aymodeler

Members-

Posts

19 -

Joined

-

Last visited

Recent Profile Visitors

-

GrandpaPhil reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

GrandpaPhil reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

EricWilliamMarshall reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

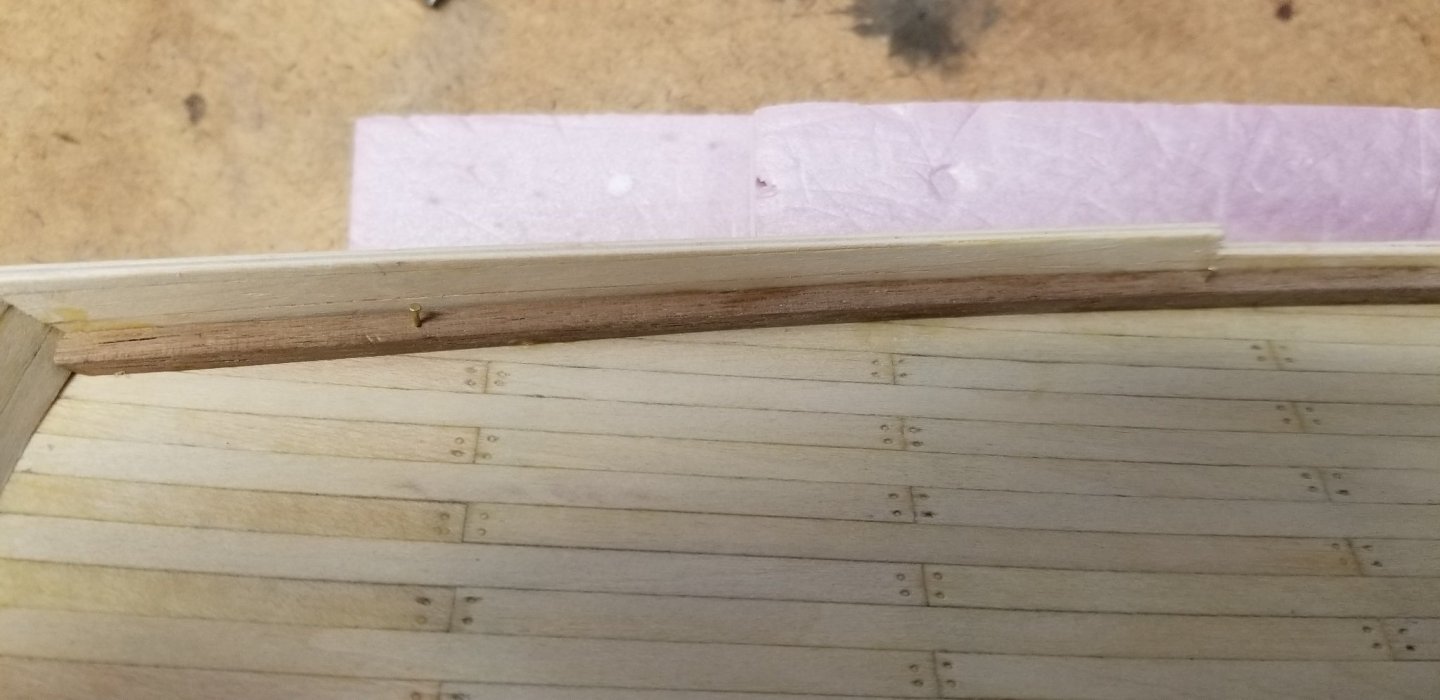

Not much new progress to report. I did get the stringers installed inside the bulwark. I soaked them in hot water then formed them around the edge of a small saucepan to get the bend near the bow in place. I still had a bit of difficulty getting them to stay tight into the corner between the deck and the bulwark and I really didn't have a good clamping solution, so I used some temporary pins to hold everything in place (filling the holes with glue and sawdust after they were removed). Unfortunately, I am dealing with a bit of health issue right now, so I will not be posting for a bit (I have high confidence that I will be back later this spring though!).

-

aymodeler reacted to a post in a topic:

Primer for small metal parts

aymodeler reacted to a post in a topic:

Primer for small metal parts

-

Agreed. I use shellac on smaller, decorative pieces. There is something about the look and even the feel of a traditional shellac finish that gives a handmade piece a sense of warmth and even soul that cannot be recreated with poly finishes. But acrylic poly is my go to for anything that needs to stand up to daily wear and tear, and with a good HVLP setup, it is fast and easy to apply.

-

aymodeler reacted to a post in a topic:

Primer for small metal parts

aymodeler reacted to a post in a topic:

Primer for small metal parts

-

I was originally thinking Binz, which is a shellac based primer, but decided to give the Tamiya spray primer a try. I don't currently have an airbrush (and these parts are a bit small for my HVLP setup 😀), so I will brush on Tamiya flat black. I only have a few small parts (one cannon, 2 anchors, and a few other small parts). If anyone is interested in seeing the kind of finish you can get with good old shellac, look for a video on applying "french polish". This is essentially a process of wiping on many, many, many super thin coats of thinned shellac with a linen pad. The end result is a deep gloss that will put any modern polyurethane finish to shame!

-

I am progressing to the point on my Artesania Latina Virginia build to where I need to start thinking about painting some of the smaller metal parts. Any advise on a good primer to use on such small parts? I will be using acrylic paints. I am thinking of just good old Binz primer as I have plenty of this around and it has always served me well (albeit in MUCH larger applications 😀).

-

aymodeler reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

aymodeler reacted to a post in a topic:

Virginia 1819 by aymodeler - Artesania Latina

-

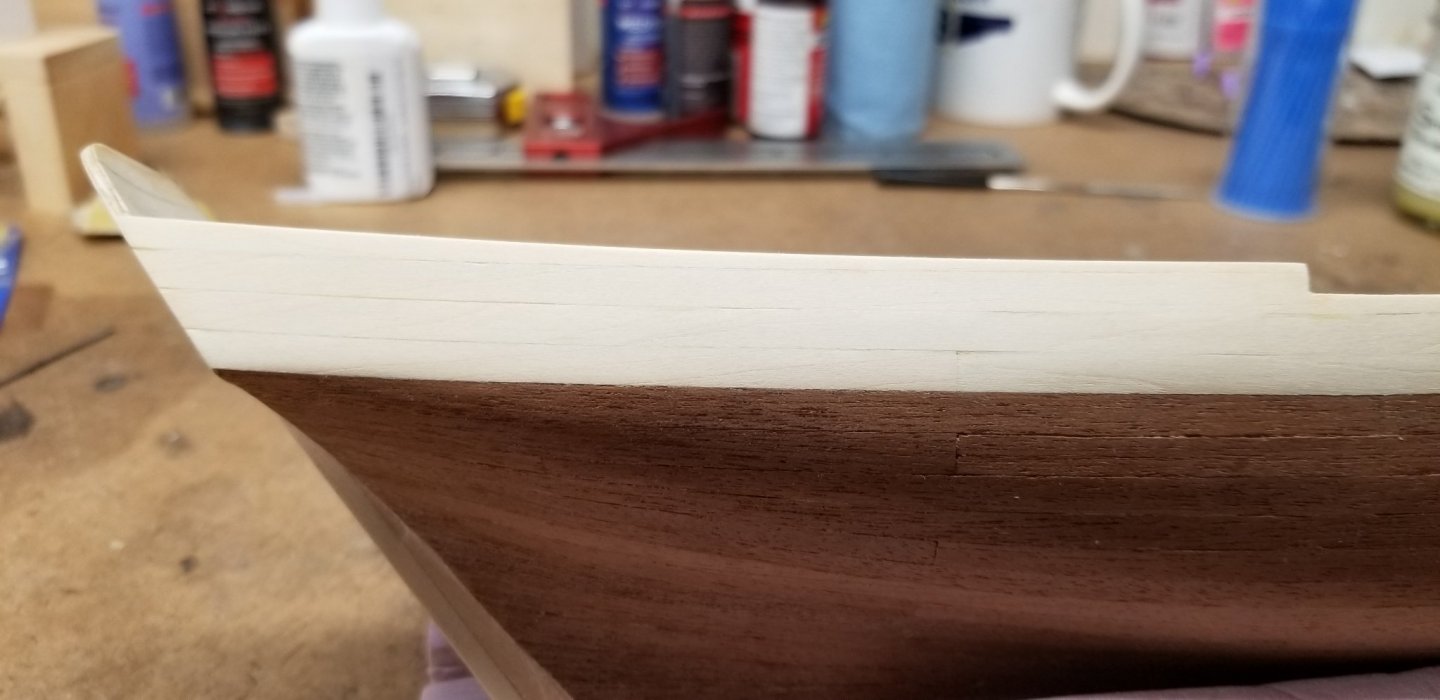

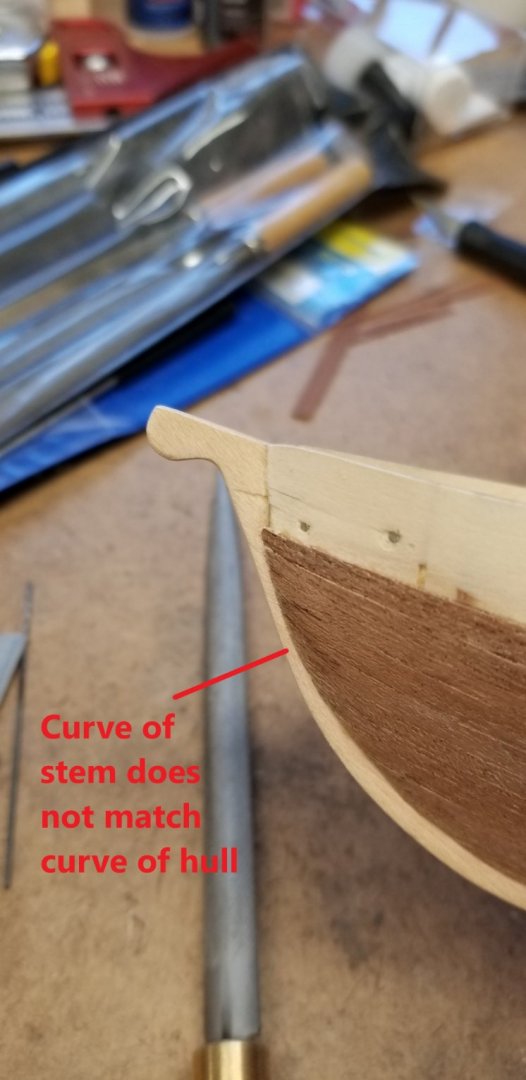

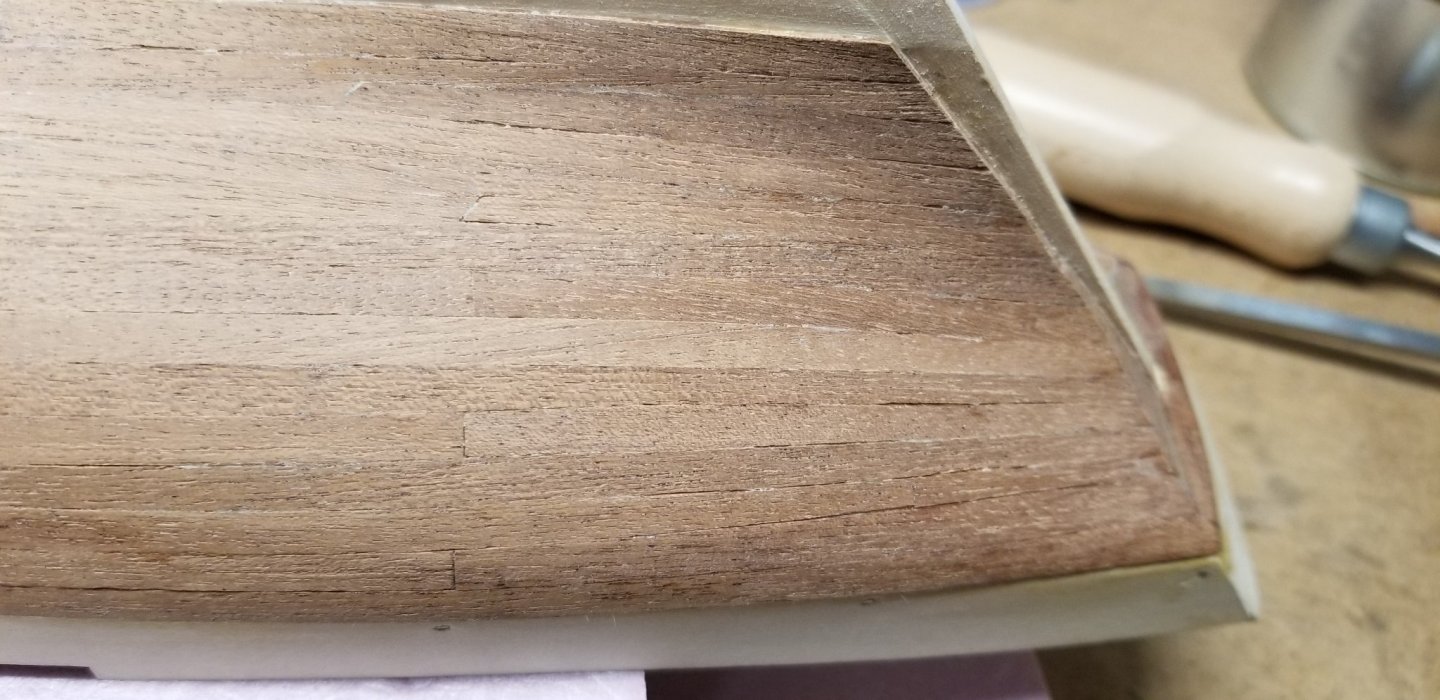

Today, I did a bit of filling of the planking gaps with homemade sawdust and glue "putty". I did this vary sparingly deciding that less is more here. After a bit of sanding, I am declaring this part done and moving on. It's not quite perfect, but it will be fine and I am quite confident that once it gets a coat of poly, I will be happy enough with it. After reading the Virginia build thread by SardonicMeow, I discovered a couple of mistakes that I made and need to address before moving on (I wish I had spent some time reading through other build threads before starting - lesson learned). The first mistake is that it apears that I did not assemble the transom properly, leaving a big gap when you try to fit the rudder. This seems to be quite a common problem as it appears in several build threads for this model. To fix this, I added a bit of material to the stern post so that the rudder will end up in line with the transom. Also, I needed to lengthen the post on the top of the rudder so that it will line up with the tiller slot. The next problem that I discovered was that I installed the stem too low down on the hull, such that the bowsprit would not sit at the right angle. To fix this, I glued a bit of scrap to the top of the stem, then rough cut it with a jewlers saw followed by a bit of cleanup with a small rasp and some needle files to get the right shape. Unfortunately, I also now see that the curve of the bow stem does not match the curve of the hull quite properly. There is not much I can do about that now, so it will be left as is. These repairs will leave some seam lines were the fixes were attached, but they are minimal and should get lost when all the remaining details are added. Onto the upper hull planking next.

-

GuntherMT, thanks for the tip. I have done something similar in the past with larger woodworking projects, and will give it a try here. I finished up the planking on the port side today. I did end up with a bigger gap on the last row, but was able to fill it like I did the starboard side. I had plenty of small cut-off scraps, so I would find a bit that was just a tiny bit oversized and then press it in with glue and the trim iron for nice tight fit. Both sides have been lightly sanded. I will try filling in some of the remaining gaps next.

-

A little more progress. Have the planking done on one side. Stealer added on the stern planking. A bit fussy but produces nice results. I ended up with a small gap near the bottom. I know the "proper" way to fix this is with a correction plank, but I just fit in a small filler piece. It will never be seen. Close examination does reveal some small gaps due to the relatively ragged edges to the sapele planking material provided with the kit. I tried to joint the edges by lightly sanding, but would have to have gotten very aggressive to get them completely square. I am tempted to apply a tiny bit of filler, but not sure if it will make things worse in the end.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.