjust moving from one to the other. I'm just not interested in having to scoot from one to the other like in a Monty Python skit. Even though it's older (70s vintage) it's in good condition and can be adjusted up/down. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Journeyman, Not a bad idea - another more economical alternative would be a consignment shop for furniture. There are still some NC furniture mfg'rs. around (Hickory included), but many of their products are made in China/Vietnam, not local. Various options, at this point. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Journeyman: I'll look into that - I actually have the space for that now! -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Journeyman, Thanks for the suggestions! I'll look into that (chair). The one I used down east for 18 years was a wooden dining table, high backed, but without a cushion. I donated it to Habitat along with other furniture to keep from having to relocate them back home. Who knew, right!!! I've actually constructed a couple simple wooden holders for long tools, etc. - here's a closeup that shows them: I may add a center one as needed. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Dr. Per, No saw dust yet!!! I have NOT begun USS STODDARD yet - only in CAD drawings which I've been working on over the last couple years or so. The model itself won't get underway until possibly next month. Once I have a functioning a/c unit in place and have completed a small amount of repairs to NEW JERSEY, then STODDARD gets the green light. My workbench height is 35" (+/-) a good height to use my drafting chair - in fact, I'm thinking about looking around for a 2nd (possibly used) drafting chair for exclusive use at the workbench. I fabricated a couple tool caddys today to hold knives, long rigging tools, & files, etc. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

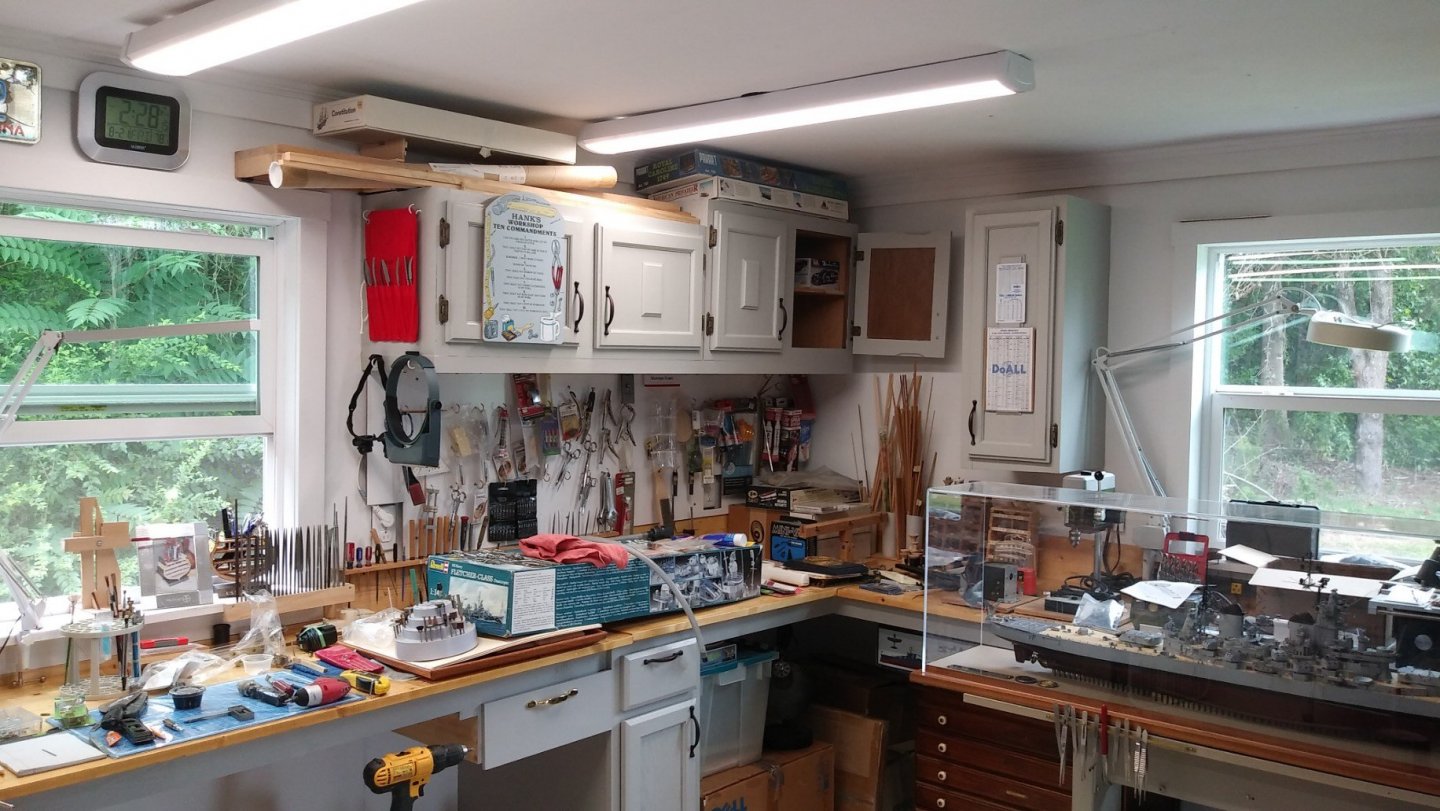

Well, still waiting on the Amazon refund to process, so only working in short sessions during more agreeable temps, etc. With a light off/on rain going on, I got out and did some more stowing of things. This idea of actually stowing away modeling tools, etc. is foreign to me - at the old location down east for 18 years I simply piled everything on a table behind me and dove in when necessary to find something. Now, with an actual shop to set up and arrange, I'm finding this an effort and actually sort of tiring. So, I thinks to meself….why not hire a professional, an arranger to do the task???? Well, I had forgotten that according to the Watch, Quarters, & Station Bill, The Admiral is in charge of these personnel decisions and the young Swiss Hottie I had picked out (from various and sundry European bridal listings) was rejected out of hand and now after a severe Admiral's Mast involving The Cat, I'm back to square one on stowing my own gear - AND....have had my internet privileges severely reduced as far as what overseas sites I can visit.🥵 So, while nursing my hurt ego (not to mention my hands, arms, back, legs, etc.) I went back out there and did a bit more stowing of gear today. Here's what things look like in the back of the shop: I'm actually making some progress in spite of what you might think! -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Well, this week didn't exactly go according to plan.... I did receive the portable a/c unit I had purchased on Monday and let it sit upright overnight (as recommended). I began installation Tuesday morning and by noon had the exhaust hose port & cover located and hose in place. Got the unit in place and turned it on. Well it kicked the breaker 3 times so I put in a 20Amp CB. Kicked that twice. Shut it off, called Black & Decker and then Amazon. Both said "send it back - full refund". So, Tuesday a.m. UPS picks it up and there we are - still hot & humid and sweating like a pig!!! Do pigs really sweat? I don't think so!!! Amazon, by the way, was very responsive to having me return it for a full refund + a promotional bonus for the trouble, so I can't fault them. I went back to further research this item and found that others had actually posted the same problems and really put the KIBosh on this model. I should have seen this, but was reading favorable reviews on the B&D website, not Amazon. My Bad, right? So, one the refund is credited, etc. I will more than likely purchase a Whynter port. a/c w/heat that has gotten very good reviews/ratings and will be somewhat oversized for my sq. footage, but this may be compensated by the very hot/humid weather when everything is considered. In the meantime I received 2 bookcases and have now assembled them and located & loaded them up! I have one more on order and hopefully will have enough shelf space to contain everything. I hope so!! Today I finished two scratch built sliding drawers on either side of my workbench station. The drawers were a couple that I had been hanging on to for a while, so now they've found a home! I will probably make a couple partitions in each drawer for small tools & accessories that I use frequently. I'm working in the cooler mornings and evenings until the a/c situation can be concluded satisfactorily. As you can see, the worksurface is a complete mess - chaos at its finest!!! But, things will get stowed, it's just a matter of deciding what goes where, etc. I do hope to at least get one more good coat of floor paint down before too long and before more things take up space. Maybe next week might be a good time for that. With the fall Beaufort, NC Wooden Boat Show now officially cancelled, I have a bit more time to do my repairs on NEW JERSEY before starting on a completely new project (USS STODDARD DD-566). So, construction continues, although at a slower pace, etc. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Back from the coast. All seemed to be in order; we didn't see any damage, i.e. - beyond what Florence caused and has still to be replaced/repaired/rebuilt. Most places were open, req'd. masks, and everyone seemed to be enjoying themselves. Visited with the New Bern Model Maker's Guild on Sat. for their monthly meeting and had a great time. My new LED Architect's Lamp was waiting for me, so I got that hooked up and amid all the clutter, should work well on the cool white setting: Of course, it's a bit hard to see - but, it should work fine once things are stowed away properly and the area ready for construction. I think I will try it with the included mounting bracket before I start drilling holes all over the place and then cry a lotEvery thing in it's own good time, right? -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Pat, Well, speaking of pegboards, I just finished a 2nd one (2'Hx3'L) and got it hung on the side wall behind a couple benchtop tools. Couple days at the coast and then back to shop work next week!!! Also, going to visit the New Bern NC model club at their Aug. meeting on Sat. noon. See what those pirates are up to these days!!! -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Ken, Thanks, I appreciate it!!! Yes, getting closer each week. Unpacking things will be a chore - sorting out and categorizing will take some time - I don't want to have to do it twice. But, no-one's timing this, so who cares, right? Hank -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Maury, Nirvana - Yes, things are progressing to a point where sawdust (plastic filings!) may soon be generated....and not by the chop saw!!!! Roger - thanks, I PMd you re. the plates. Hank -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Did a little clean up today, more un packing, and storms off & on, so I'm looking now for workbench lights. I've surveyed my stash of half dozen various desk lamps, etc. and have decided to donate the lot to Habitat Re-store. I did mount my old round fluorescent fixture on the back of the drafting table, but I may replace it eventually, also. Looking for LED worktable lamps (w/long bulb, etc.) as the brighter & smaller lamps are the way to go. I'm mainly concerned about the mounts. Roger Pellett mentioned a while back about a metal bracket he had made so he could move his lamps as needed. Great idea, Rog. !!! I'm thinking of possibly 3 lamps and 6 metal mounting plates to be located along the workbench at the back, out of the way. My machinist friend could make these easily for me - he's just finished a seat mounting plate for my wife's artist chair (came from Amazon - wrong size for wrong chair, go figure, right?). 6 or so 2" sq. plates would be a breeze for him. My only concern is that the 1/2" dia. hole for the lamp's mounting pin should really have a collar below it welded to the plate. I guess the first thing would be to decide on the lamp fixture, purchase them, and then make the plate/collar to suit; that sounds like a plan to me!! So, anyhow - here's the shop today: So, we'll see what happens next week... -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Well, today was kind of a catch-up day of sorts: Got the shelf along the partition/long wall painted & installed. Began, assembling framed artwork & such and grouping into subject matter for hanging, etc. Had to break during the hot afternoon, but returned to work there this evening. Thunderstorms tonight, welcome cooldown from the day! Starting to open boxes and get things sorted out, all along with putting up more shelves and so forth. So, it's an organized mess!!! May have more pix tomorrow late or evening as things progress. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Thanks, Roger!!! Wed. night - Well, today I order a portable a/c unit for the shop - Black & Decker 14k BTU w/heat - got a used "very good condition" (small cosmetic blemishes on top/sides) from Amazon at a good savings over buying the same item as brand new. So, in a week or so we'll see if this pans out. I read reviews, did research, and watched an installation video of the basic unit which sort of sold me on it. Not a whole lot of affordable ones out there sized for my shop and including heat. Today/tonight I got the ceiling finished and then started work on a wrap-around shelf that will go 12" below the top of the walls on one side - for my collection of annual gas tanker trucks, etc. Here is the shop as of evening: So, depending on the weather and The Admiral tomorrow, my schedule is flexible....! -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Da ding be dere!!! Of course, once the interior work is completed, I'll roll another coat of paint prior to actual usage of the shop - I gots a whole gallon to use!!!! Well, this a.m. the HVAC Guy shows up on time, removes the old mini-split and installs the new one - only here 2 hours or so and it's cooing things quite nicely!!!! While he's not experienced with portable a/c units, I gave him a tour of my shop and mentioned my plans for a port. a/c w/heat and he thought that this might be an excellent choice given size, windows, etc. So, I'm in the research mode on that end of things. This afternoon I did the the 2 LED lite fixtures installed and they are working great!!! It's really bright in there with the new fixtures turned on. The two units come with std. B/W/G leads that need to be connected to the power source (110v or 120v - normal elec. supply current. So, having a spare, unused #12 wire coming from the junction box in the attic space above the shop ceiling, I ran that to a new std. receptacle box (1st Picture below). I had two unused older extension cords (3 prong) and I cut off the female ends of both cords, stripped the wires and connected them to the leads (b/w/g) in each of the LED units with wire nuts. So, after drilling a 1 1/2" dia. hole in the ceiling for each lite fixture, I ran the cord thru the hole to connect to the new receptacle box. Once I put the covers on each of the fixtures, I then secured them to the ceiling and returned to the next receptacle box. I wired a new dual receptacle, put the cover on and plugged in the cords. Operating off the wall switch, everything was on!!! (2nd Picture below). So, tonight I plan to get the remaining ceiling panel in place and then do touch up on paint, etc. Once the ceiling is finished, I'll concentrate on other things in the shop itself - HVAC, getting tools arranged, things unpacked, etc. Then, possibly address the exterior painting, roof, etc. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Oh, Pat - da deck be scuffed!!! Fer Shur@!!!!!! But, I appreciate the comment as I've strived to get it as neat and clean as possible. Of course, just walking in the shop draws dirt - just like Pigpen and his sandbox!!!! Evening work: I put down a single 3' wide strip of construction paper in the center of the shop while I'm working on the LED fixtures. Made progress tonight and have one unit ready to go. Once I've wired the 2nd unit, I'll do the attic wiring and then locate the connection points for the fixtures. With the HVAC guy coming in the morning to work on the house, I probably won't get out to the shop until late. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

The Admiral's RFO has been postponed until such time as I'm able to "properly" amend her digital calendar; my first attempt at sliding in an unscheduled visit w/o being caught was unsuccessful and I was duly introduced to "The Cat" - I should be able to regain full usage of my shoulders, neck, and right ear (her aim is not that precise!) in good time.🥵 -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Monday, 27 July 20: Morning activities included removal of unnecessary "stuff" from interior of shop and touching up wall, baseboard, & cabinetry paint. Construction paper was removed from deck and sweep down was held on said deck. Paint repairs logged for touch-up after elec. lighting work is completed. Due to high heat/humidity noon chow call was piped down early. Arrangements were made with S.O.P.A. Chief at end of street to provide transportation availability for ship's movement in early afternoon. All preparations for moving ships were completed by 1330 and Fleet Operations Recovery & Distribution vehicle F150 arrived to escort 2 naval vessels to their new moorings. Vessels shifting berths are USS NEW JERSEY (BB-62) and U.S. Sloop of War PEACOCK. Loading of aforementioned vessels was completed at 1340 and transit to new berths commenced. Arrival at new berthing accommodations was completed at 1355 and F.O.R.D. F150 departed to conduct local exercises before returning to home port. USS NEW JERSEY is now located in Construction Area "1" in workshop for necessary upkeep and repairs. Sloop of War PEACOCK is now residing in her new permanent berth in Ship's Study & Library, Room Alpha. The following photos are available for publication: After evening chow is piped down, further interior work on shop will proceed. -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

You got that right, Jack!!!!! (Roger)!!!!!! LOL!!! Seriously though, I'm still on my first can and I used probably the last I'll need for a while this morning when I filled in the last of the floor panel screw holes. The shop floor is now painted (2 coats), it's drying, and I'll begin this afternoon putting in the remaining baseboard. Once that's completed, I can begin to move things around and some "stuff" out. I hope to get the new lite fixtures installed early this week. Maybe have a late Sunday afternoon update with pix. Sunday evening update: Floor and baseboards are in. Some paint touch-up next on everything! Began moving things tonight and will pick-up again in the morning. Hope to also get started on the LED lite fixtures. Then, the real fun begins.....! Pix tonight: -

Converting a Backyard Shed into a Model Workshop

Hank replied to Hank's topic in Modeling tools and Workshop Equipment

Thanks, Al!! Well, I'm not there yet, but making progress!!! We will expect to see a full report on your shop revamp this fall - right? Today's progress: after another morning hour of moving "stuff" & various wood over to the small shed, I spent a couple hours mixing Durham's and filling in all the cracks, holes, etc. - Done for today to let things set up and dry. Will resume work tomorrow. -

I agree, in fact - I used a very fine grit dk. gray sandpaper for the helo deck on my NEW JERSEY battleship model (1:200 scale) - spray adhered to the plastic underneath. Being that your model is 1/144 scale, you might want to check around for deck decals that are made in that scale for a FLETCHER class DD. I do know that the Revell 1/144 FLETCHER DD kit (Revell Germany) includes decals for the main deck non-slip walkways (I just looked at my kit). Hope this helps! Hank

-

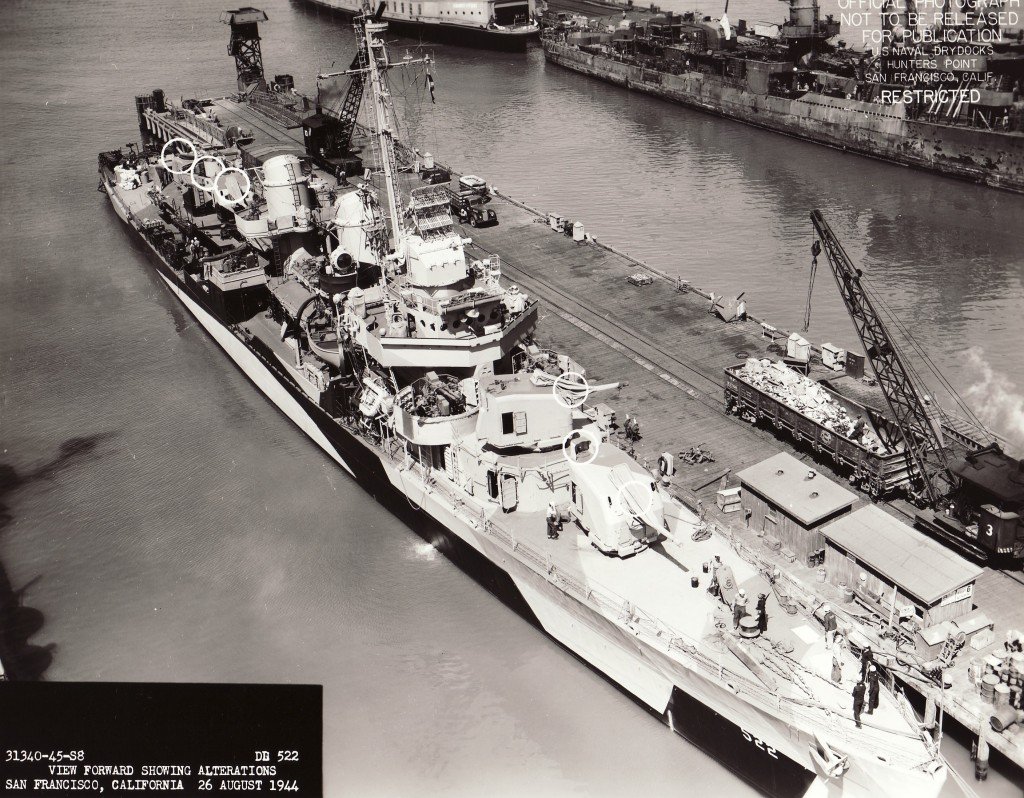

Re. FLETCHER class DDs in WWII & deck paint: It would depend on if the ship you were modeling was painted in a camouflaged paint scheme, which one, etc. or not. This would also depend on the time frame you are depicting your model. If it was not camouflaged, then the std. navy paint scheme for that time period would be indicated. Generally speaking, the deck would be Deck Gray (Haze Gray which was mentioned earlier by another respondent is for vertical surfaces, not horizontal surfaces). The main deck of FLETCHER class DDs also had some form of non-skid deck treads or walkways laid out (such as shown in Don's model pictured in his earlier post). This was usually black in color, as mentioned earlier paint mixed with sand to give a "gritty" surface. Here is a good shot of DD-522 in camo showing her main deck in 1944: As you can see, there is no walkway or deck treads laid down; the main deck & above levels follow the camo pattern from the sides of the hull. Sorry, I don't have a suitable photo of a FLETCHER during WWII showing the main deck with std. paint scheme. A good source for authentic paint chips for USN WWII era ships is from Snyder & Short - https://www.shipcamouflage.com/ and is well worth the money! Hope this helps, Hank

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.