-

Posts

148 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by highlanderburial

-

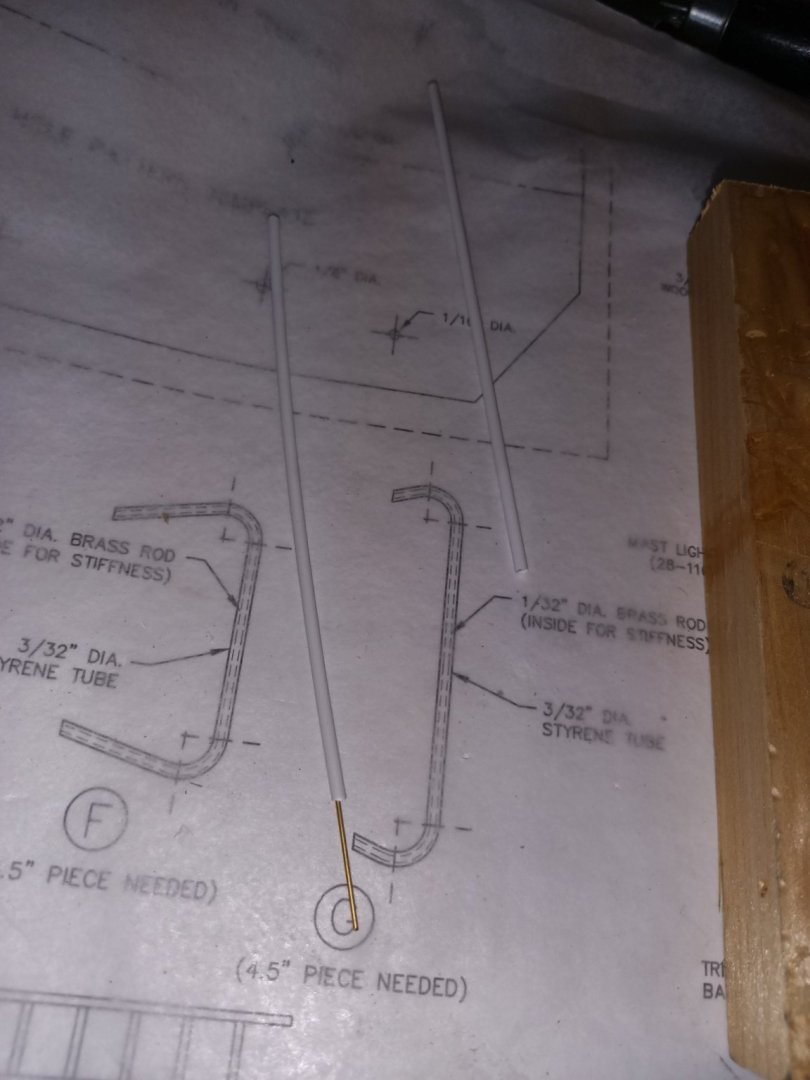

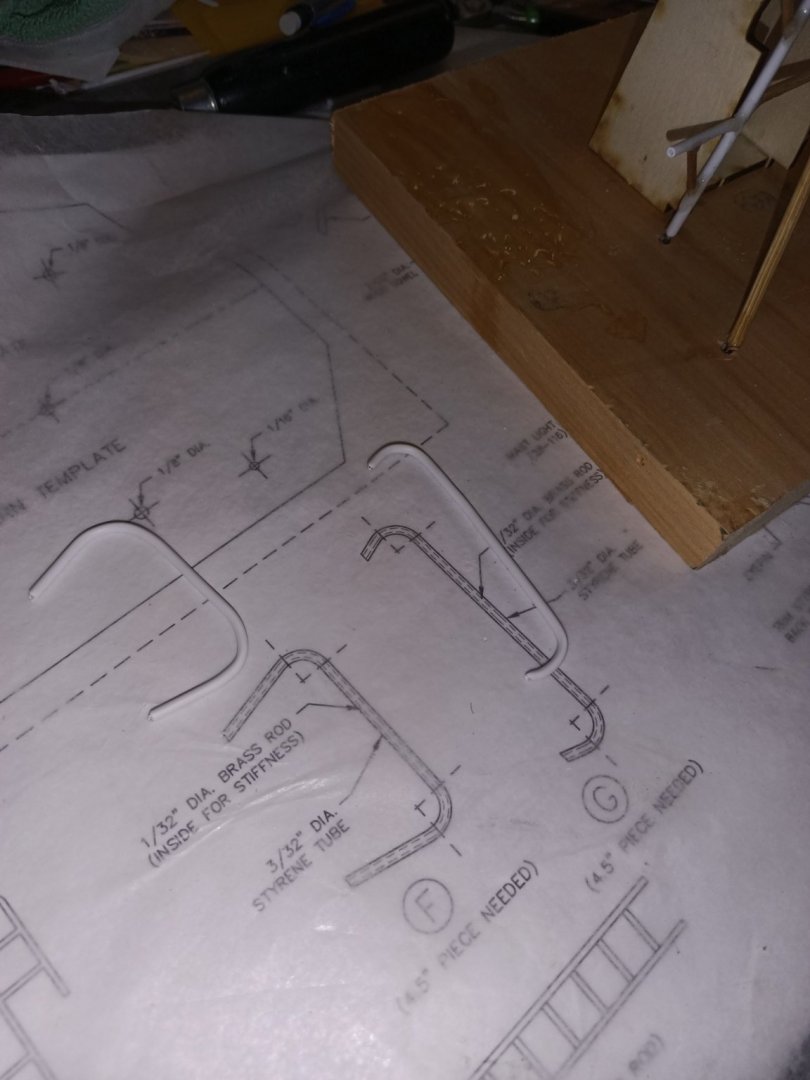

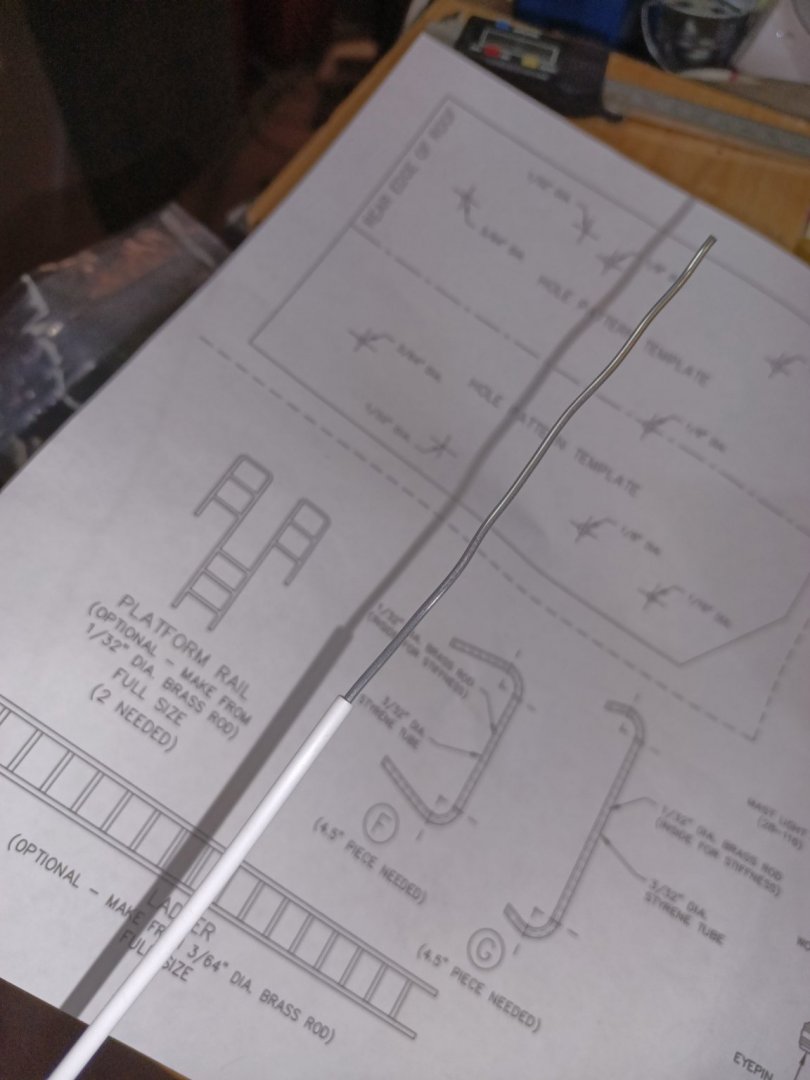

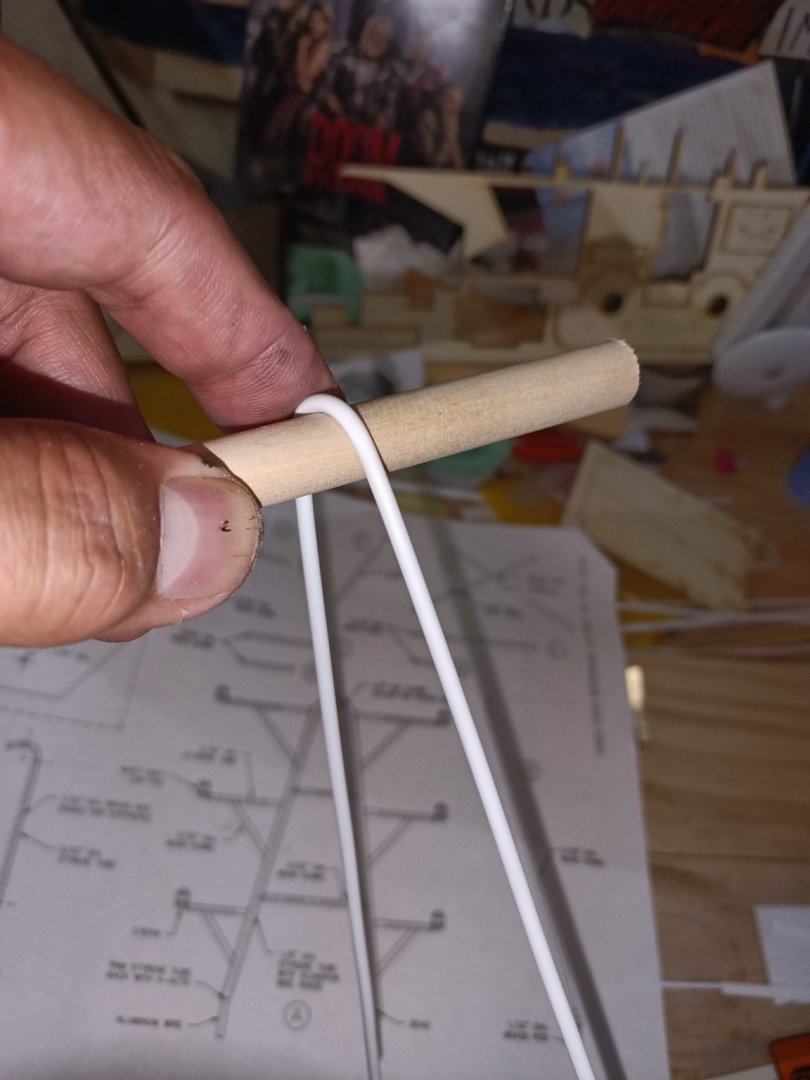

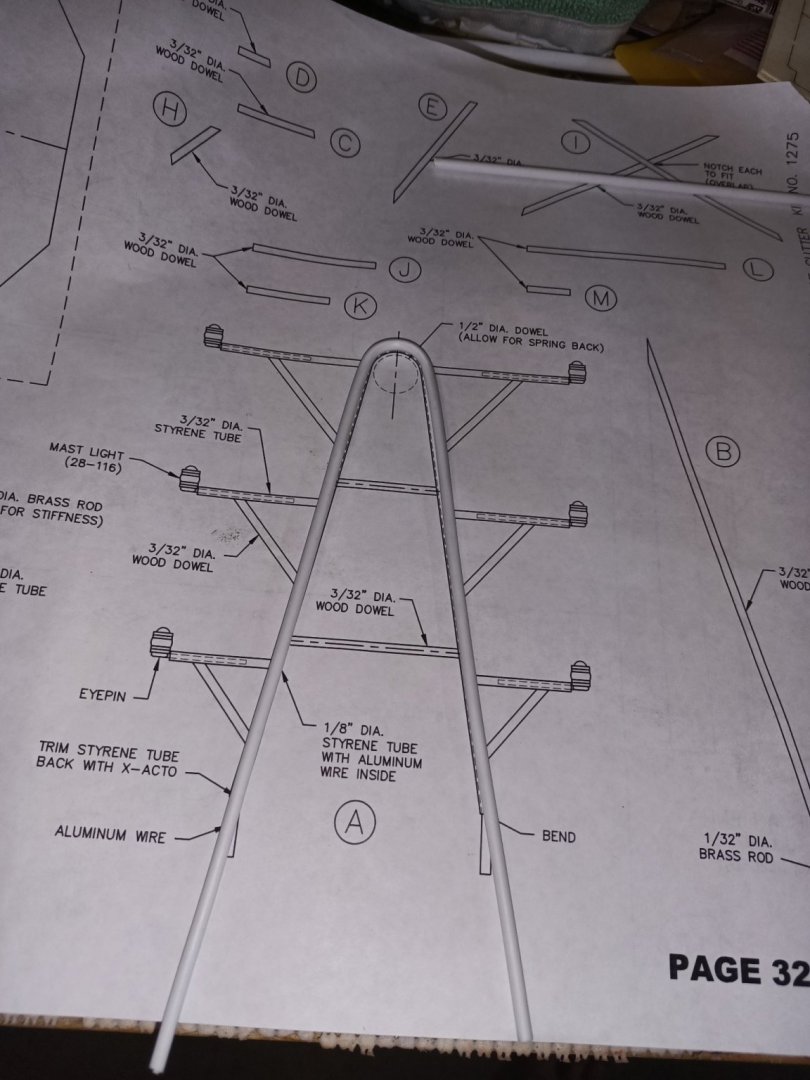

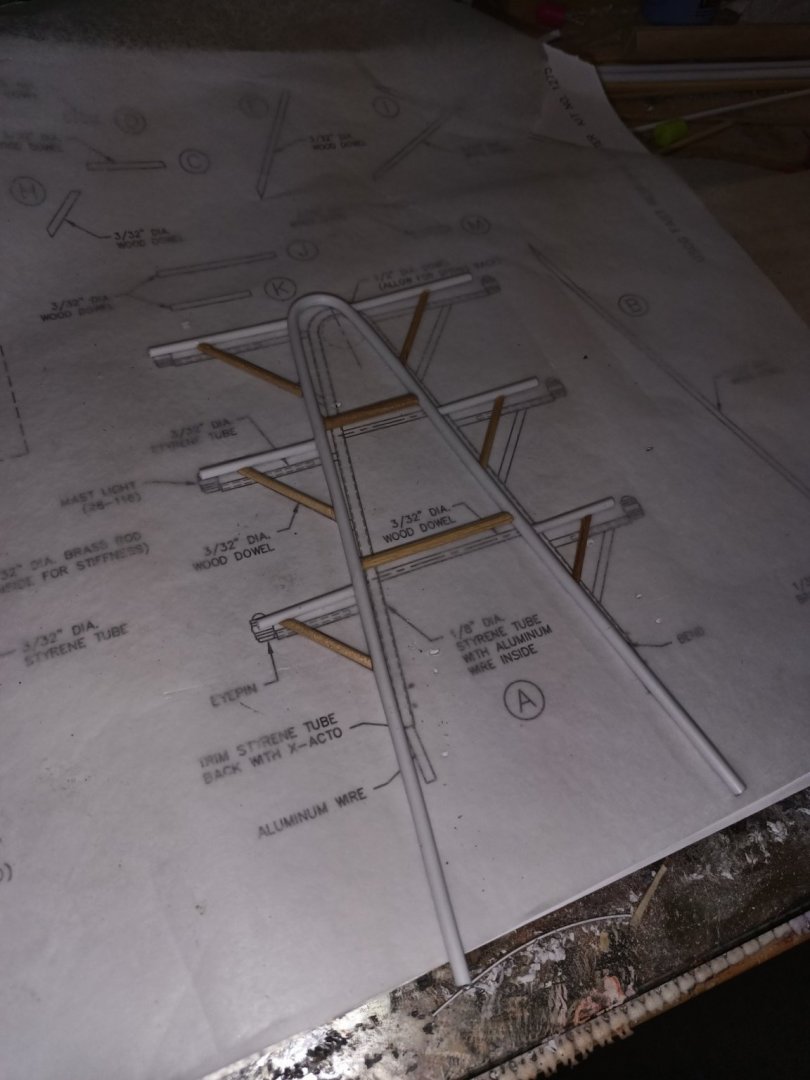

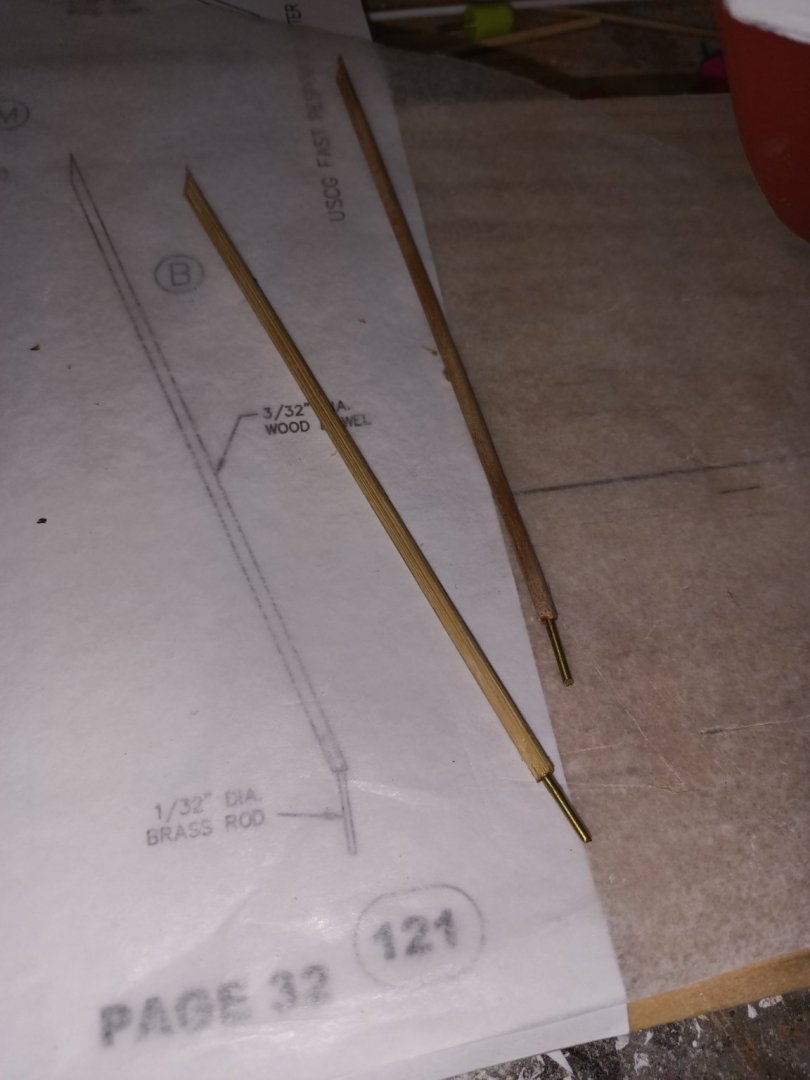

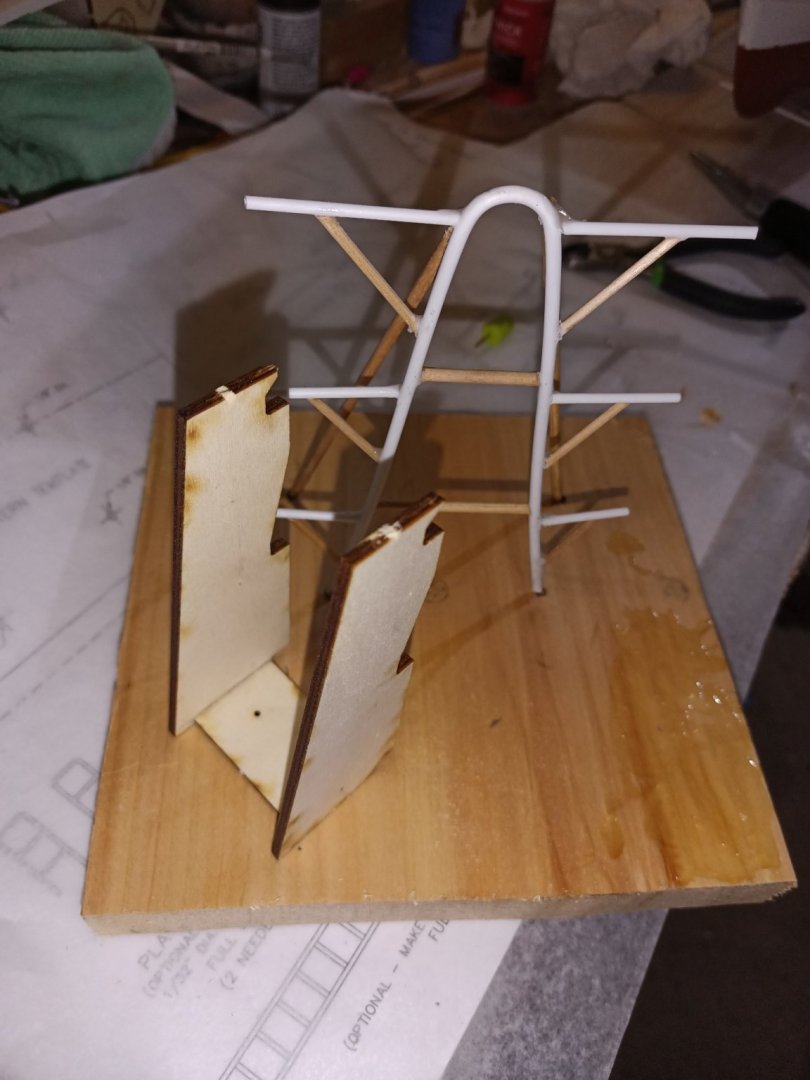

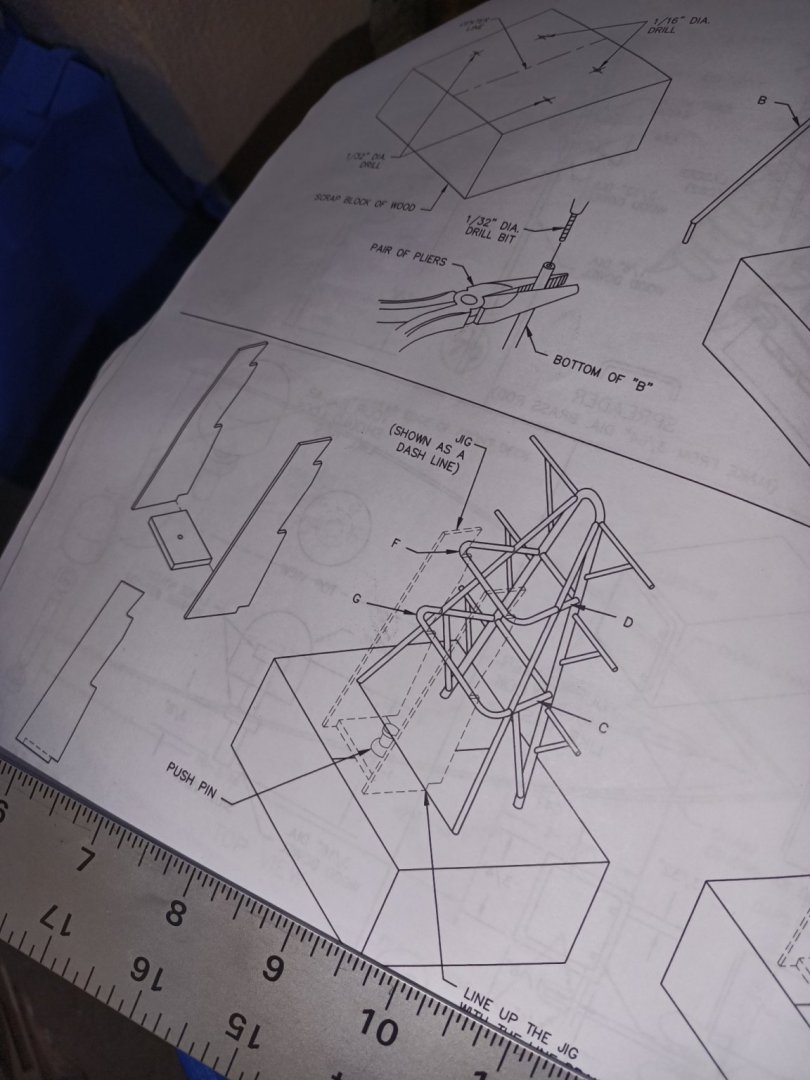

Mast work begins. I think the kit shorted me a dowel but I had extra. The kit gives you a jig to make to hold up the radars and connecting beams. The main part of the "A" frame is some 3/16 plastruct tubing but you have to push through some very malleable aluminum wire. This keeps the plastic from deforming and lets it hold its shape.

-

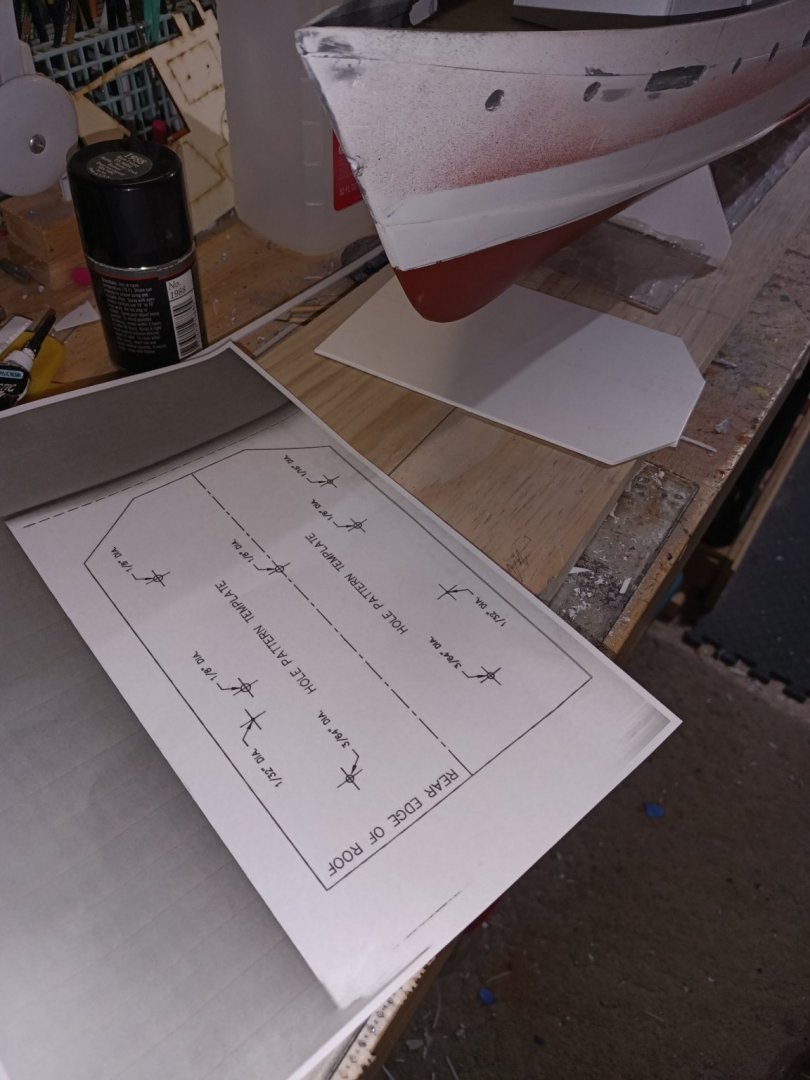

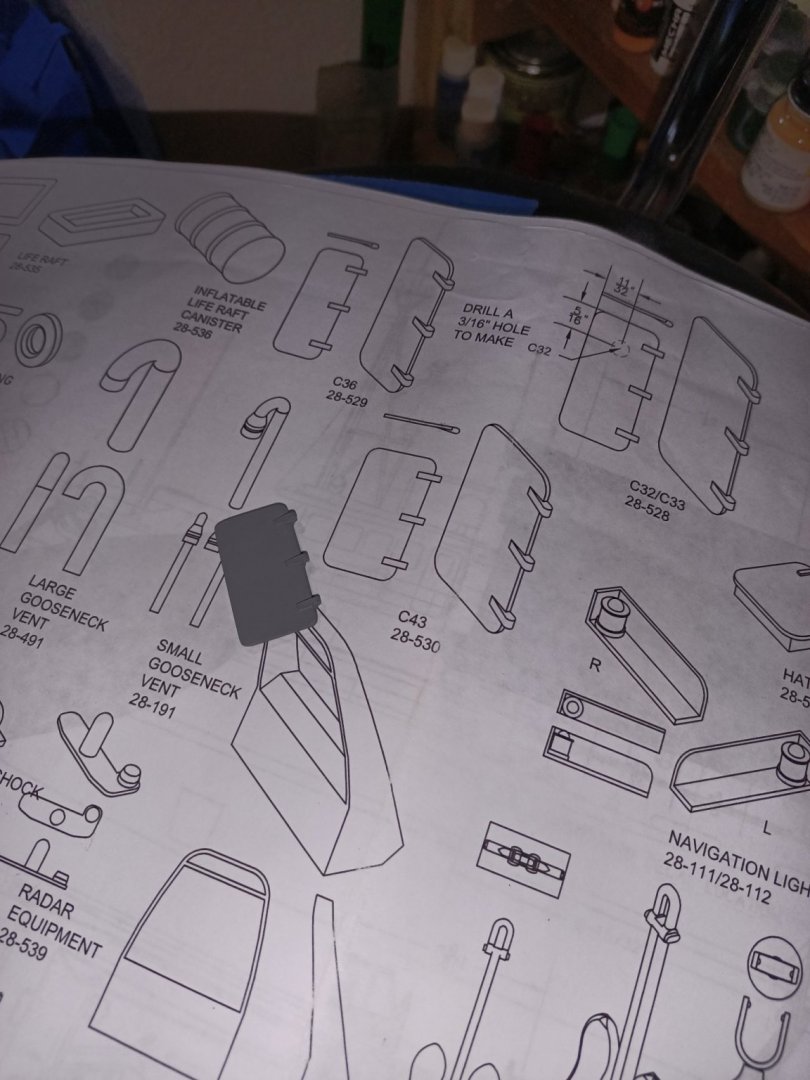

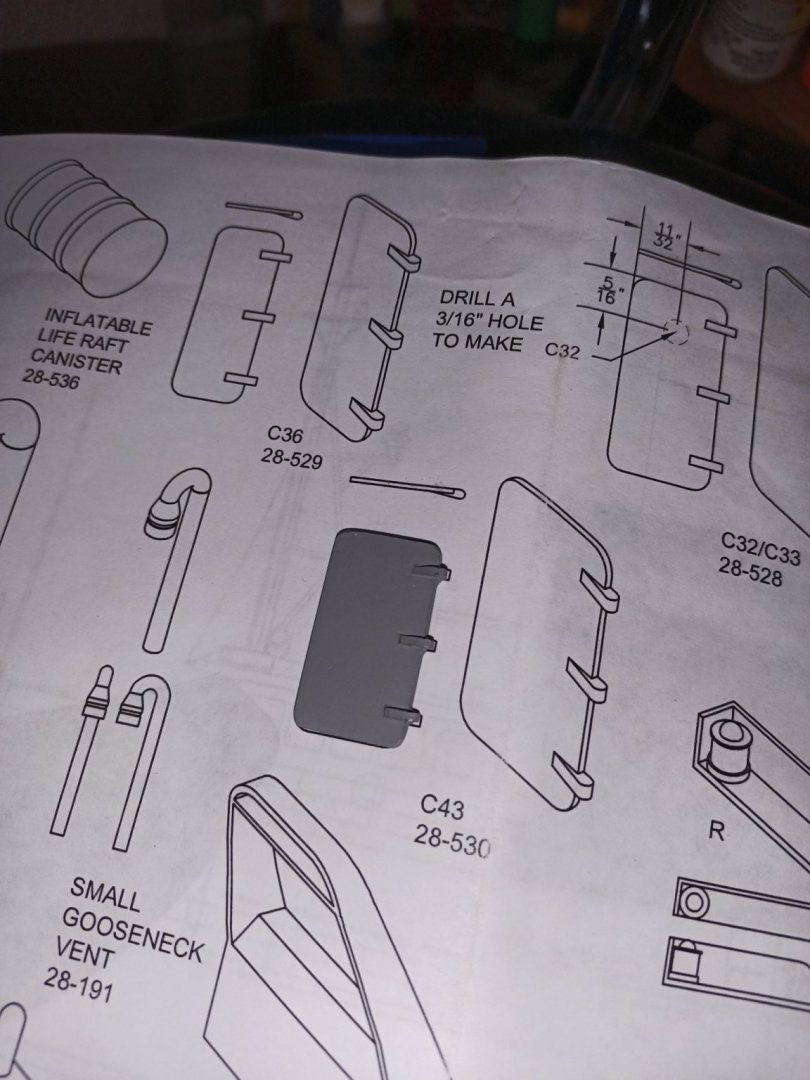

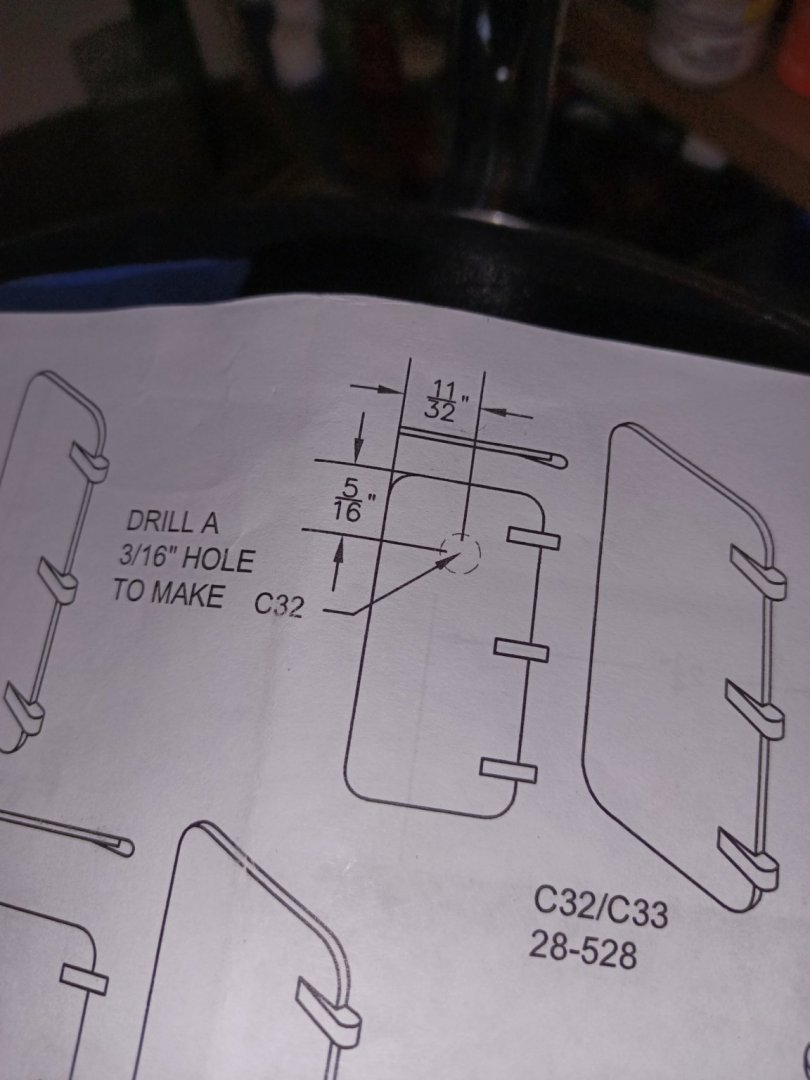

I started working on hatches and scuttles. As a note to all those attempting this build should note that there are 3 different sizes of doors. I spent 40 minutes figuring out which ones were which when I could have simply held them up to the parts sheet. See photo. You will need to use a 3/16 drill bit to cut port holes in the water tight doors. You also need to do this with 2 different doors each with hinges both left and right.

-

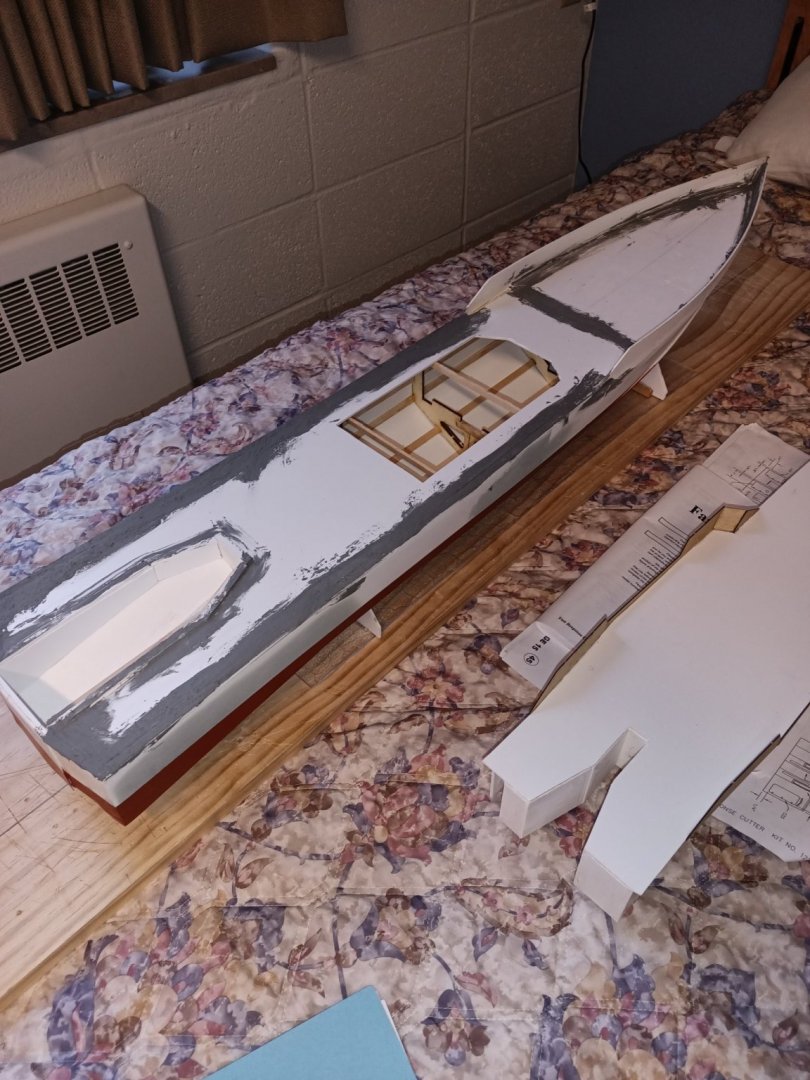

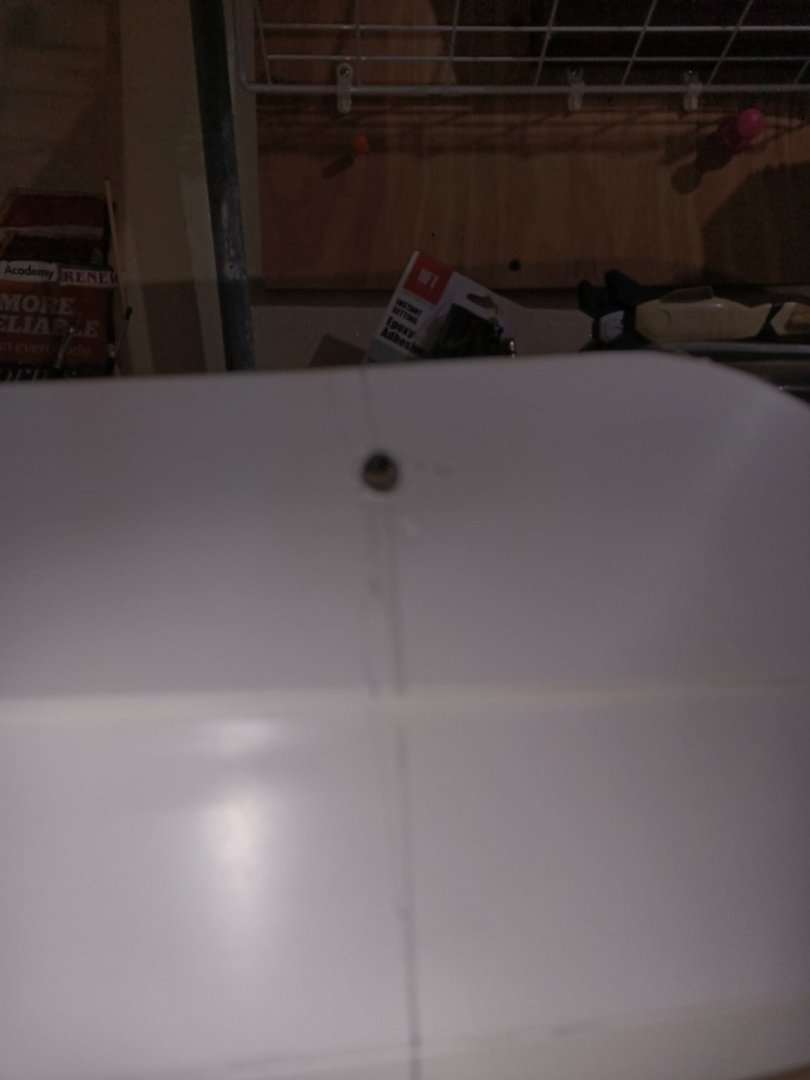

Today I puttied up some more low spots. The real ship has a bow thruster but the model makes no call out for this. I measured back about 4.25 inches from the hawser hole in deck and drew a circle around the boat to find the placement. I never like cutting a hole in a perfectly good hull. I used a small starter drill bit as a starter. I then moved up to 3/8ths then 5/8ths. The plastruct tube in inserted was larger than that one the outside diameter. MAKE SURE you glue one side prior to cutting the tube flush or it will pop out.

-

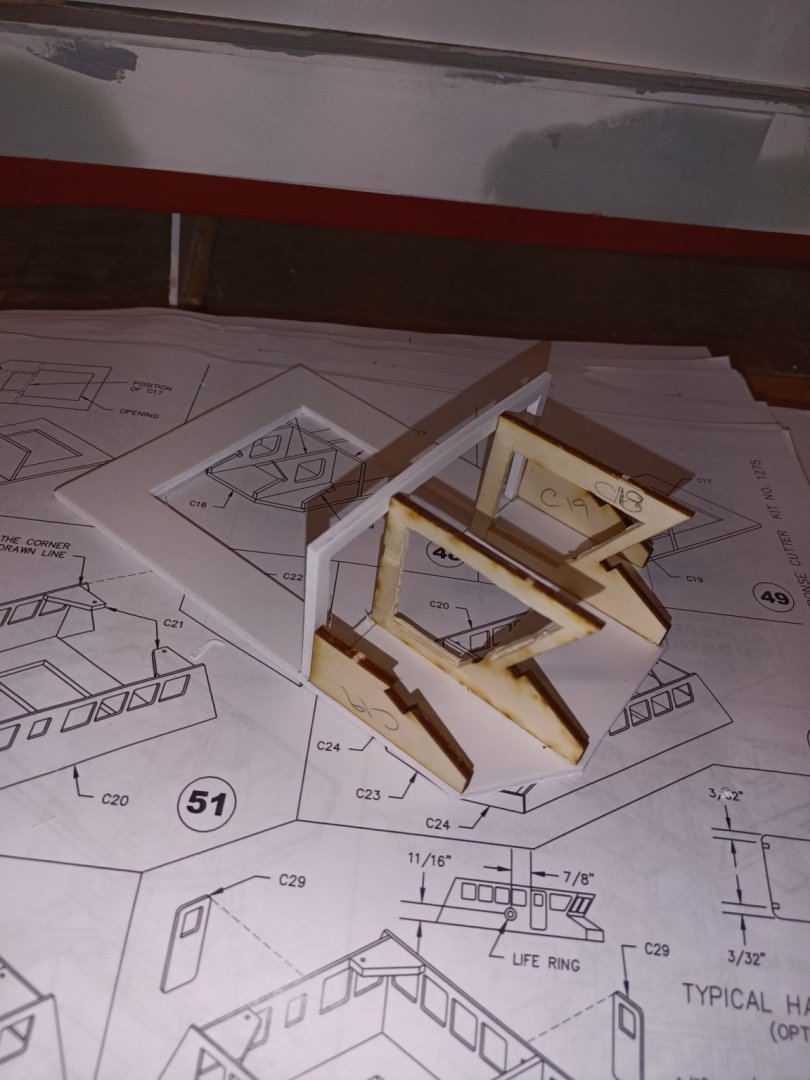

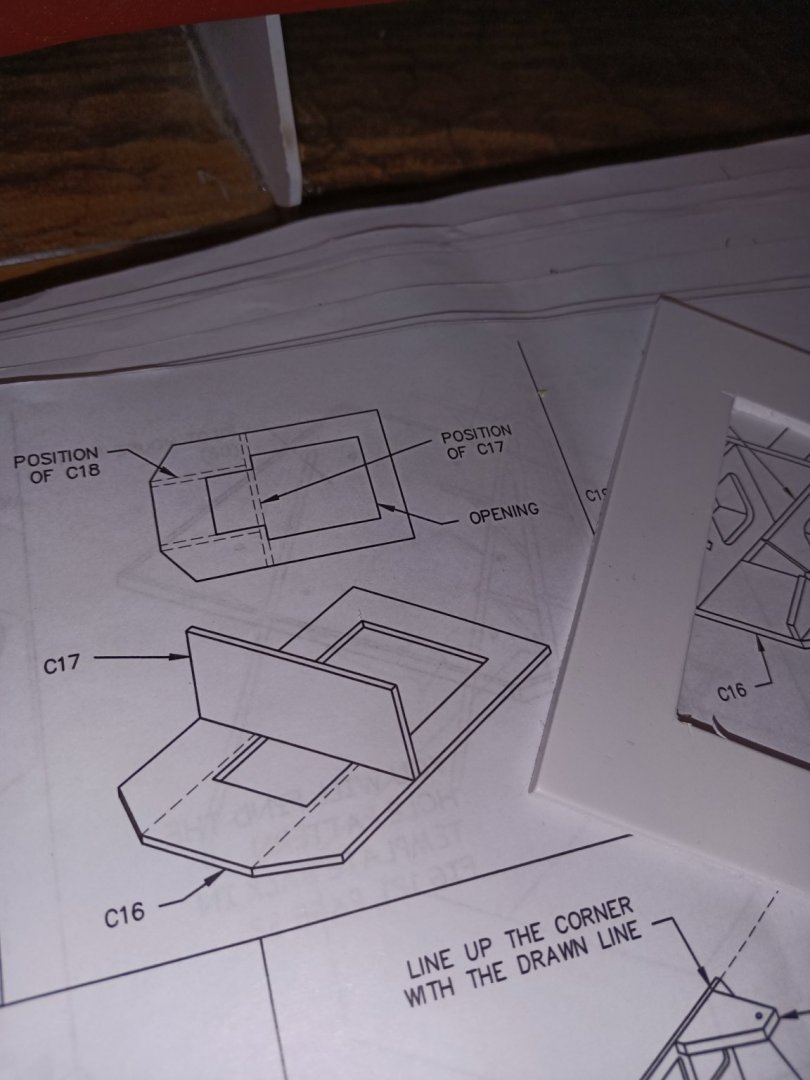

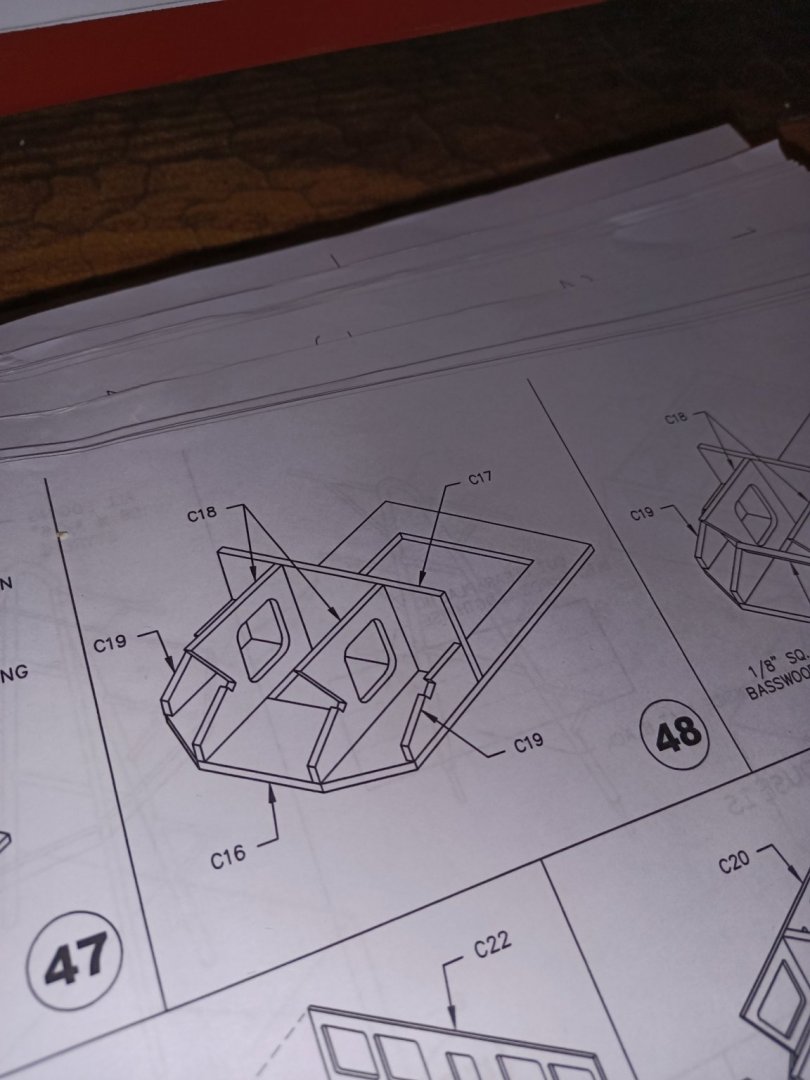

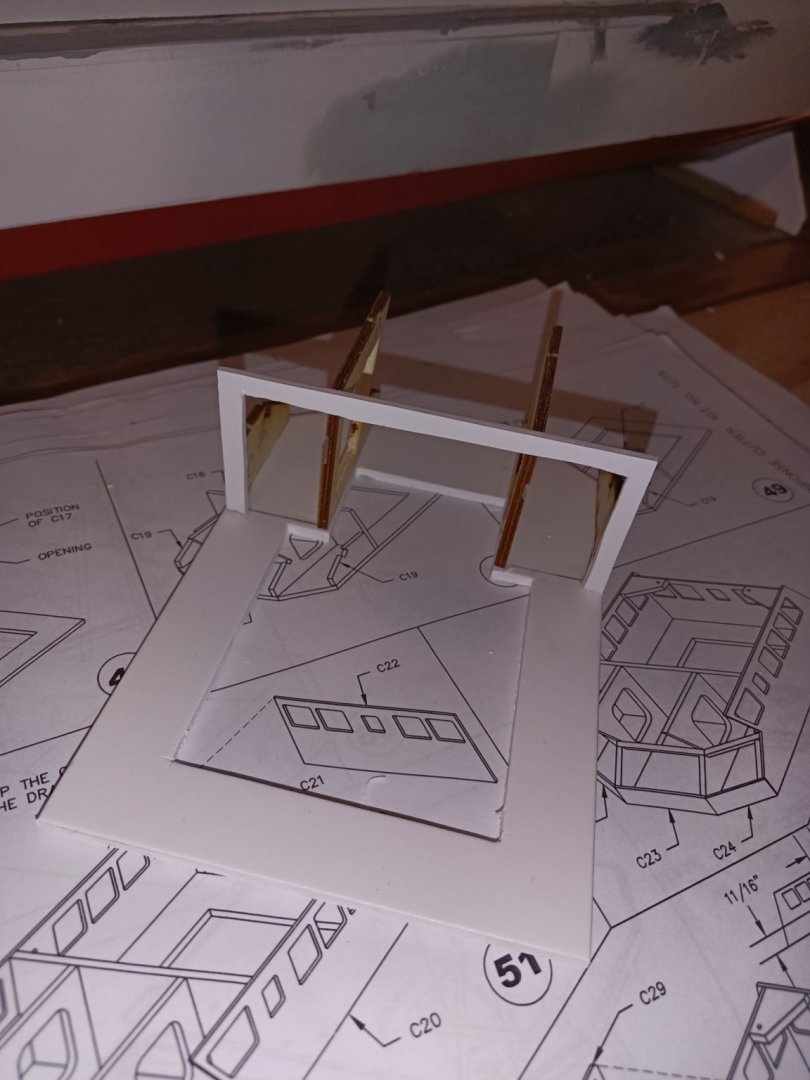

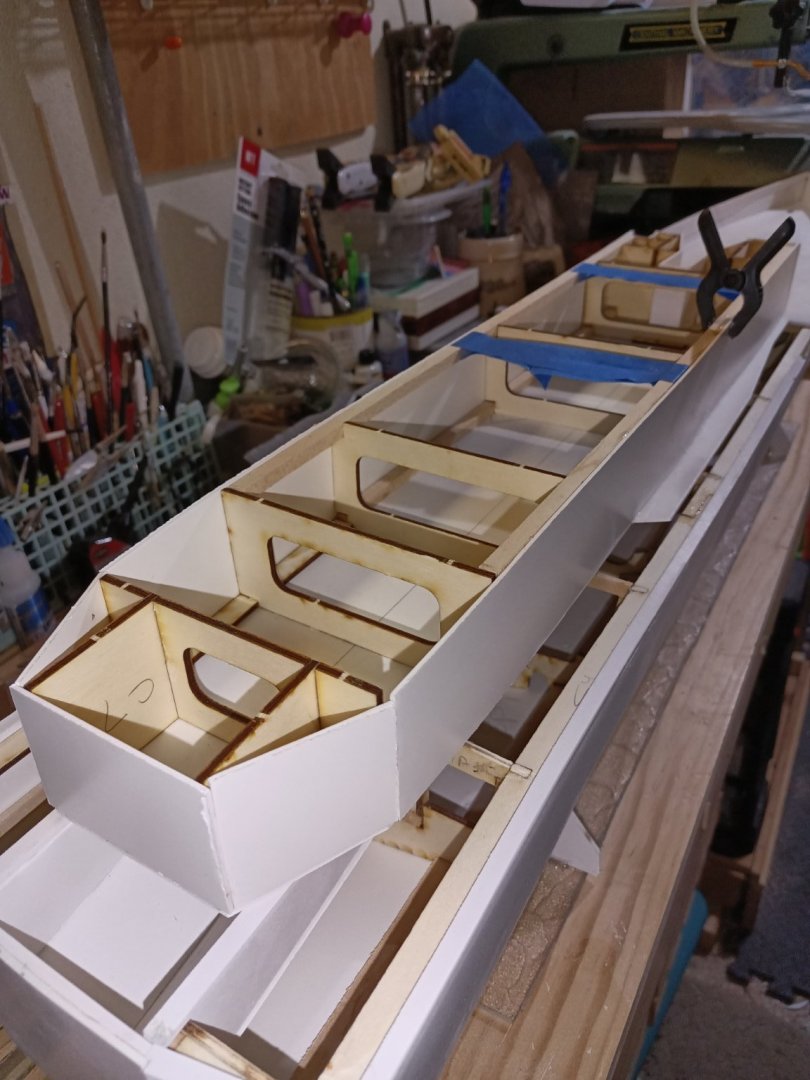

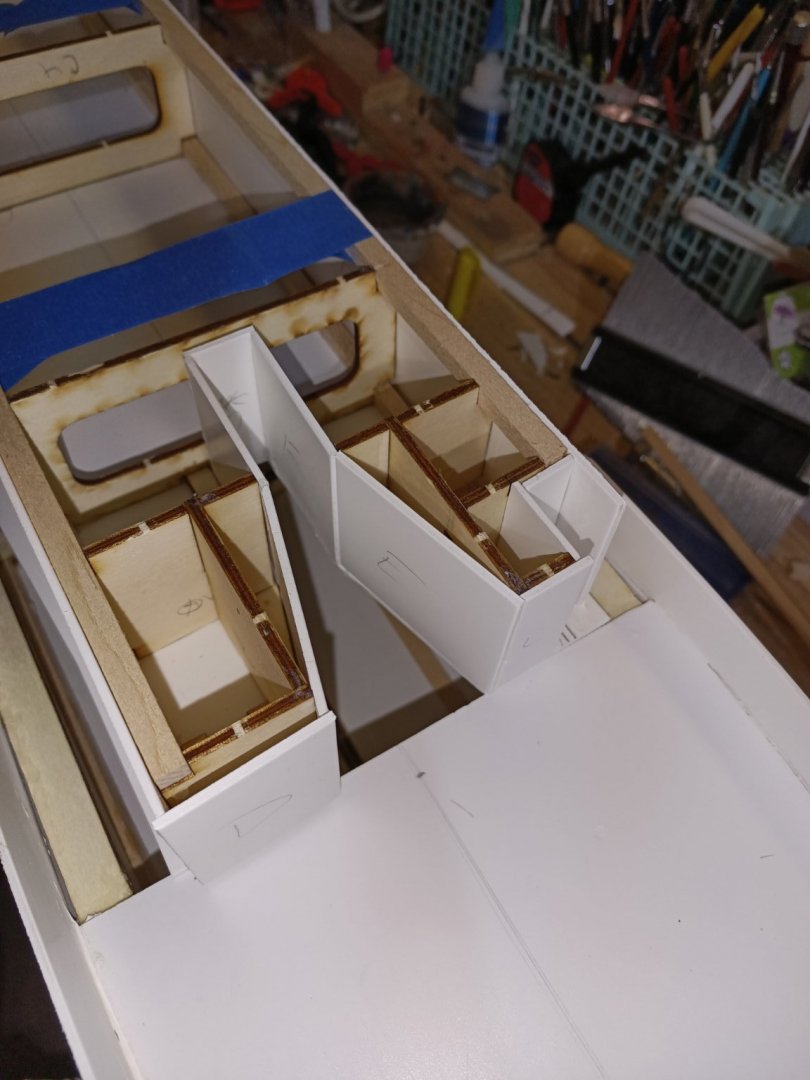

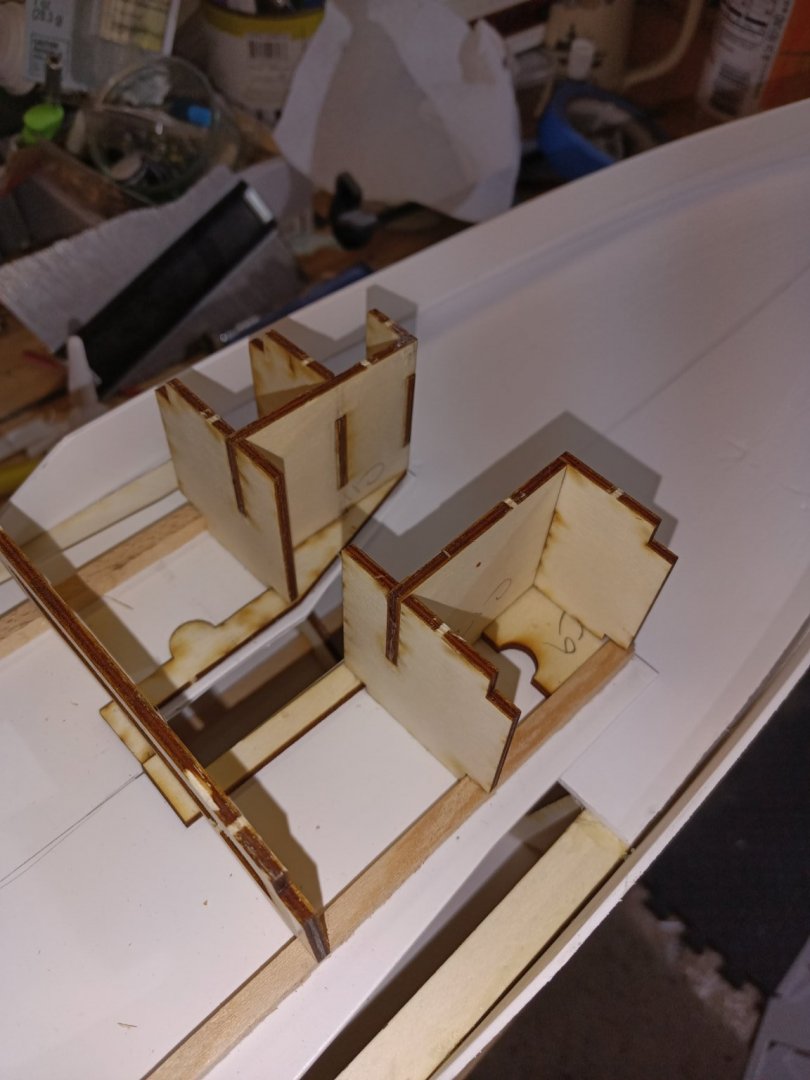

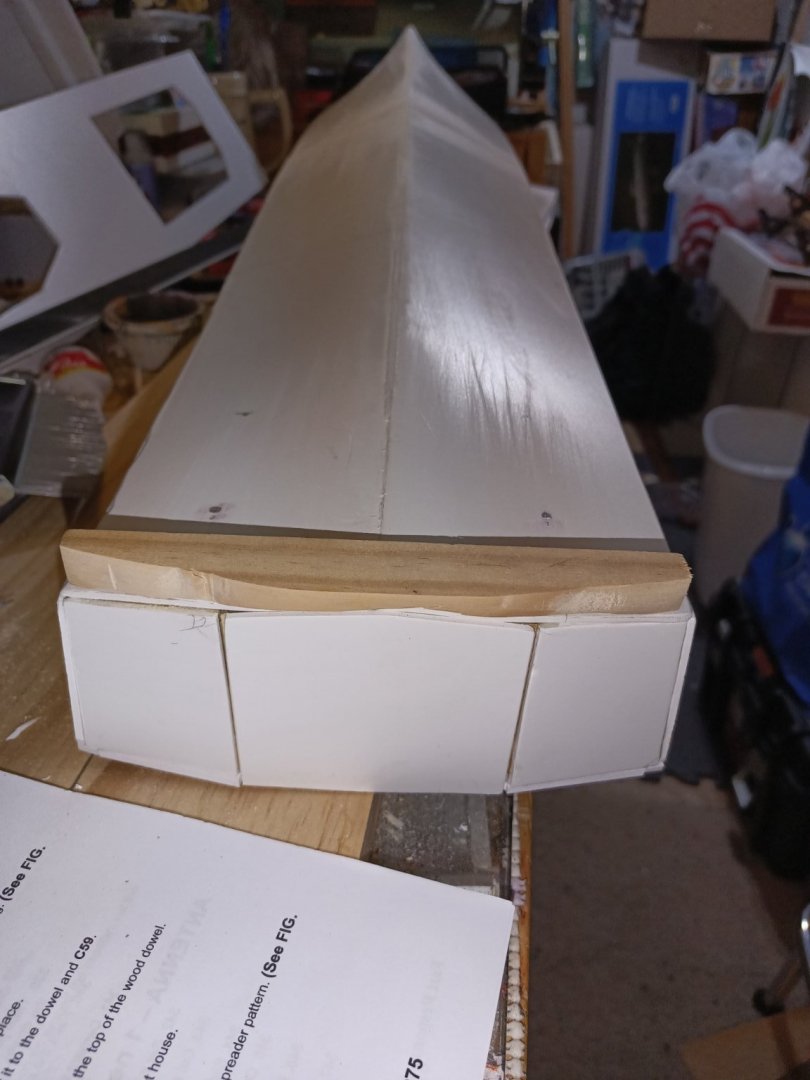

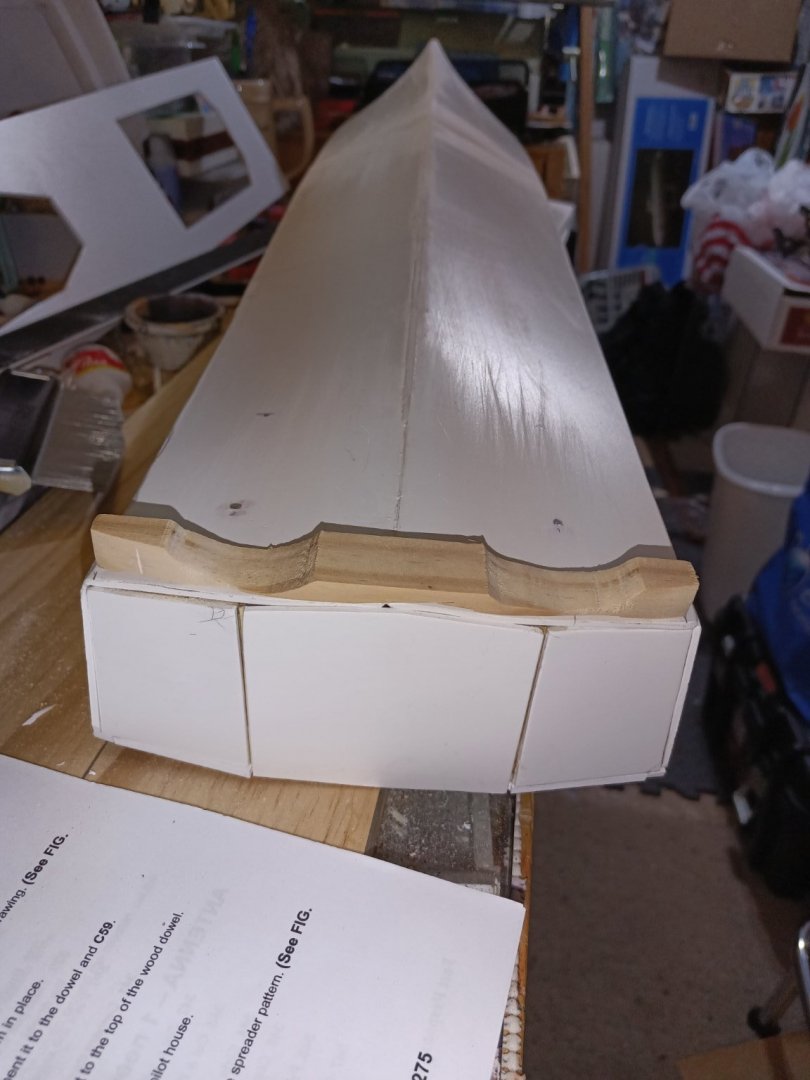

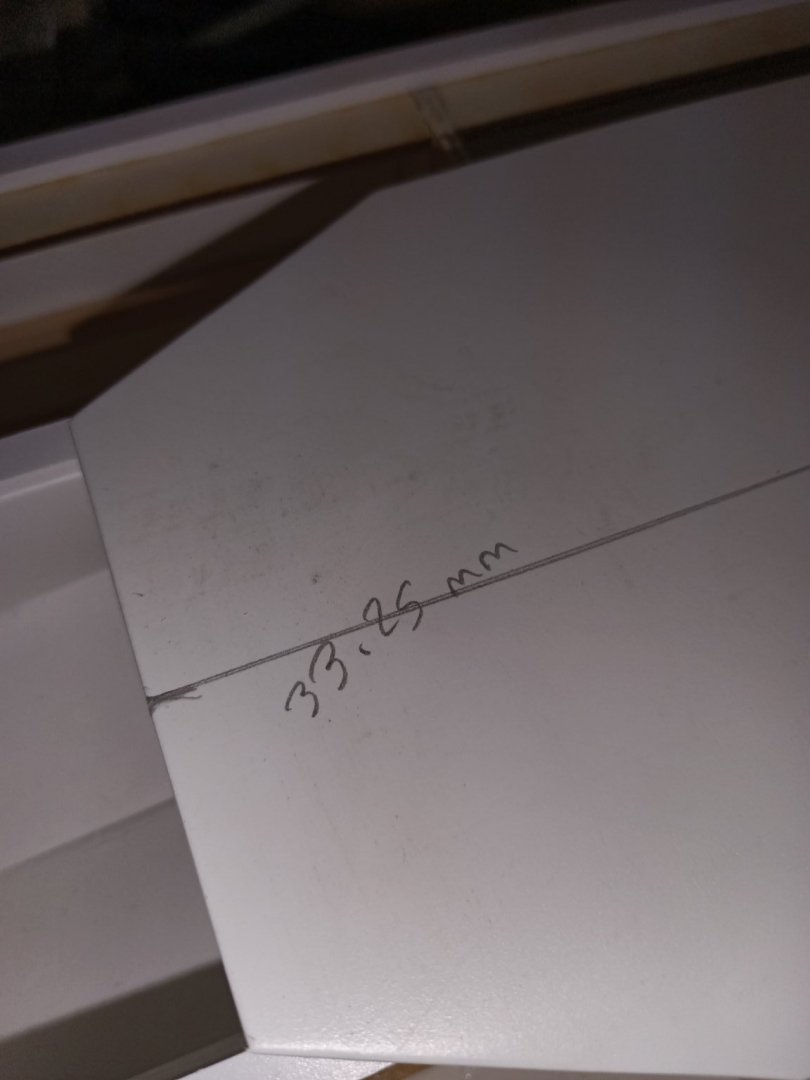

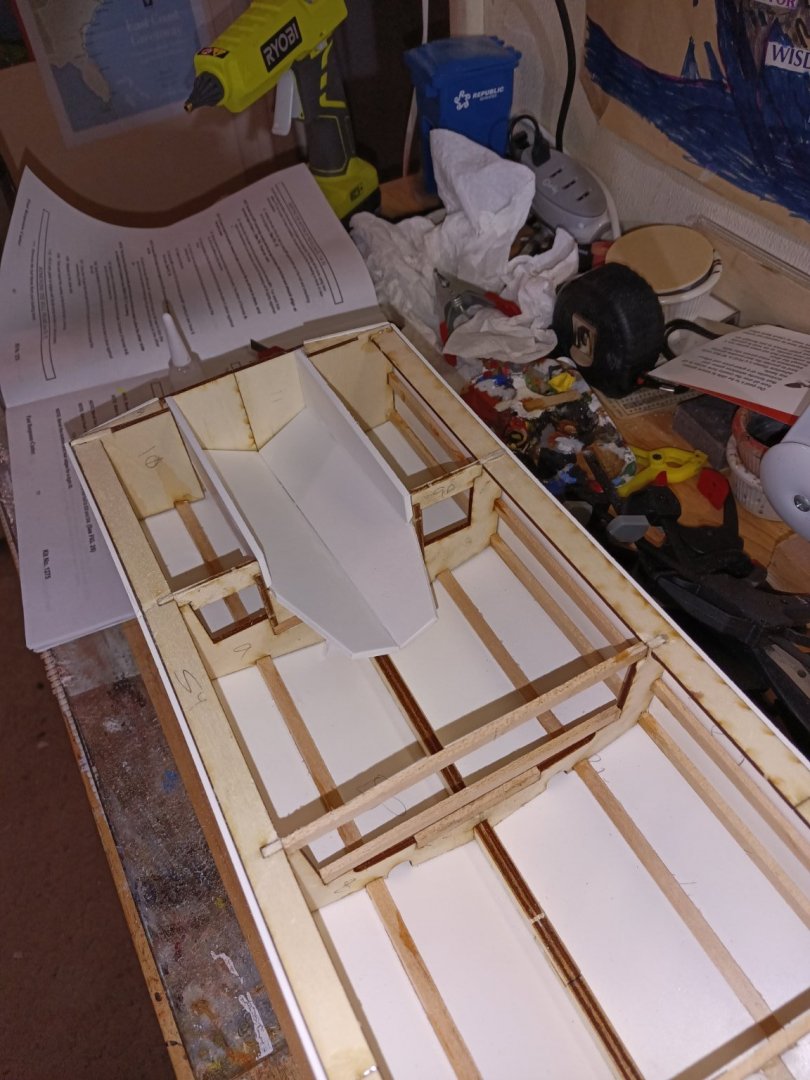

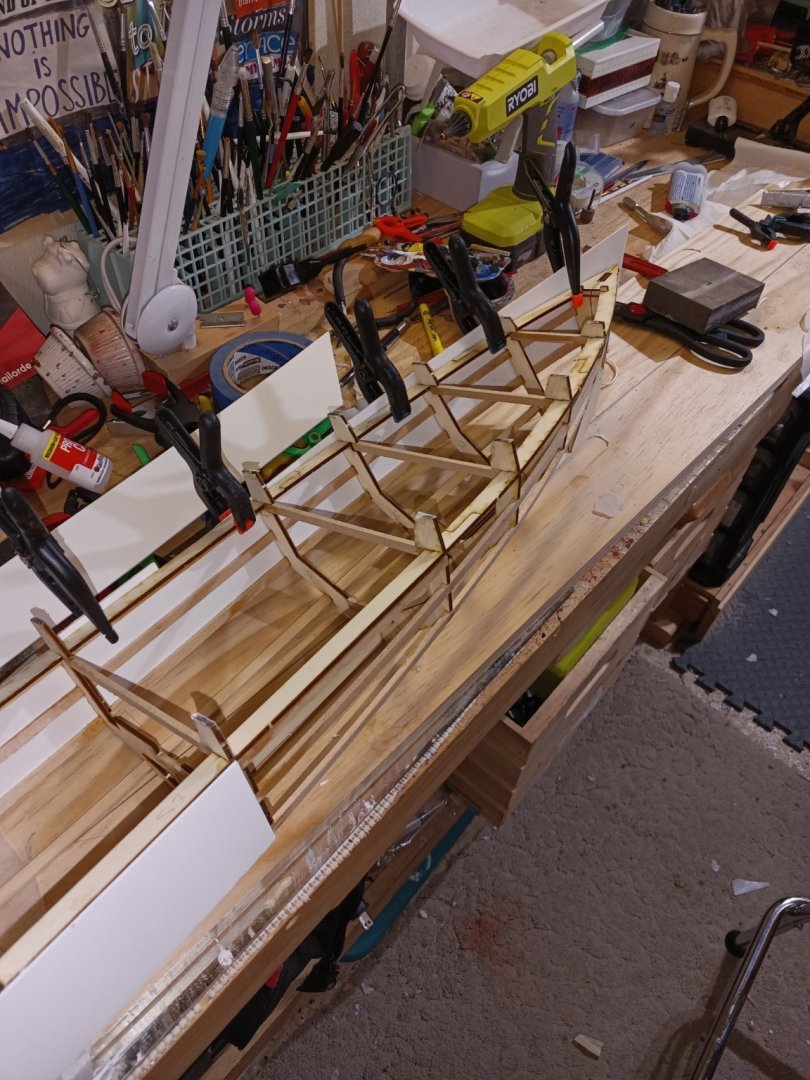

I used a lot of epoxy putty and sanding to get the tunnels complete. So far I am glad I did it because the stern will look sharp once the anti fouling paint and draft marks are on. I slapped some black paint on the stern to look for high spots when I sand it a final time. A shipmate sent me a photo of the stern of another FRC soon to be launched. This helped me out so I will post it here. I also started building the roof of the 01 deck and installing bulkheads. These are super tricky and the port and starboard structure rails are different sizes. The instructions are a bit ambiguous with the markings but just got slow and make sure you test fit a few if the basswood "C" bulkheads prior to gluing in the rear C9 flat panel guides.

-

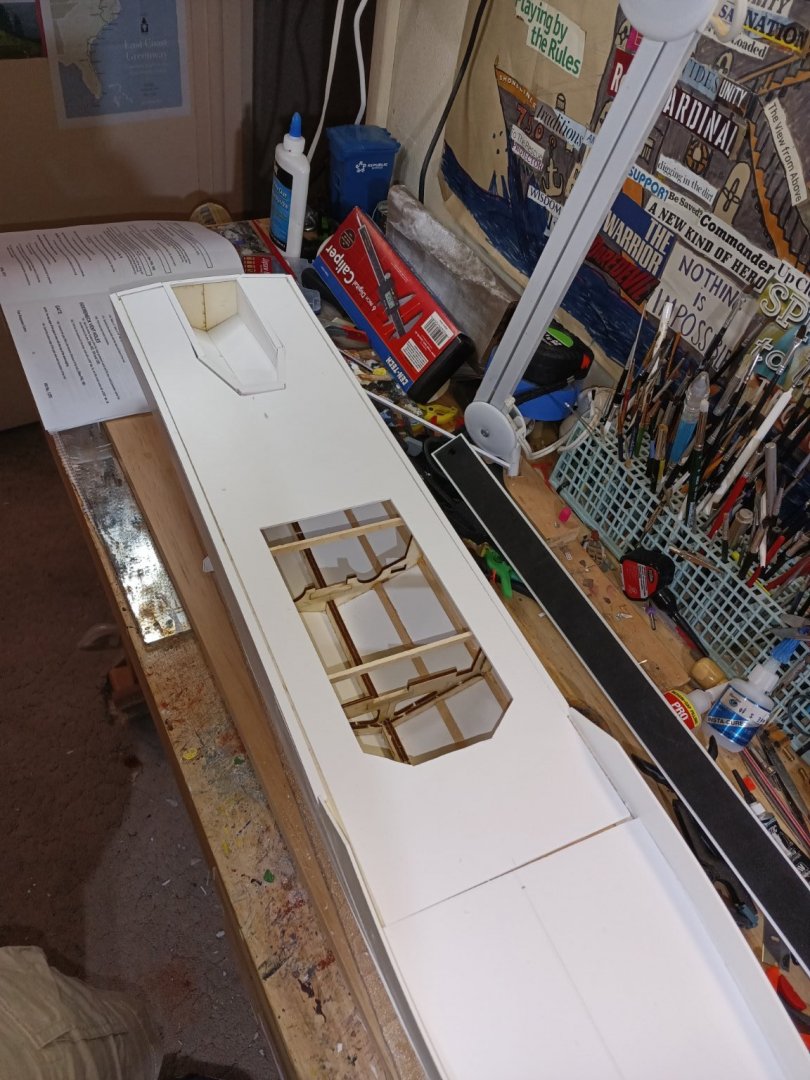

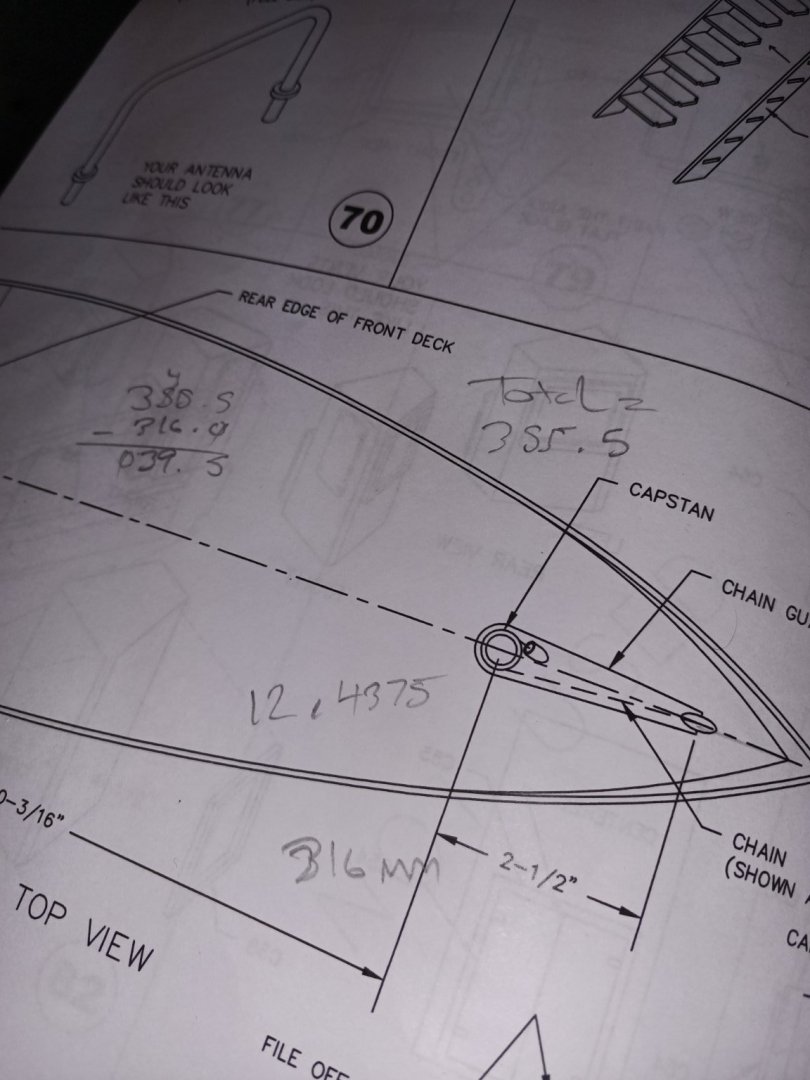

I finally got the courage to cut out the anchor chain tube in the forecastle. The diagrams on where to put the hole in the deck. Use a small bit first and go slow. Move up to a 1/4 inch bit. Slide the 1/4 inch tune up into the hole and cut flush. The boat door was glued up on the stern. The back deck was also cut to fit as a slide in.

-

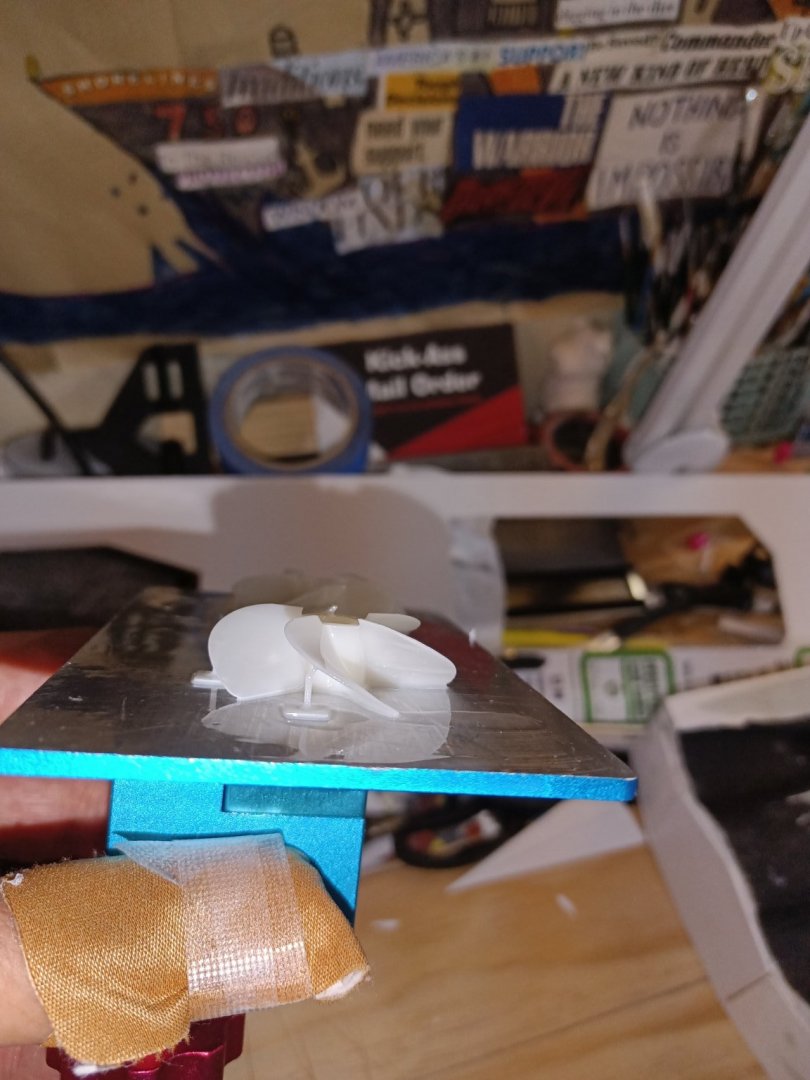

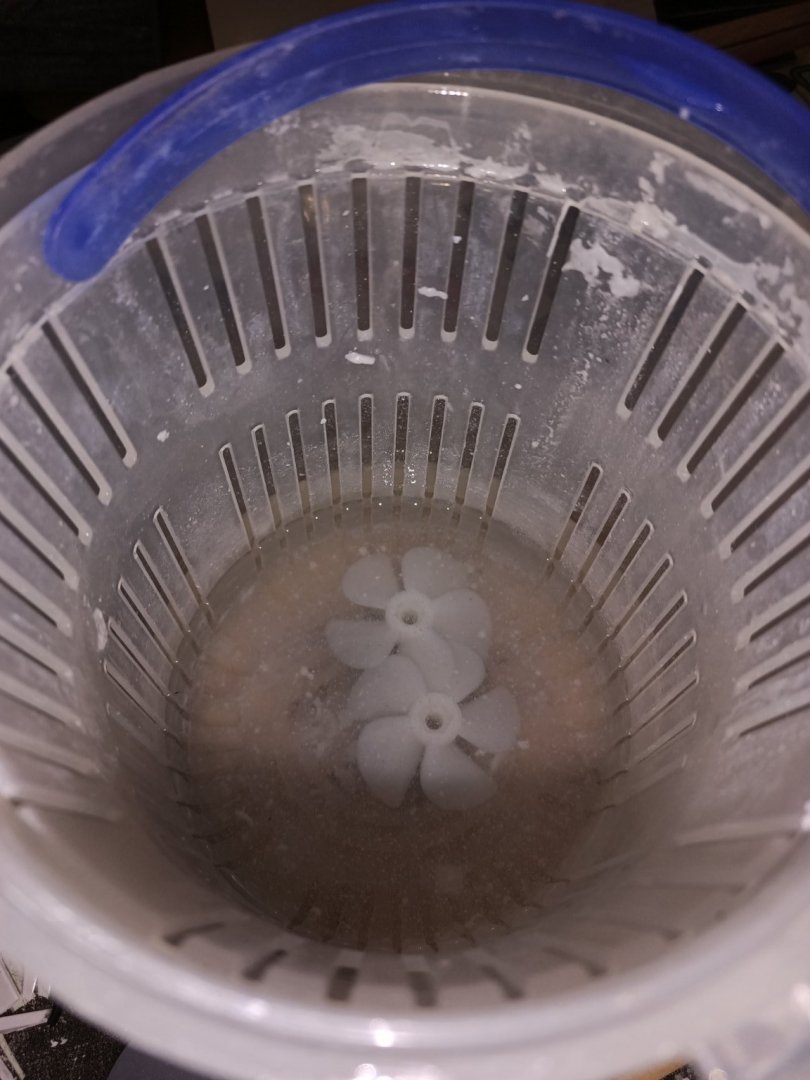

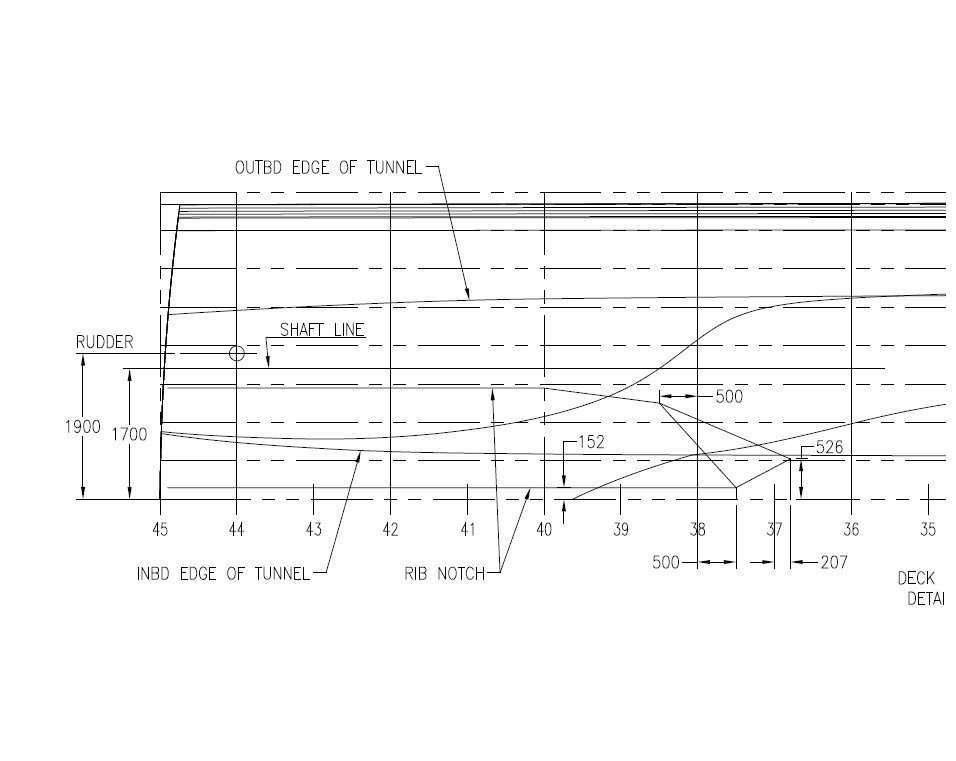

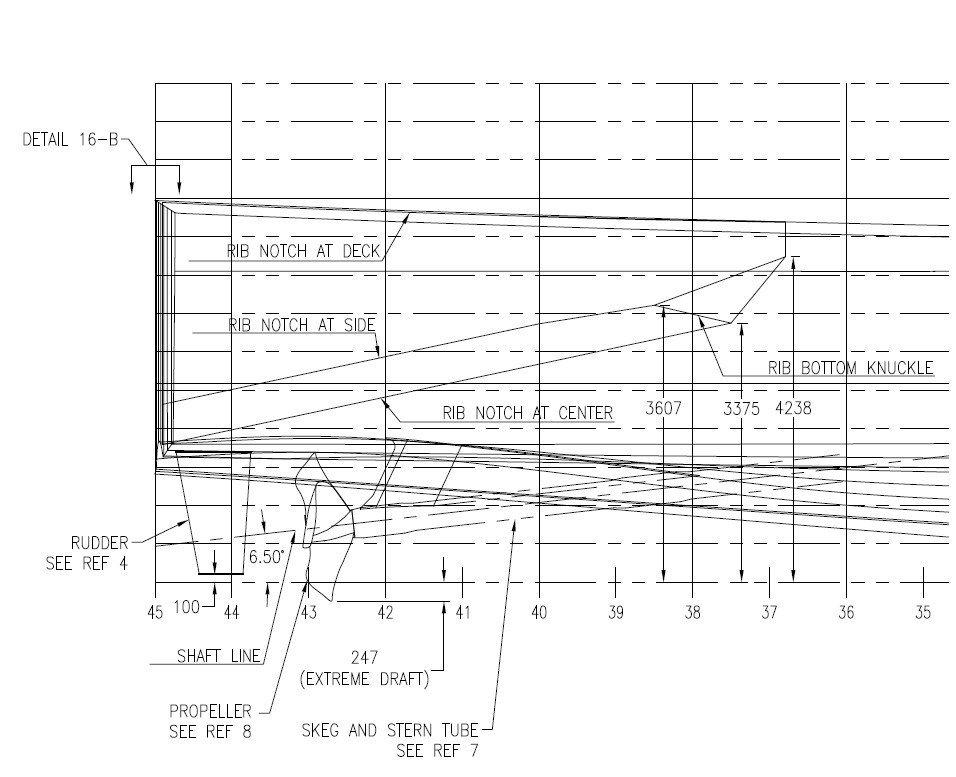

I created a couple of 3D print files today. The props on the FRC's are four bladed. I have seen various photos of the real ships but several of them seem to look different. I settled on the 4 blade model attached here as an .obj file. This kit comes with NO PROPS so you are welcome! In addition I needed two decently scaled rudders to replace the brass flat plate and copper tube stock that Dumas included. While the rudder I made (on the computer) is still not perfect to my liking I will be playing with it. I started the print about 20 minutes ago for the rudder so I want to see if the file is viable in the real world at this point. In 1/48 the rudder from tip to hull protrusion should be about 19mm high. The fore and aft length should be similar at around 17mm at its widest. propeller.obj Rudder final scale.stl

-

I have been laying out the rudders. The kit clearly makes some changes from the original cutter for R/C operation. I looked at the actual line drawings of the cutter and see that the rudders are very far back on the actual ship. I scaled the drawing up from 1:50 to 1:48 which is what the kit scale as. The picture I took was of where the kit says to put the rudders stocks.

-

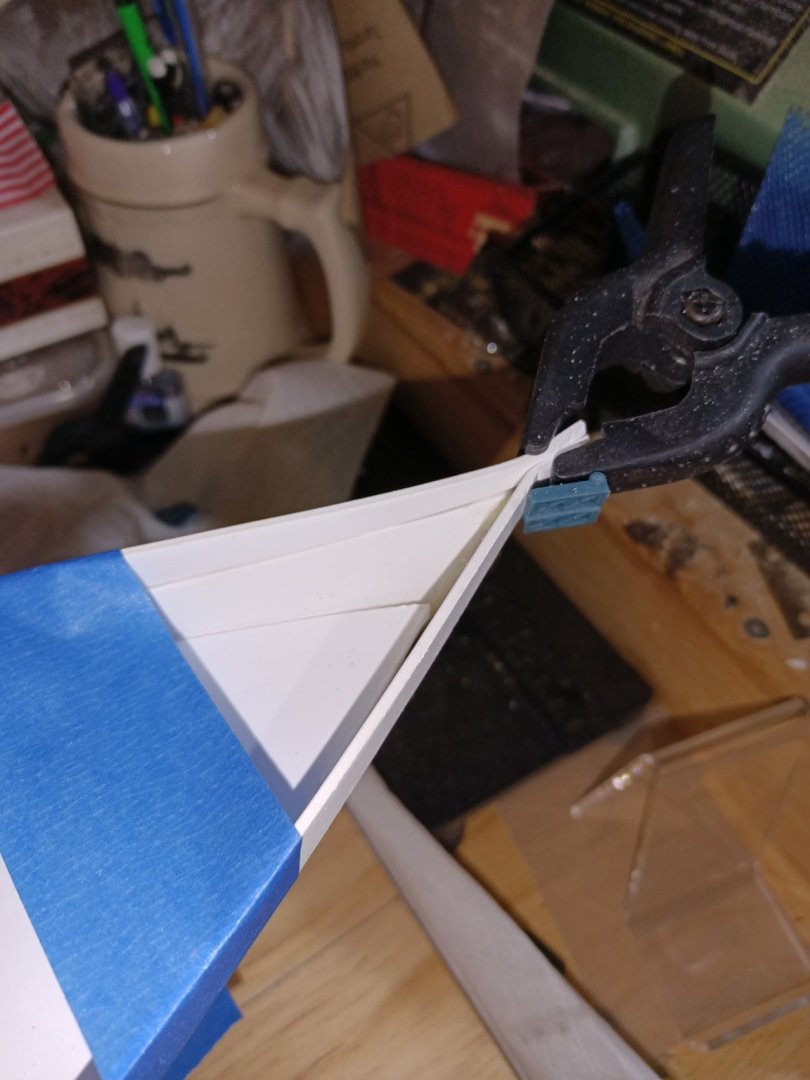

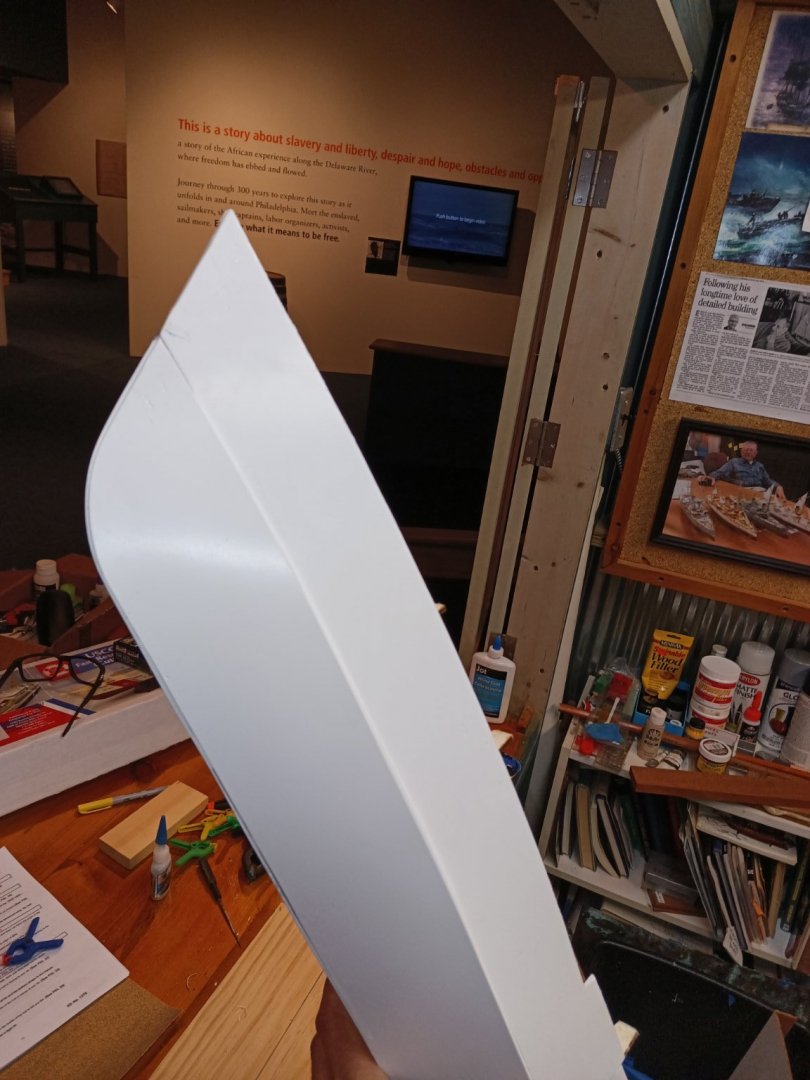

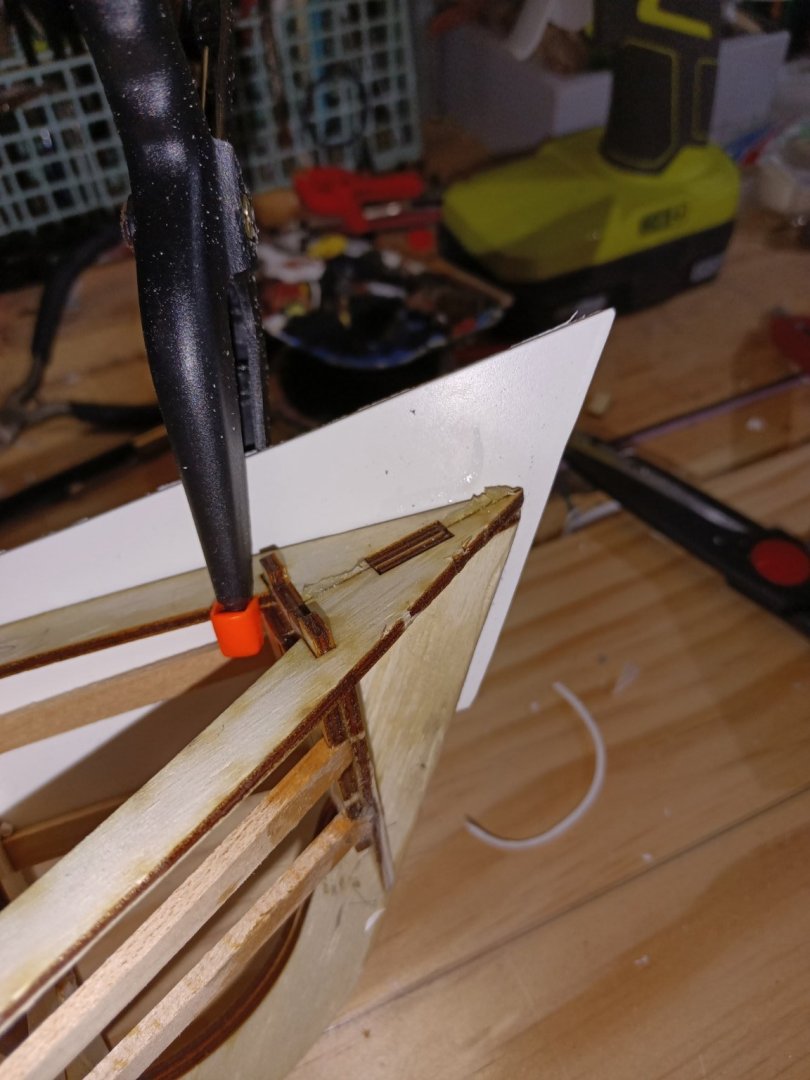

The final bow rail pieces were fitted. There is a jig provided in the kit to true these up relative to the deck. Since both pieces extend beyond the stem I decided to simply bend the plastic back and use it as a clamping point. The worked well. They boat well in the stern went in fairly easy but your need to do a bunch of angle tapering to get it to fit. The plans say to sand the pieces flush with the frames. I highly encourage you to do this prior to glueing them in.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.