bigcreekdad

NRG Member-

Posts

436 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bigcreekdad

-

I was intending to use cherry for the inner planking, but yet another piece of cherry broke as I was feeding a piece into my Byrnes thickness sander. I'm convinced I picked up some bad cherry at Woodcraft. So, I decided to use walnut (also from Woodcraft). No problems with this, and layed 4 pieces. Wow...do I love the contrast of the walnut and the cherry! What do you think?

-

Have faired and sanded inside and out. The photo suggests otherwise in places, but all ribs are pretty even on both sides. Still a minor amount to do, but I'm starting to cut the inner plants and flooring. Was going to do most of the inner in cherry, but I'm still having breakage problems. I've broken enough in this hobby to know these breaks are not from undue handling. Bought the cherry at Woodcraft. Might just have to buy from the suppliers others use on this sight. Decided to use walnut instead for at least the inner planking closest to the keel. BTW, the two pieces you see are not attached. Any way...Onward!!

-

Effie M Morrissey by allanyed

bigcreekdad replied to allanyed's topic in - Build logs for subjects built 1851 - 1900

Very impressed! Keep going.- 15 replies

-

Bit the bullet and rebuilt the broken frames. Required me to remove all frames from the keel, and thus build ,a new keel as well. All frames mounted, and added several spacers for holding proper spacing as well as added strength. All drying now. Will need to do some serious sanding to fare everything up. In the meantime, need some suggestions for the inner planking and decking. I'm going to use pear from the outer framing. I have some holly, and plenty of cherry, but would love to hear some thoughts from others.

-

Work station clutter

bigcreekdad replied to Senior ole salt's topic in Modeling tools and Workshop Equipment

Give up...been there, done that, and it just gets worse. Drives my wife absolutely nuts, so she stays out of my den....so, it's not a completely bad thing. -

Saw is about 15 months old. Today it started changing speed during a cut. Stopped it, restarted and the variable speed dial at first didn't work (no change in speed) then it did. I started cutting again and it start to slow down mid cut. Reinstalled the blade, just to do something, but it continued. Anyone experience this? Moved to this saw from a basic Sears unit. Thought I was stepping up. Pretty disappointing. Update....found the speed adjuster loose. I retightened, and also found I had the recently installed new with pins, incorrectly tightened with the adjustments that are used with pines blades. Seems to be operating OK now. I've got some cutting to do tomorrow, so I'll see if works OK.

-

I have started, then scrapped my progress 4 times now. Lousy frame cutting, breaking frames, 3 tries coming up with an acceptable jig to get the frames to set at a good consistent 90 degrees.. I'm darn near ready to scrap it all again and start from scratch. Before this, I ended up scrapping a scratch build Hannah, and based on advice here, thought I'd give a cross section a try. I want to make another attempt at the Hannah someday, but I now realize fully well that if I can't master a cross section, I'm never going to be able to do a decent full scratch. A few questions....I've been using cherry for the frames. I don't know if I just have had some bad pieces (bought at Woodcraft), but my frames seem to break easily. at the joints. First question....is there another wood for the frames I might try. Second, I've not been tree nailing the frames where they overlap. Is this mandatory and would this cut down the breakage? Any help would be greatly appreciated.

-

I've had a cheap combo belt/disc sander for several years. I use the belt sander to fine tune frames after cutting them with my scroll saw. Yesterday, the table adjustment control broke (plastic of course) and the table will not set at 90 degrees from the belt. I tried using the disc, but there is too big a gap between the disc and the table, so trying to work with small pieces is very difficult. Bottom line...time for a new sander. I realize that the Byrnes sander is the standard, but my price point is around $200 max, and also, there is usually a bit of a lead time on getting borne's products. Any thoughts on good sander in my price range?

-

Excellent job. I'm just now doing deck fittings on my Pickle. I hope my end product is even close to yours. So.....what next for you? I will next begin the Fair American.

- 76 replies

-

- caldercraft

- finished

-

(and 1 more)

Tagged with:

-

Wow.....Thank all of you for your service. The best of the best.

- 440 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Gary....great job! Is that a fly tying vise in the pic of the deadeyes and copper wire. Might you be a fly tier?

- 206 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

If we learn from our mistakes, I must be pretty smart now.

bigcreekdad replied to skipper1947's topic in Wood ship model kits

I use the galloping horse thingy when my wife asks if she is still beautiful. BTW....Your ship looks awesome!! -

Gary I am very impressed! The Fair American kit is "on the shelf", and will be my next kit build after I finish the Pickle. To even come close to your ship would be a big accomplishment for me. Your build log will be visited often when I start her. John

- 206 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

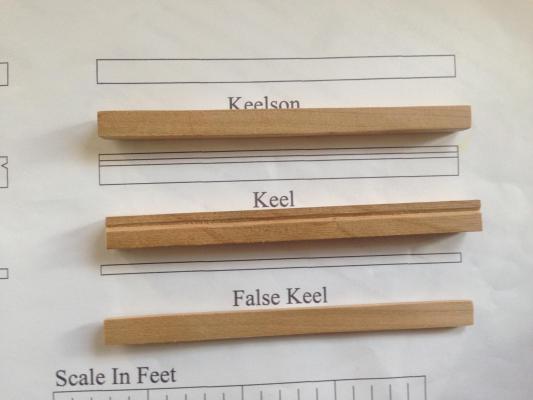

I started this at the advice of several members after a failed attempt at my first POF build...The Hannah. So far, I think it was darned good advice. Hopefully, I'll complete it and will be pleased, and will then move on to another attempt at The Hannah. I chose cherry for the keel assembly and the frames. Not sure about the rest. I've got a nice supply of Swiss pear and boxwood, as well as some ebony and bloodwood (which looks intriguing). Not to mention plenty of cherry left. Any thoughts or suggestions from others are welcome. I'm posting today a pic of the keel assembly pieces, as well as completed frames 0 and 1. Hopefully more to follow.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.