bigcreekdad

NRG Member-

Posts

439 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bigcreekdad

-

I'm replanking the ship after an abysmal attempt at tree nailing. I'm planking over the original, and will sand down quite a bit when complete. I'm still uncertain whether I will tree nail or not. I'll post a pic of the replanking when complete. In the meantime, I'm toying with the idea of not mounting the swiveling cannon in the bow. Frankly, I think it looks a bit goofy....no offense to those who have built the ship with the cannon. Any ideas on some deck furniture to take the space?

-

ARGHH! Plans needed for Mortar Vessel Convulsion UPDATED

bigcreekdad replied to bigcreekdad's topic in Wood ship model kits

Kinda disappointed....no help here, and no response from Caldercraft. My fault, but I really hate to scrap my build. -

My mizzen mast has broken below the trestle tree. I had to remove the whole mast, which necessitated cutting away a ton of rigging. Stupidly, I threw away the plans after completion (BIG lesson learned there). I will be doing a lot of rebuilding here. Are there any builders of this kit in the USA who still have their plans? If so, would you be willing to ship them to me? I will copy and ship back right away, and pay all expenses. Otherwise I will contact Caldercraft and purchase a new set. Thanks Mates. Update...heard from Jotika today. Plans available at very reasonable price.

-

I'm going to scrape with the razor blade, as advised, and the apply a medium dark stain. If I'm not satisfied, I'll plank over it. This is doubly frustrating as I bought and milled my own planks with some very nice maple I got at Woodcrafters. Thanks for all the suggestions. Live and learn I guess. I do want to treenail my next ship (Fair American), so I will put way more thought into it.

-

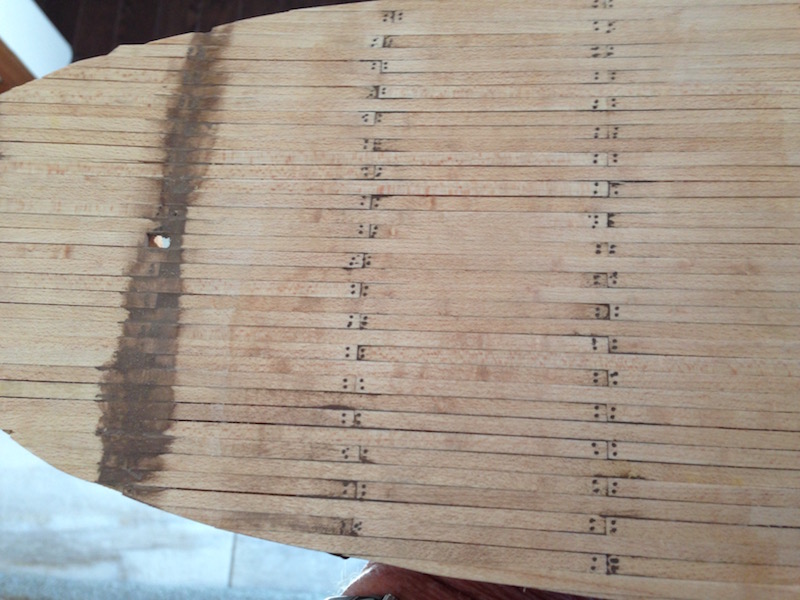

Used my smallest drill bit. Hole alignment leaves much to be desired, but I'm more disappointed in how this looks other than alignment. I used wood filler.....maybe too dark, but I'm not at all thrilled with this. Any thoughts? I'm far from looking for someone to convince me it looks good, so have at it.

-

I've built 4 ships....the Convulsion was my favorite. Go for it!!

-

Actually...didn't sleep on it. Decided to quit whining and proceed. Keel has no warping, and half the bulkheads are installed.

-

I just finished the Pickle, and after cleaning up, thought about my next build. On the shelf were both the Fair American and the Dos Amigos. I decided on the Amigos, and pulled out all the box contents. I was quite surprised at the wood quality of the laser cut parts....seemed thin, flimsy, and....well, cheap. I usually read a few build logs of others of the ship before going too far. I found only two for this ship, but both builders seemed to echo my thoughts. It appears that other wood was substituted in some cases. I have a bit of pear and boxwood that I plan to use on my Triton cross section build, as well as to plank above the wales on the Fair American, and I really don't want to use it on the Dos Amigos. I'm half tempted to put it all back in the box, and switch to the Fair American. However, I know if I do, the DO kit will remain on the shelf. Been used to the higher quality (IMO) of the Jotika kits (Pickle, Sherborne, and Convulsion), and Model Expo (Bluenose). Gonna sleep on it.

-

I'm rigging my Pickle build. Plan sheet 4 of 6 shows 2 tackle pendants on both the main and the foremast. I see no rigging attached to them in any further plan sheets. Any Pickle builder out there to help me out?

-

Is there any easy way to do this, without investing in a loom?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.