-

Posts

13 -

Joined

-

Last visited

-

Sorry for the delay in updating my build log.... No I am not !!! truth is I have been away on holiday for the last 4 weeks, but now refreshed and regenerated I shall return to the build with some gusto... so here goes again. "Salty Sea Dog" - has I said before thanks for the link to the Model-Expo site for the book and plans by Ronnberg. Sadly with the delayed post from the USA to UK they didn't arrive before the holiday so had to make do with reading Banburek's book on HMS Sherbourne ready for my next build. But now having got them they look very detailed and should provide a very good source of reference. "Q As Revenge" - the kit does in fact have the outer planking already "spilled" and is precut and preshaped ready for fitting as per the advertisement you have seen. Once I have got my head around to being back in my workshop and not walking in the hills of Wales I will get some photos published on here to help in your decision on your next purchase. Just be aware that the plans and instructions are both written in Italian... albeit with an English translation. That said if you have built a couple of kits before or can follow the pictures I don't think you will have any problems. Back soon.

-

Jay 1 reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

Jay 1 reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

-

Jay, At your request. This is not a modified set of veneer calipers but a dedicated instrument. Great little tool especially when used on a sheet of glass which ensures that everything is level. I have two pieces of toughened 5 mm x 30 x 45 cm and a very big piece of 7 mm which just about covers my building board which is 1 meter x 50 cm. The height gauge comes from a company here in the UK but you will find them on the web at www.machine-dro.co.uk they are expensive but to my opinion worth their weight. Will try and catch up with the rest of the post in next day or two and update the log to show my progress on the internal planking.

-

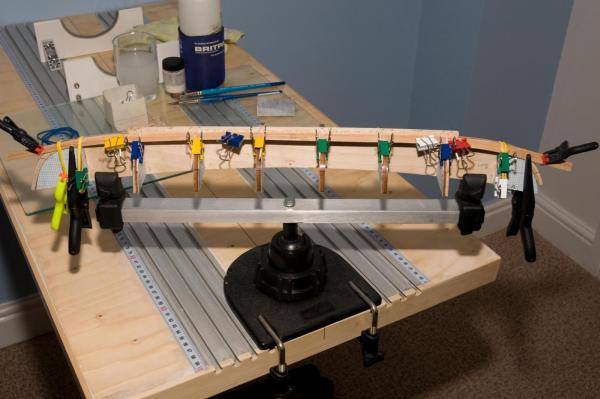

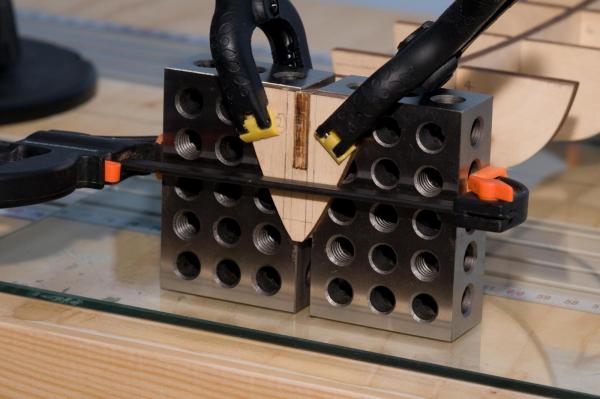

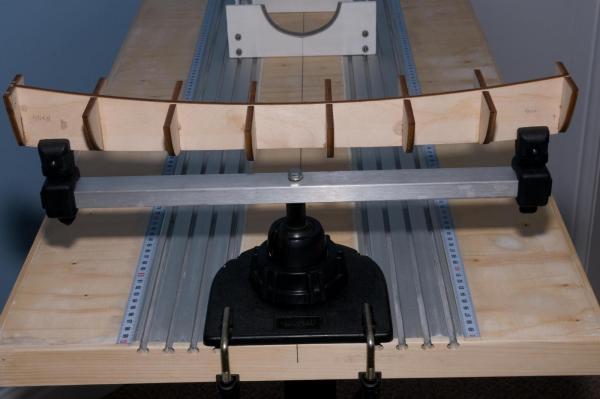

Progress report. Fixed the problems with the false keel and core. Buck (Salty Sea Dog) Is there any other way of ensuring that everything is upright and true. I tried with clamping a couple of engineers squares to the pieces on other models but found the 3-2-1 blocks gave a better result and are worth every penny spent on them. At times if I am truthful I think about investing in another couple or four. On wards... Fitted the extension pieces to the bow and stern ends of the false keel core and chamfered the ends once I had pinned them into place. This chamfering is to increase the seating of the internal floor planks. Then took to marking out the levels for the internal floor planking onto the false keel and core. The main assembly is inverted at this point and the structure has been leveled using datum points drawn onto the plans and then copied to the piece. Once completed the levels were drawn into place... and then I disassembled it all and all the relevant joints and areas where i don't want the planking to stick when glued together were covered in clear tape. (sellotape) The final job before I could start on the planking and really get this project up and running was to build a small jig to sit the floor planking into so that it could be tapered correctly at each end. Each of the false bulkheads were measured with a ticker tape and the results divided by 9 (the number of planks) to give the dimensions of each plank at the relevant bulk head. Cutting the planks... . ... Hip Hip Horray !!! at last the first planks laid... Its taken 14 days to get to this point. But as we all know all too well if the frame is not straight and true the model never will be... one second extra spent in the planning and preparation stage will save a full day trying to correct the faults later. ...and the other delays... Well we all thought De Resta was going to get pole... but settled for the other Brit instead... just a shame that normal service was resumed before the end of the first lap... is this World Championship #4 coming up ?? Sarge

-

Jay 1 reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

Jay 1 reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

-

trippwj reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

trippwj reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

-

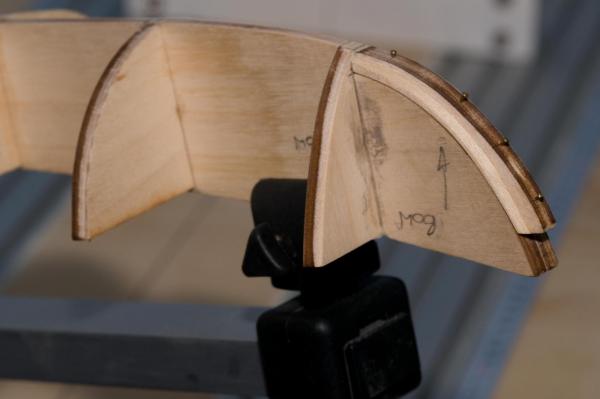

Sorry for the delay. Has I said at the start this was in part going to be slow due to my shift work schedule. But I now have 5 days off so with a little bit of luck will get some progress made. (subject to the Captain's Orders and having a break to watch the F1 race at SPA) Onwards... Some days ago I dry fitted all the bulkheads to the Keel piece to make the False Core. All appears to be well. The joints are a little on the tight side, in fact a little too tight when the glue is applied. Progressing they were all glued in and were / are upright and square. I did notice at this time though that the bulkheads (number 2 and 9) at the stern and bow ends didn't sit flush with the ends of the keel piece, but thought no more at this time. The ill-fitting Bow Bulkhead (2) - Stern has same fault. After they were dry and the clamps removed the entire structure was offered up to the plans I then noticed that the entire thing was +/- 5 mm over length. This was undoubtedly caused by the design fault in the laser cut parts. Solution... out with the Isopropyl Alcohol and break open the joints. Re cut the joint some 2.5 mm back by hand as it was not possible to get the core into or under any machinery due to the other bulkheads and then reassemble. The remade Bow Bulkhead joint. Progress to-date - False Keel Core ready for assembly of Bow and Stern pieces then the internal planking can begin.

-

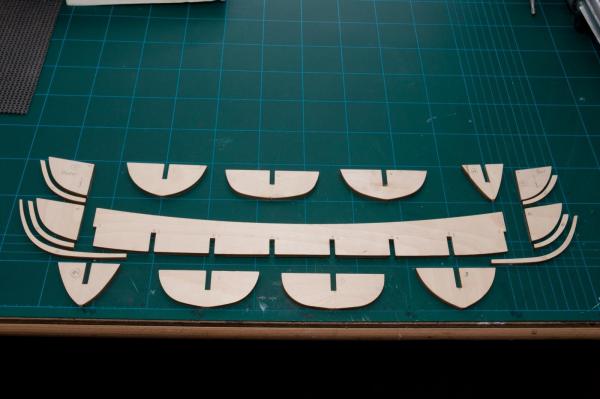

Spent most of yesterday evening cutting out the false bulkheads and the false keel parts and tidying up the edges. The first dry fit went well and all is in order for gluing the assembly together. Also spent some of the time coping bulkheads 4 and 7 so that I can make a cradle to sit the part constructed boat into whilst I work out how I will display the model when finished. Cutting out the False Bulkhead and Keel Parts - Proxxon Saw at the ready - (school boy error !!! watch is still on wrist... where is the Health and Safety Man when you need him) The False Keel and Bulkheads ready for assembly Thanks for your enthusiasm keep watching. Sarge

-

Looks like I have some avid "Whaleboat" watchers on here. I will try not to disappoint. First the admin to answer some of the points above in no particular order. Great Galleons ; no sadly the kit does not come with instructions for davits or boat cranes. This is an idea I had thought of myself as a way to display the finished model being as the keel will be on the thin side and not much room to get screws or nuts and bolts in, to secure to a plinth with pedestals in the traditional fashion. Sadly there is not even a stand supplied with the kit so one of the first tasks is to build one along with a cradle of sorts to fit onto my built table / jig. I do however have the old plans for my Modelshipway "Charles W Morgan" so may be able to put these to use to get something worked out. But below... Buck - "Salty Sea Dog" ; thanks for the link to Model-expo. (which does work). I have tried to order both the book and the associated plans but to no avail. When ever I try to check out my order it states I am not selecting the correct postal method and no matter what I do I get the same response. I have emailed to company but have had no reply so far. Phoning from the UK is not an option as the listed number is a toll free USA number only. Right popcorn at the ready part 2 below.

-

fnkershner reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

fnkershner reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

-

SkerryAmp reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

SkerryAmp reacted to a post in a topic:

New Bedford Whaleboat by sarge - Amati - 1/16th scale

-

"Welcome to the 21st Century..." That's what my son said when i told him of my intention to start a builder's log for my next project. Well here it is, and here we go !! Kicking and screaming and all that stuff.... This will hopefully be my build log for Amati's New Bedford Whaleboat. 1/16th scale with a few modifications ad changes of materials to make the finished product a little better that the standard kit. But a word of warning before I start. It will not be quick and the updates may be a little spasmodic due my shift workings and my desire to concentrate on the building rather than the blog. But I will do my best to let you have equal shares of my time. So, welcome, sit back, relax, and here we go. Feel free to add comment, critique, and general observations. I assure you all is welcome, good or bad. We are all here to learn, no man is born perfect, but with practice we can aspire... I suppose I should start with the ubiquitous shot of the box and the contents. First thoughts are all seems to be there and all the wood looks straight. But I will make a second check as the contents are unpacked and put away into the drawer system in the workshop. The second copy plans have been hung on the wall and the list of amendments that came with the instructions have all been modified and the parts renumbered accordingly. However I still do notice that the false keel / building jig, now comes in a single piece rather than the two depicted in the plans and instructions. What other faults might we find....other than its all in Italian.

-

Might a make a suggestion for the fabric. Try using "cotton lawn" this is available from http://www.craftycomputerpaper.co.uk and comes in A4 size sheets which due to their paper backing will go into any standard computer printer... all you need now is a scaled image of the flag or ensign you wish to print. The same material can also be used to make sails.Simply copy the plans to a computer art drawing program (I use Photoshop) re-scale if required; change the colours from black lines to a suitable brown shade and all the reef bands and cloth lines are ready to print. But please be aware the printing is visible on both sides of the material so is no good if you want to show written words etc as above in Modeler12's post

-

Sephirem, You could also try a very small amount of cyanoacrylate (super glue) on the last 1 cm (1/2 inch) of the rope. This also helps and makes threading blocks etc much easier. Just be sure to cut the rope nice and tight to the knot once it is laid up. I tried the heat gun method some years back but all you end up with is a globule of melted material at the end which is extremely hard to thread through blocks etc. Incidentally Allan's suggestion of running bees wax across all lines is very well founded. Most importantly it lays all the very fine fibers down which would otherwise attract mass amounts of dust once your model is complete. (with or without a glass display case)

-

Echo by jml1083 - cross-section

sarge replied to jml1083's topic in - Build logs for subjects built 1751 - 1800

Jim L, I will be following your build with anticipation. The cross section Echo project is one I was following on MSW before the crash. It is a project i would sincerely like to have a go at but feel my budget would not run to some of the expensive machine tools required. I shall continue to watch and learn... then one day !

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.