-

Posts

635 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ilhan Gokcay

-

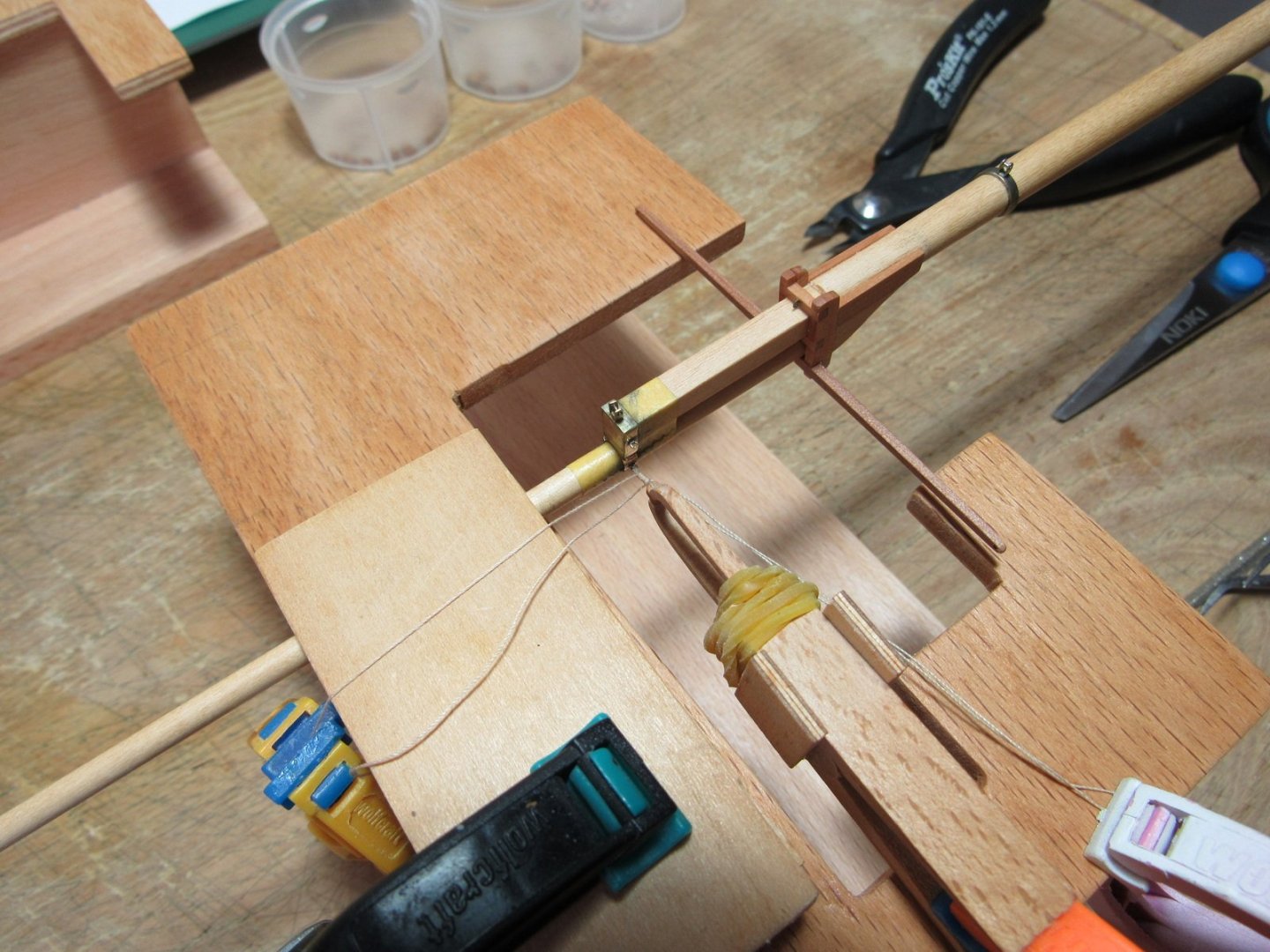

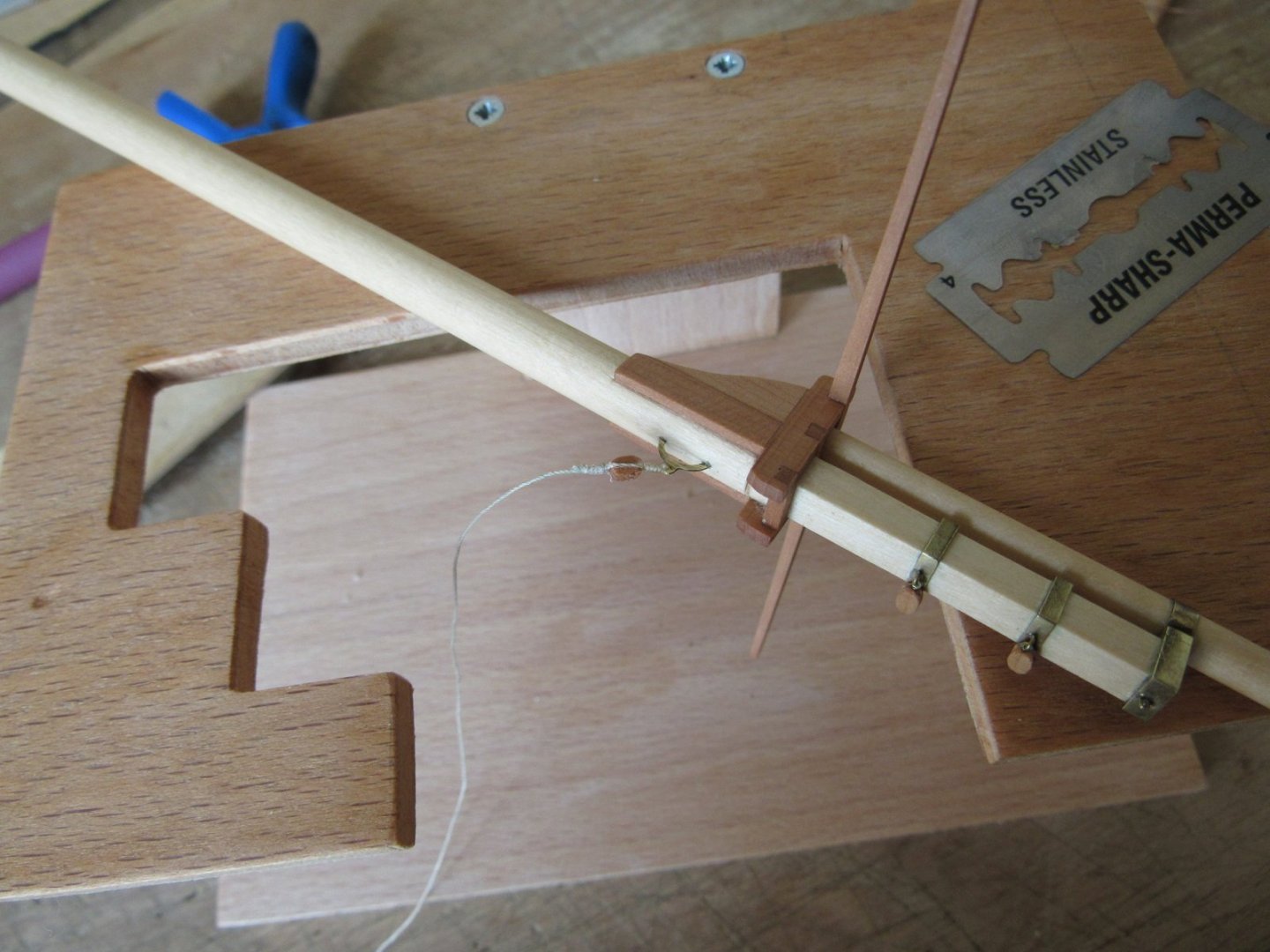

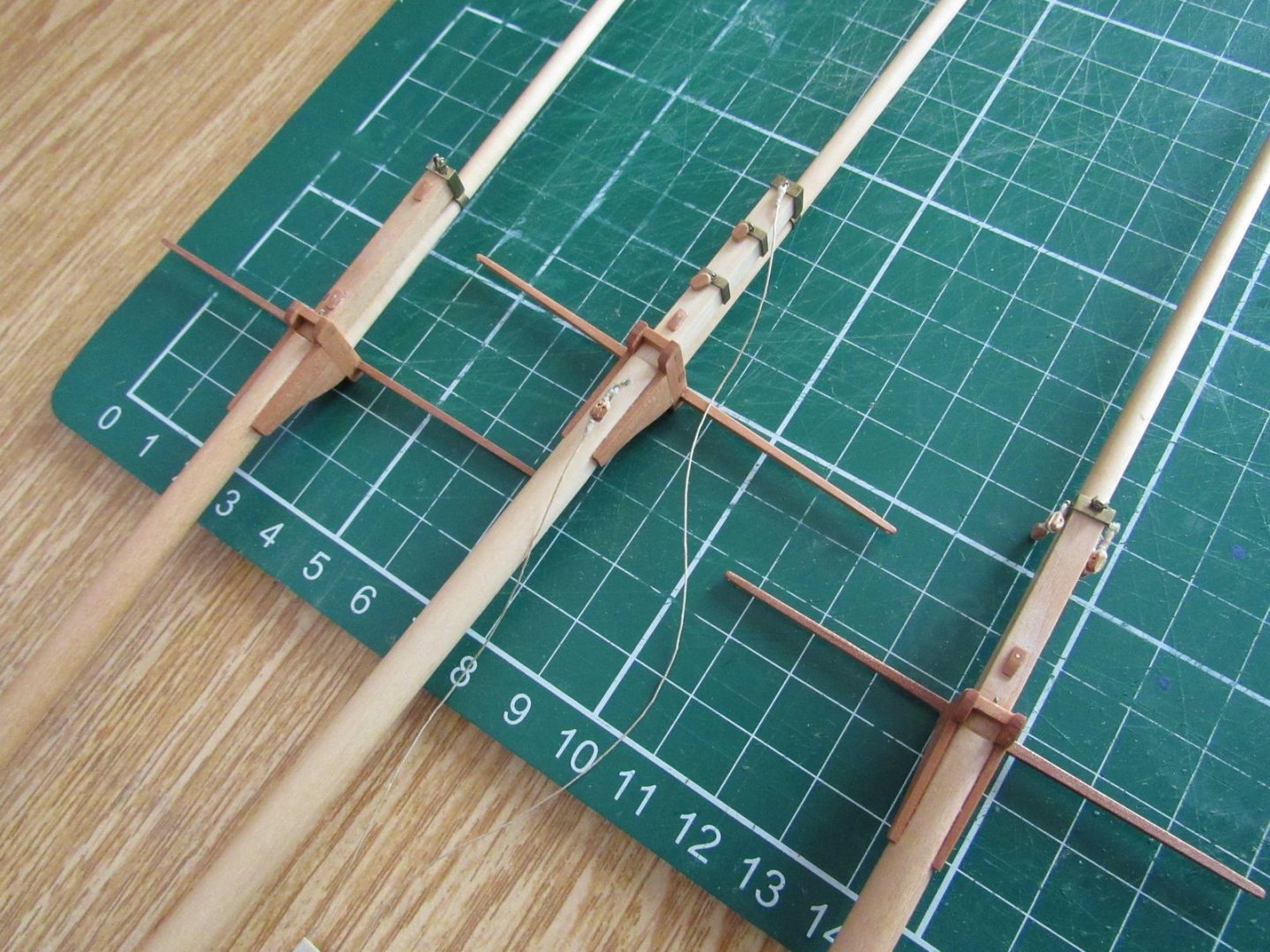

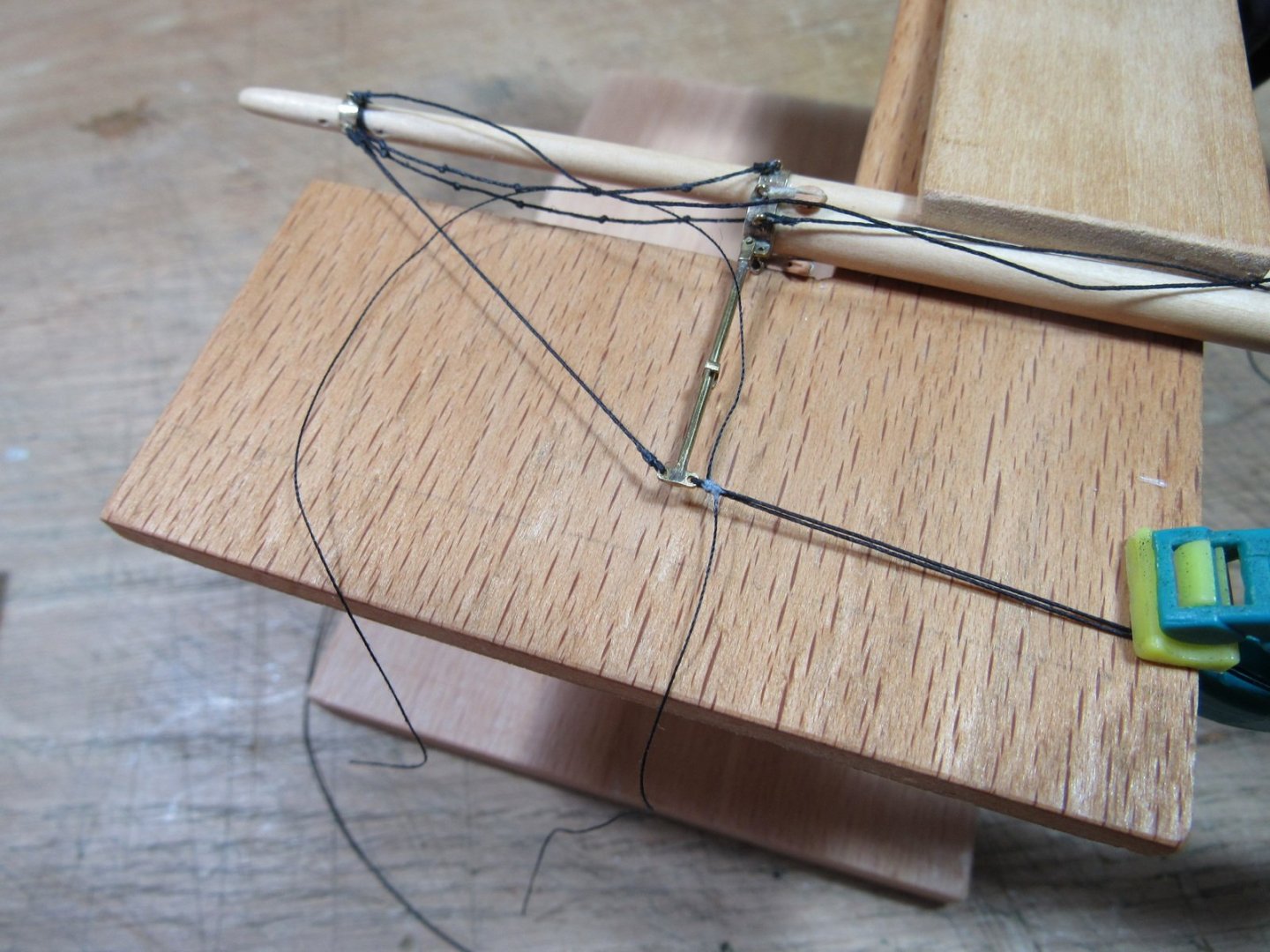

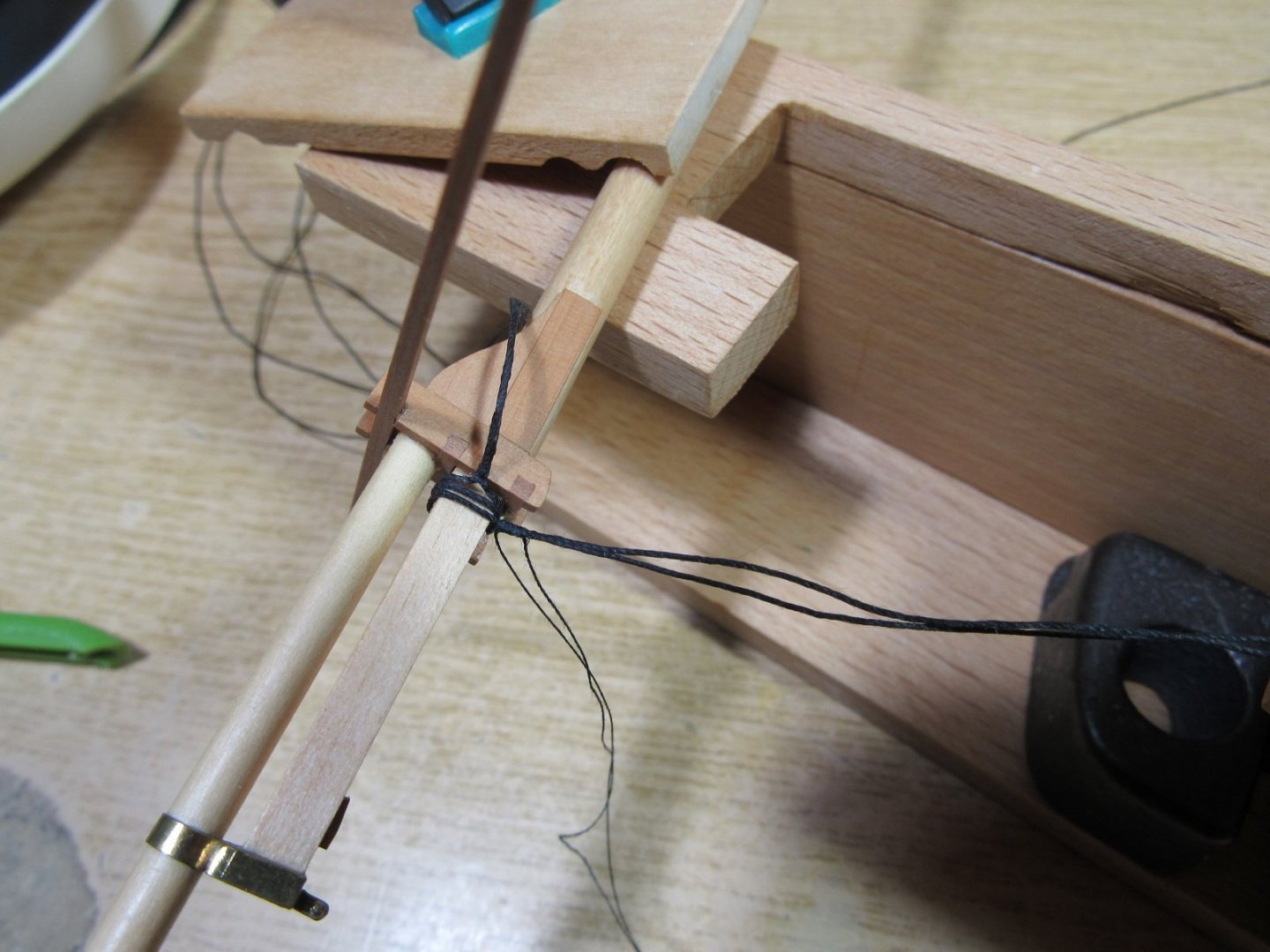

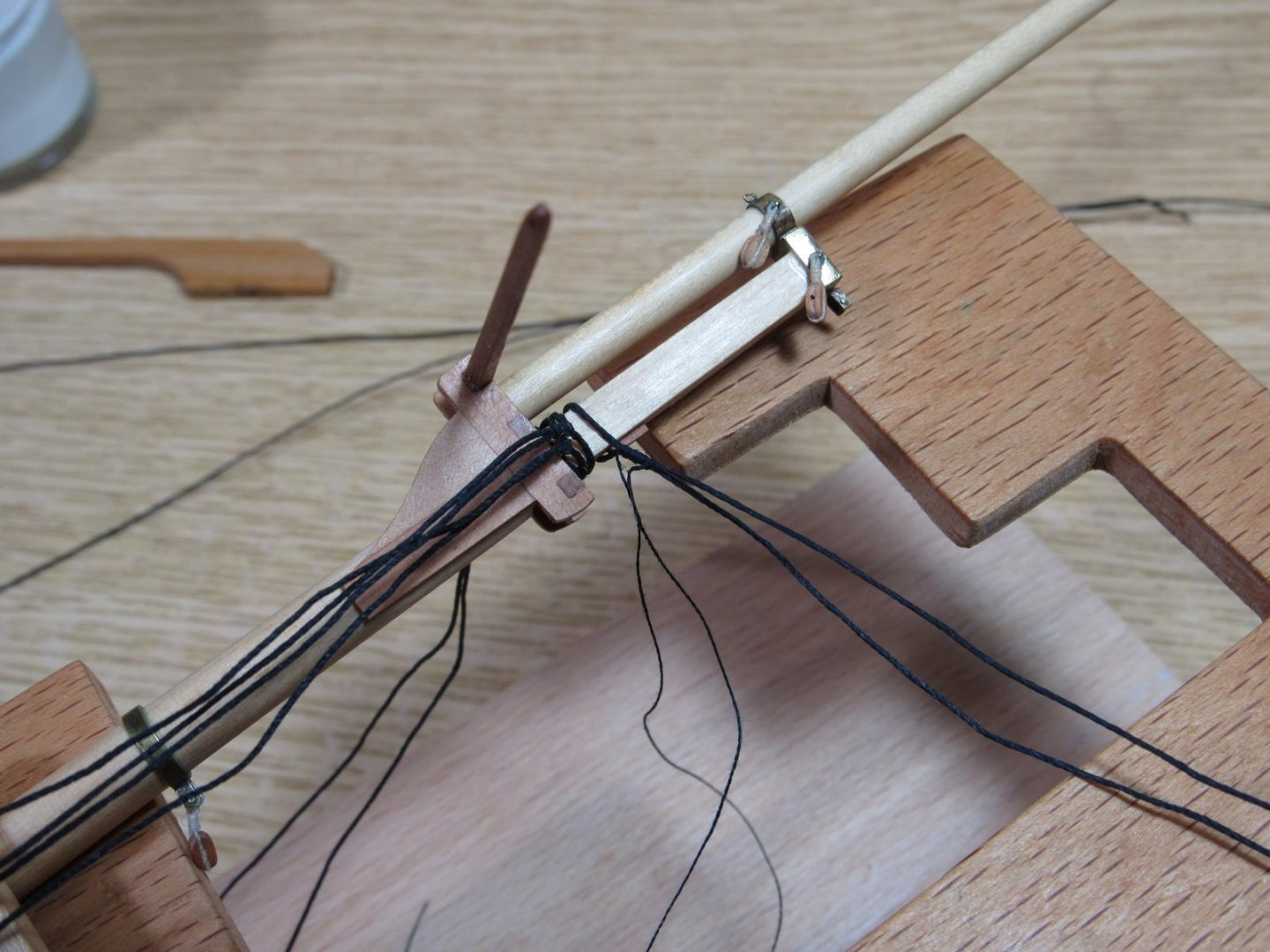

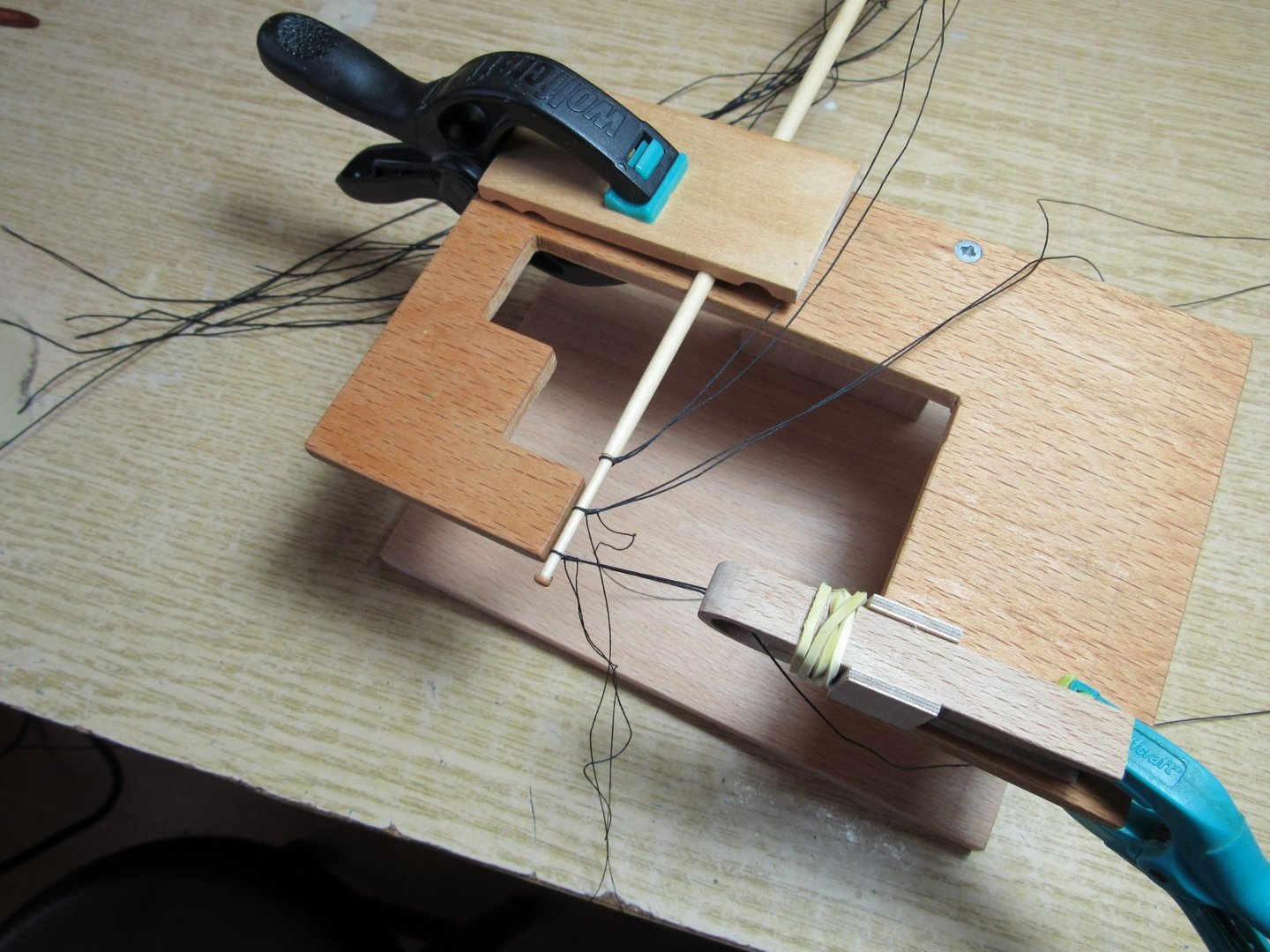

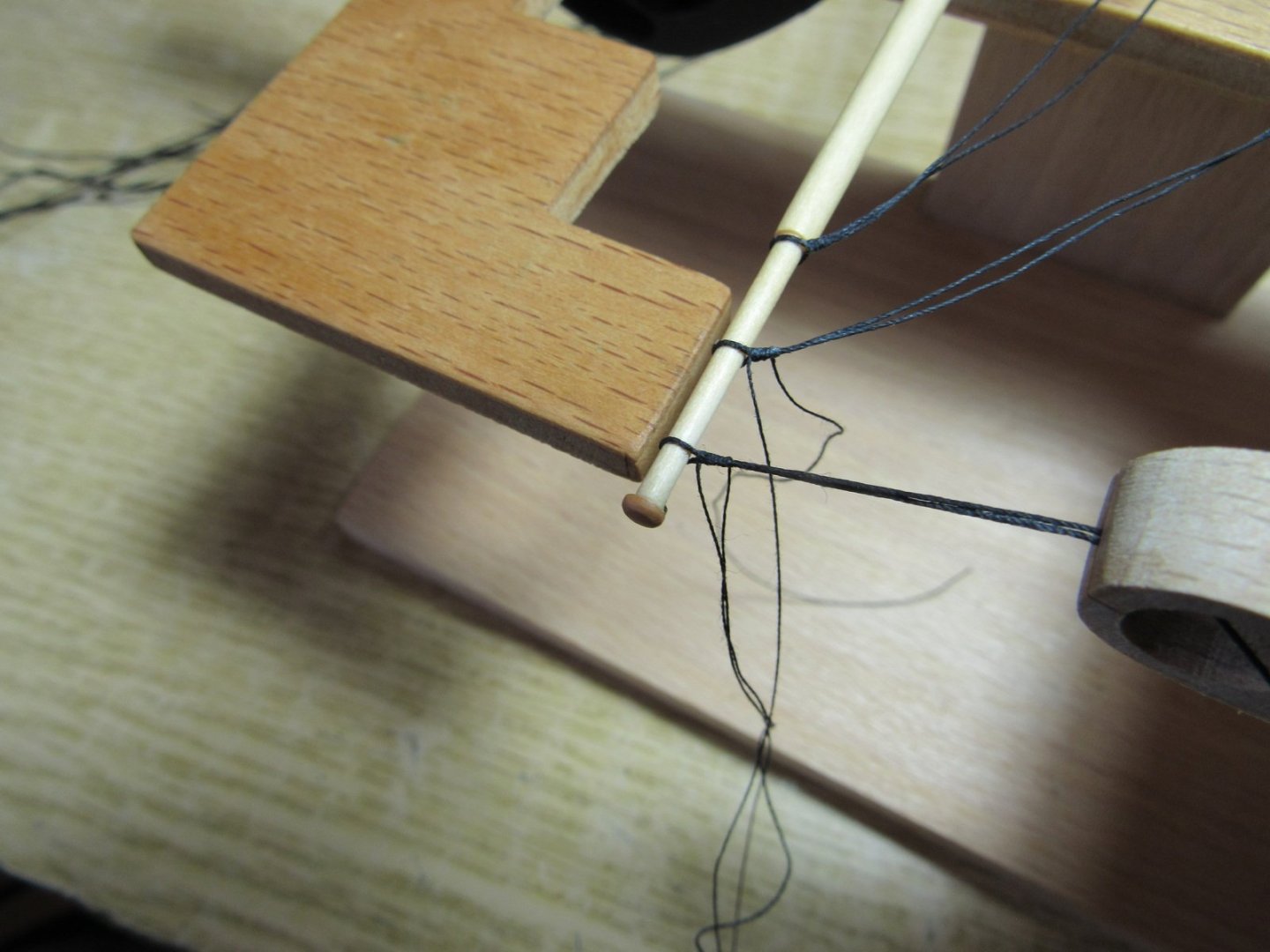

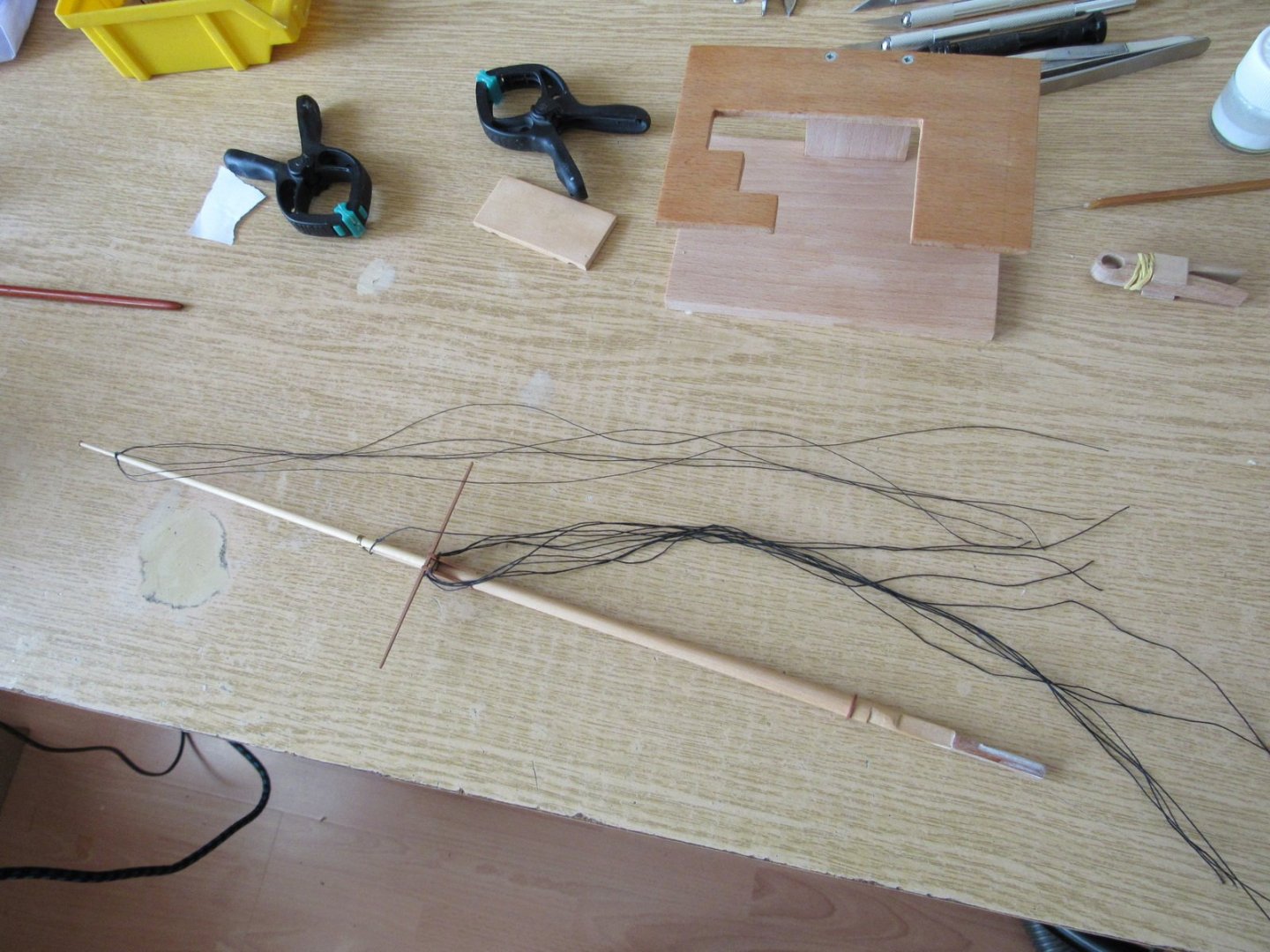

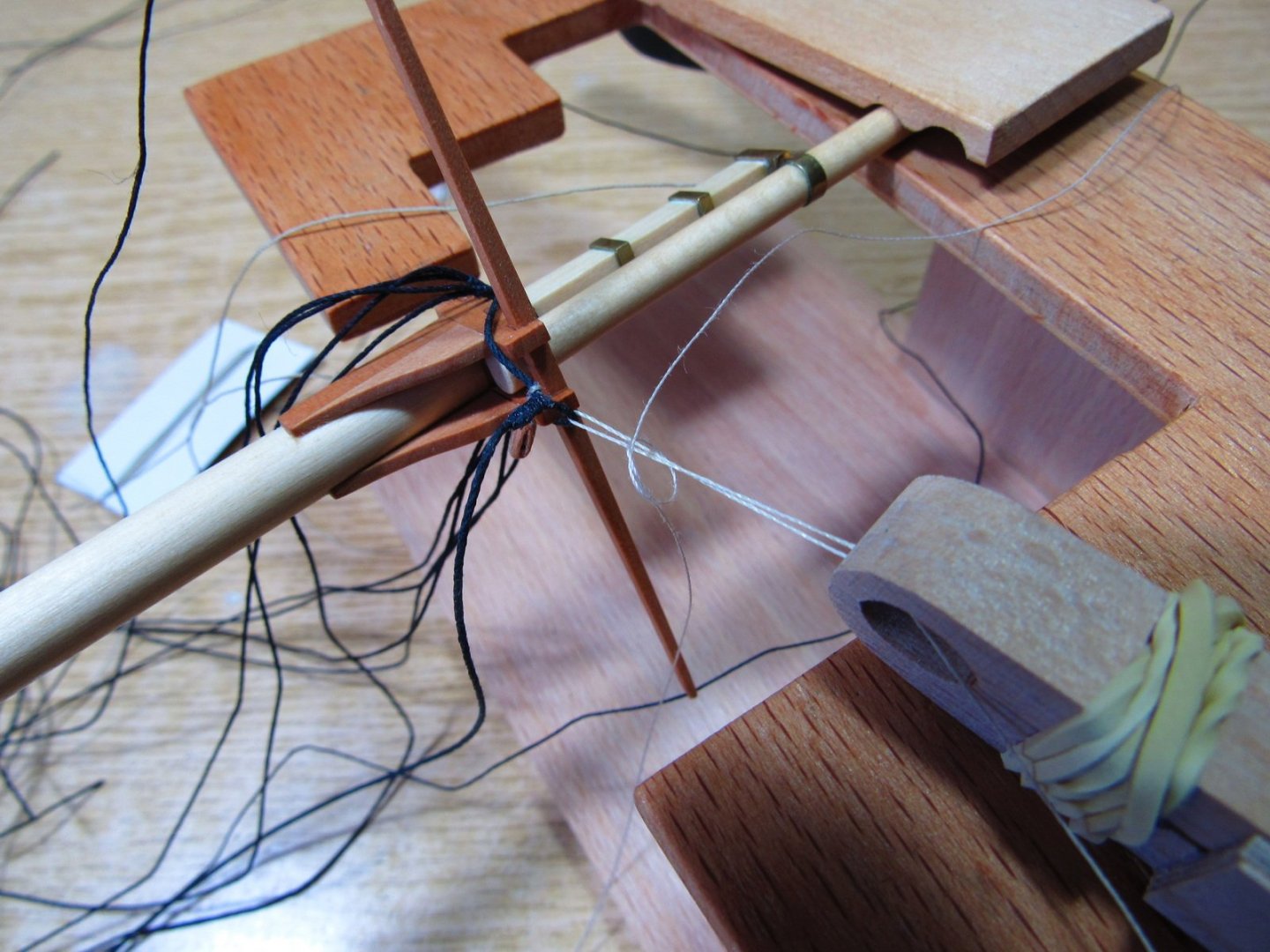

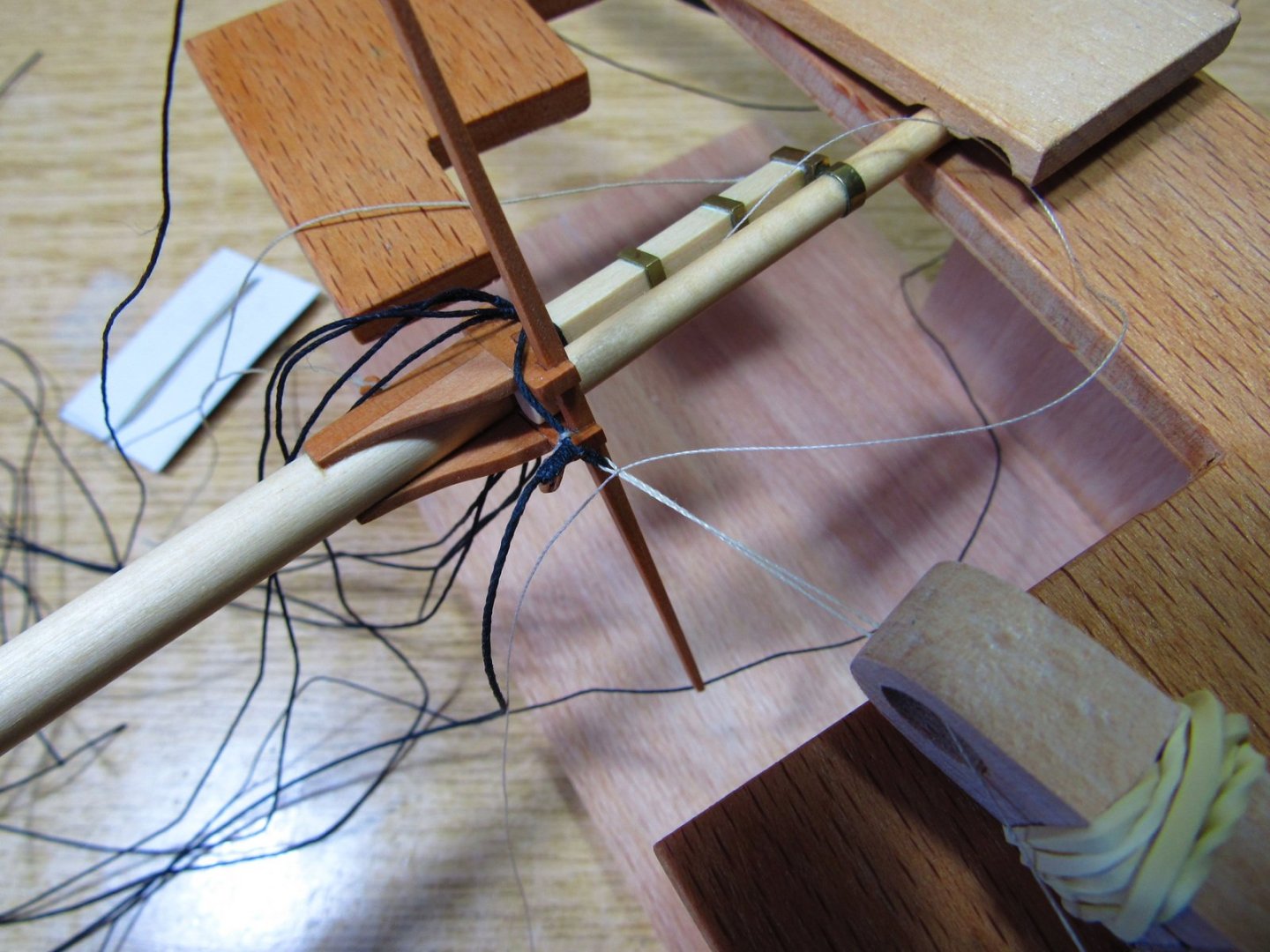

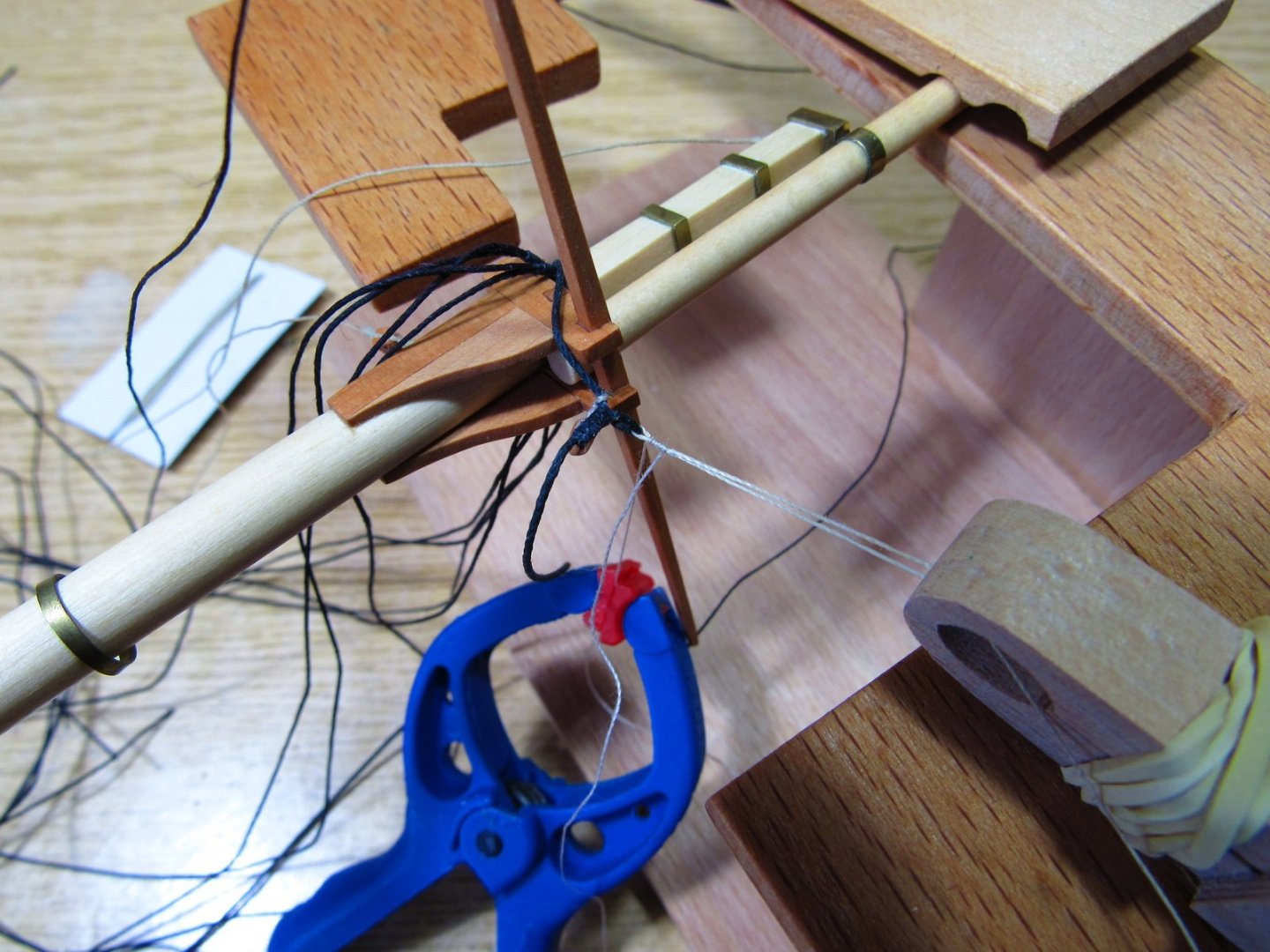

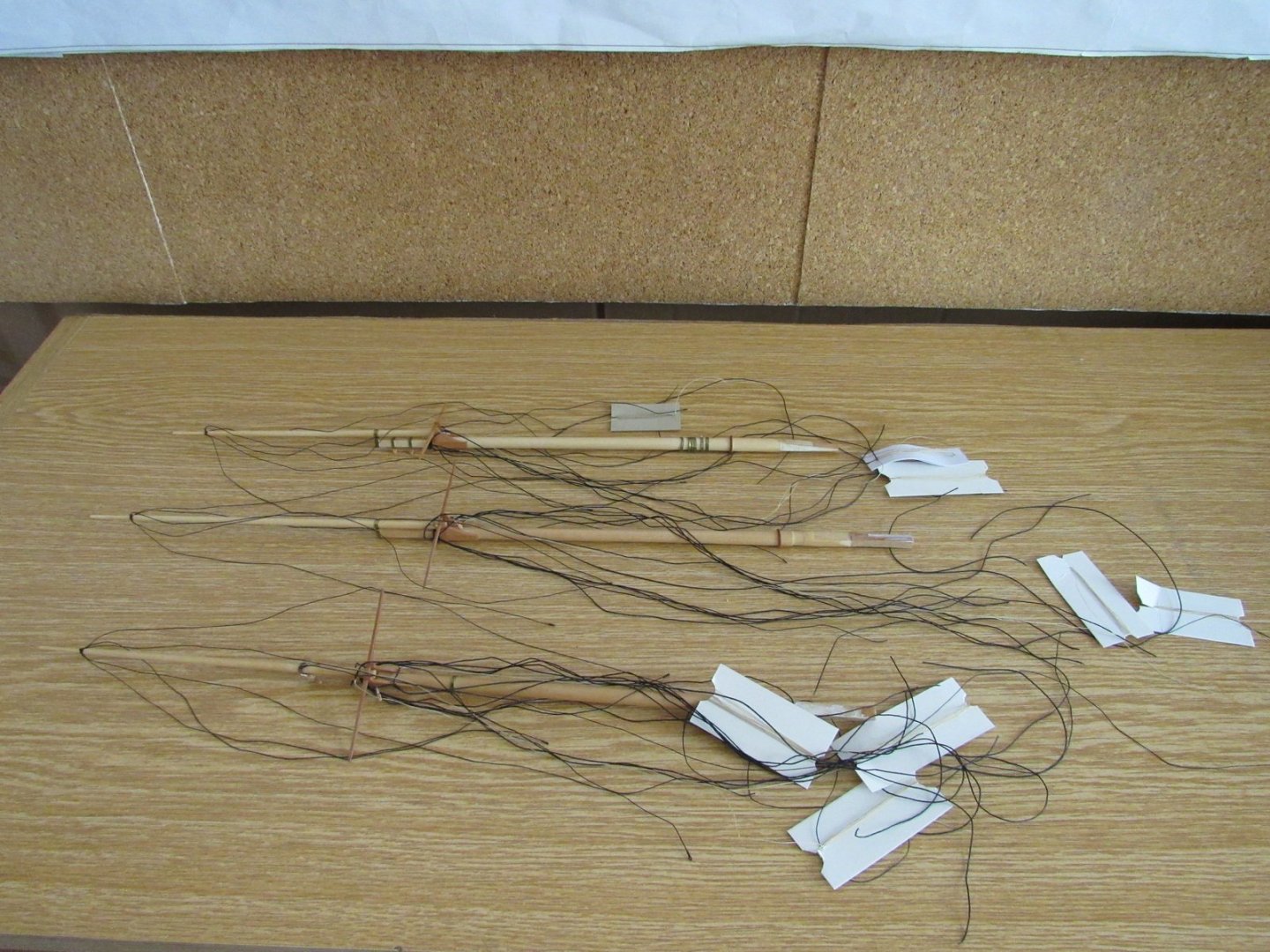

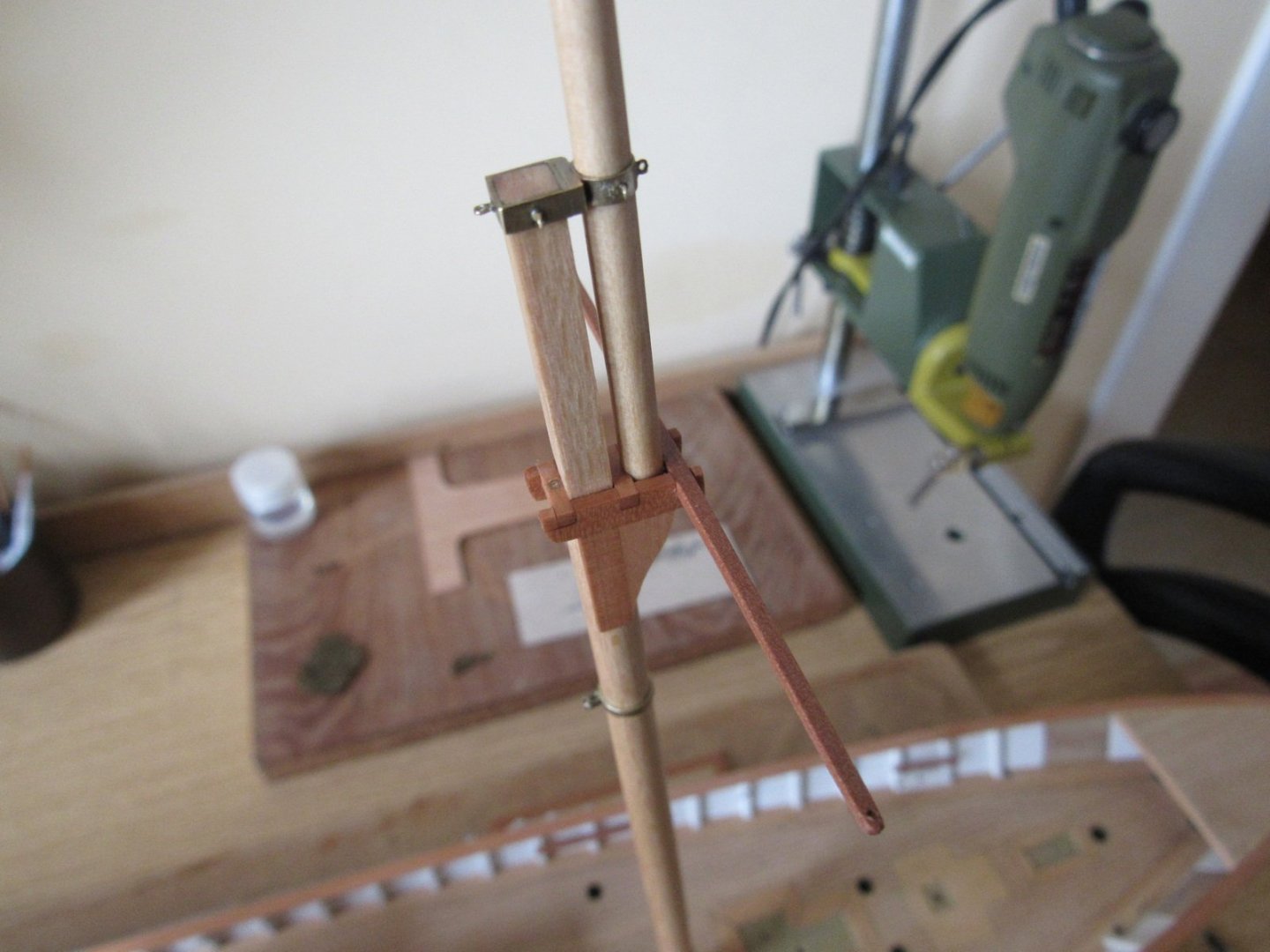

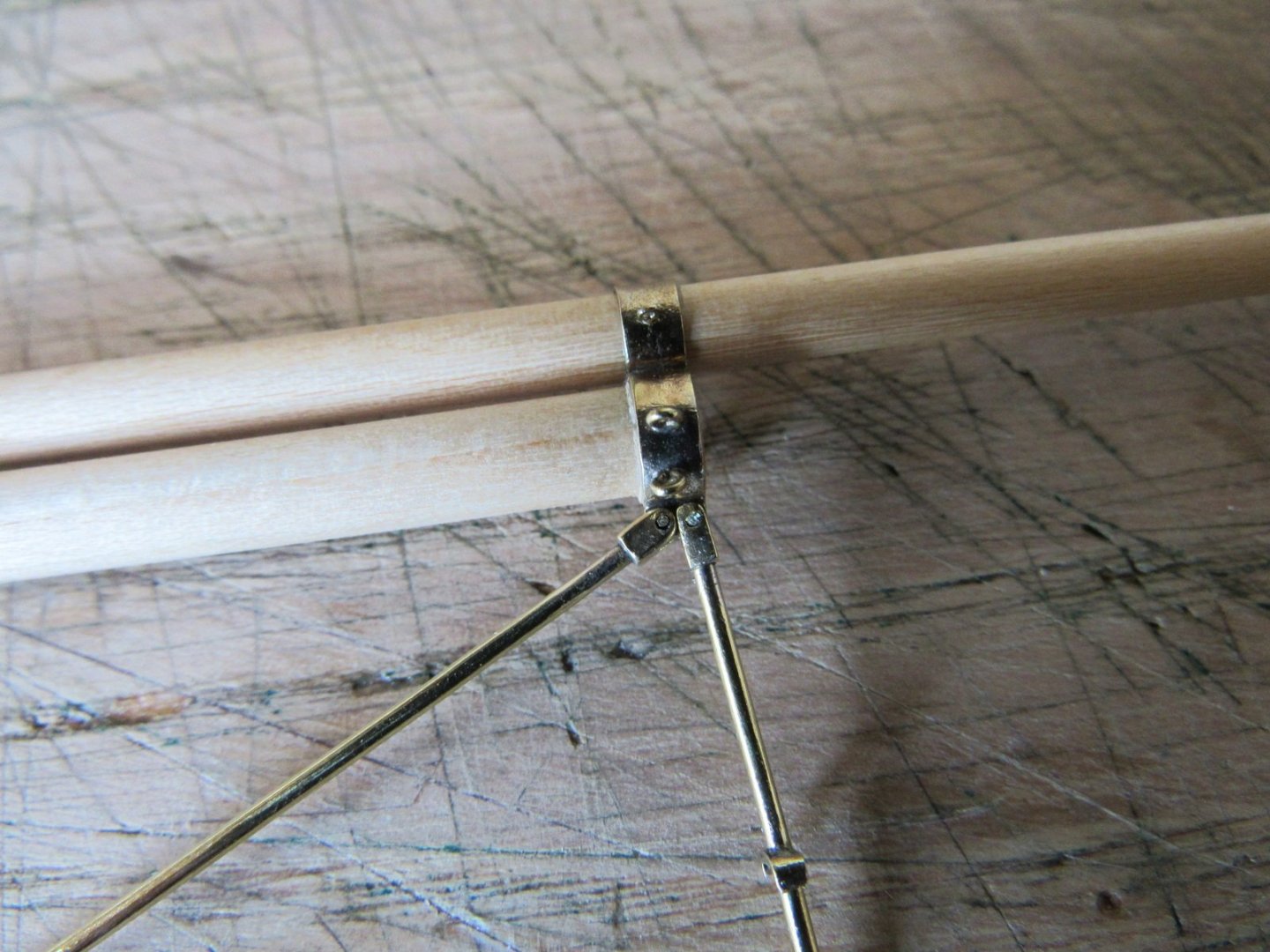

Completed the rigging on the masts. I will not glue the masts. They will have a tight fit. I used diluted white glue for the rigging. Takes time but better than CA which is too stiff and probably not durable.

-

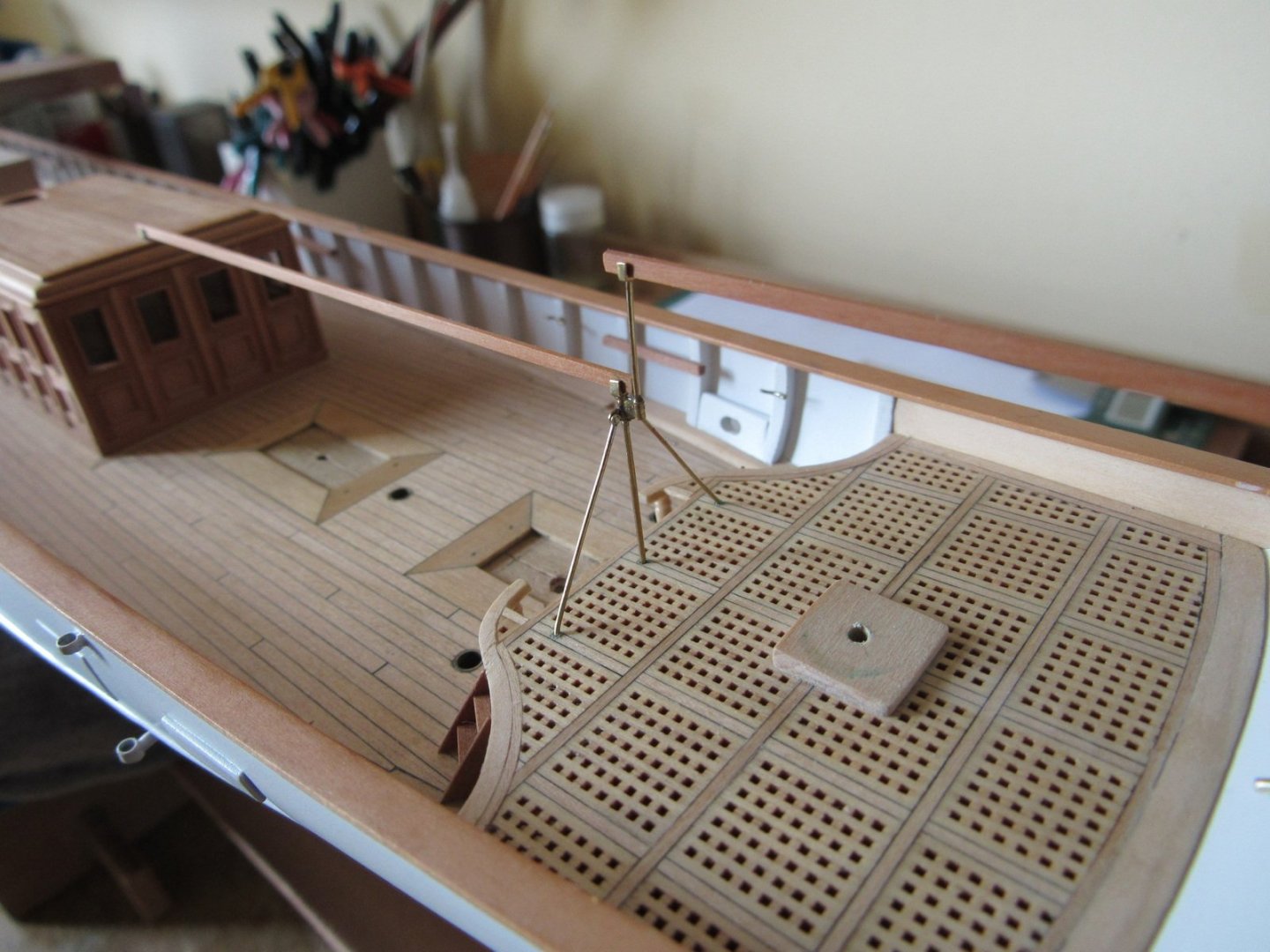

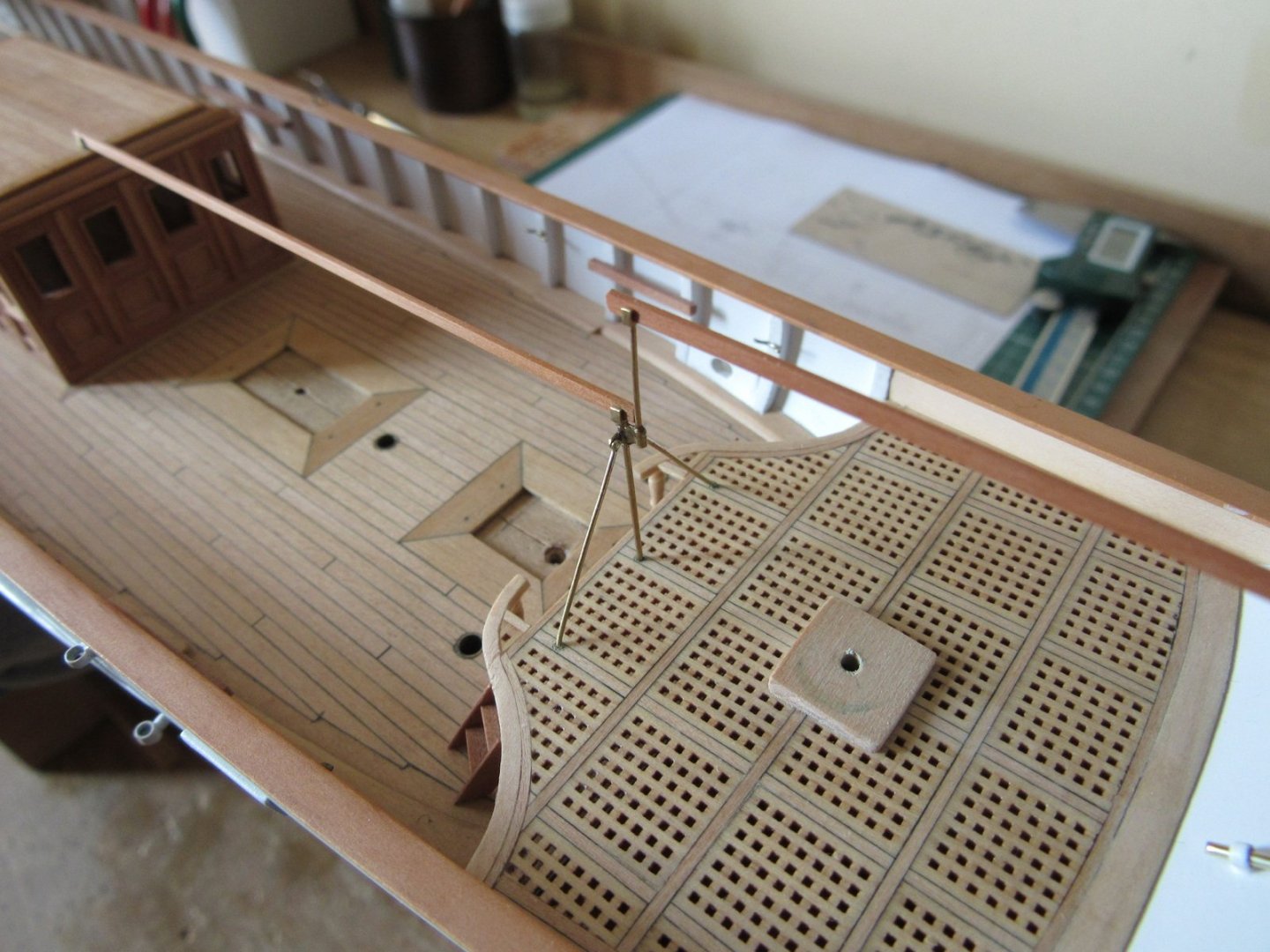

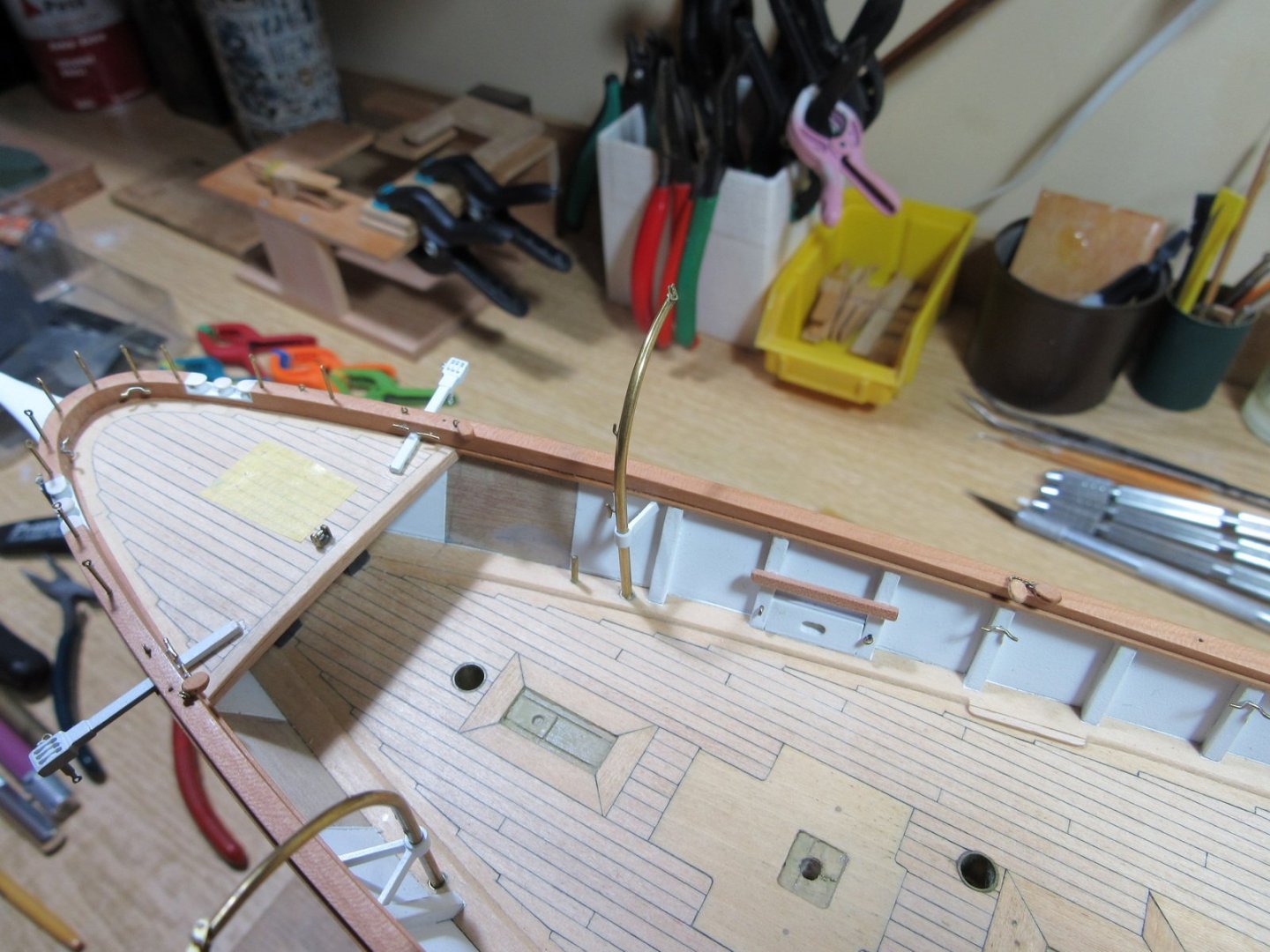

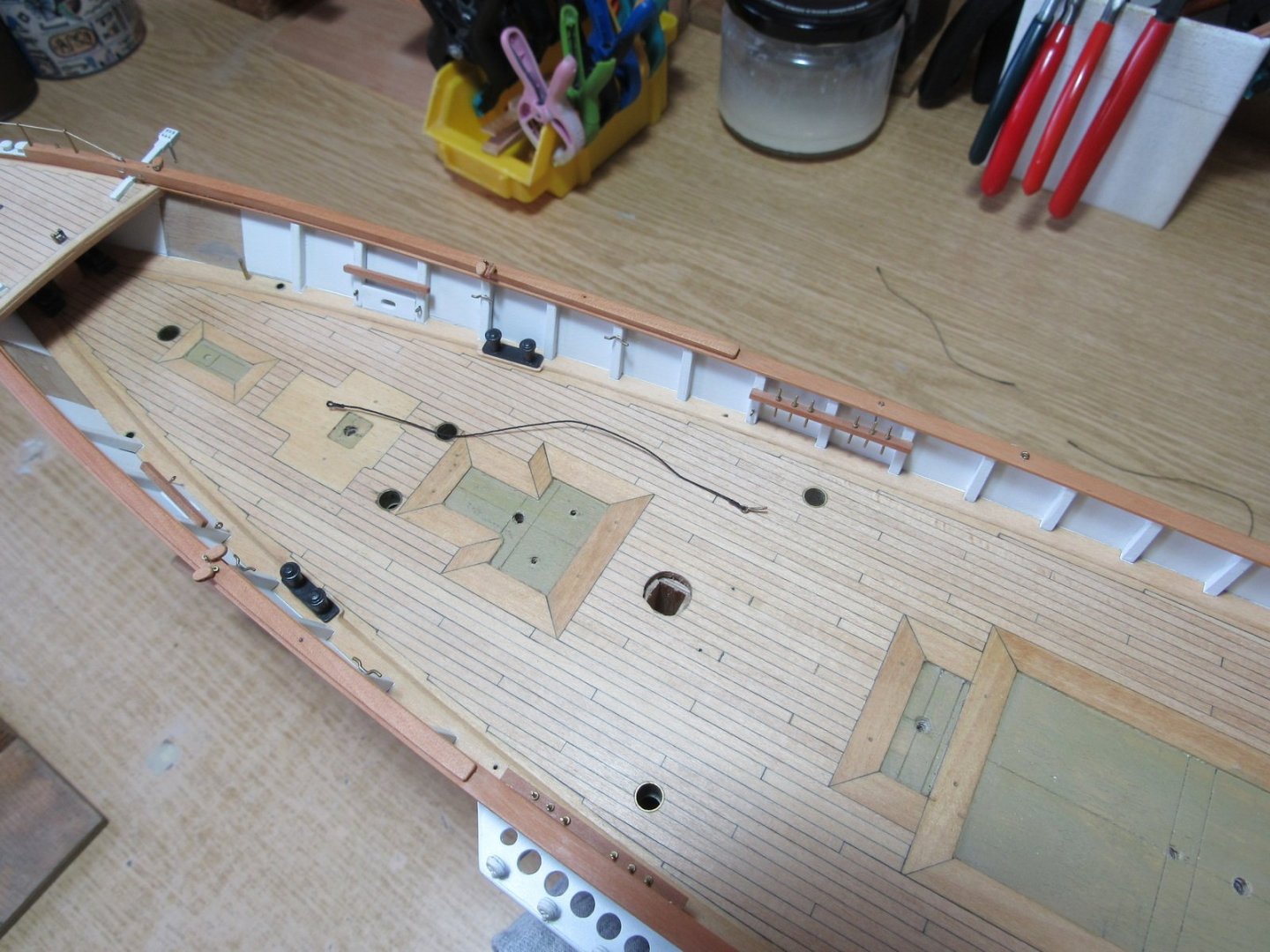

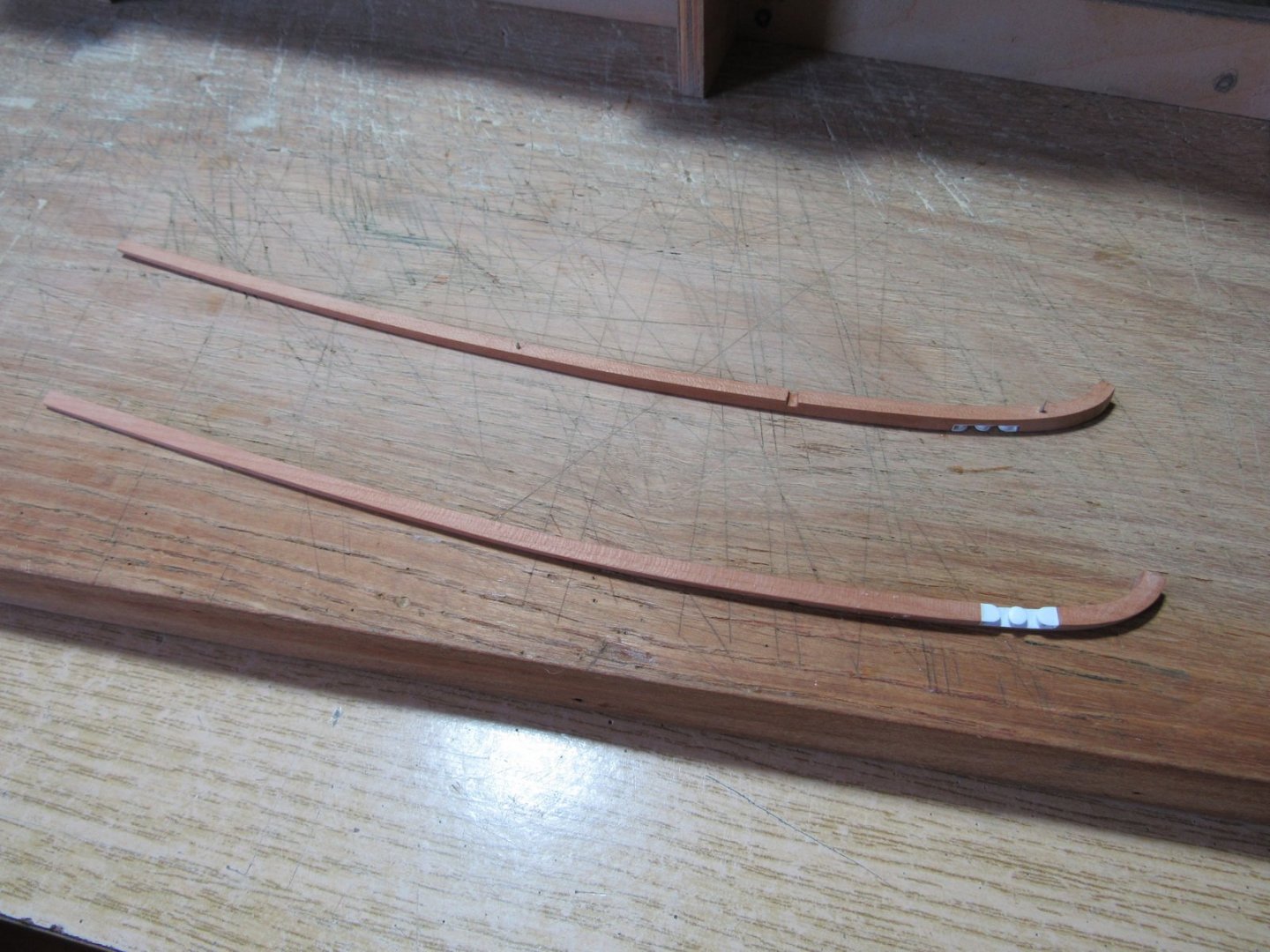

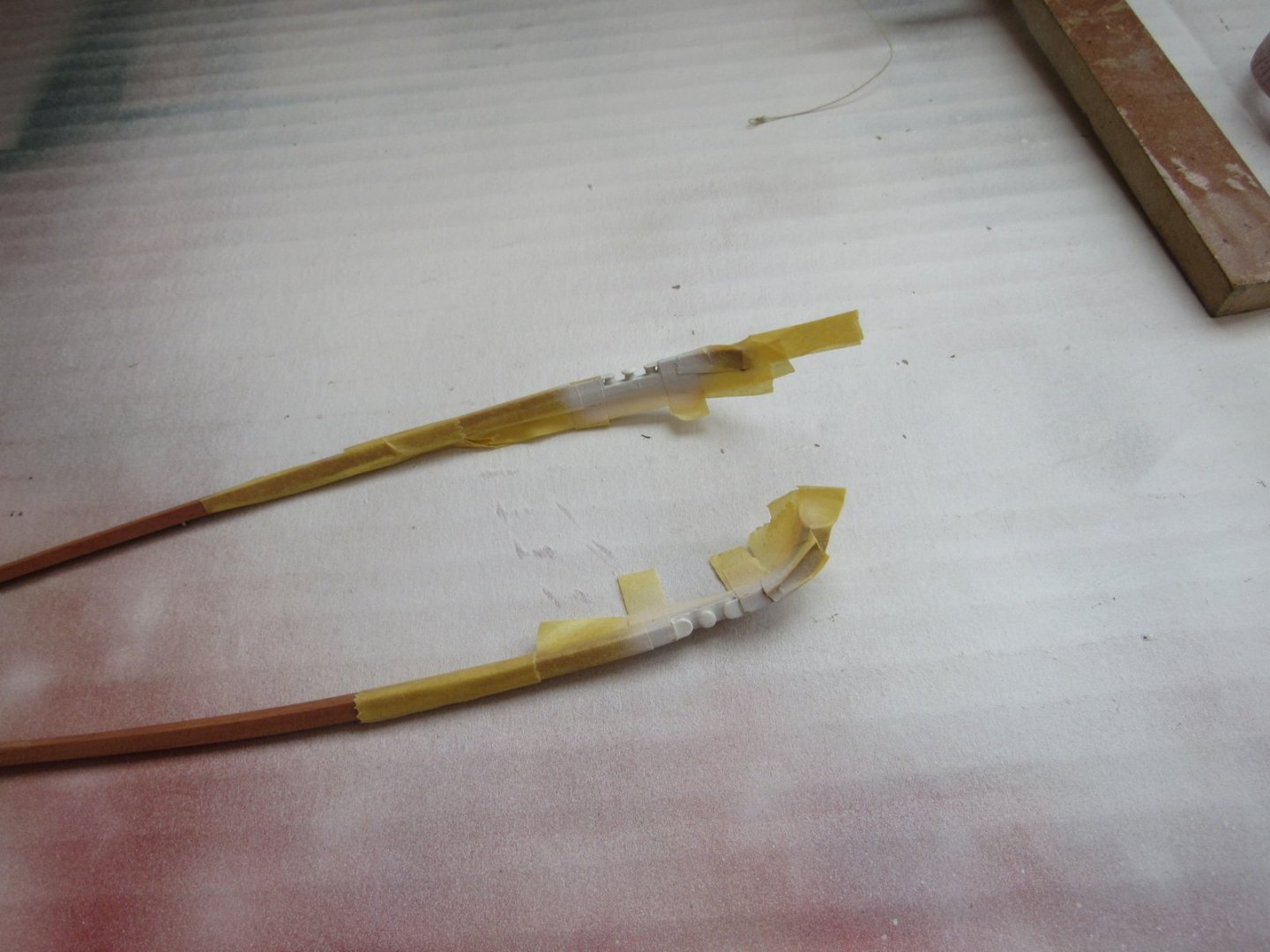

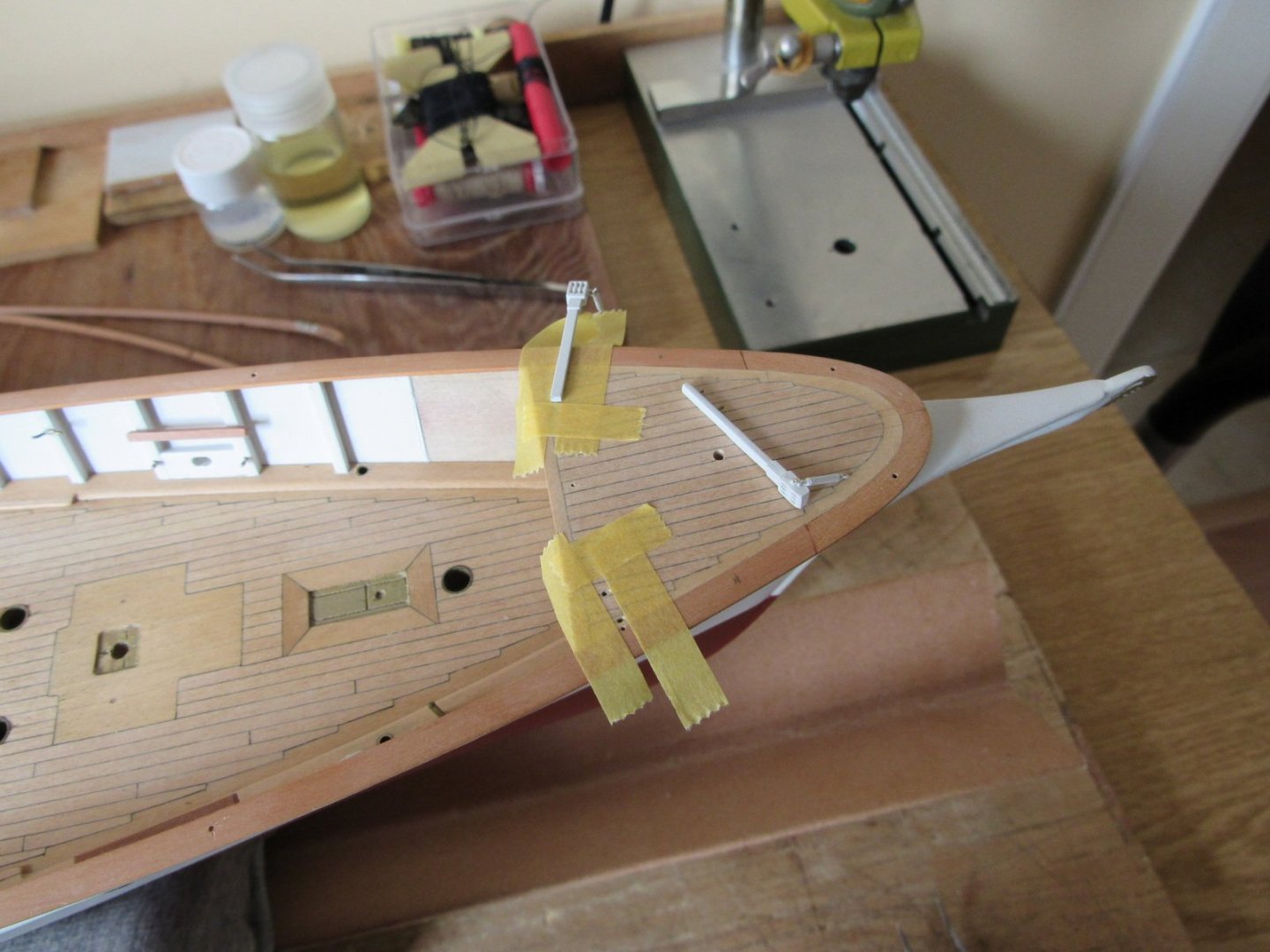

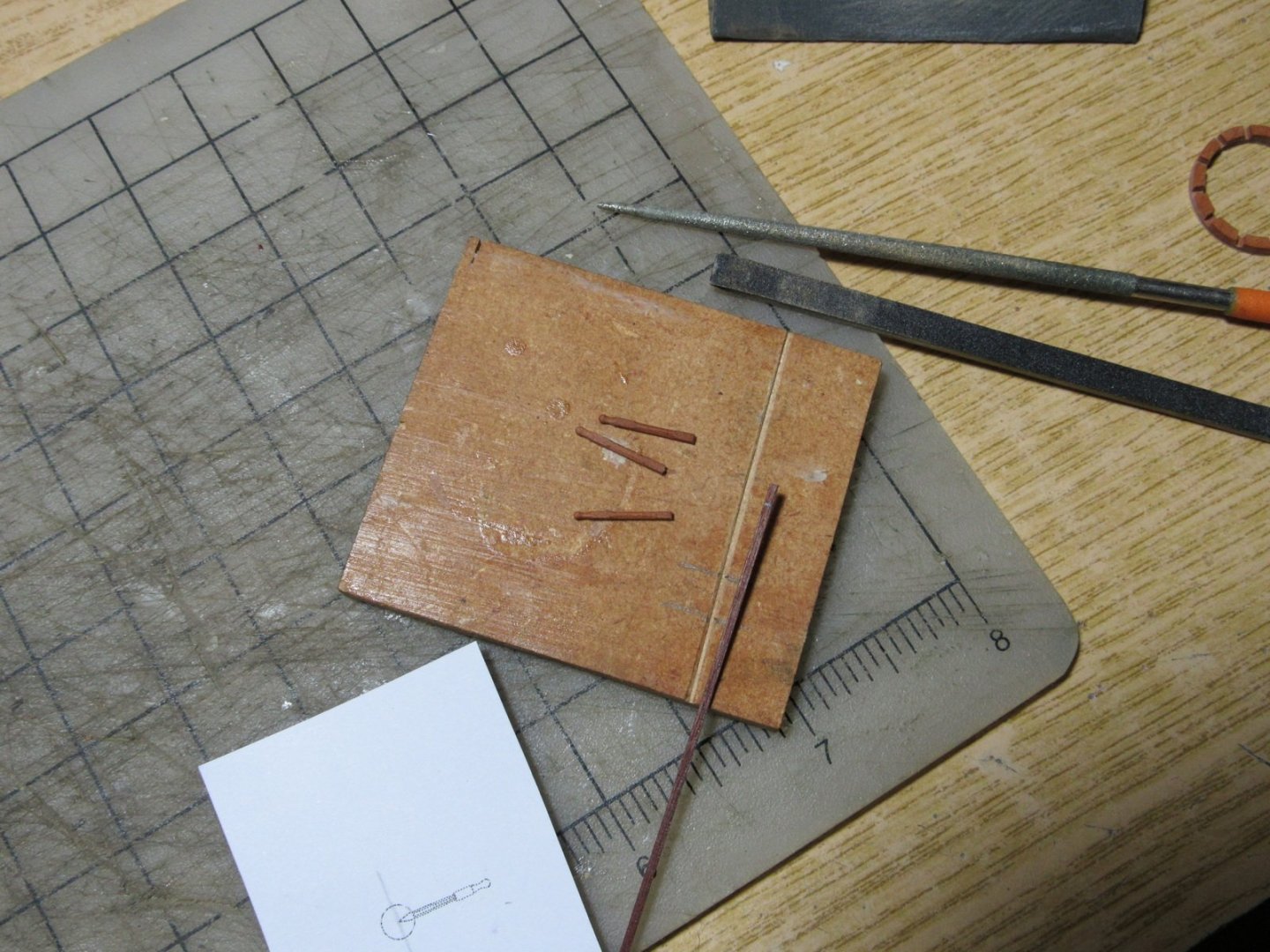

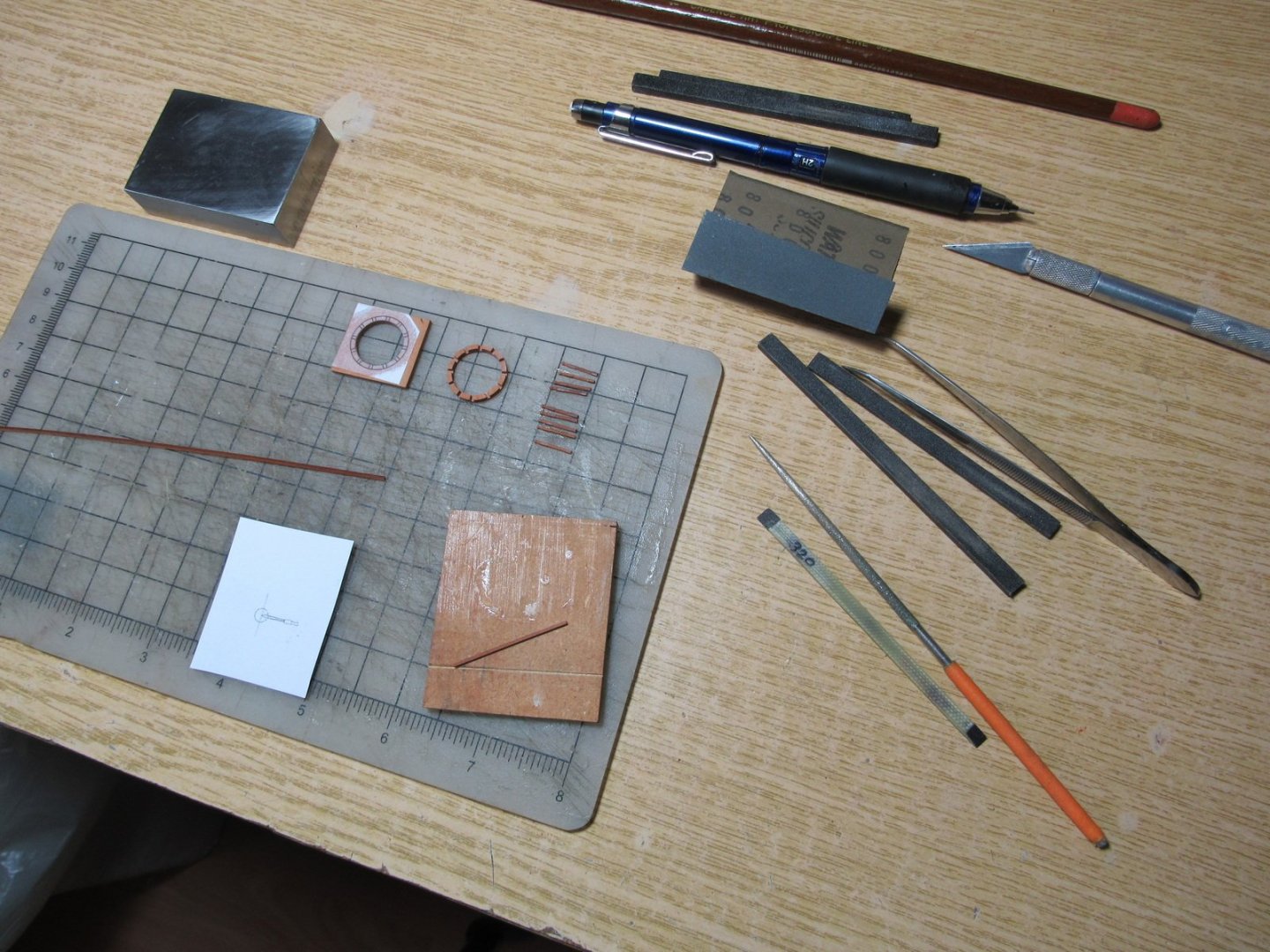

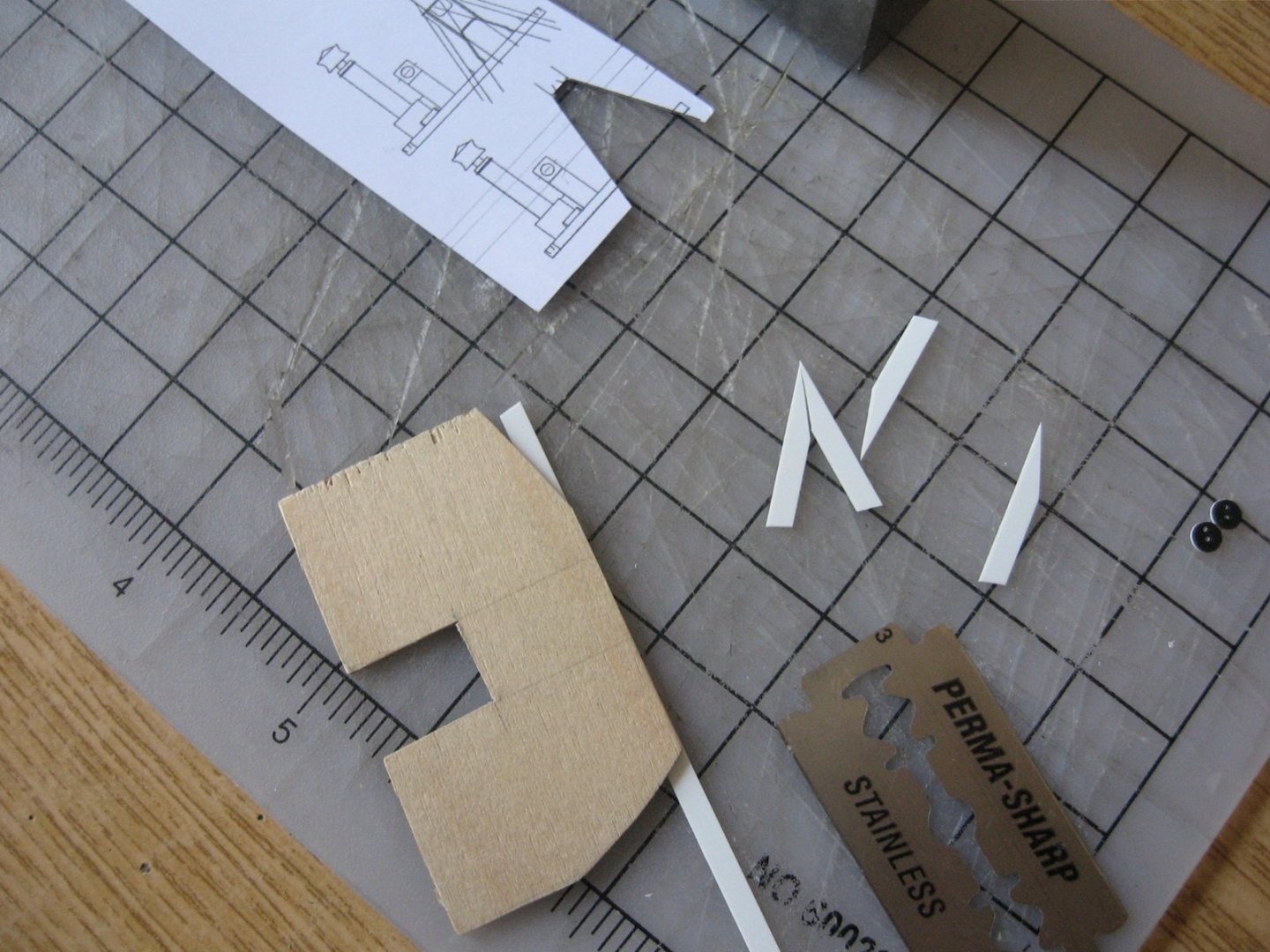

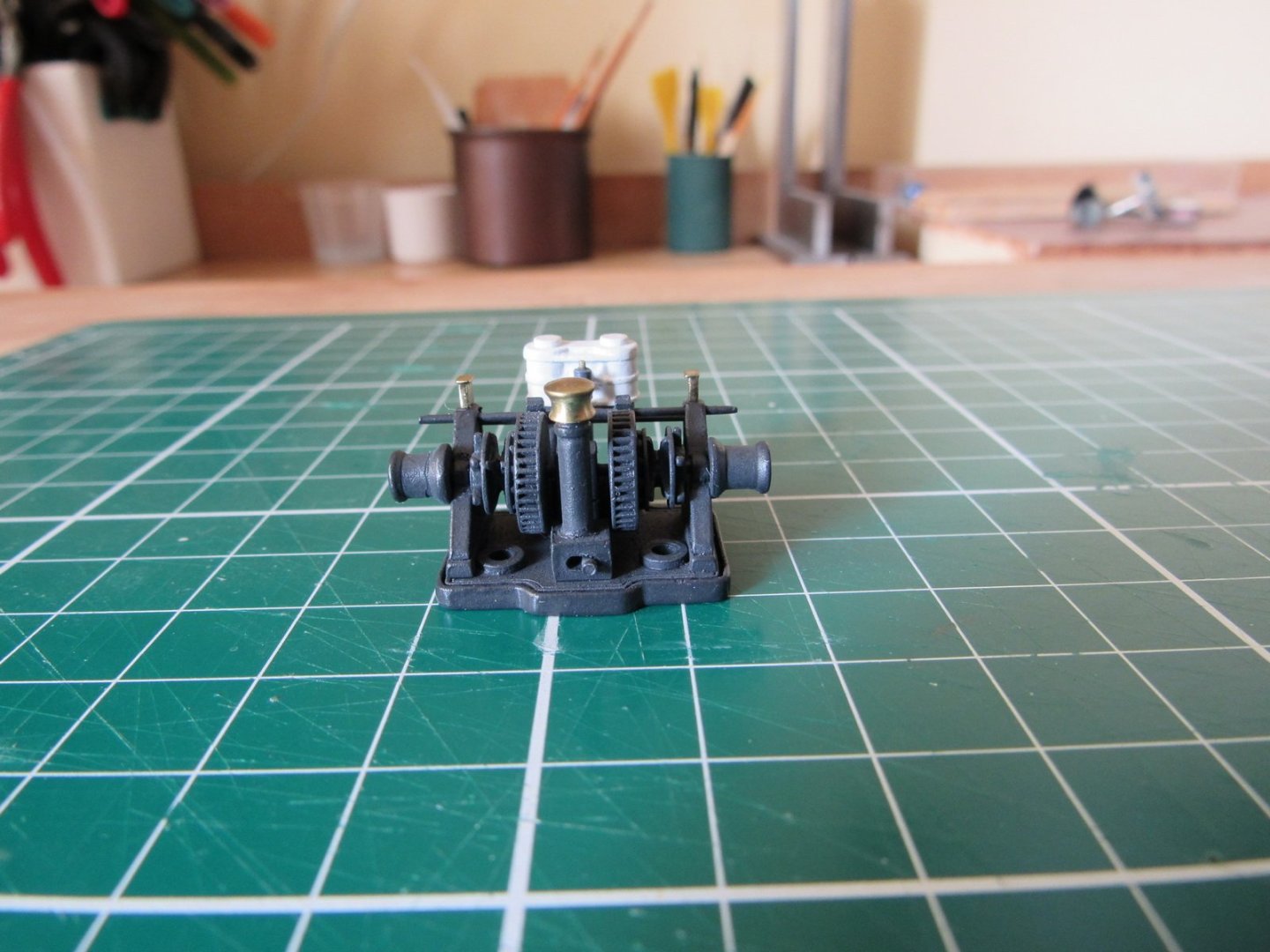

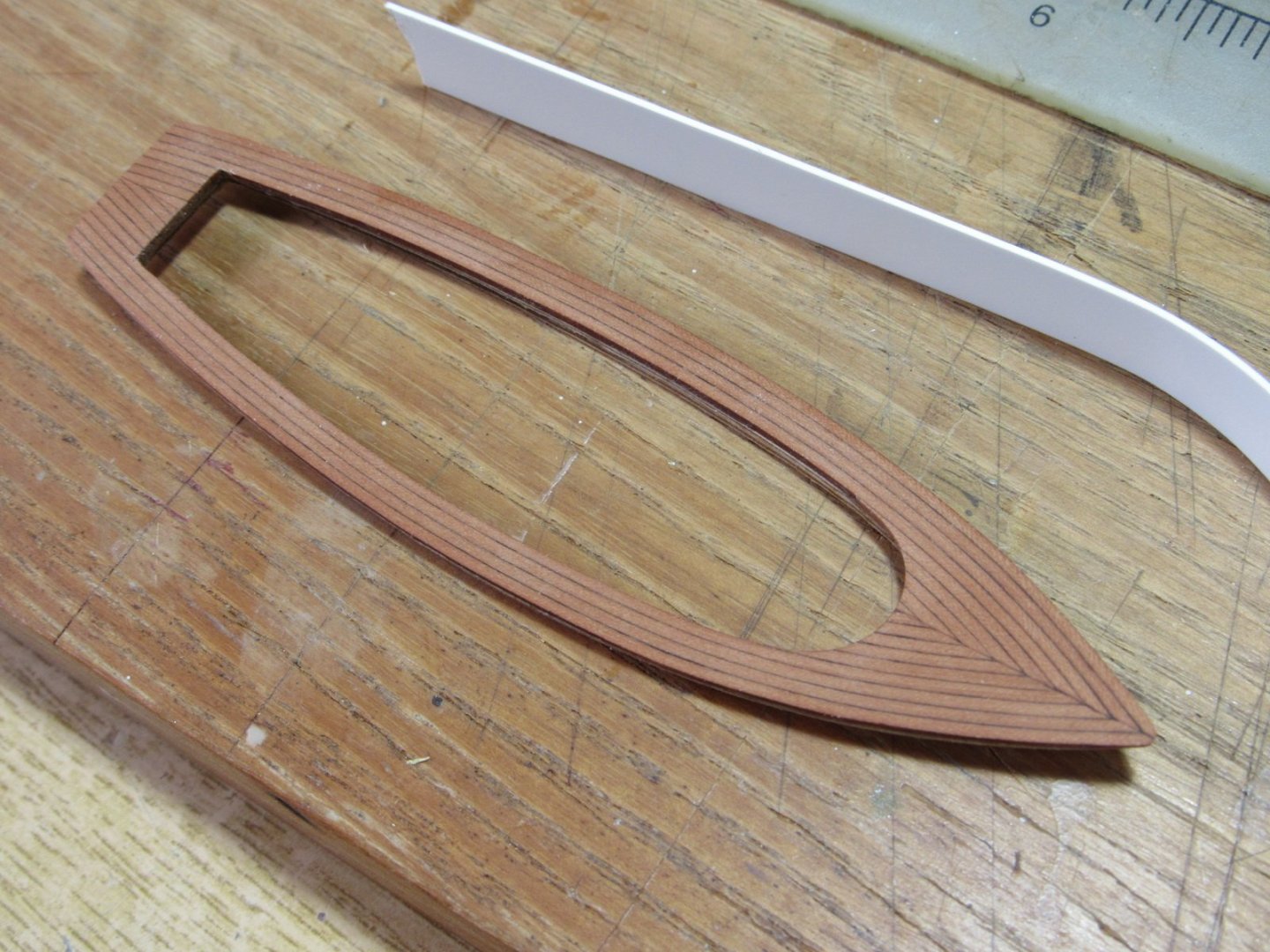

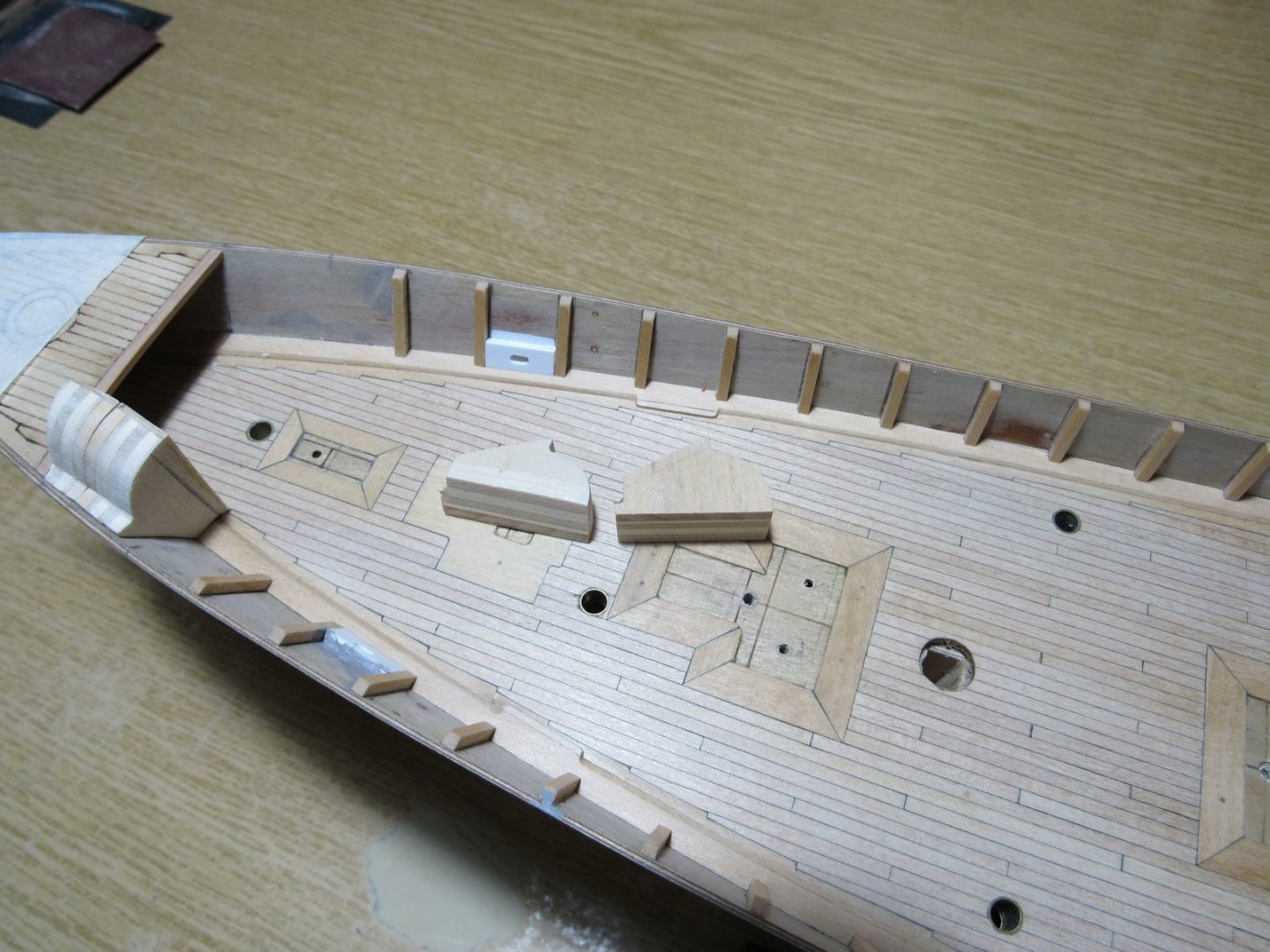

All parts finished. Happily back to hull. I finished the rail at forecastle. I've cut the shape from 6 mm pear sheet, fitted, surfaced, outfitted and glued.

-

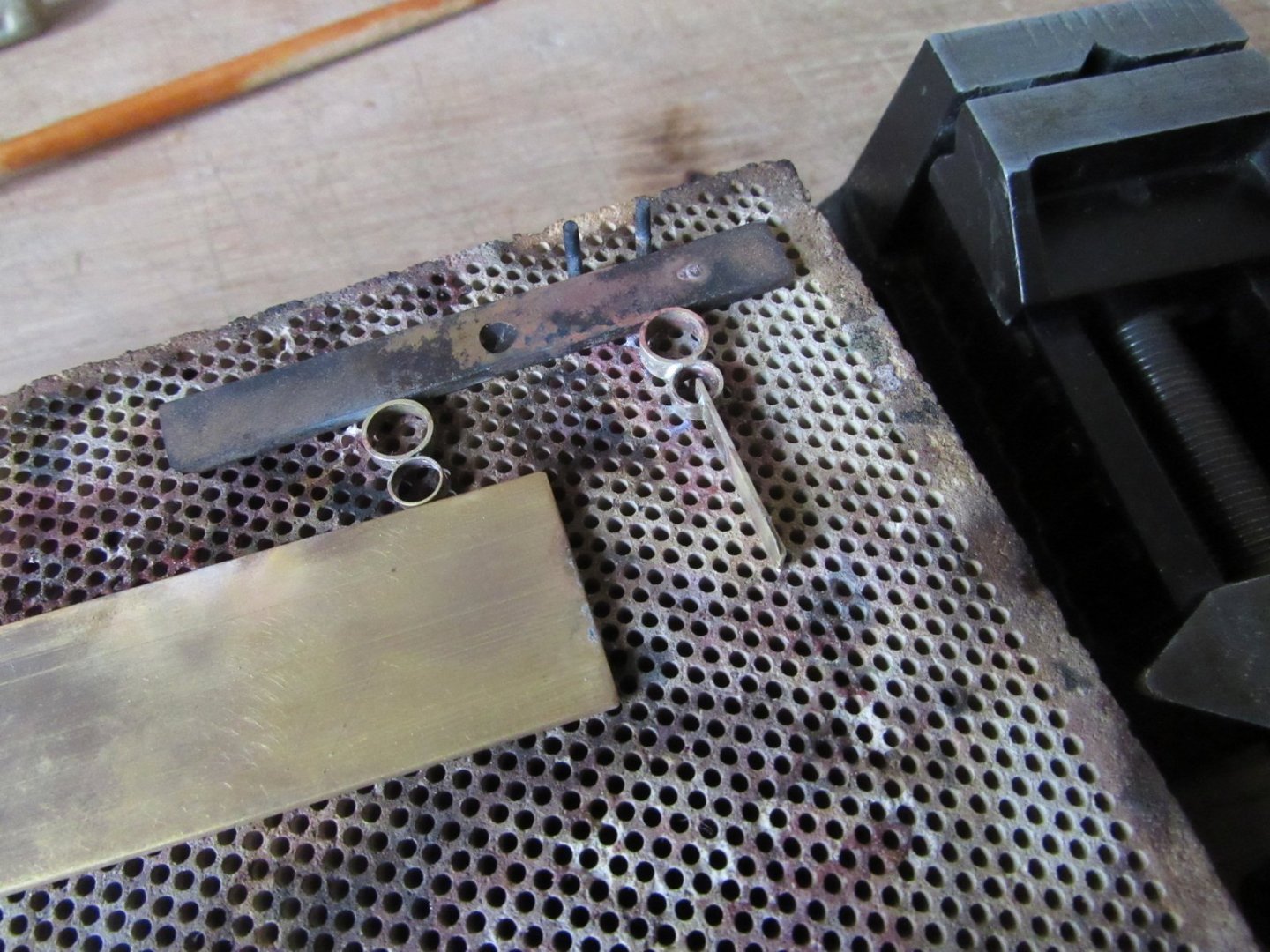

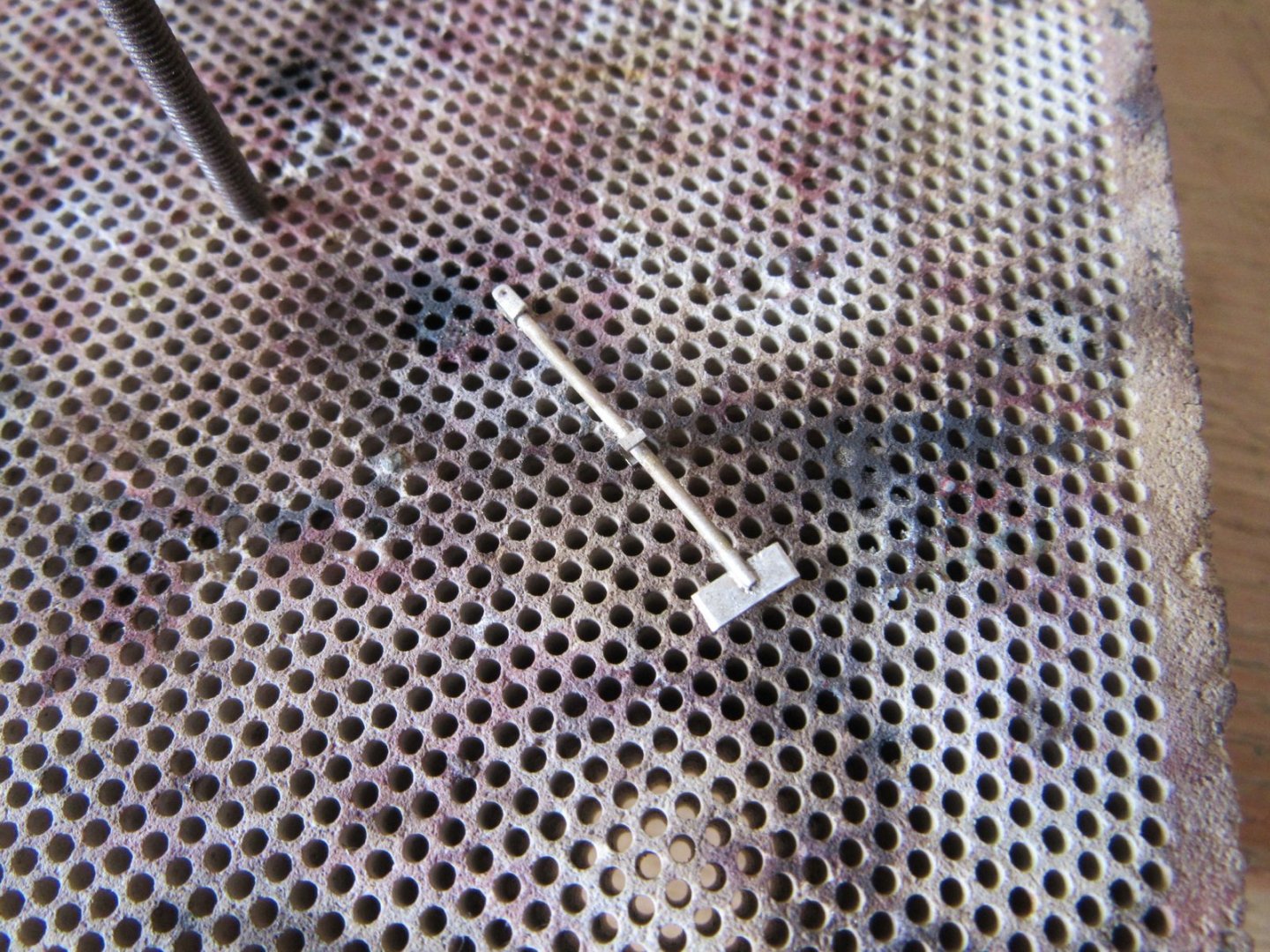

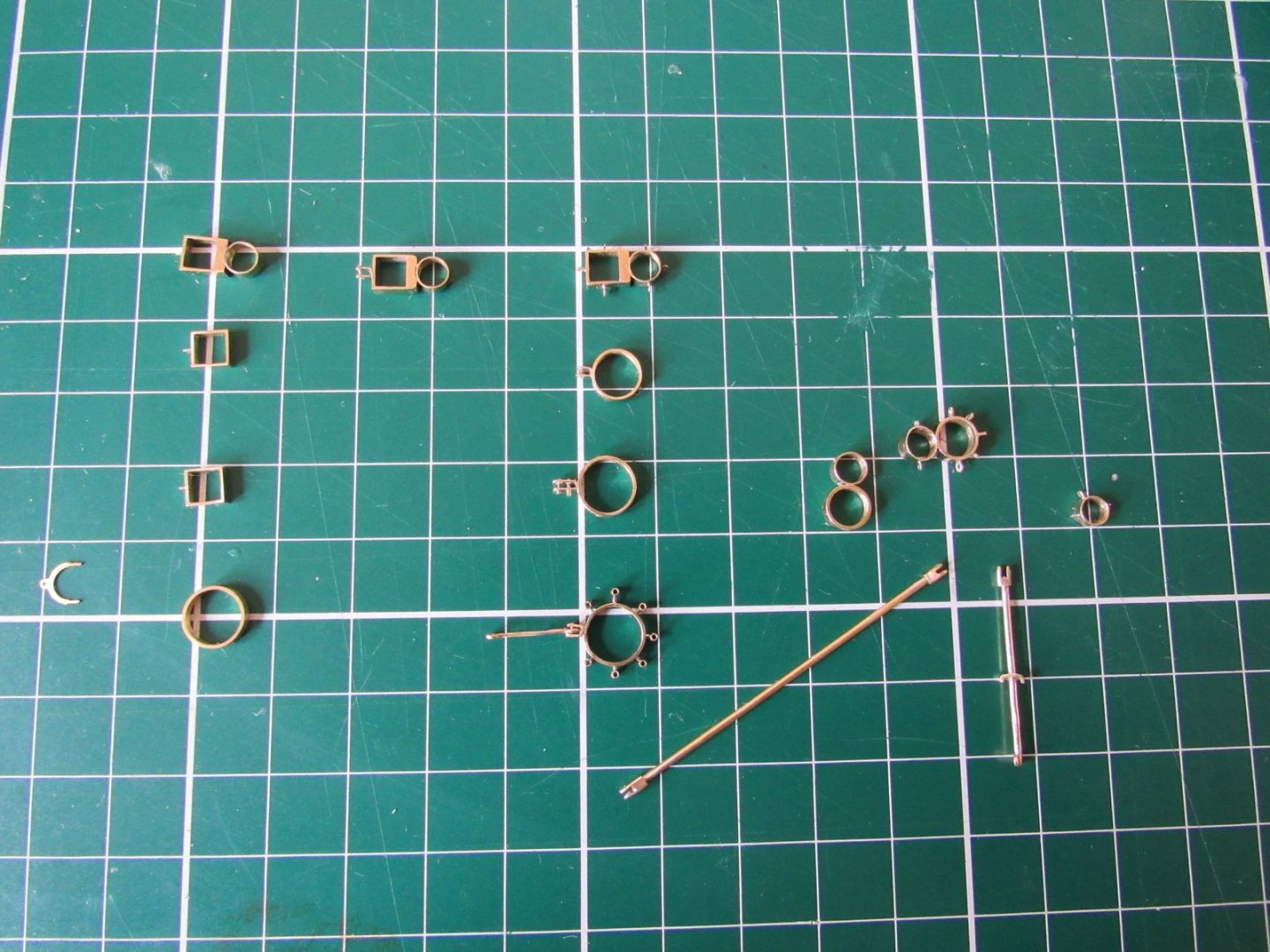

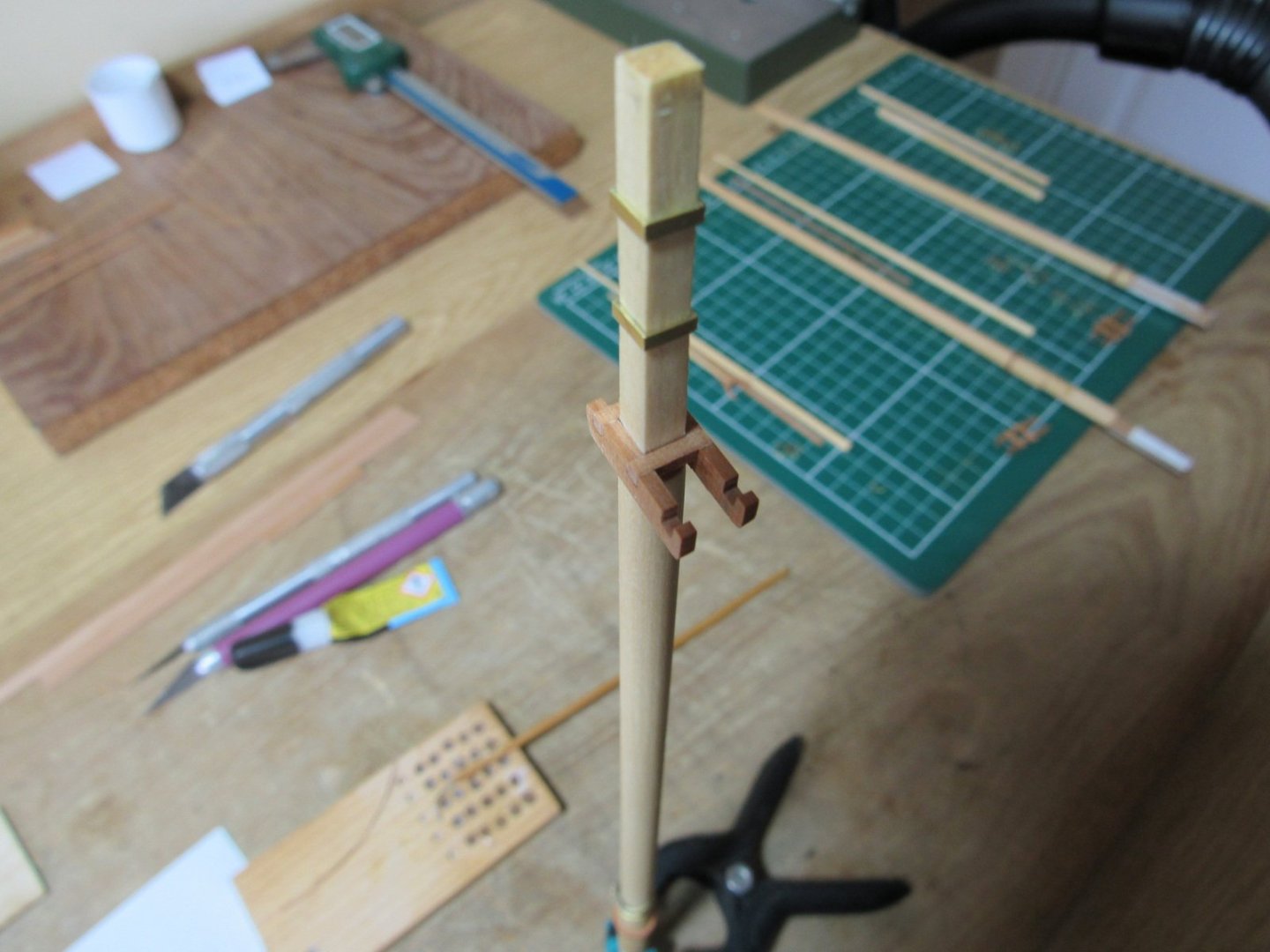

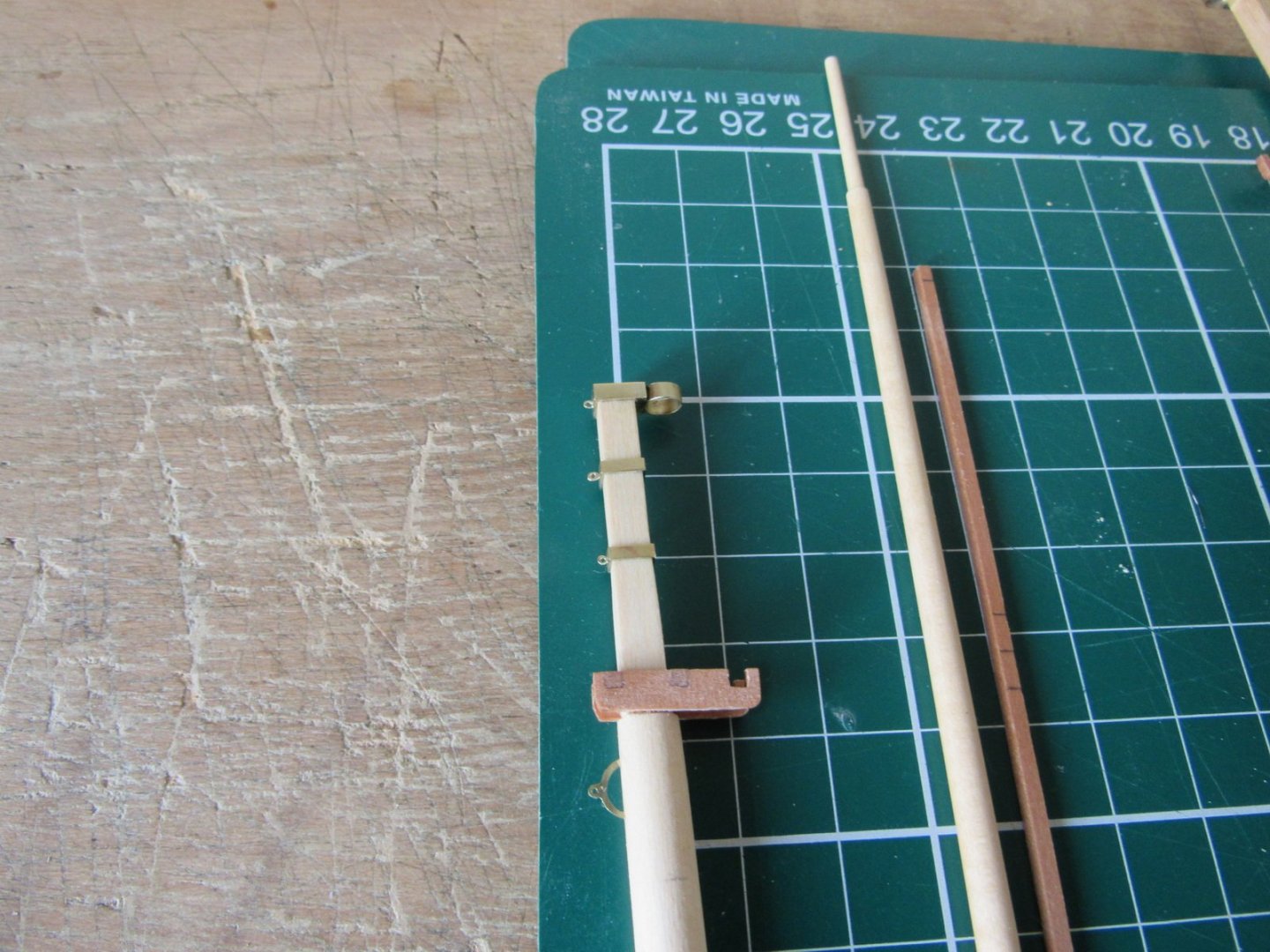

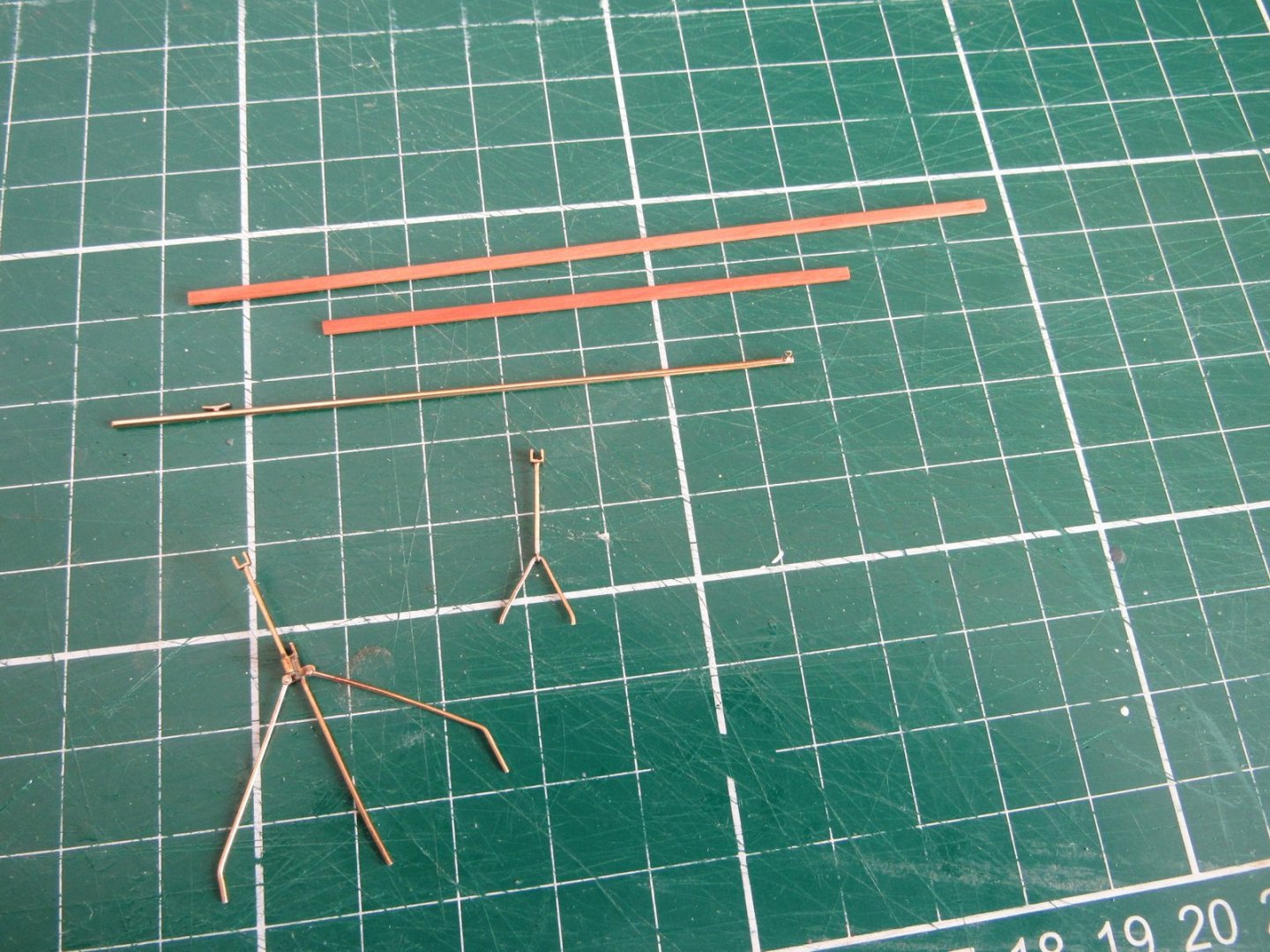

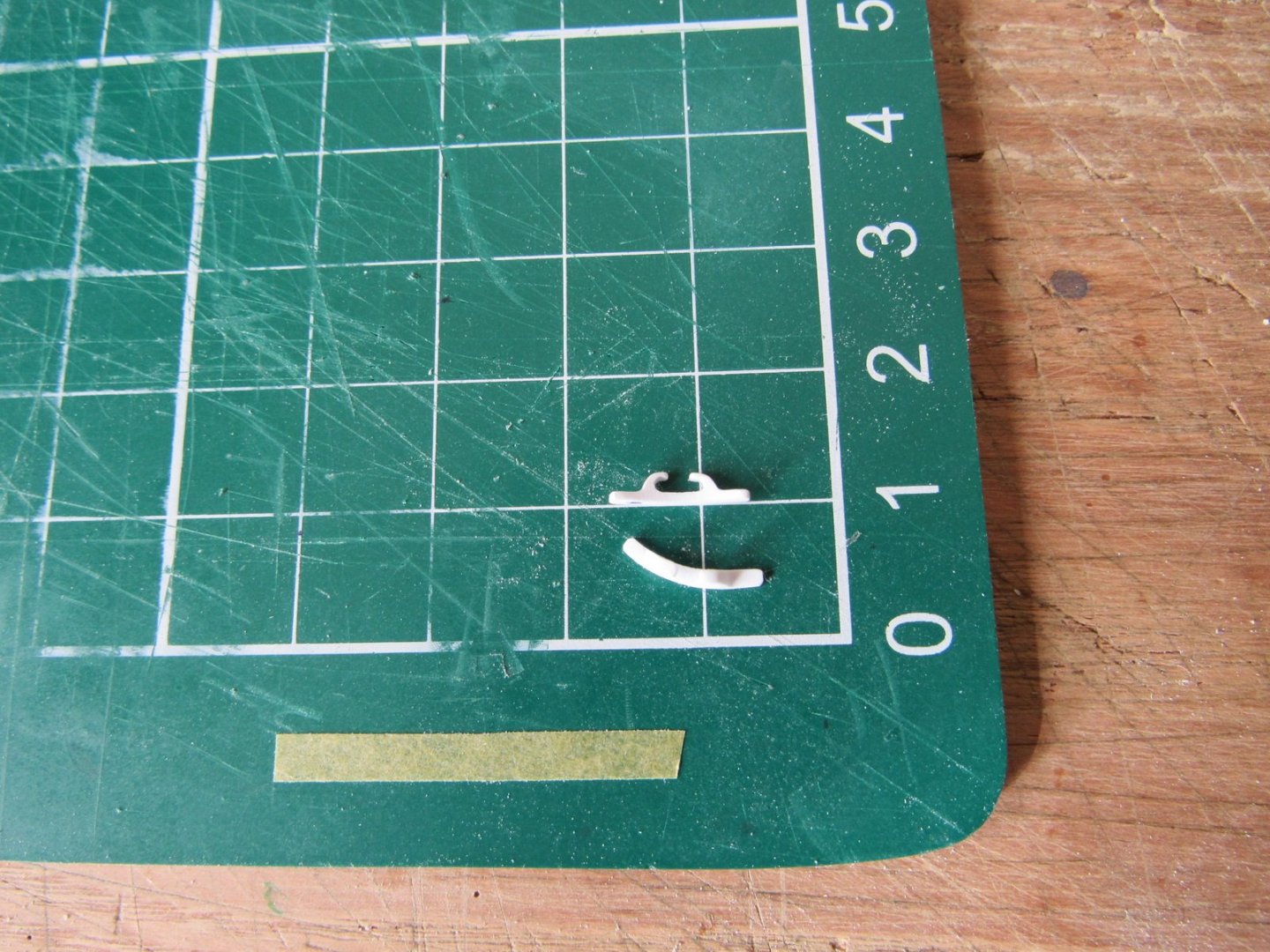

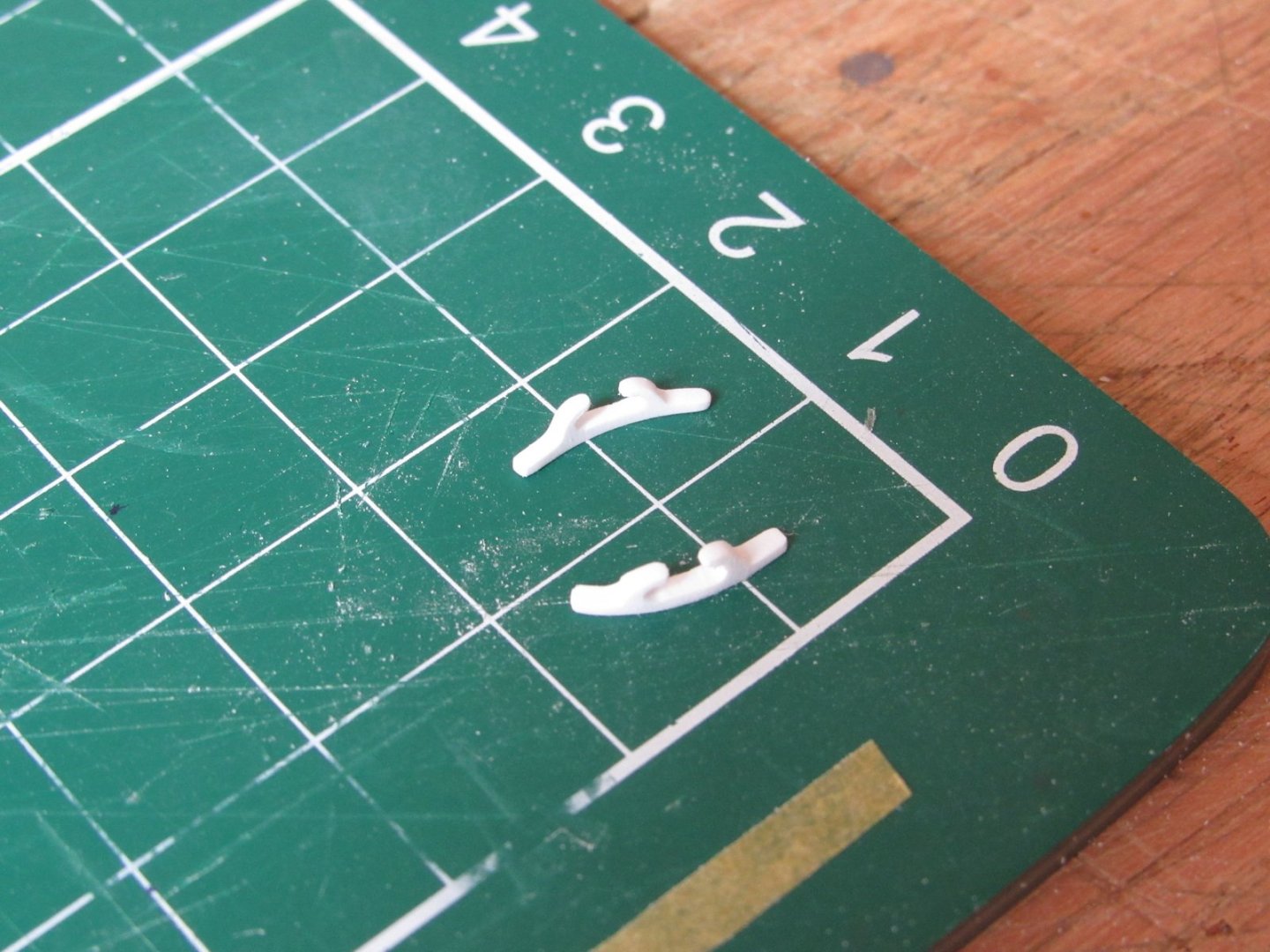

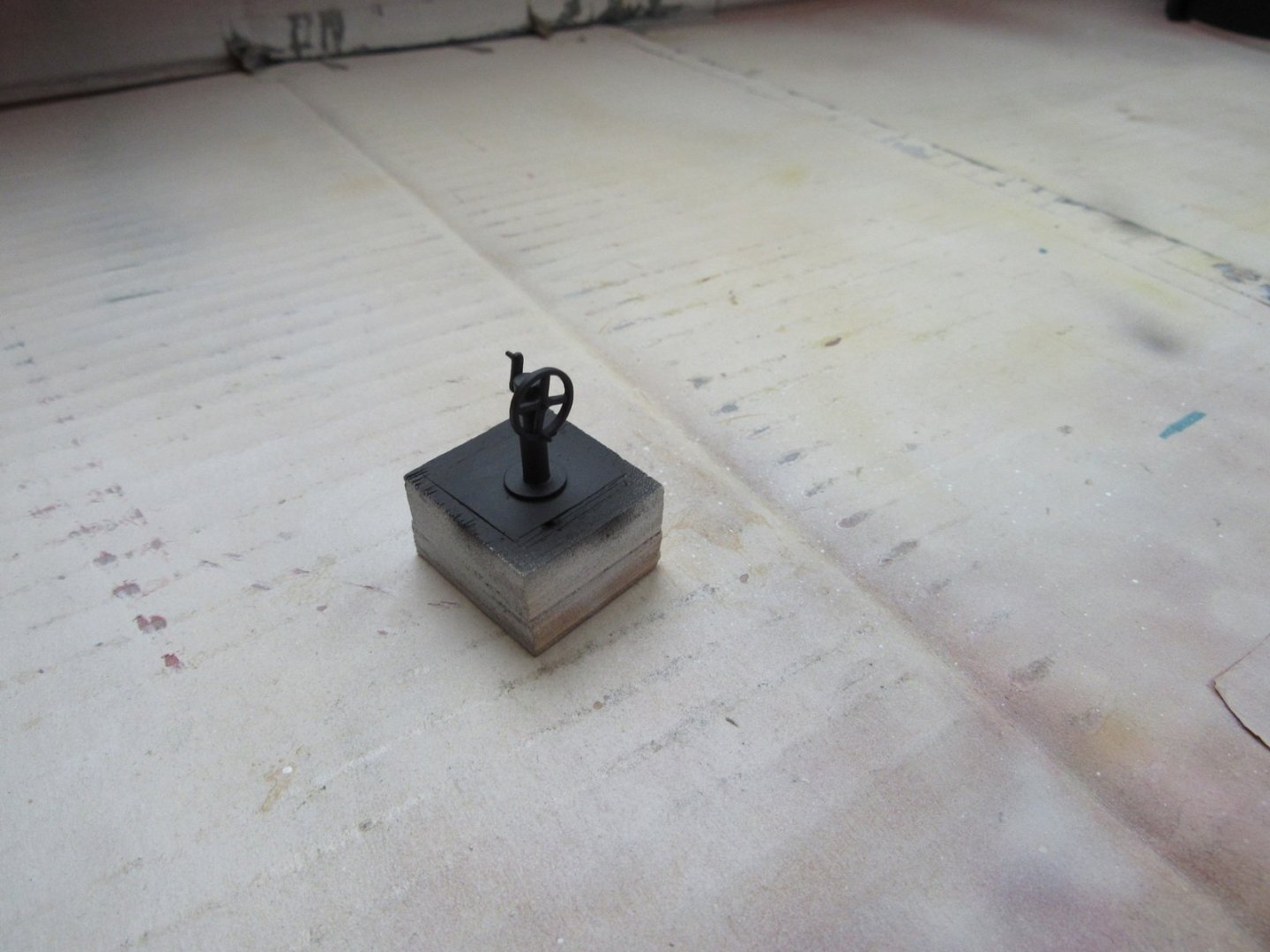

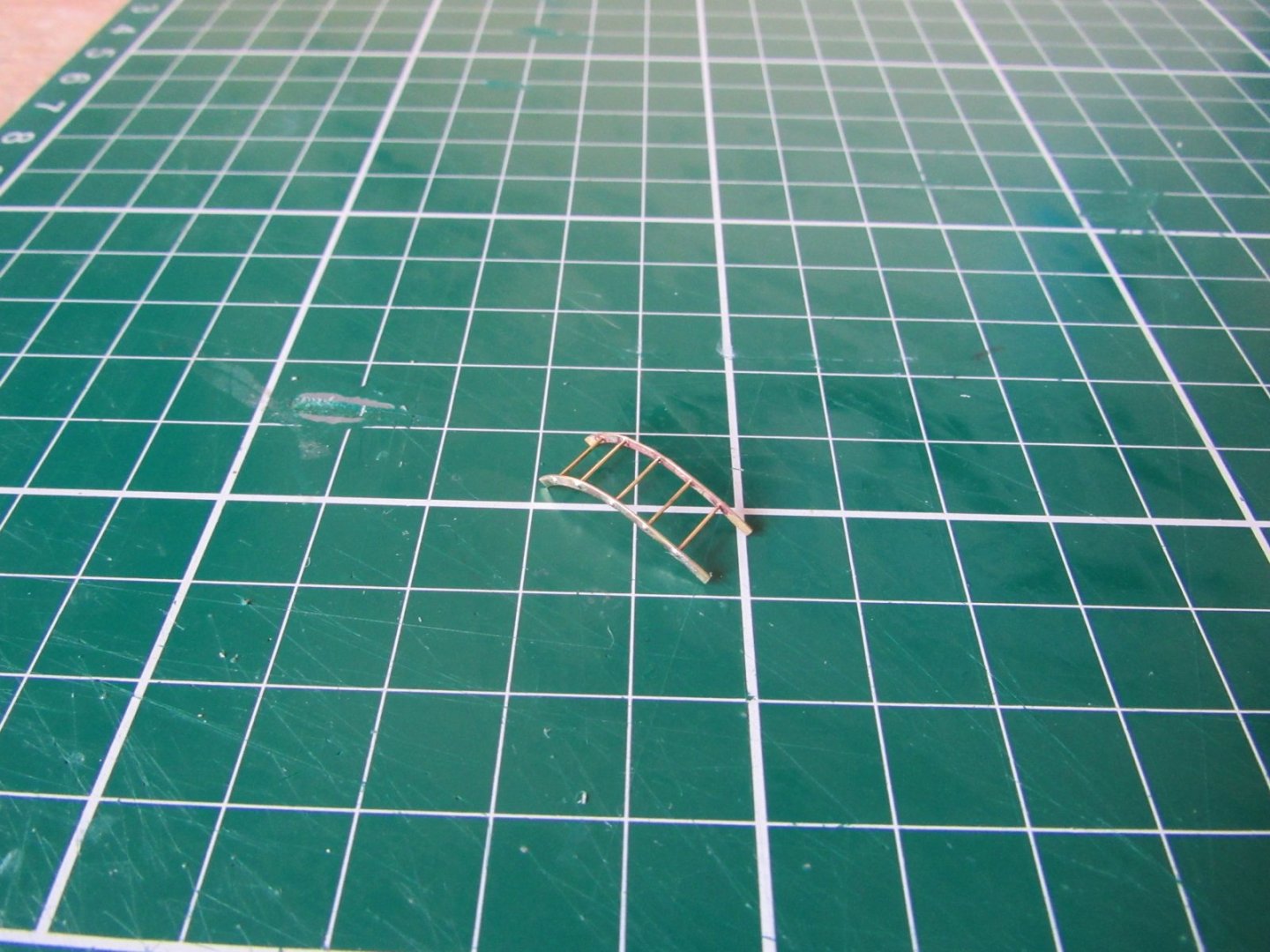

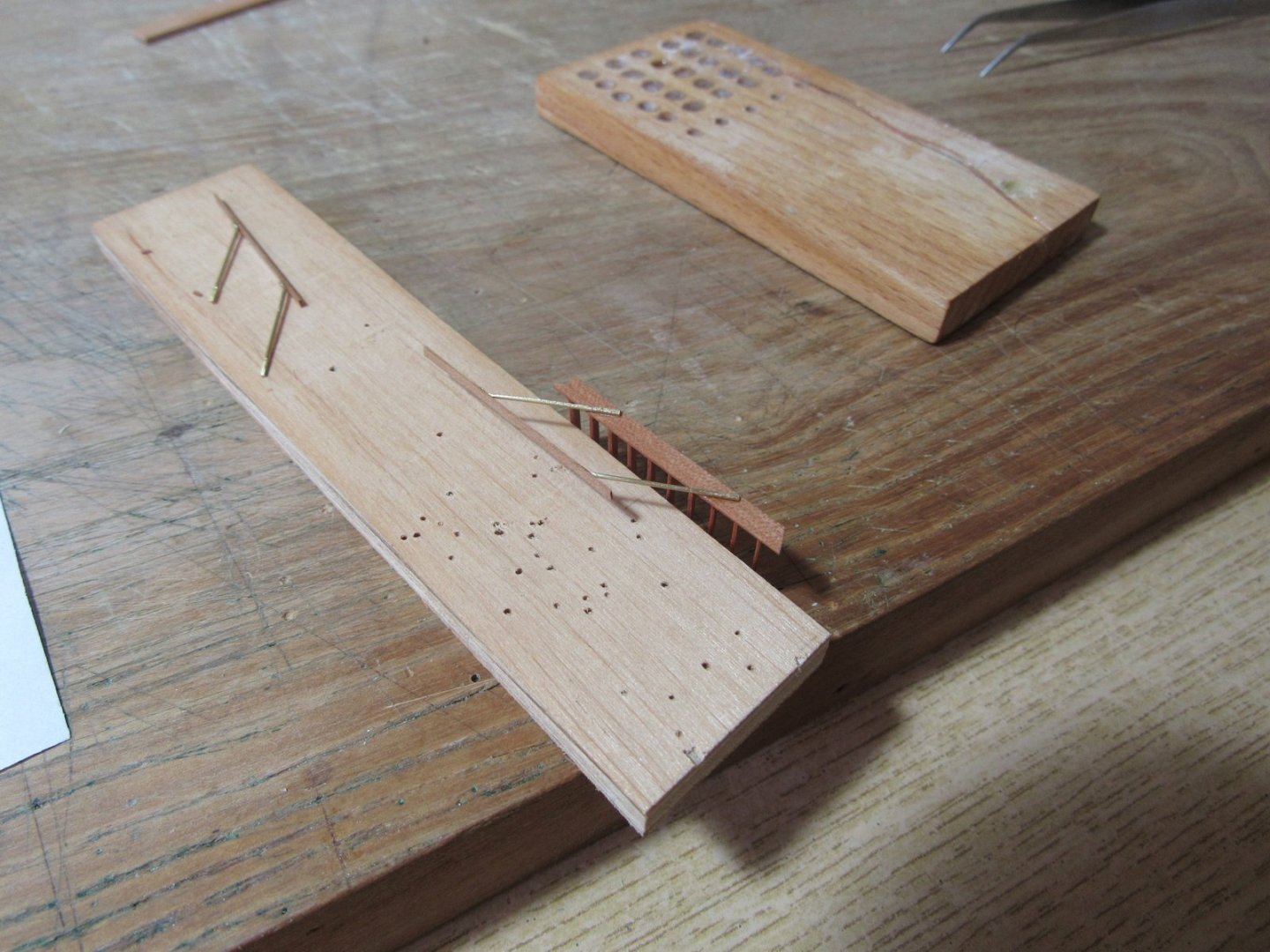

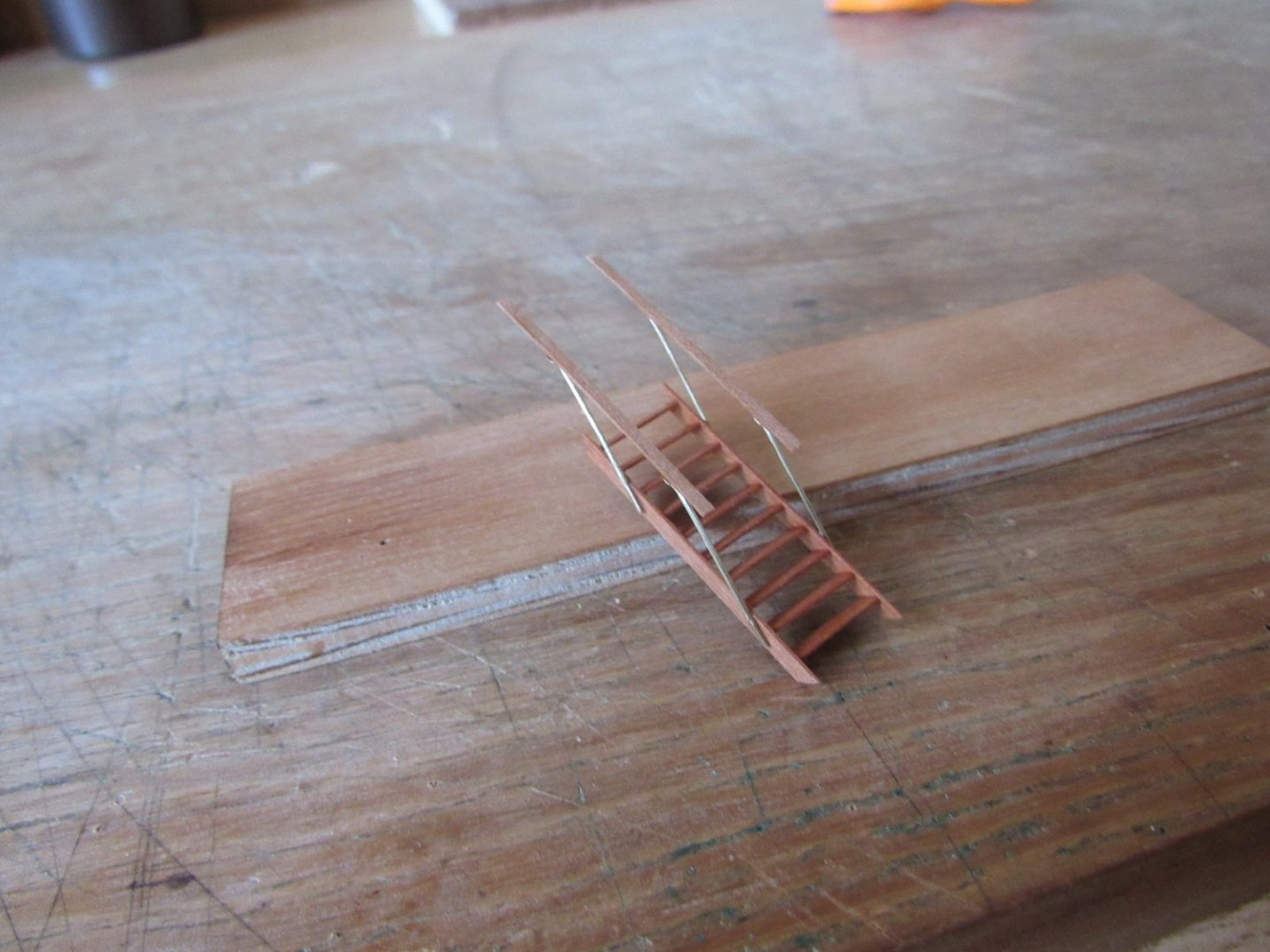

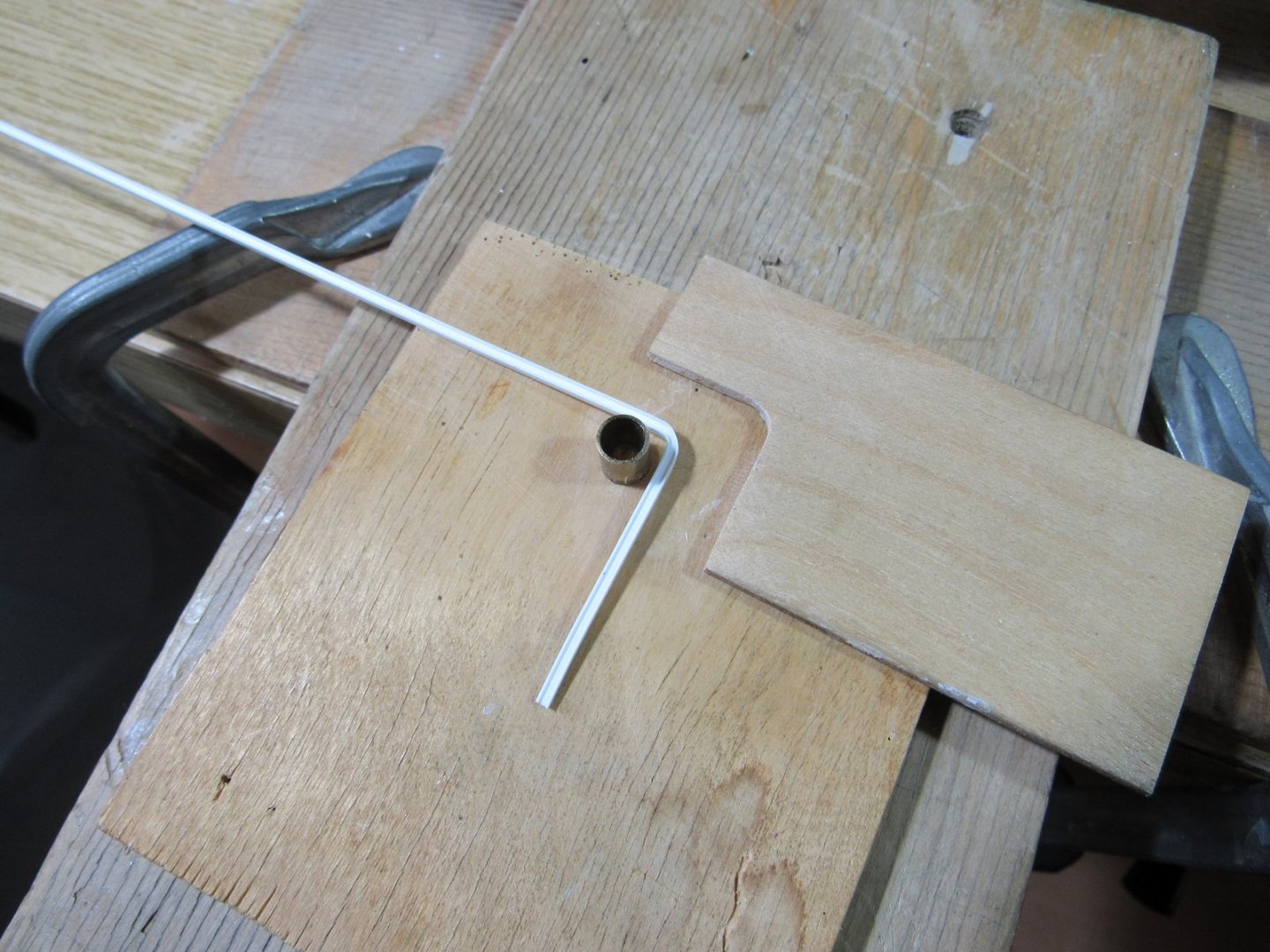

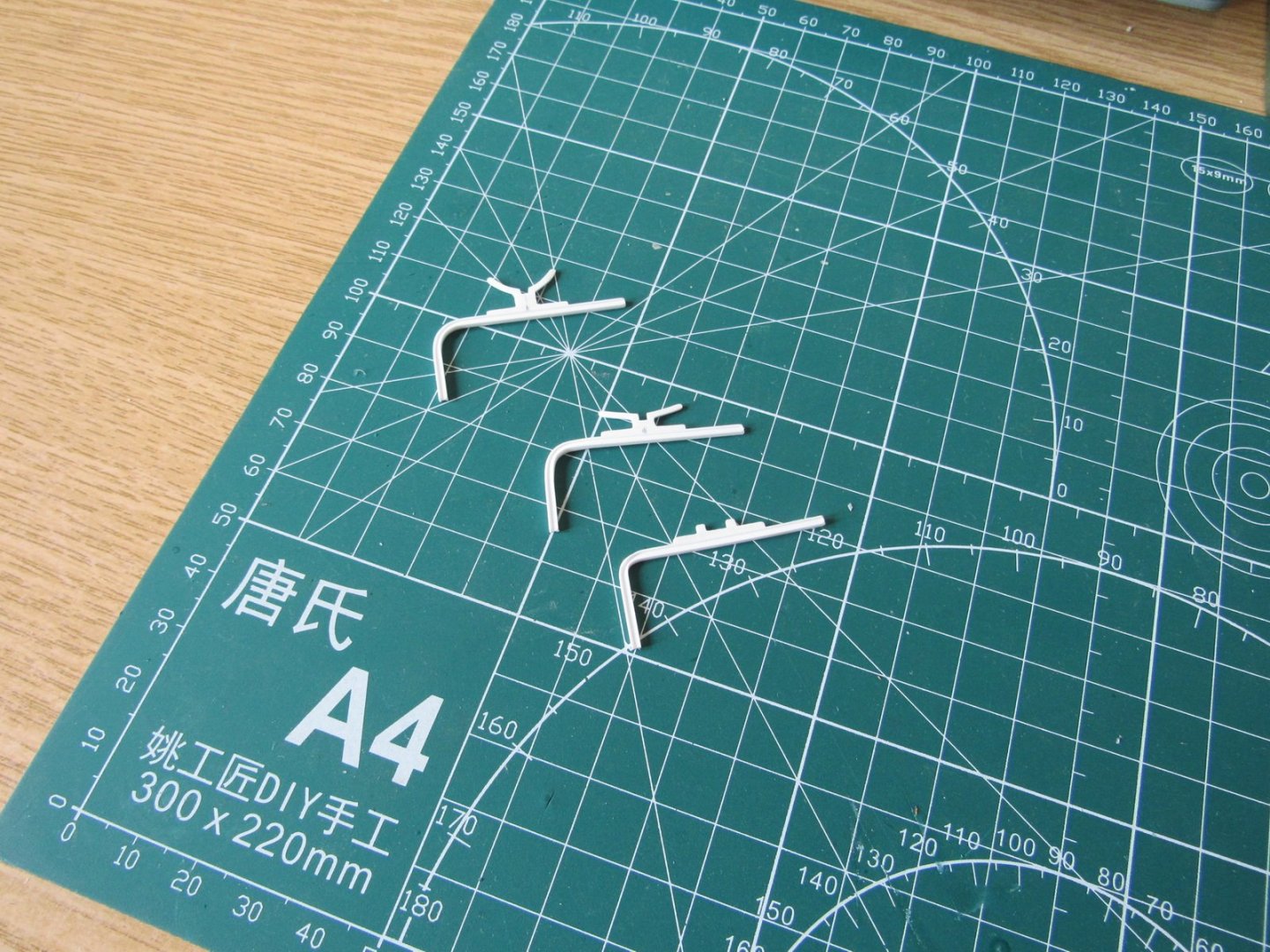

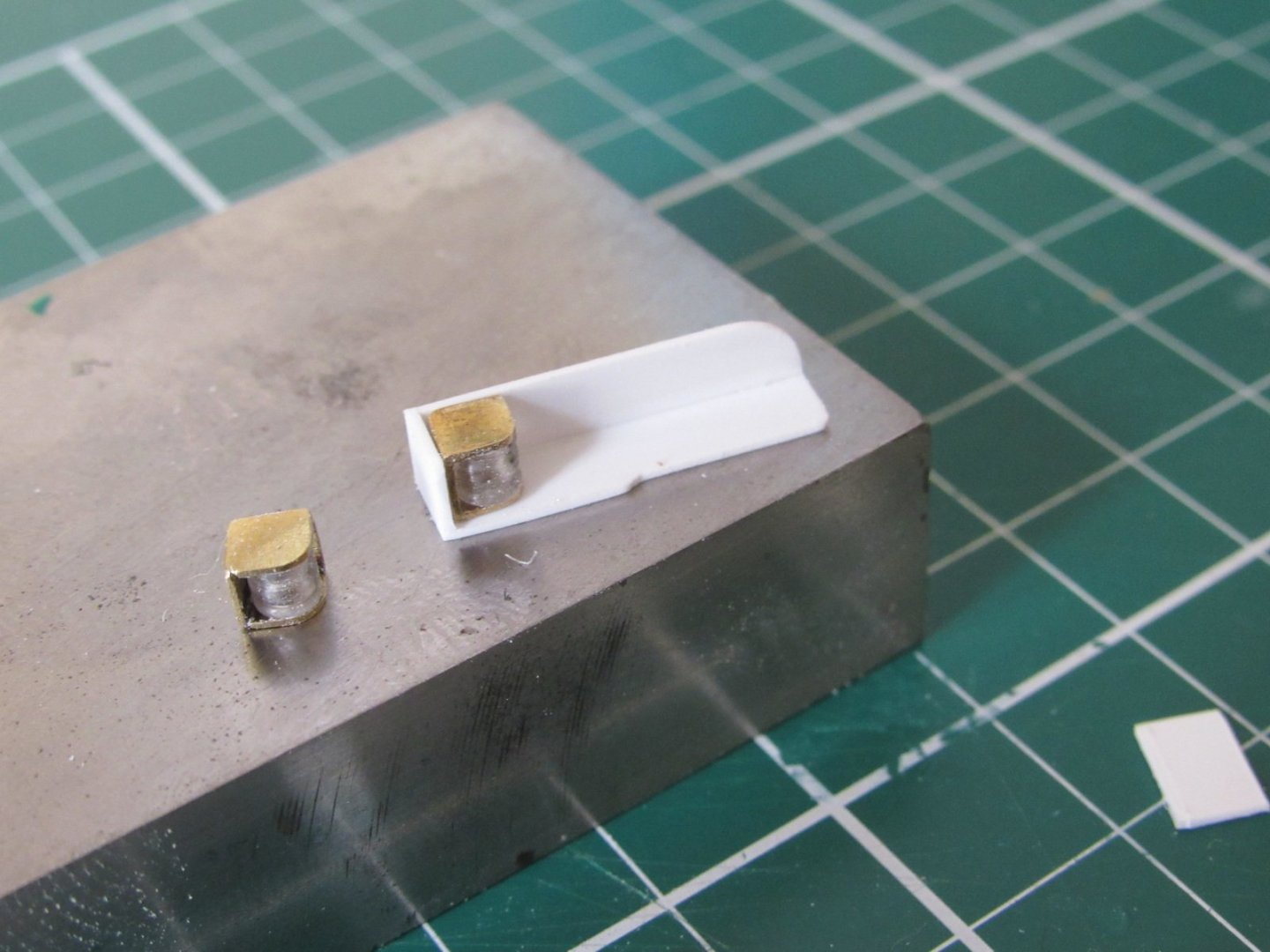

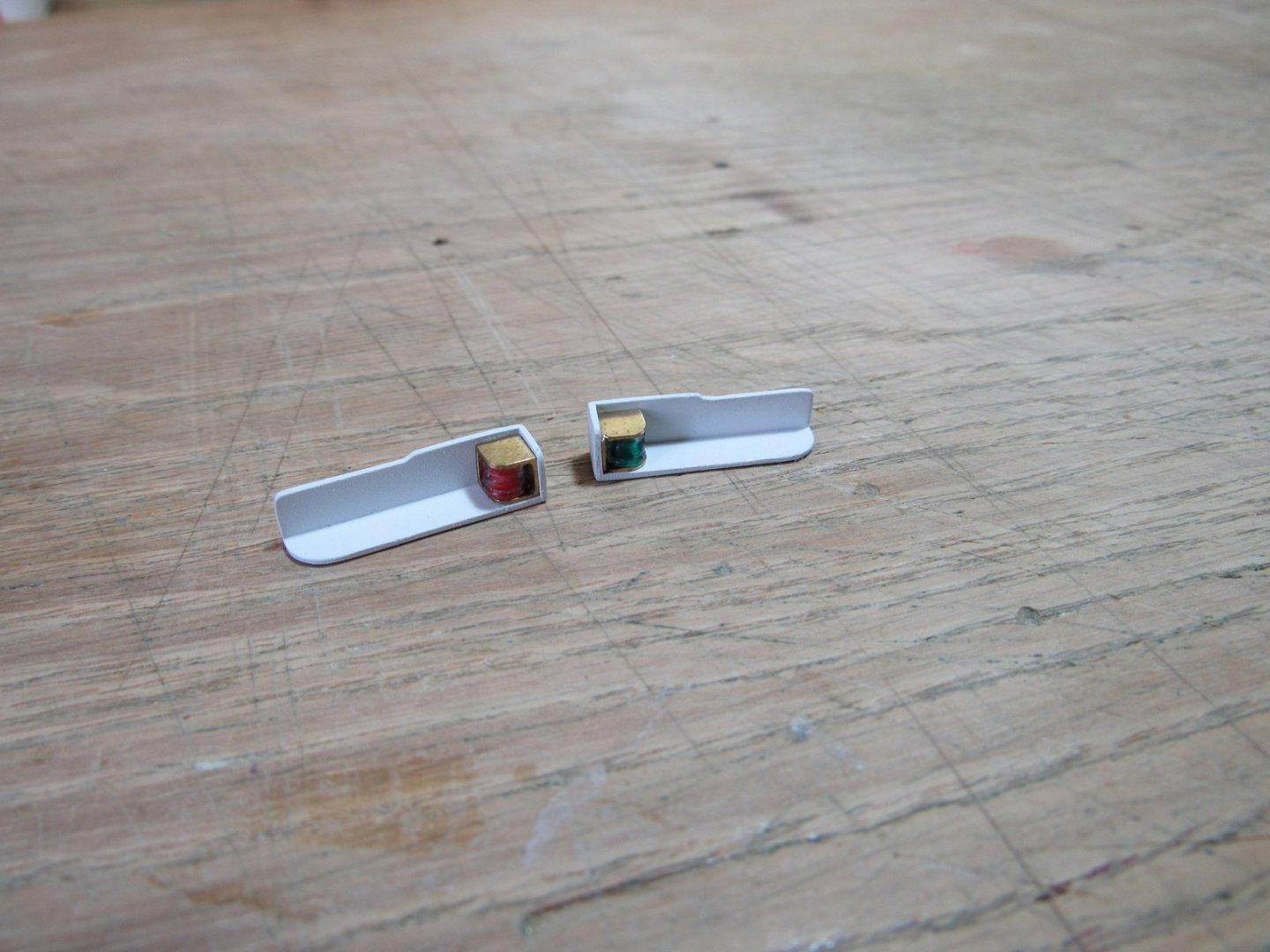

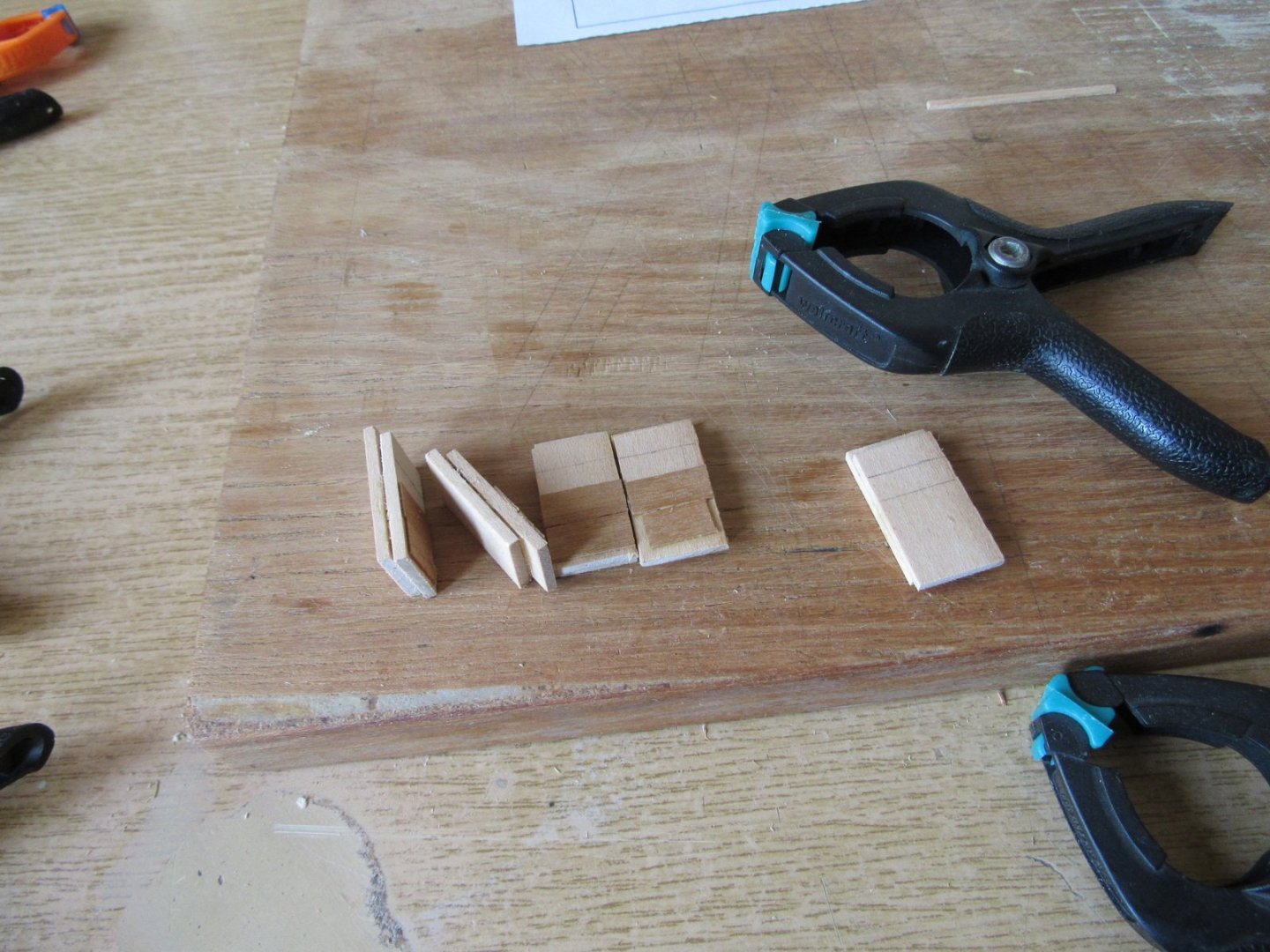

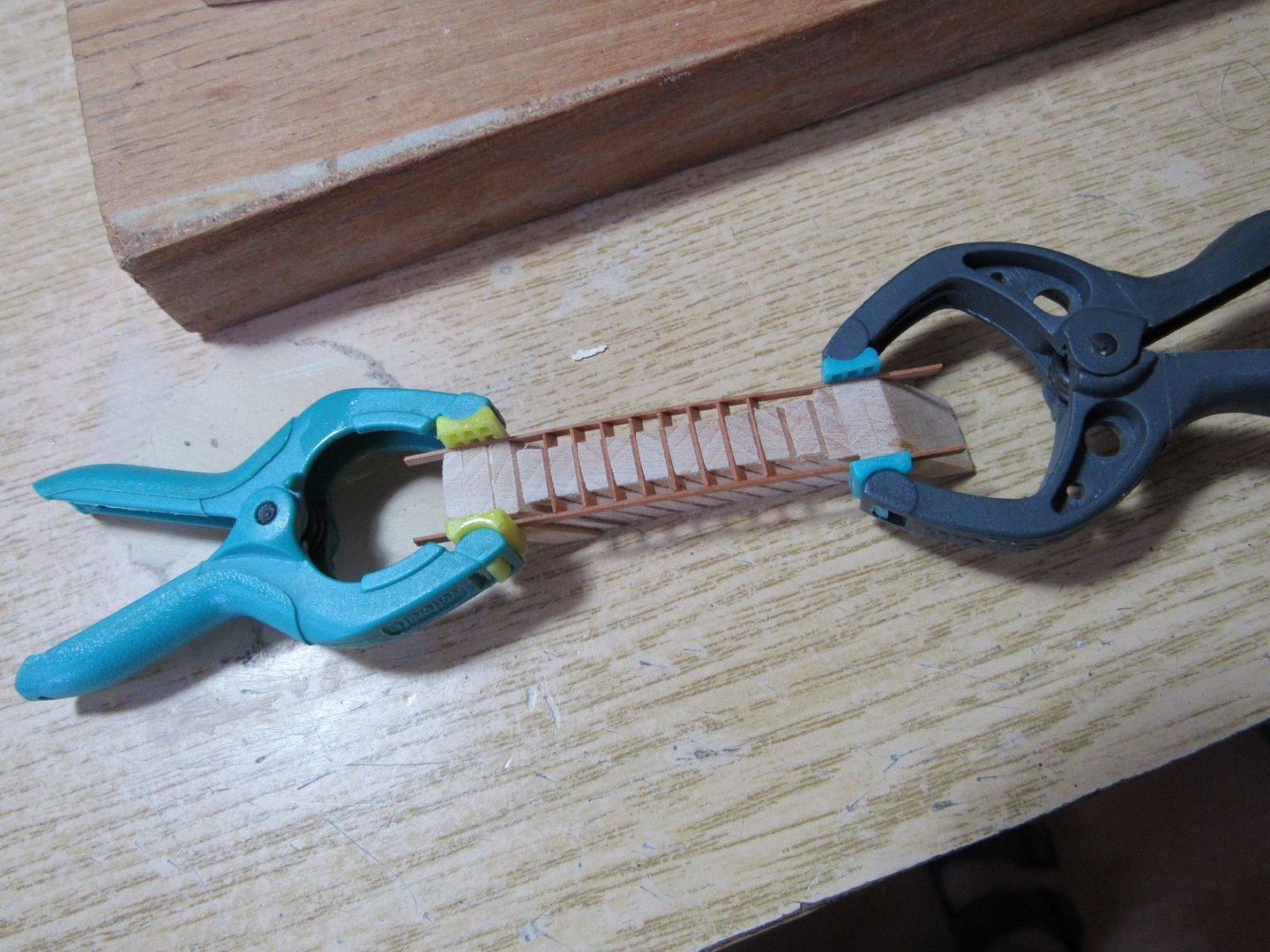

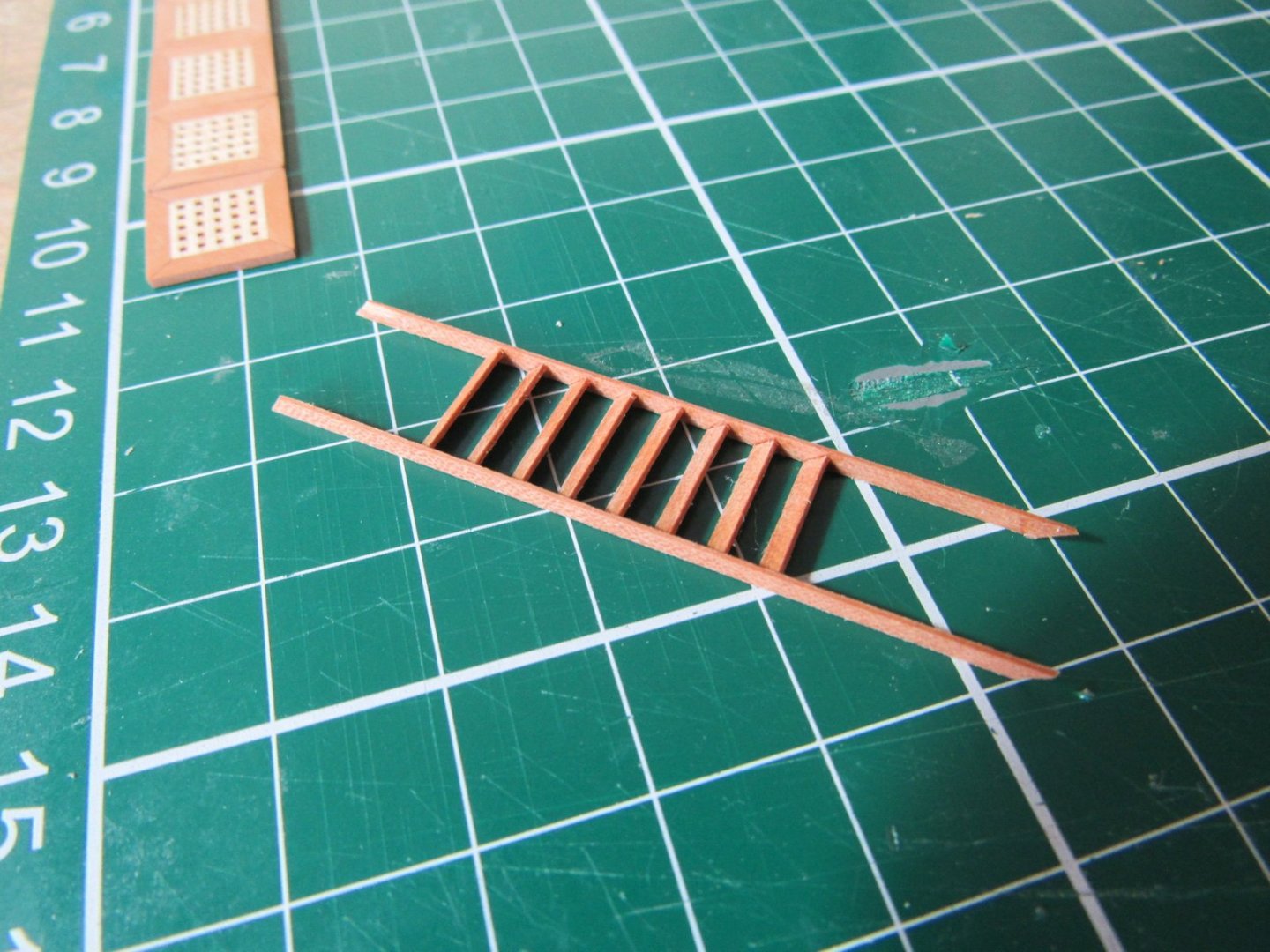

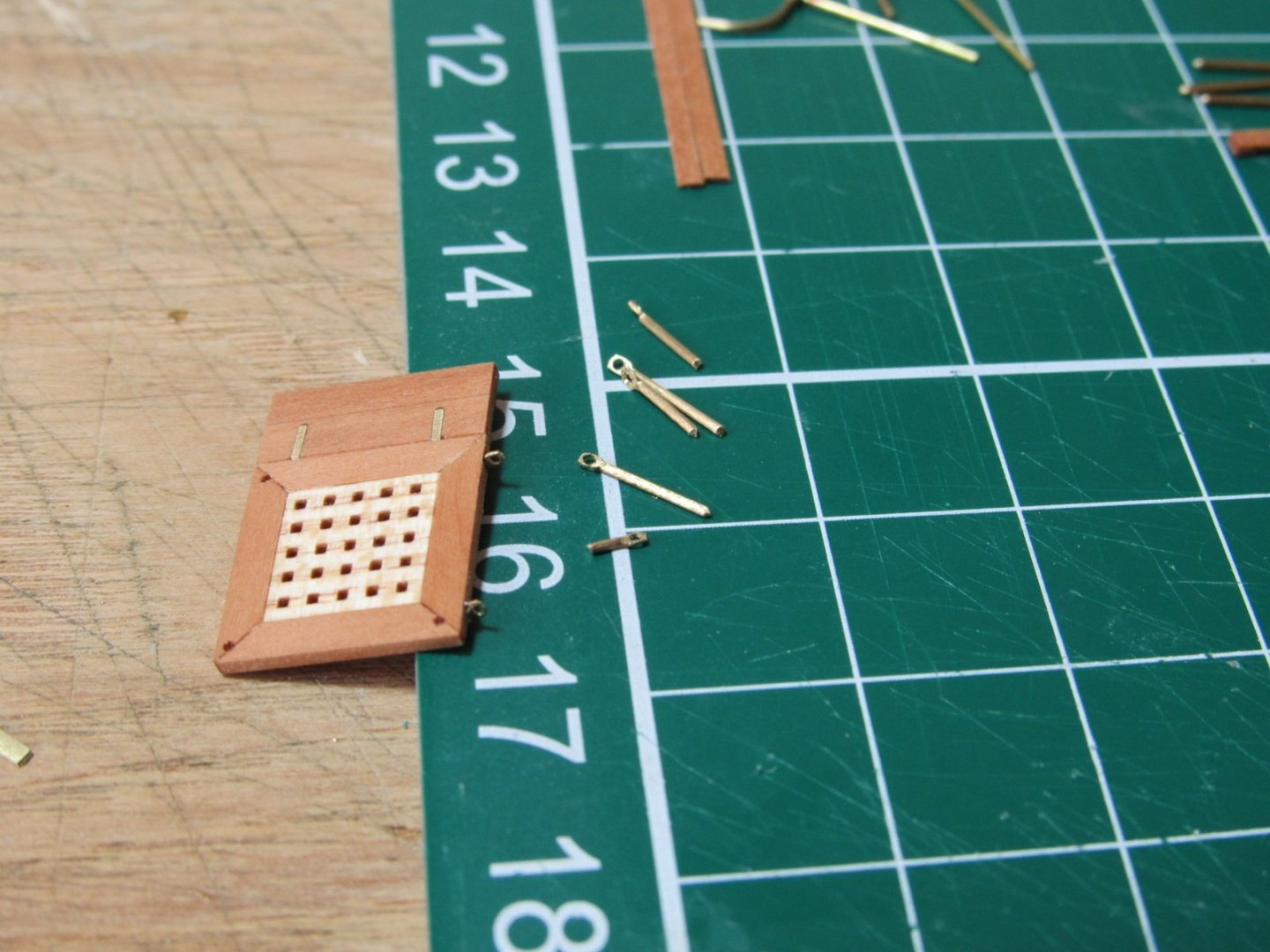

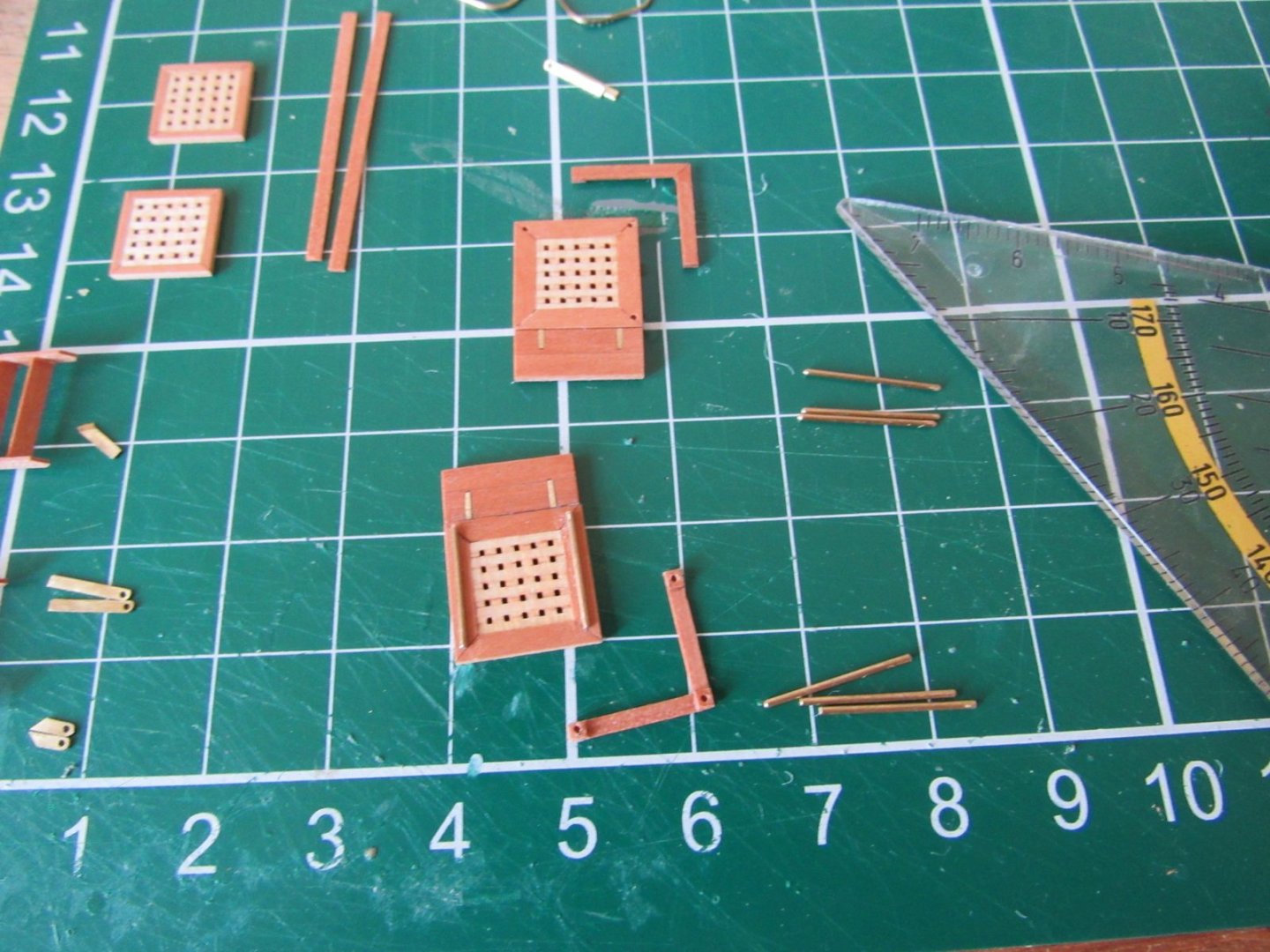

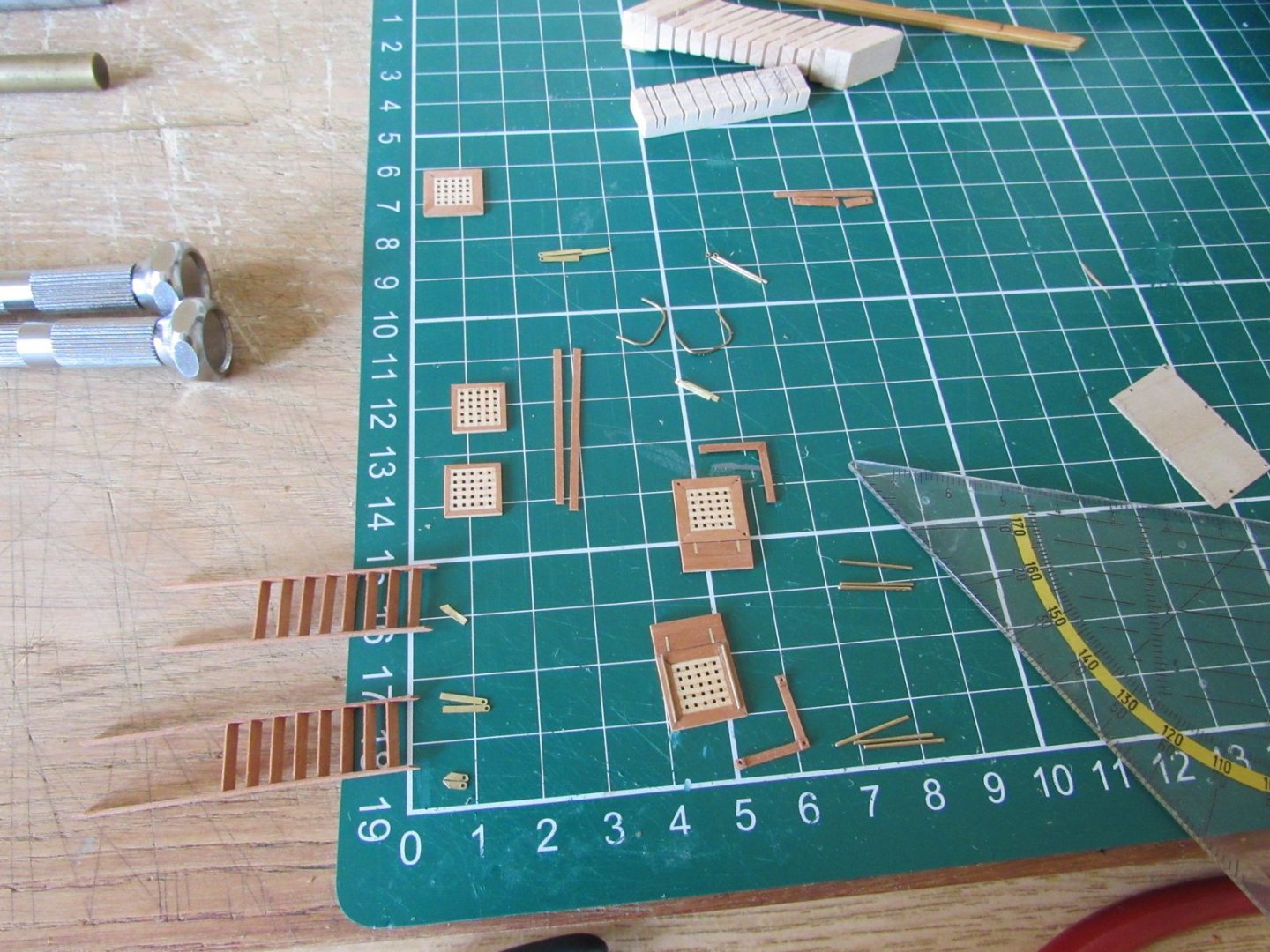

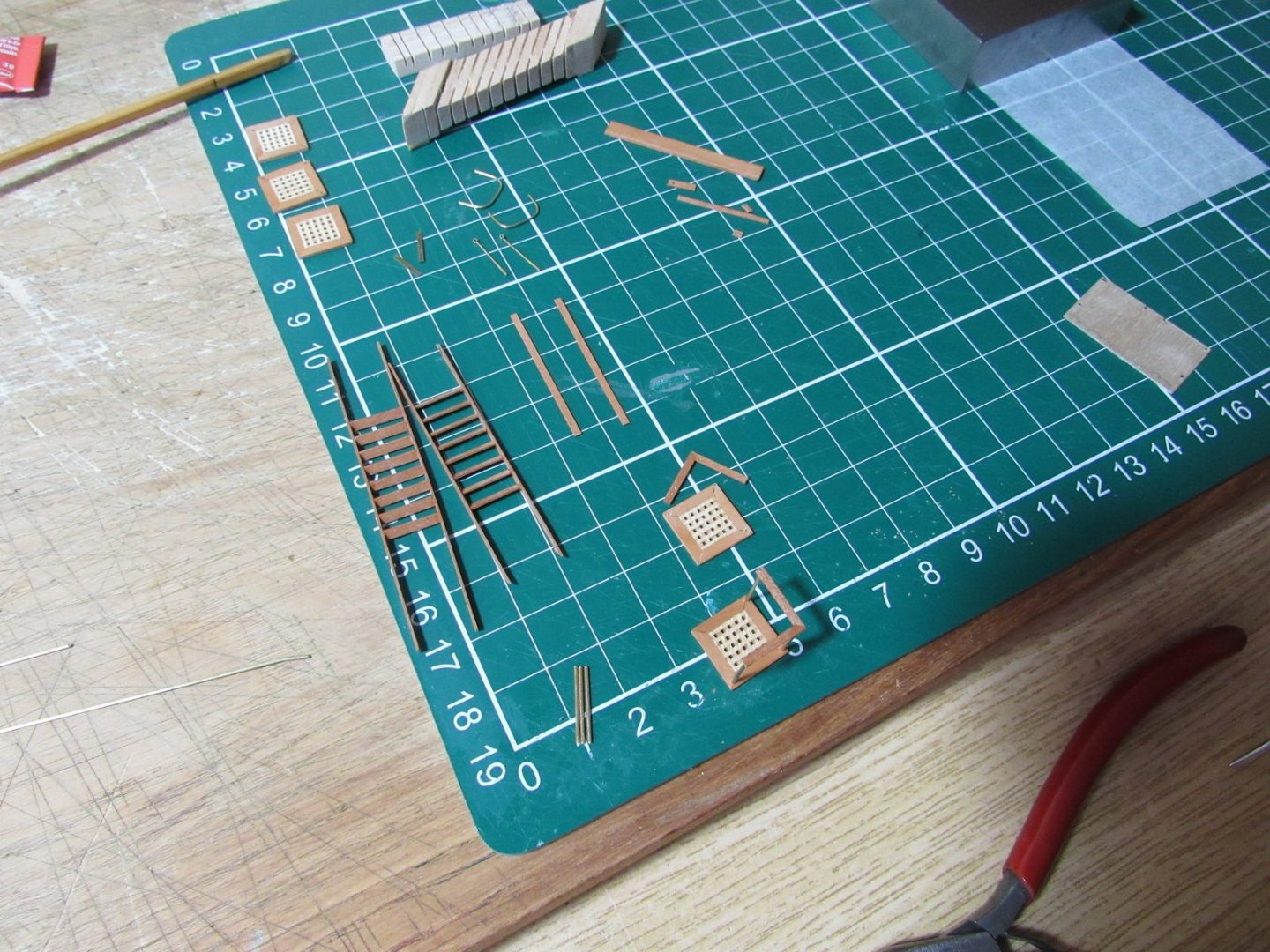

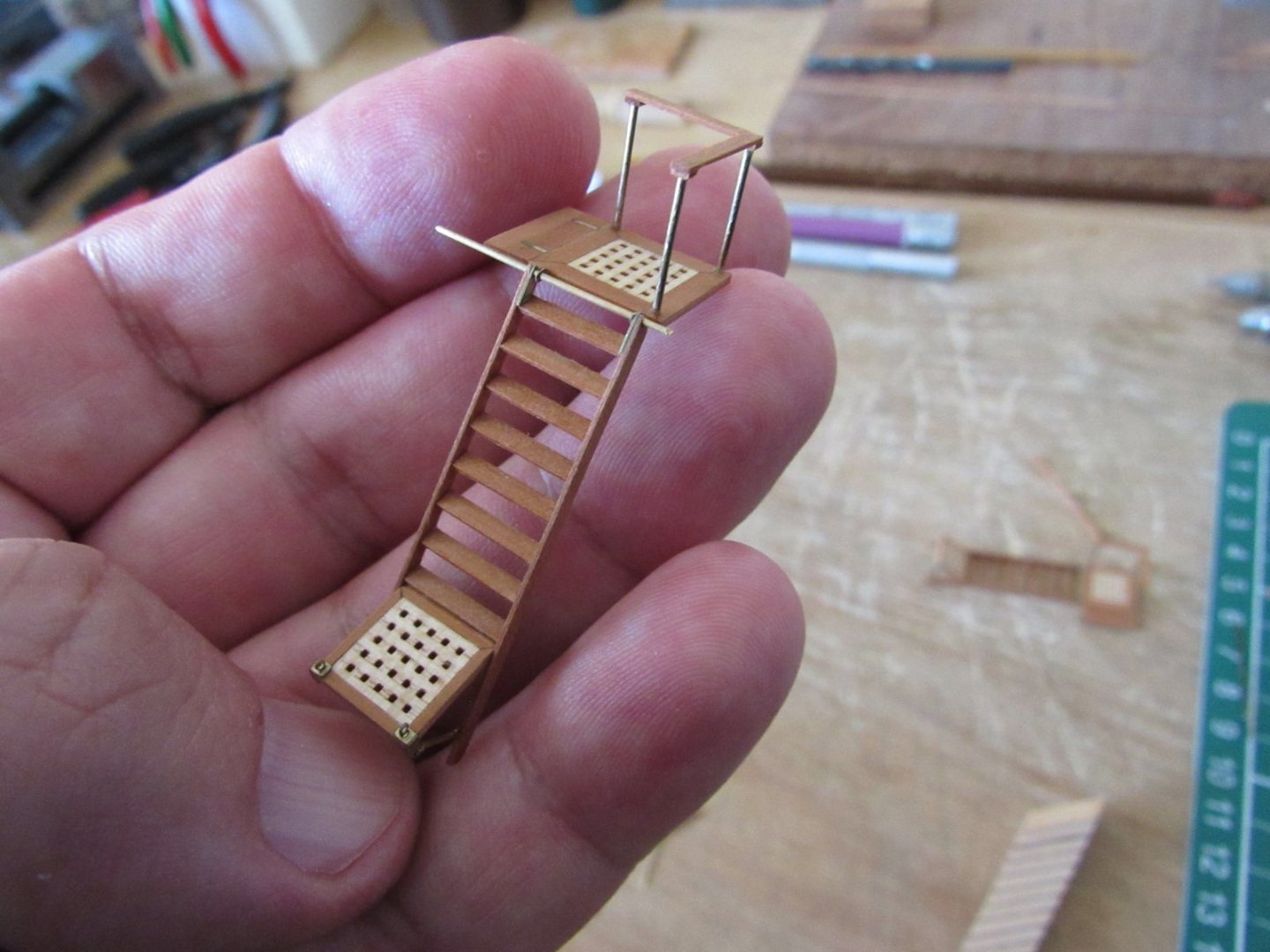

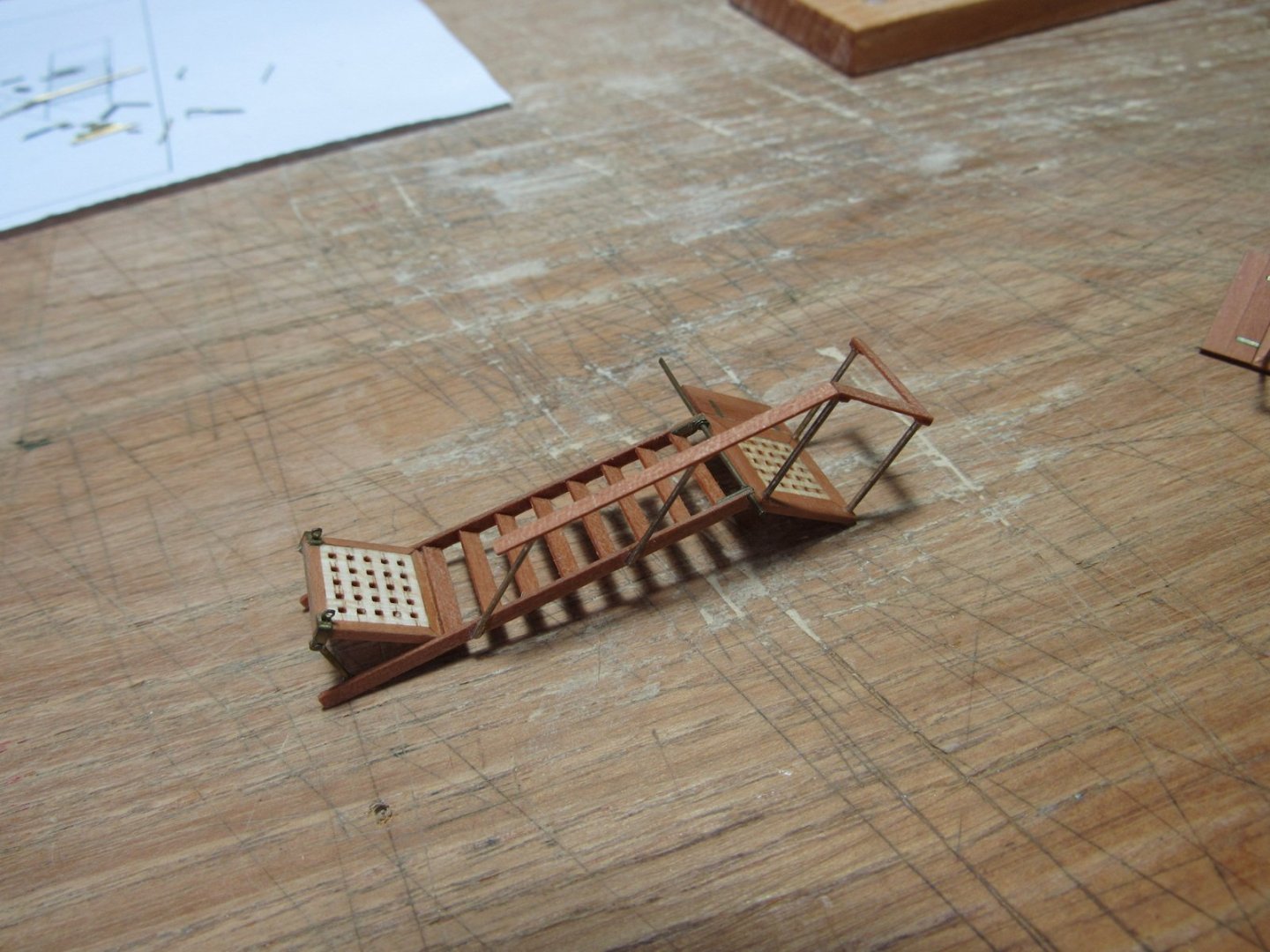

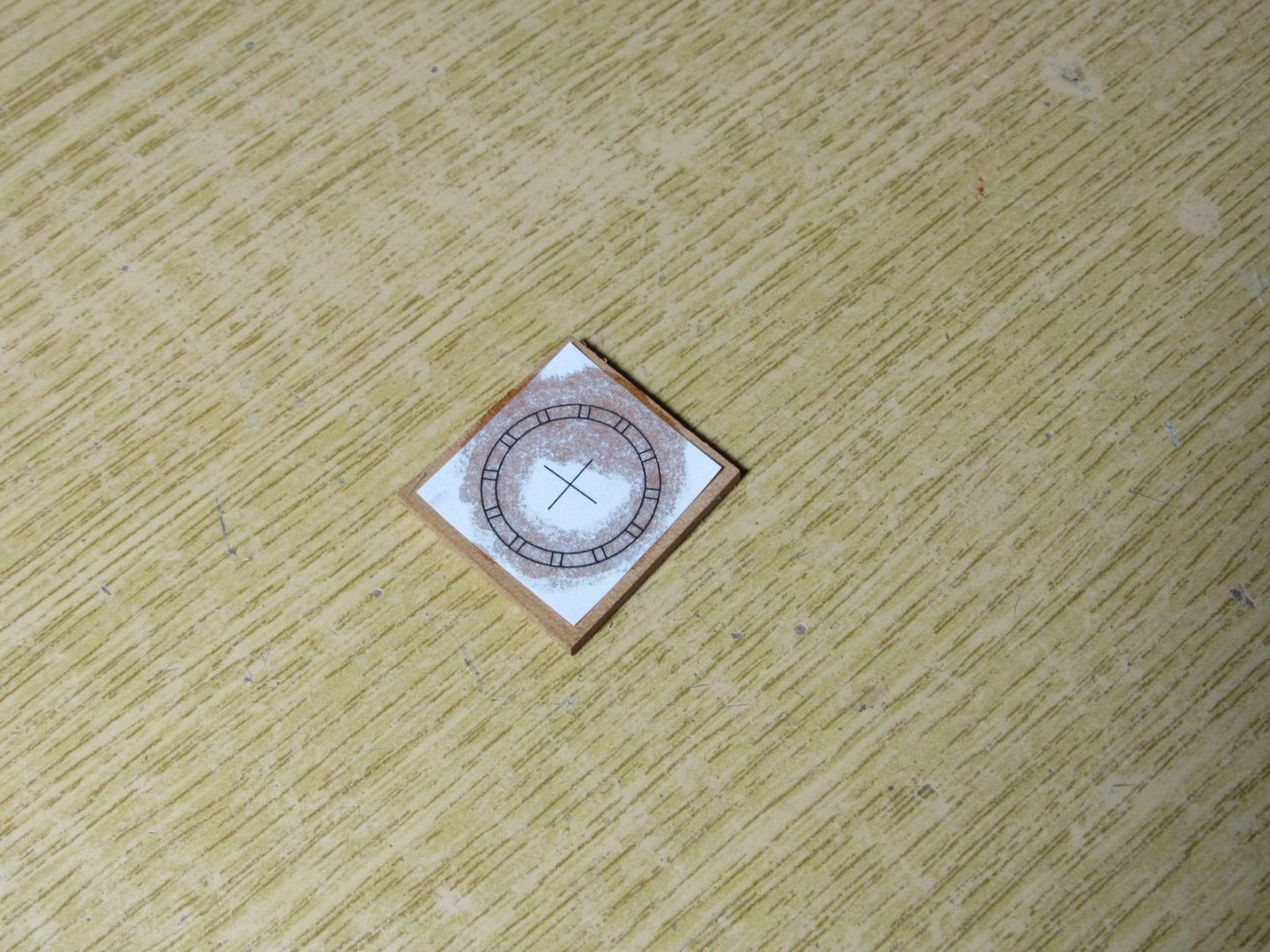

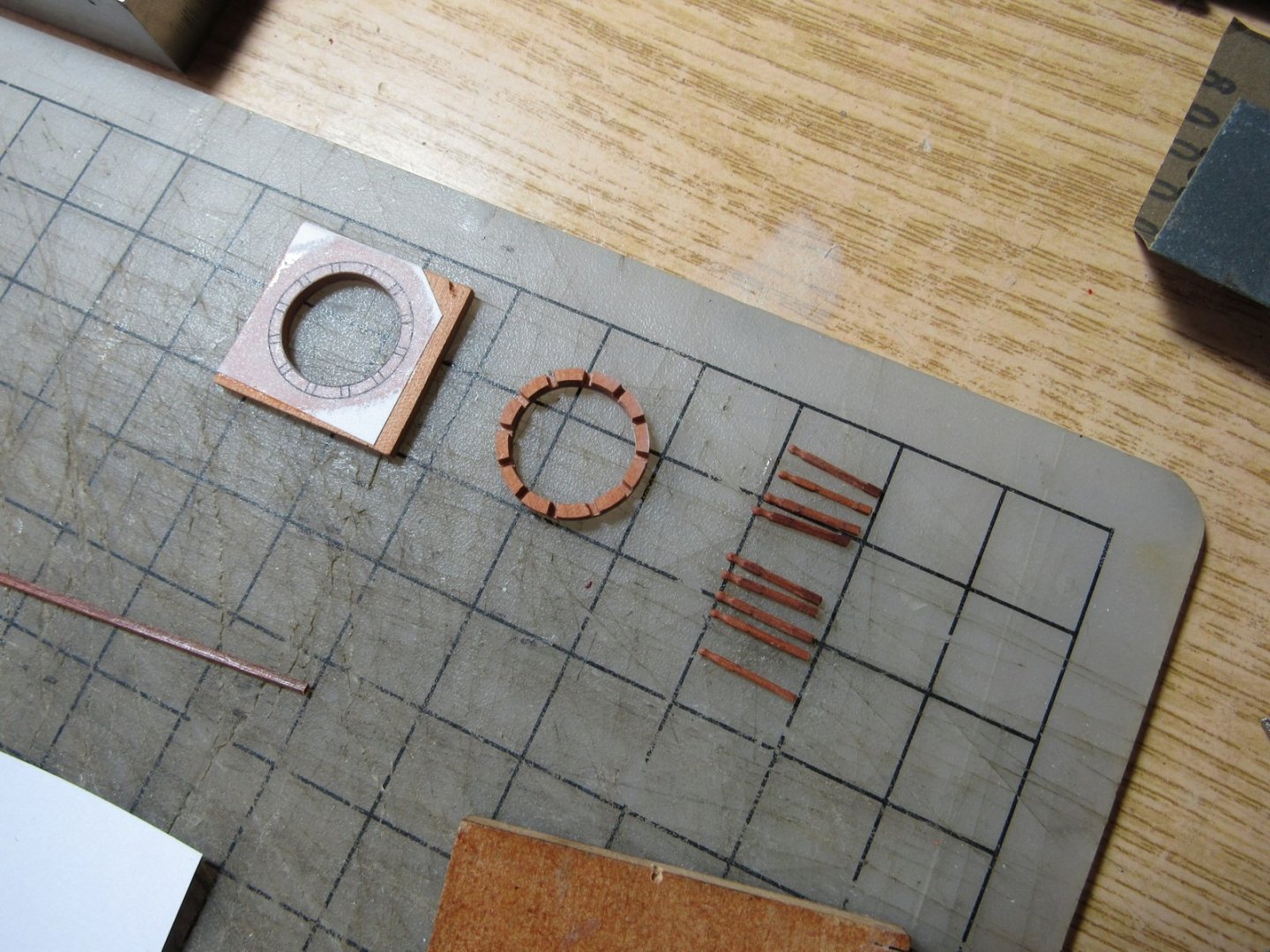

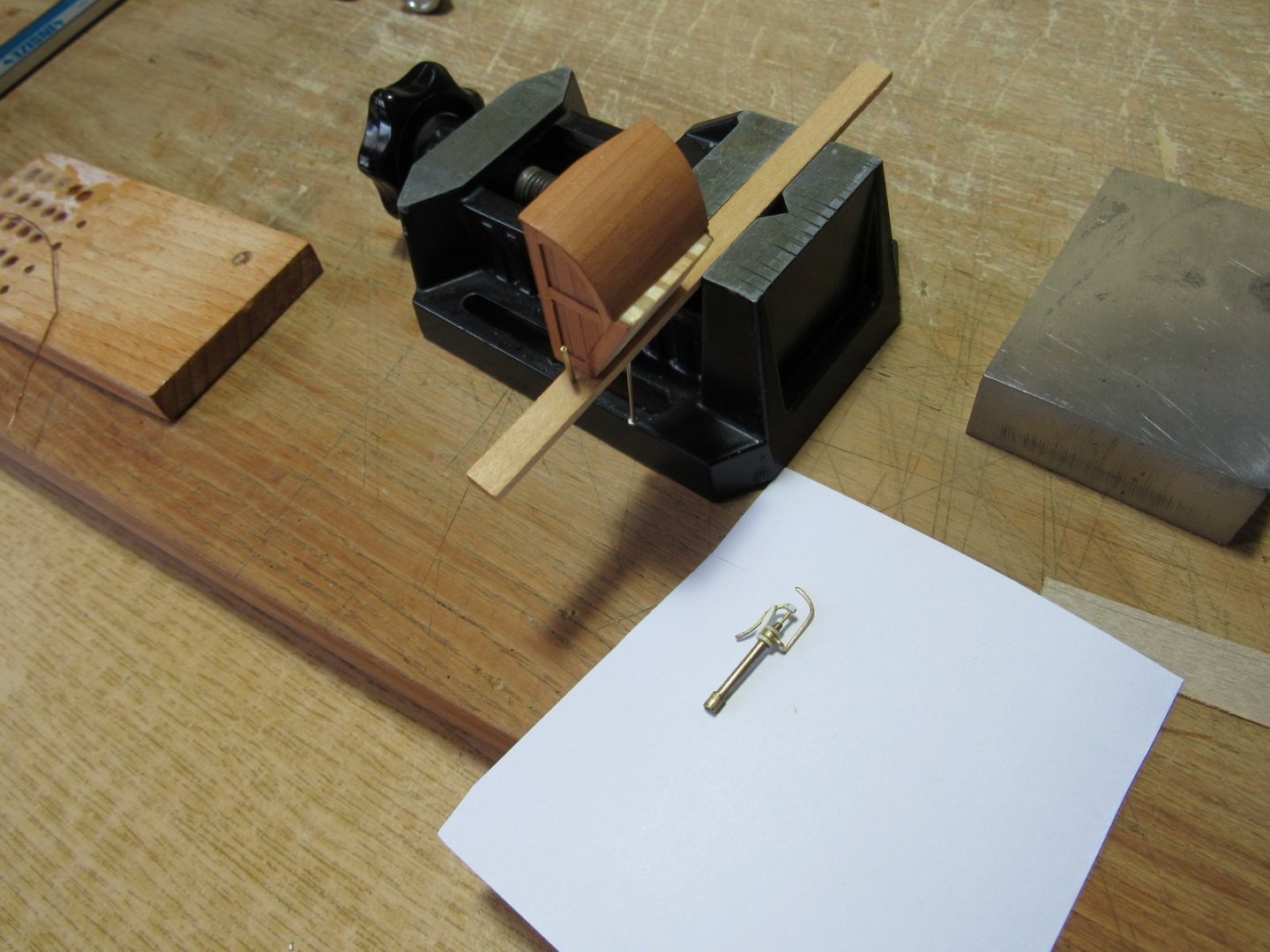

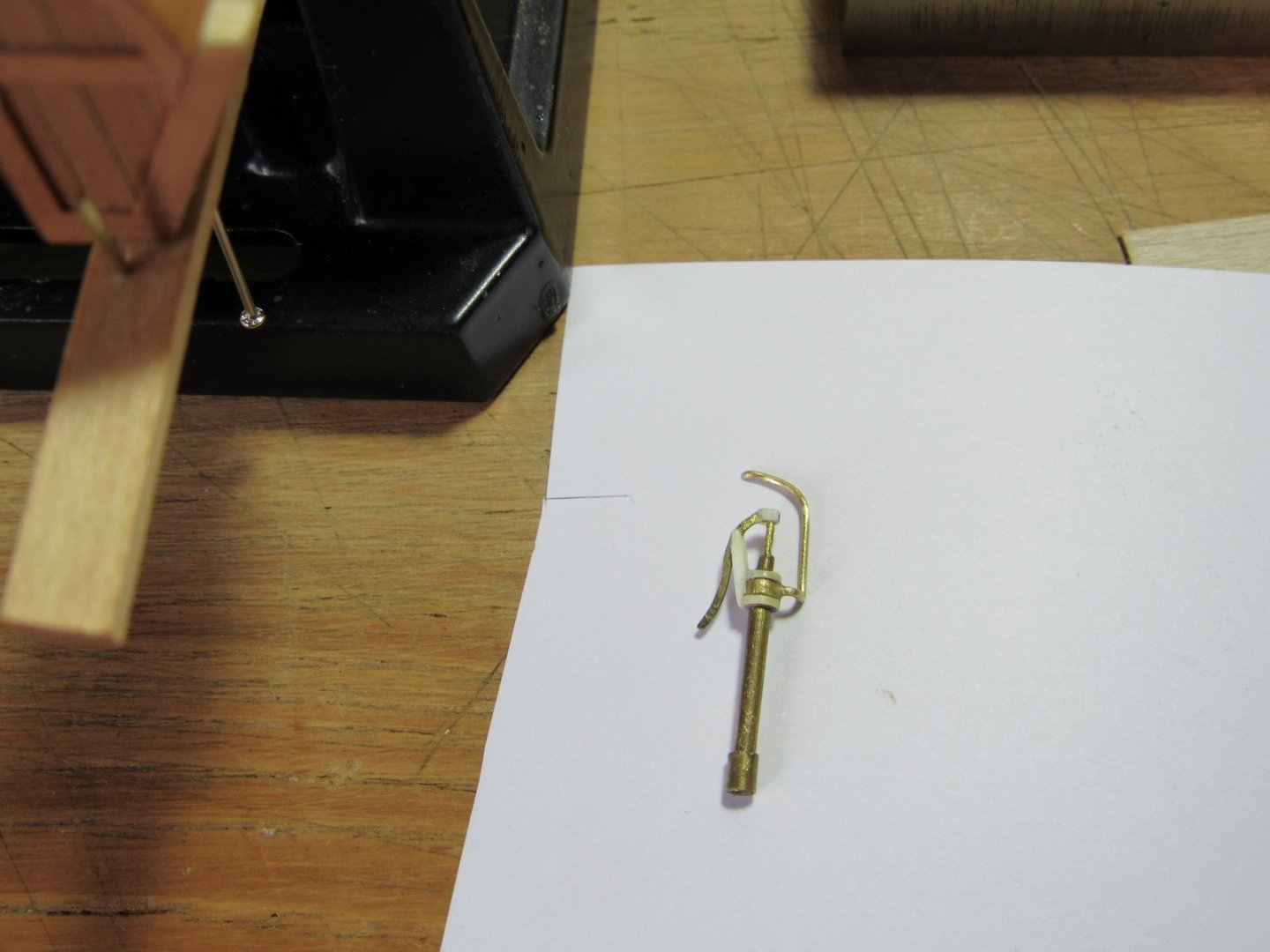

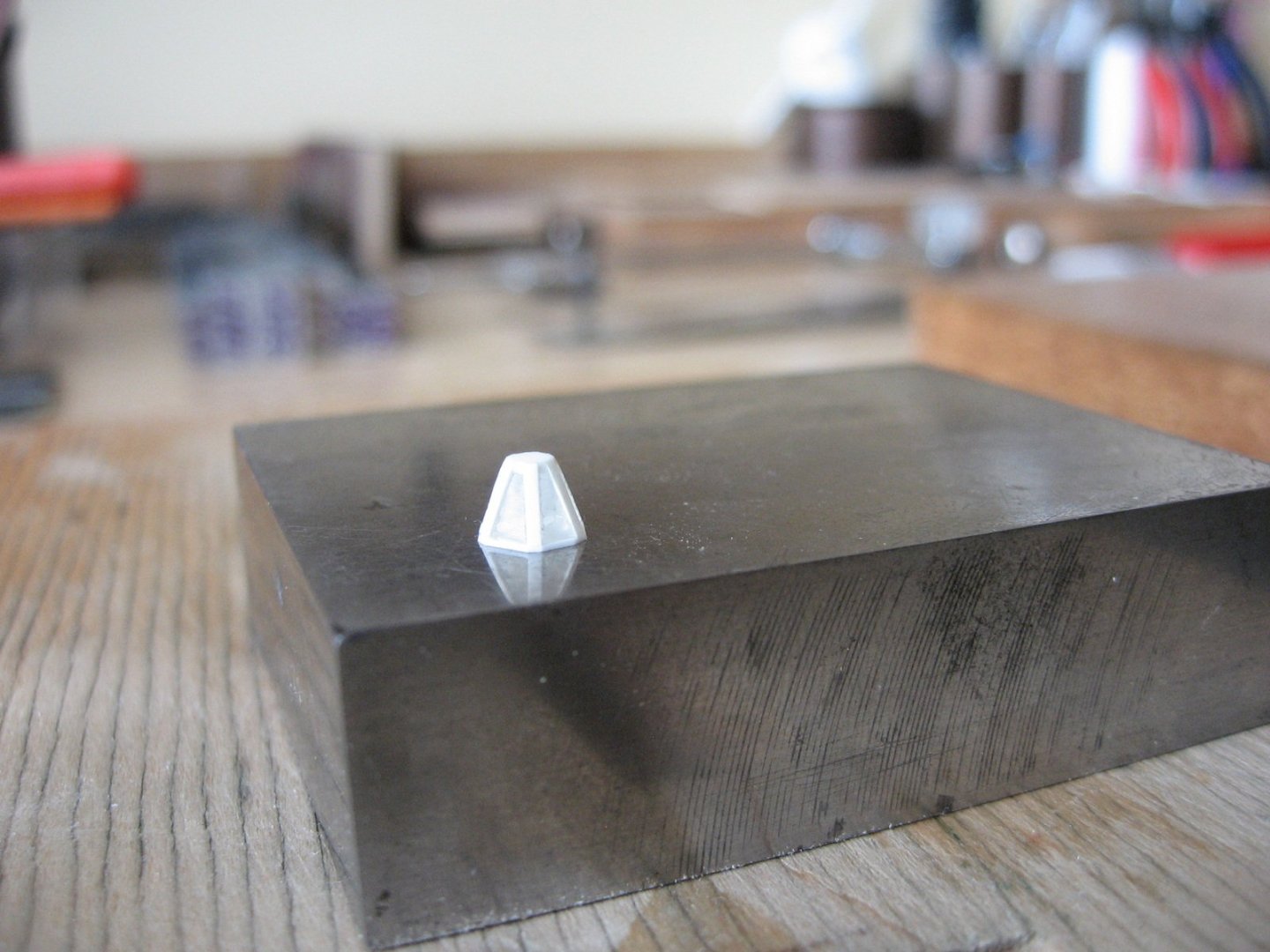

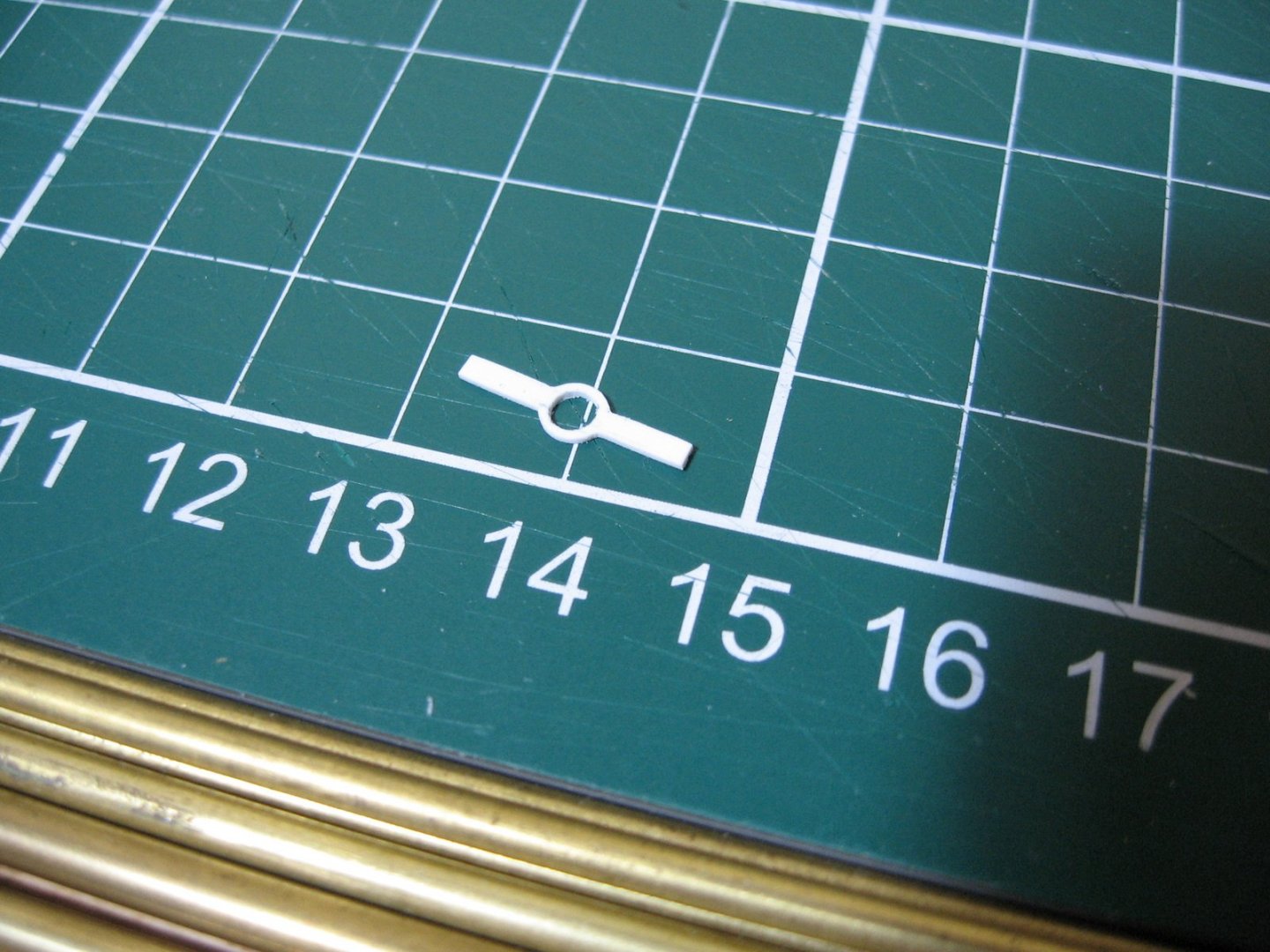

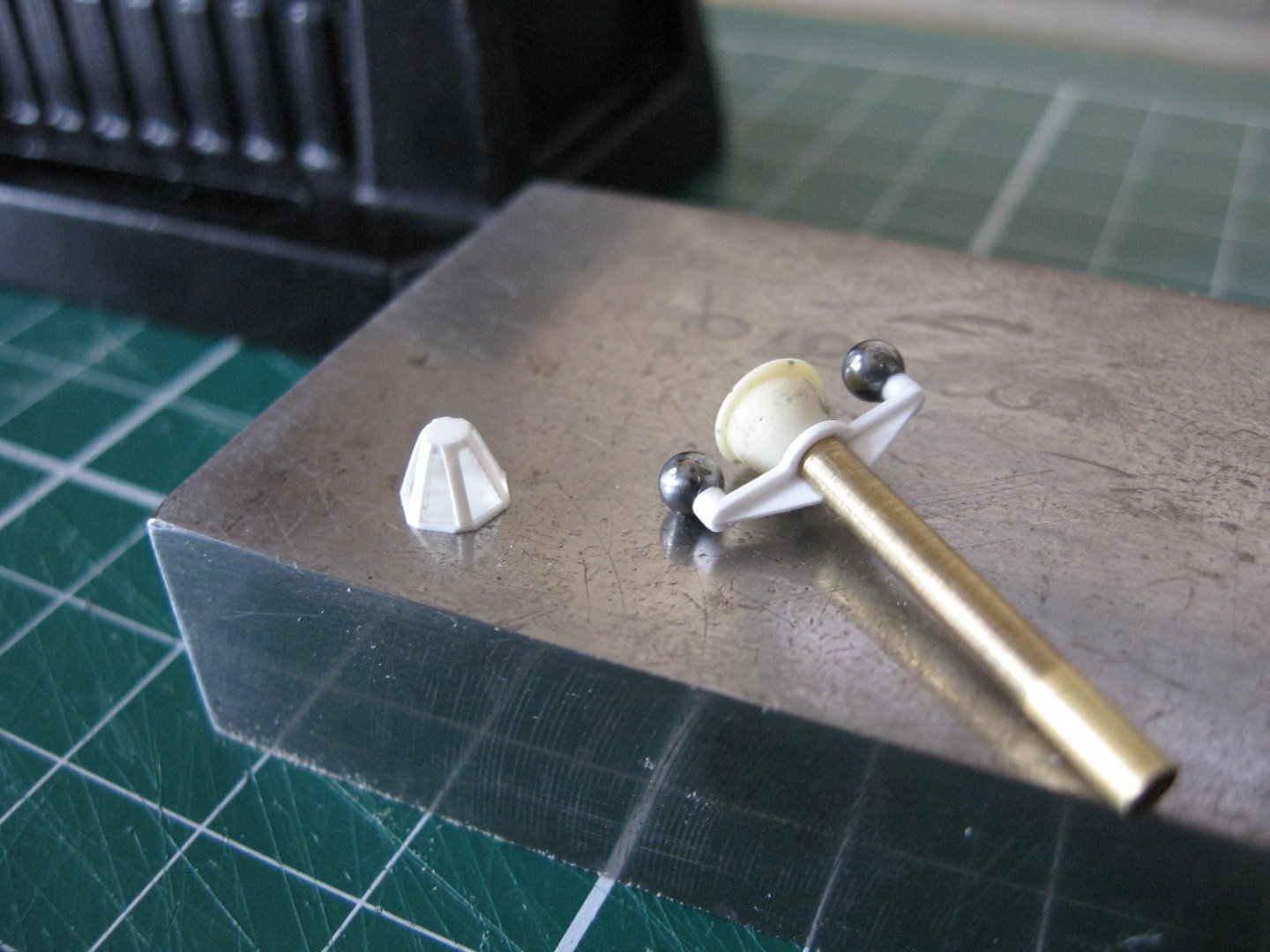

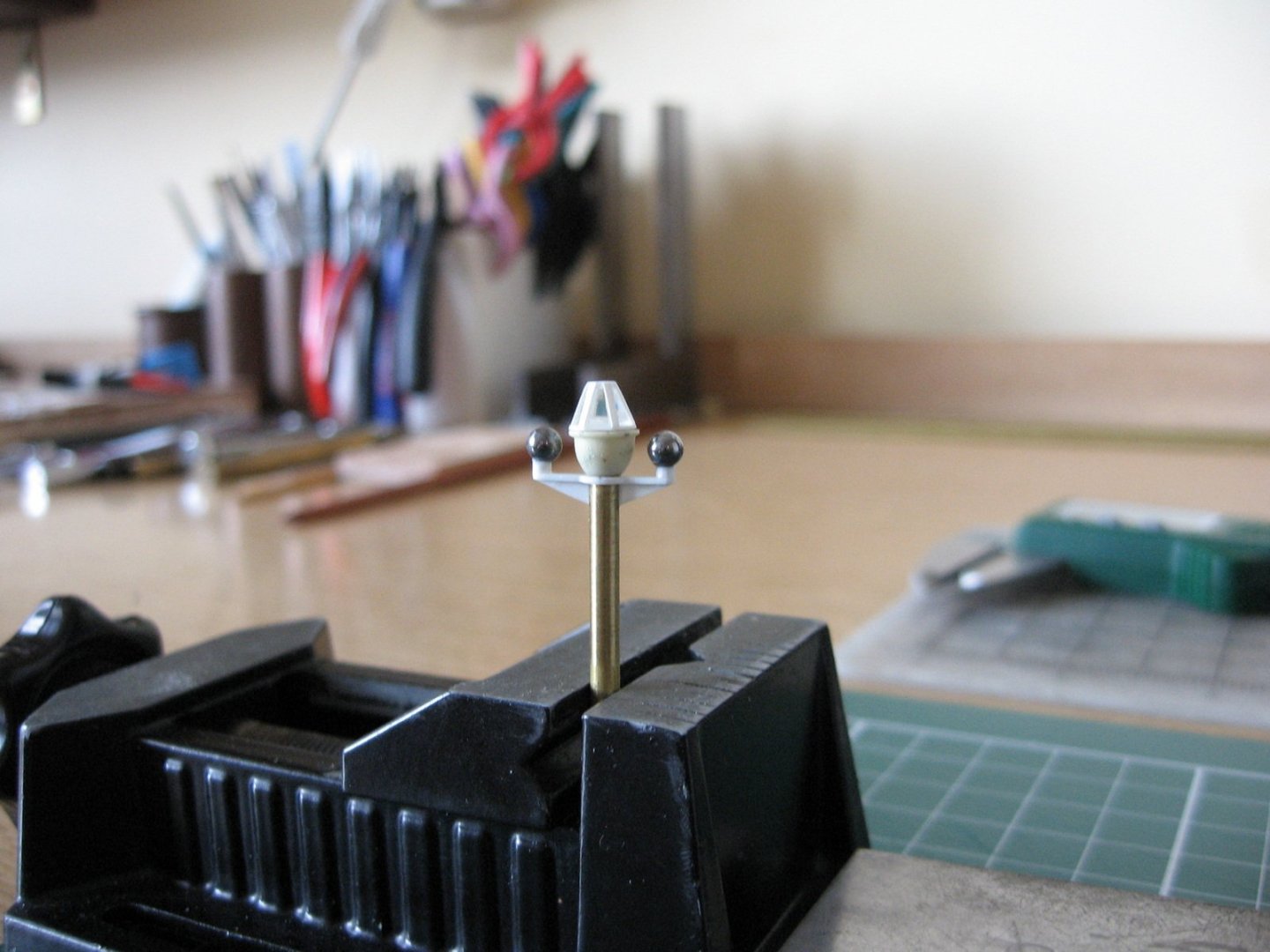

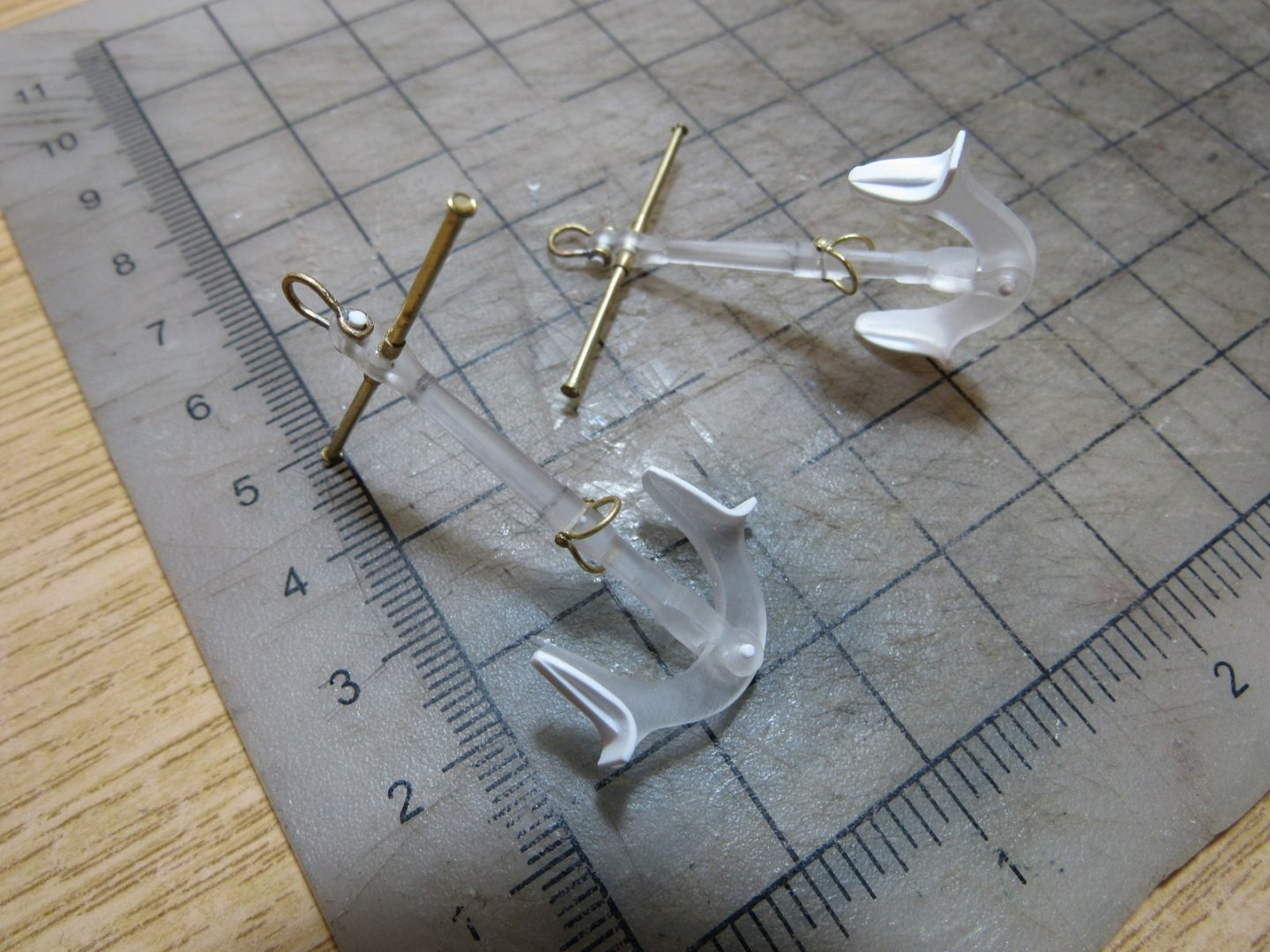

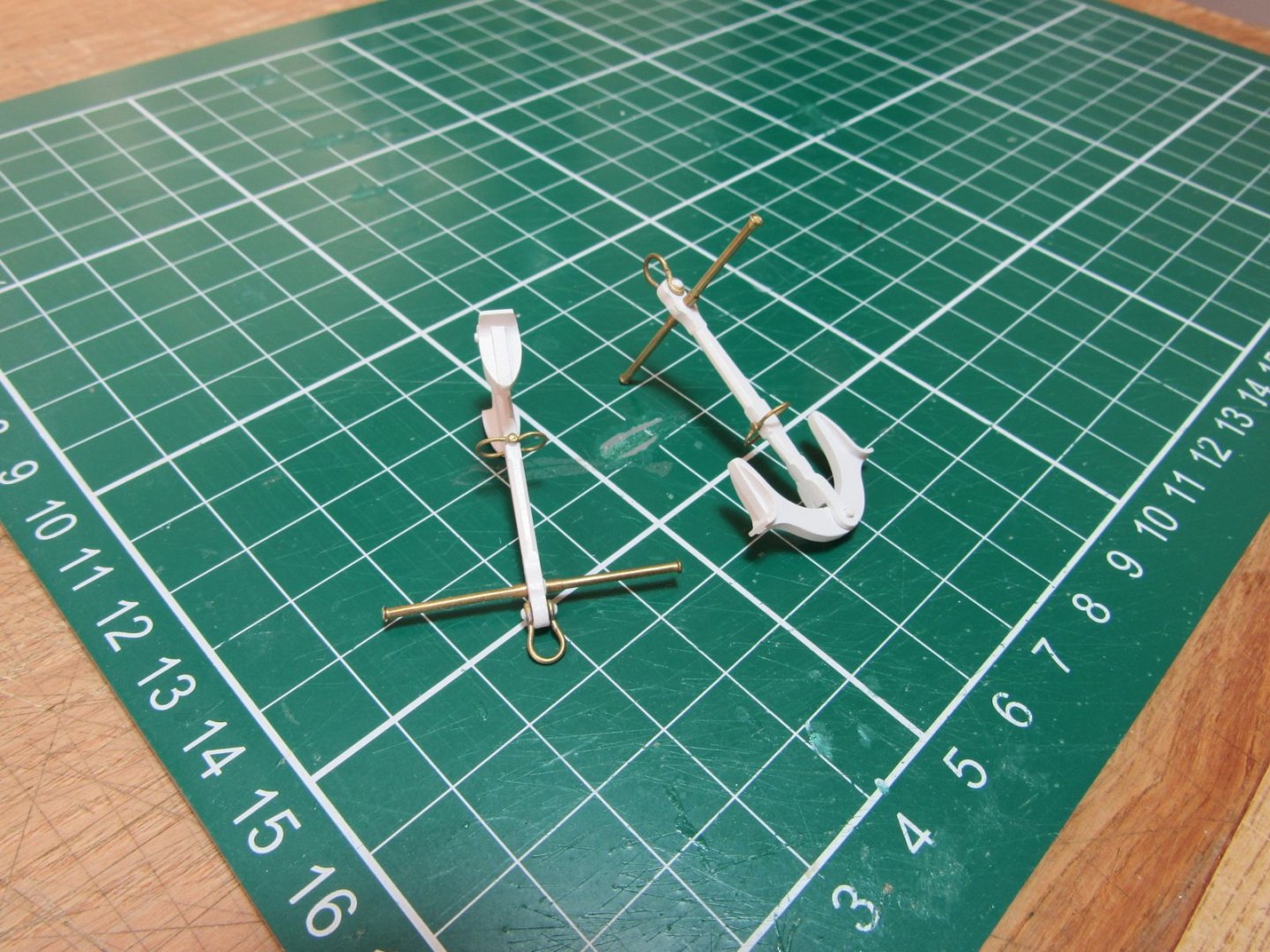

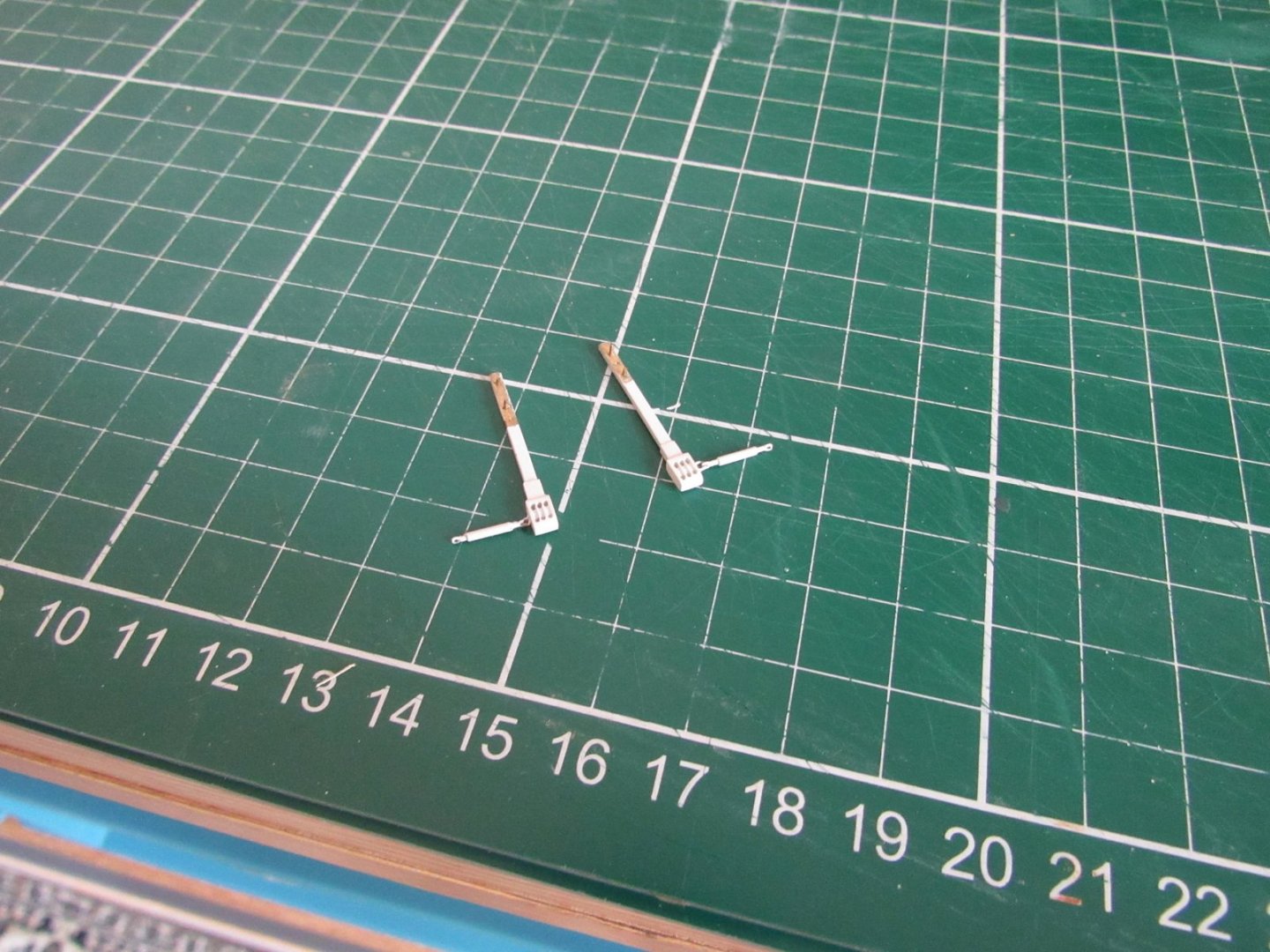

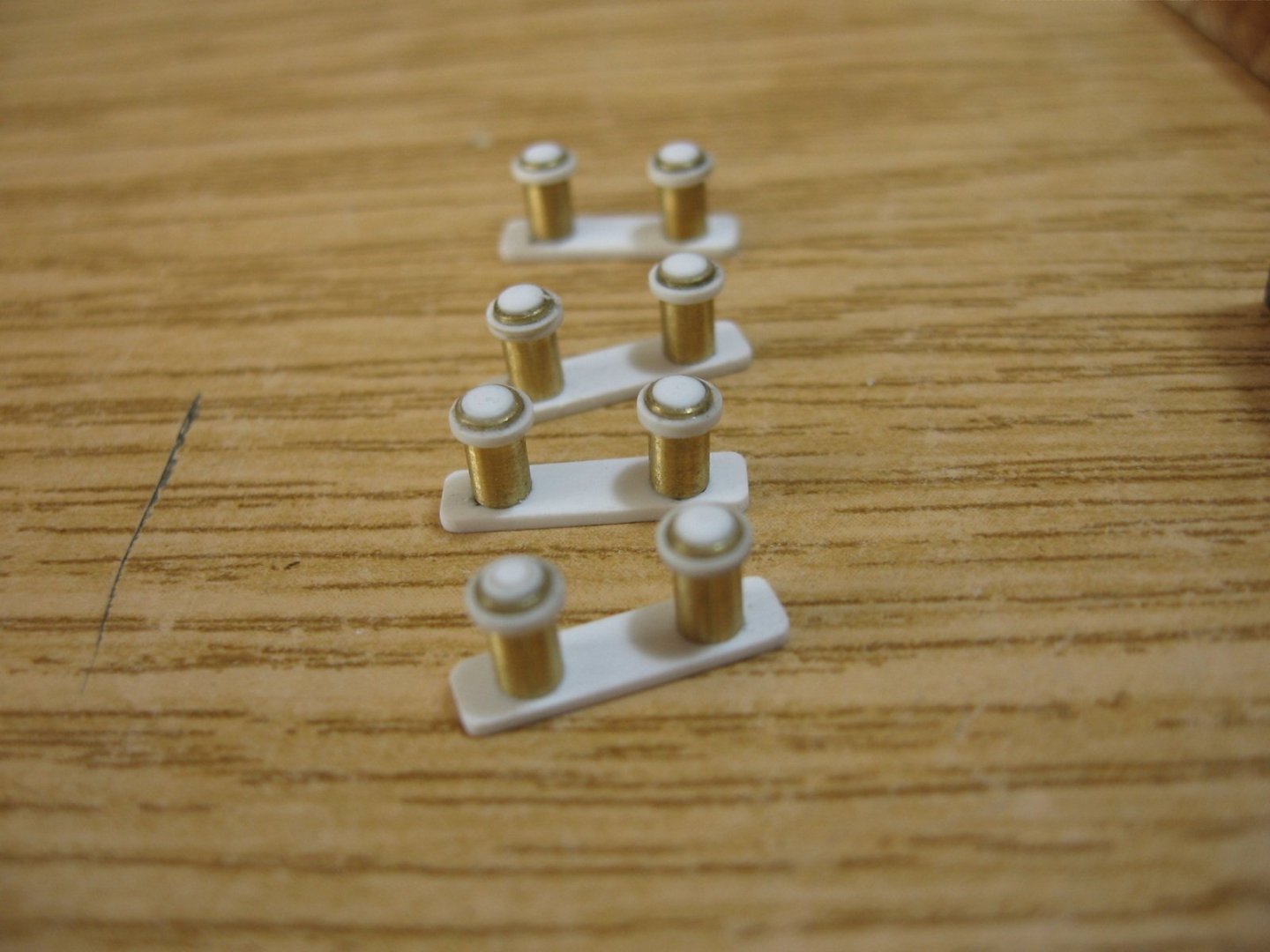

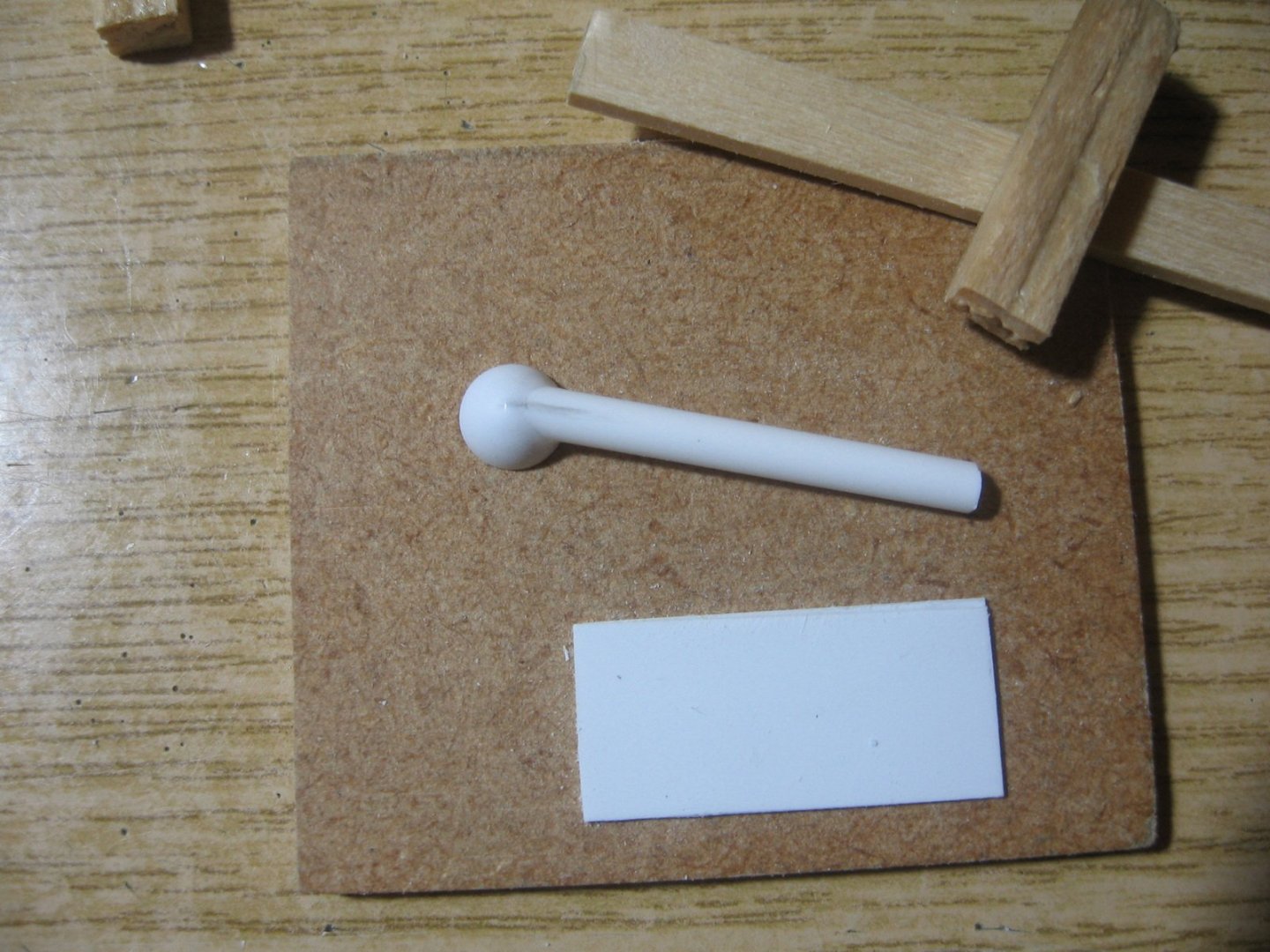

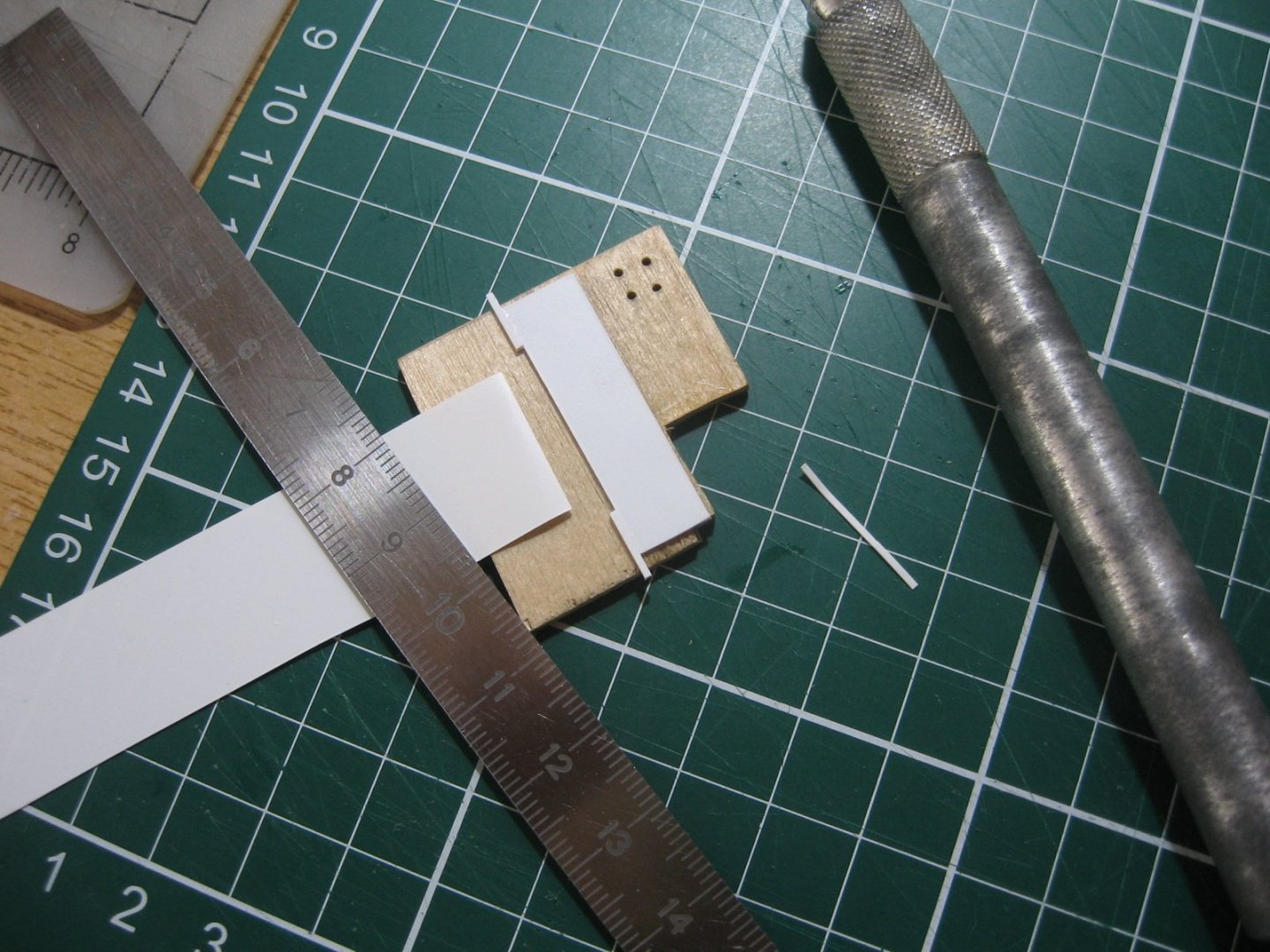

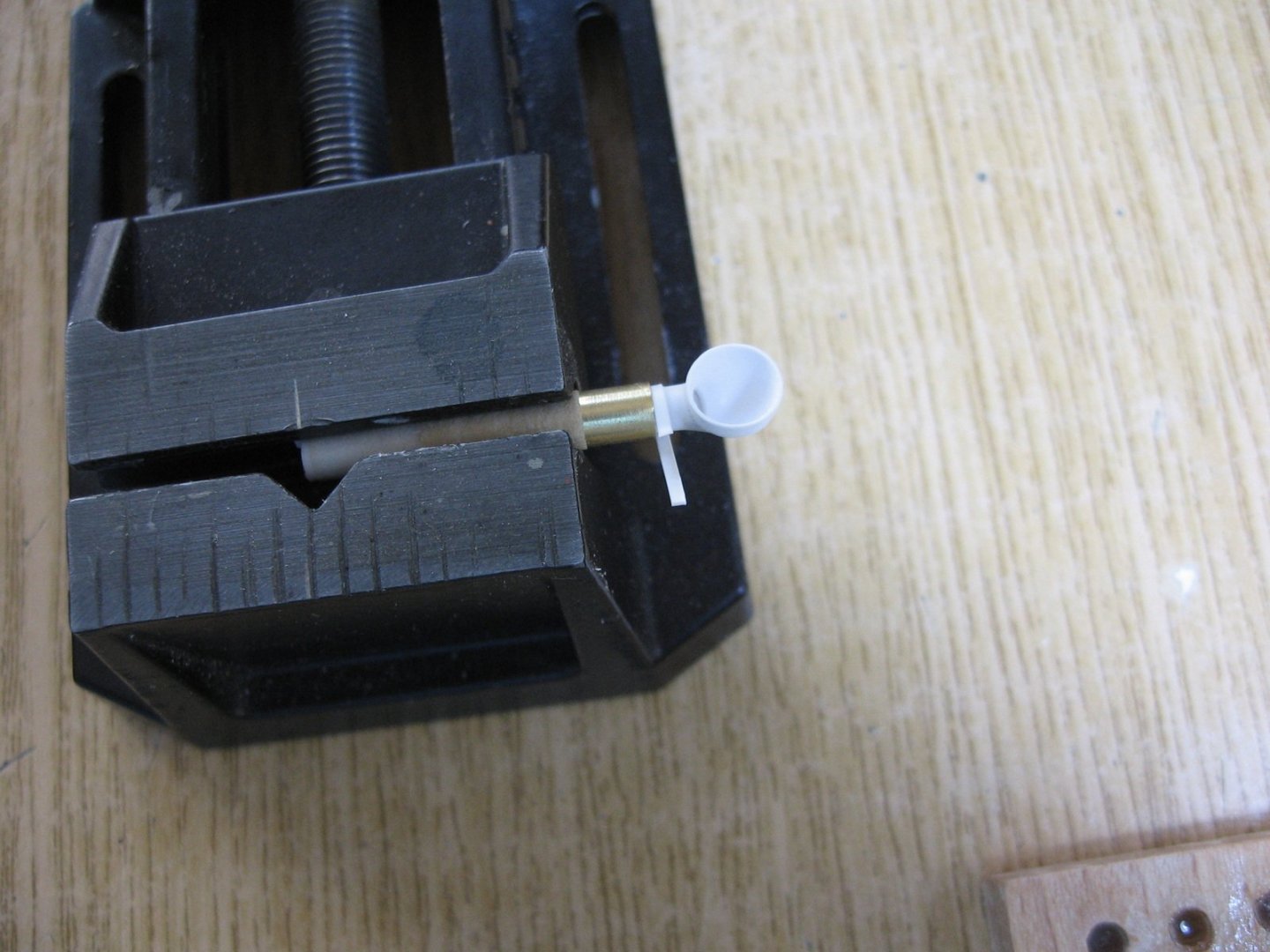

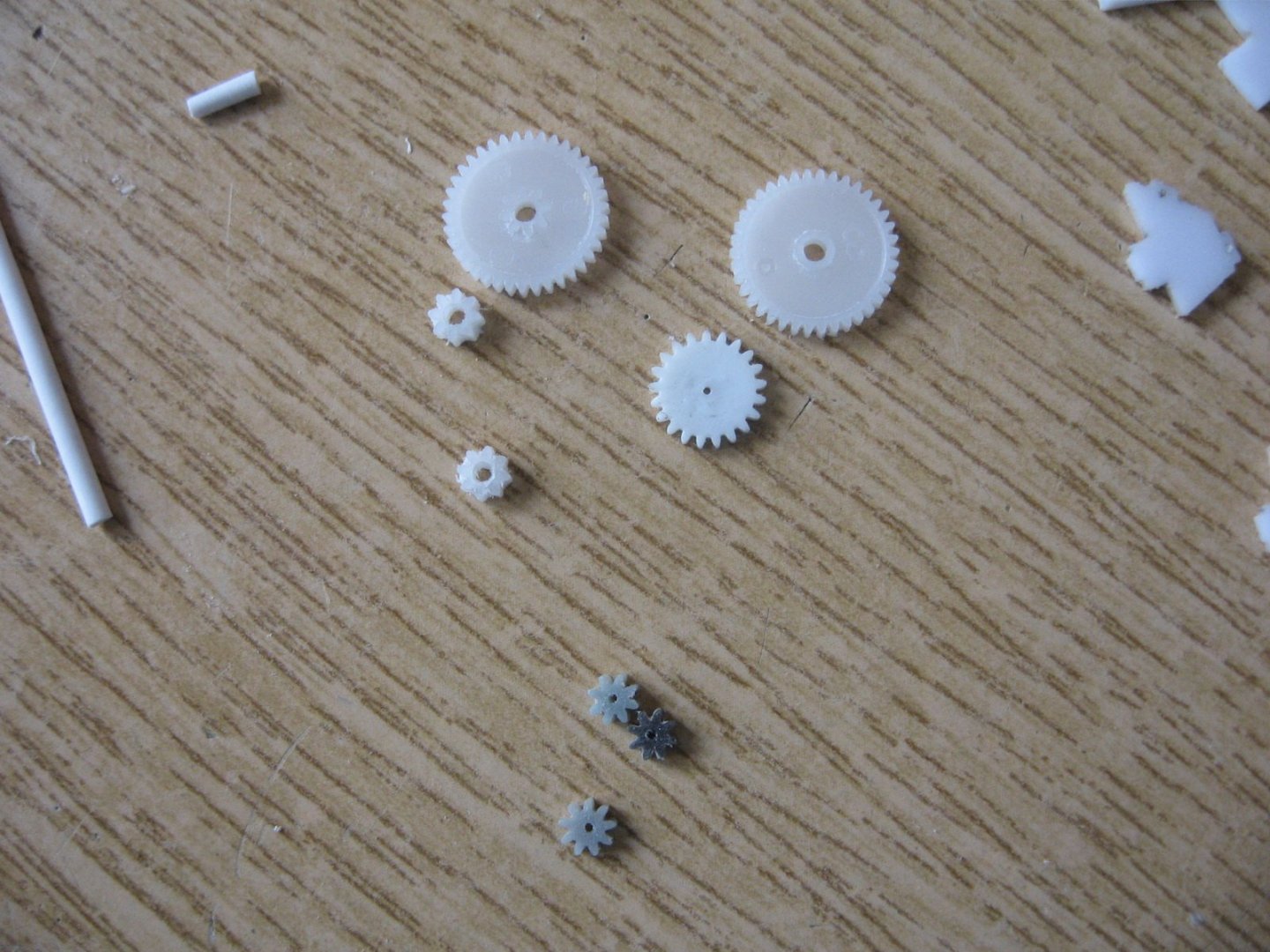

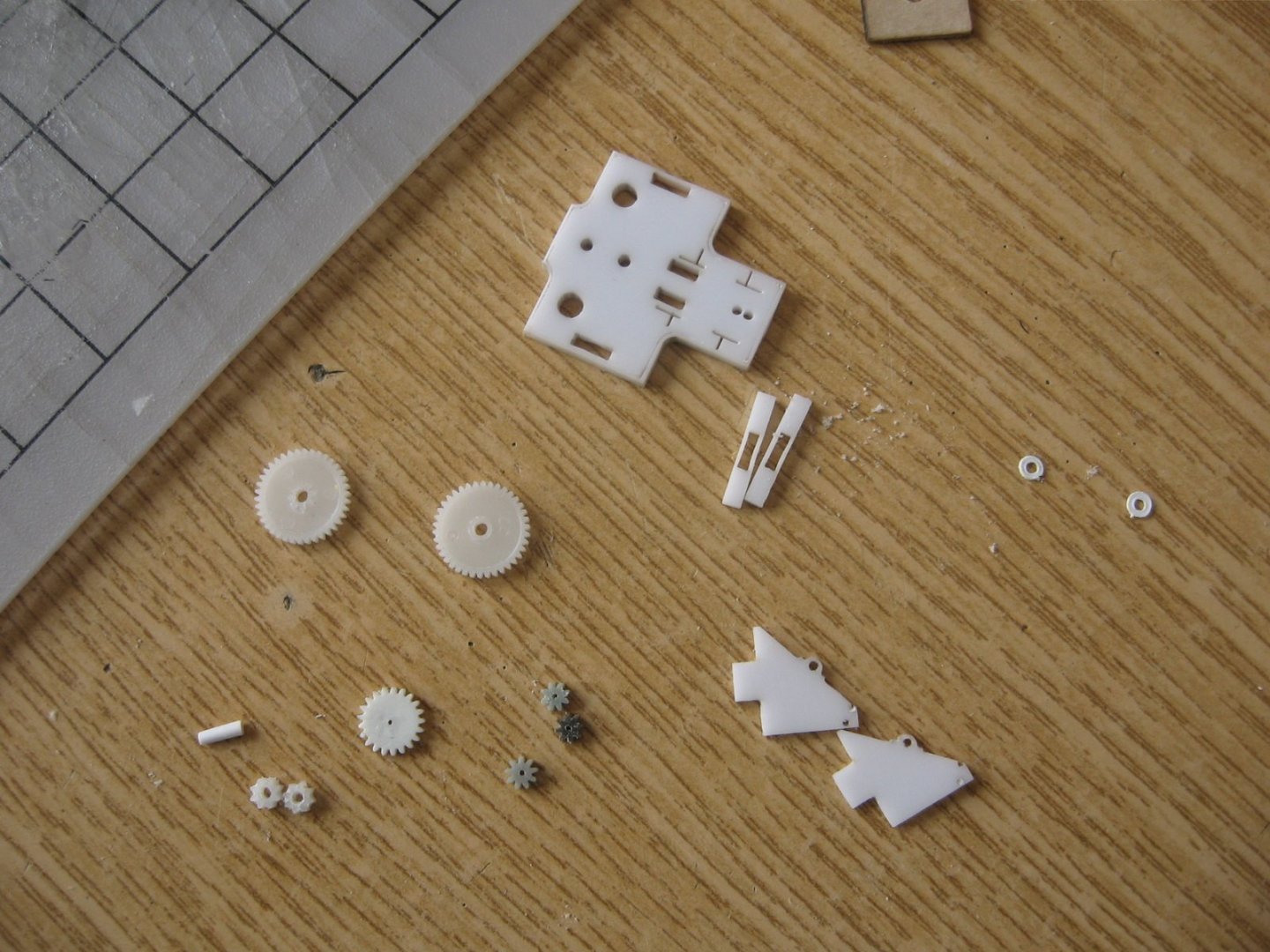

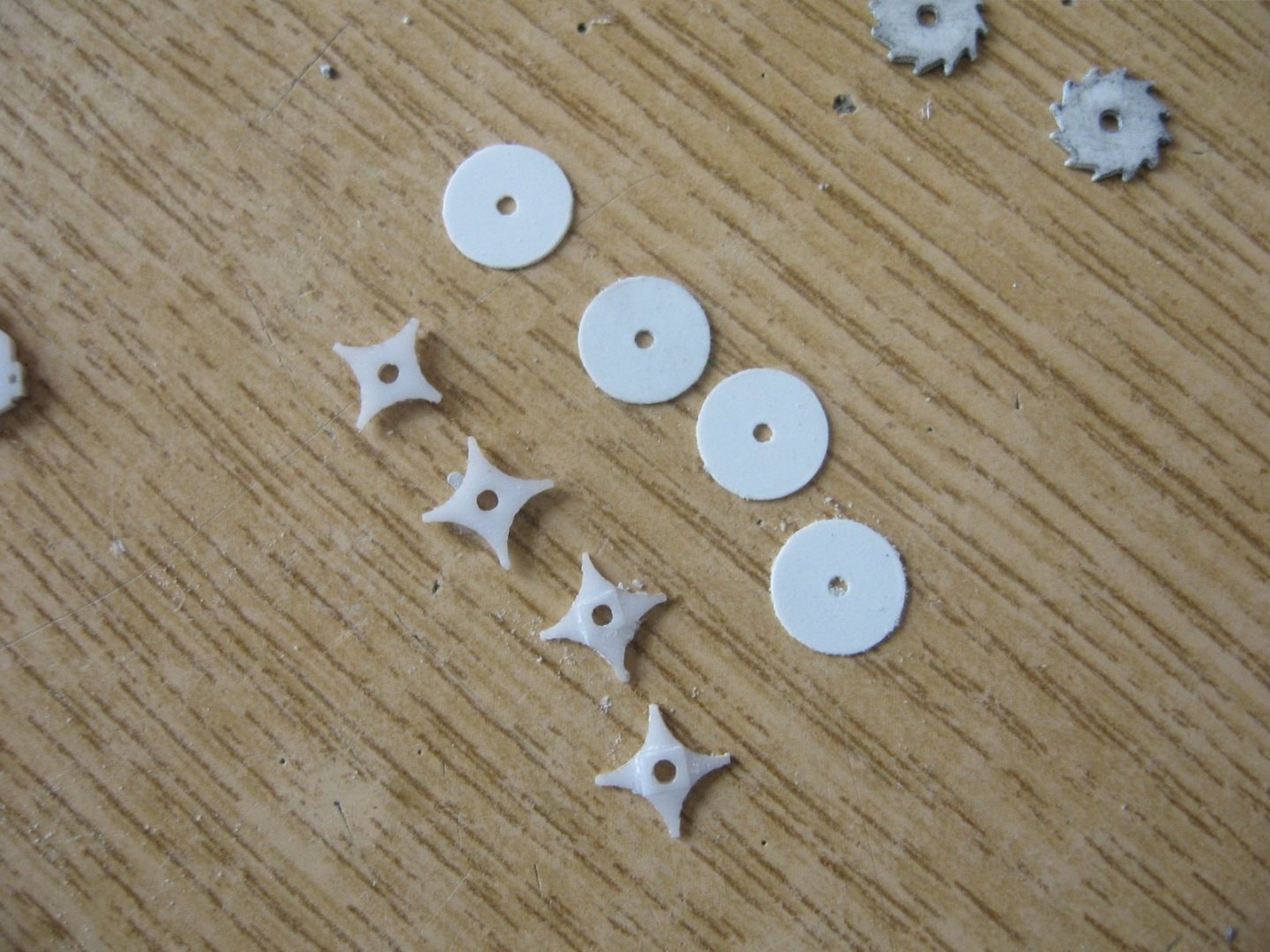

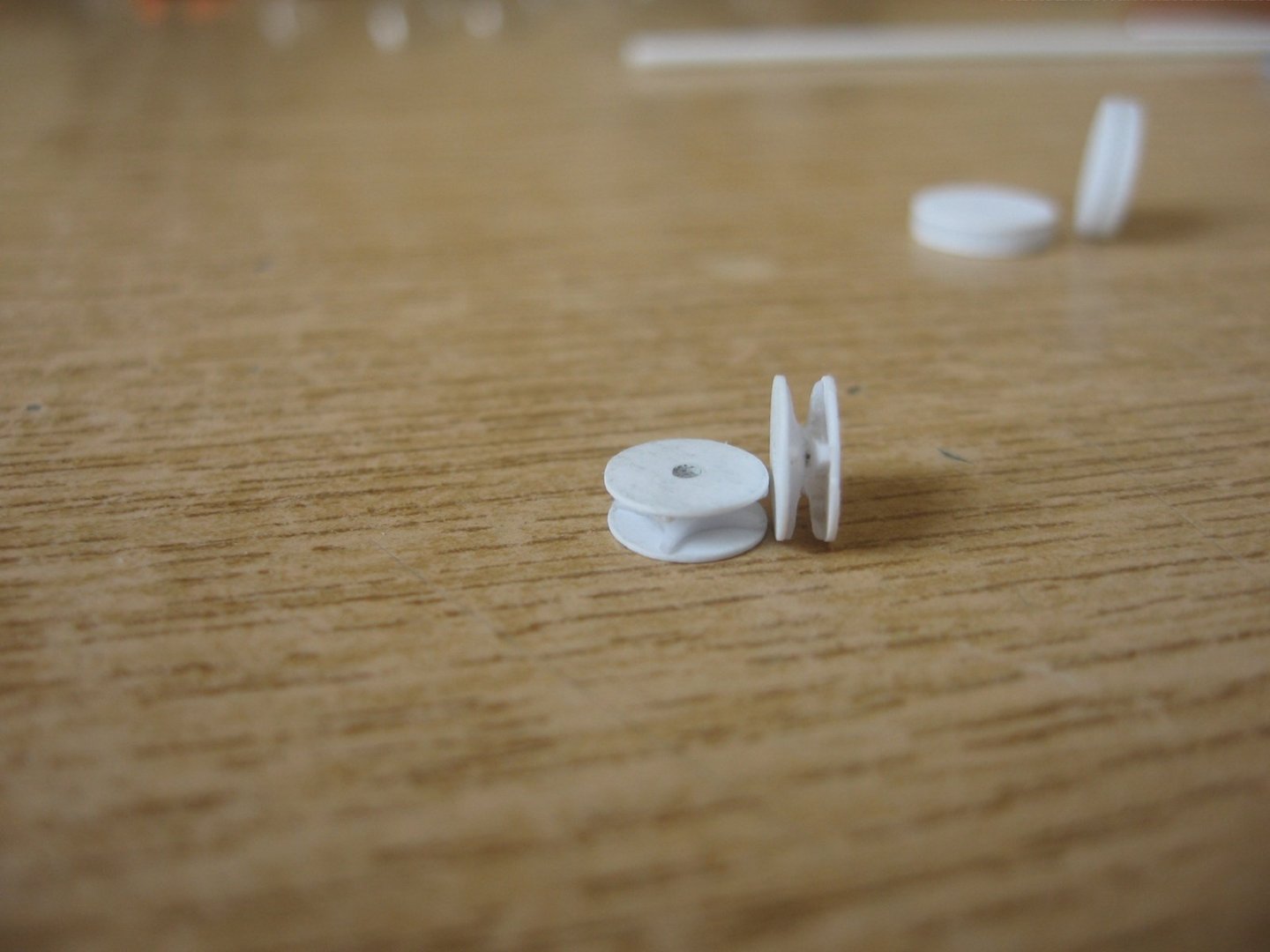

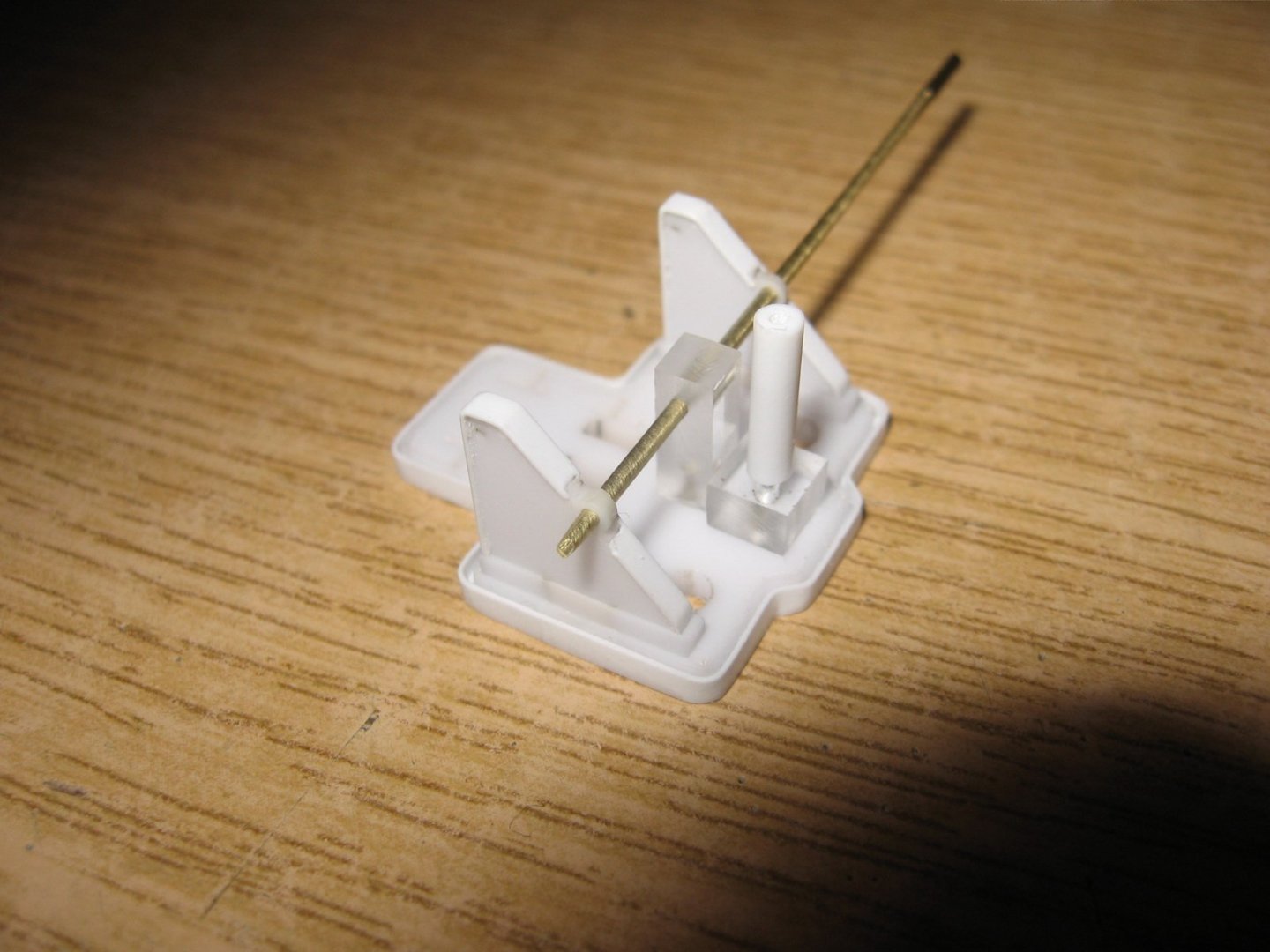

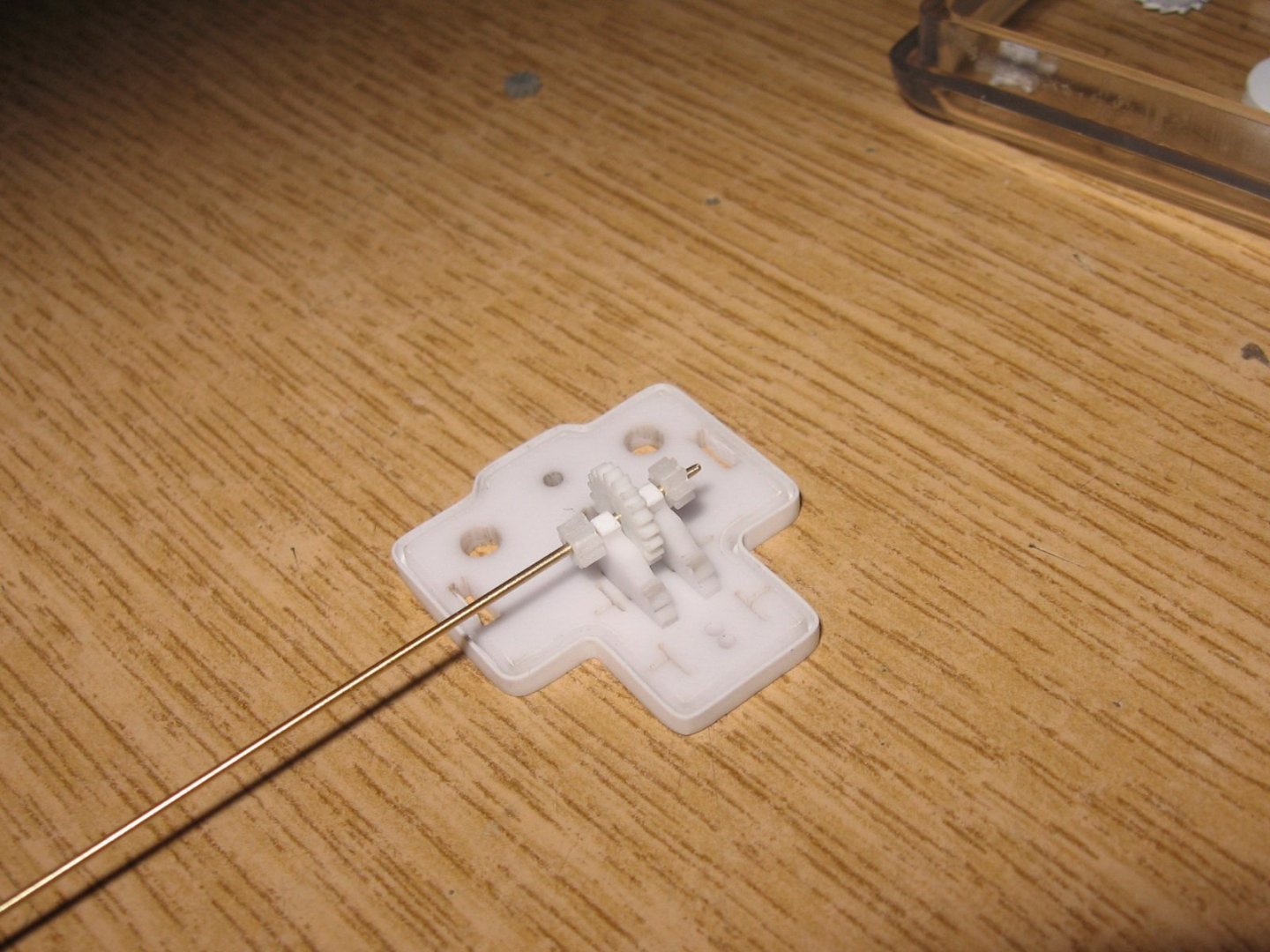

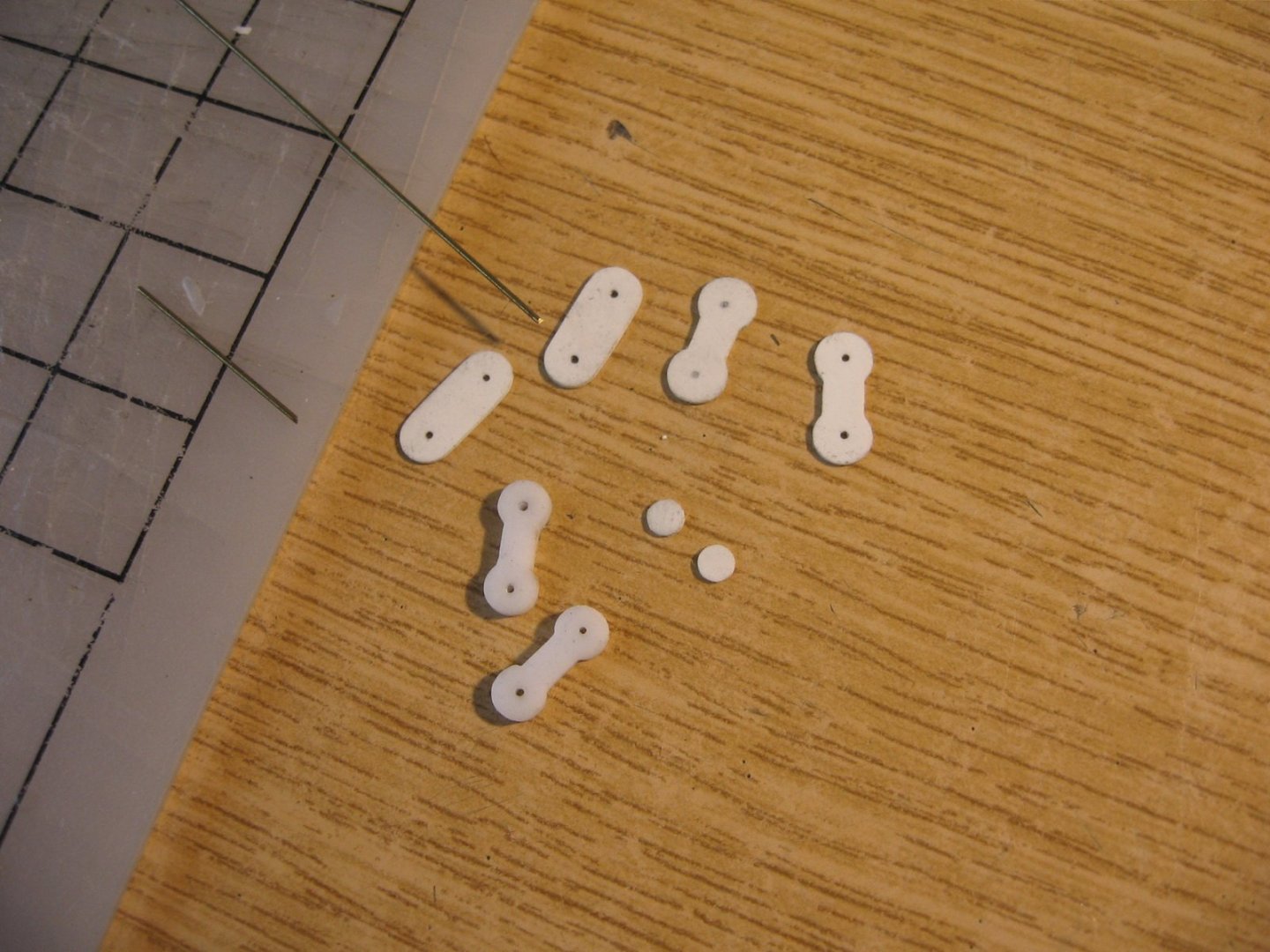

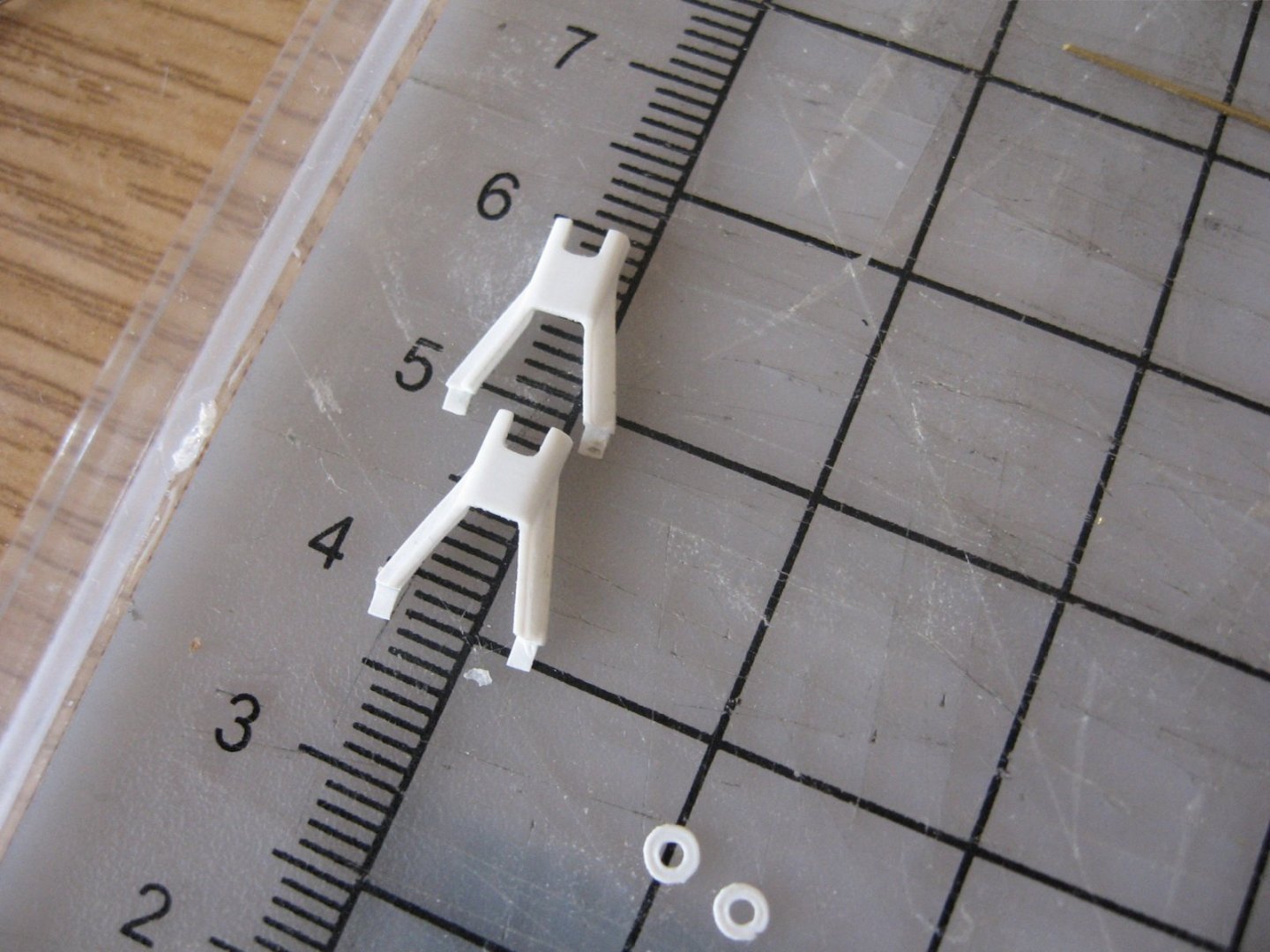

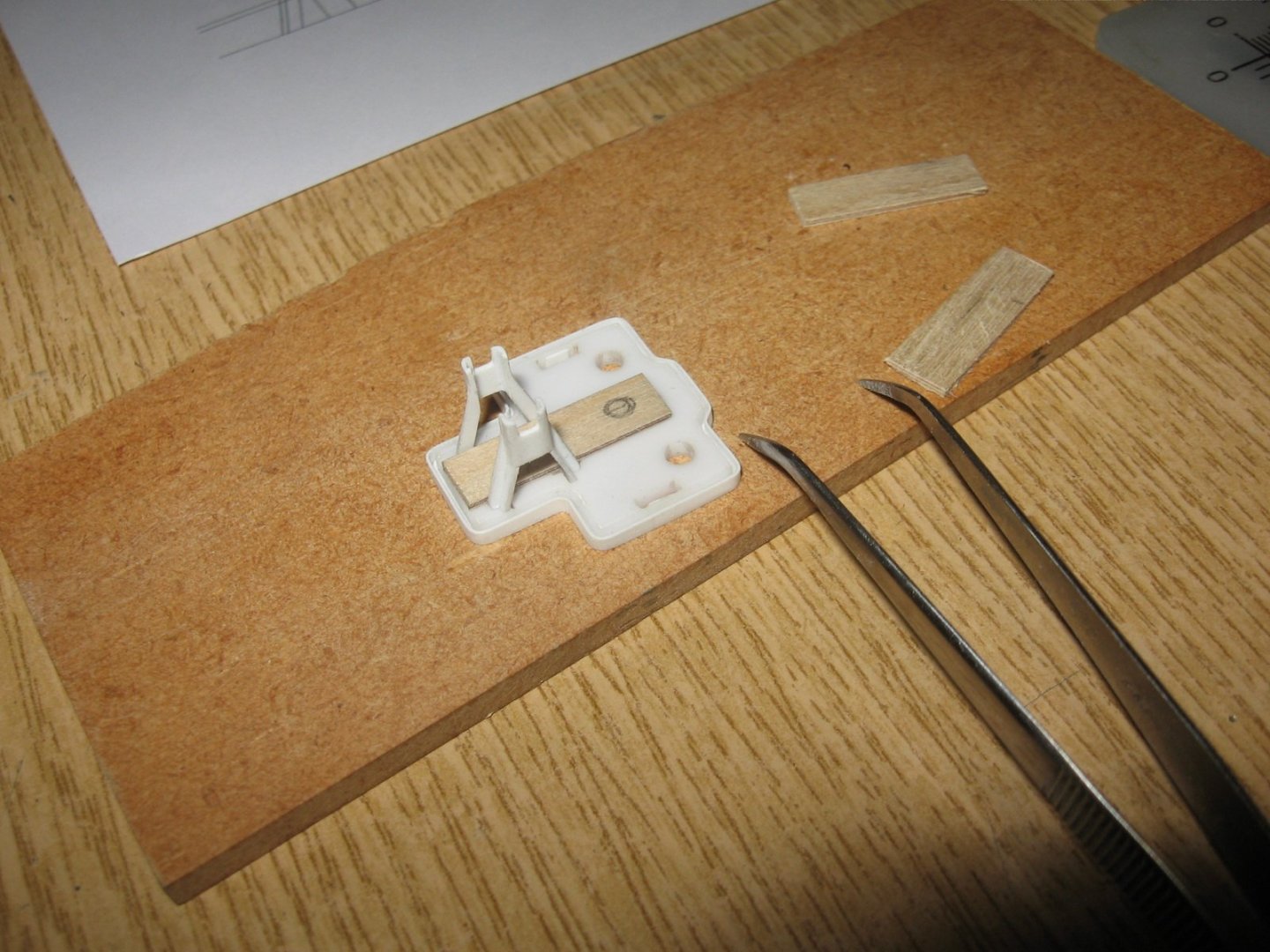

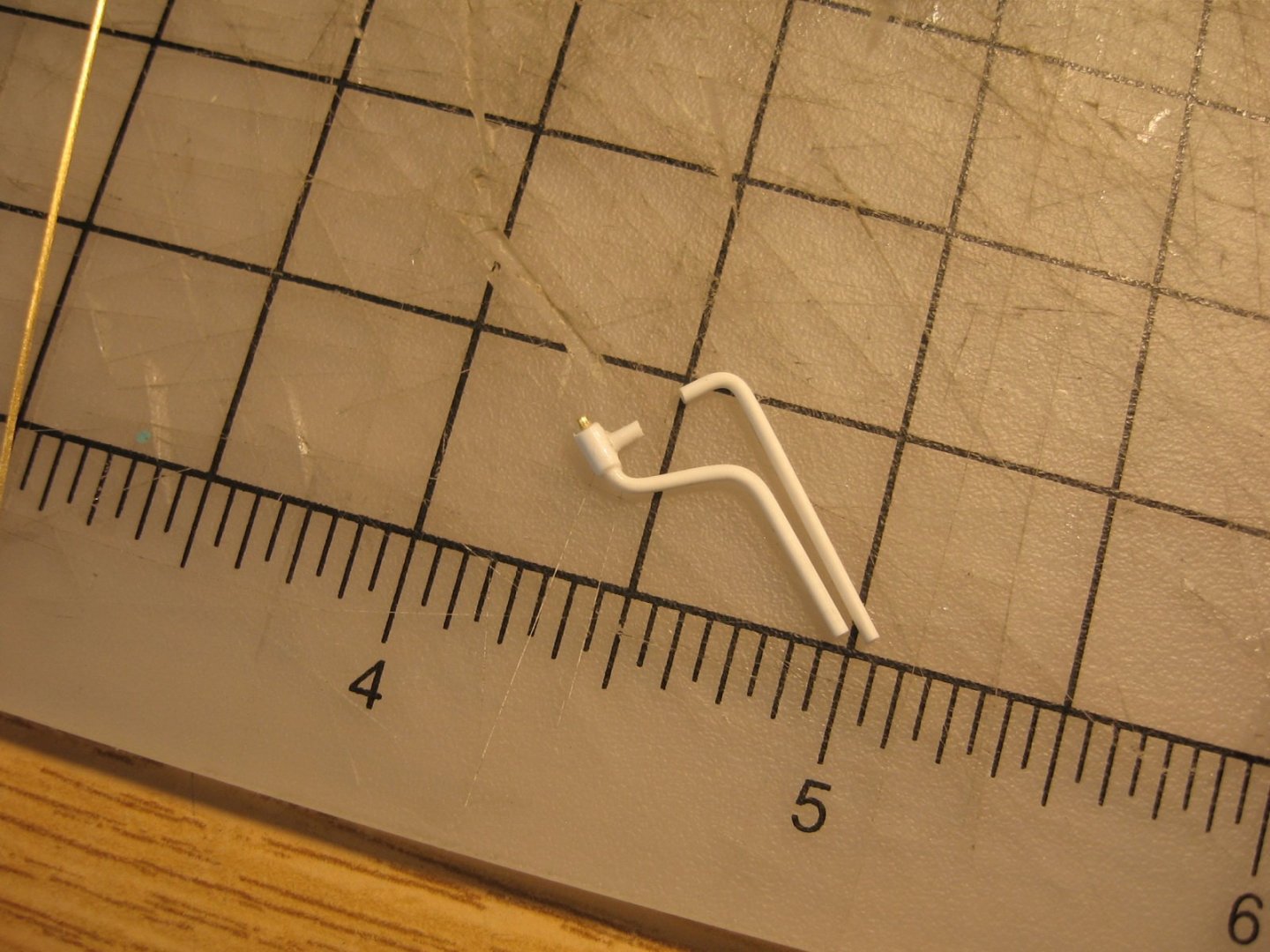

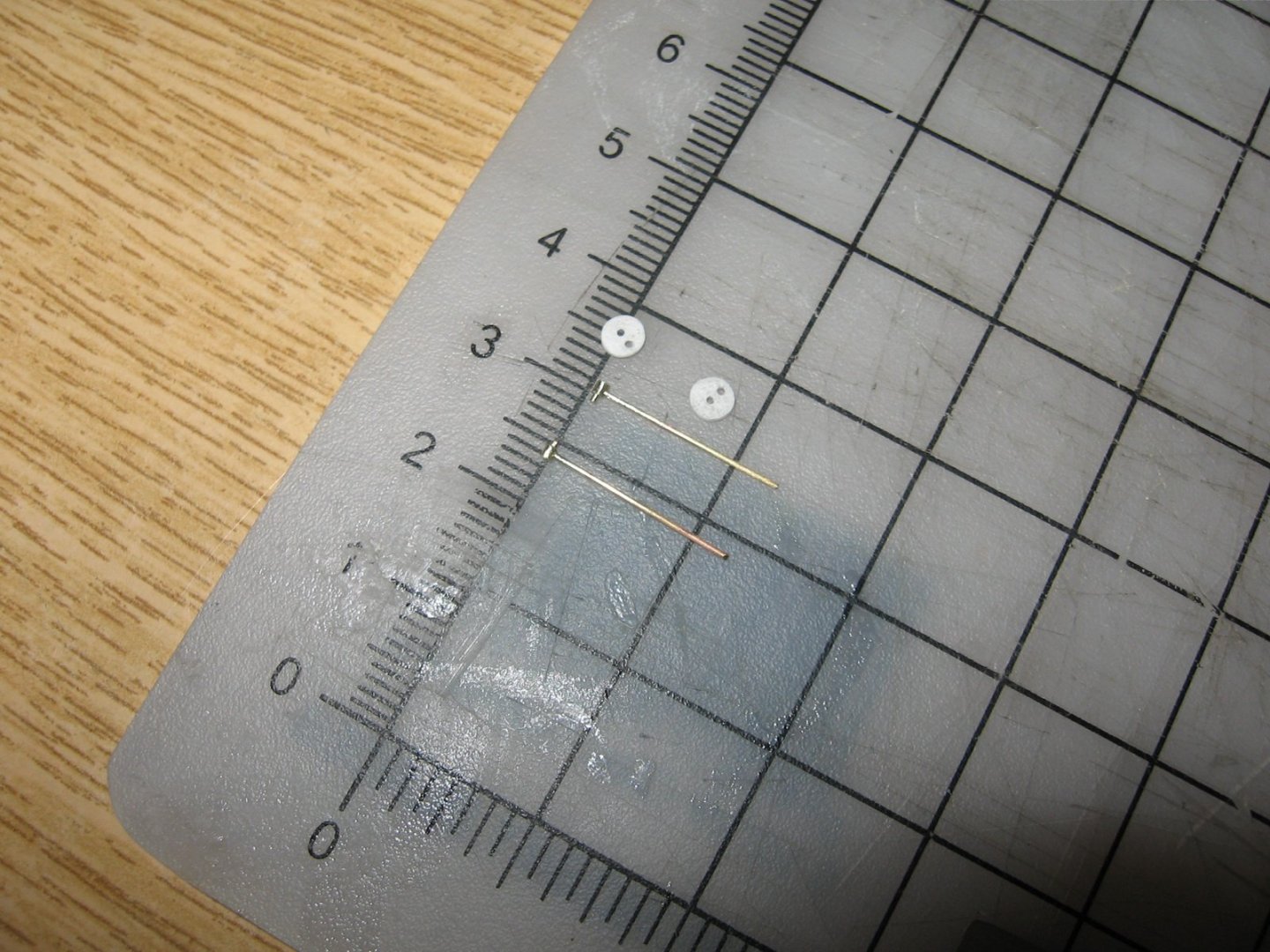

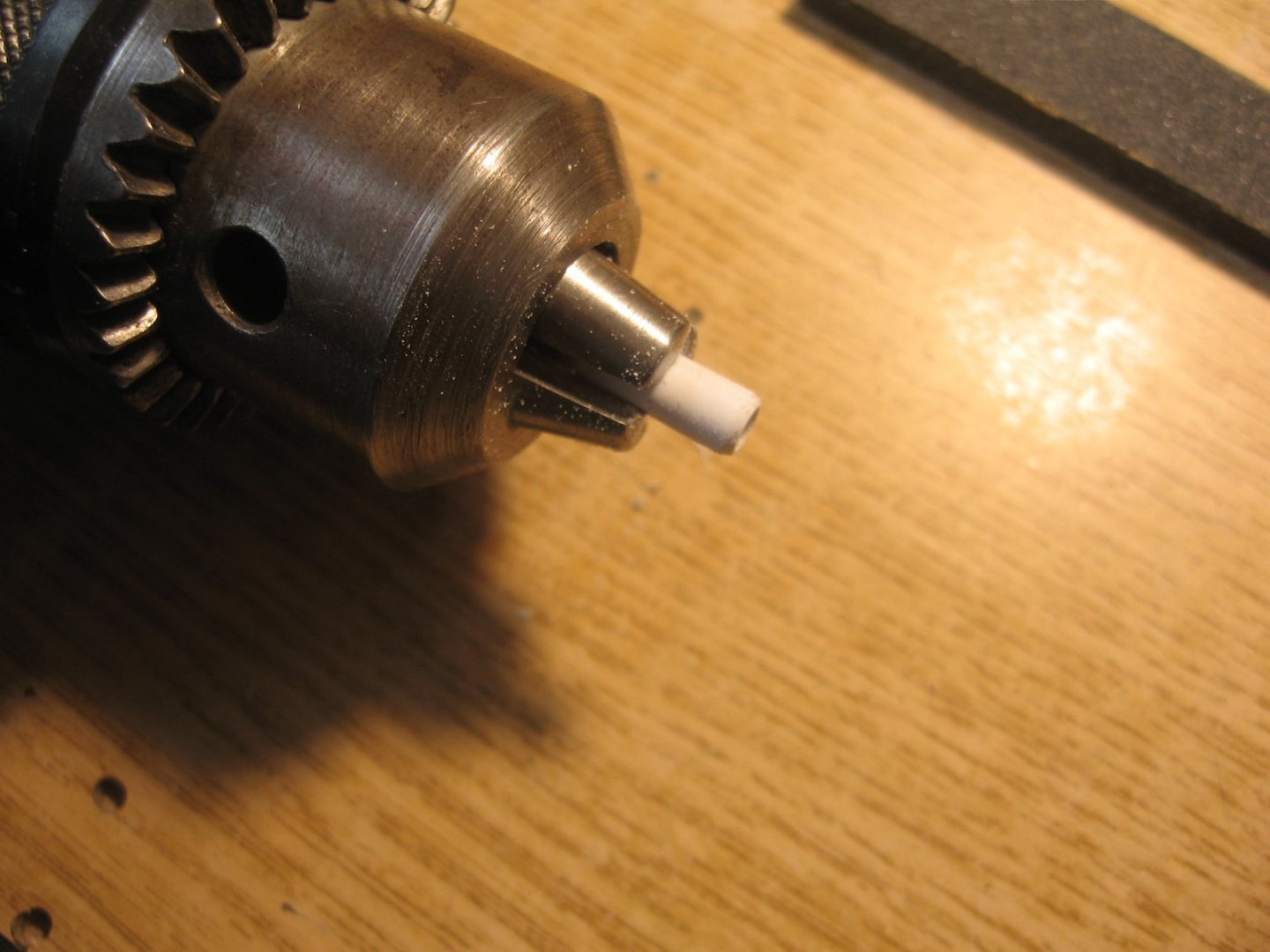

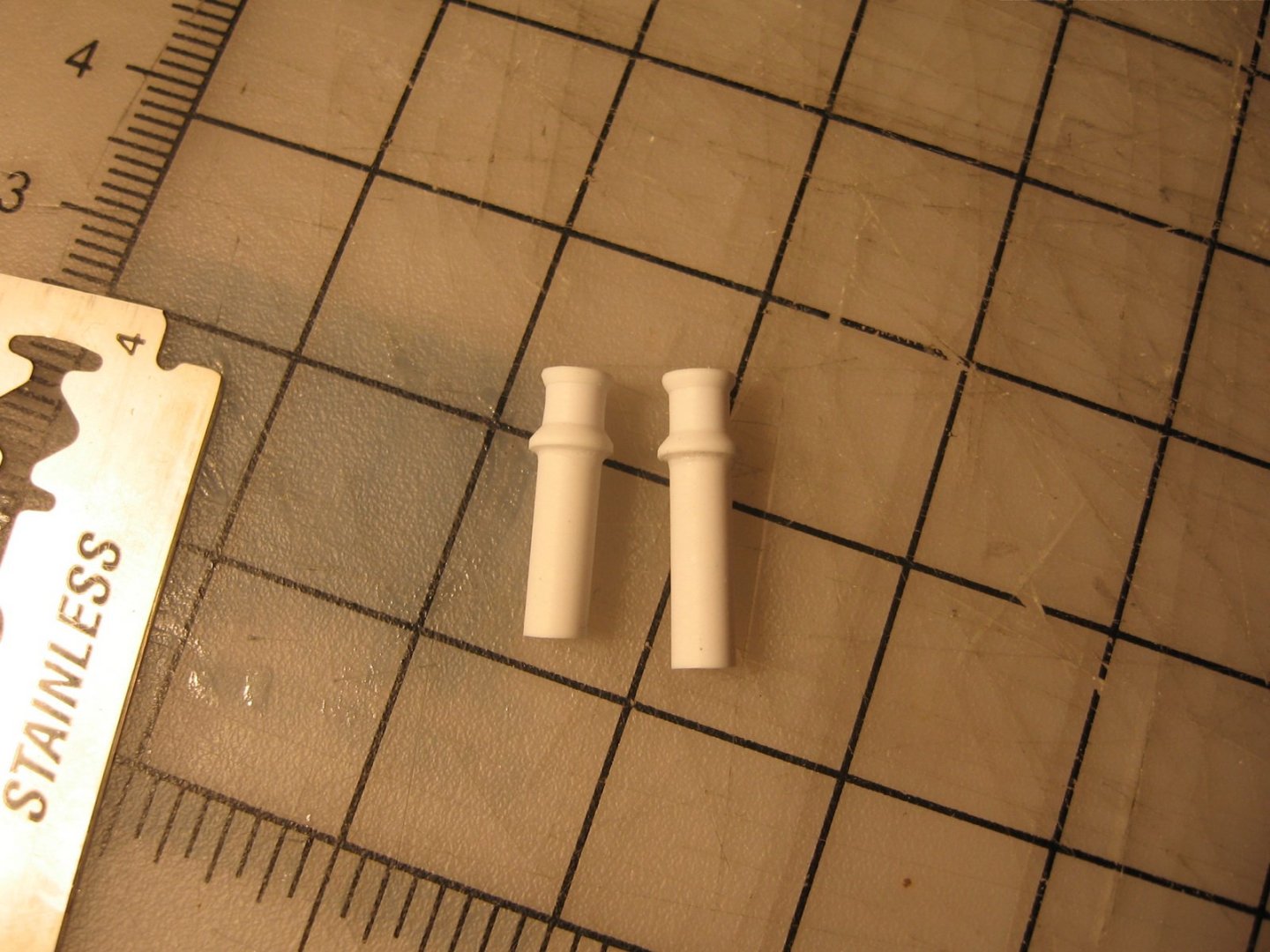

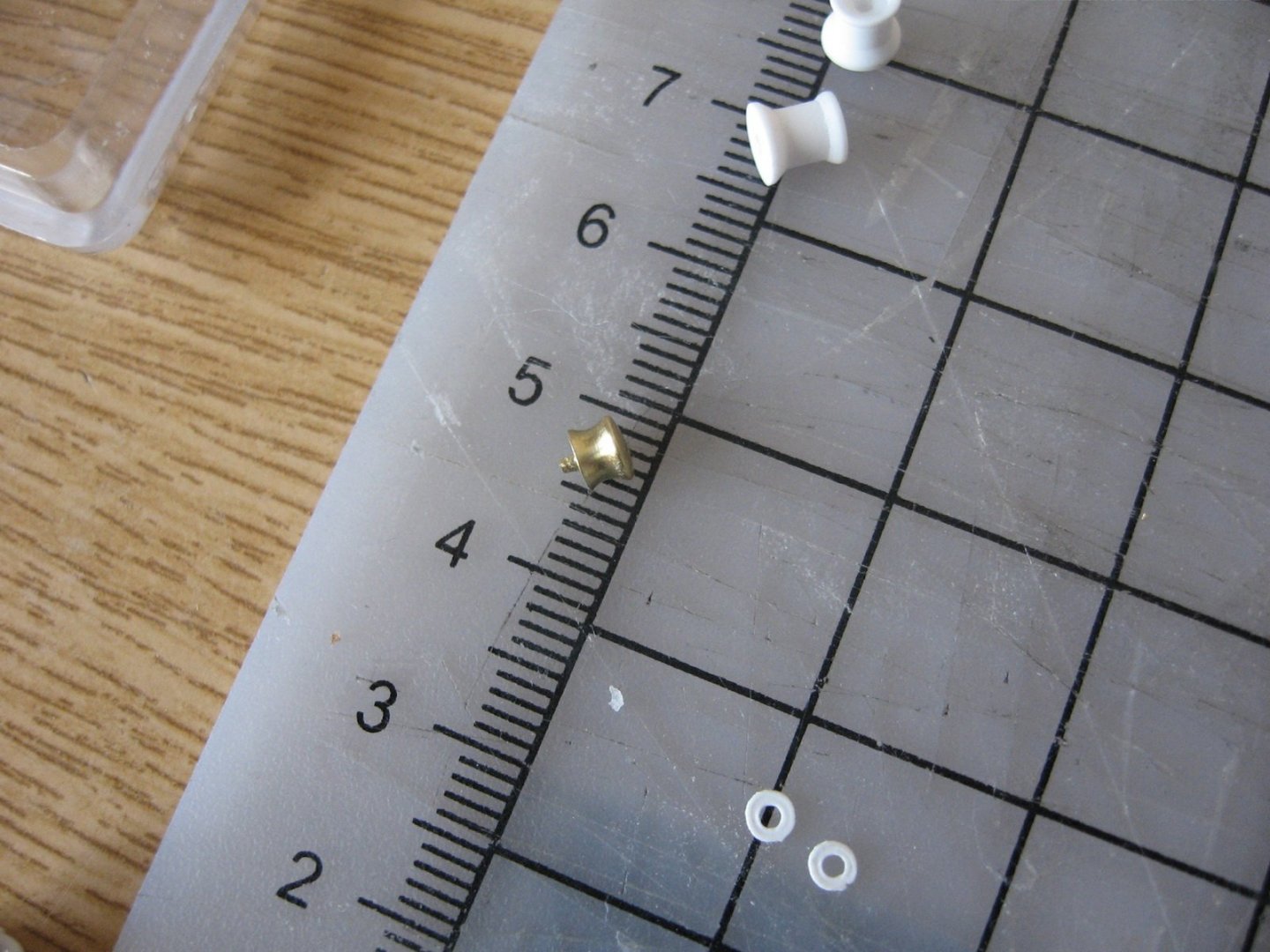

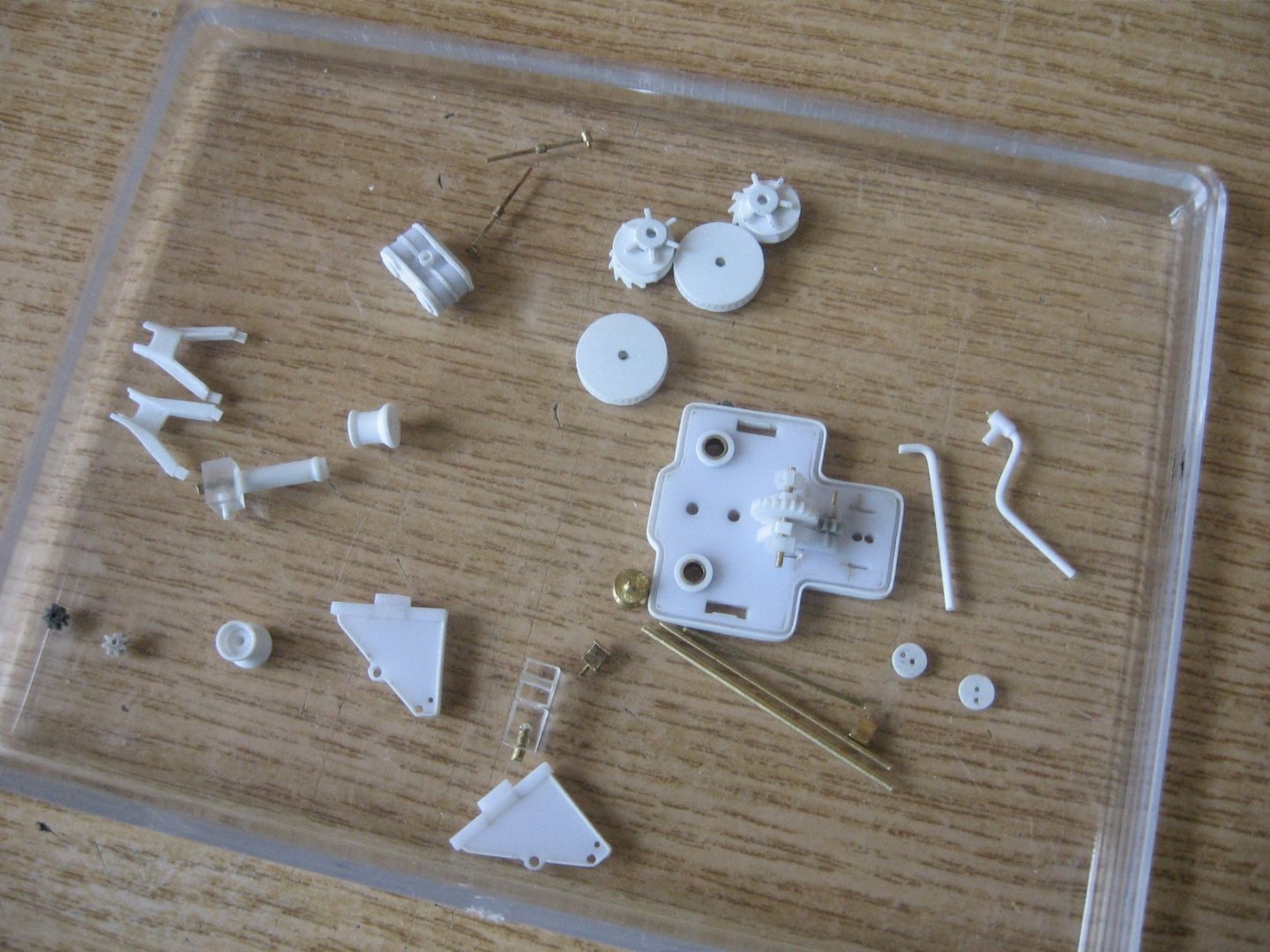

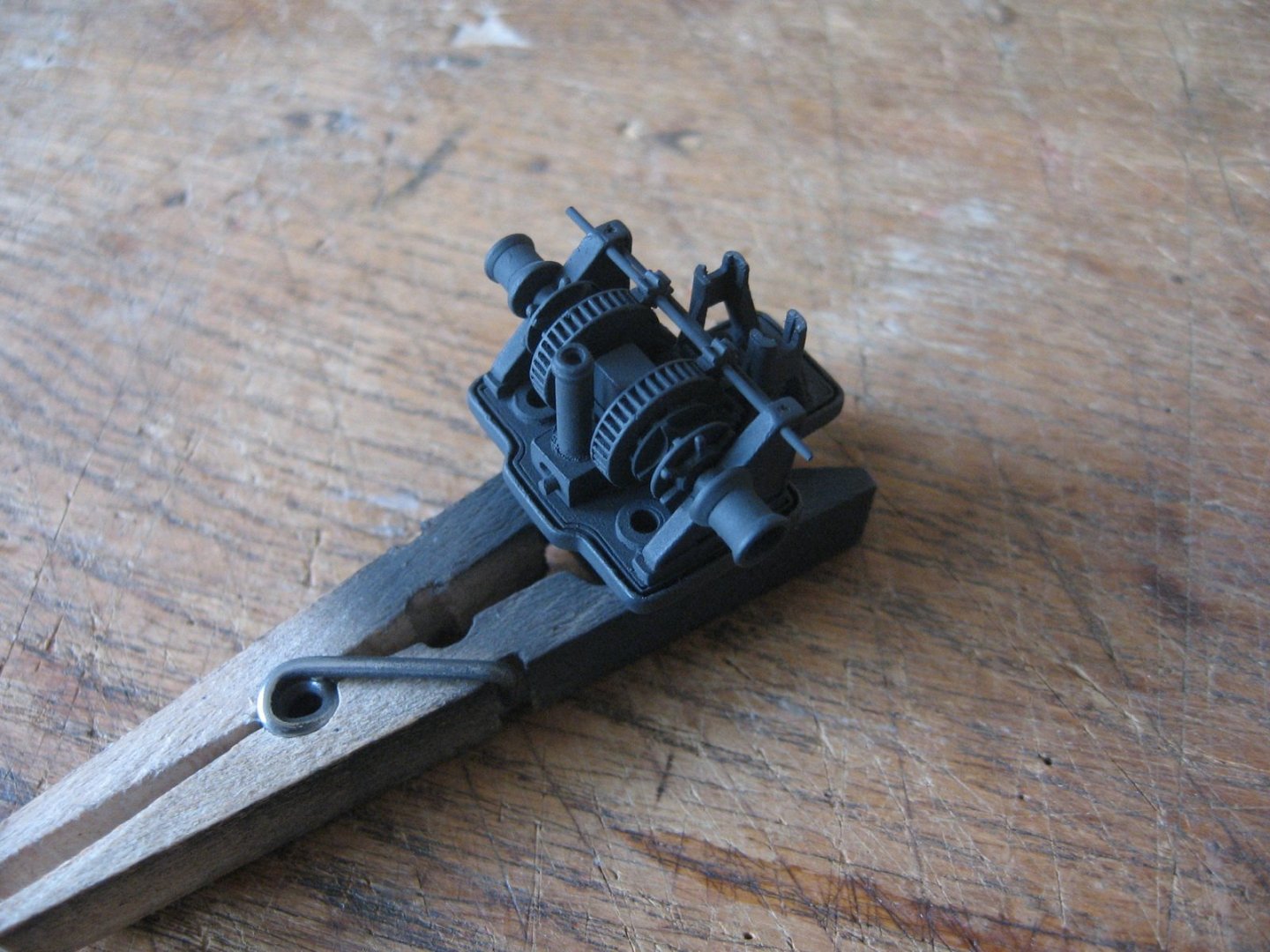

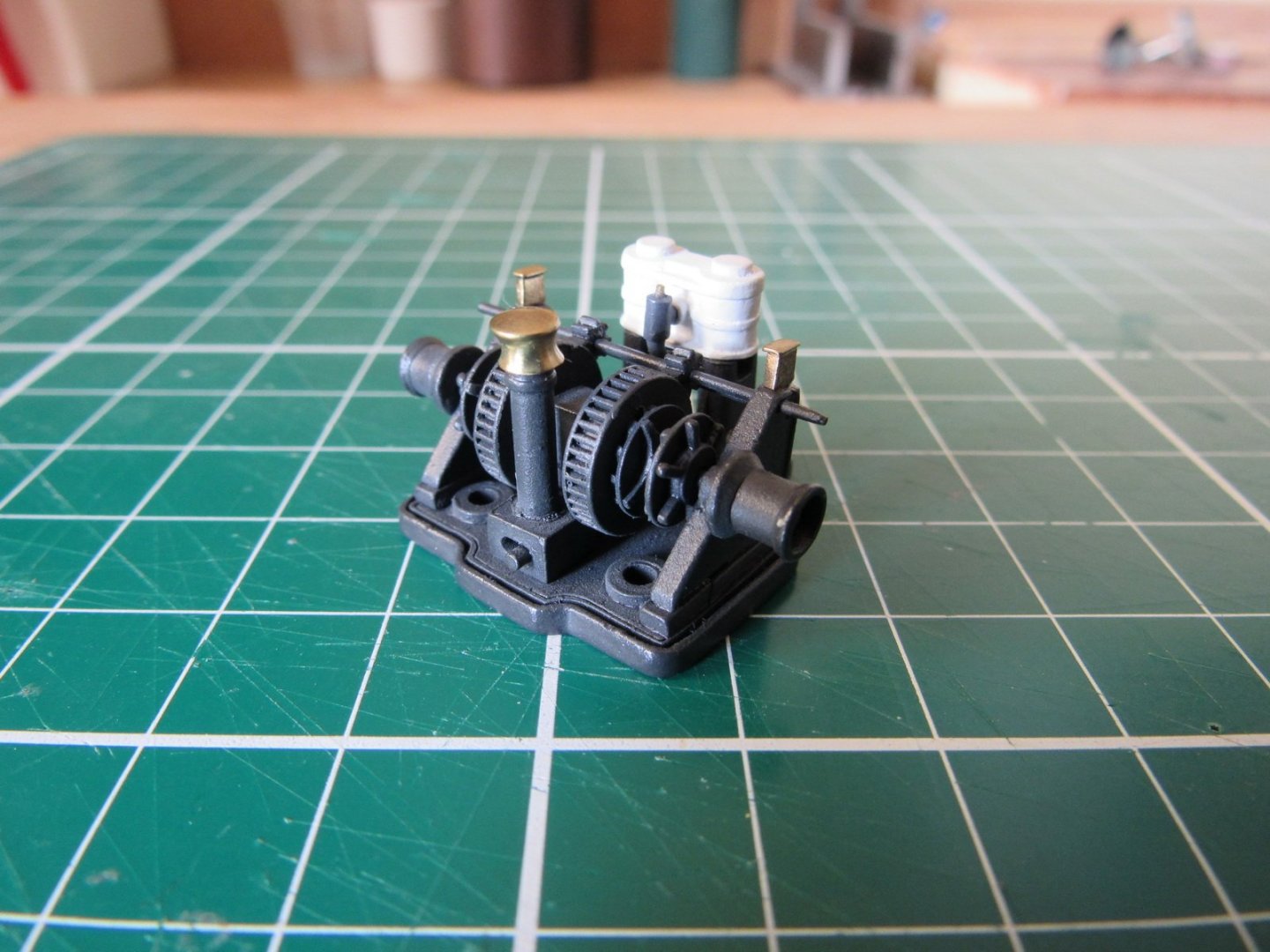

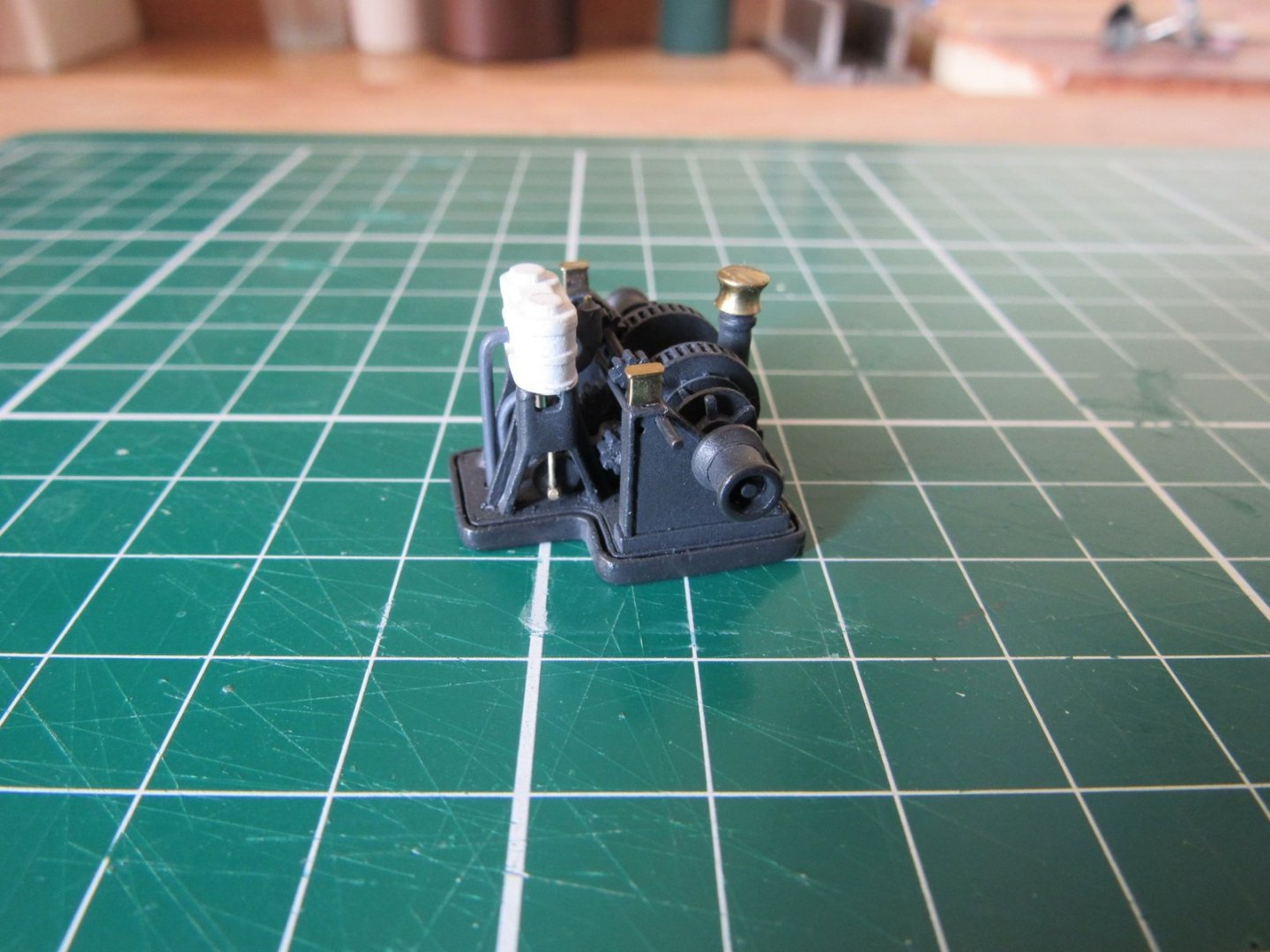

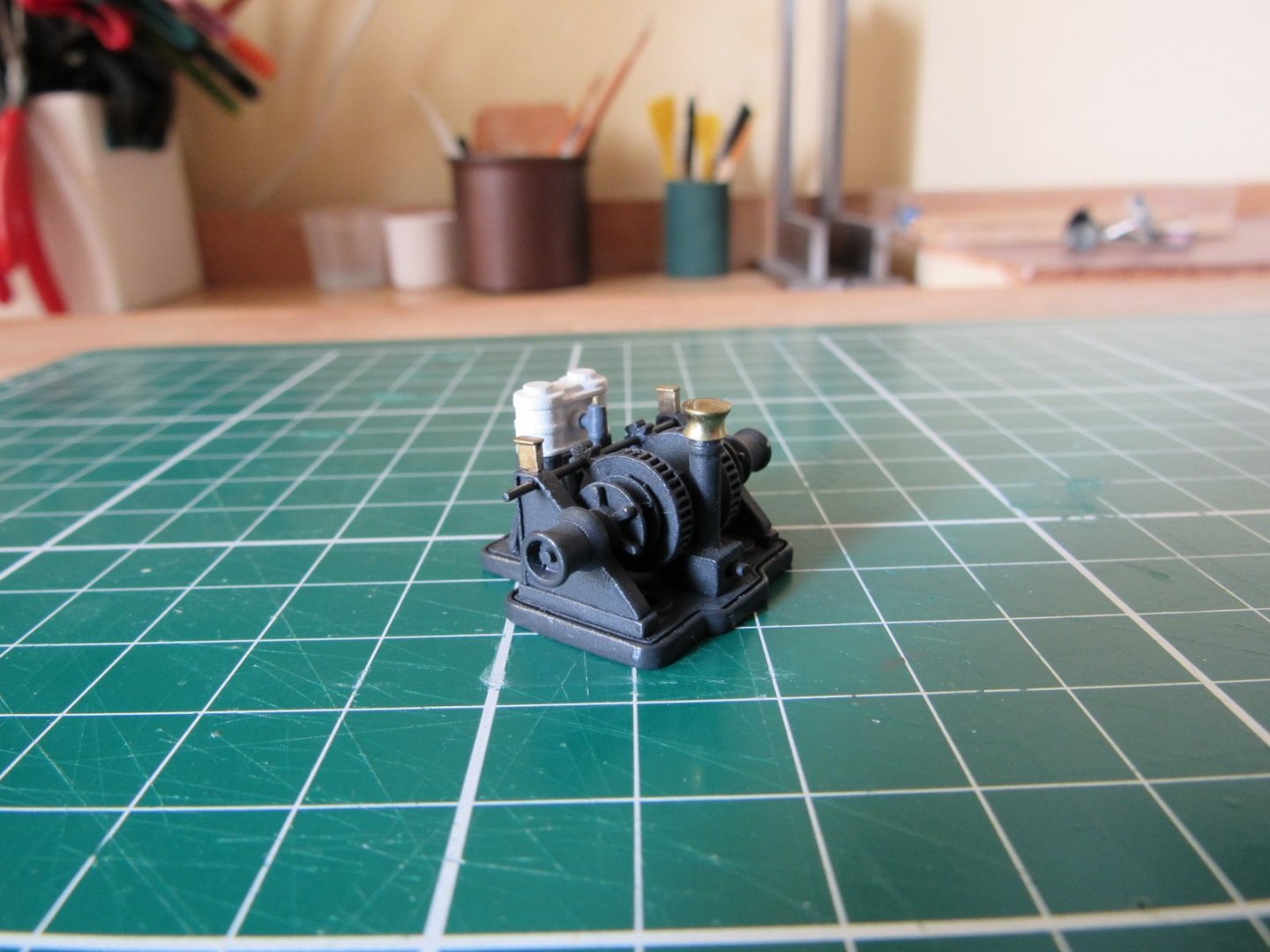

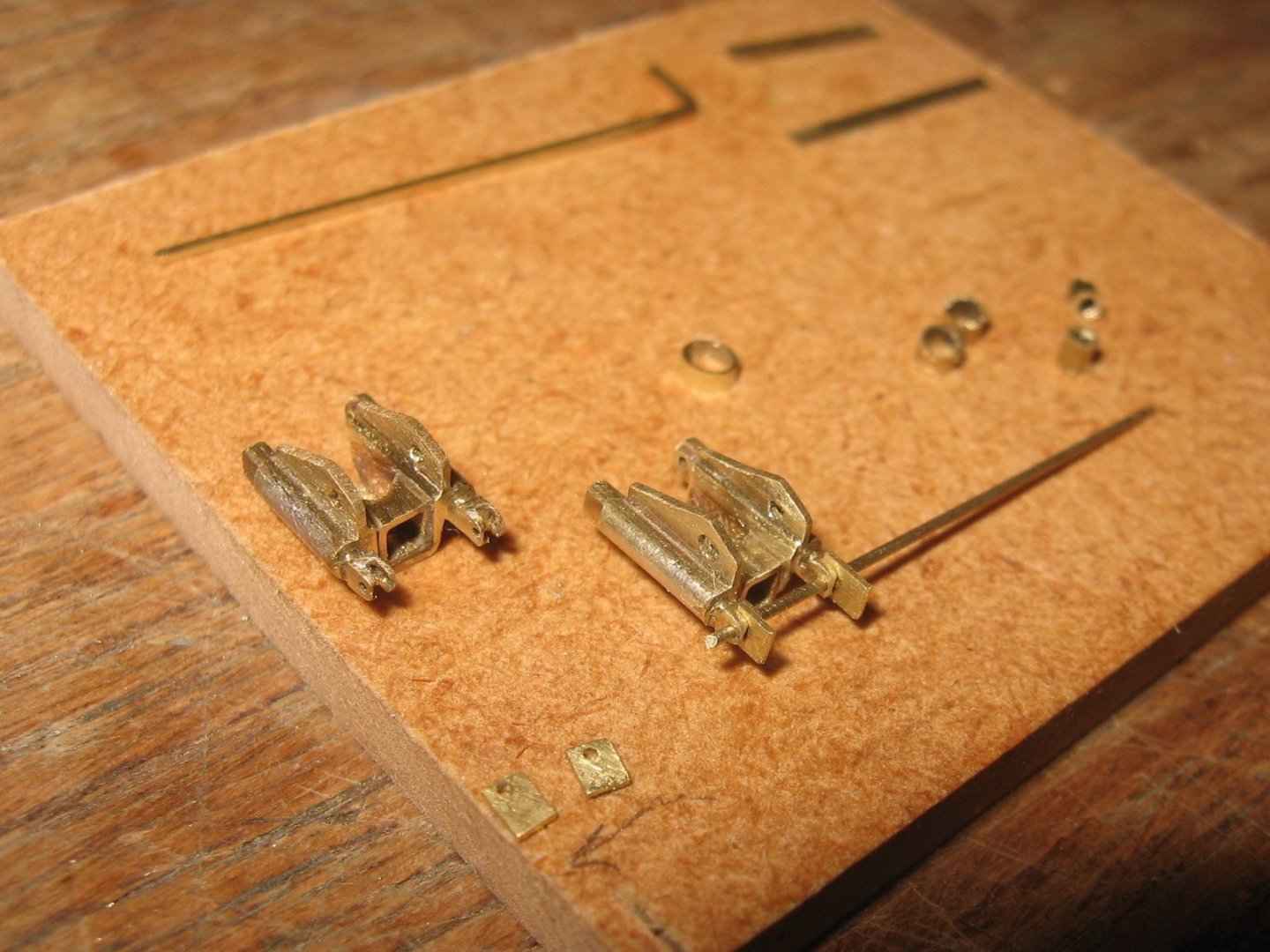

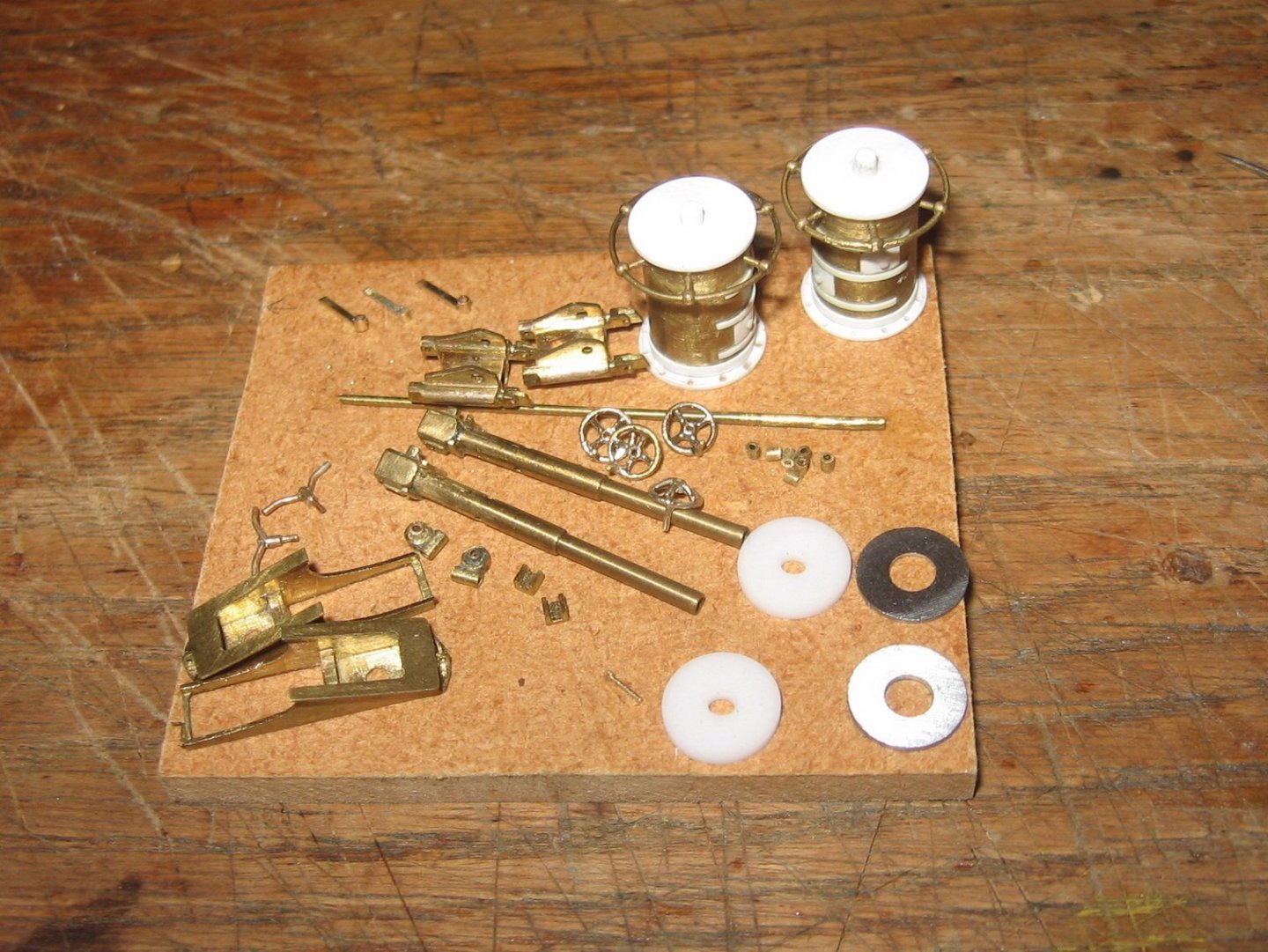

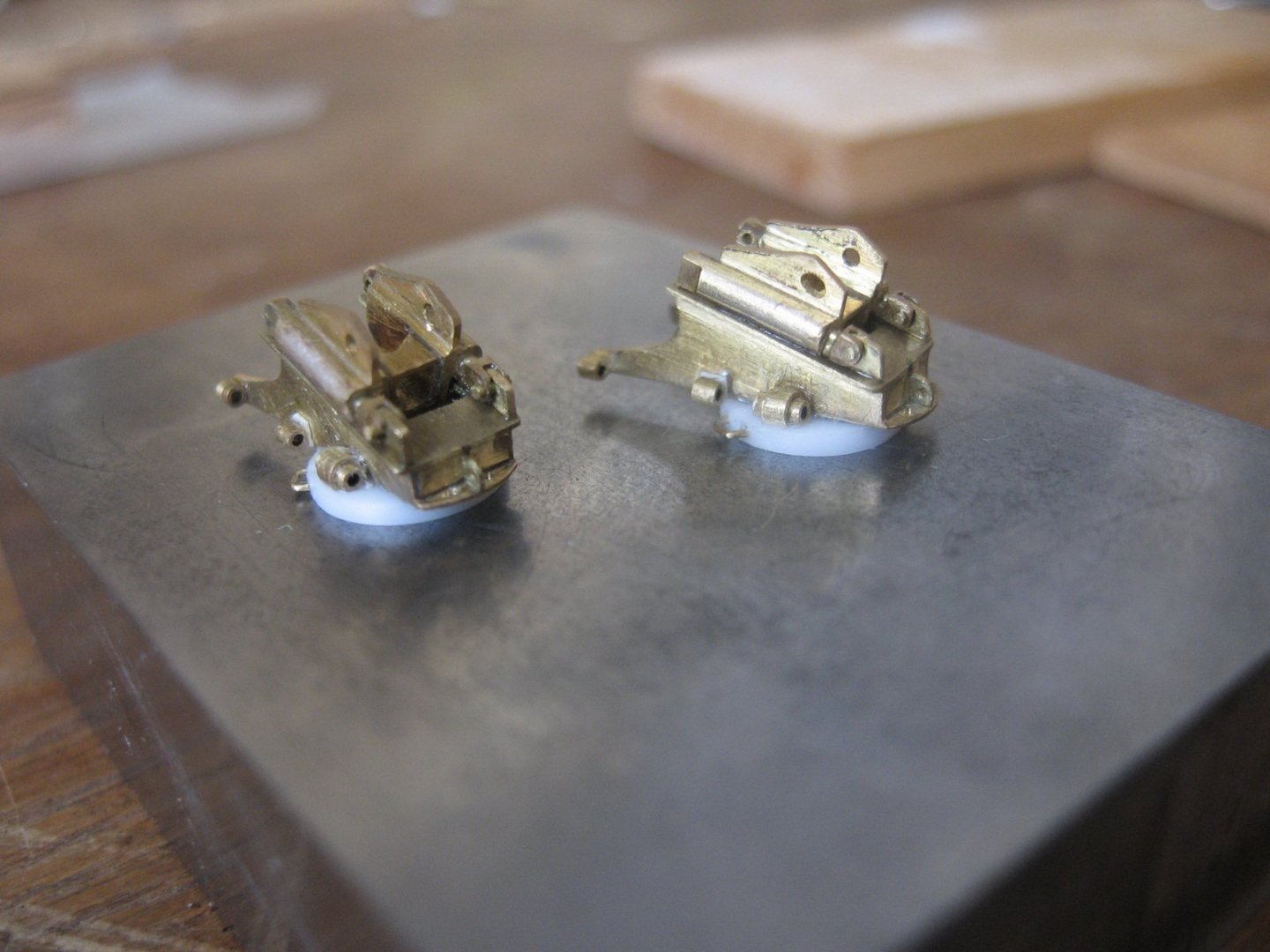

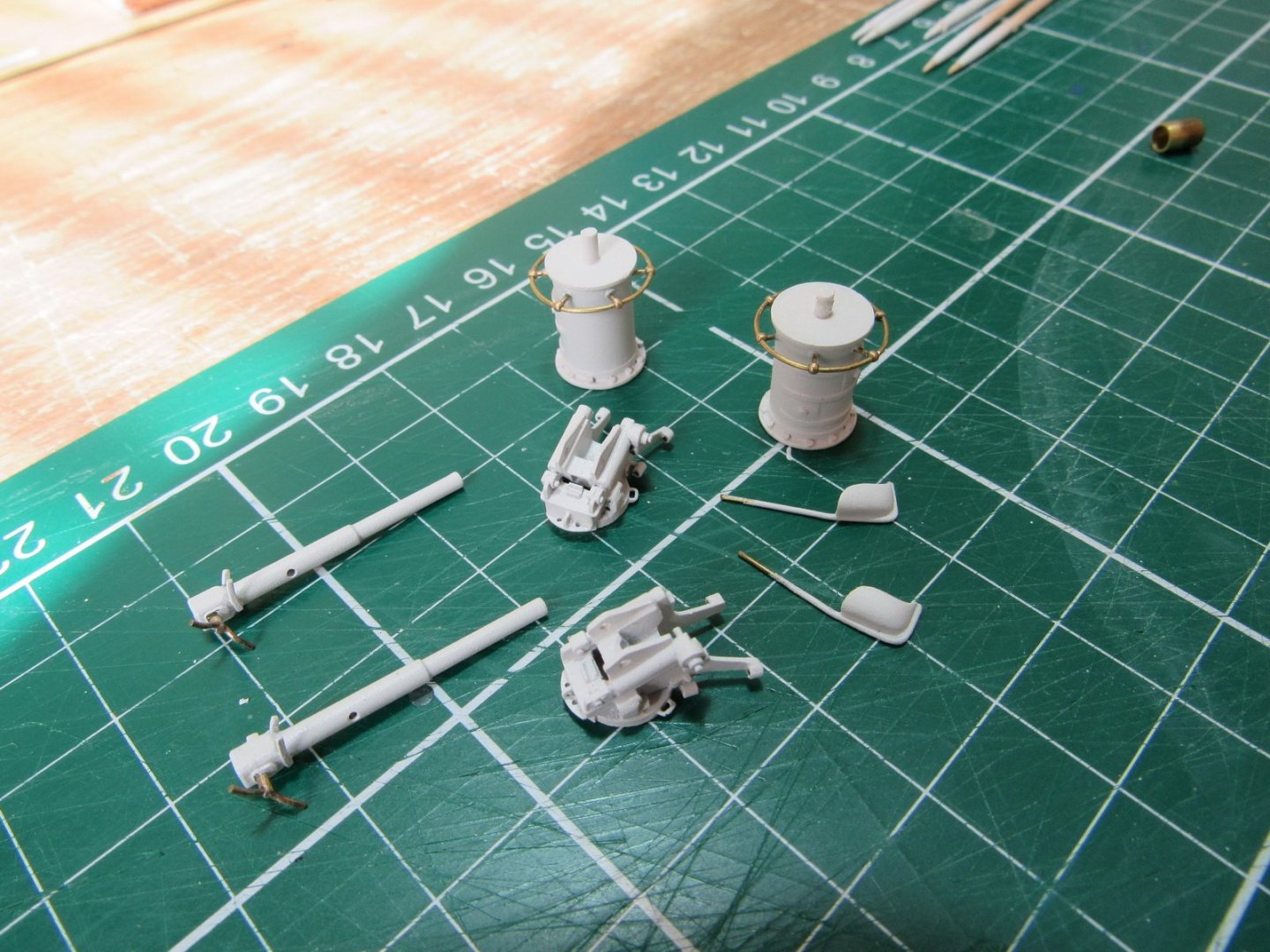

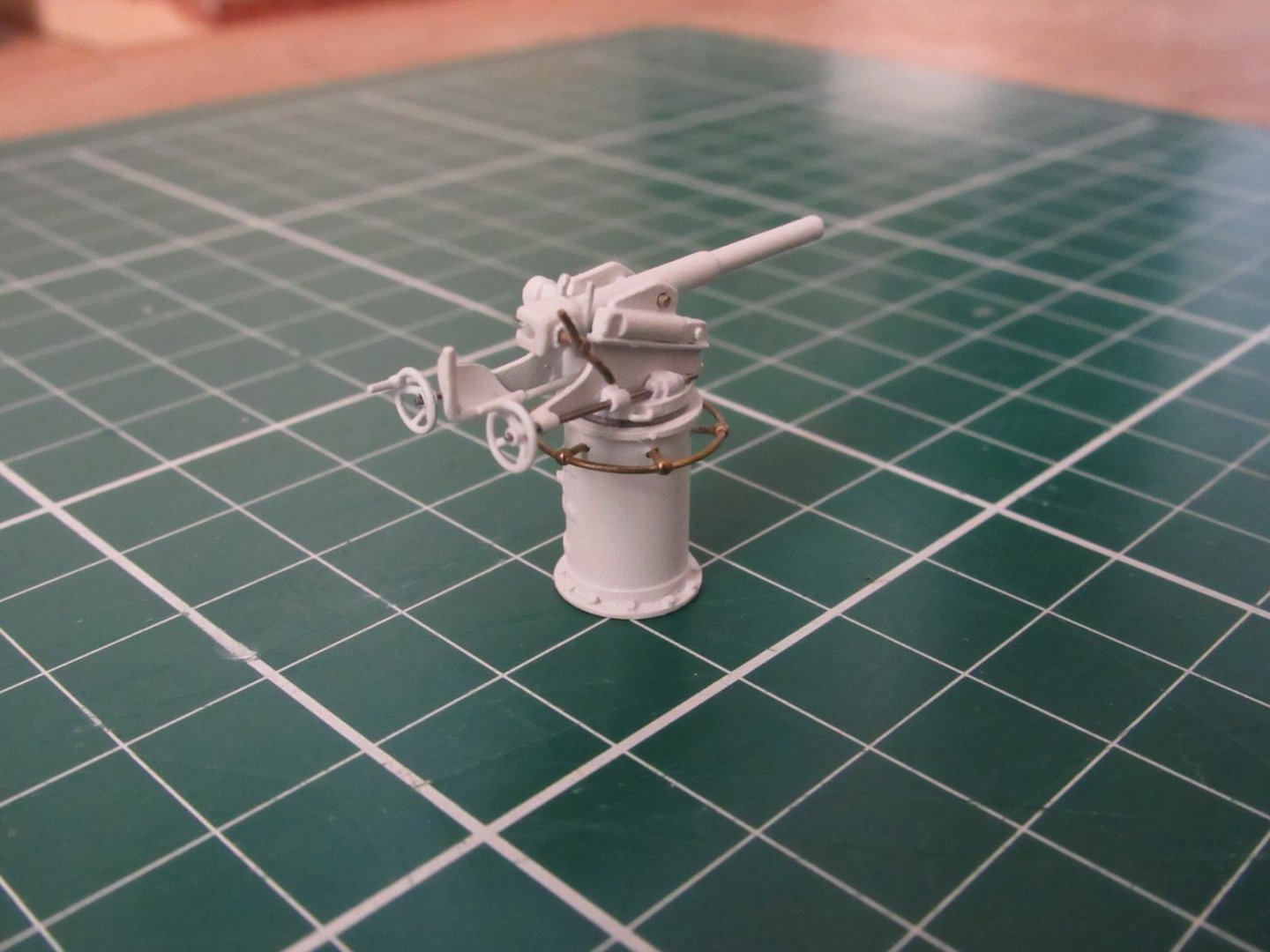

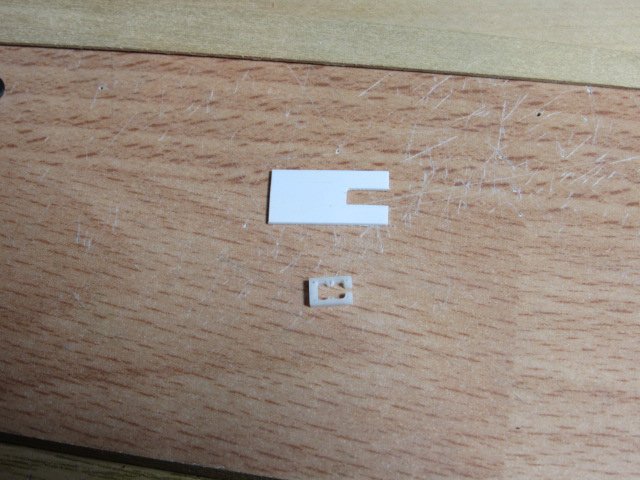

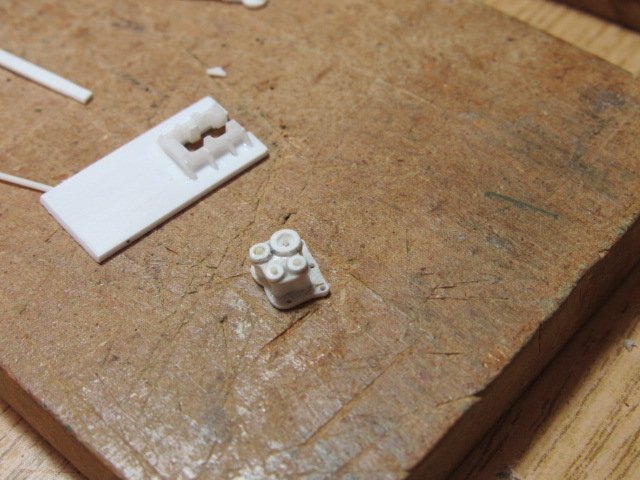

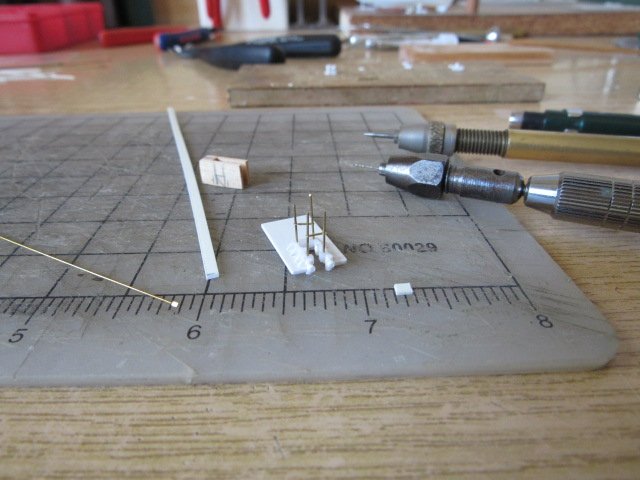

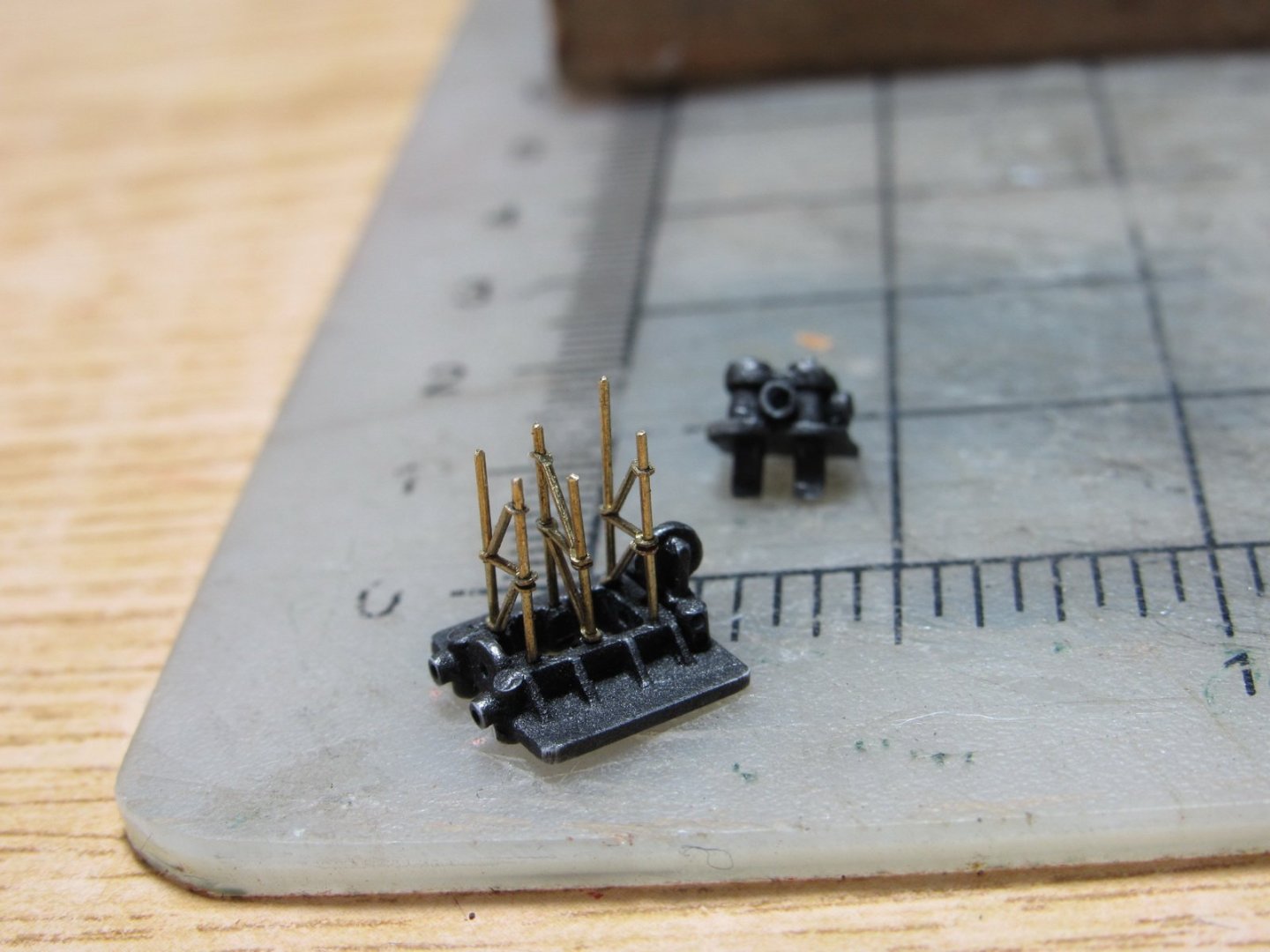

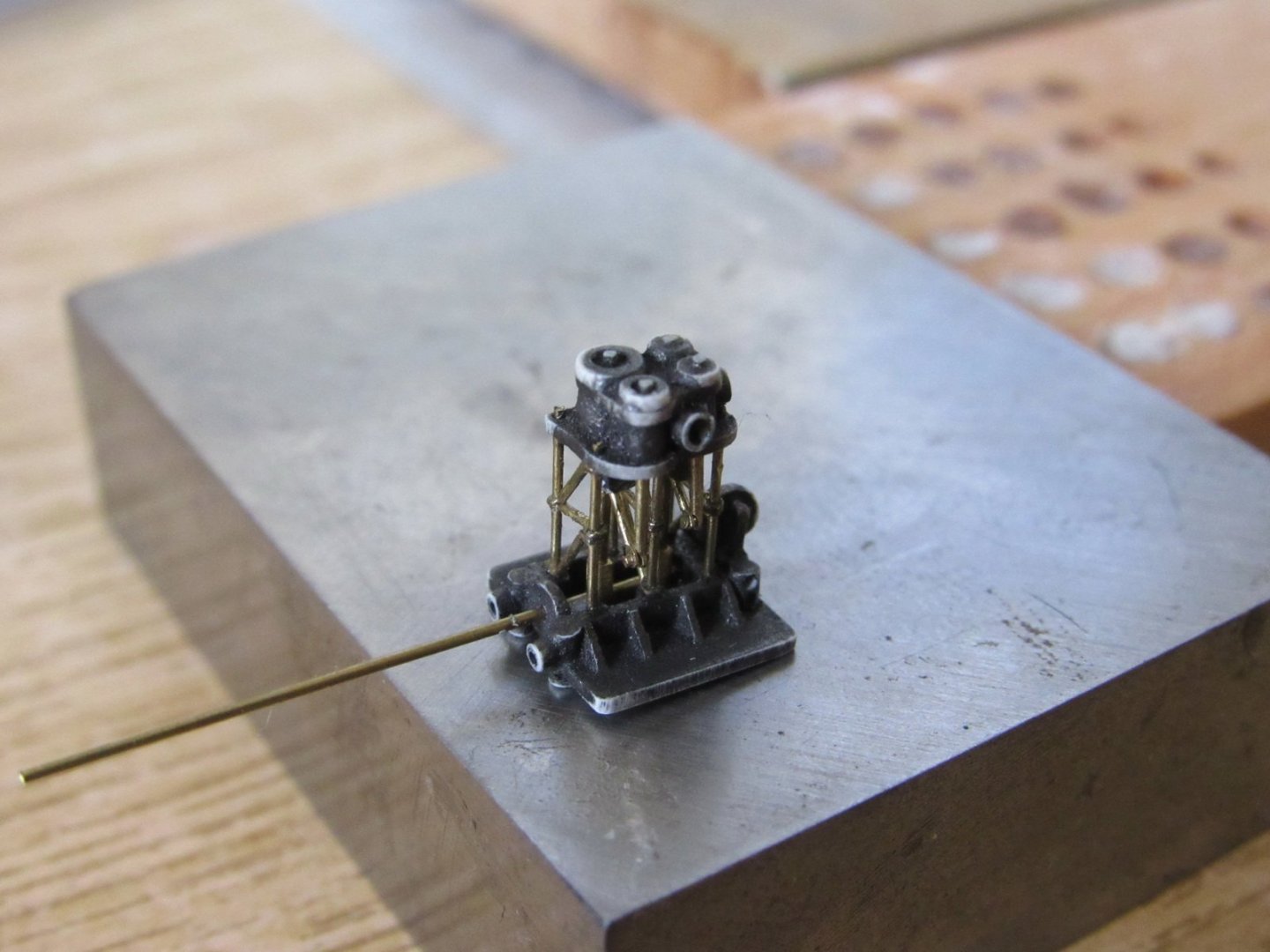

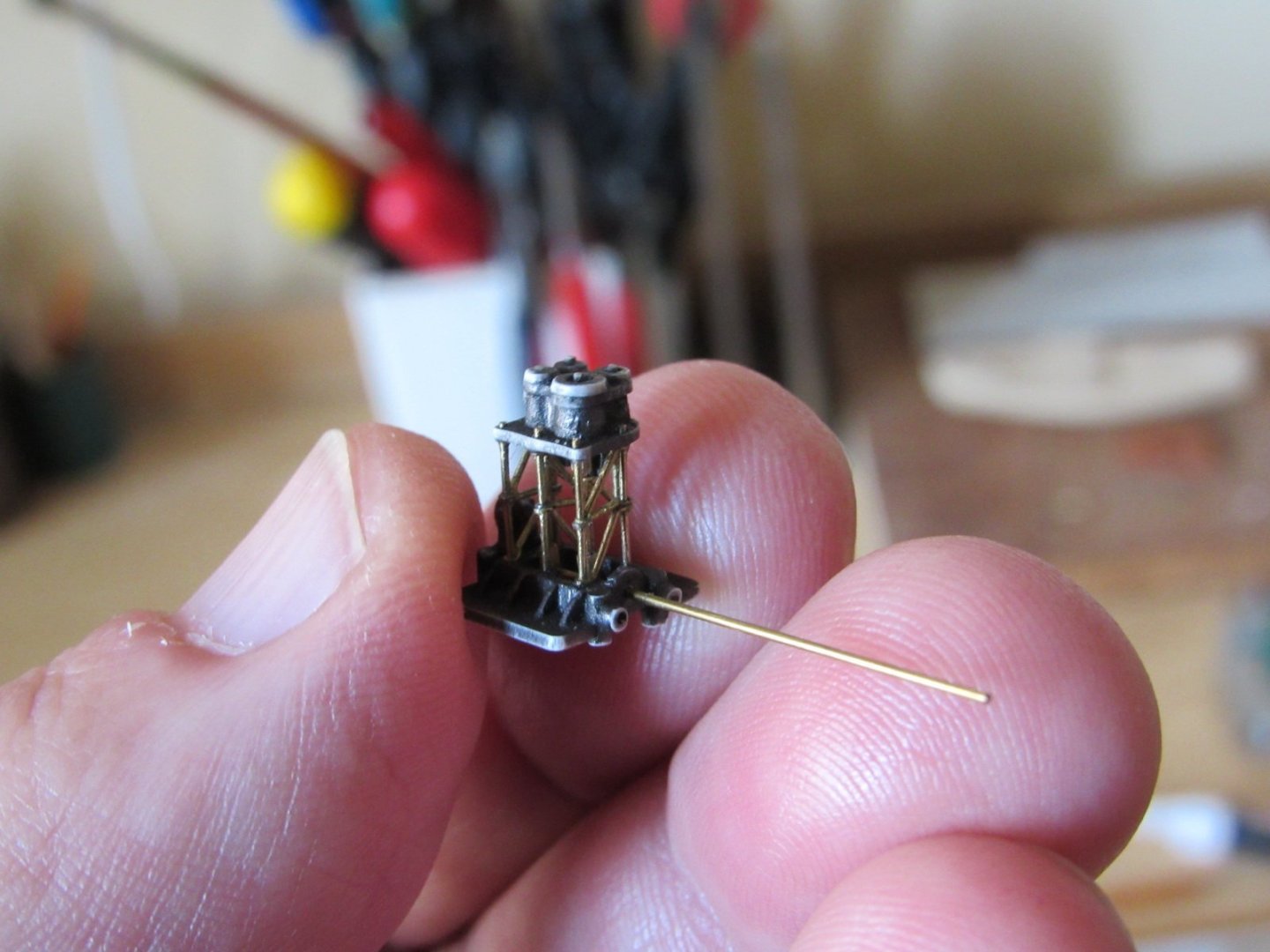

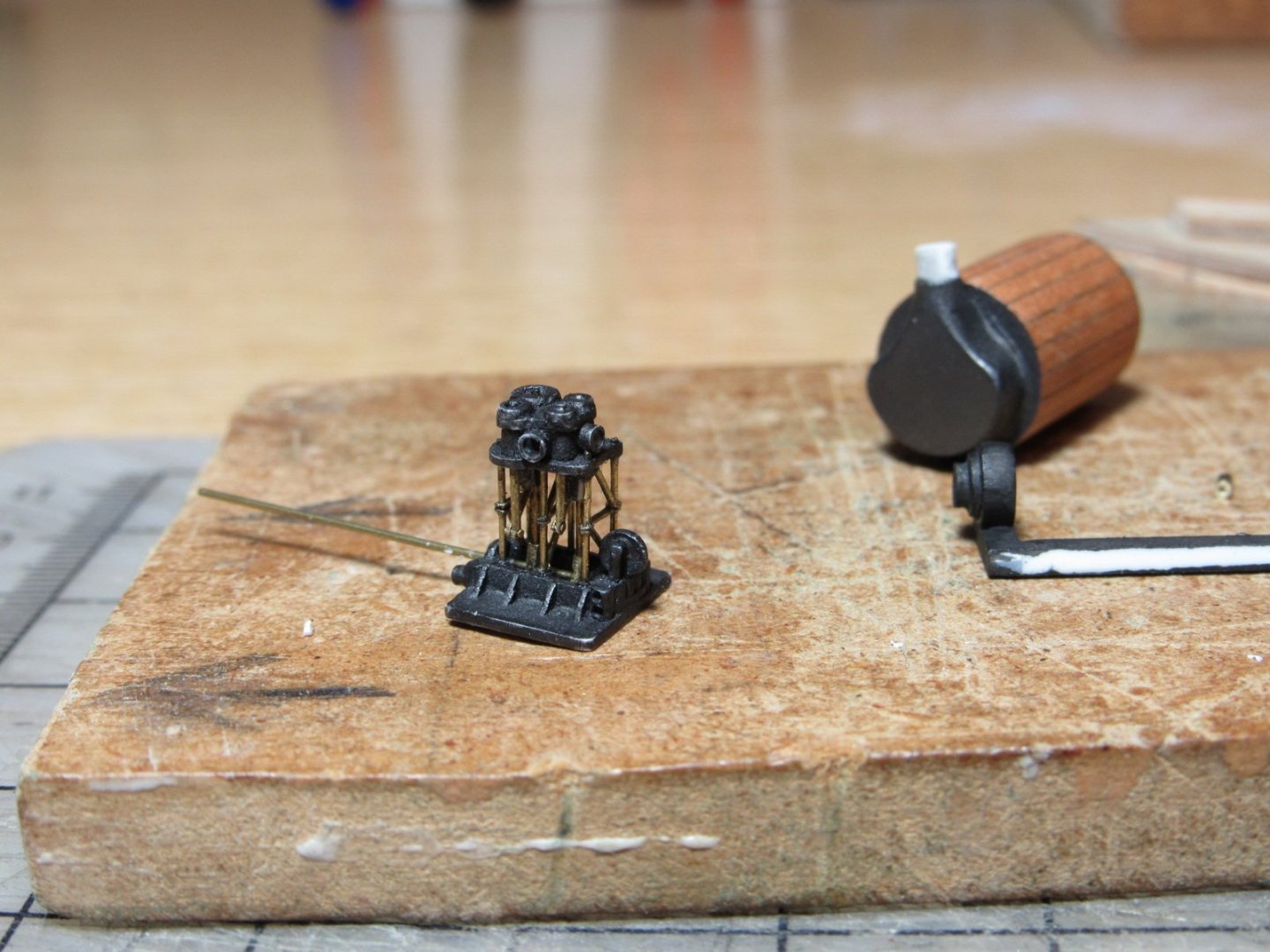

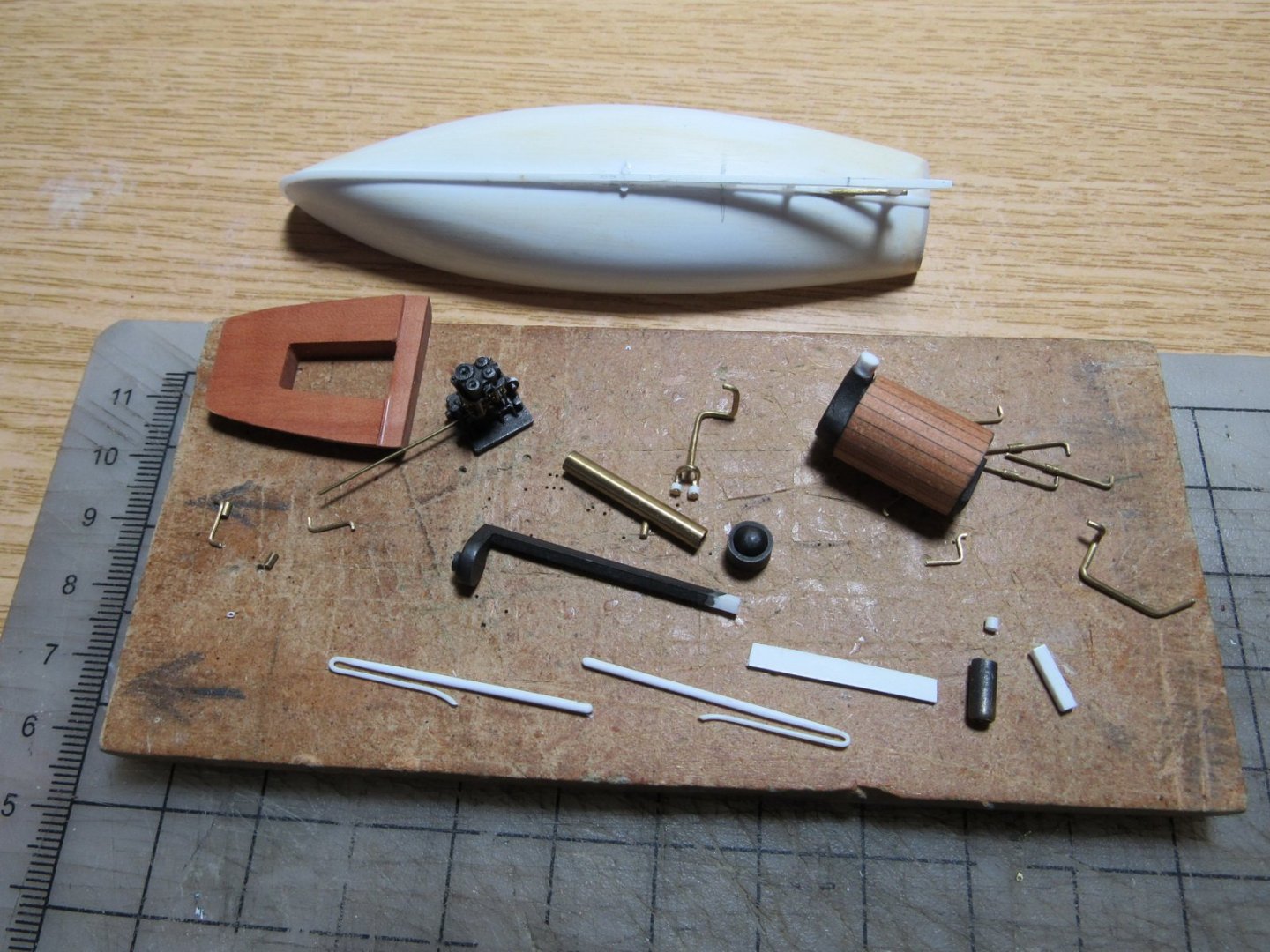

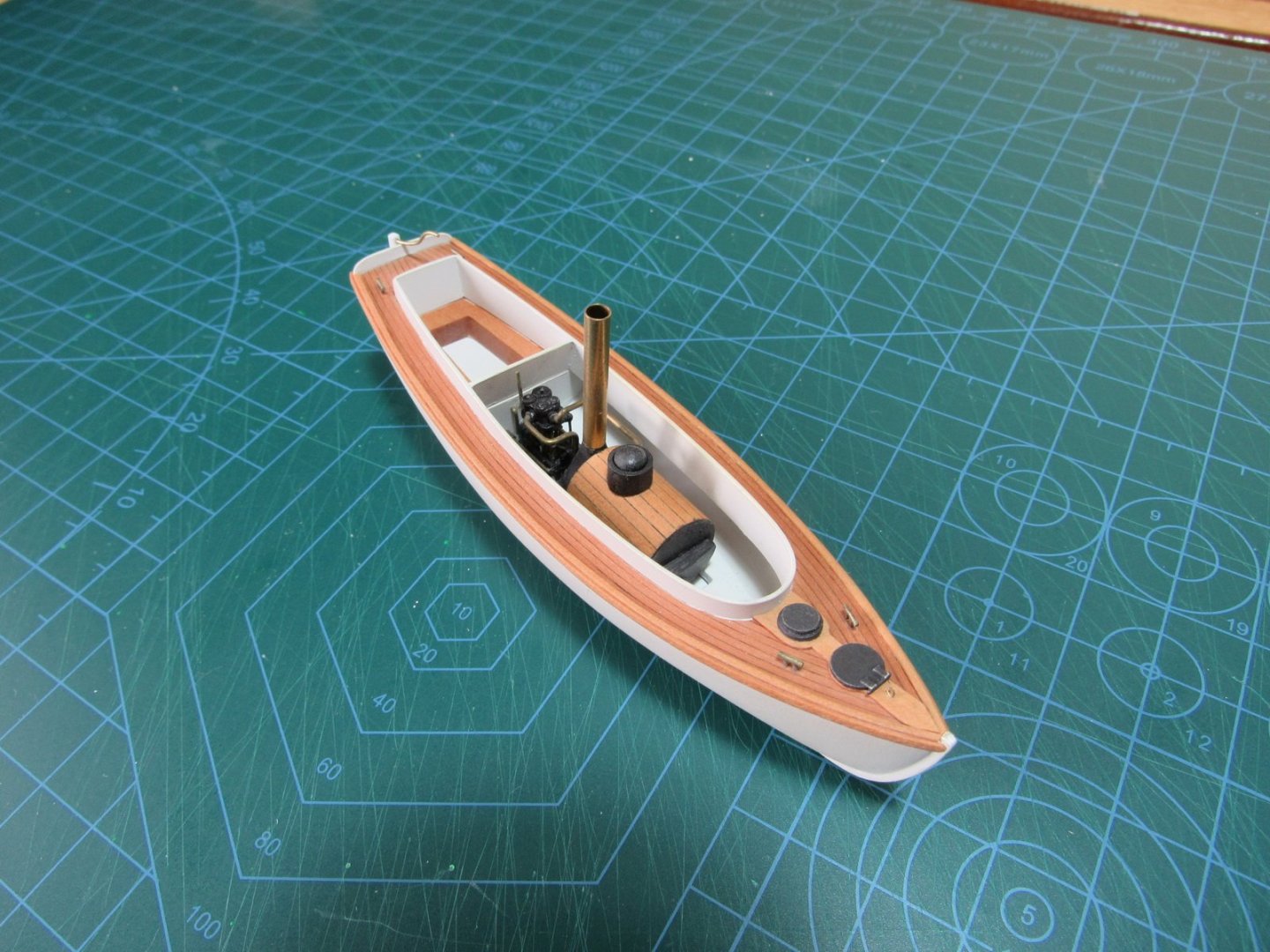

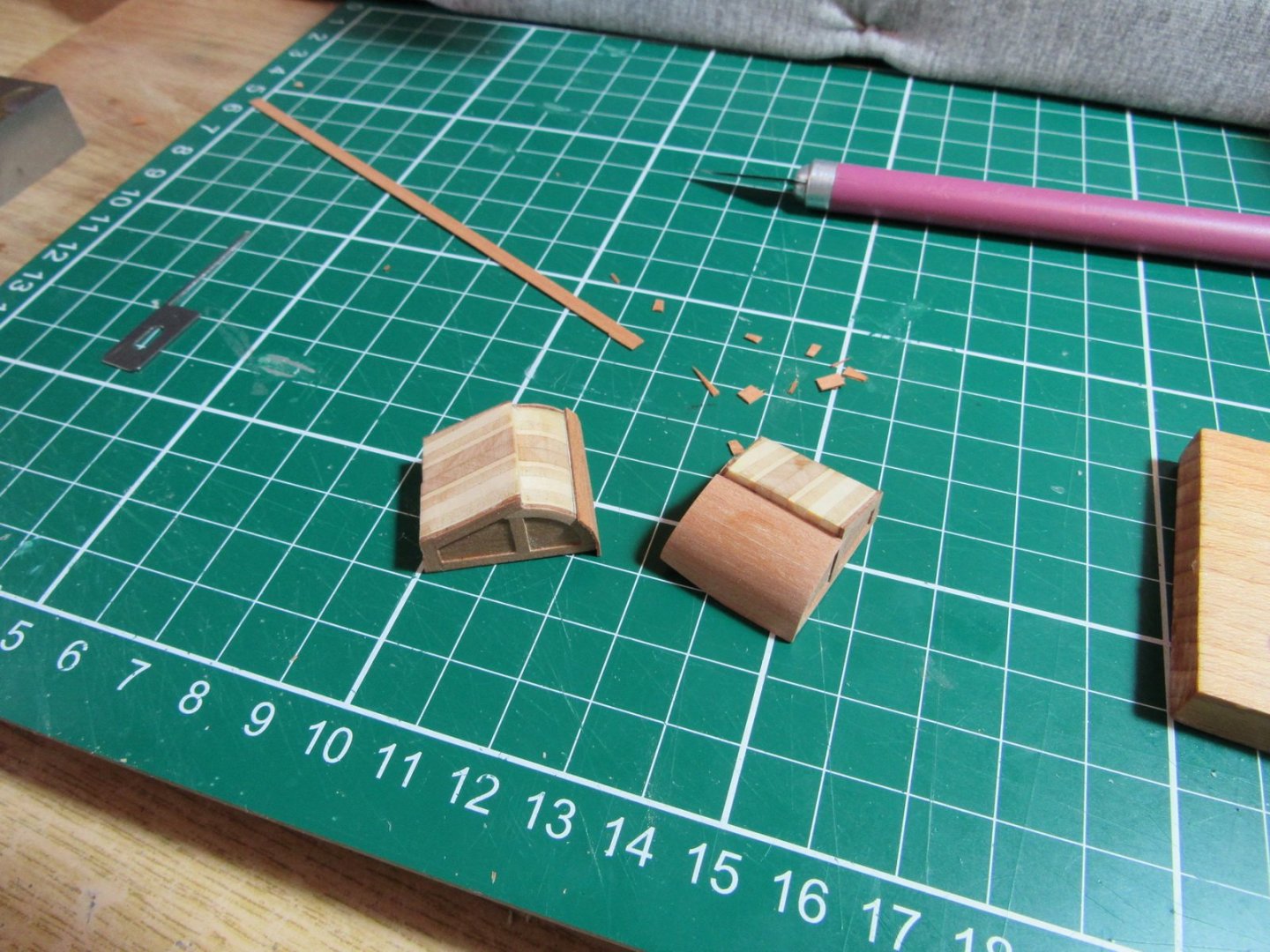

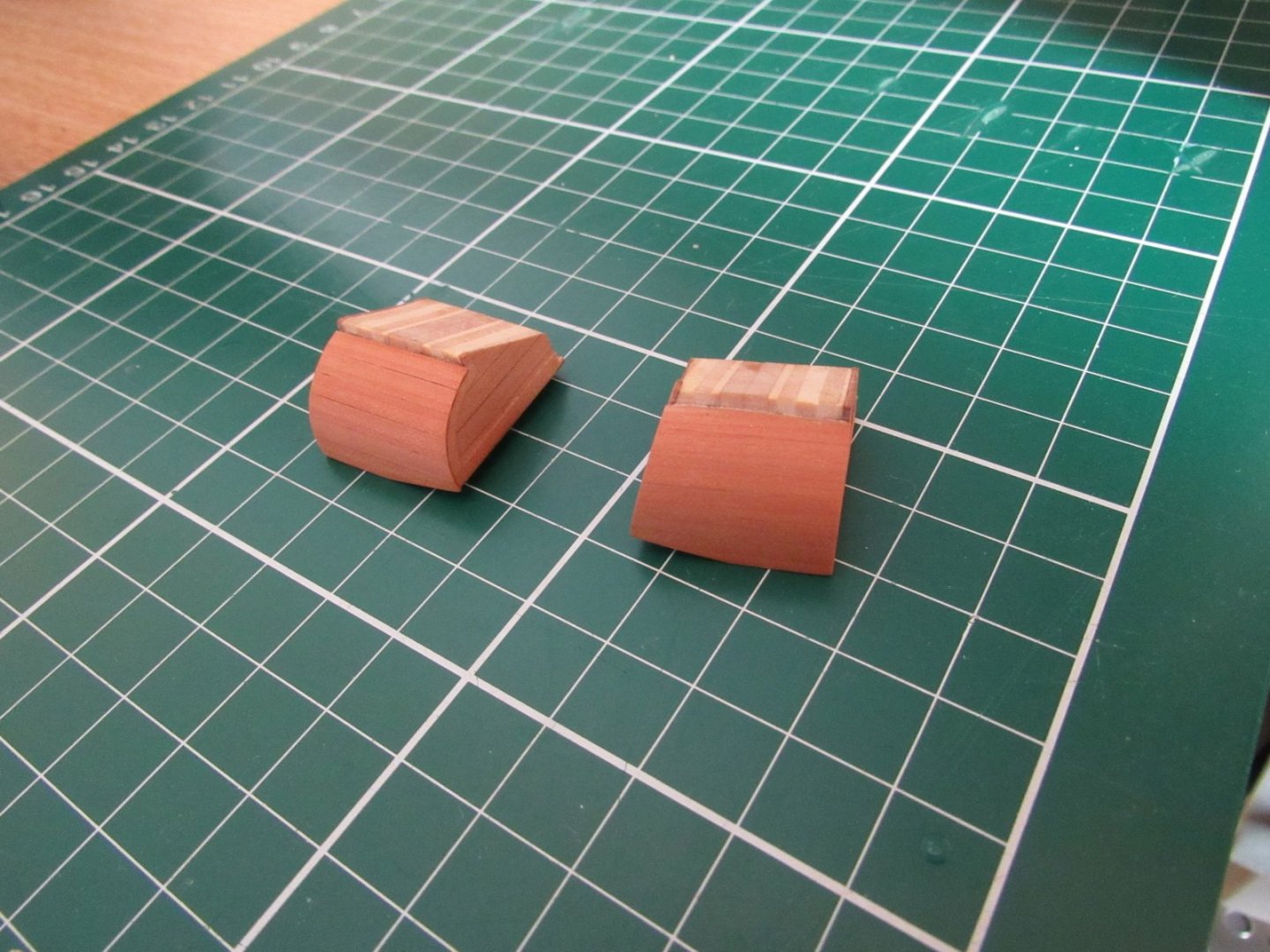

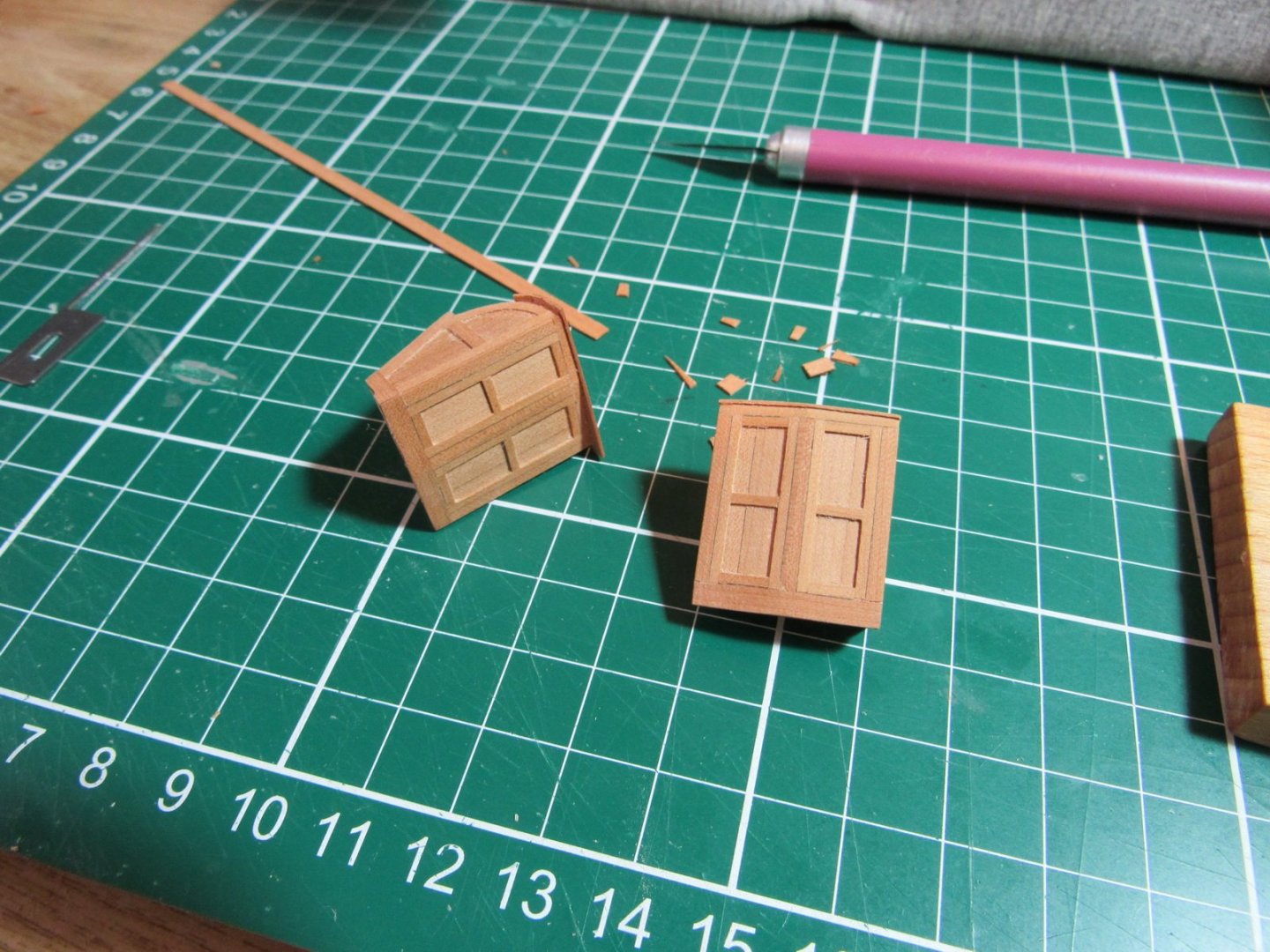

Various parts -Belaying pins -Fairleads -Bilge pump -Ladder to the bridge -Ladder to the forecastle -Cradle for steam launch

-

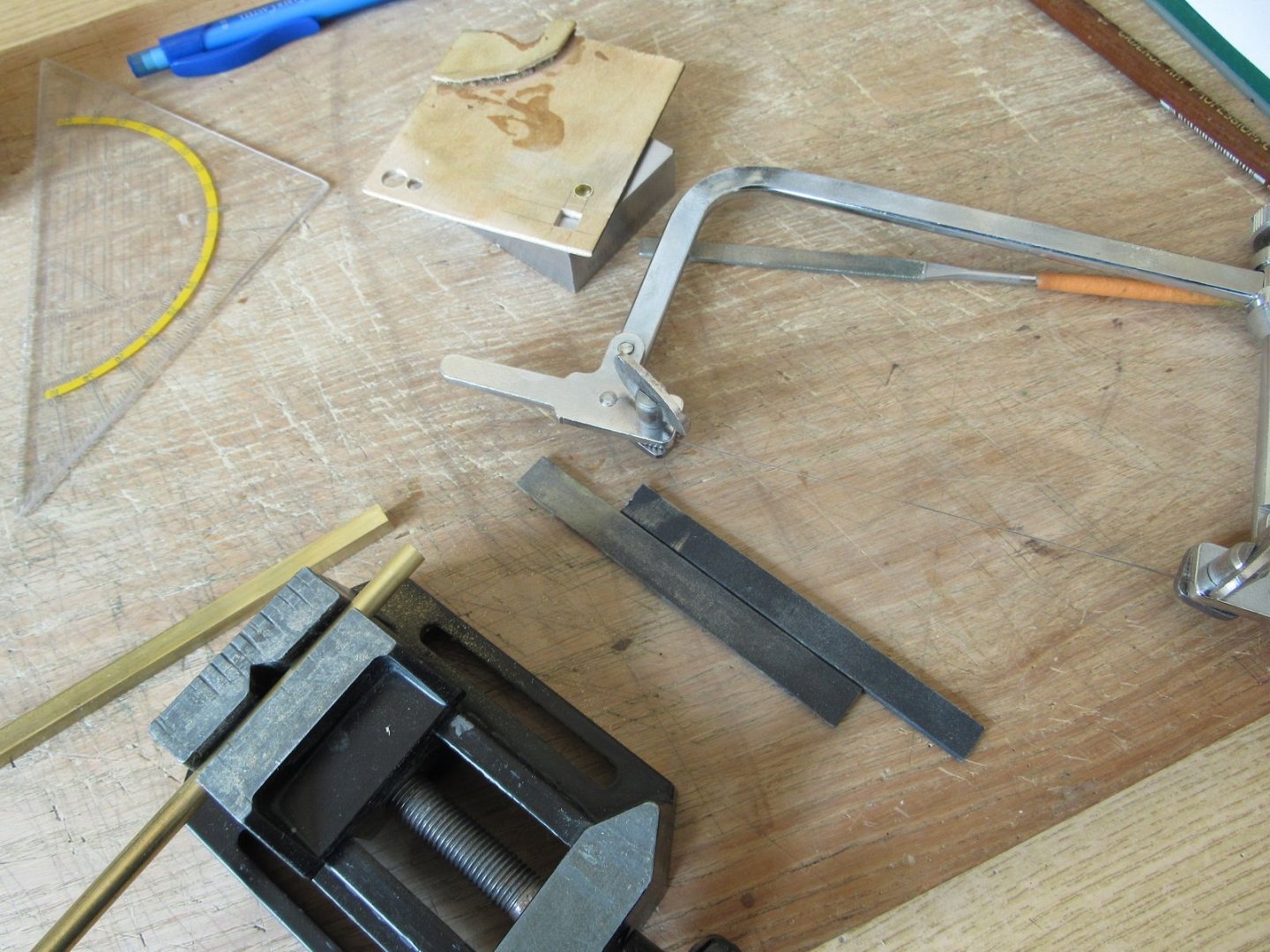

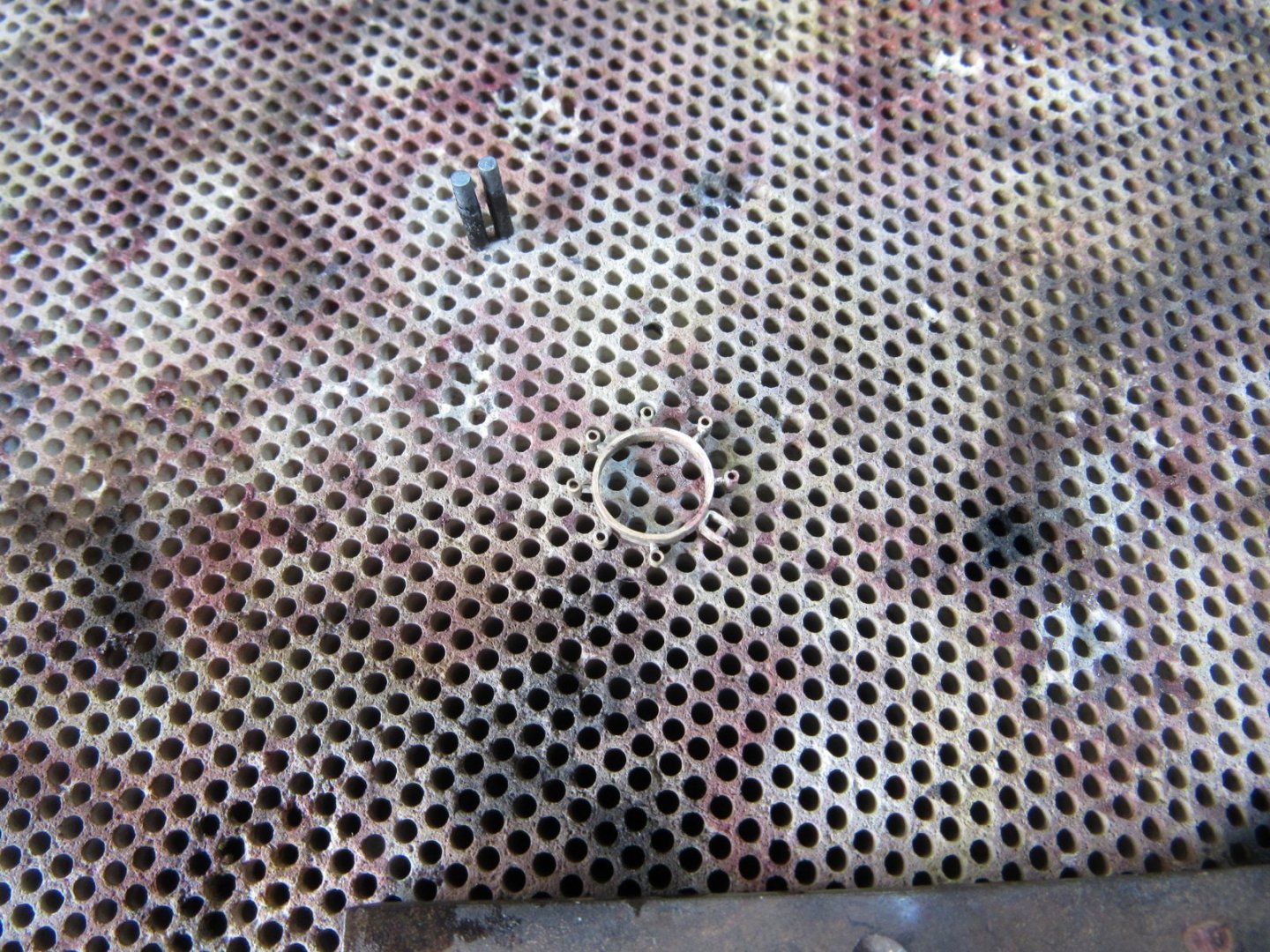

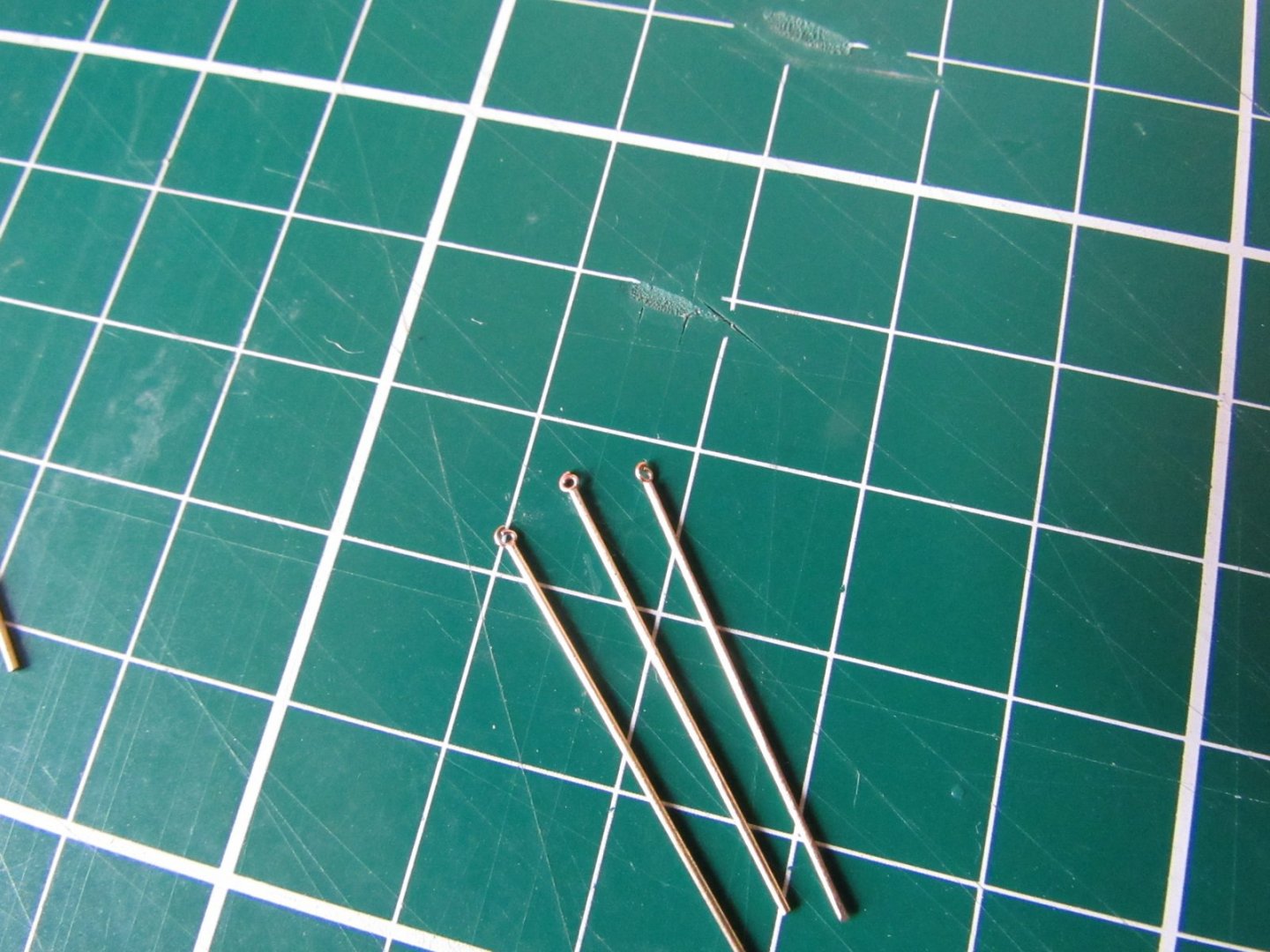

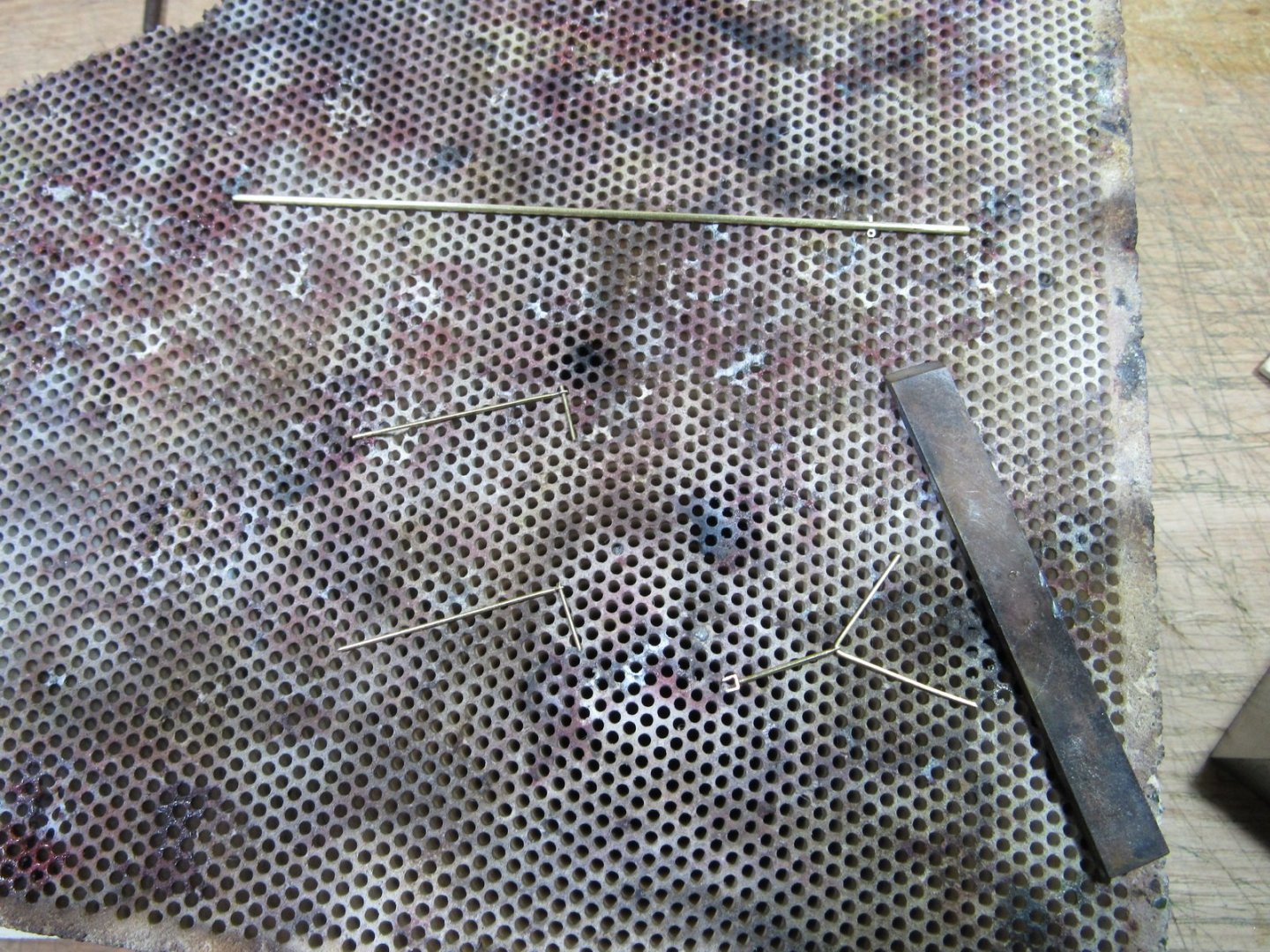

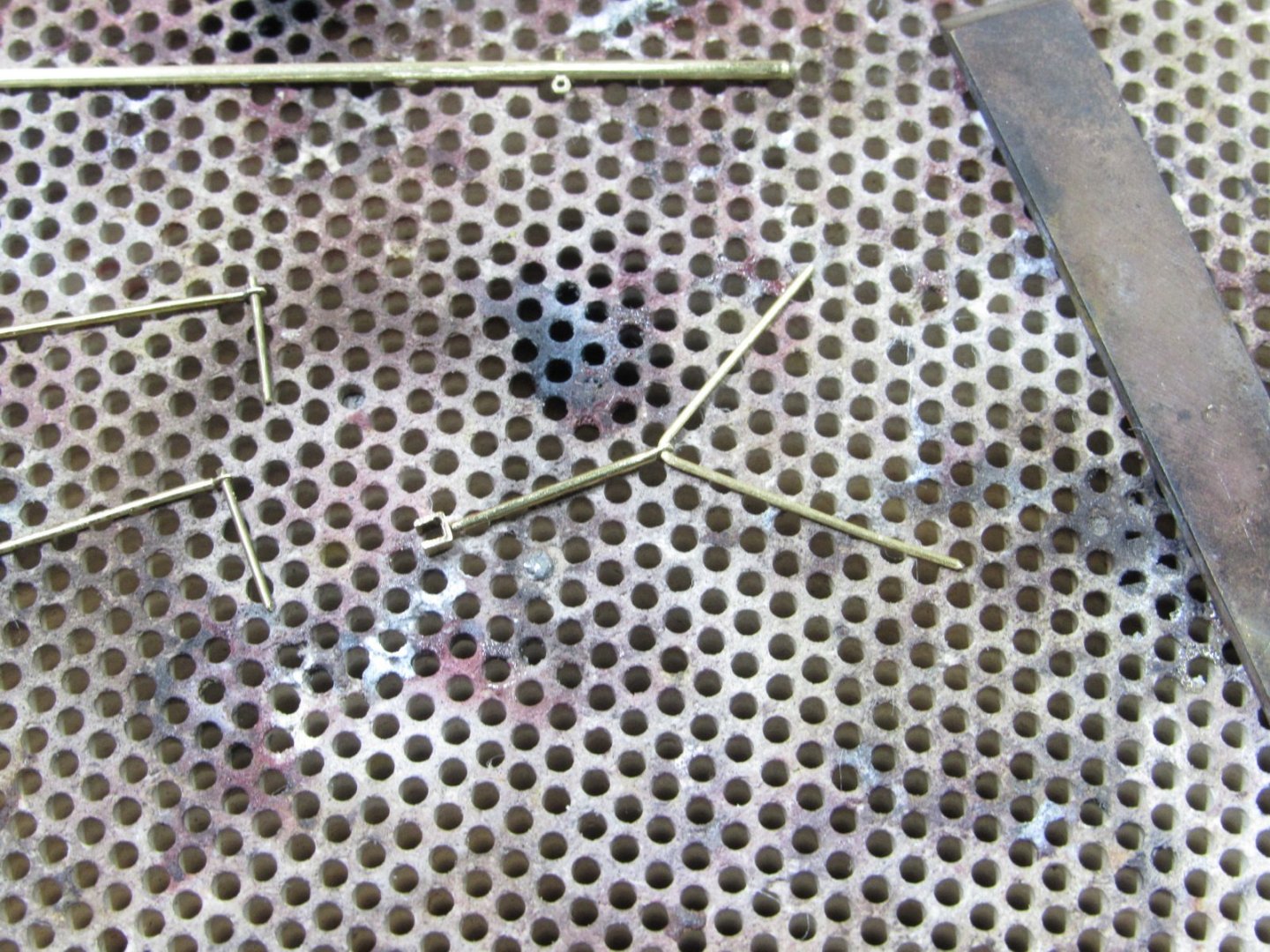

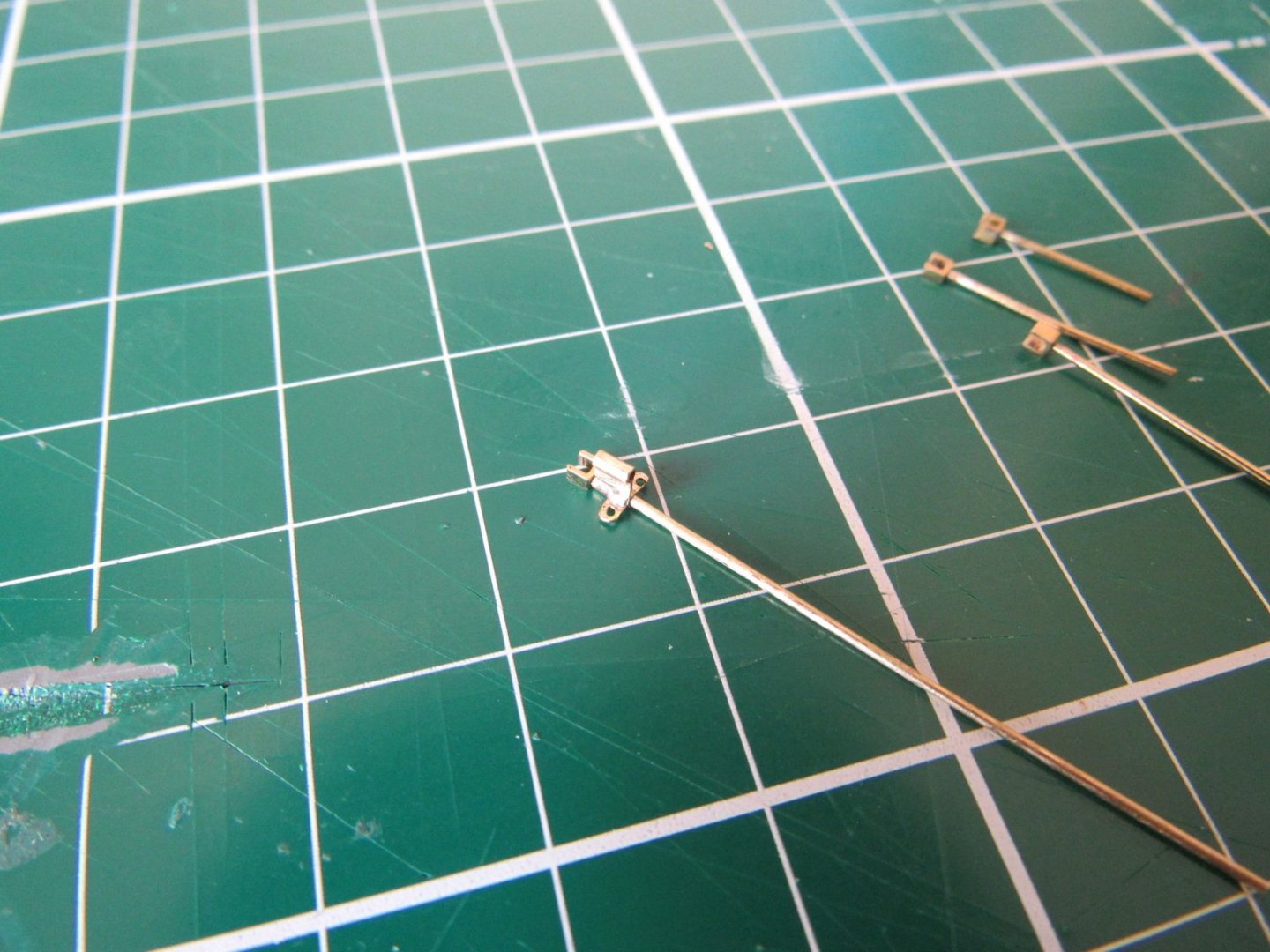

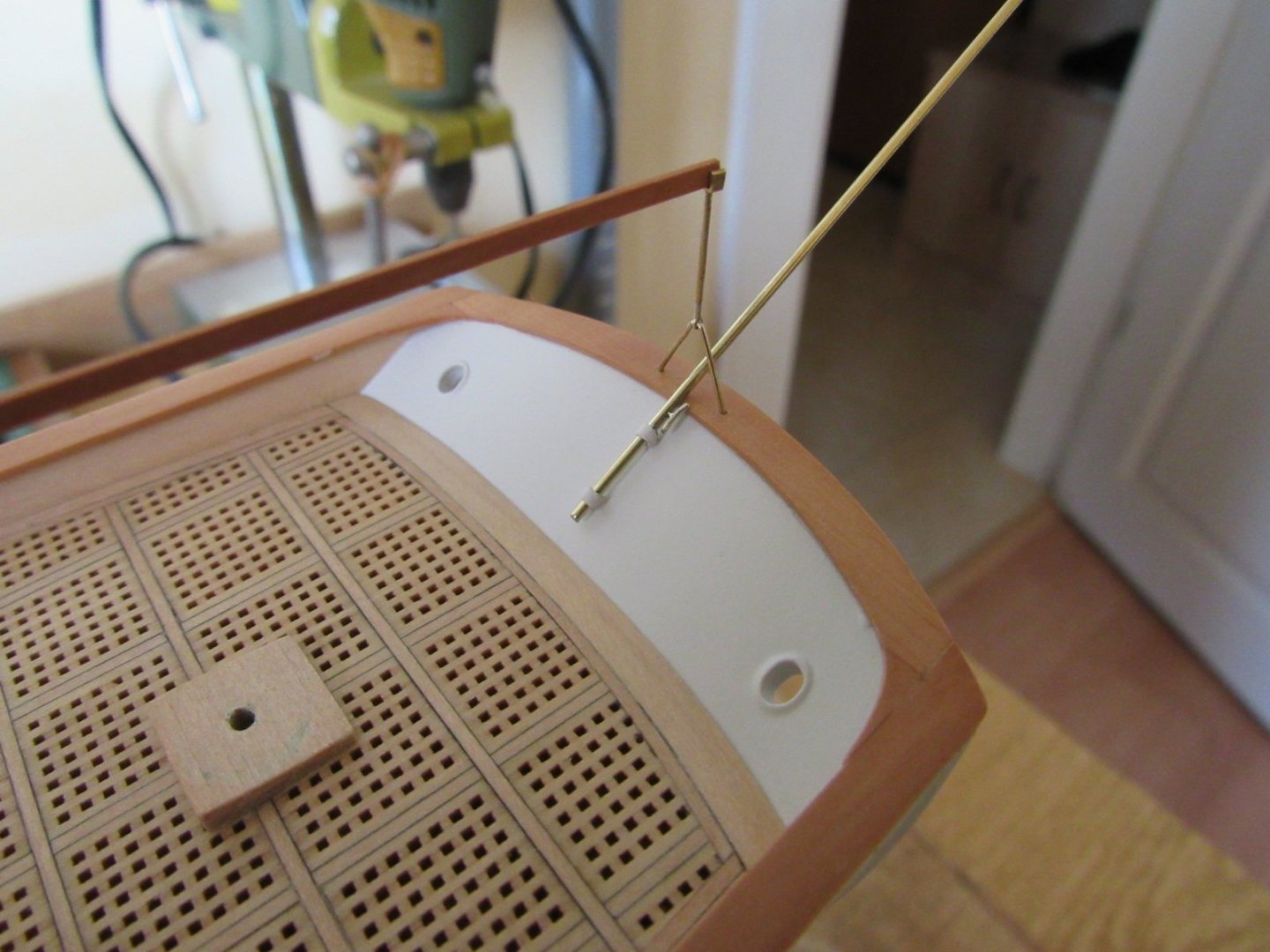

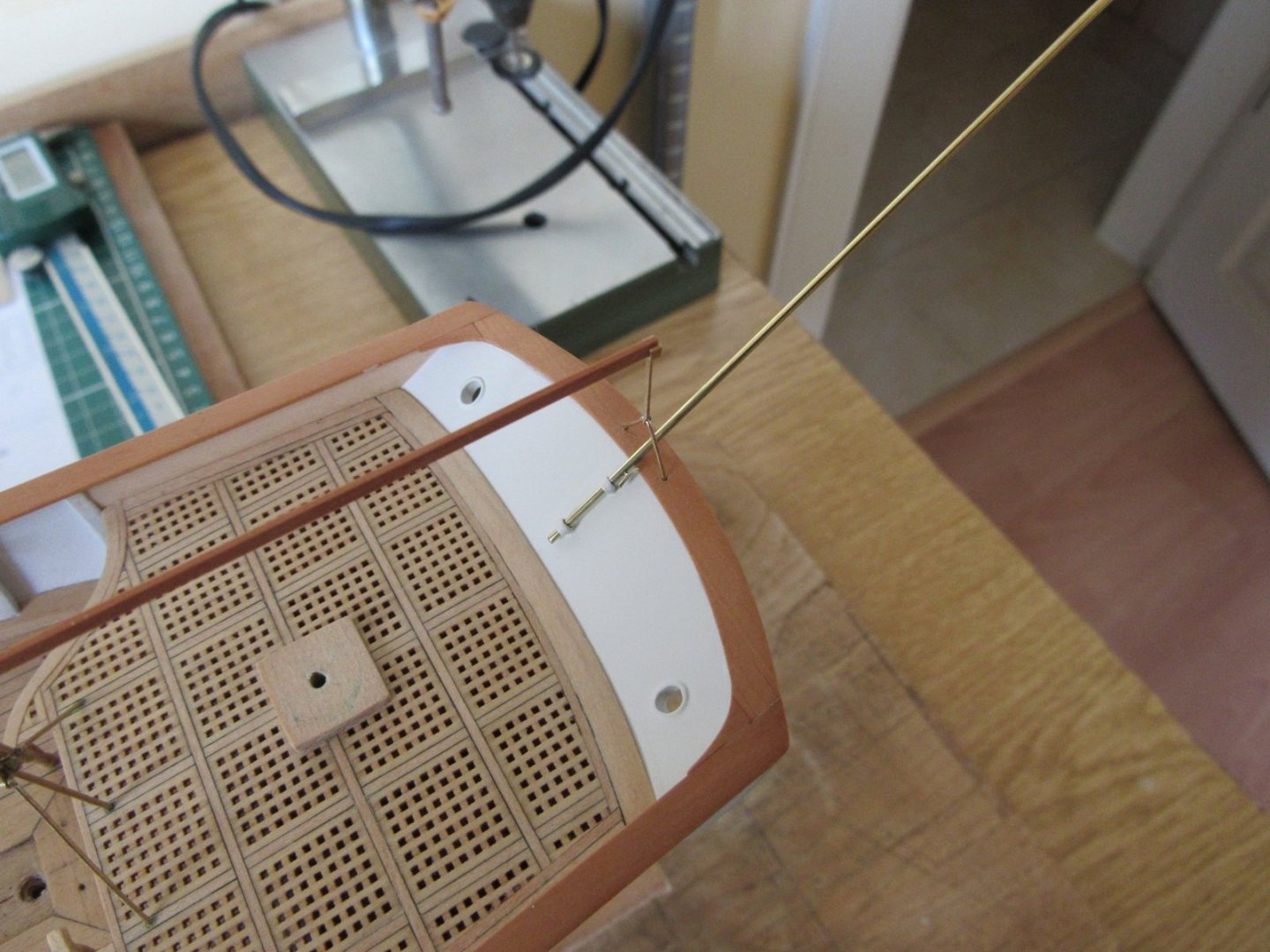

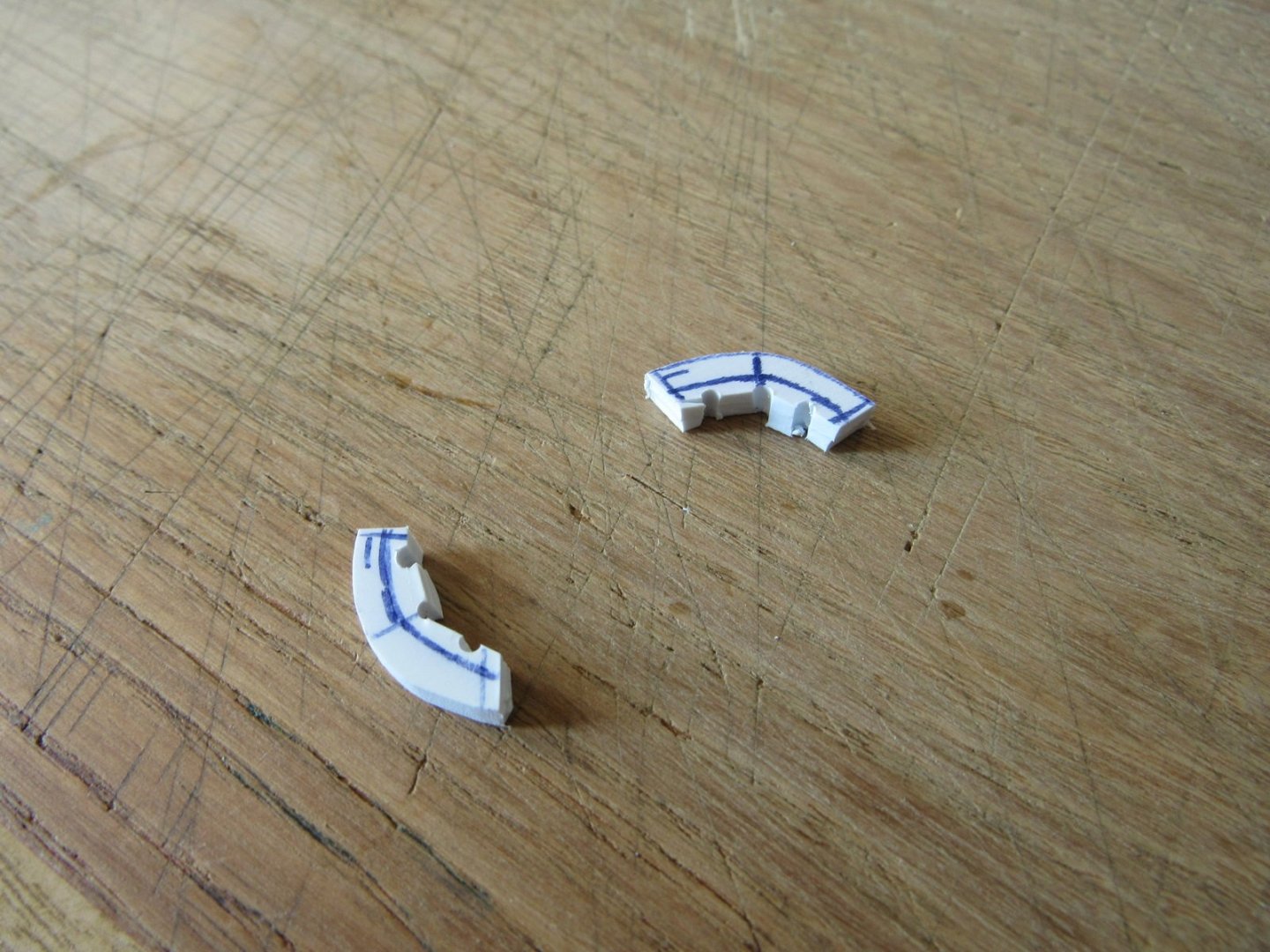

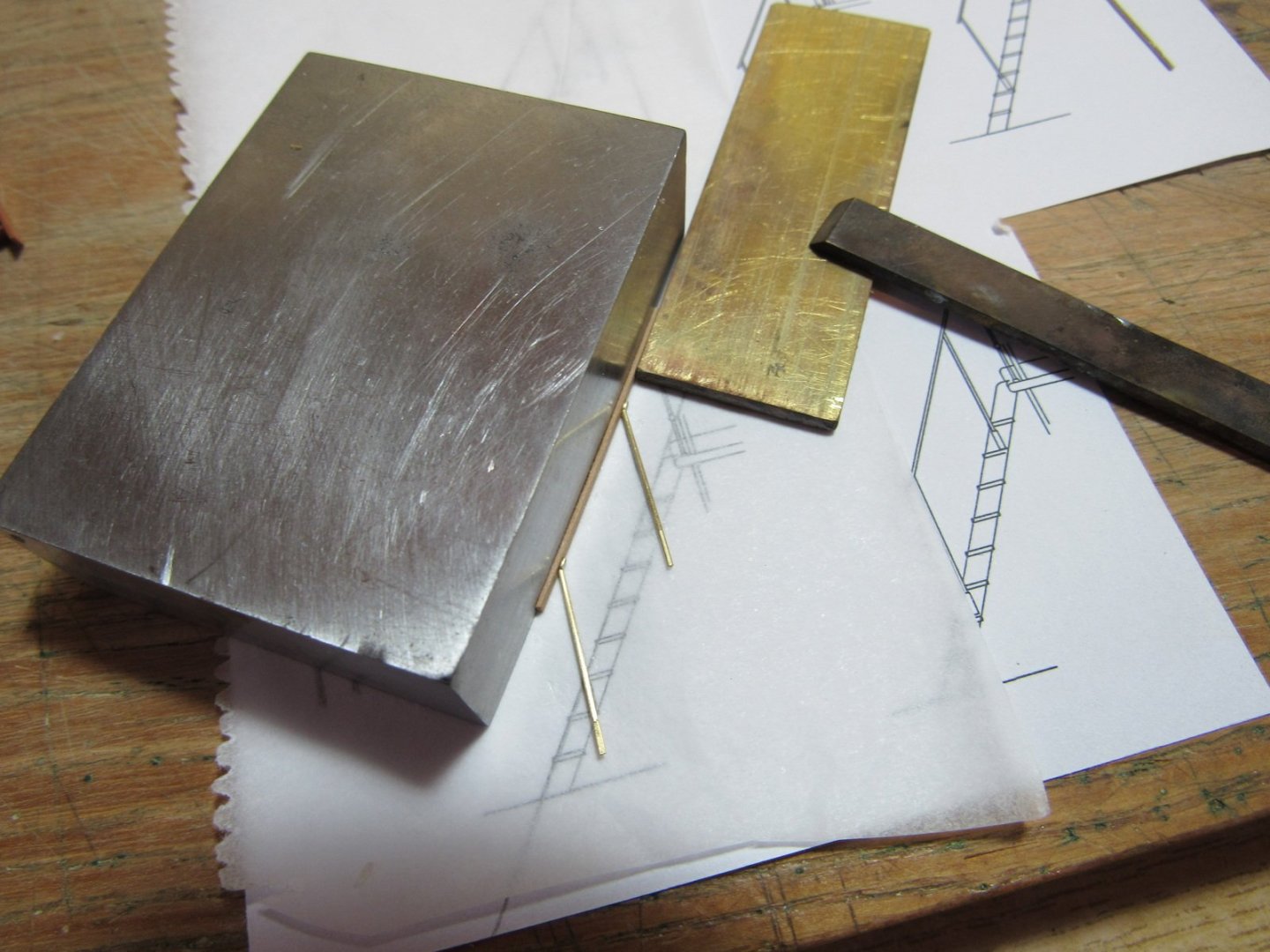

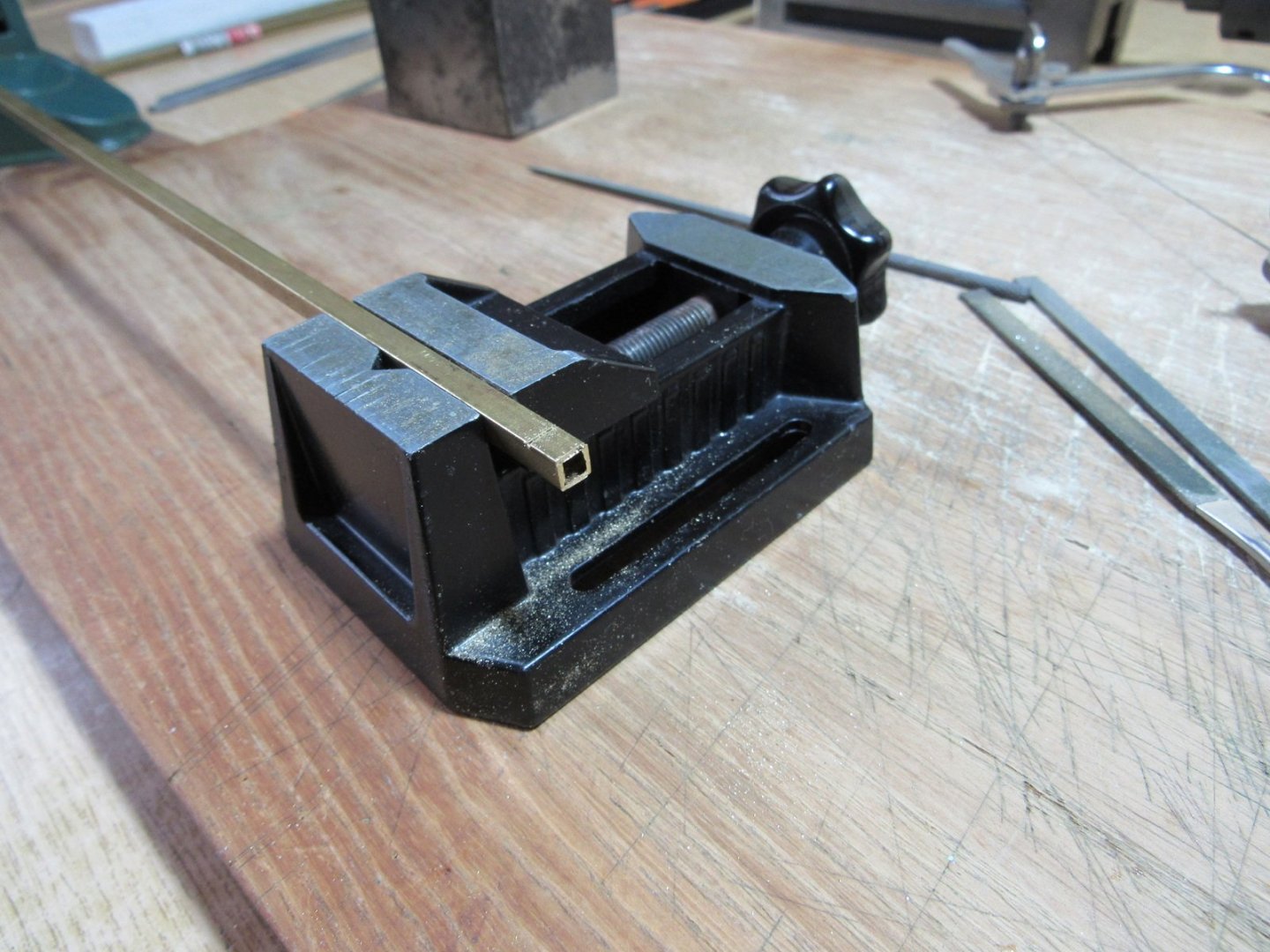

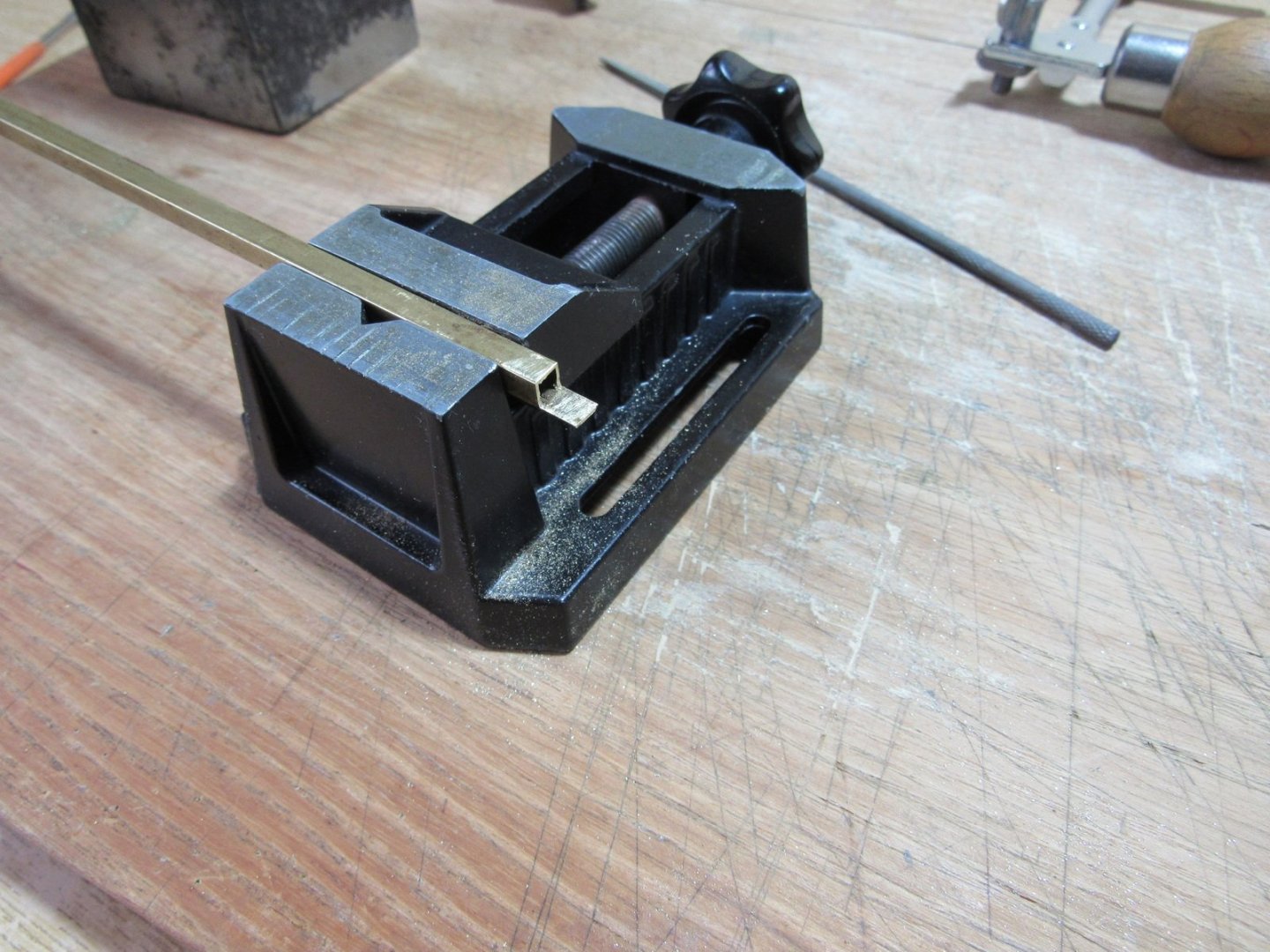

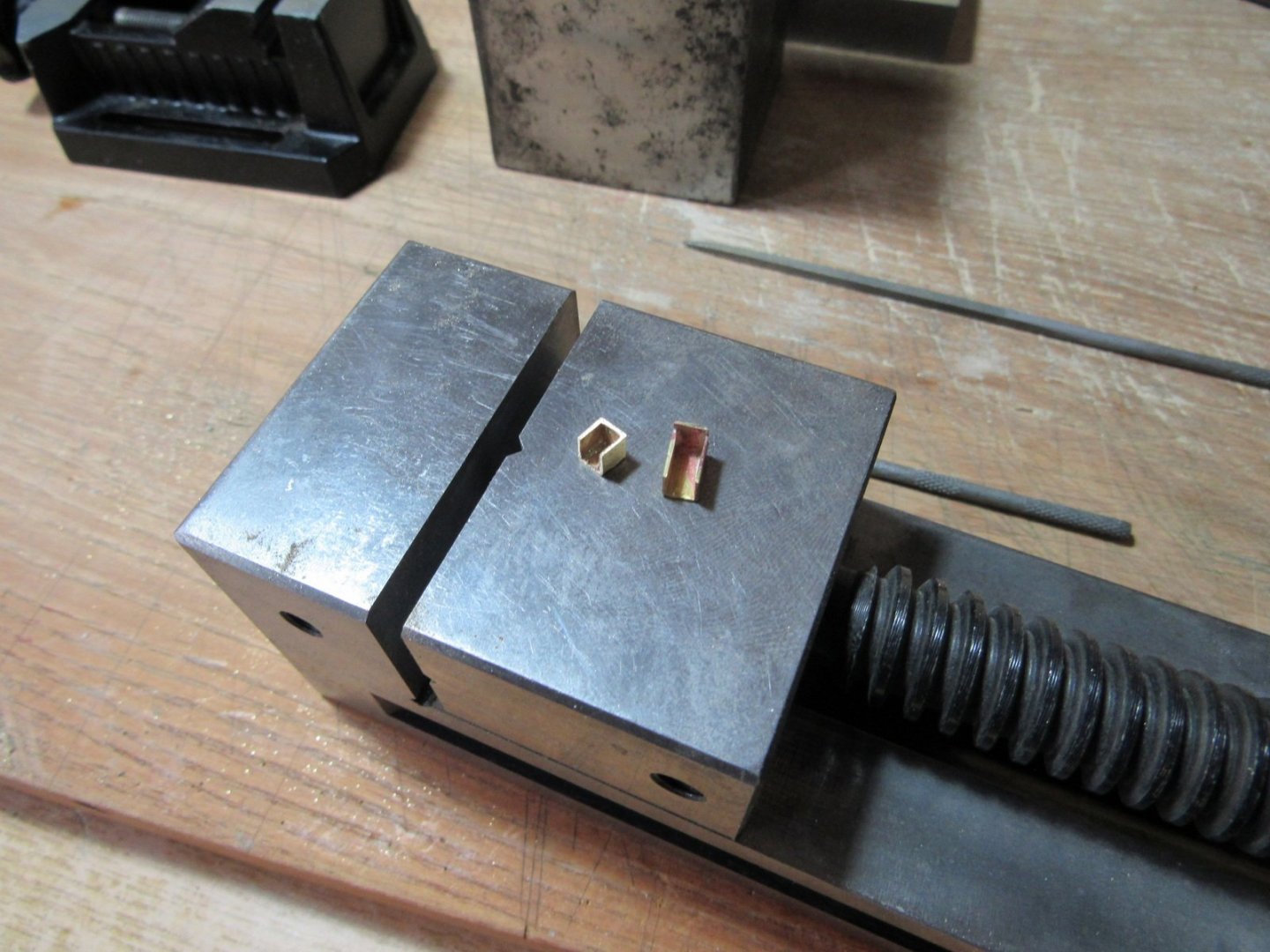

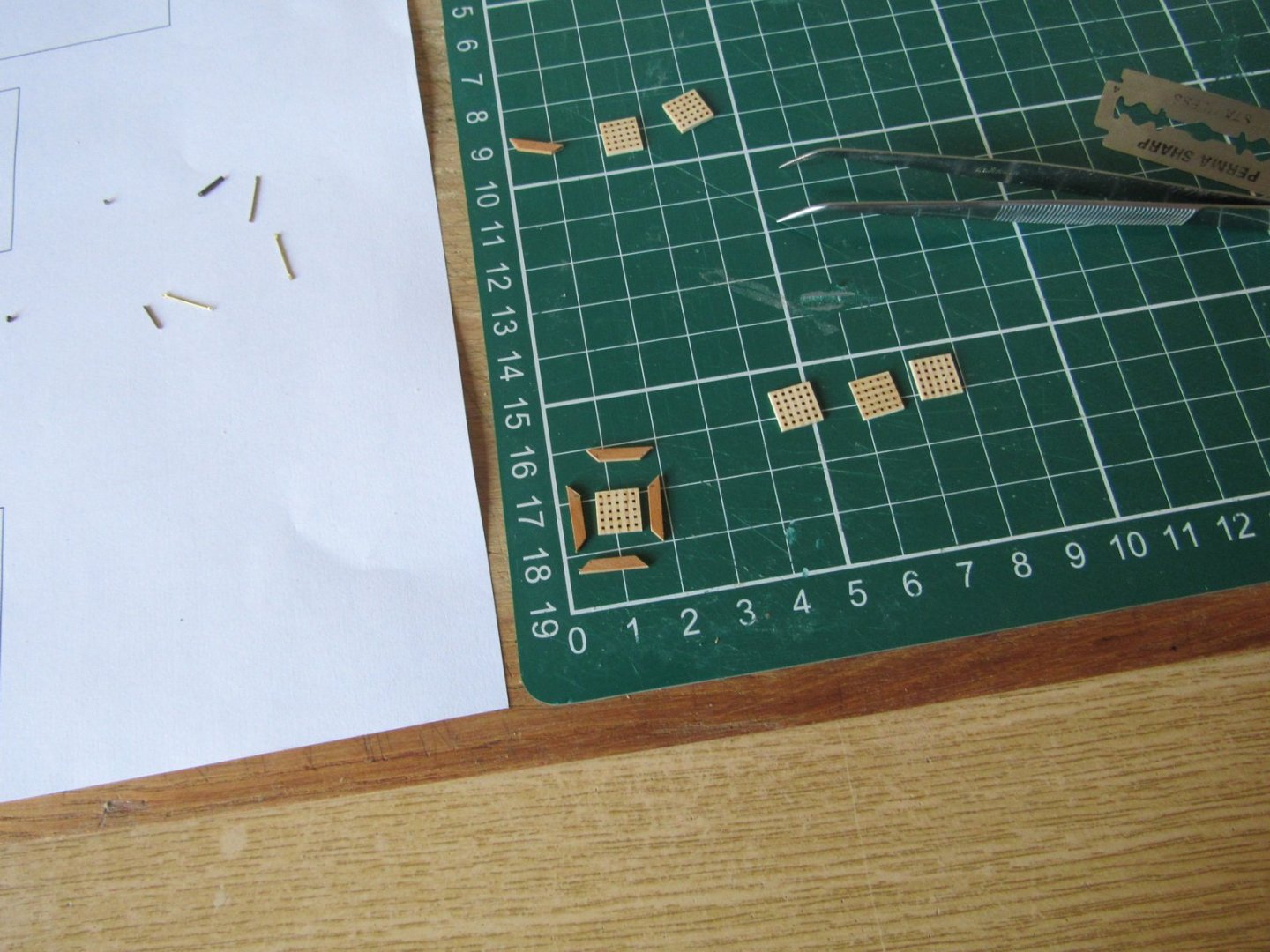

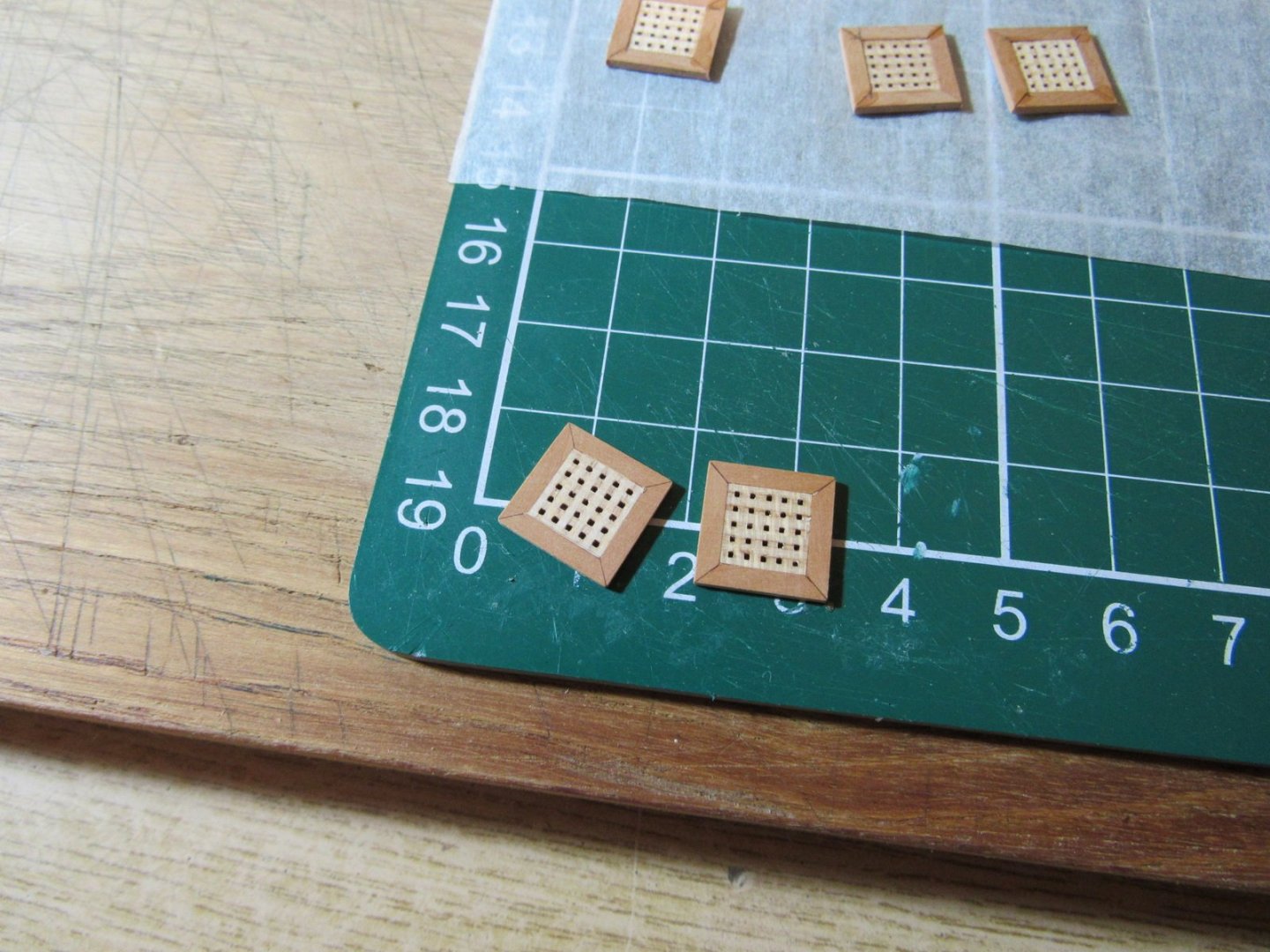

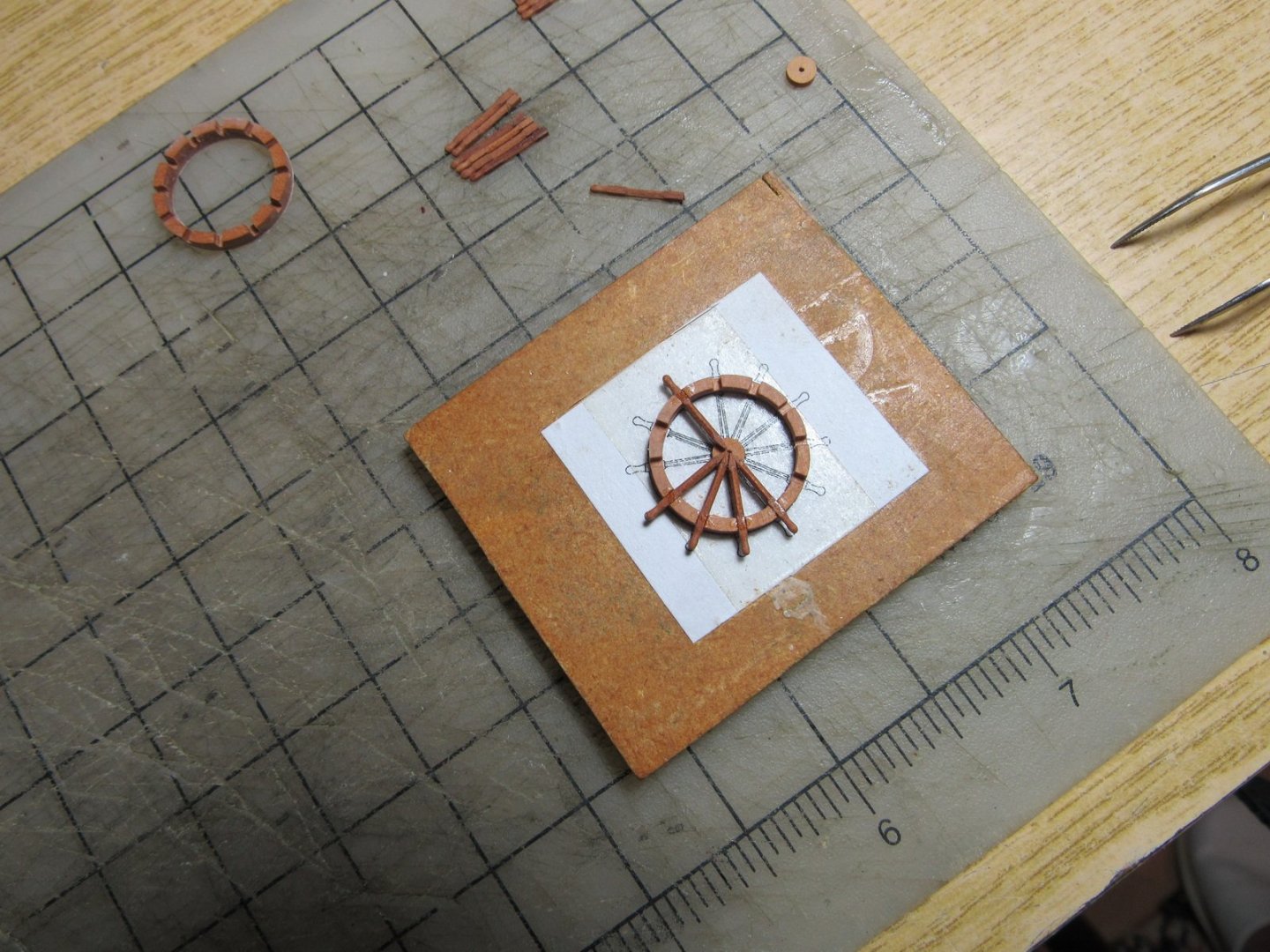

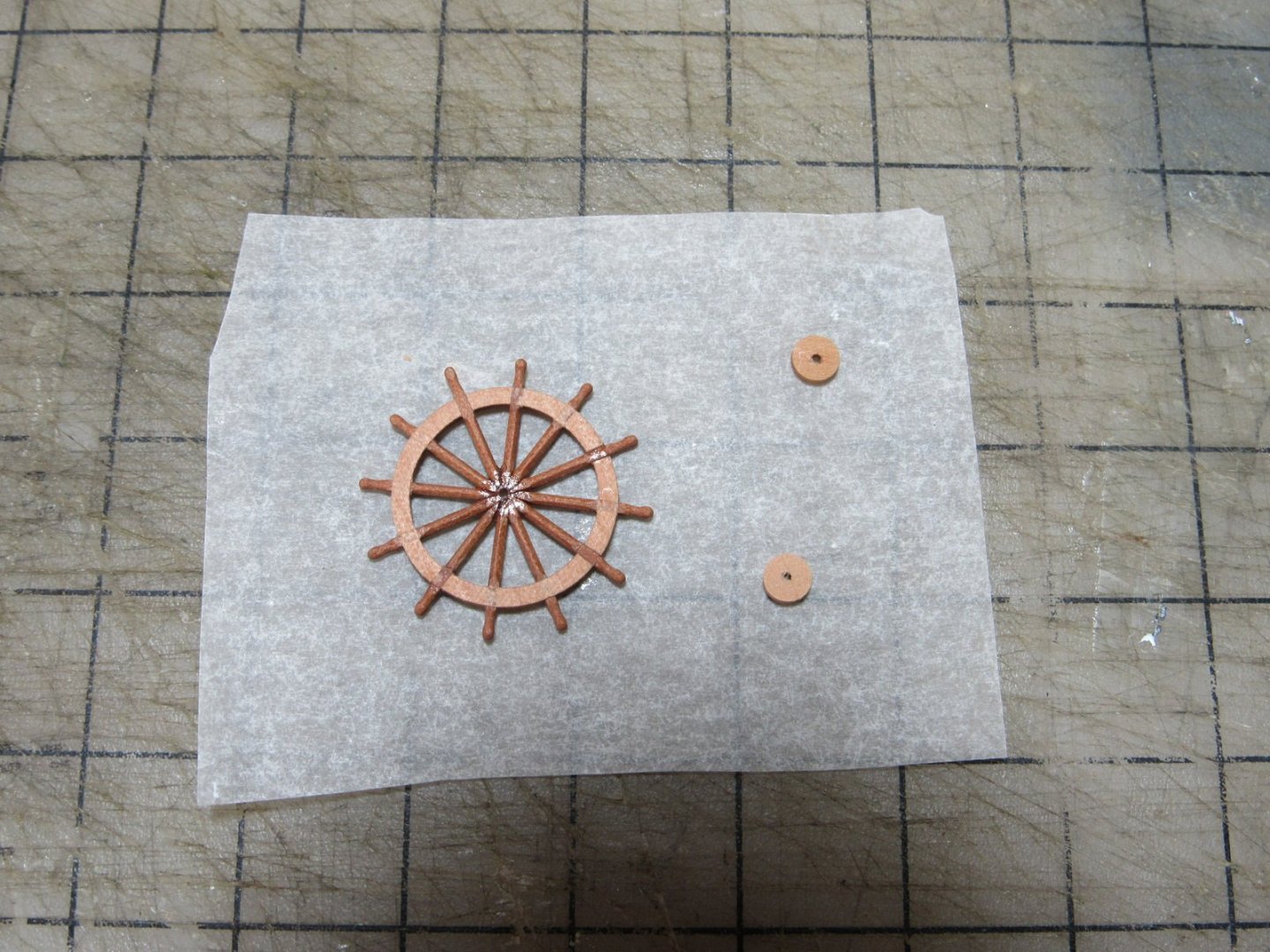

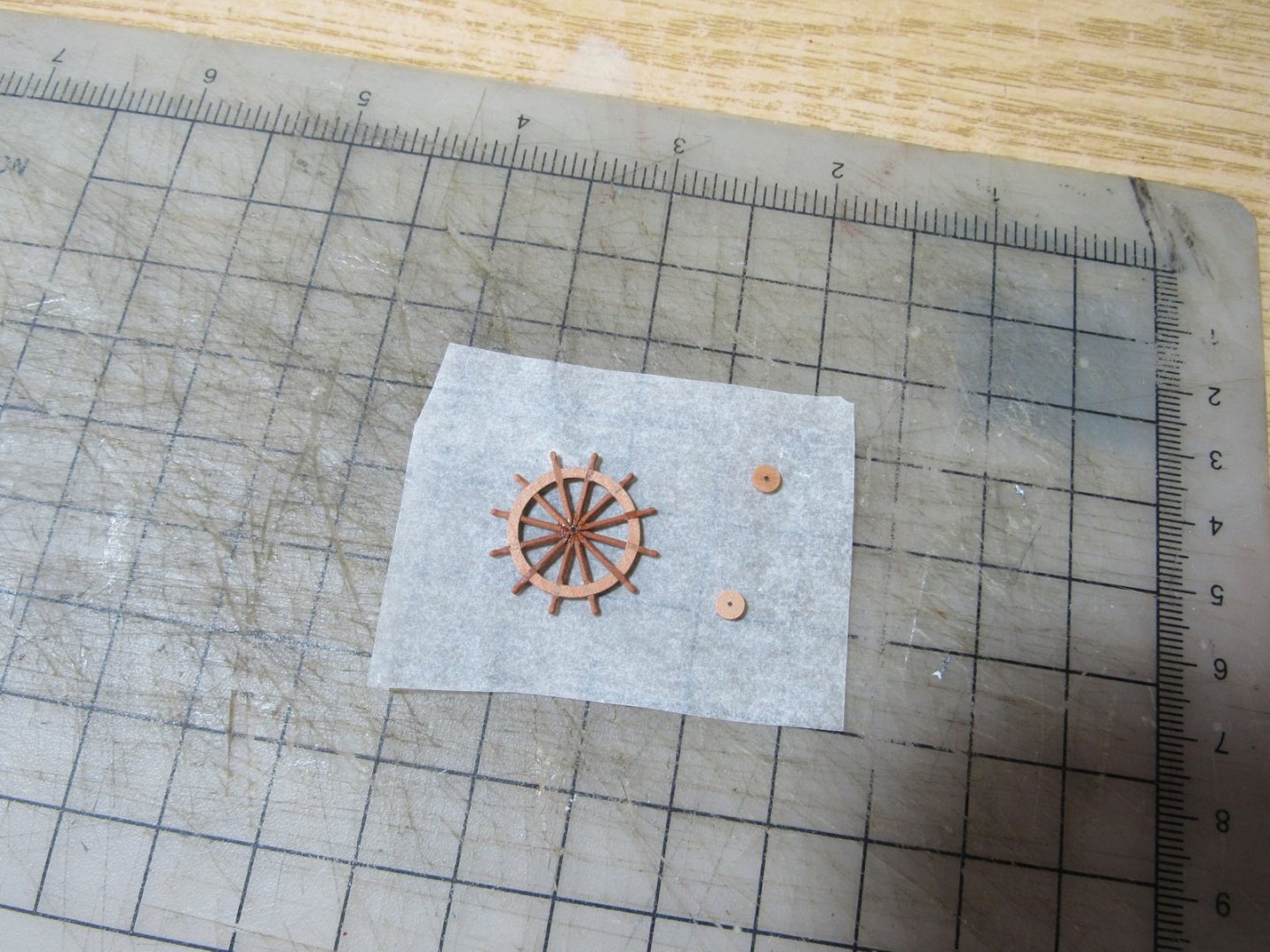

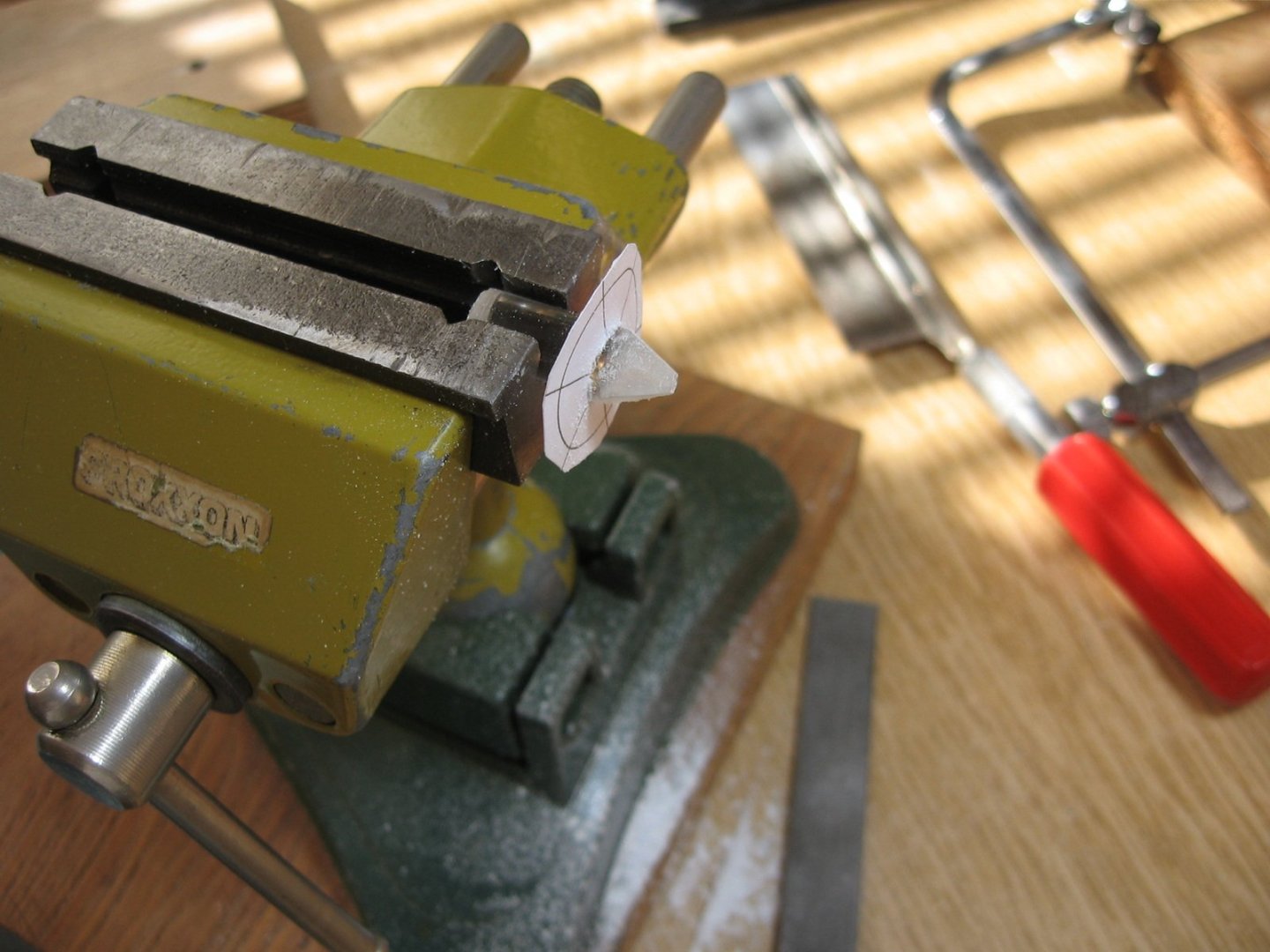

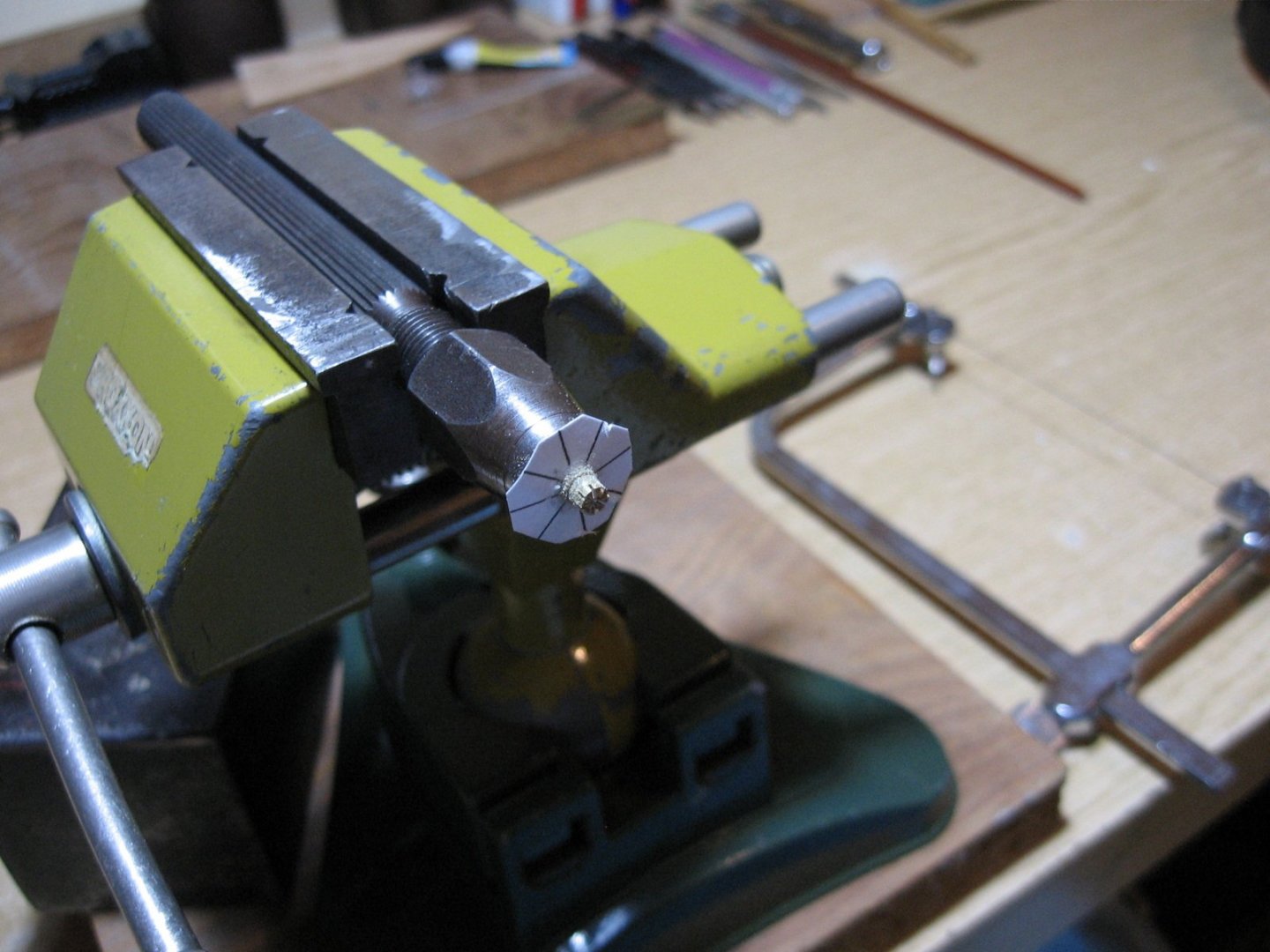

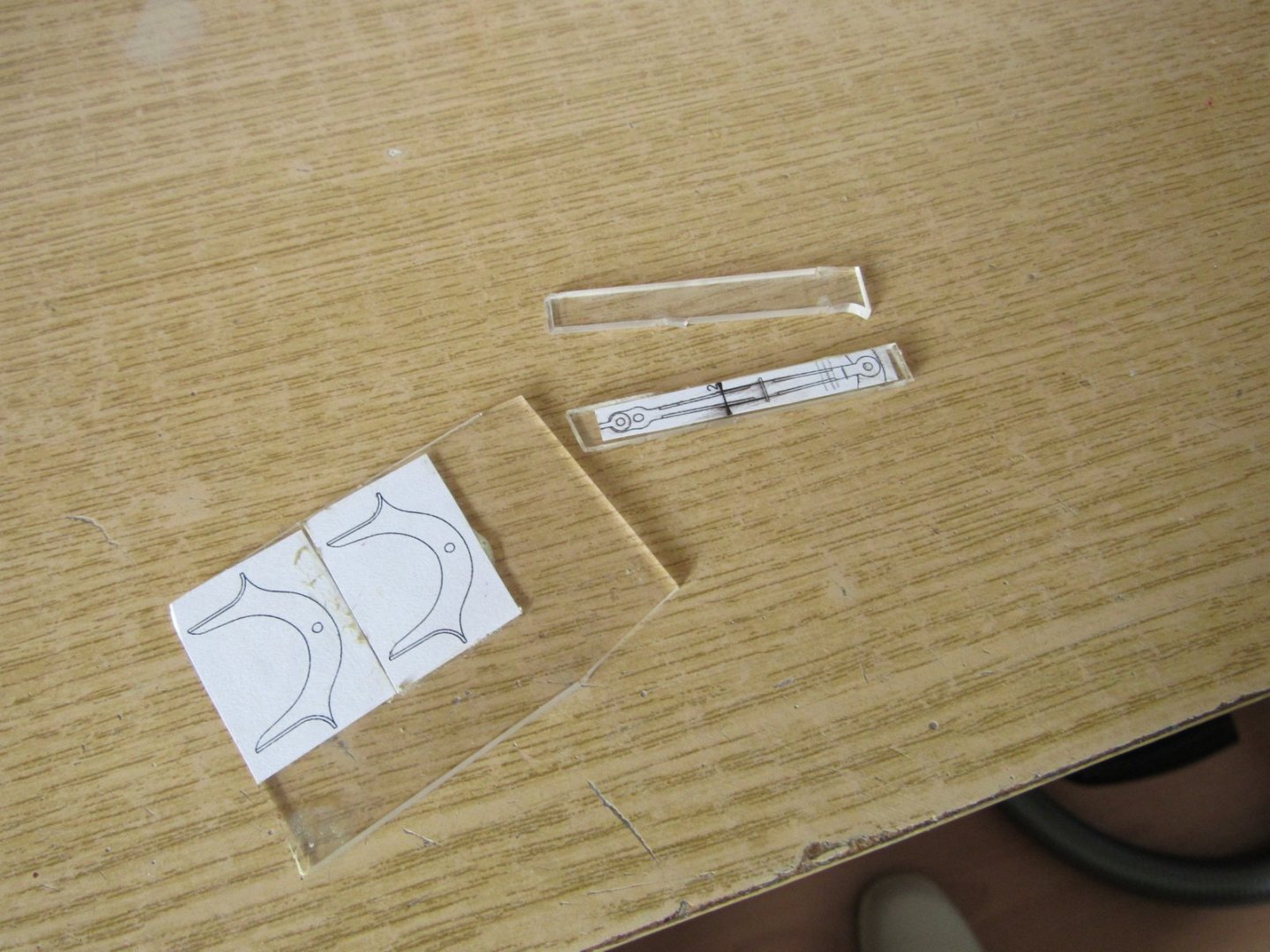

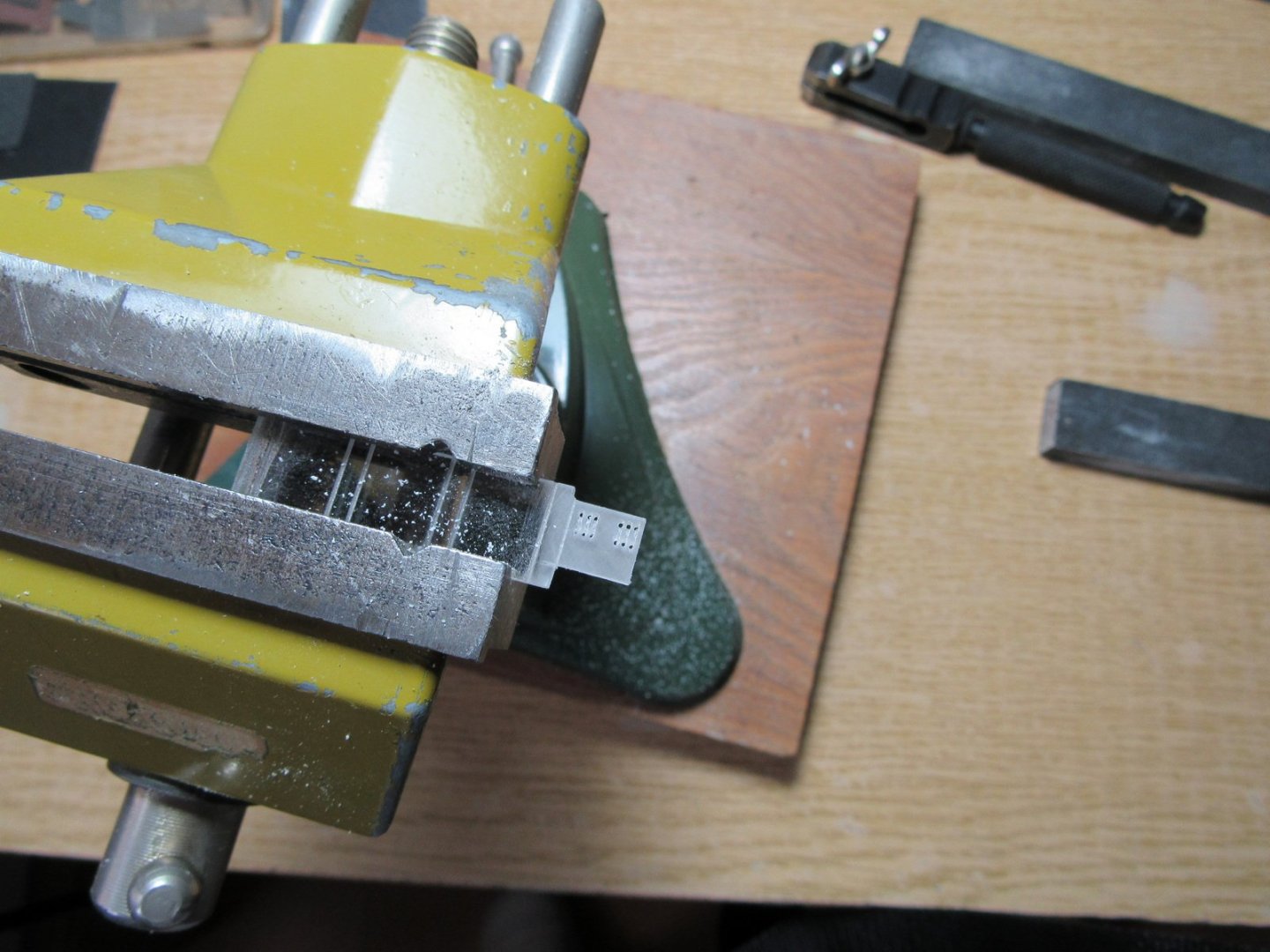

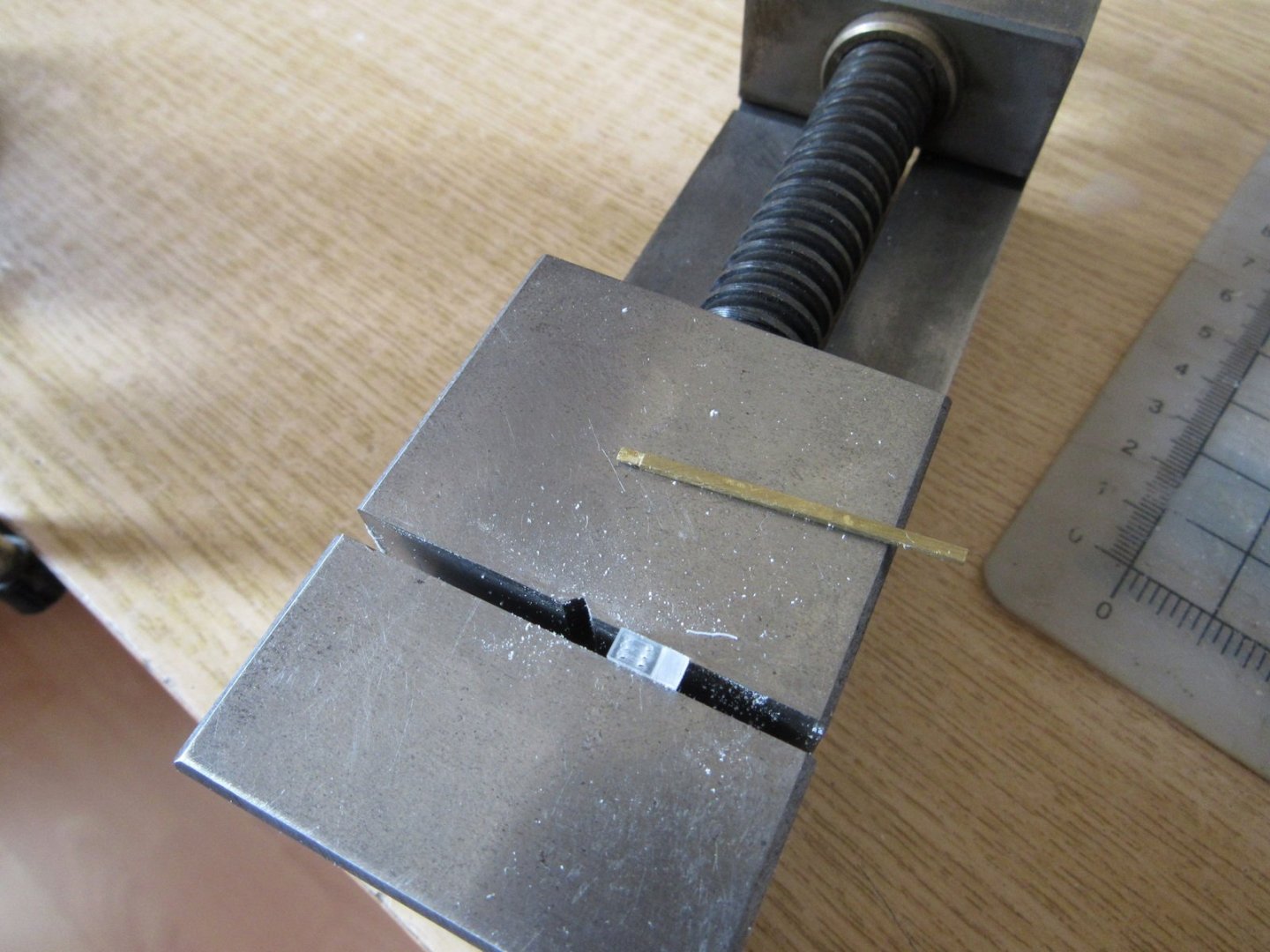

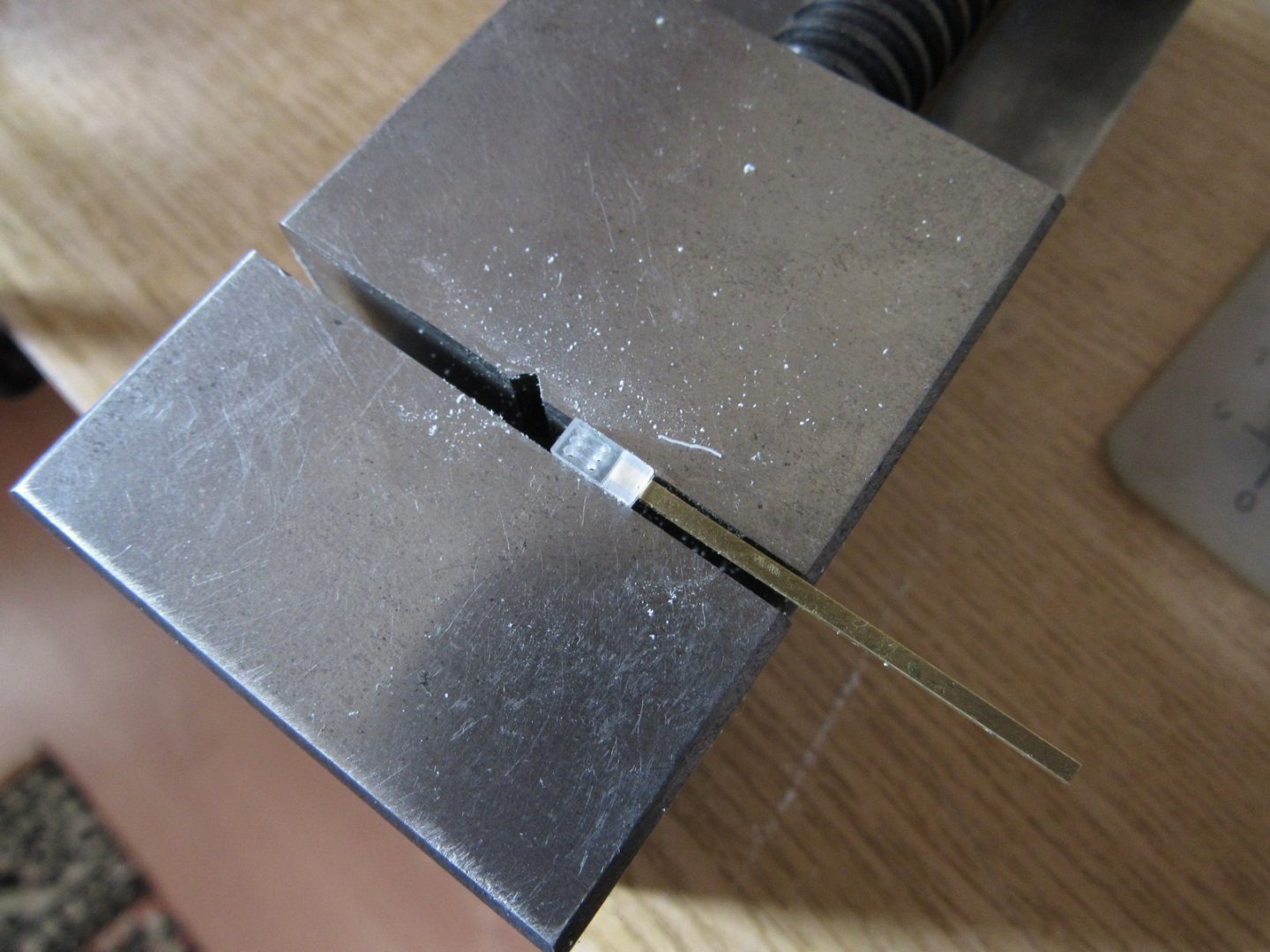

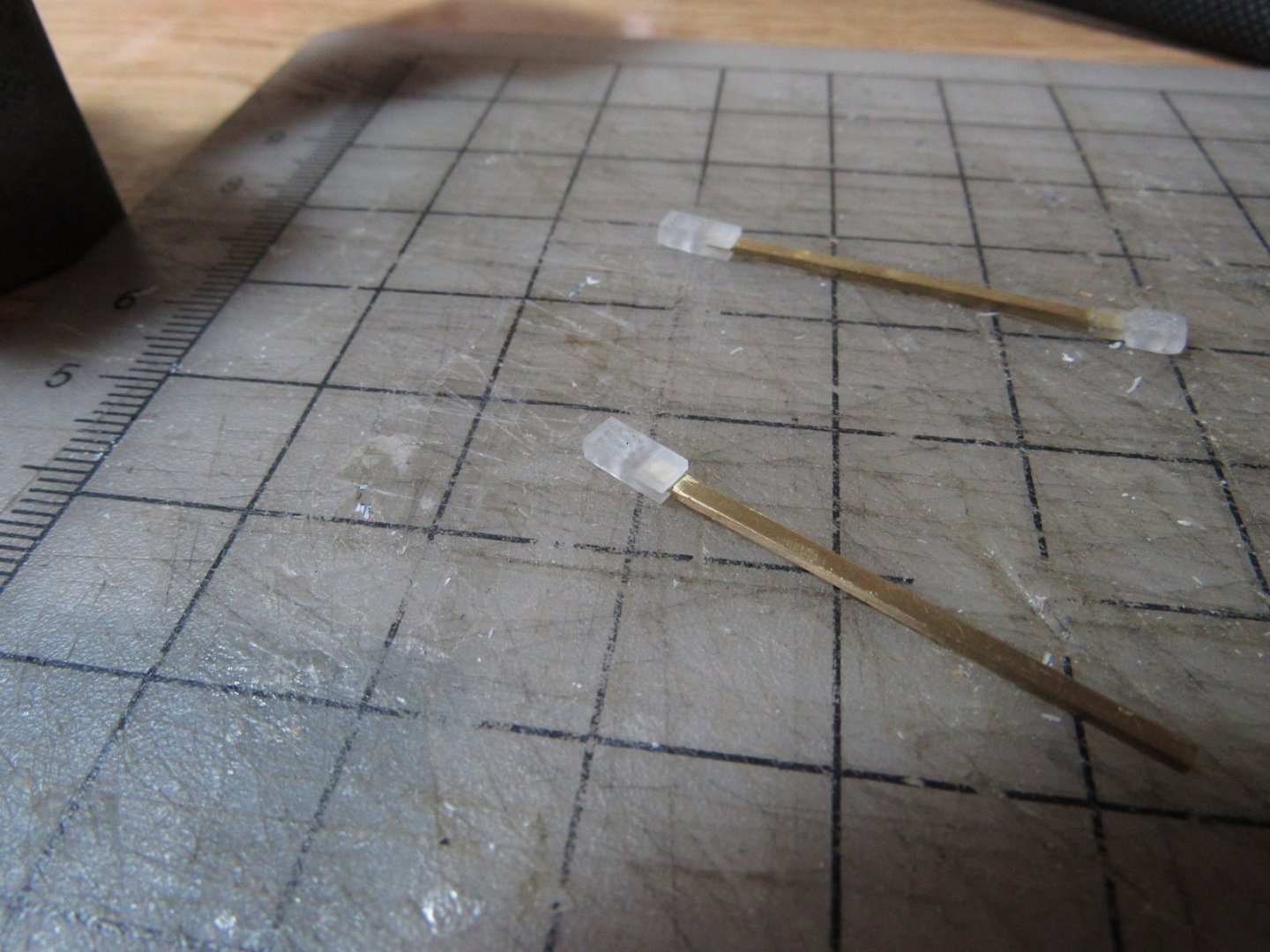

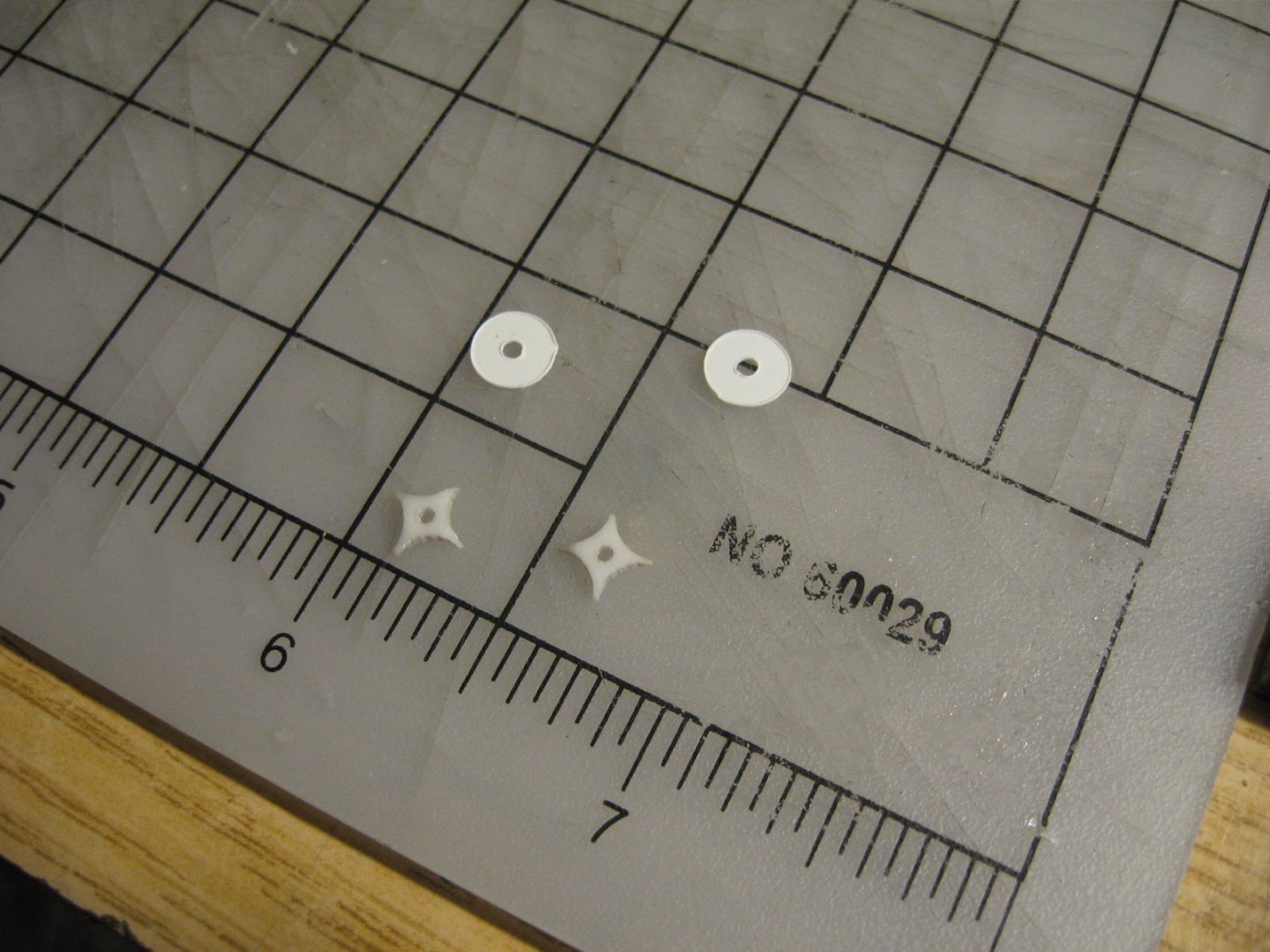

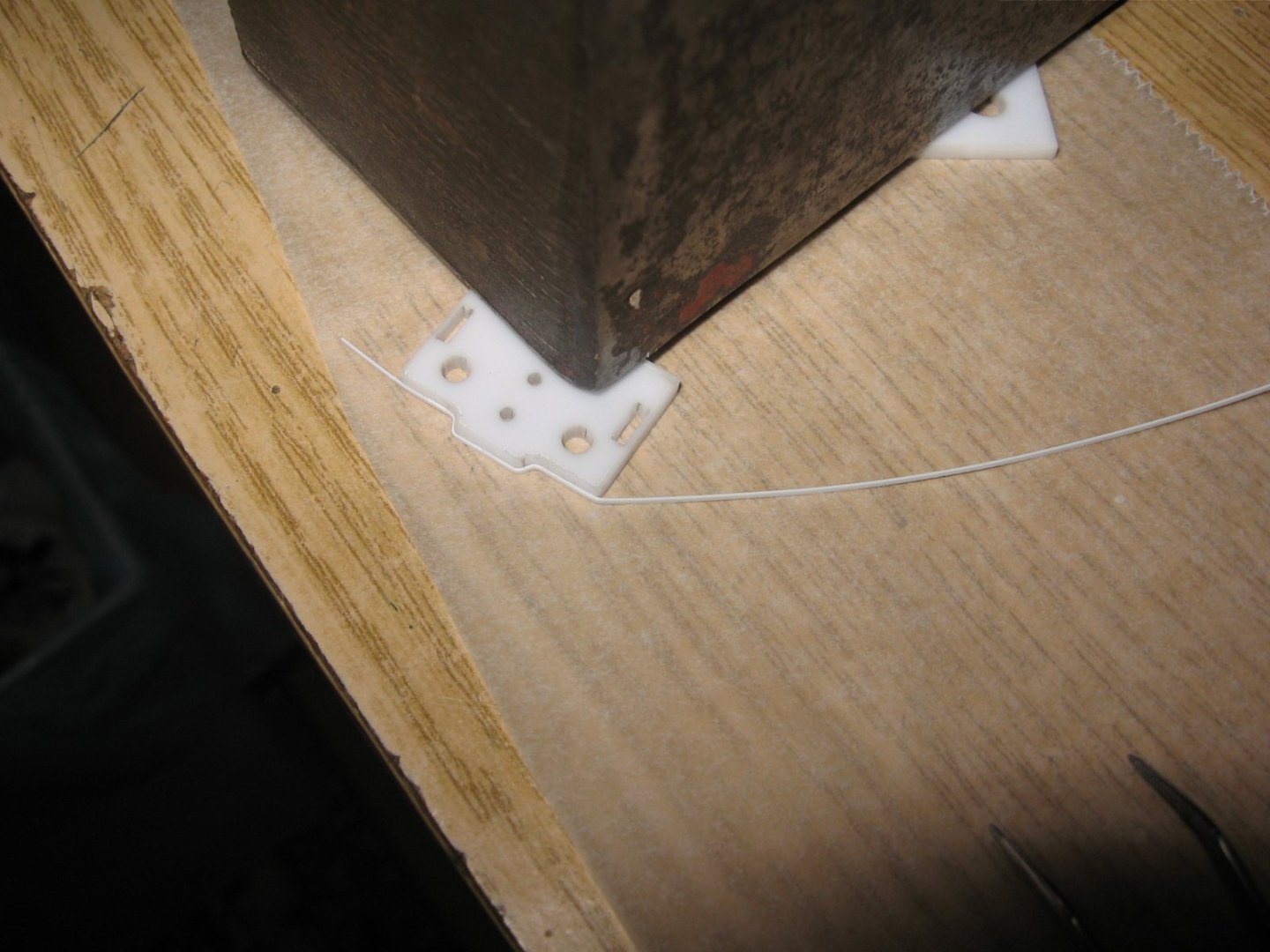

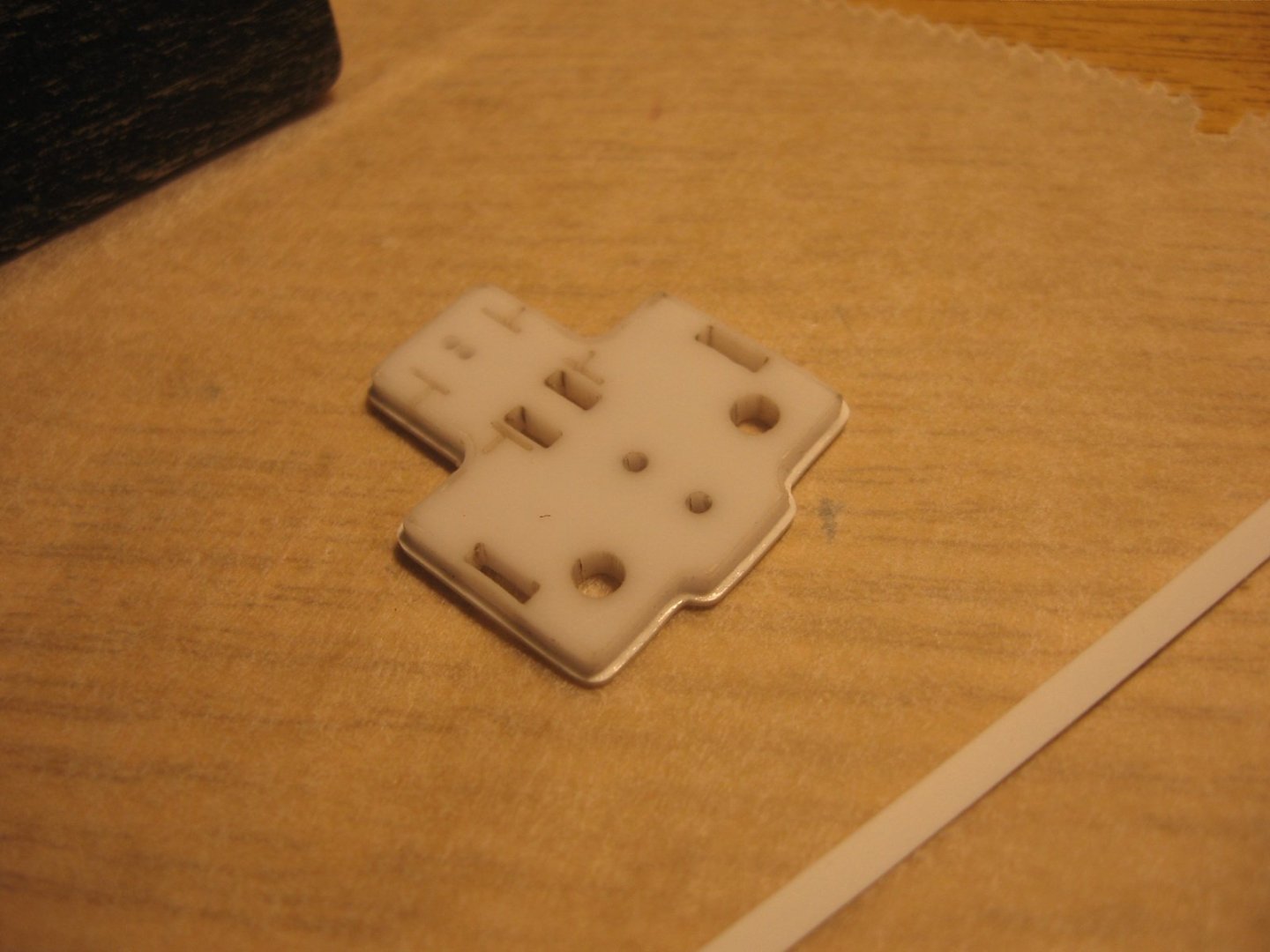

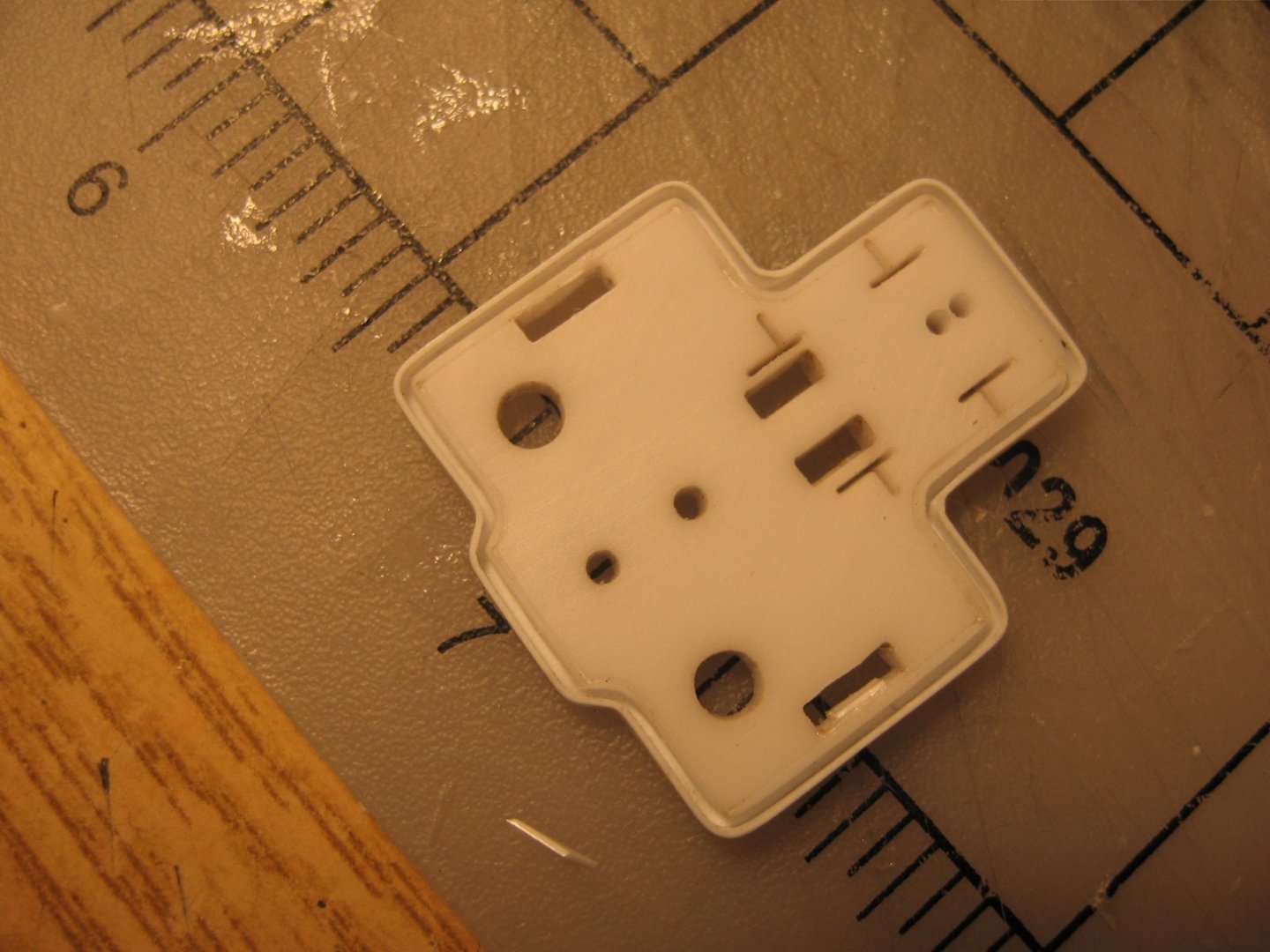

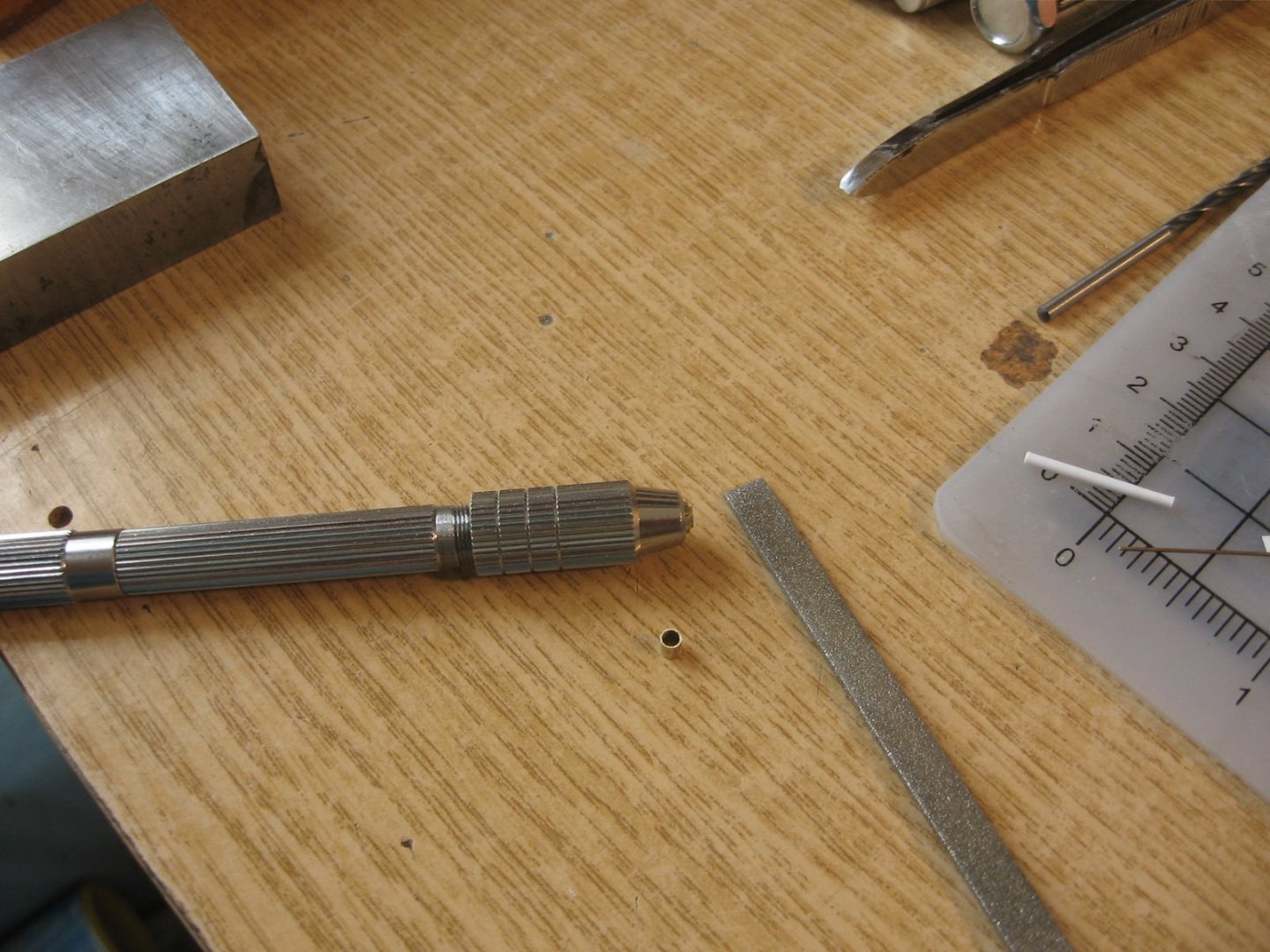

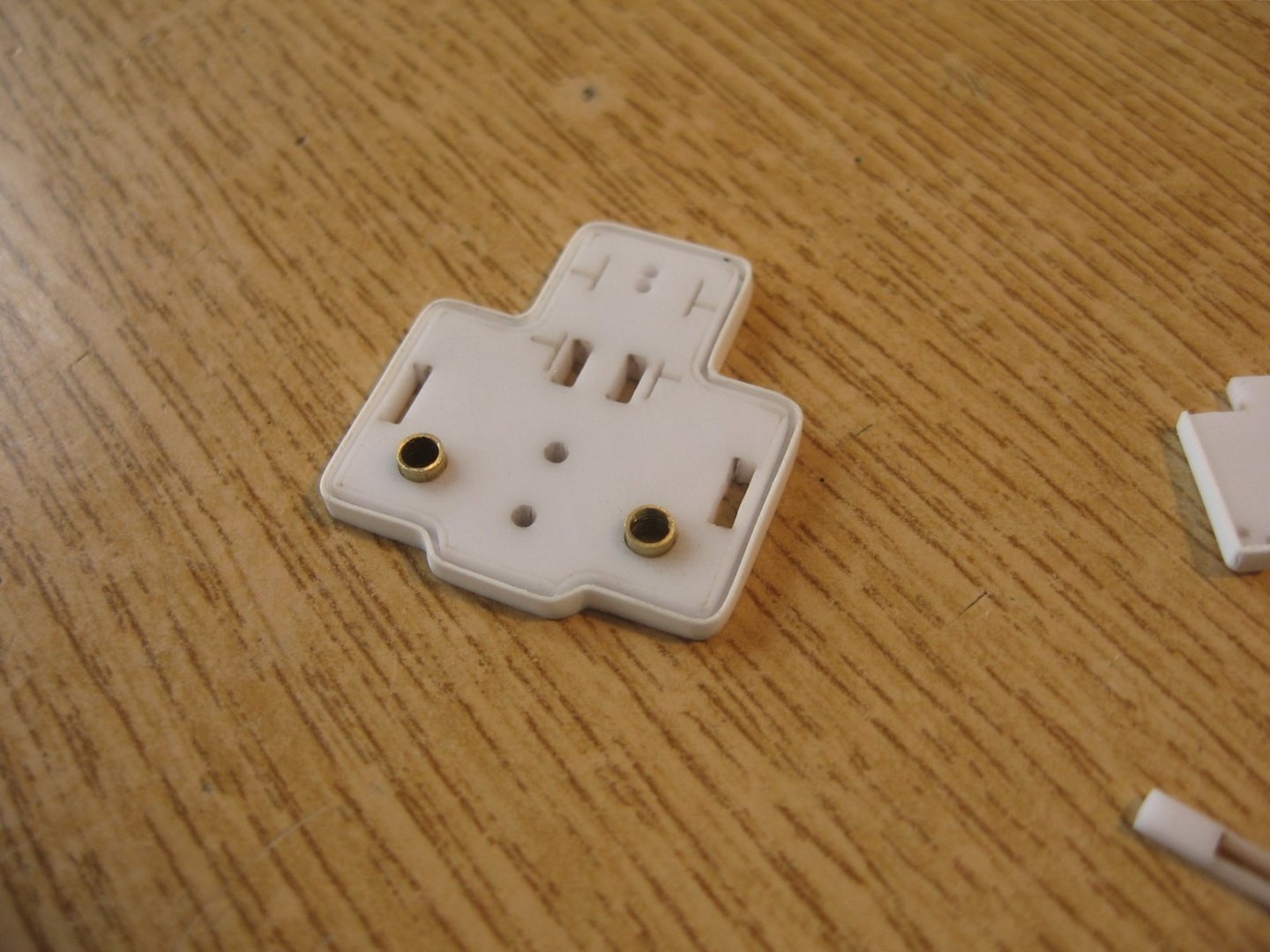

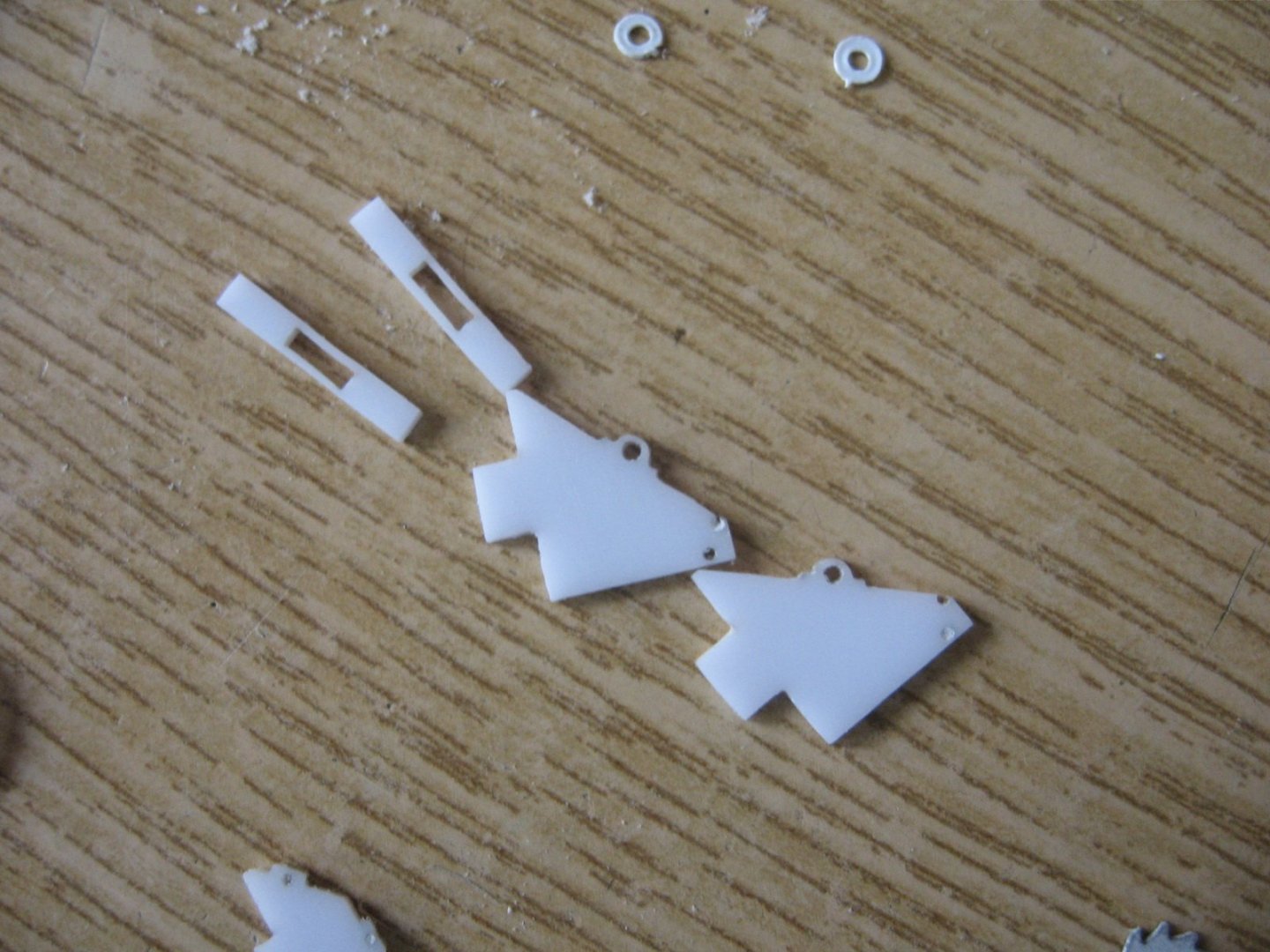

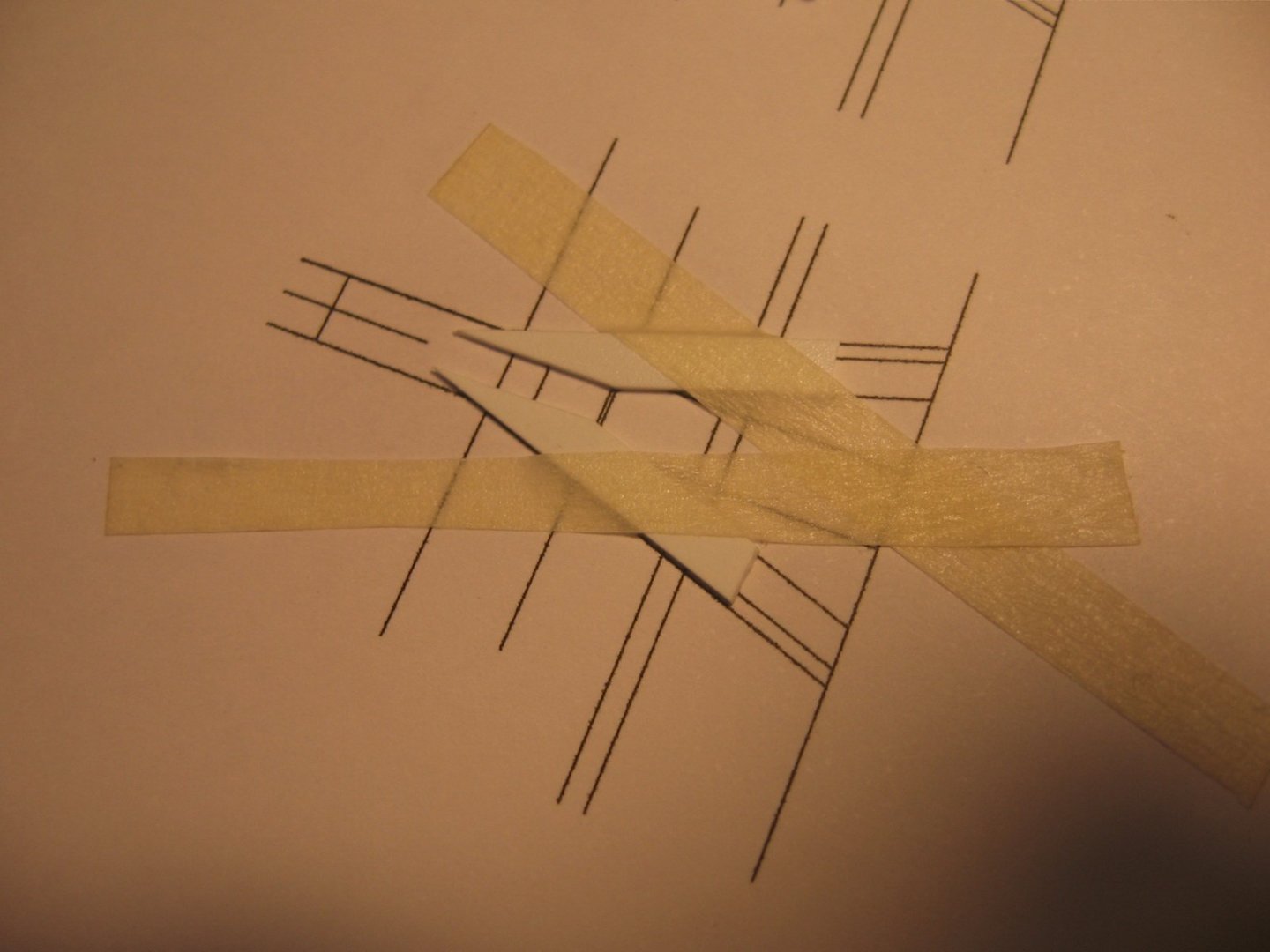

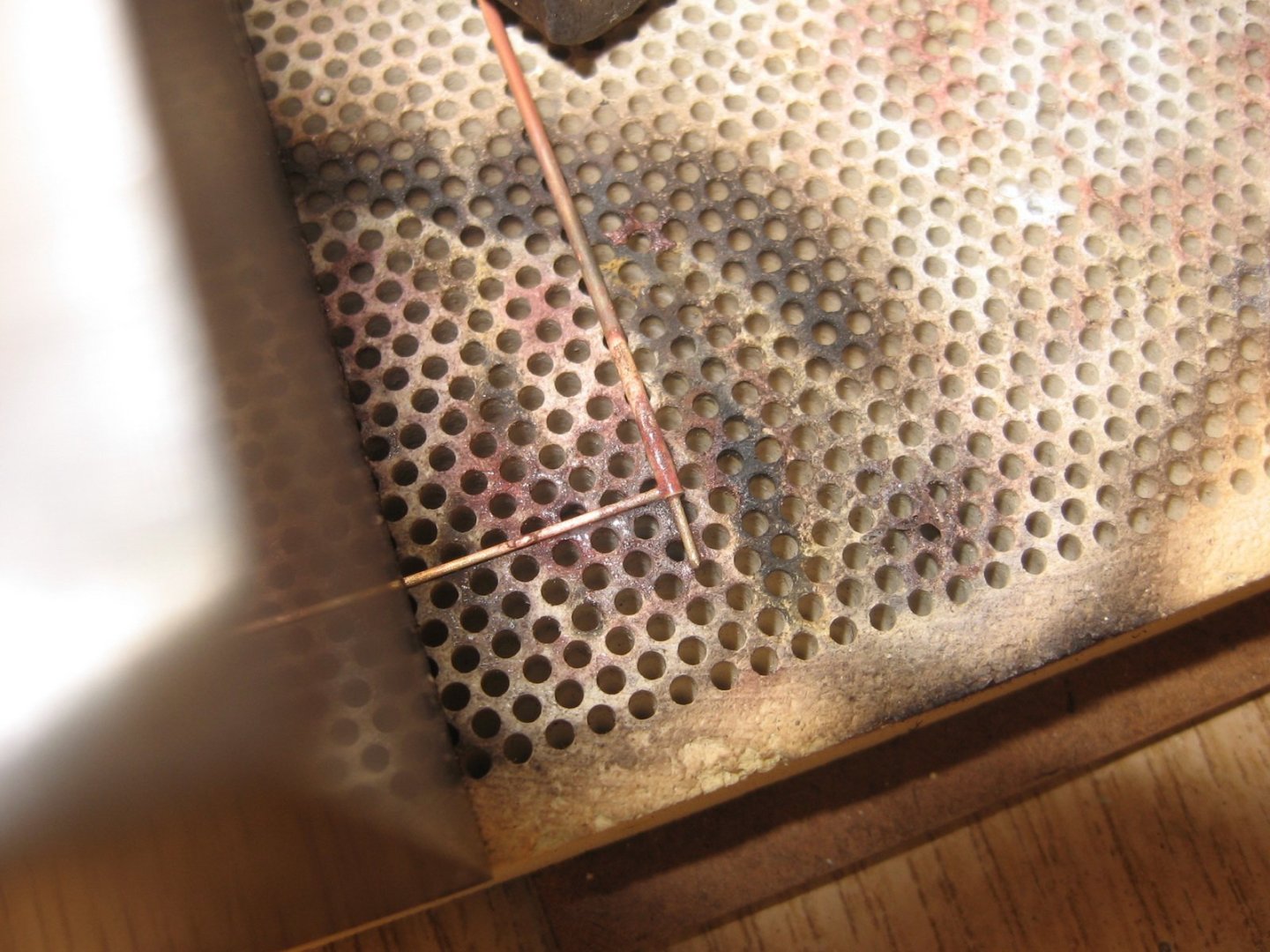

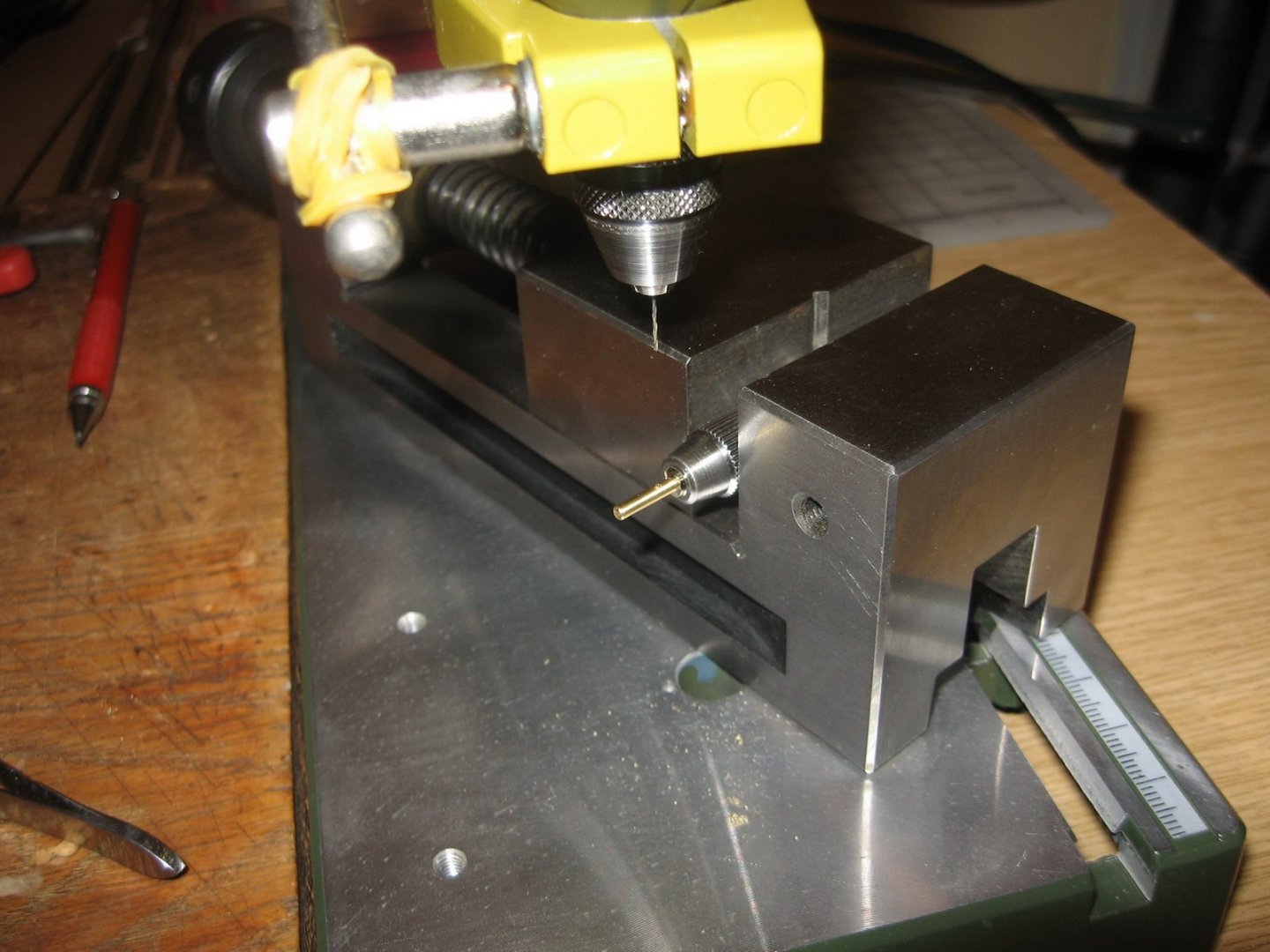

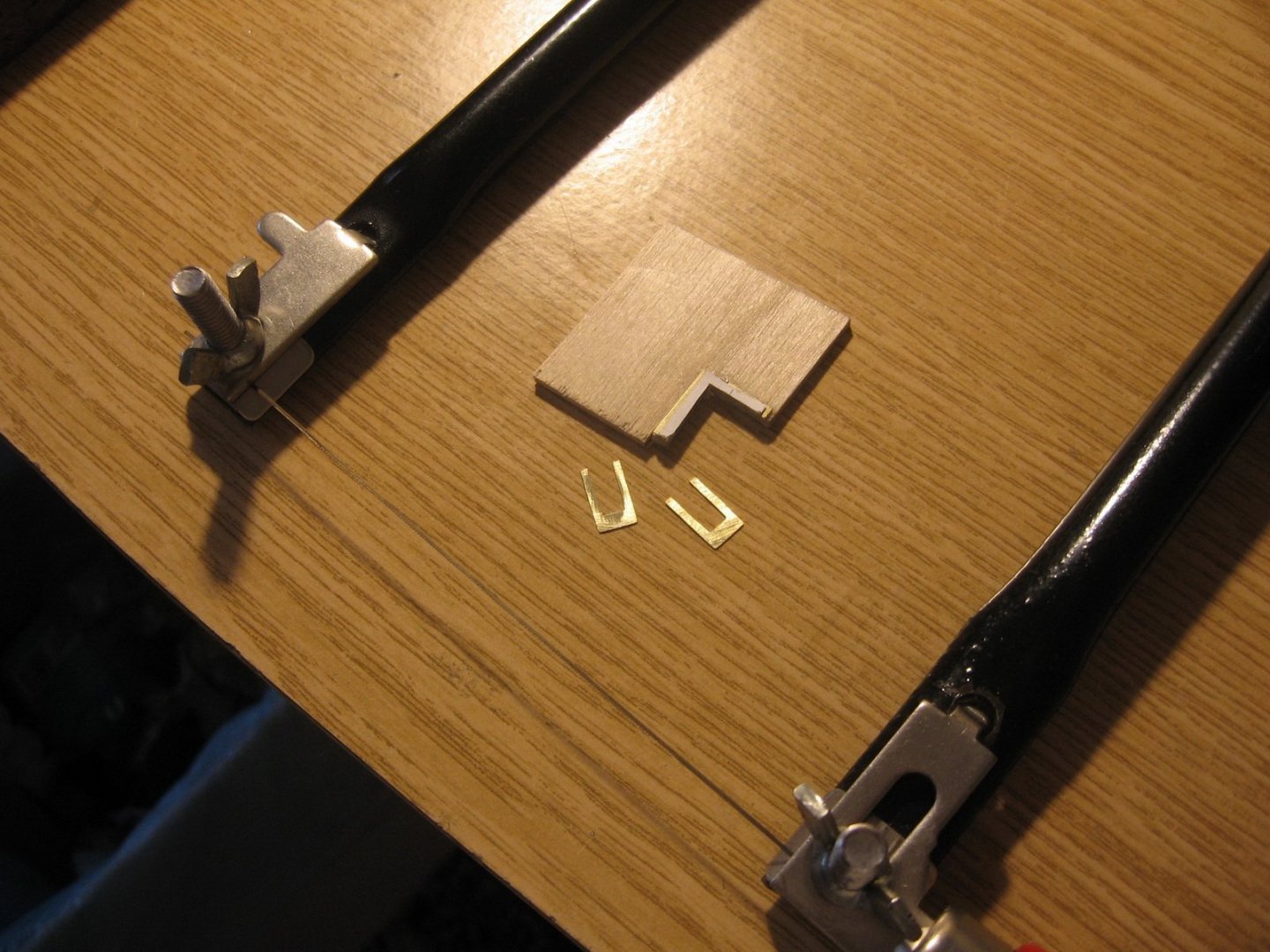

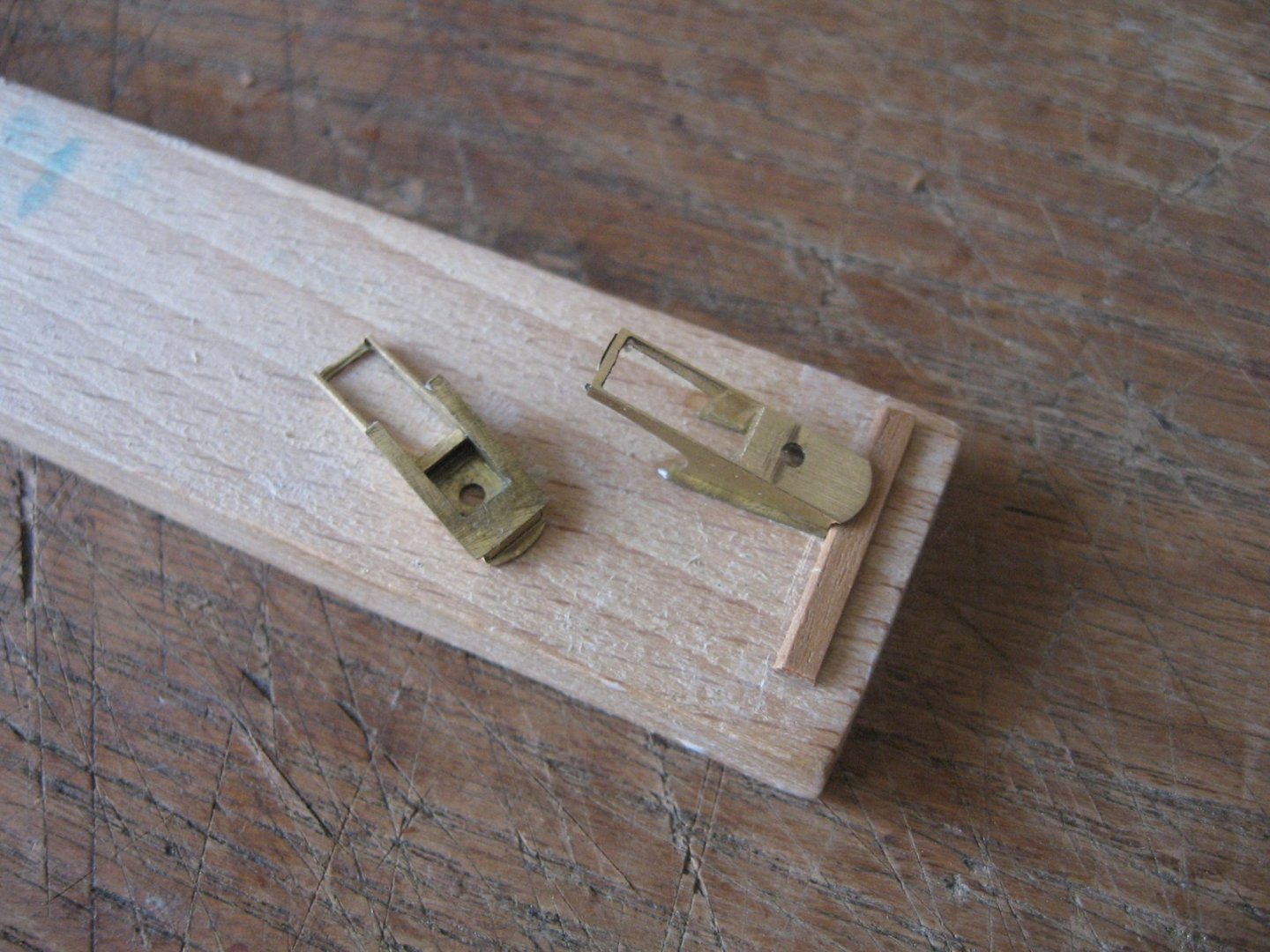

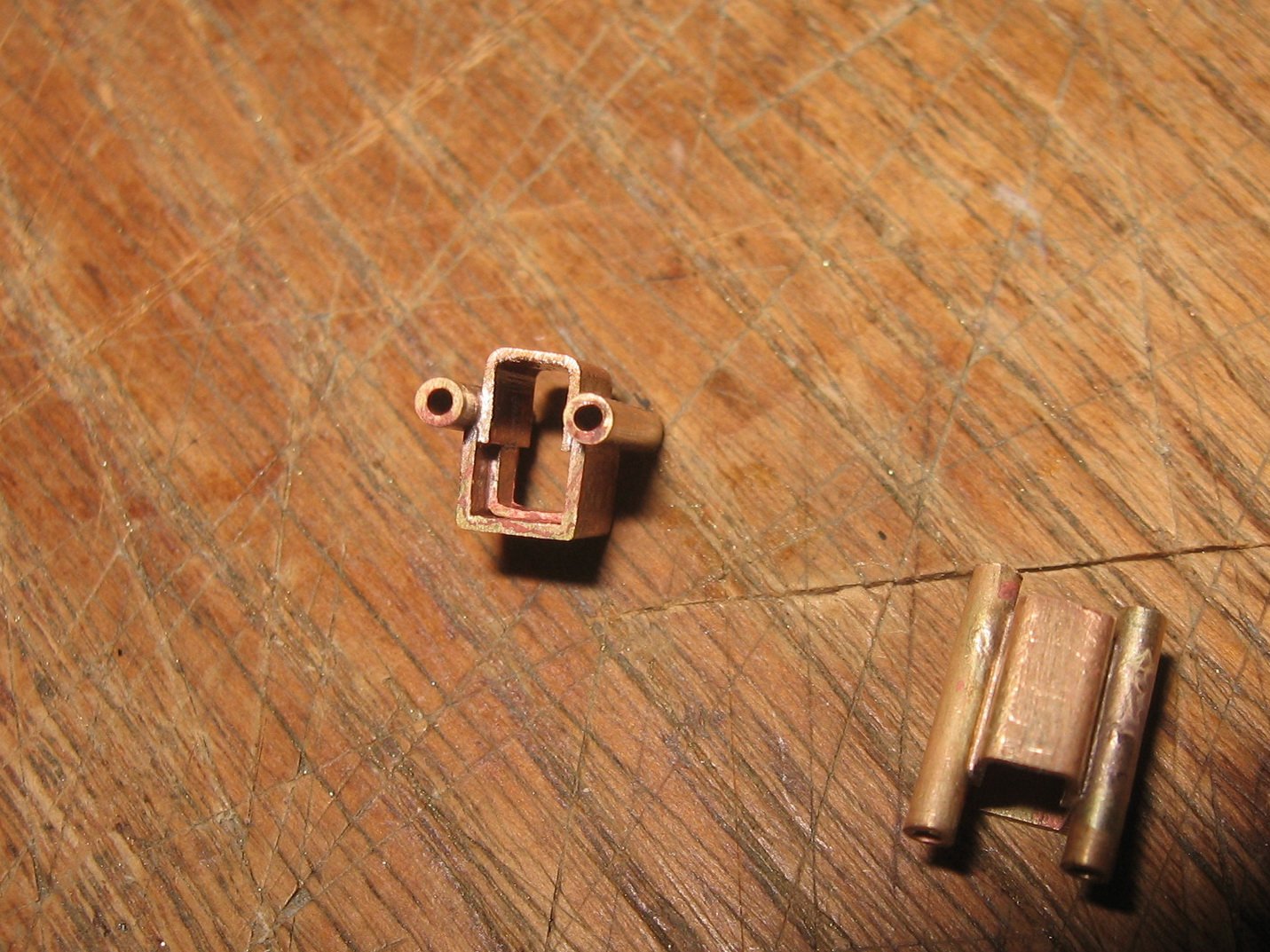

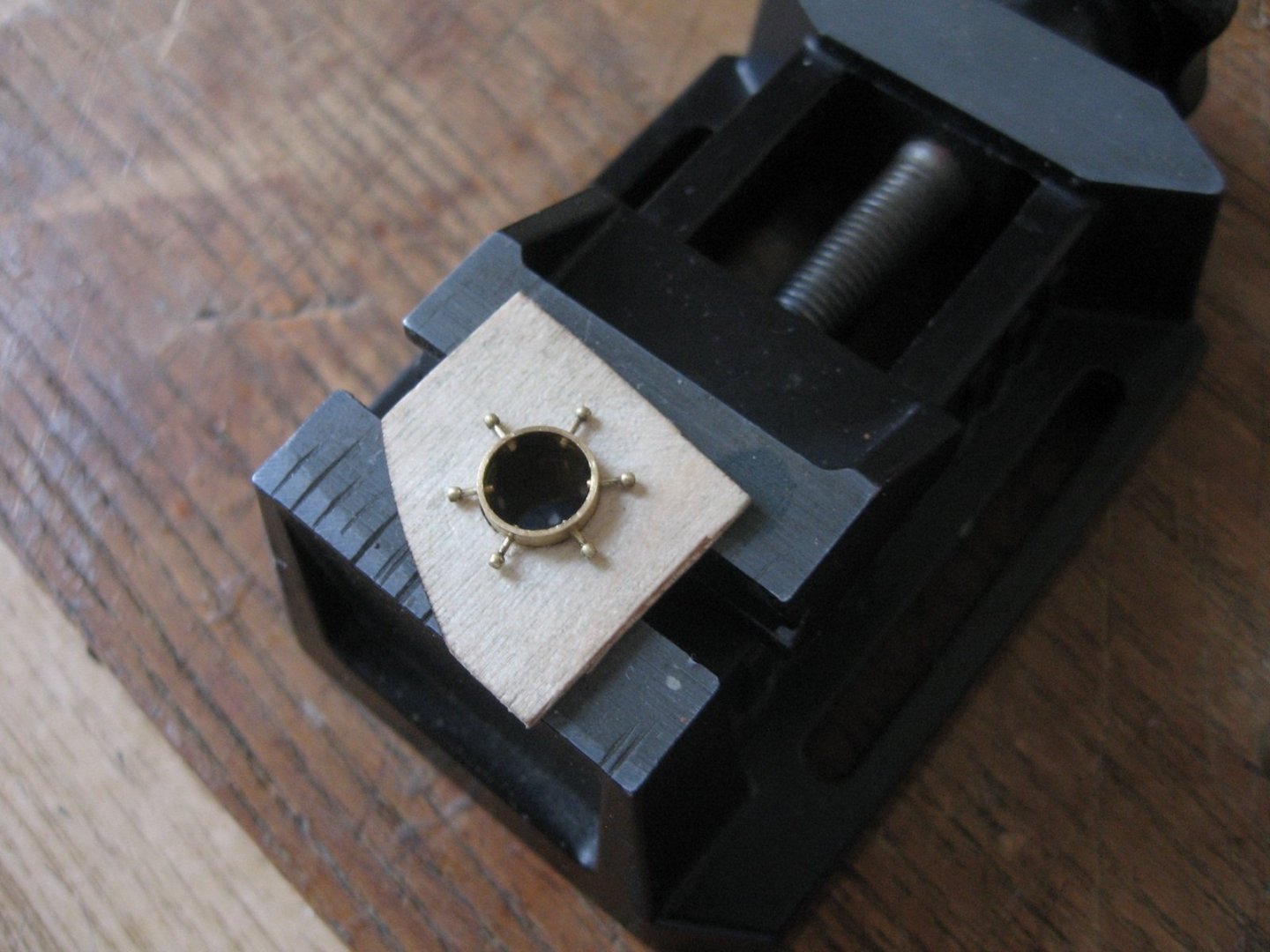

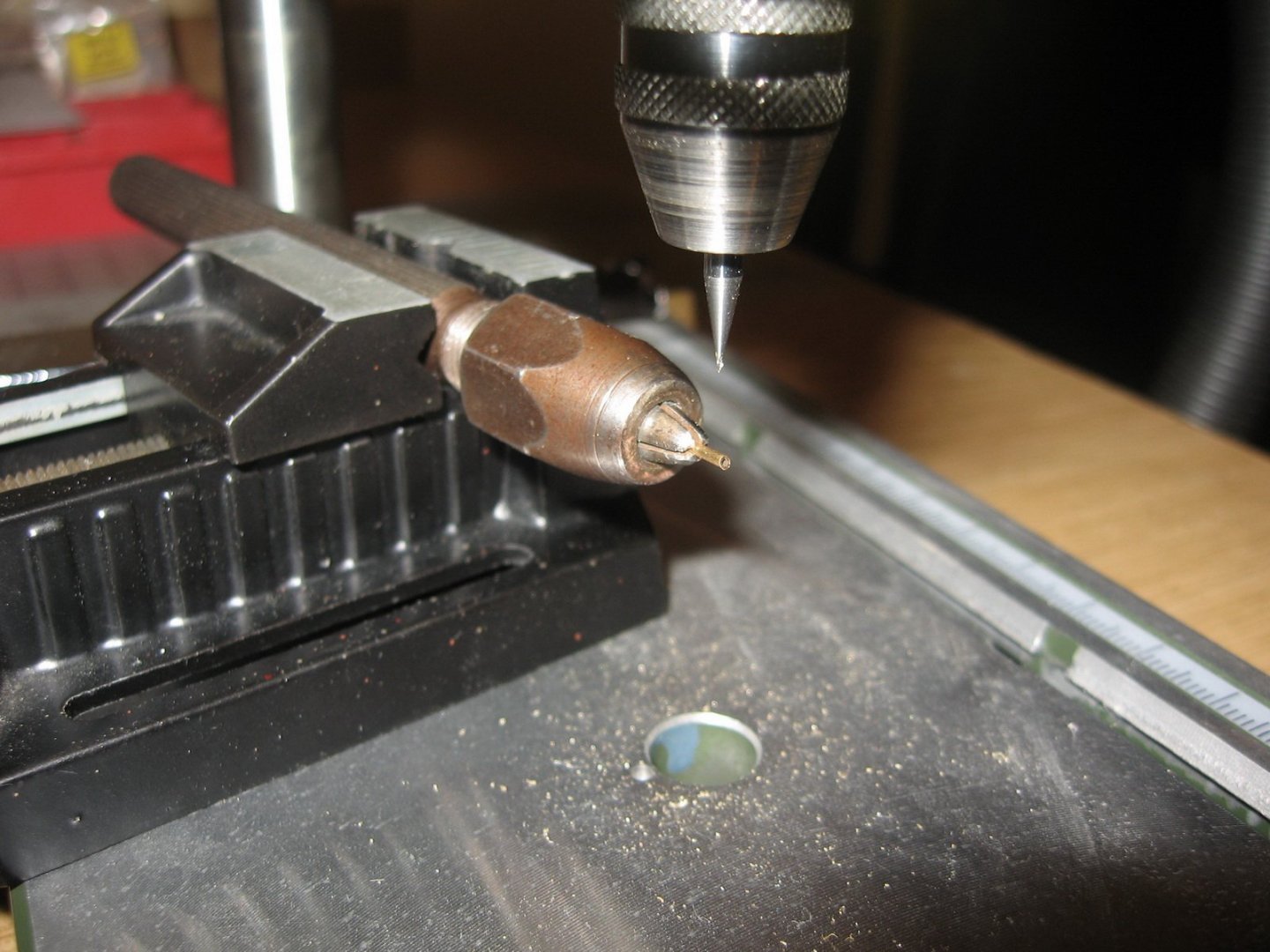

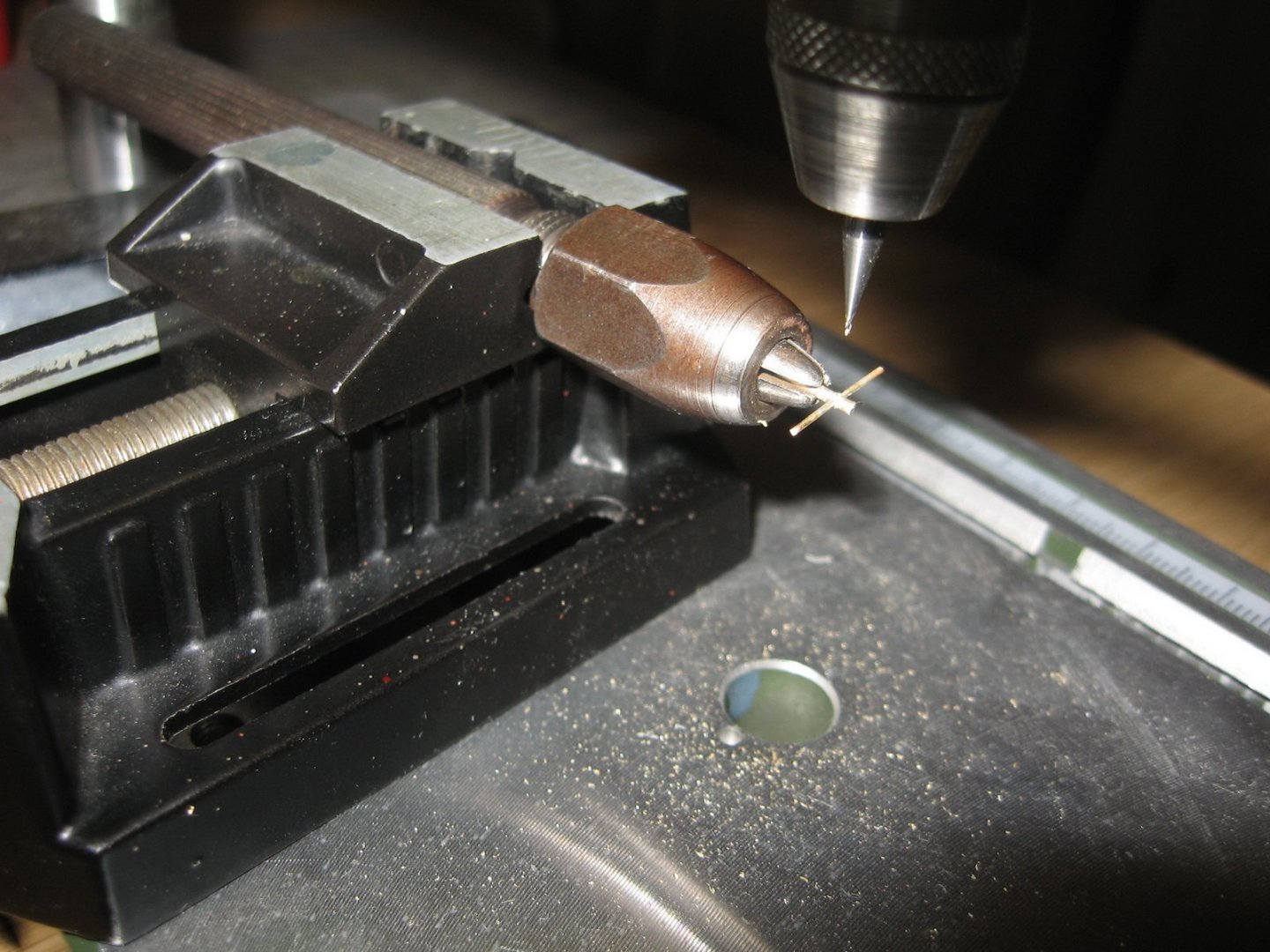

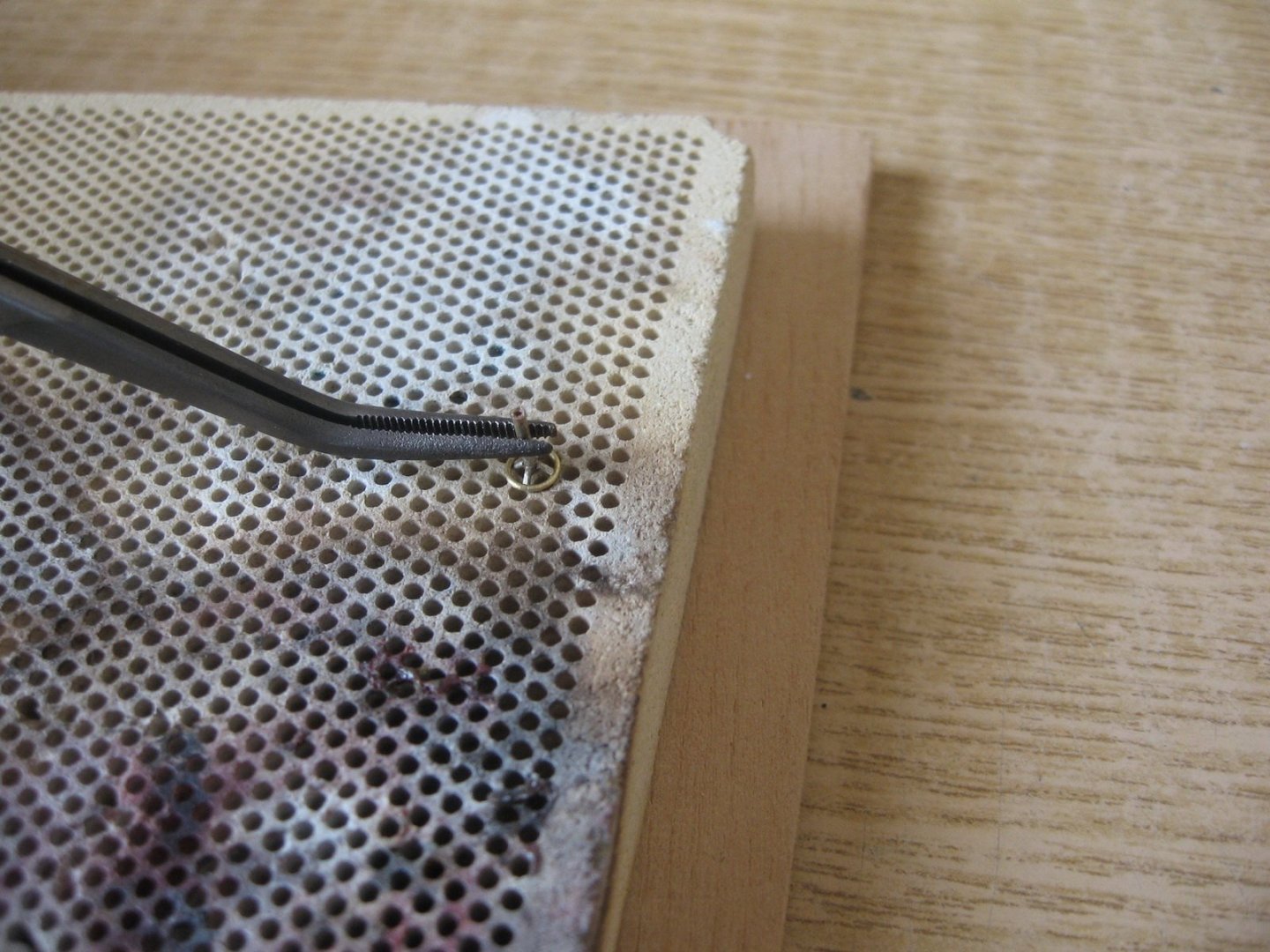

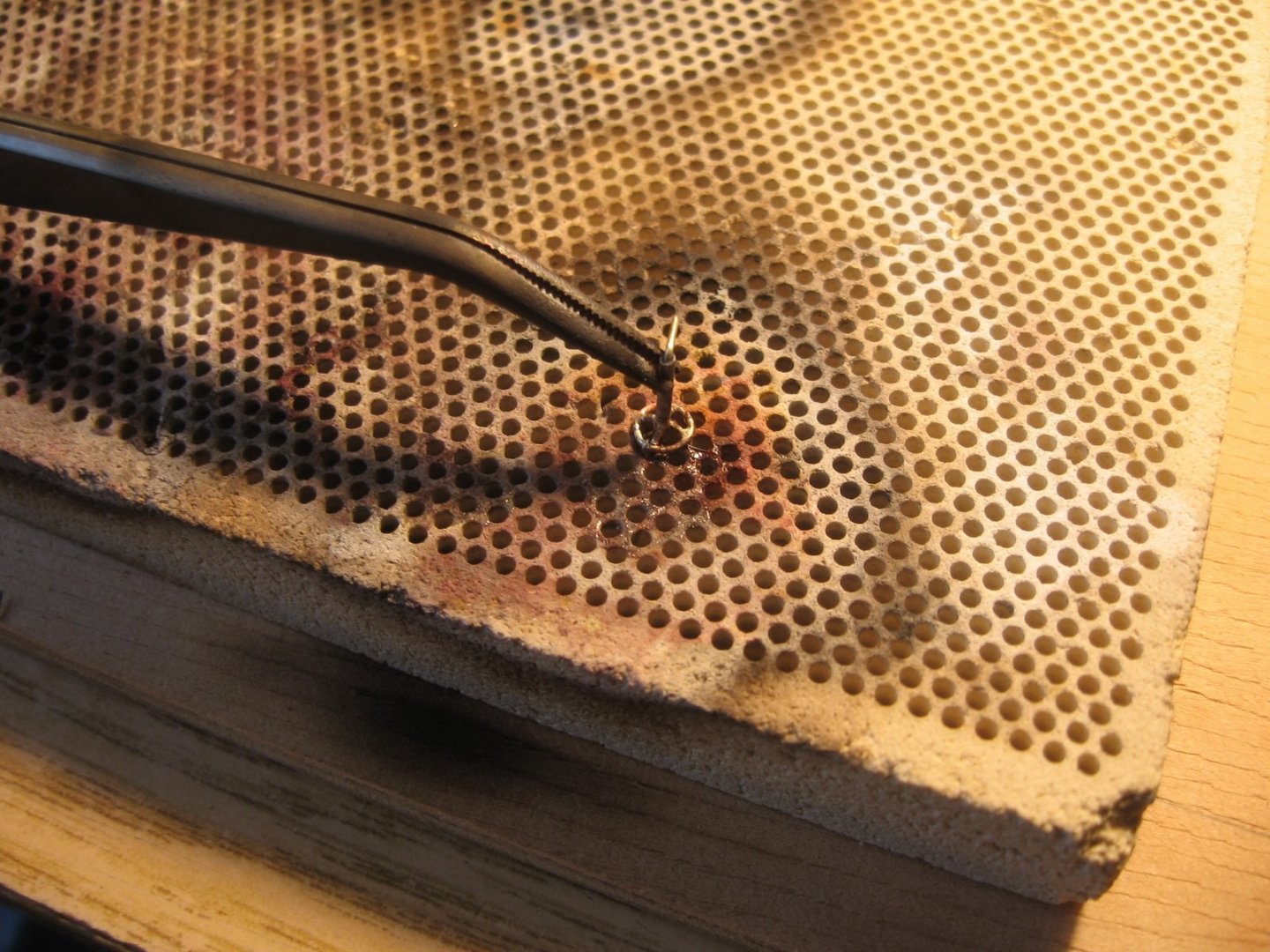

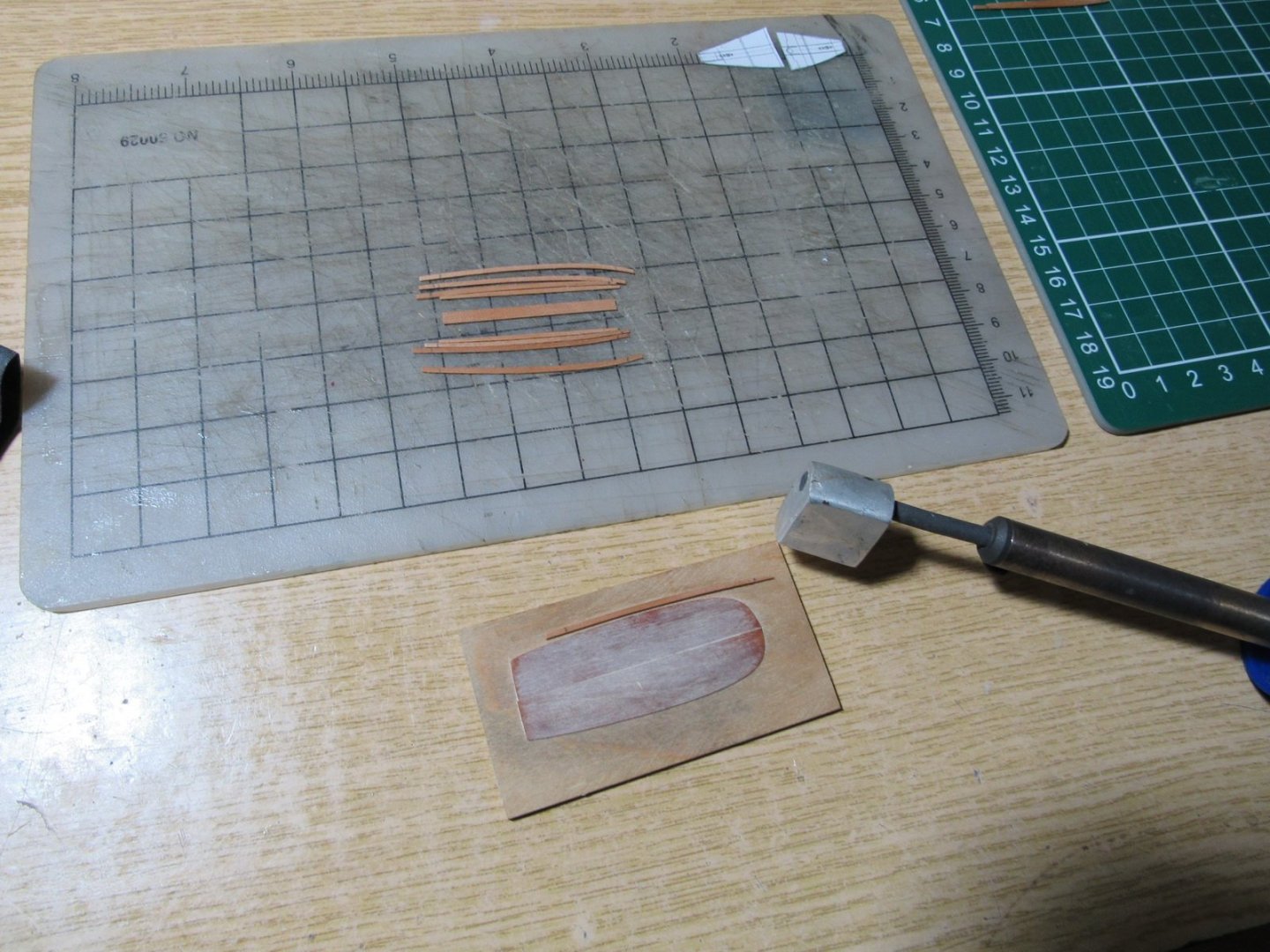

No Pat, sorry, my mistake. I did not have photo etching at this "Loreley" log, it was here. I shared here how I've done it.

-

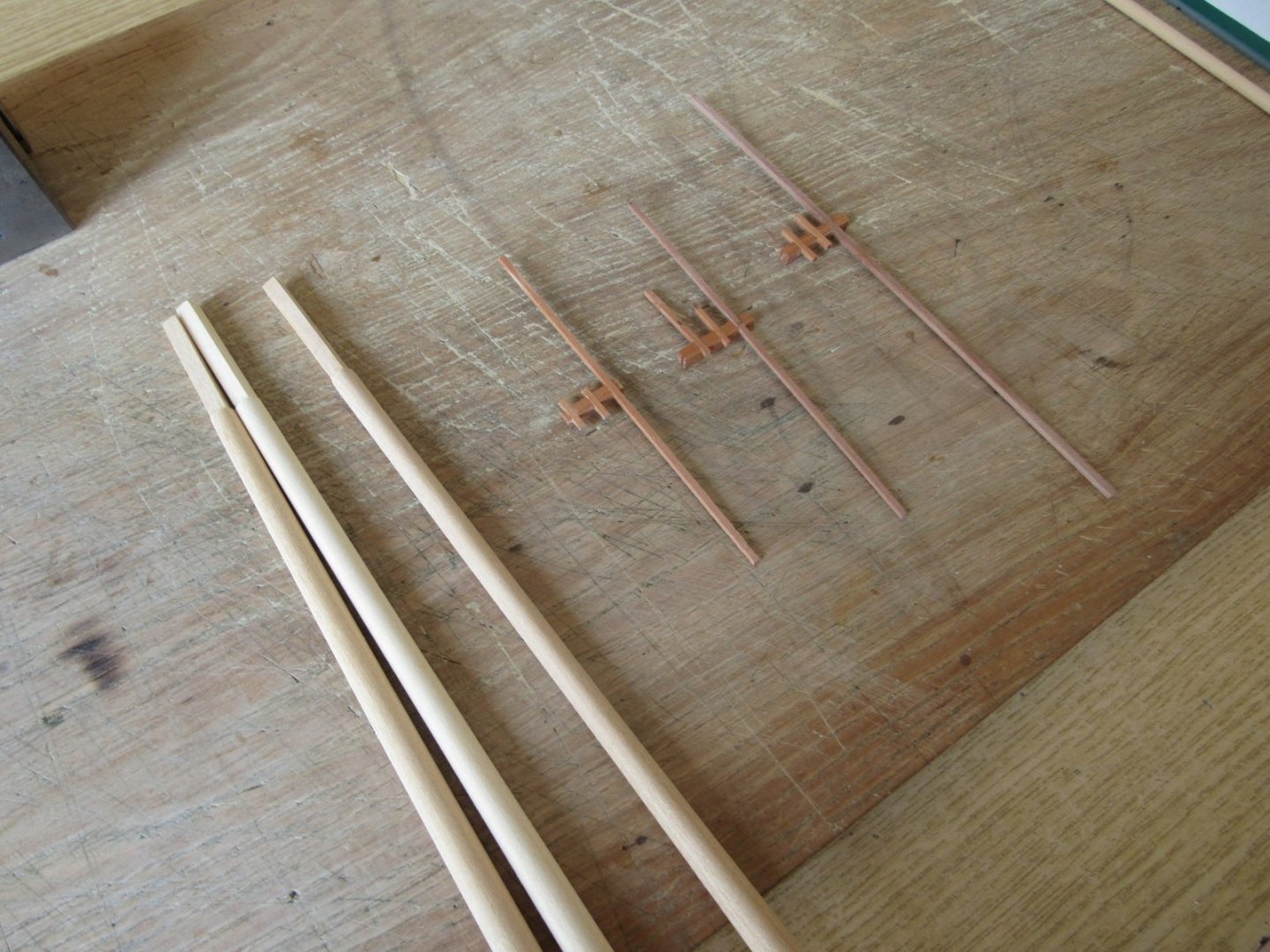

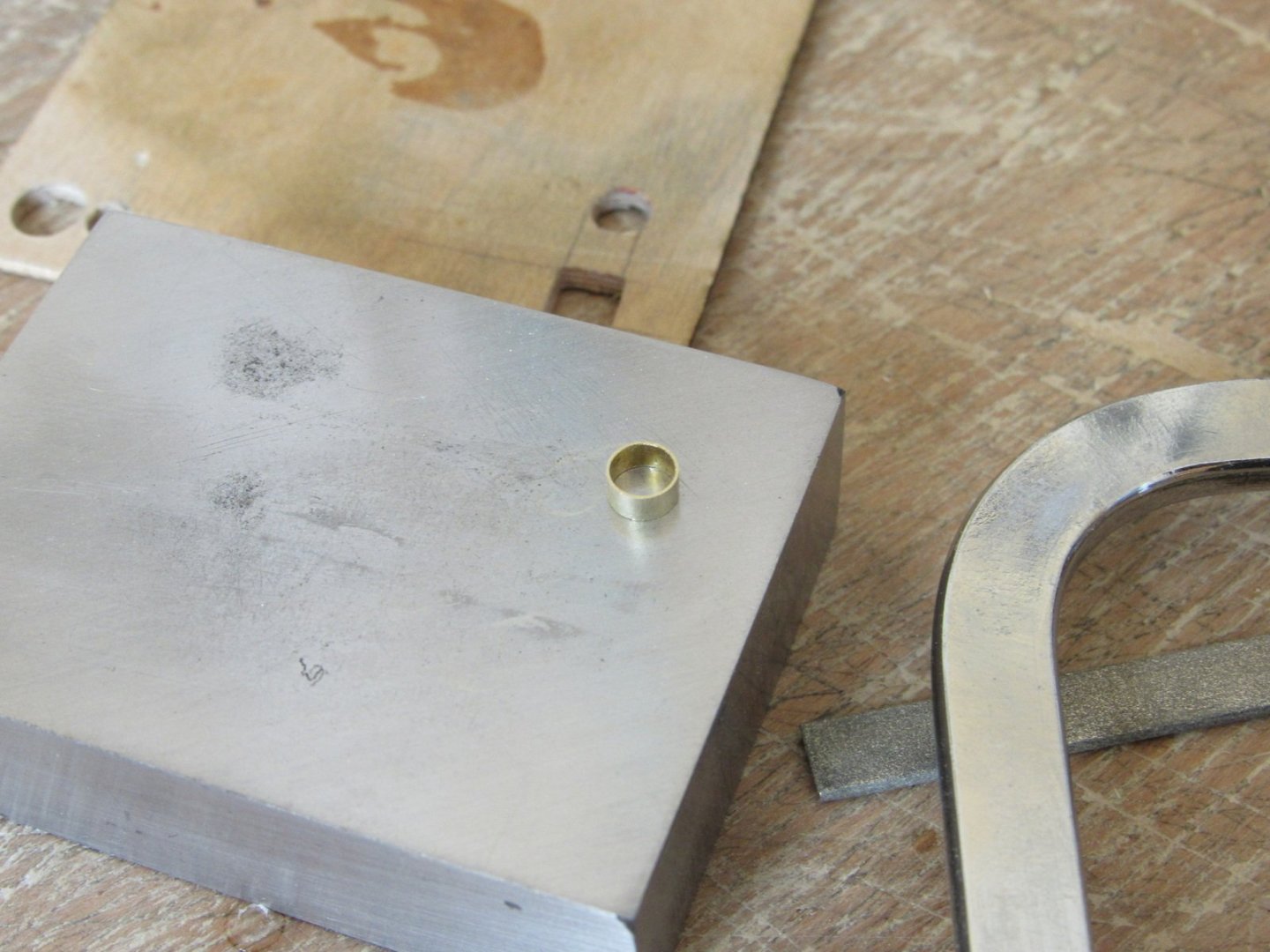

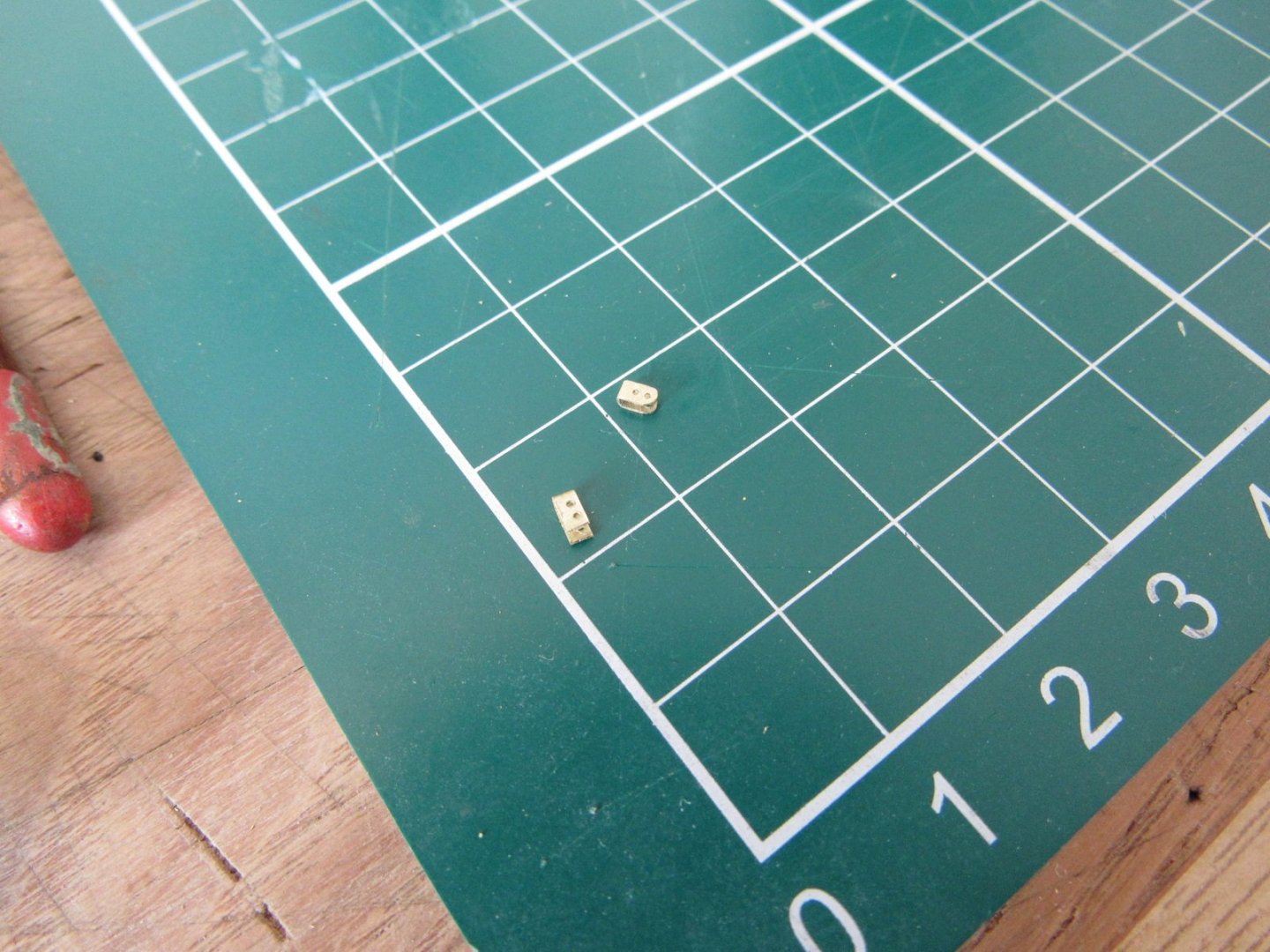

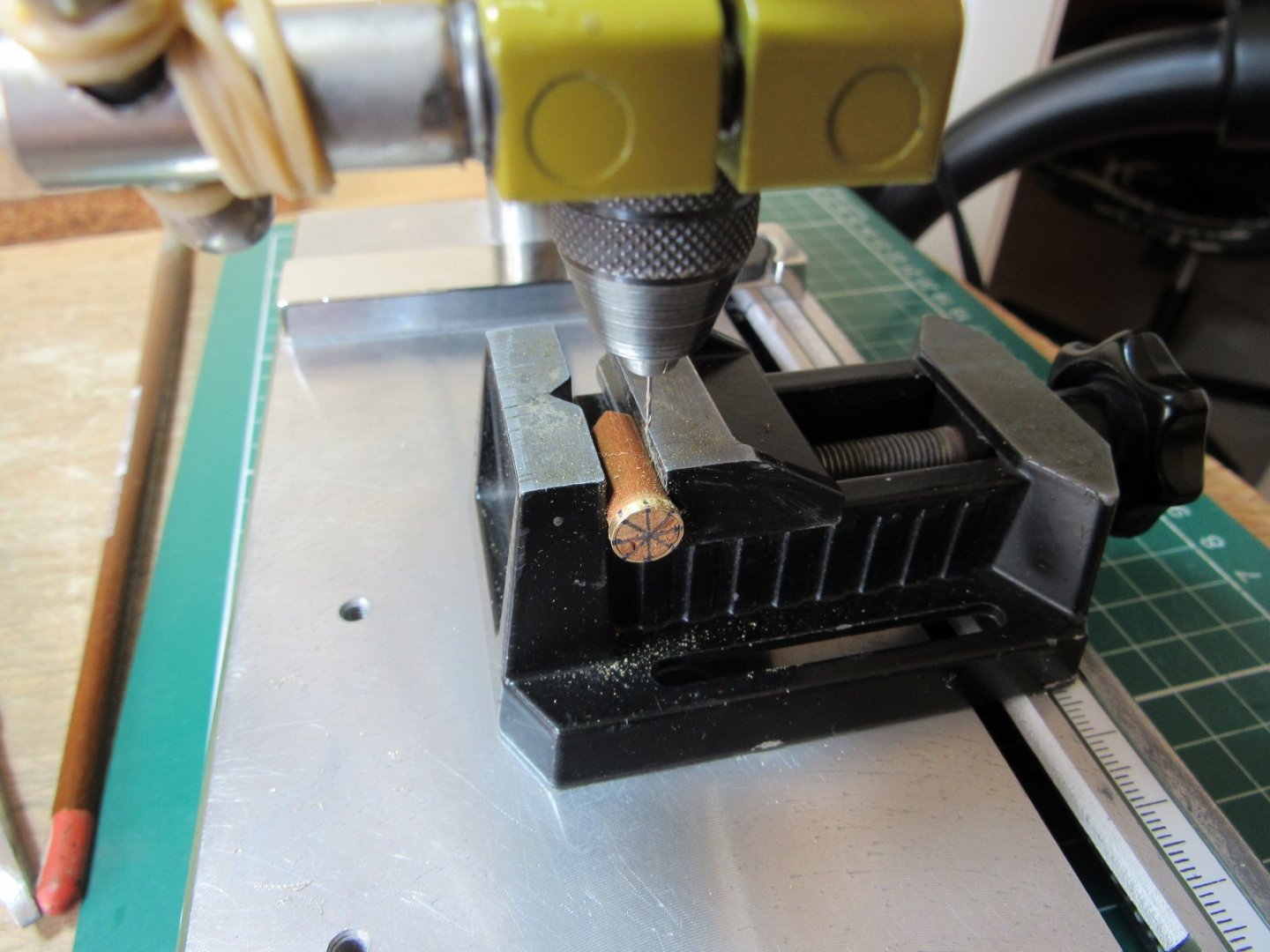

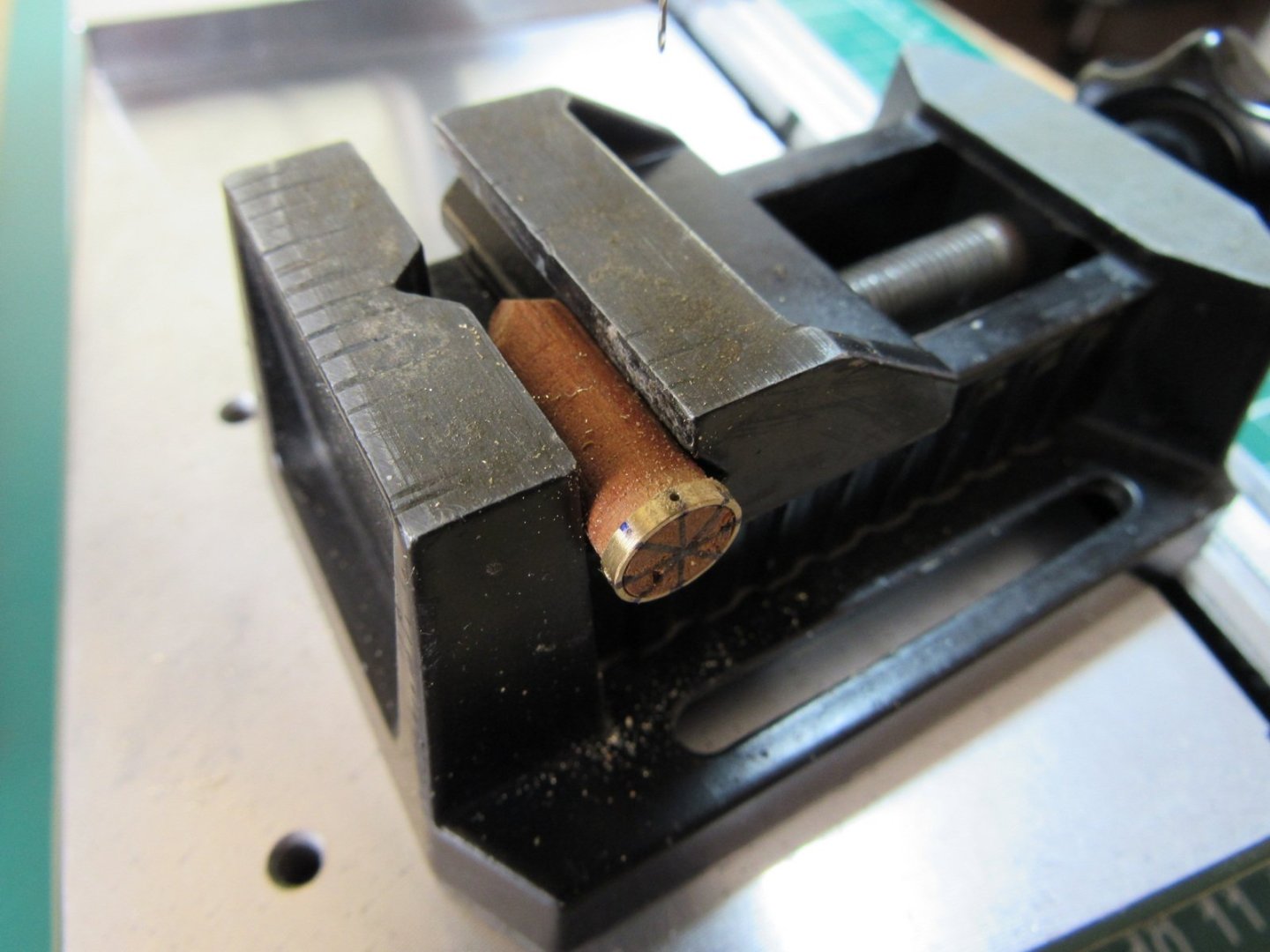

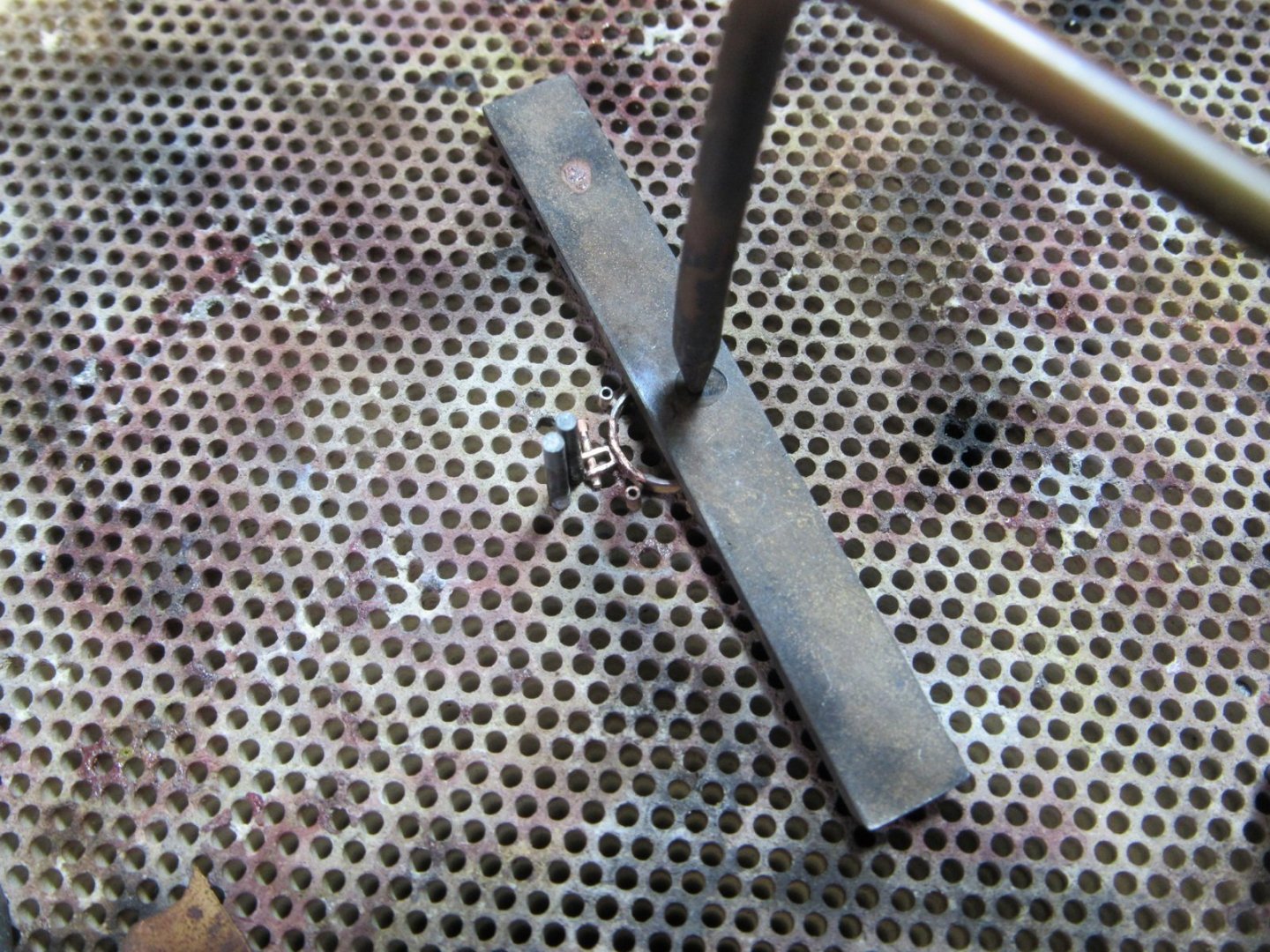

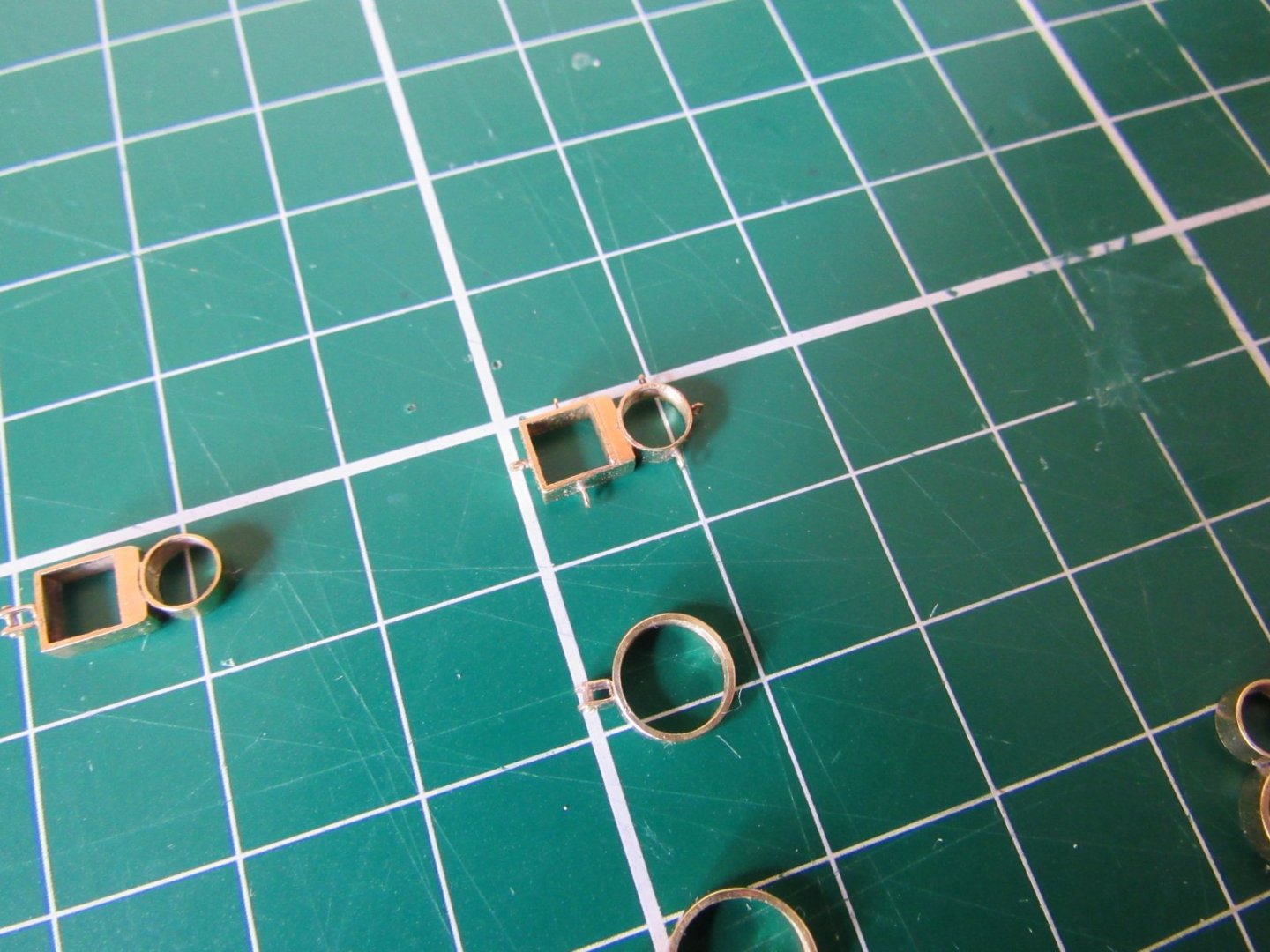

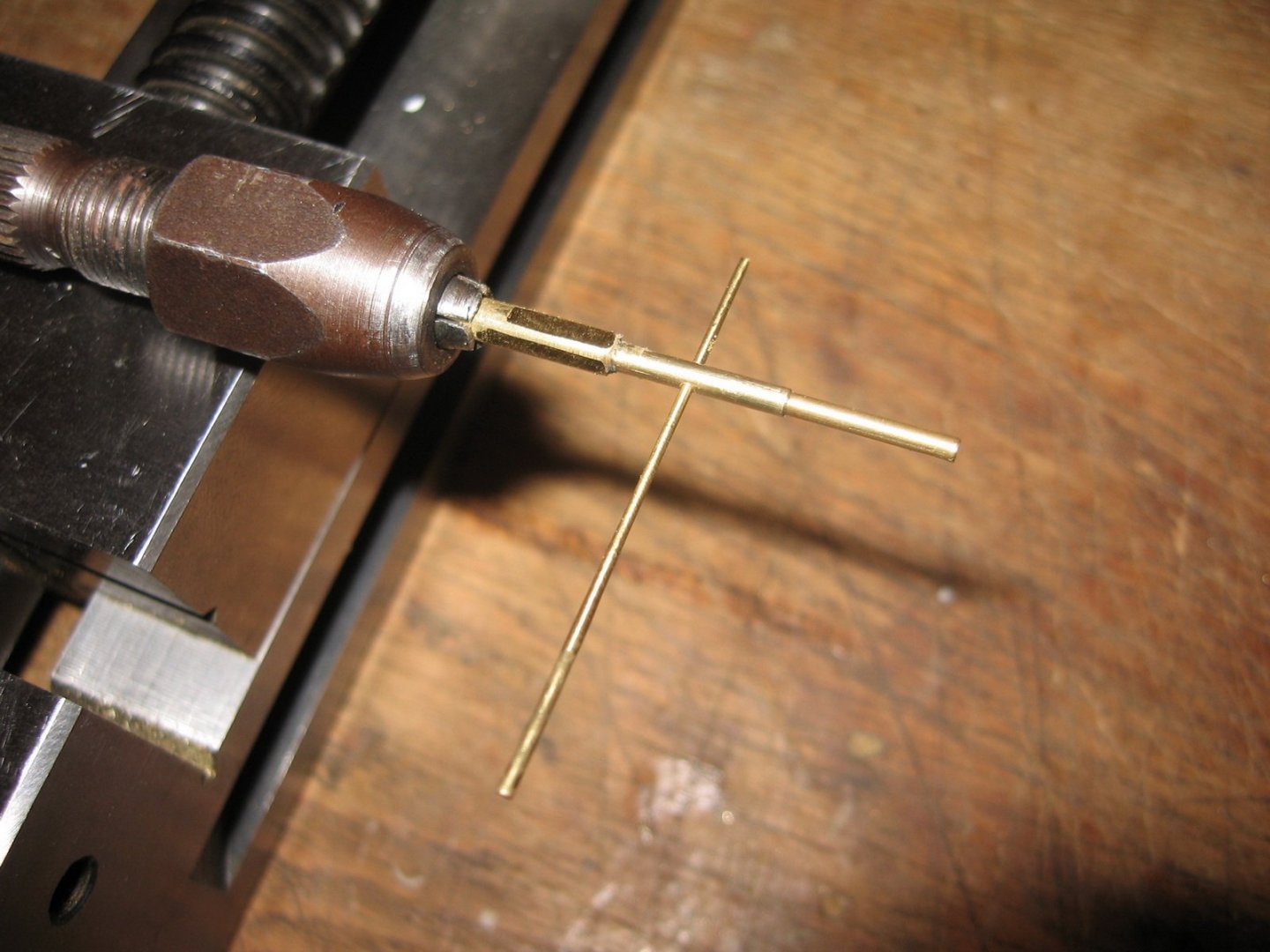

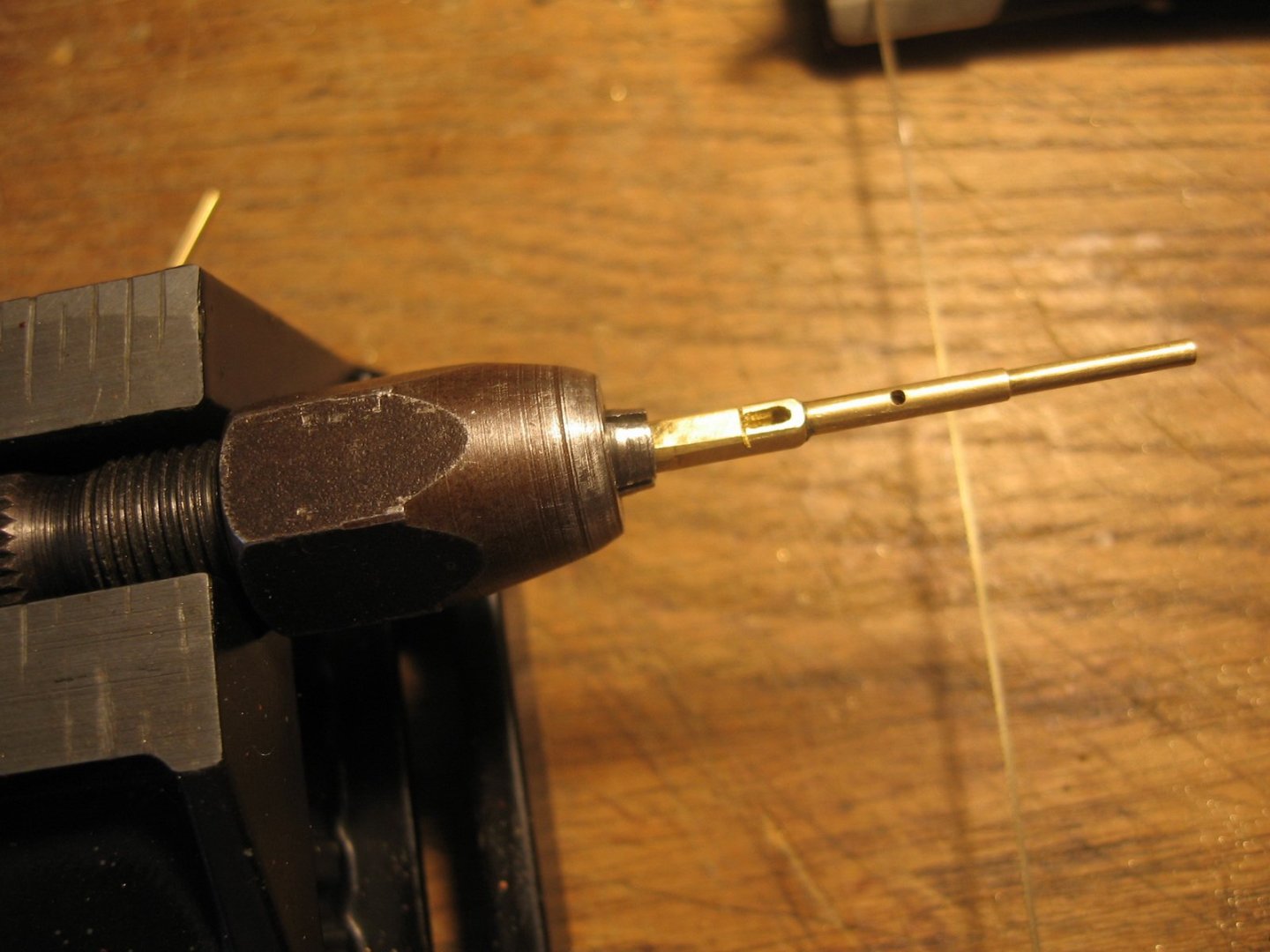

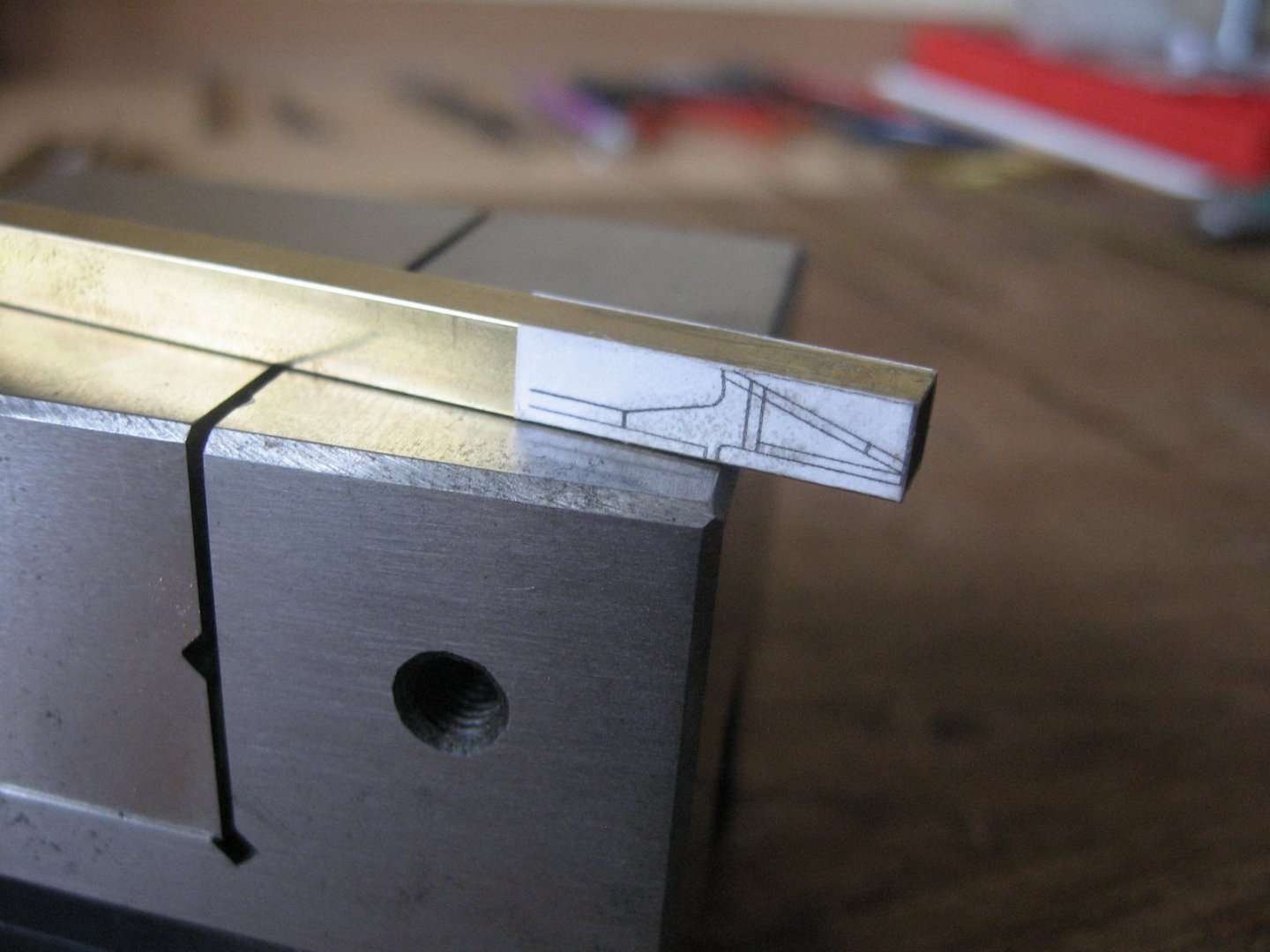

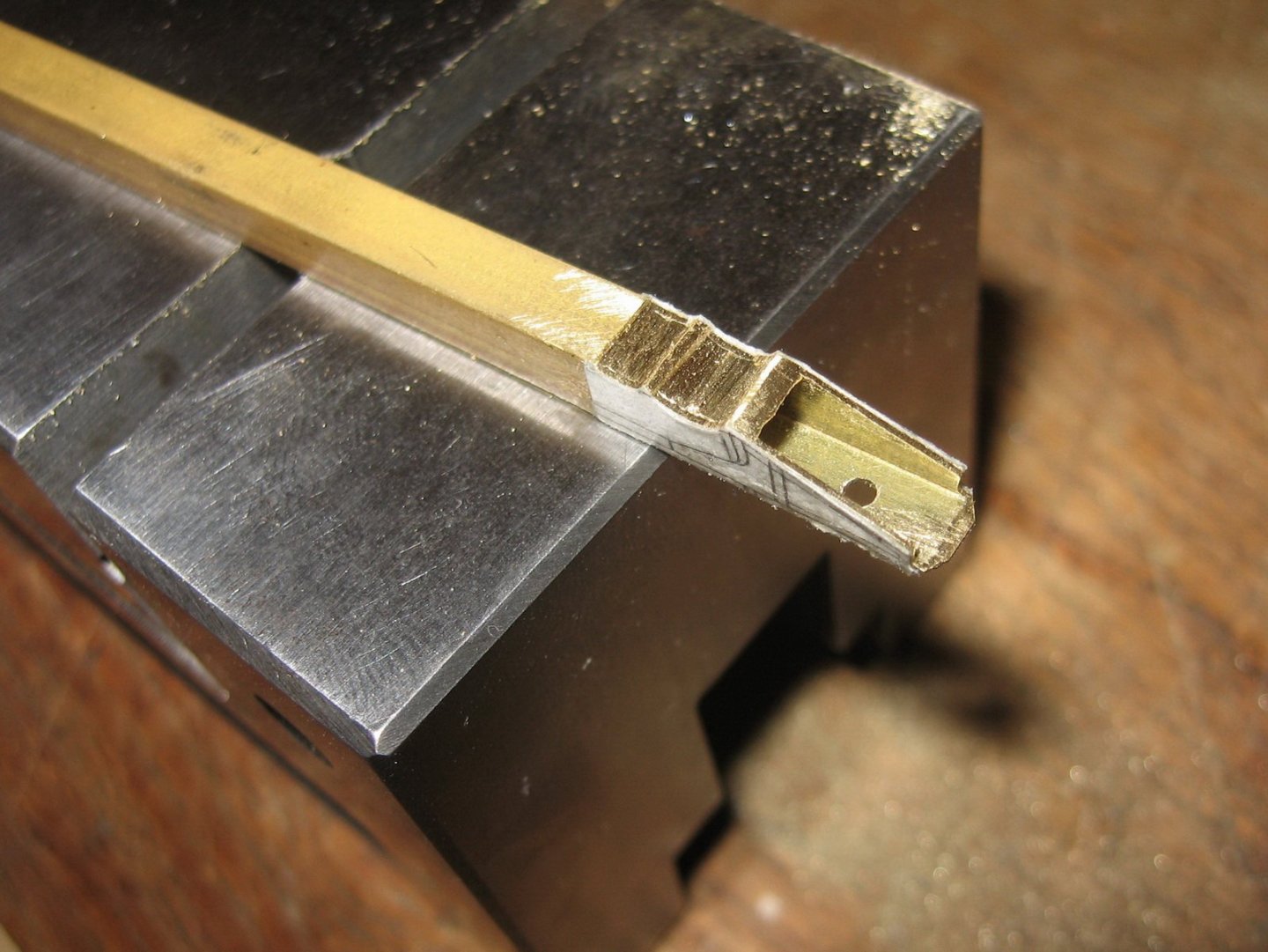

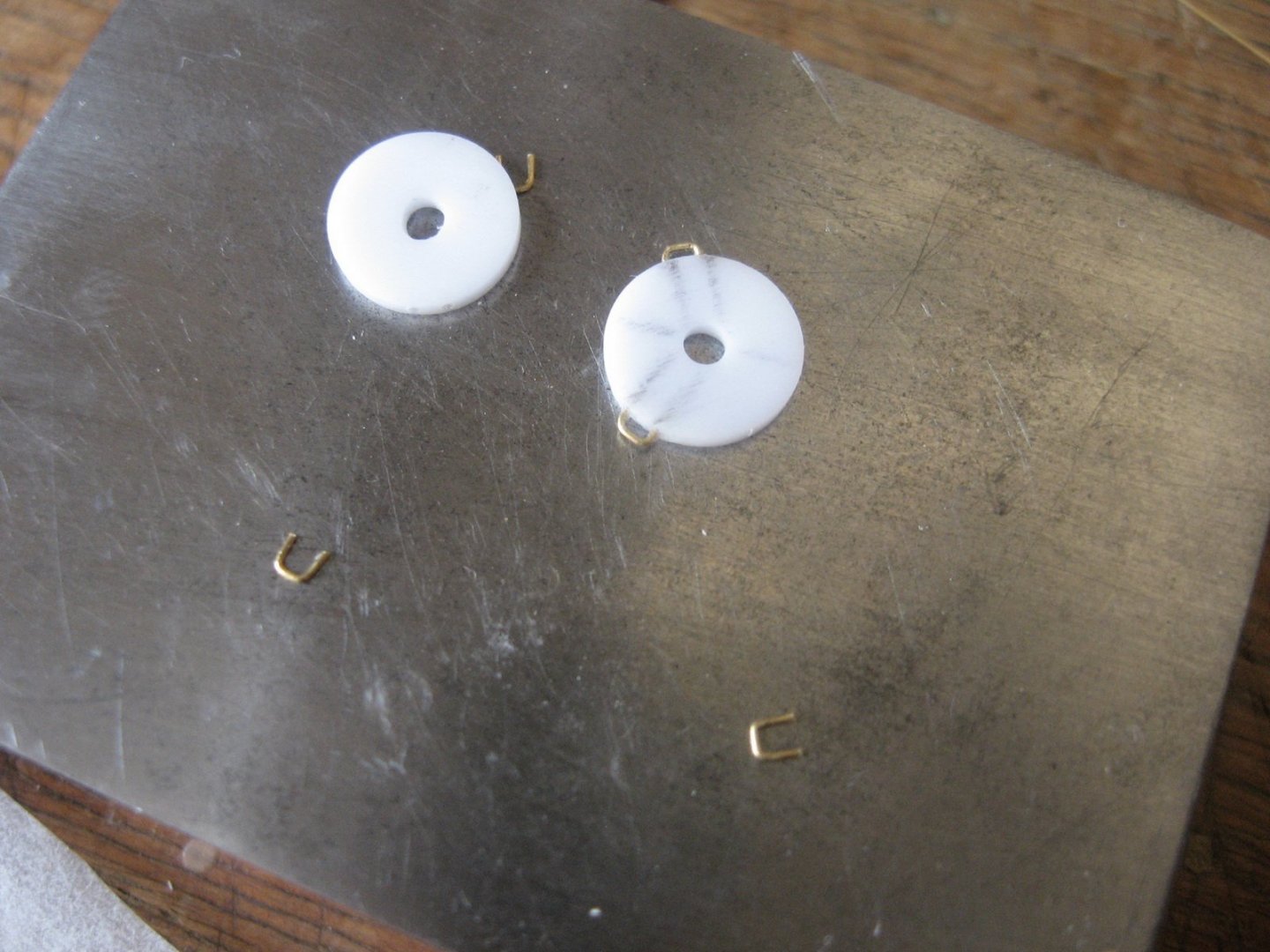

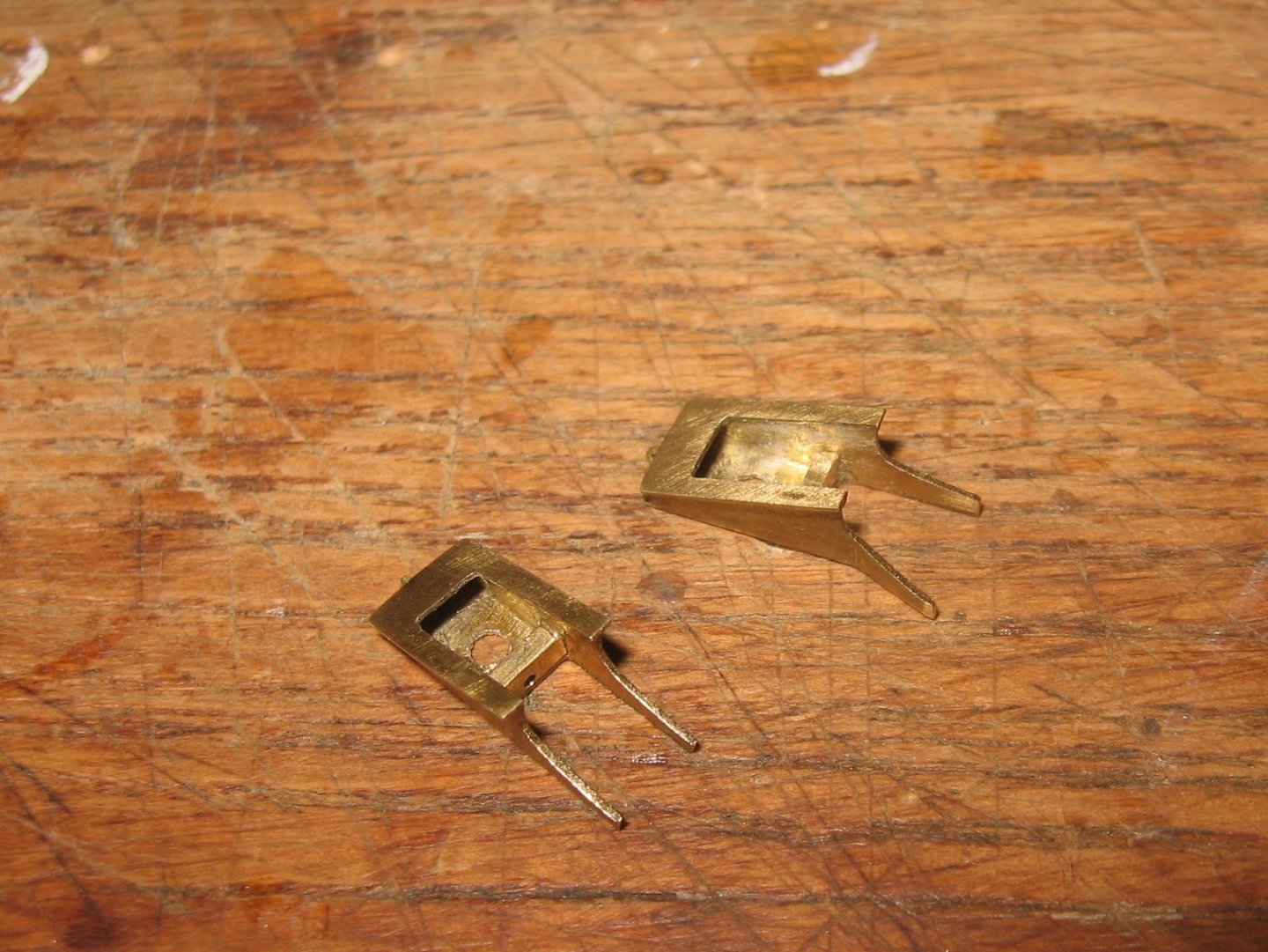

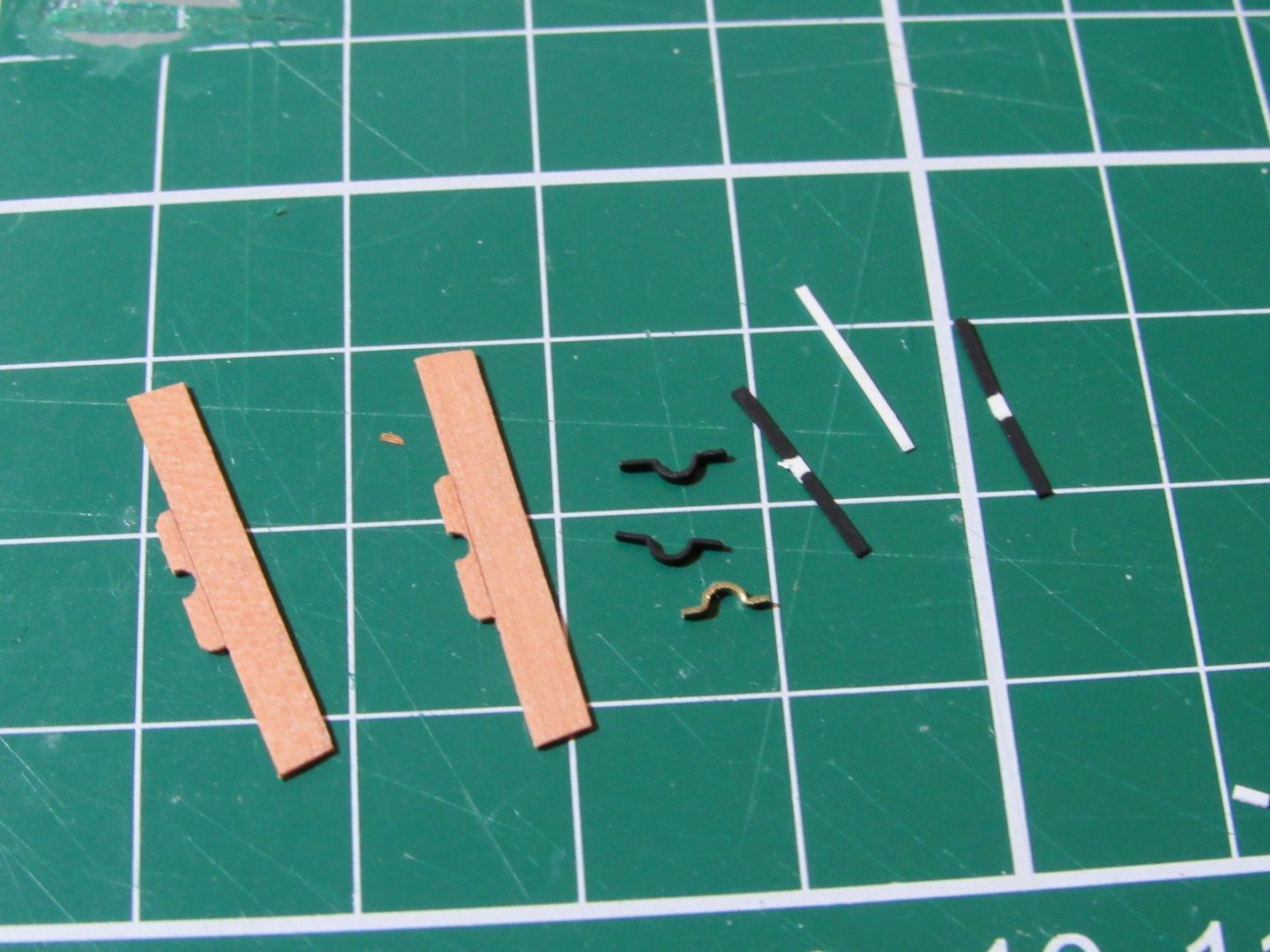

Hi Pat, they are photo etch parts. I did share previously how I do them. Blue transfer paper, Fe3CL,...

-

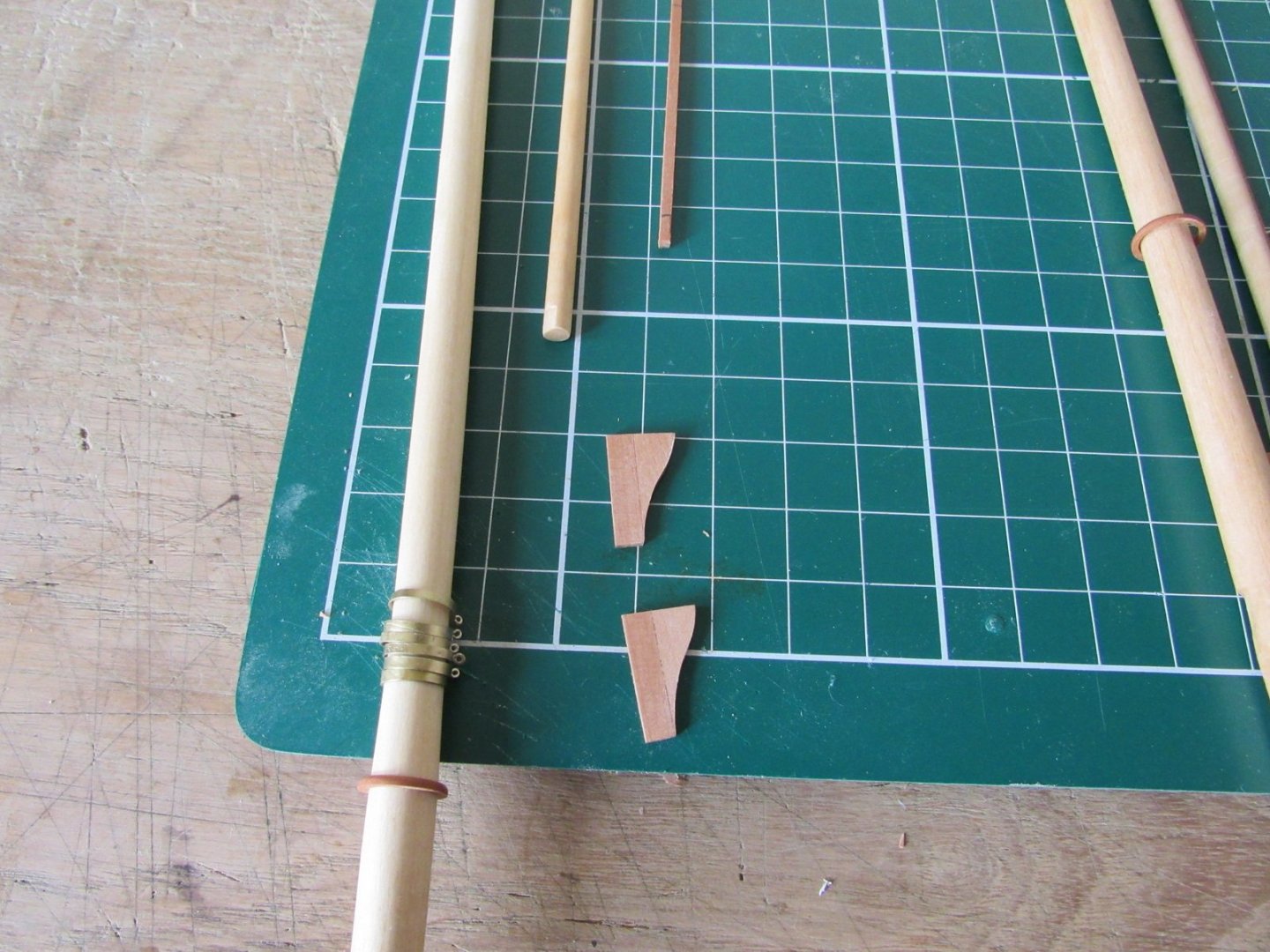

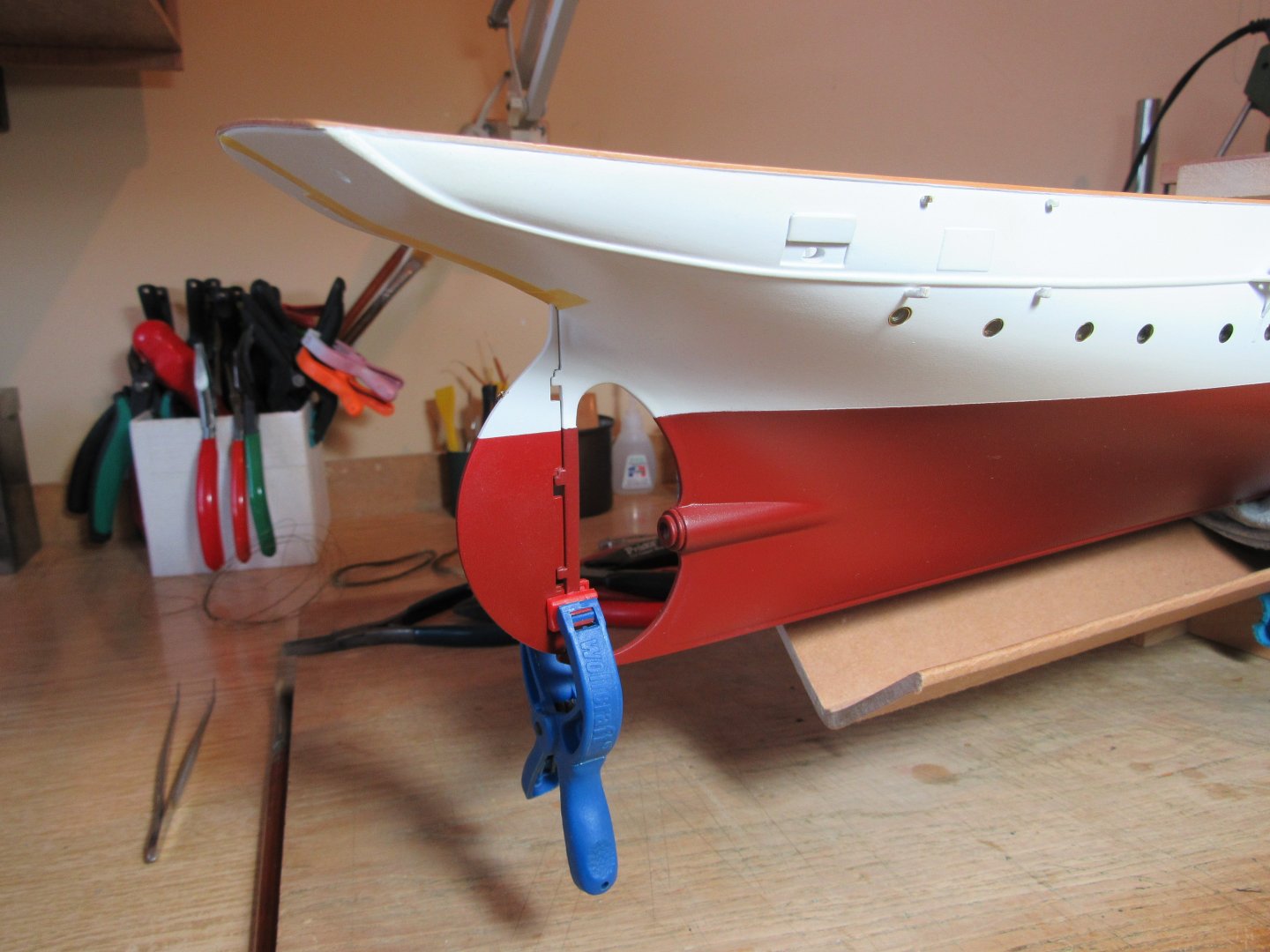

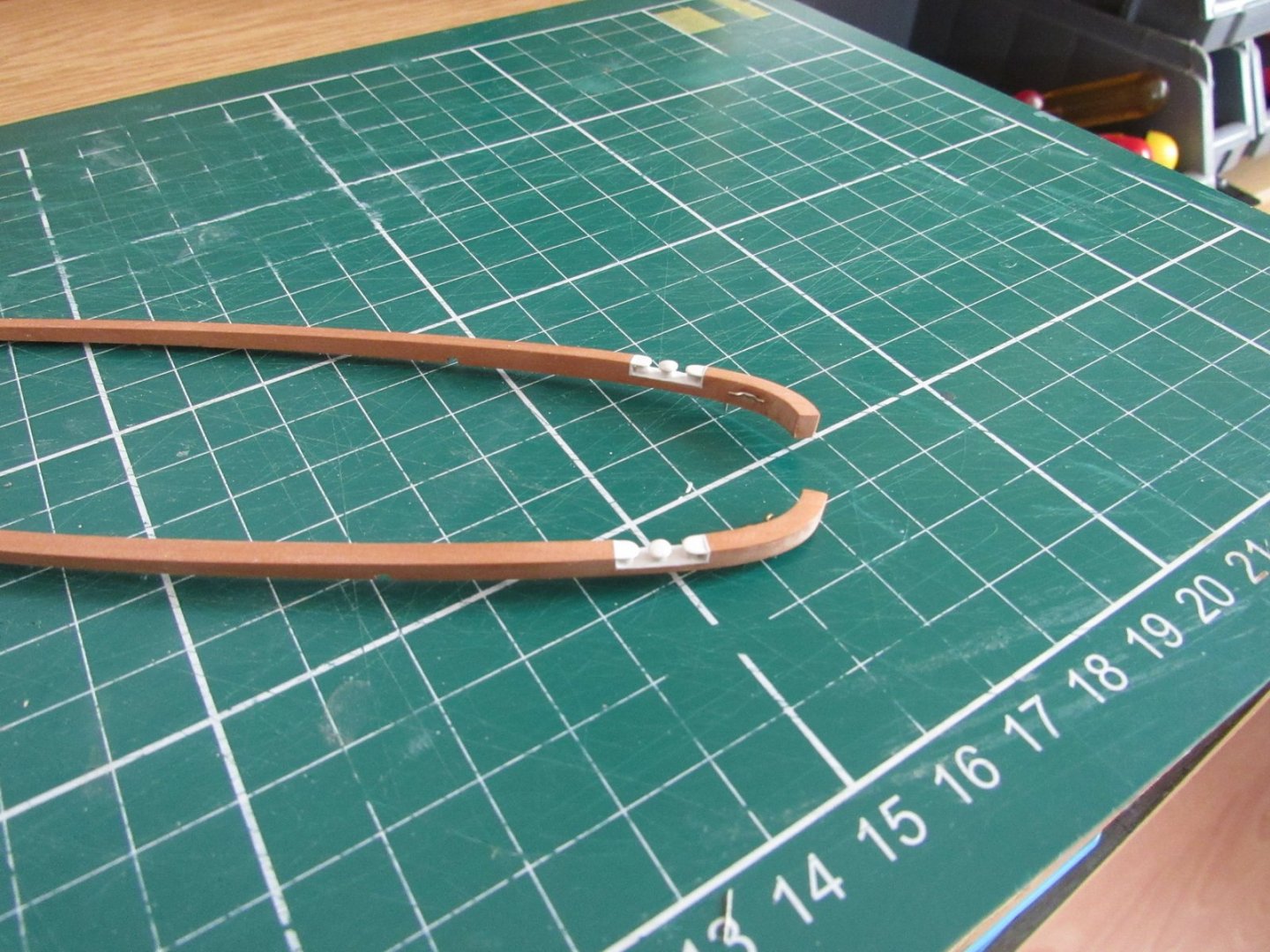

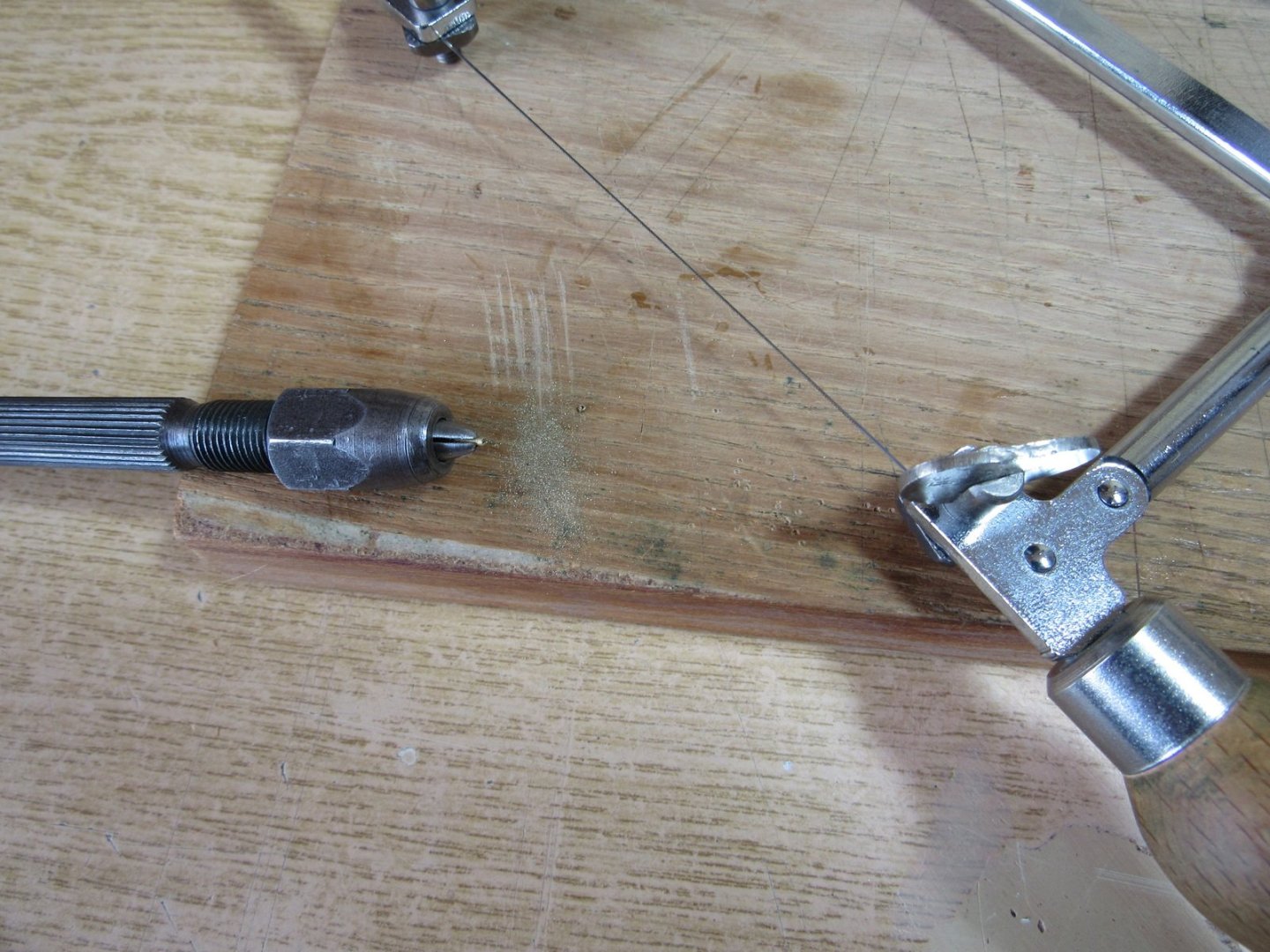

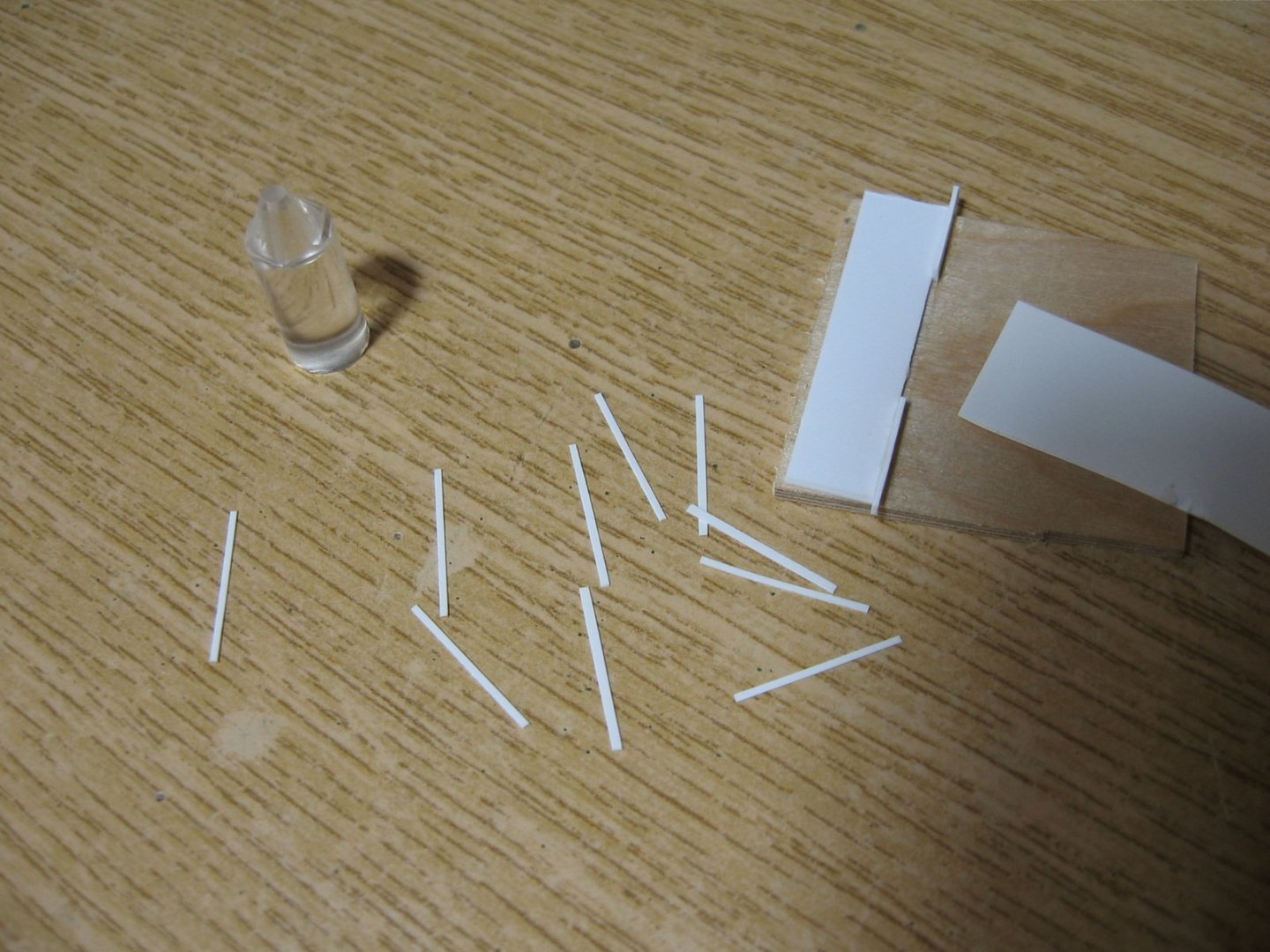

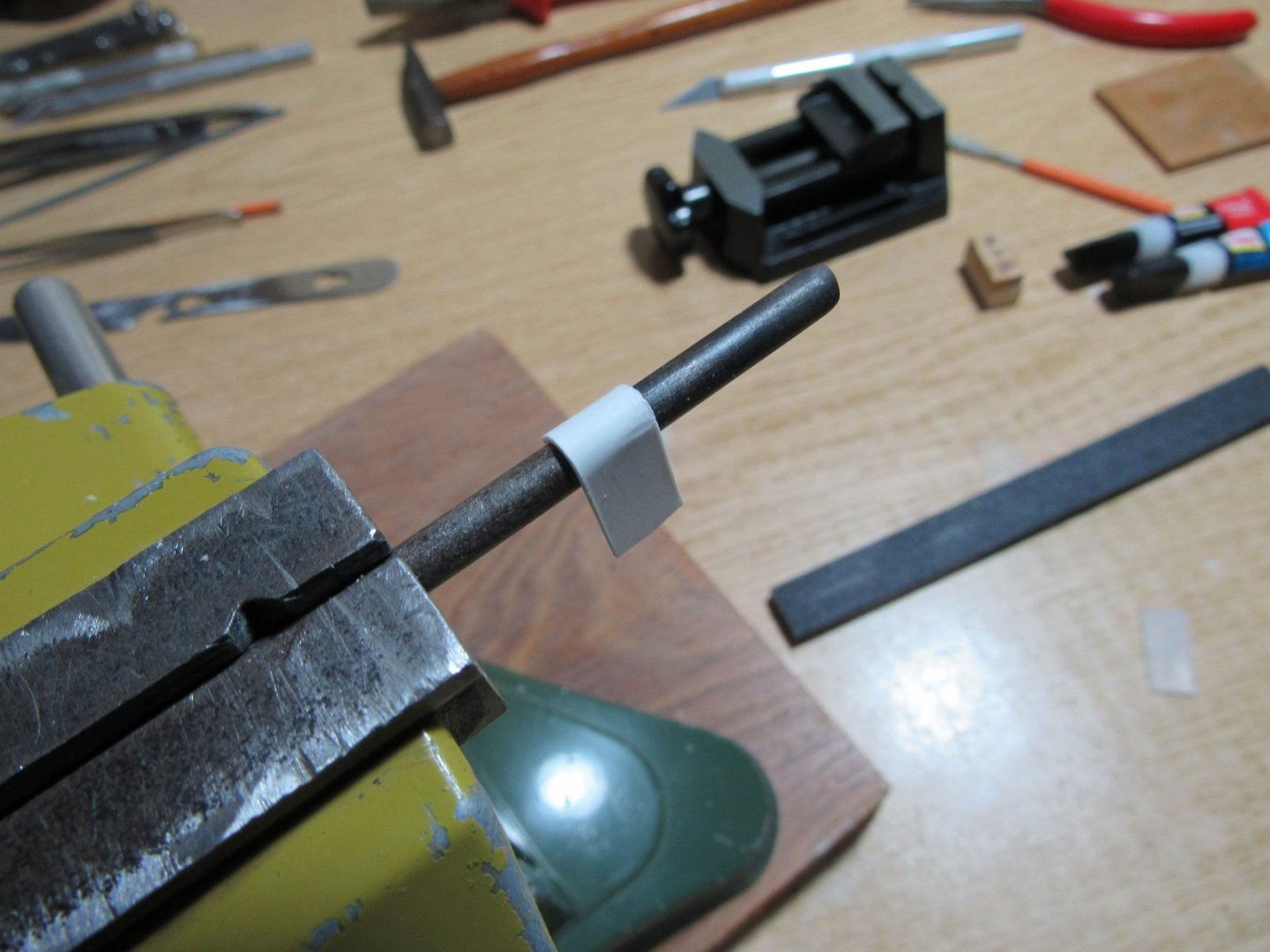

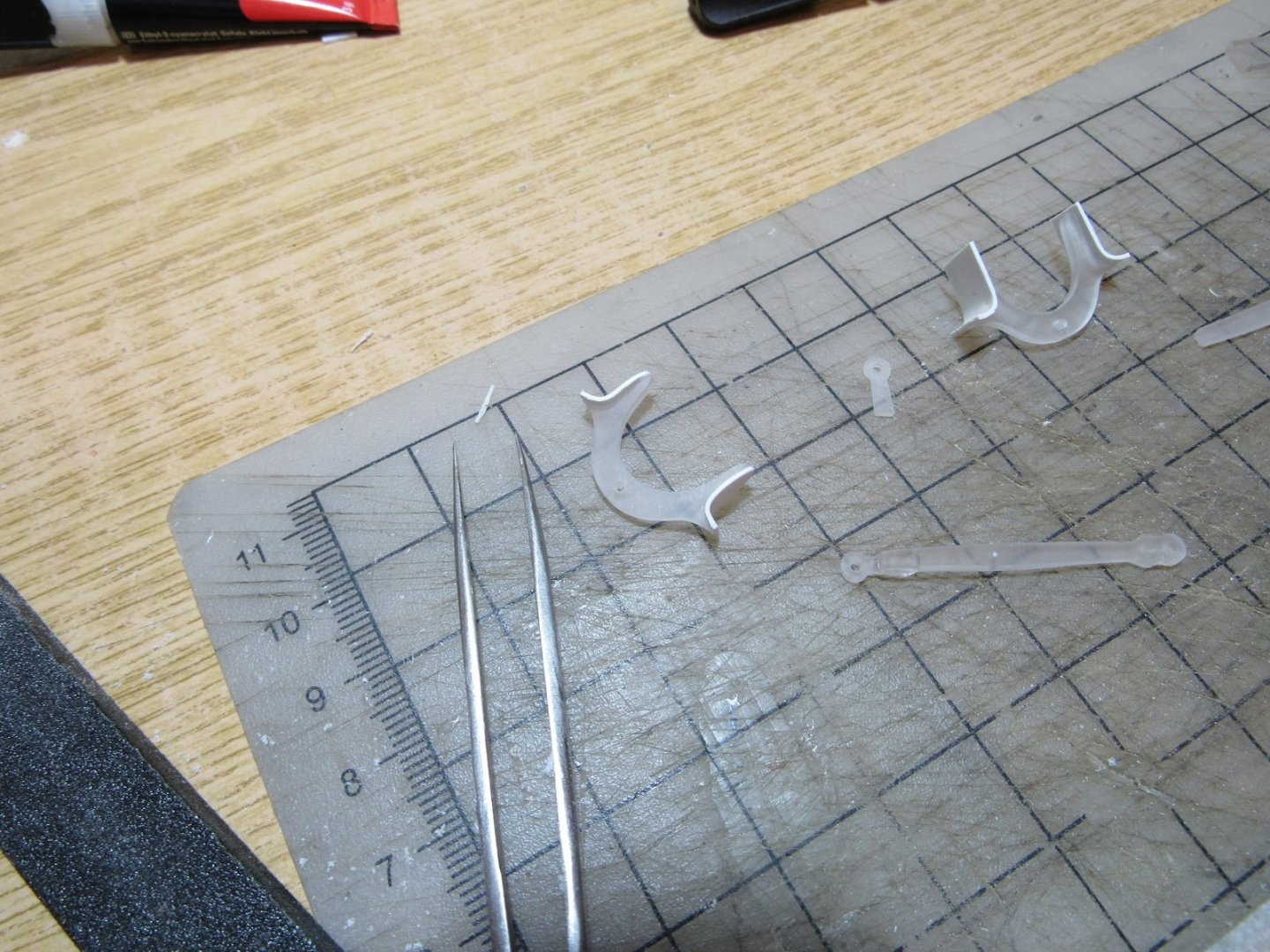

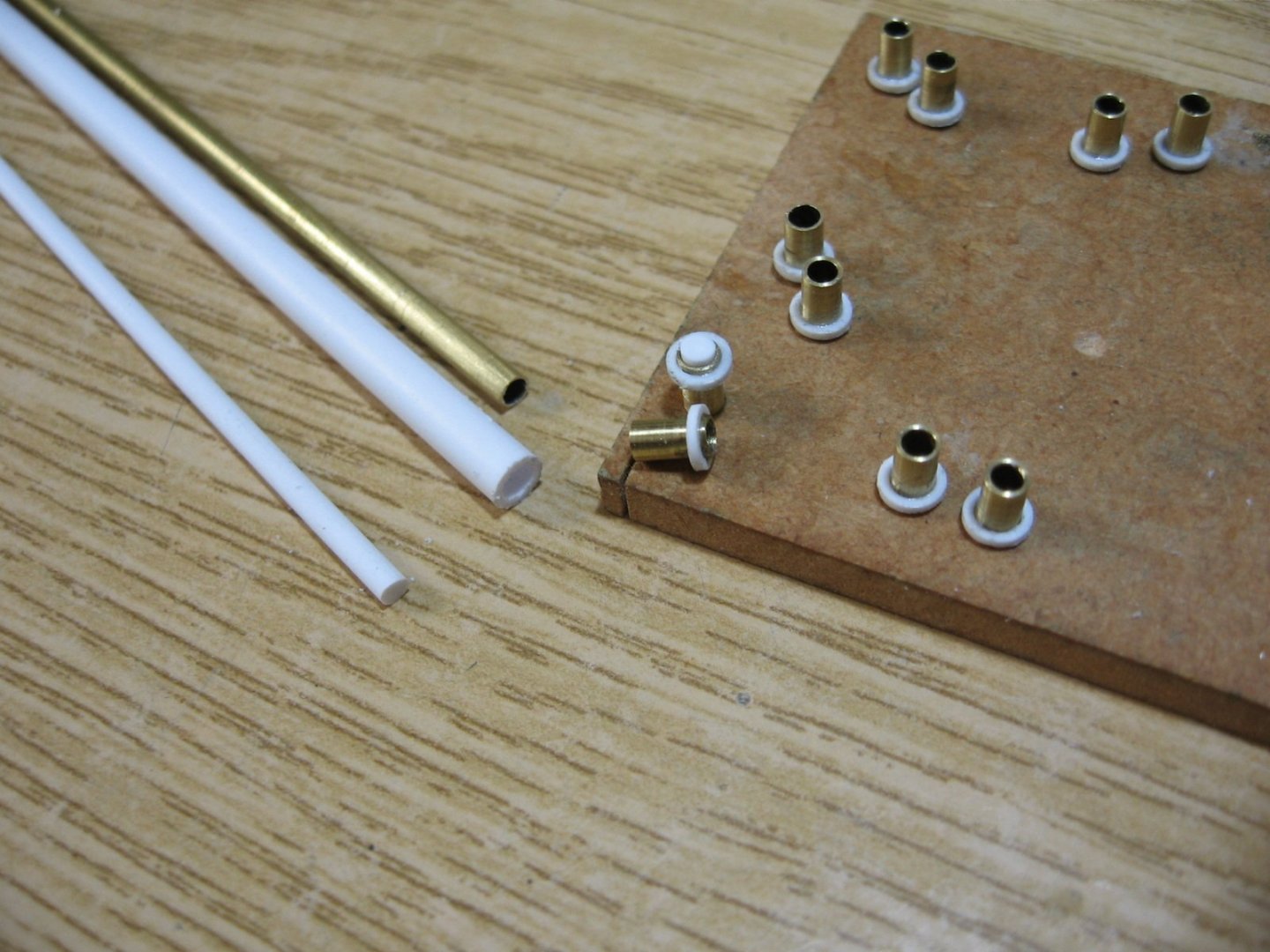

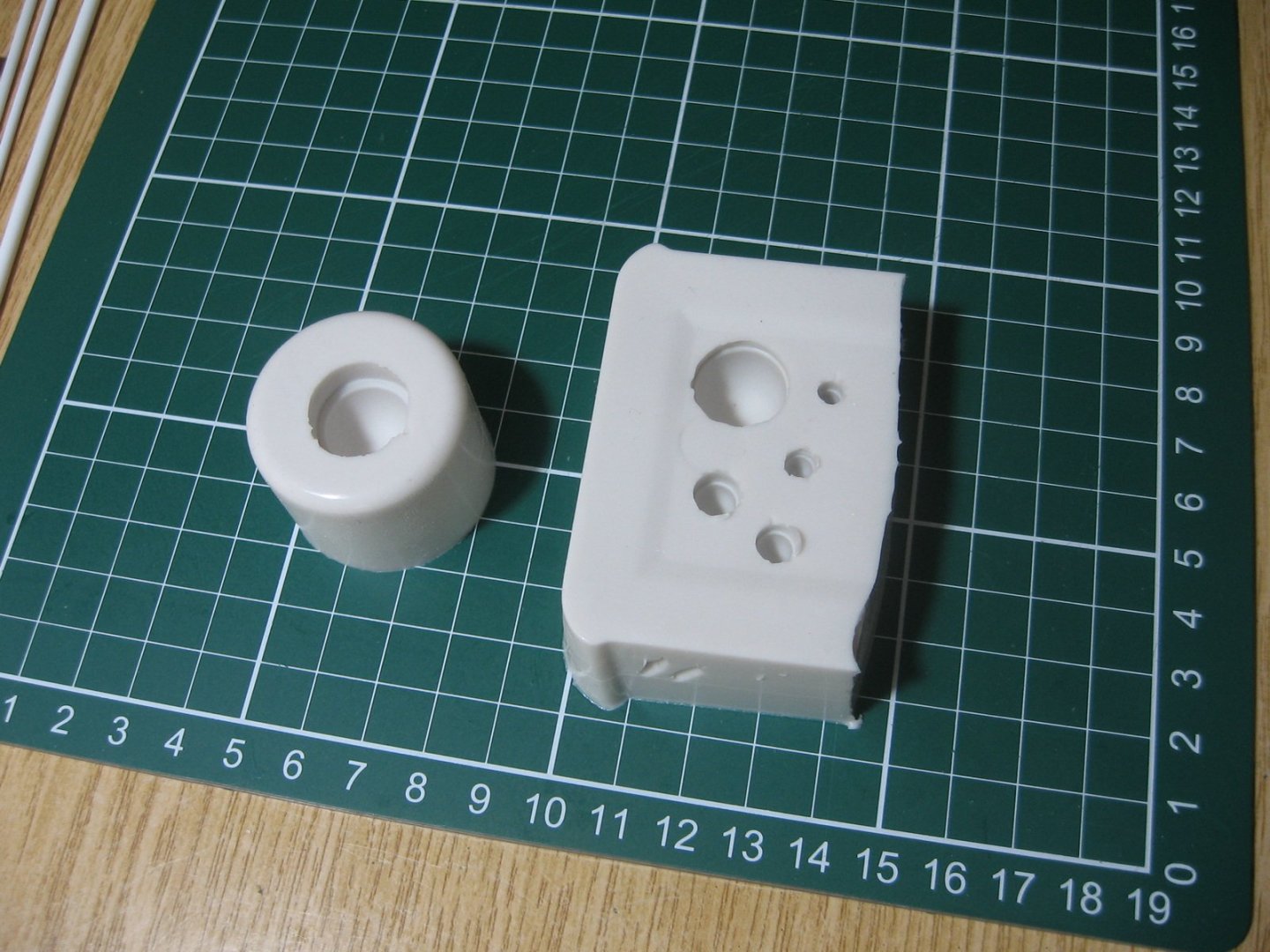

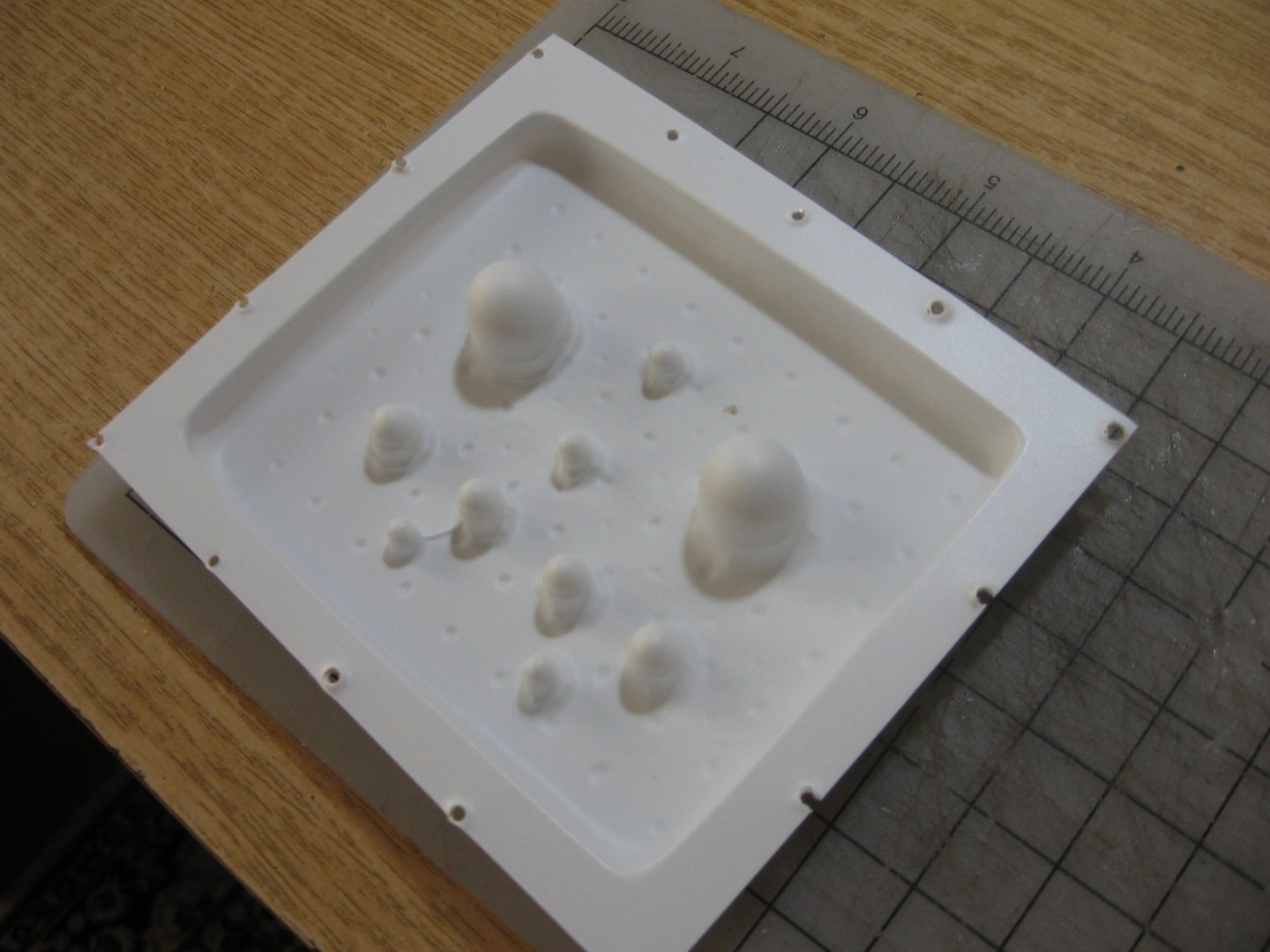

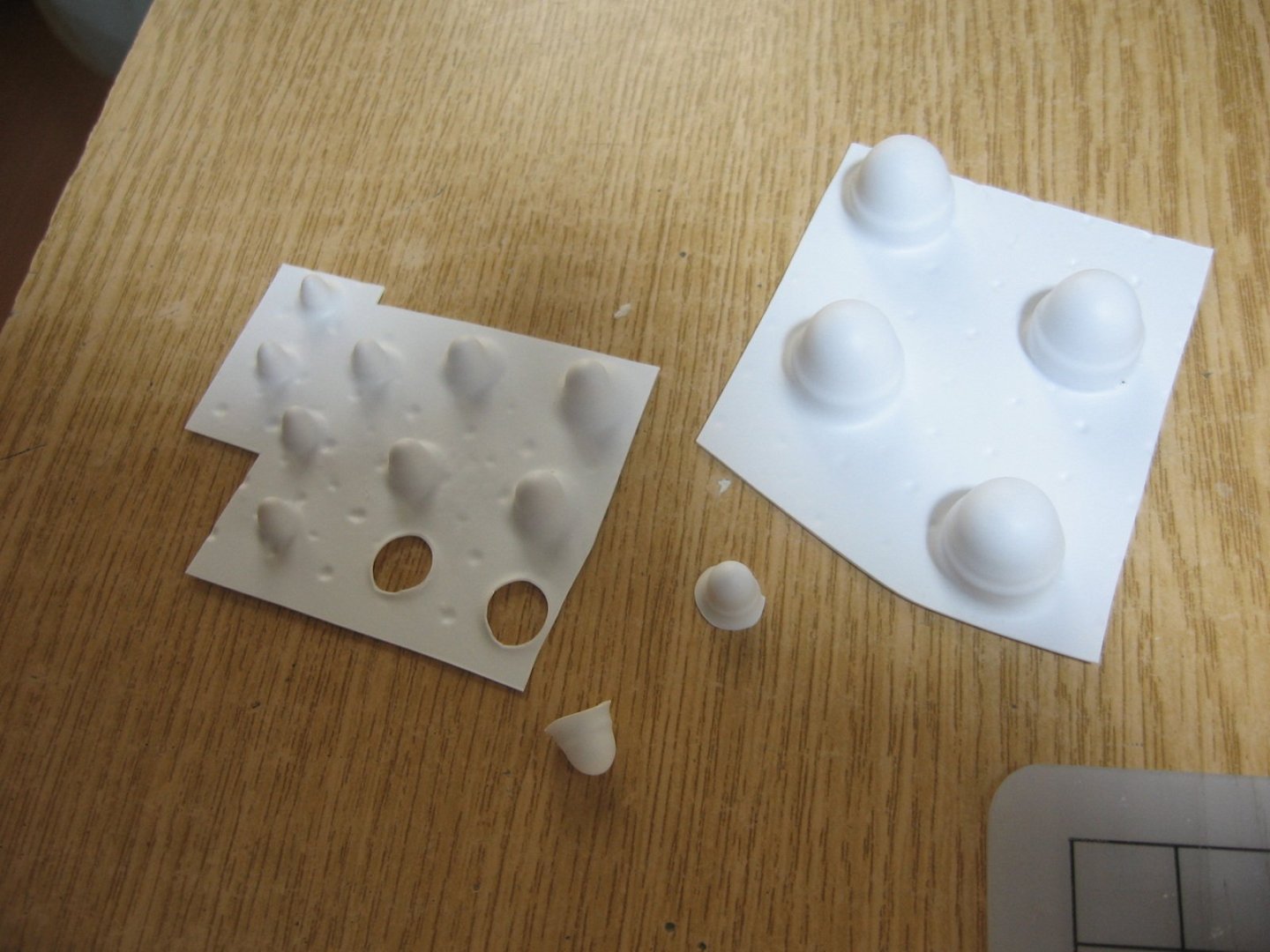

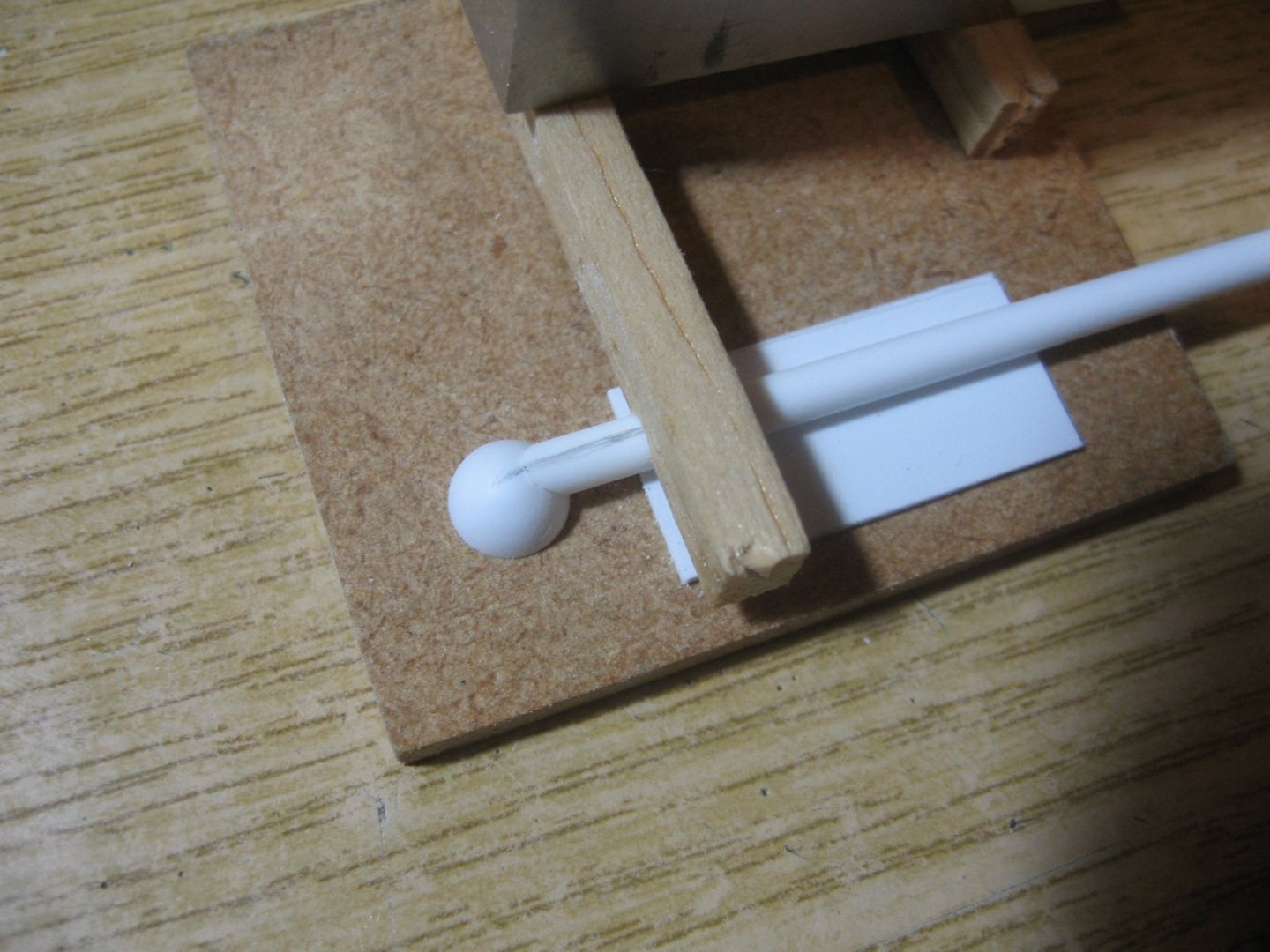

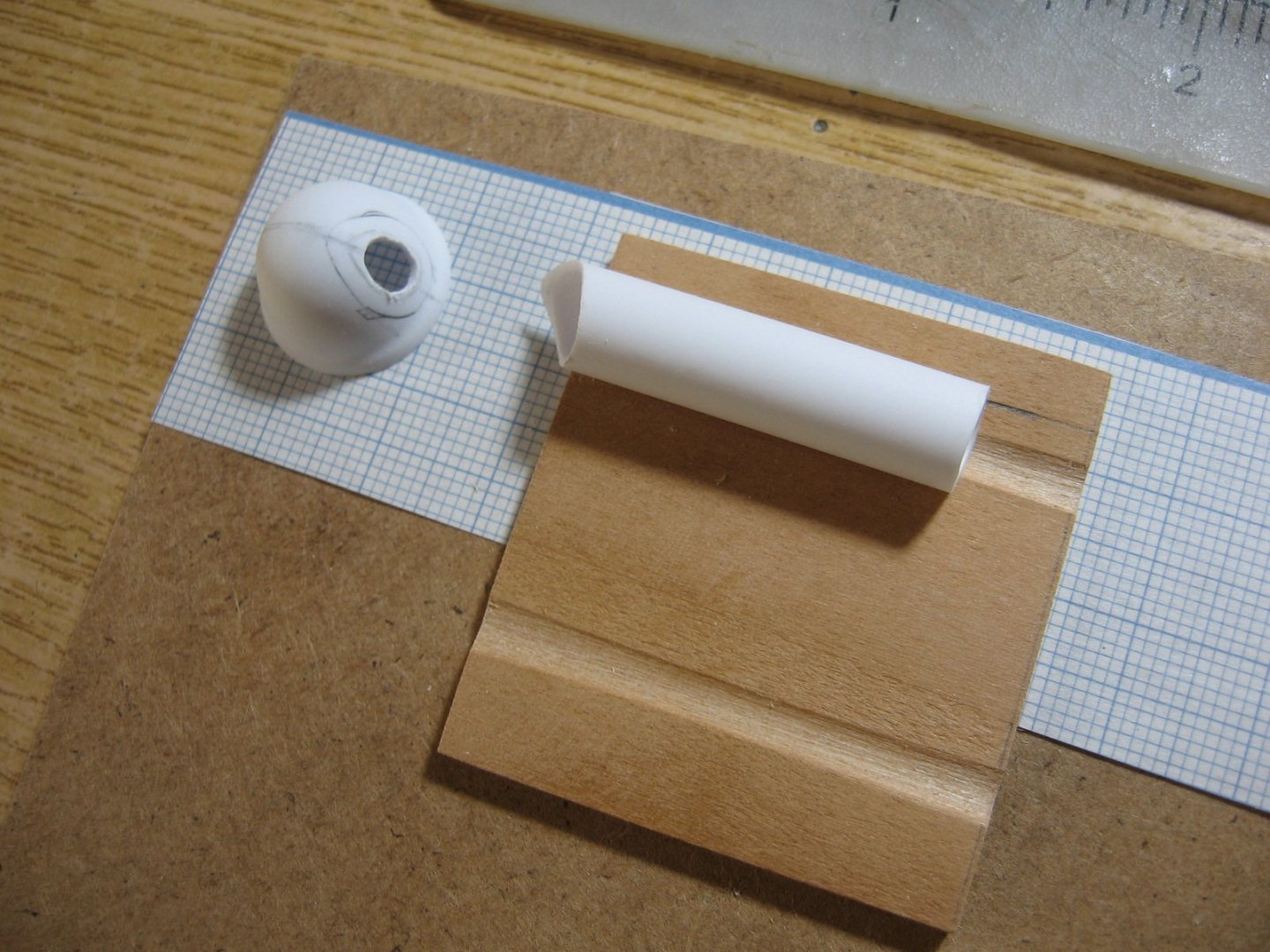

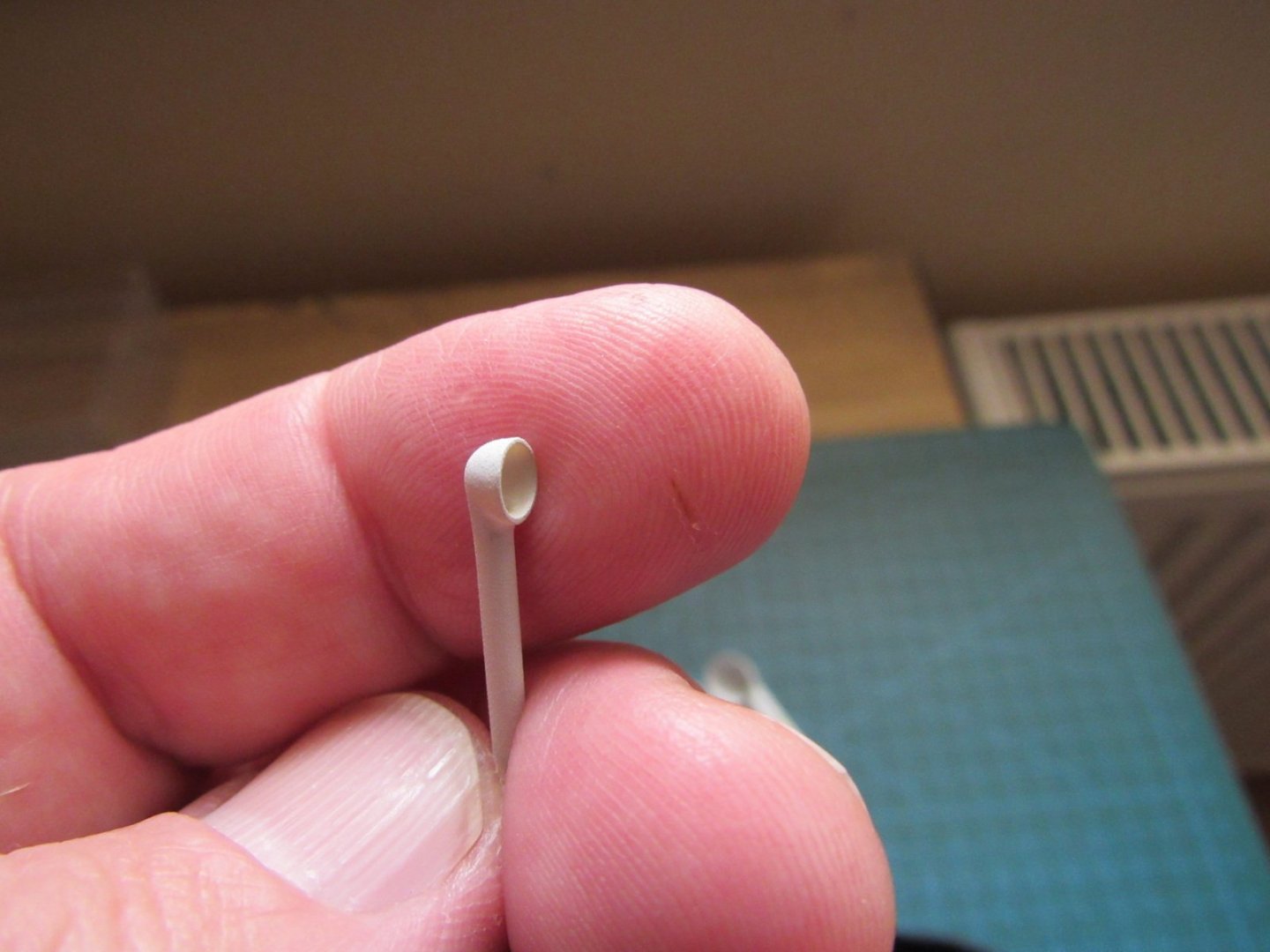

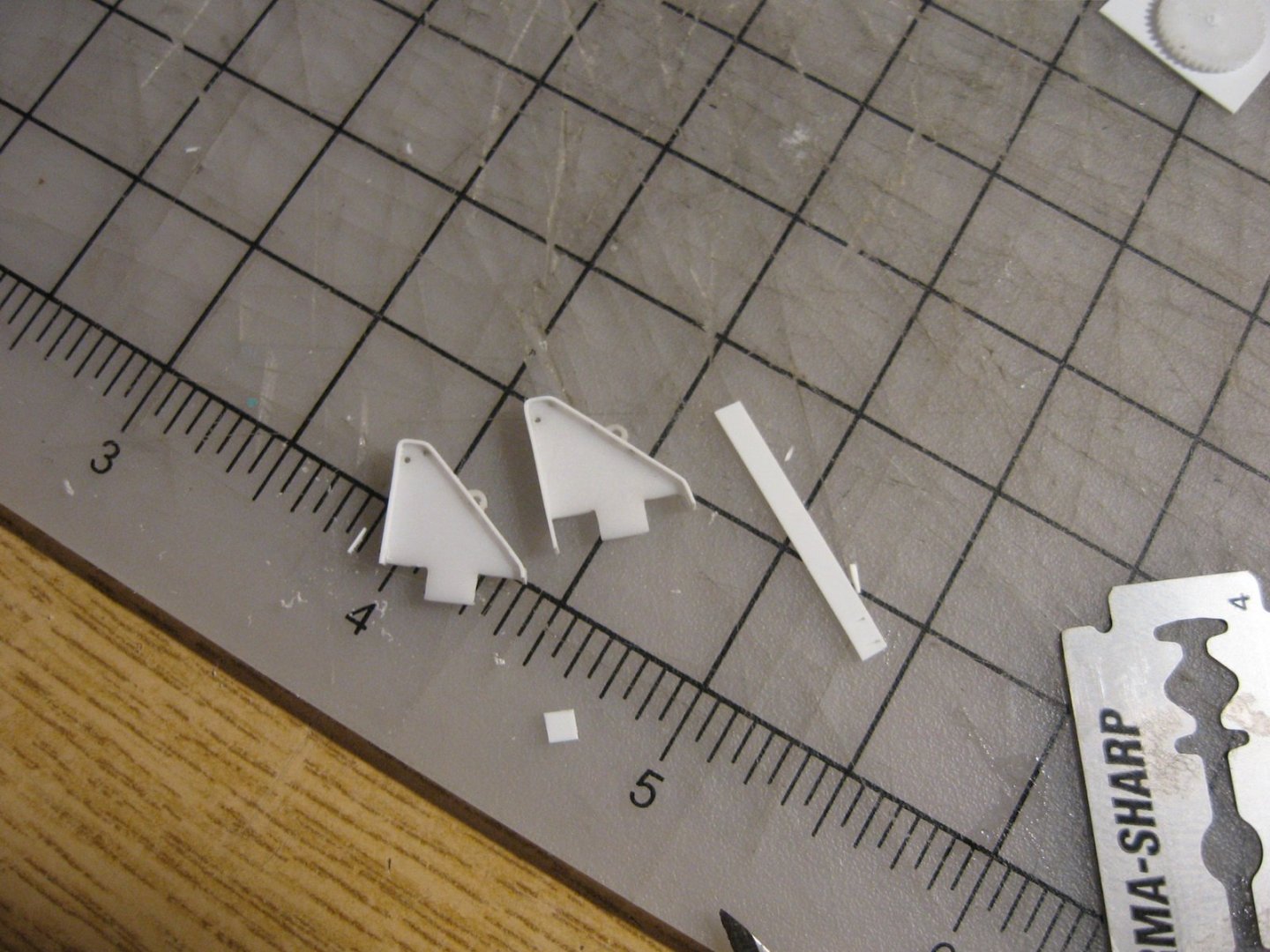

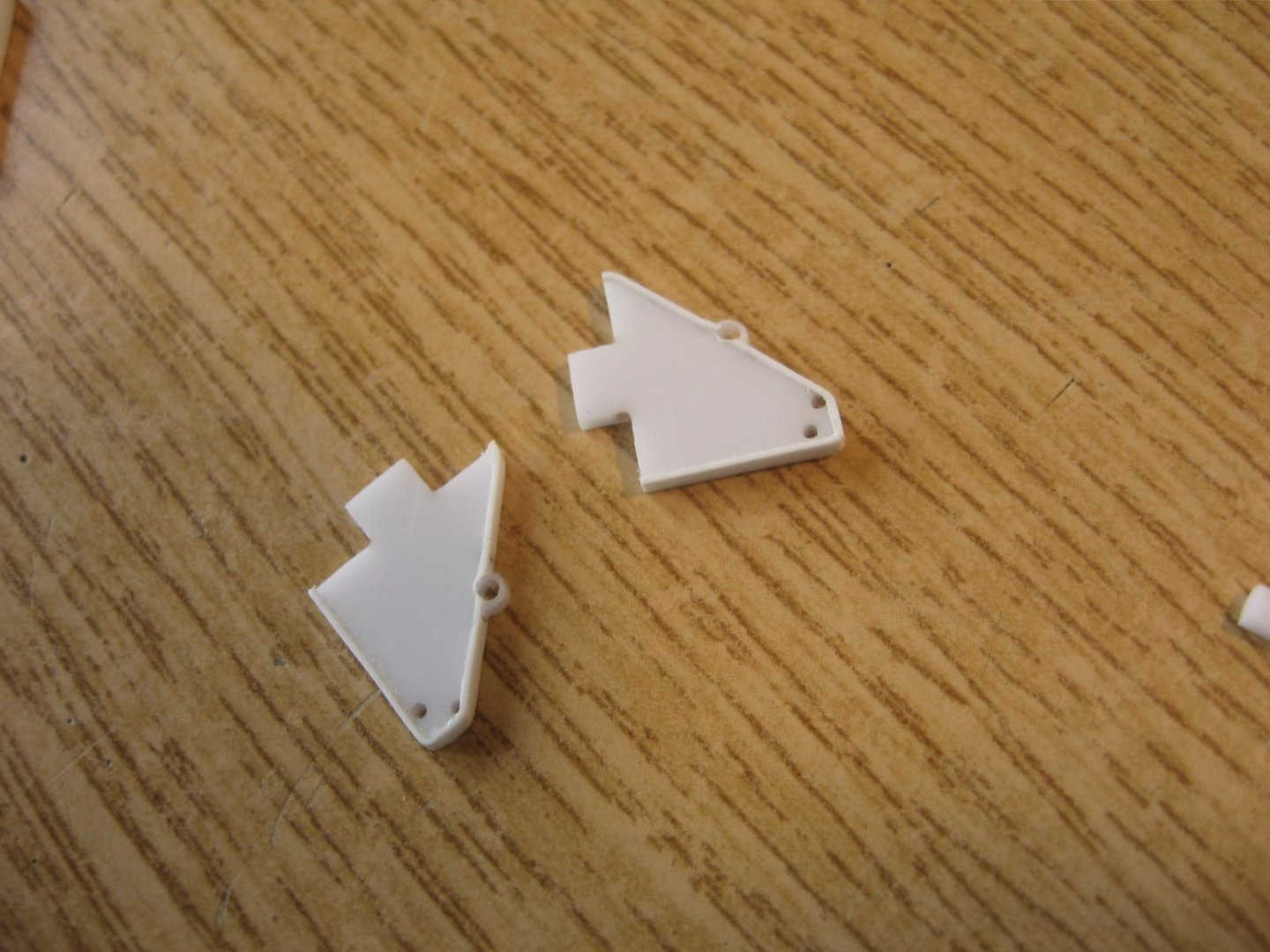

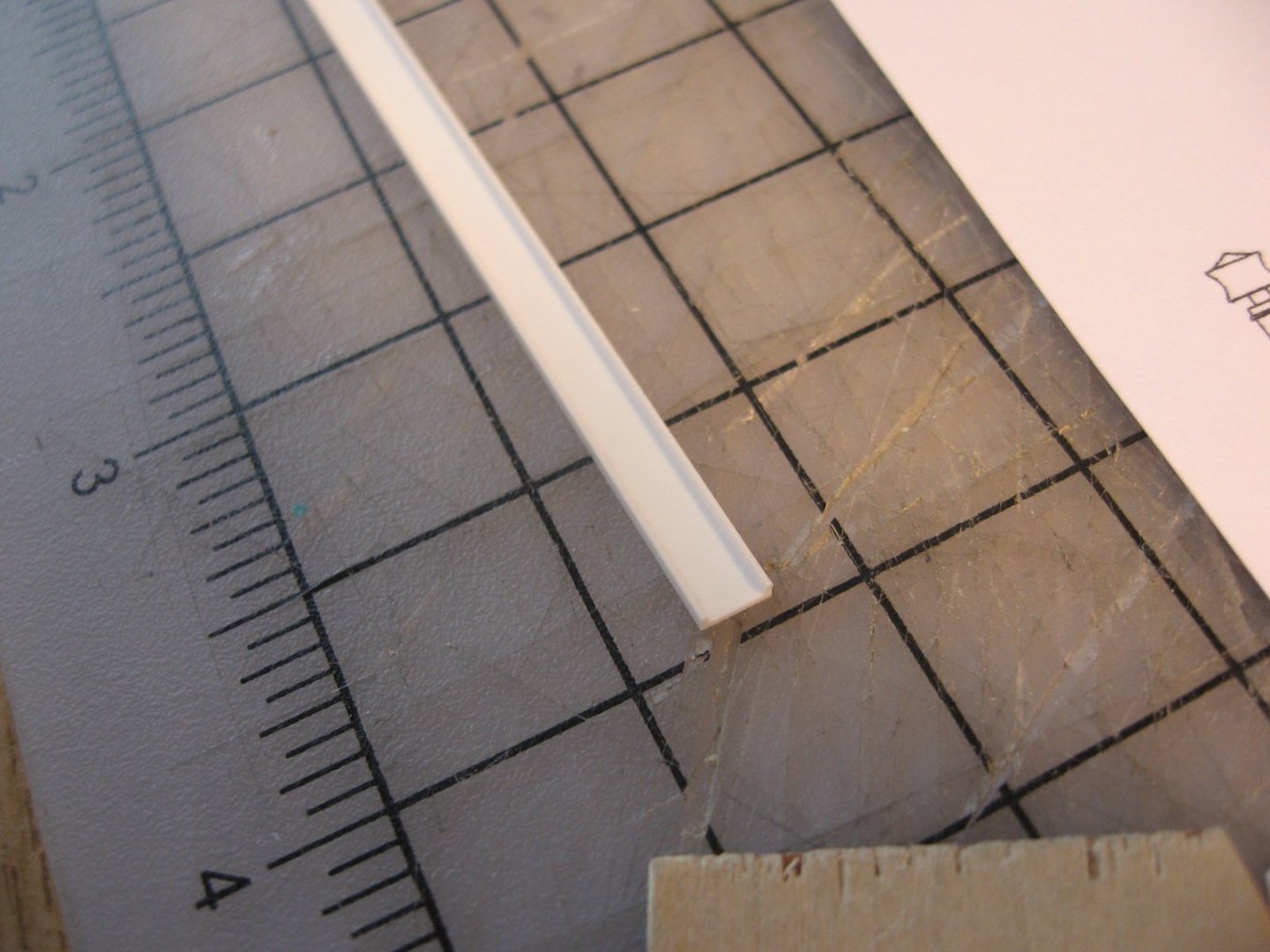

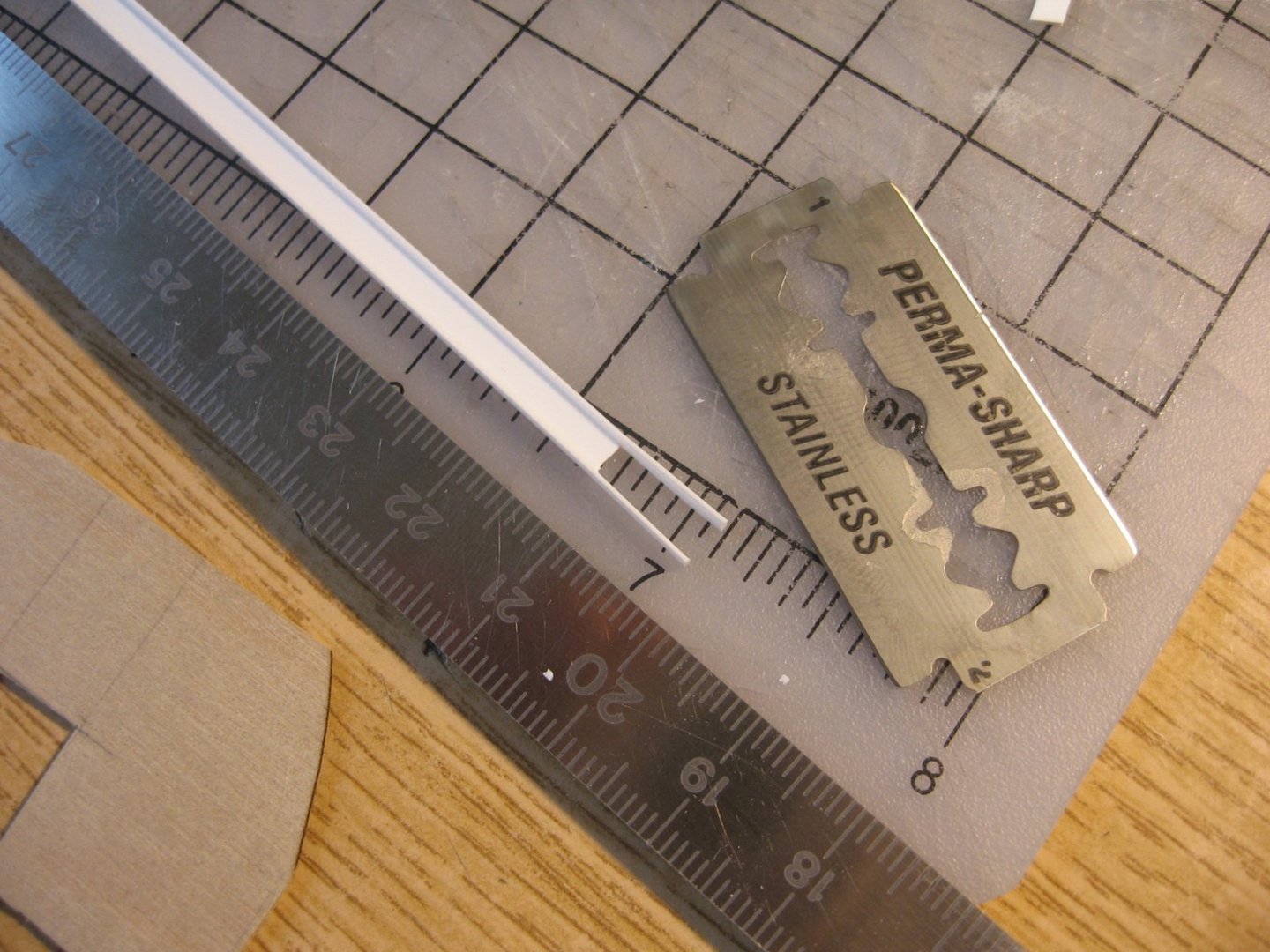

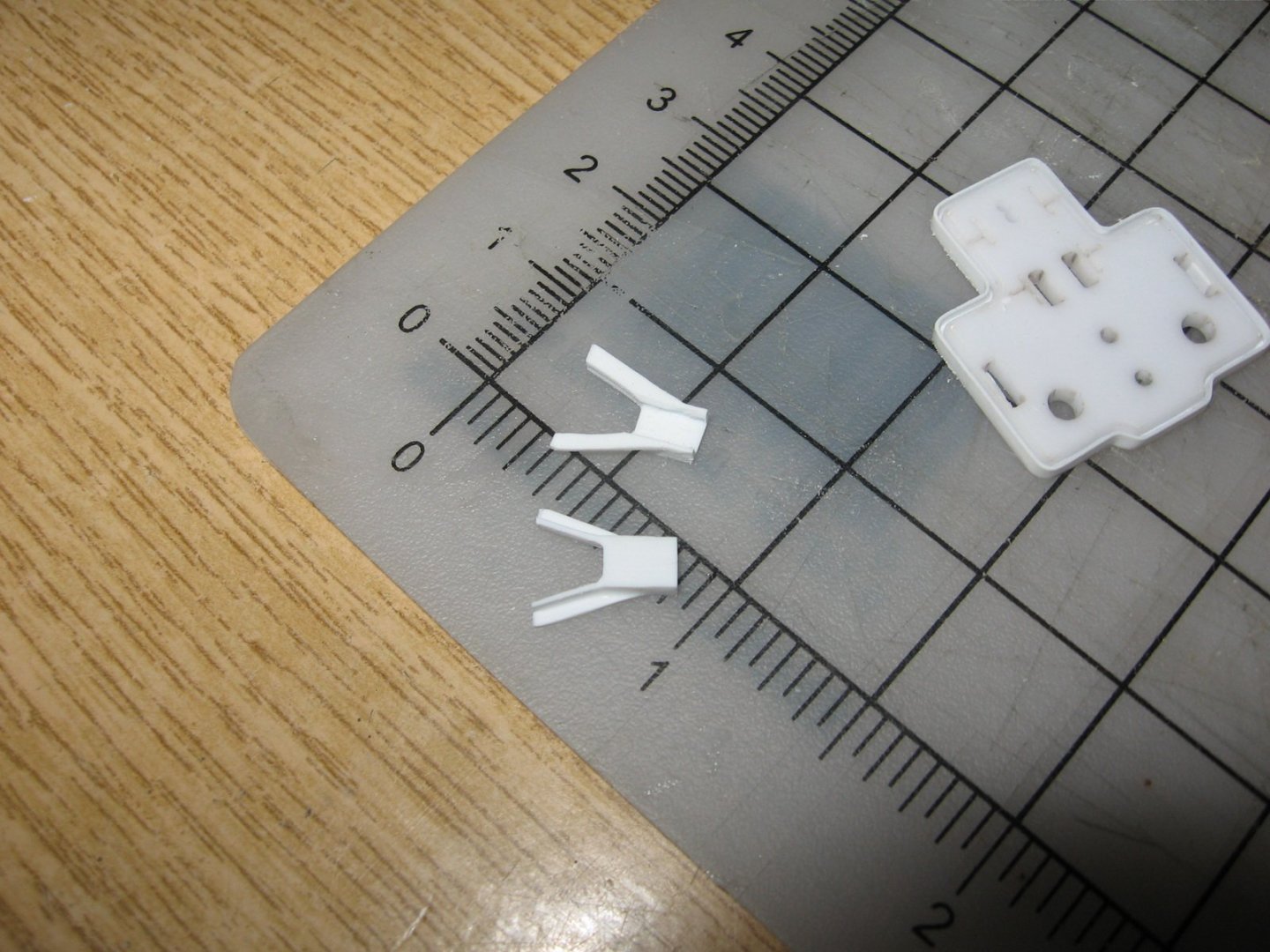

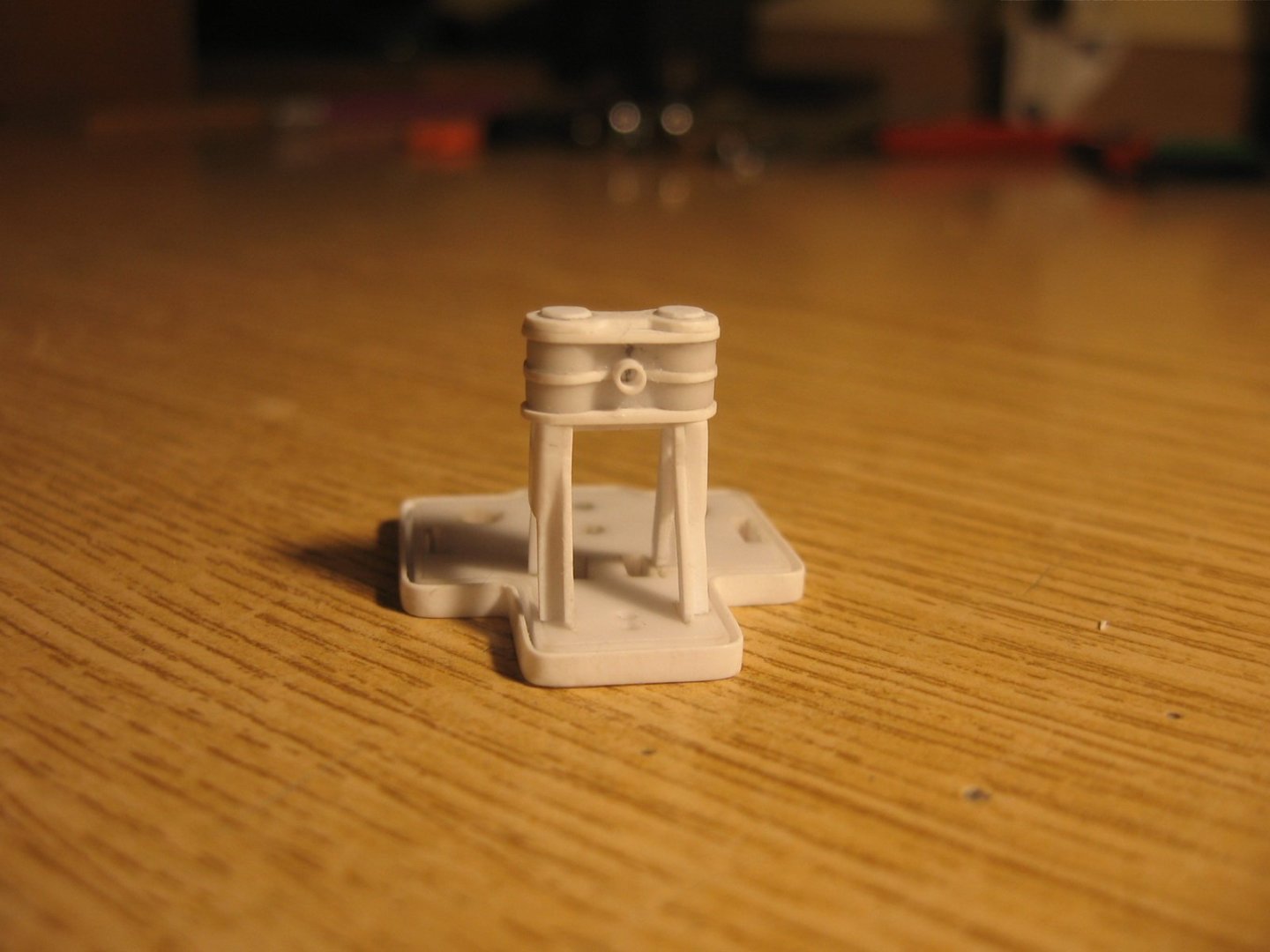

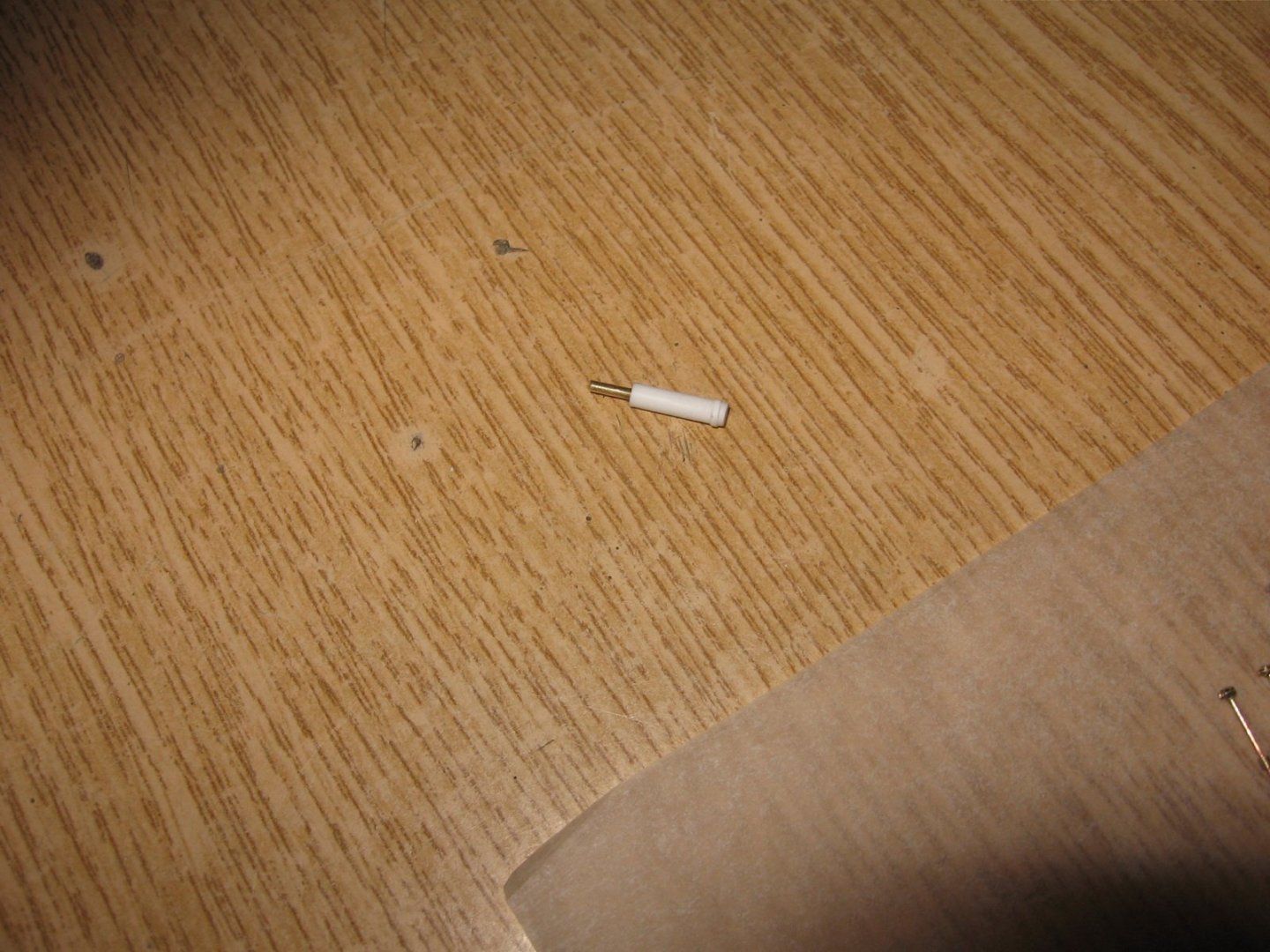

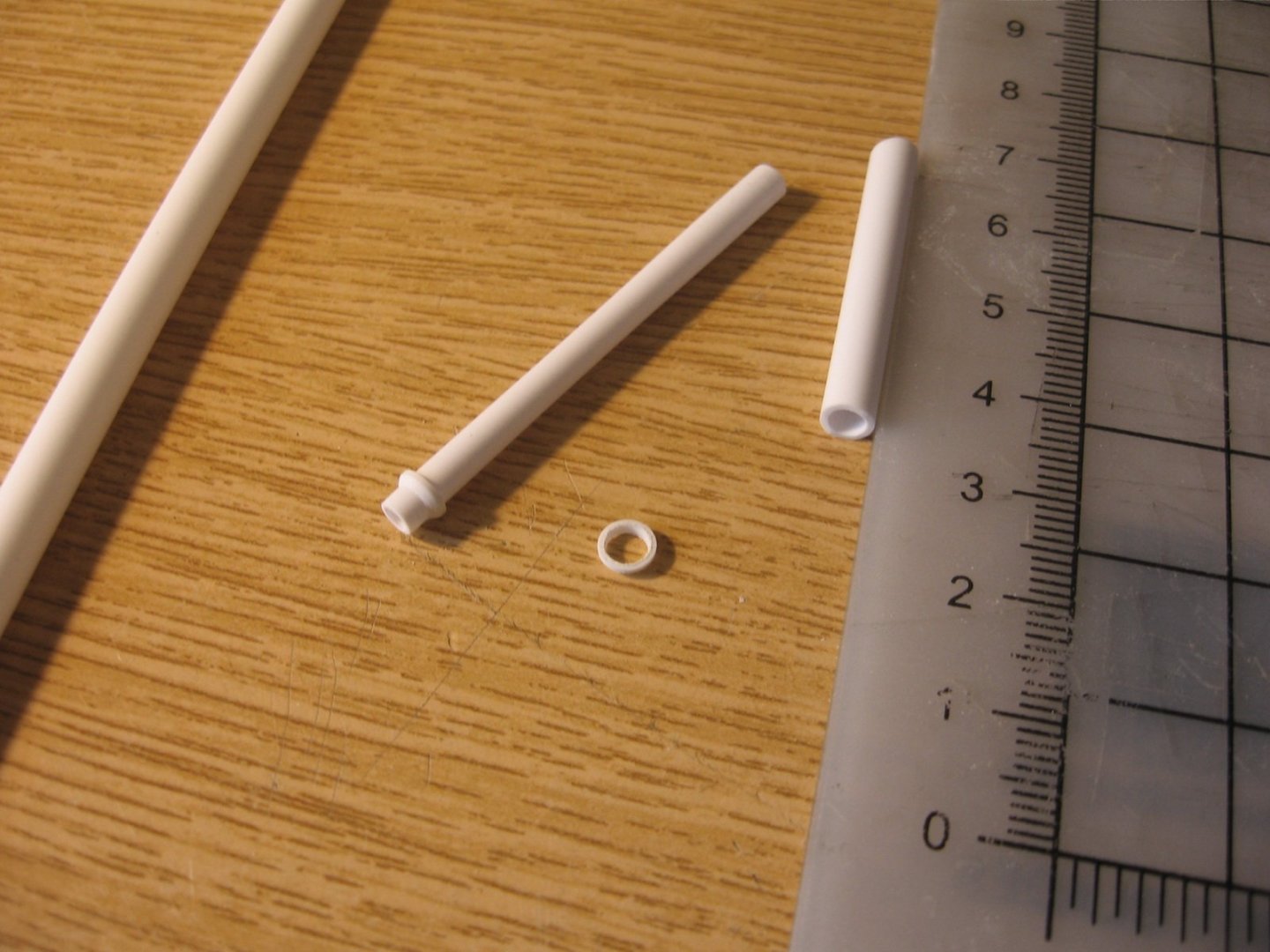

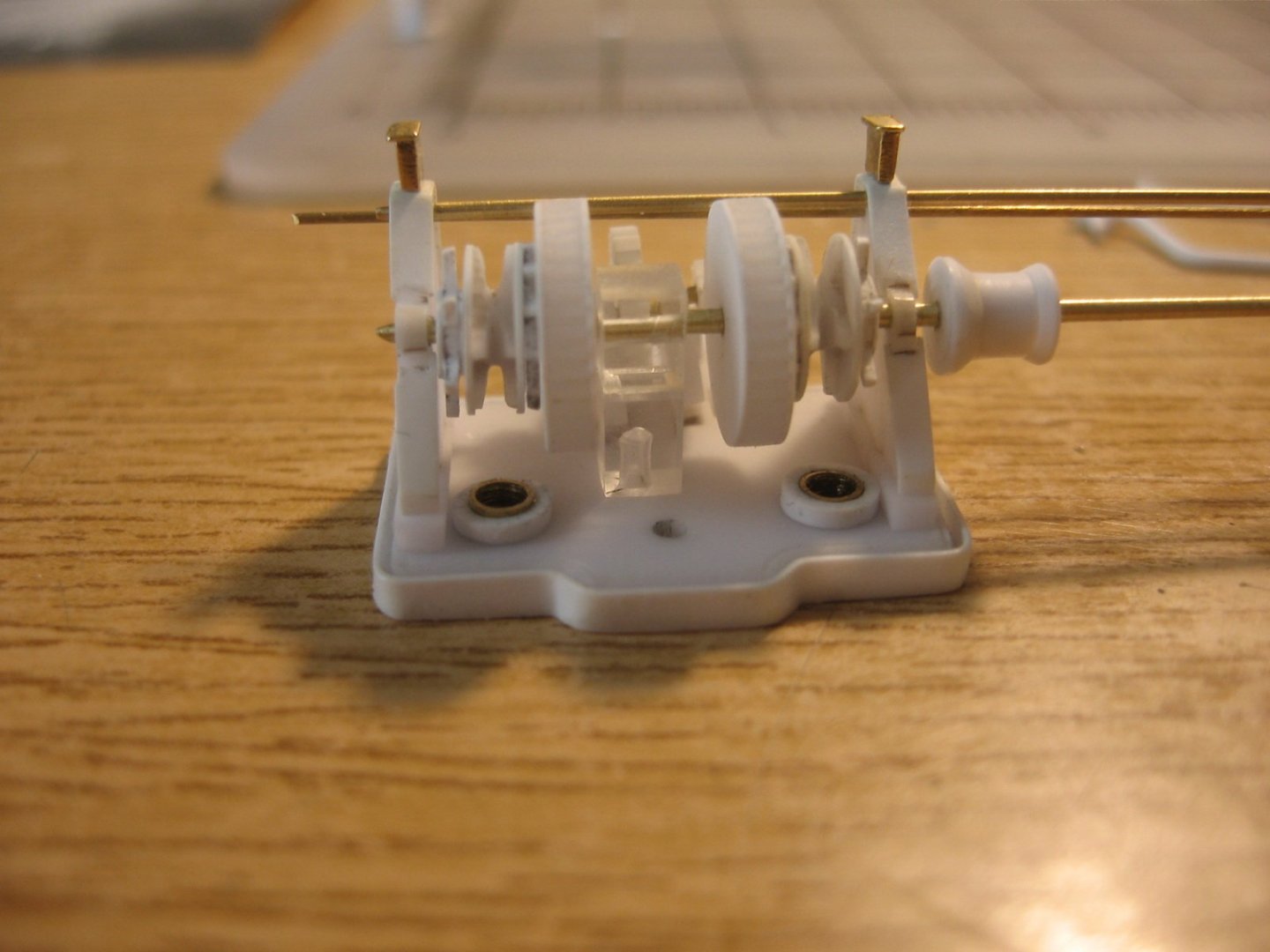

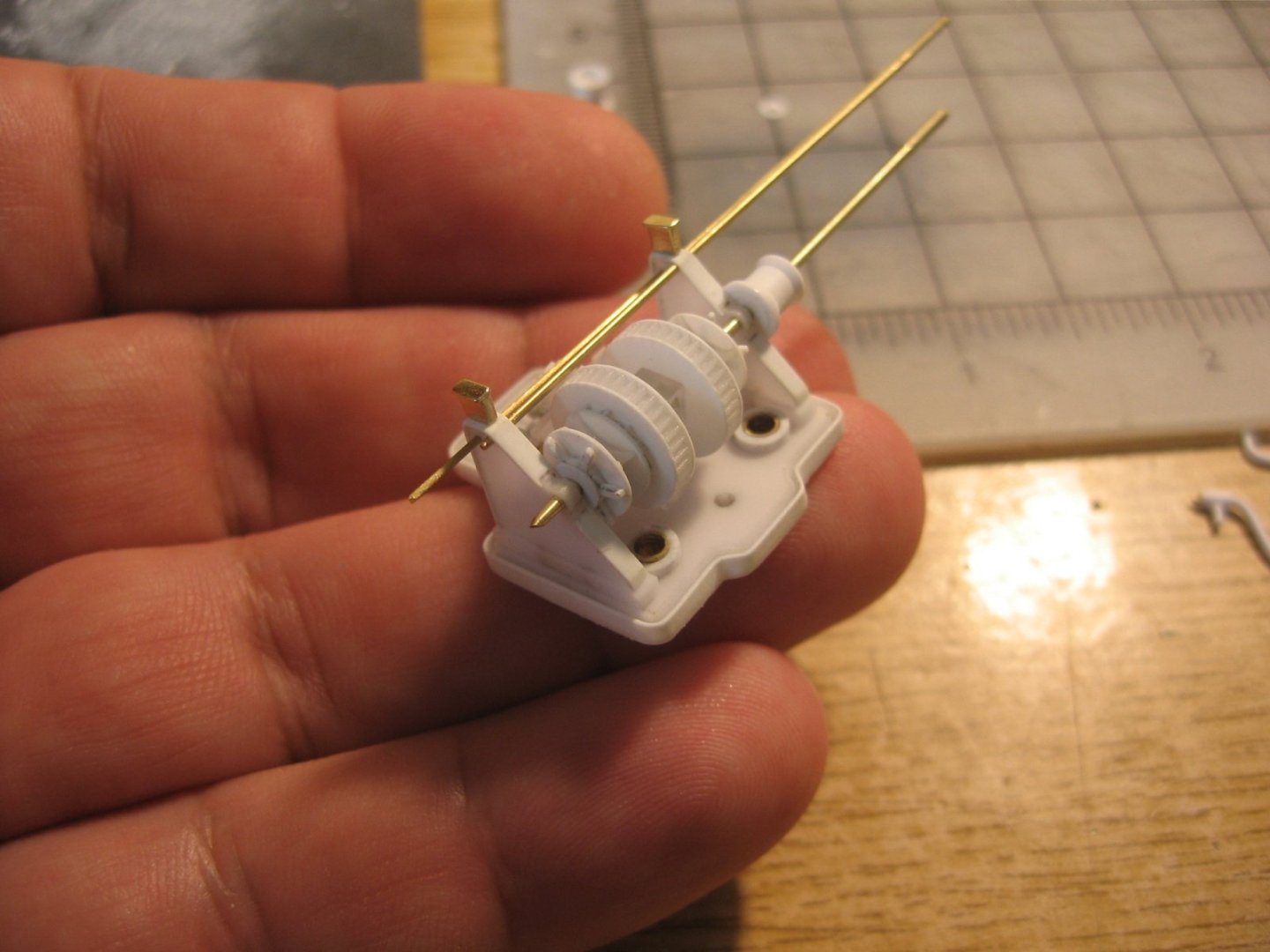

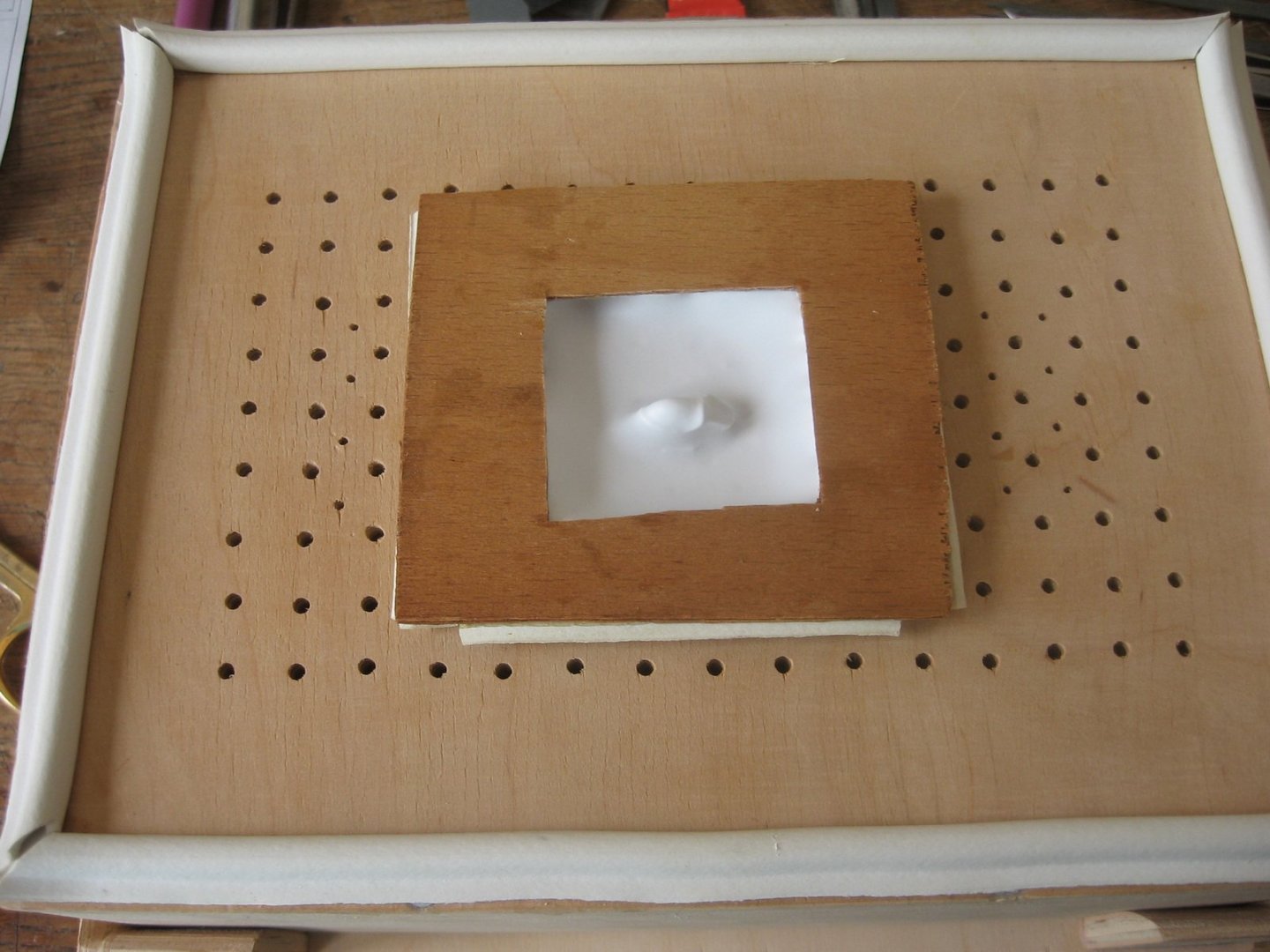

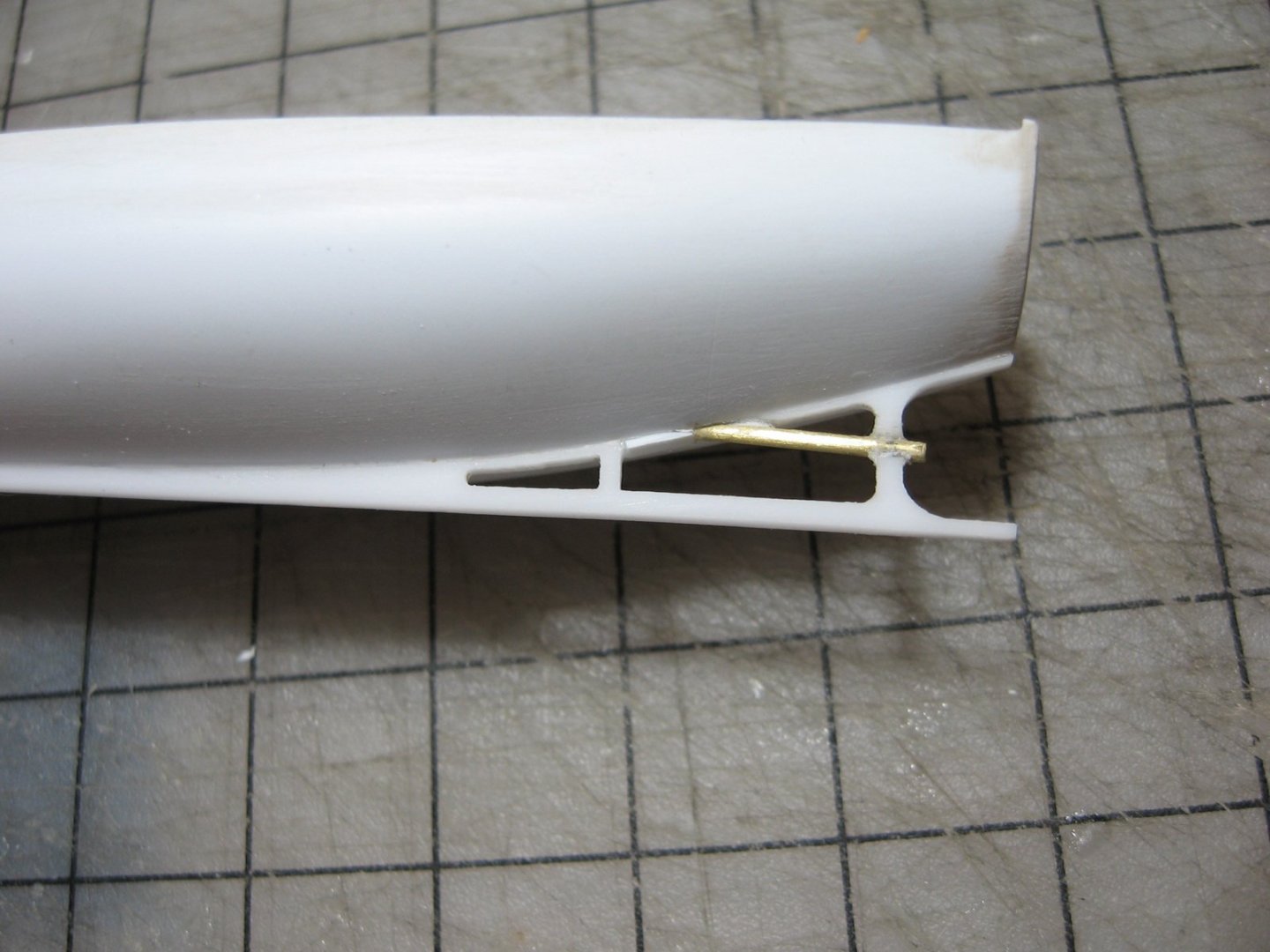

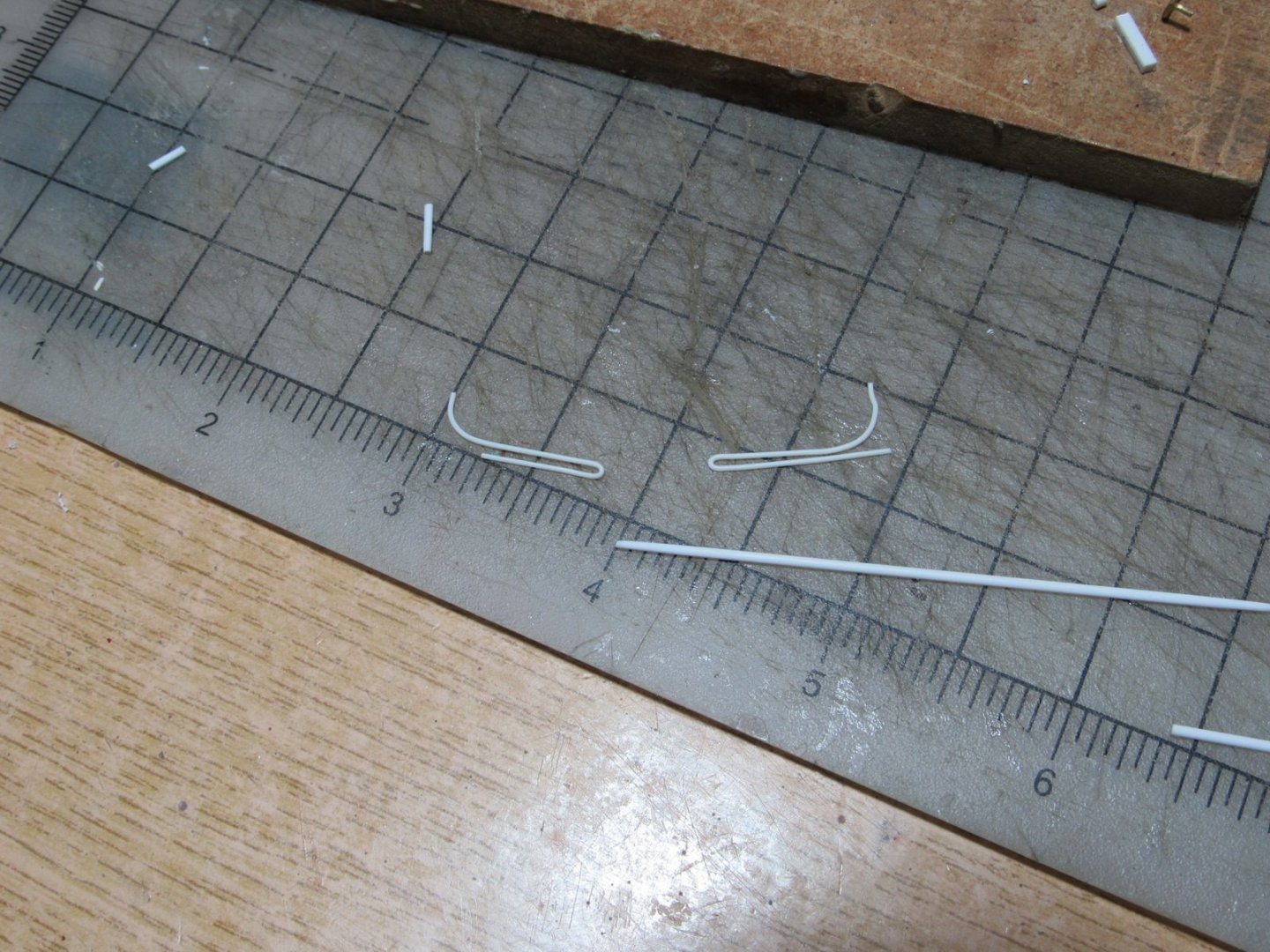

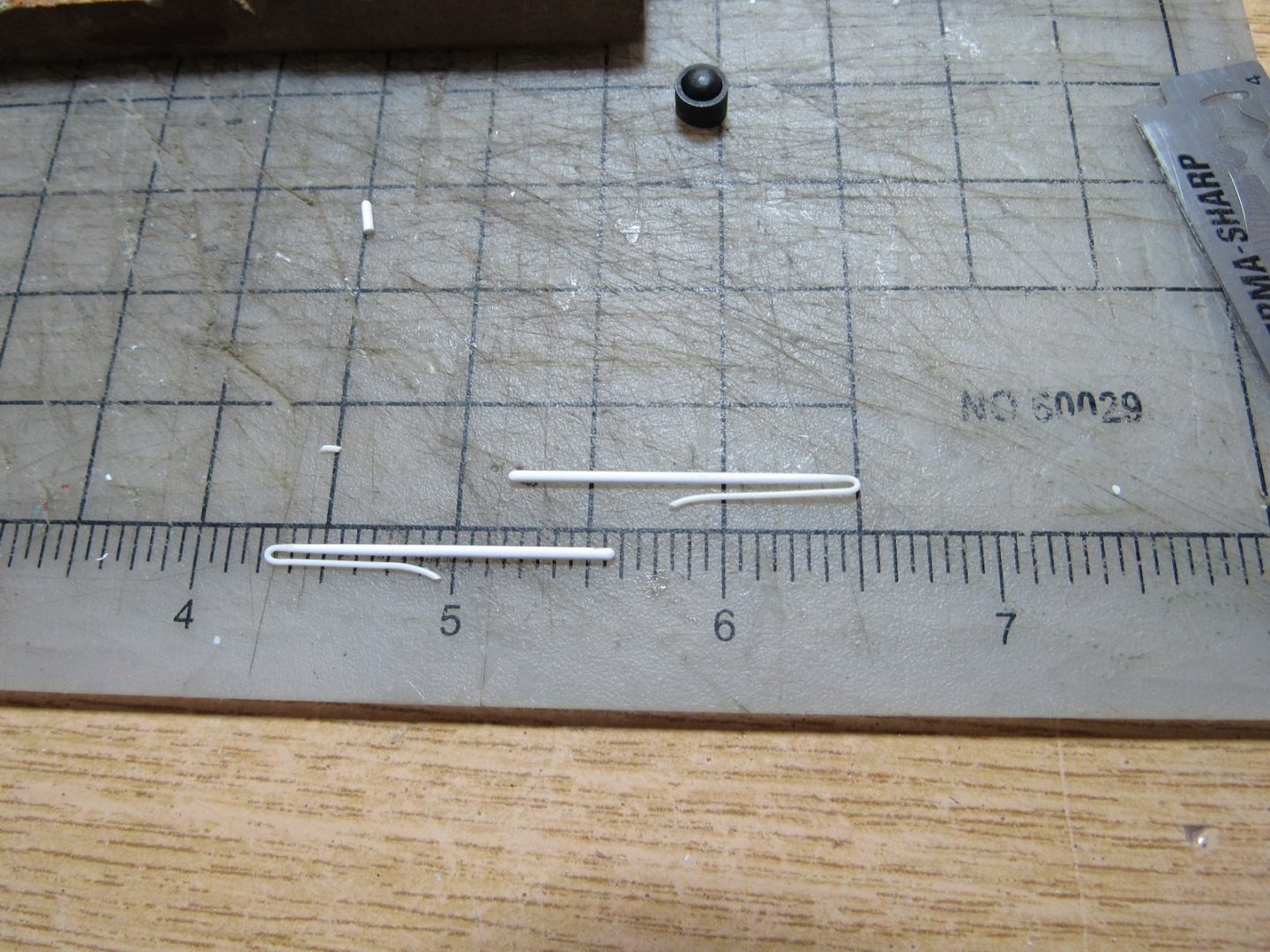

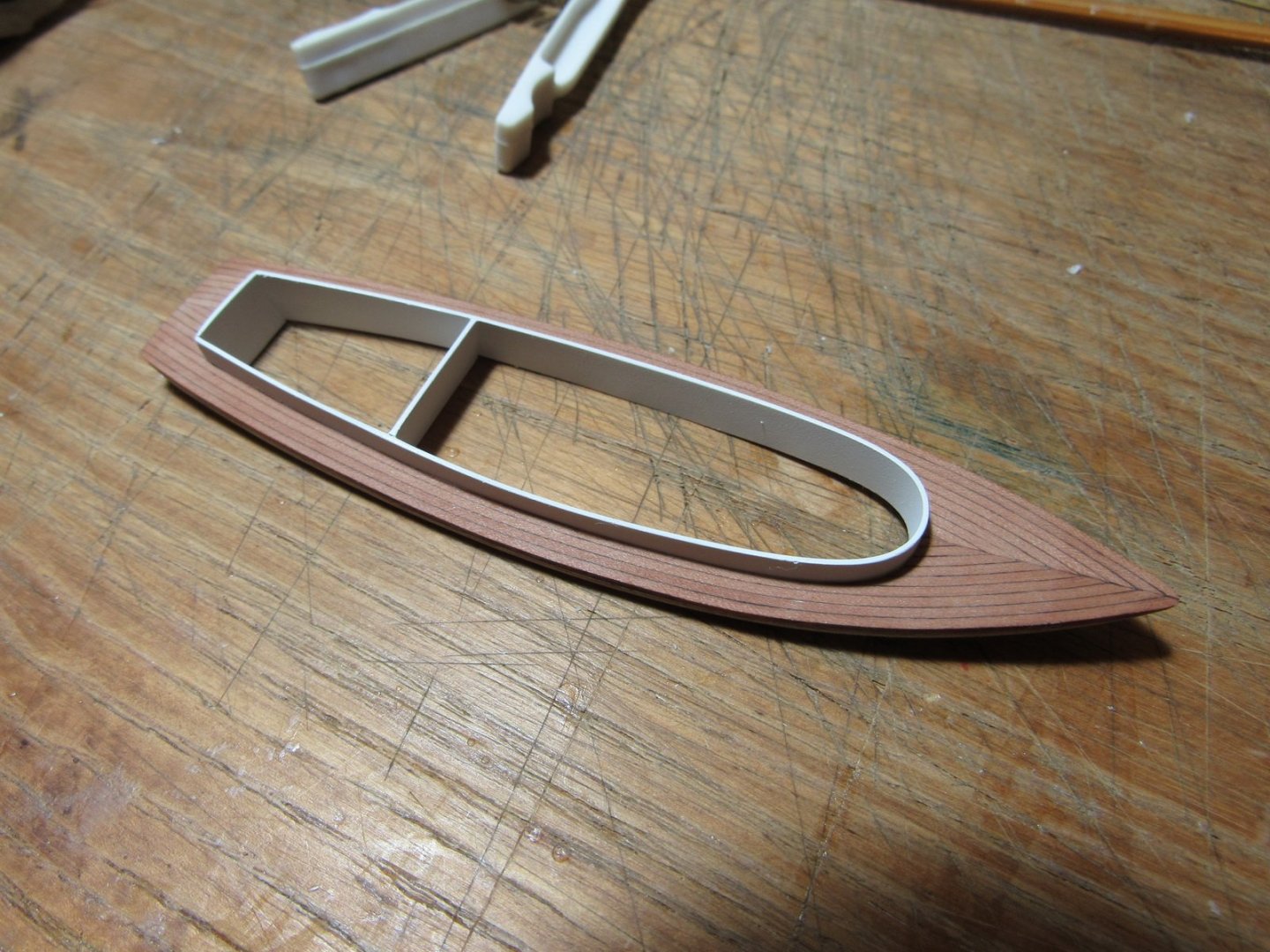

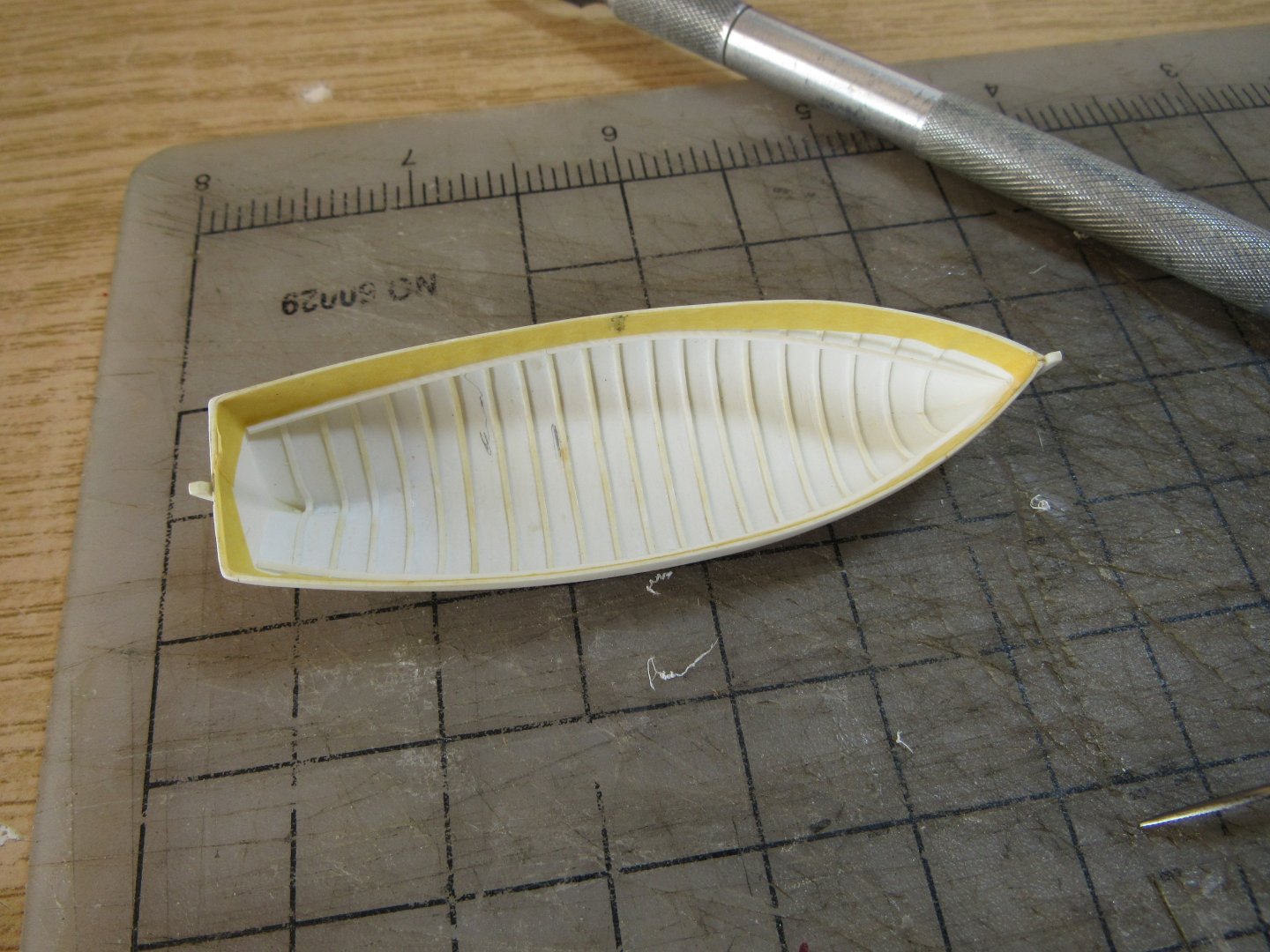

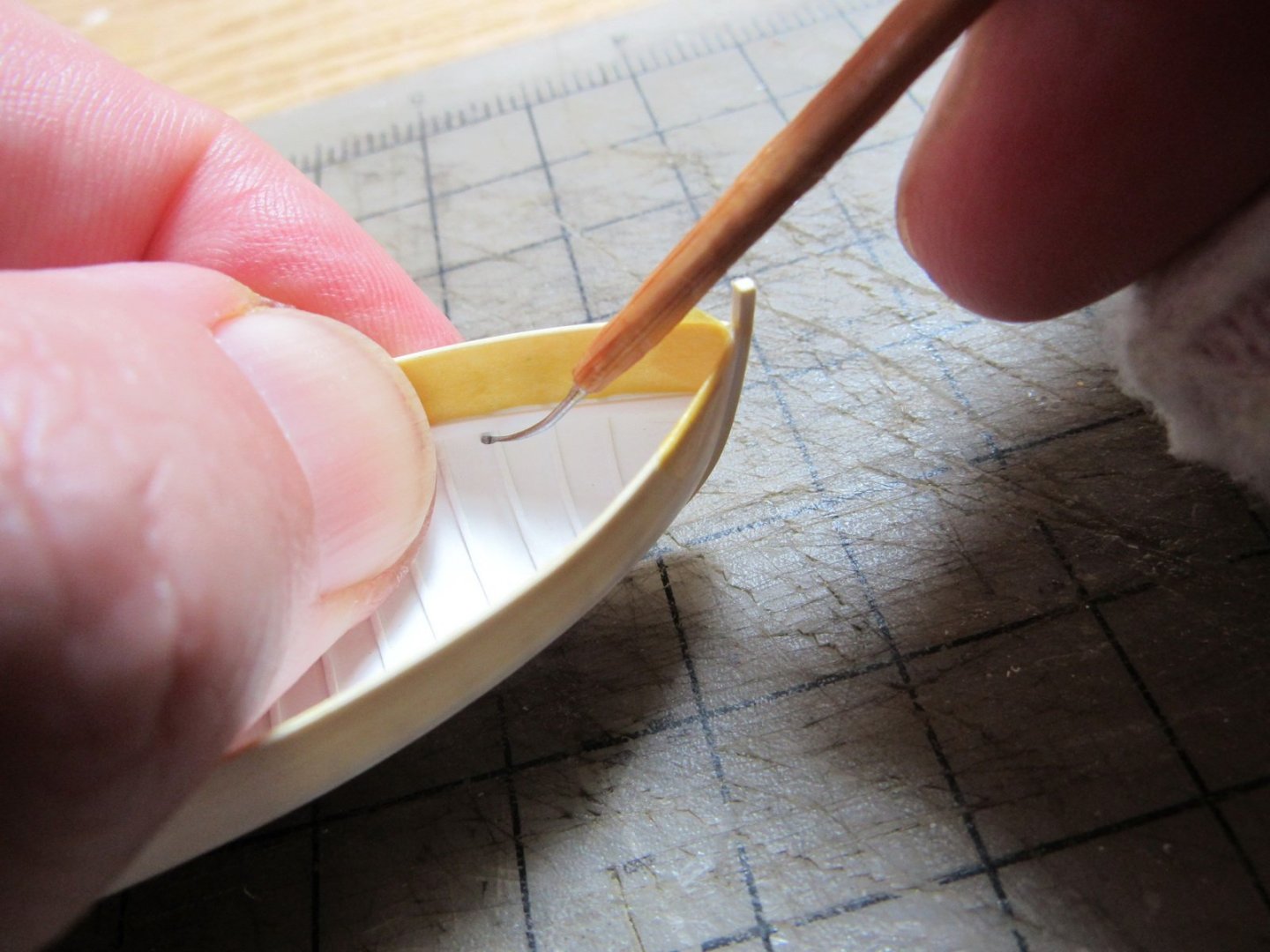

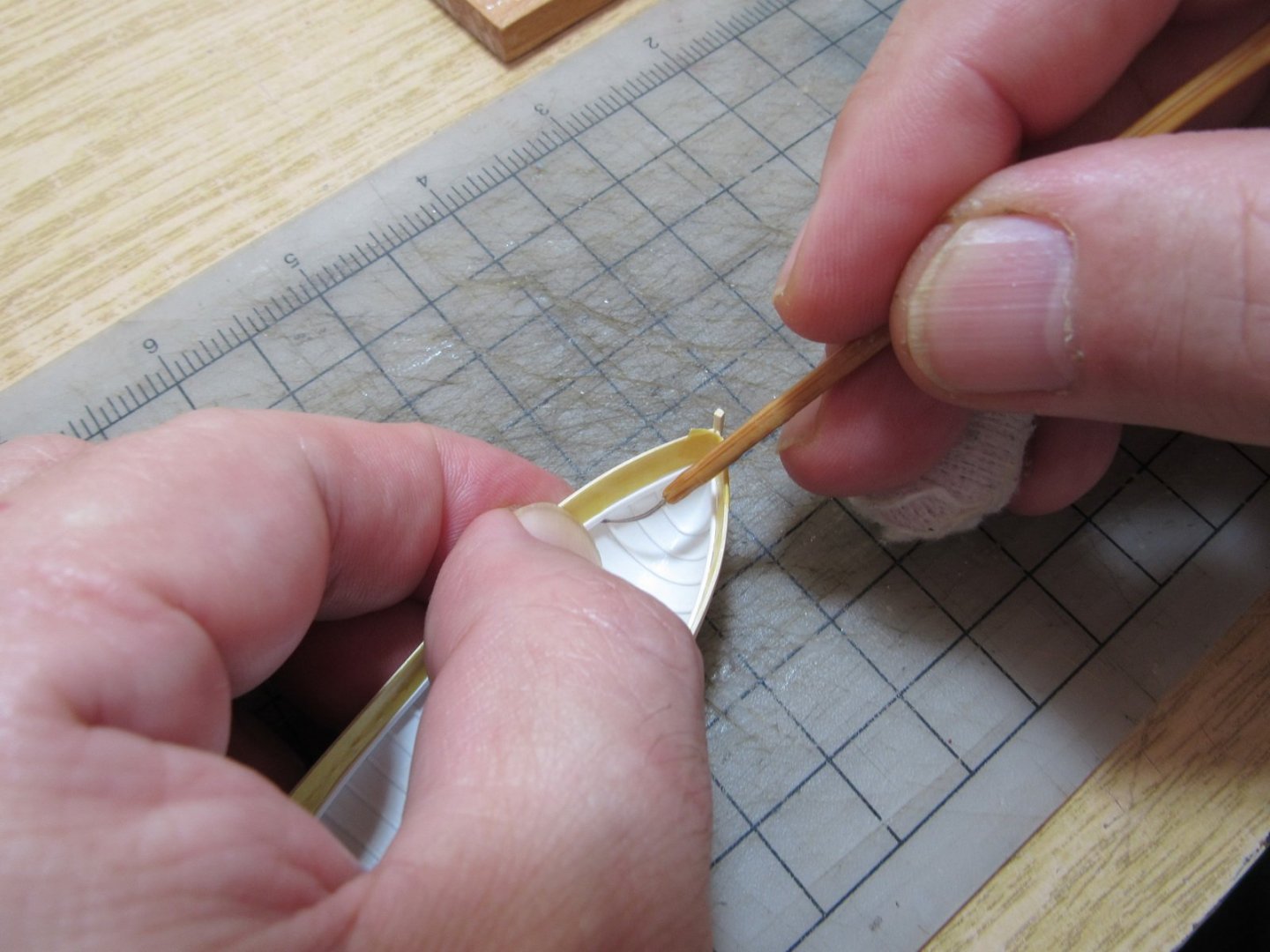

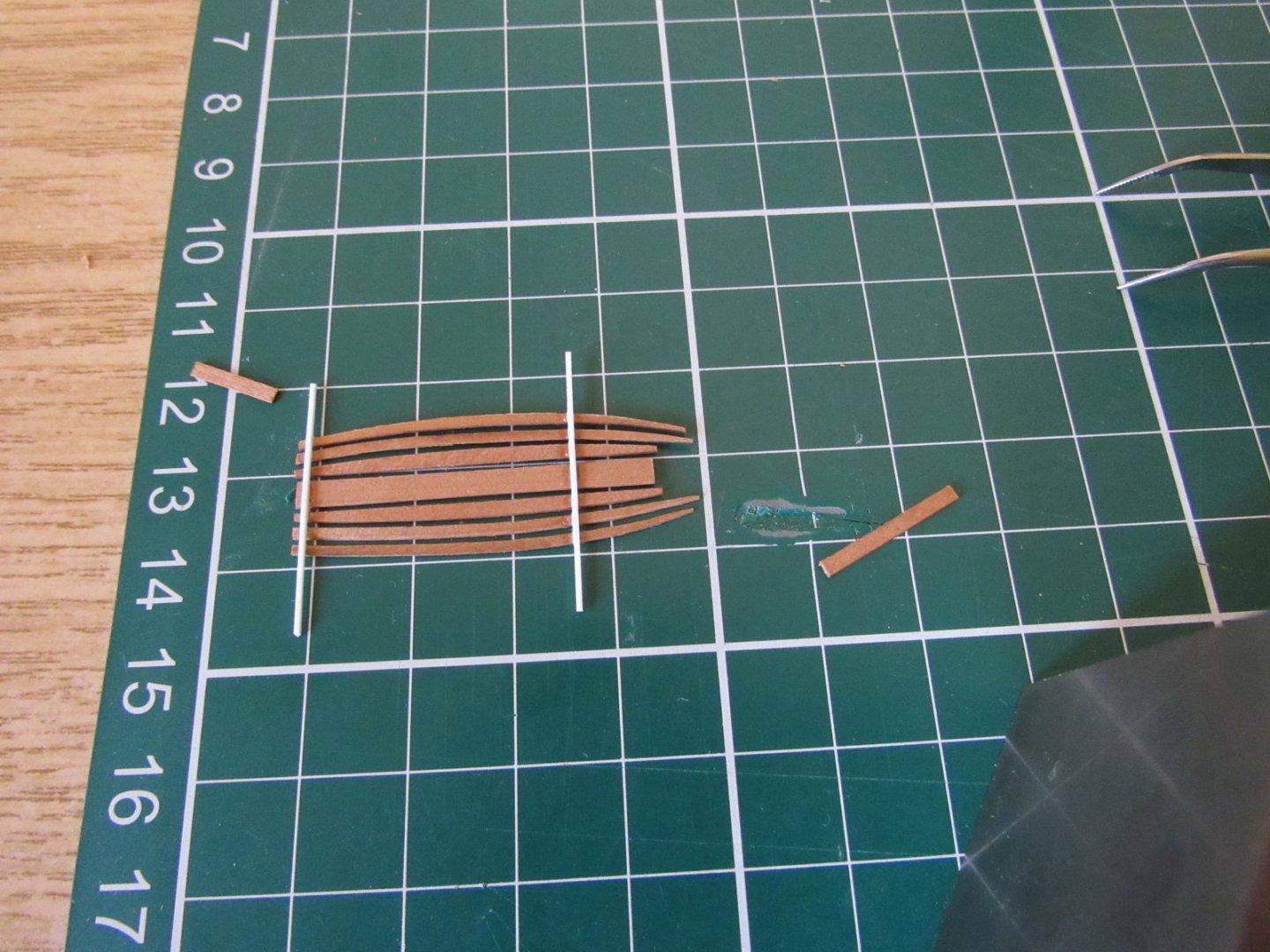

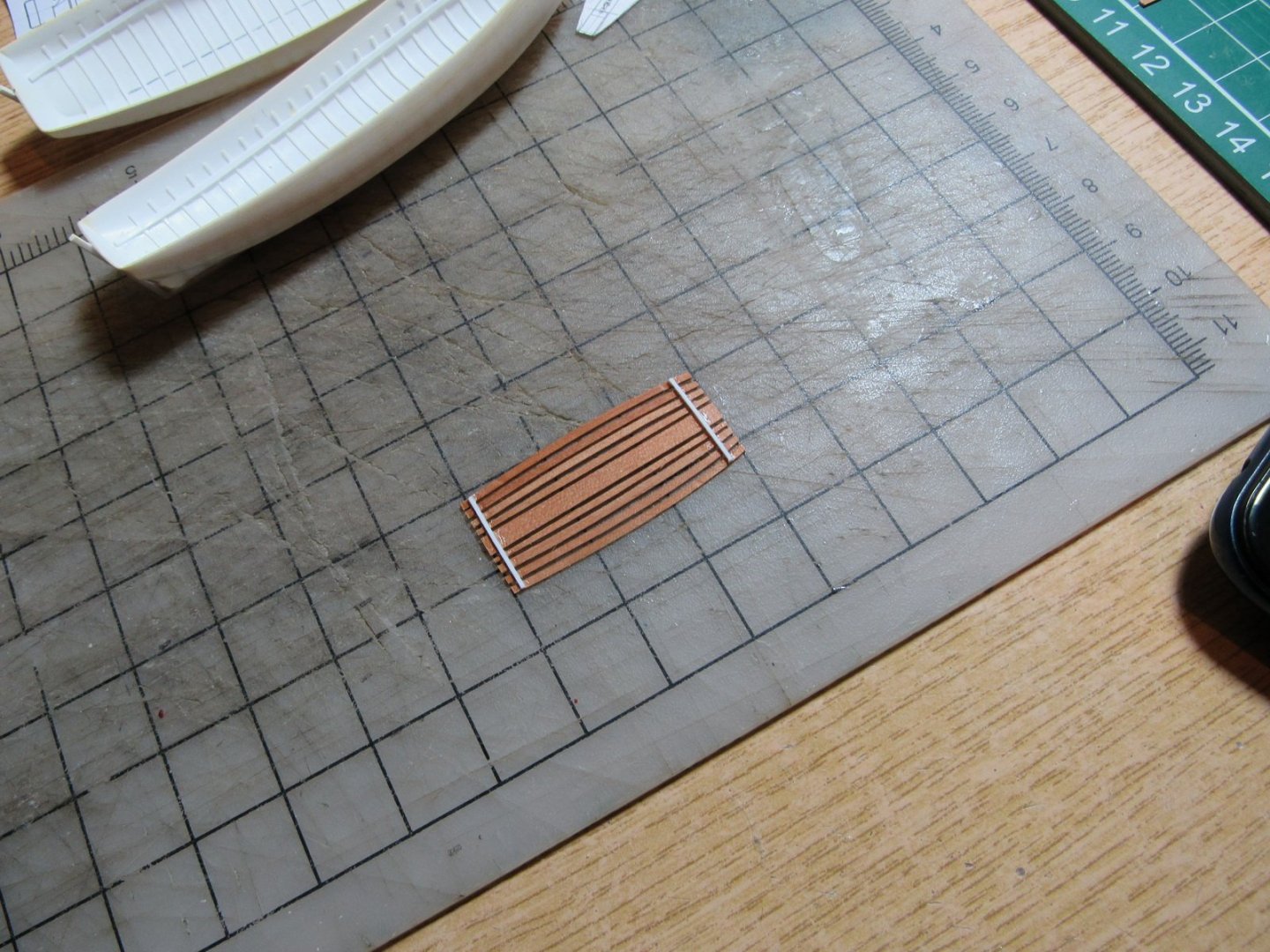

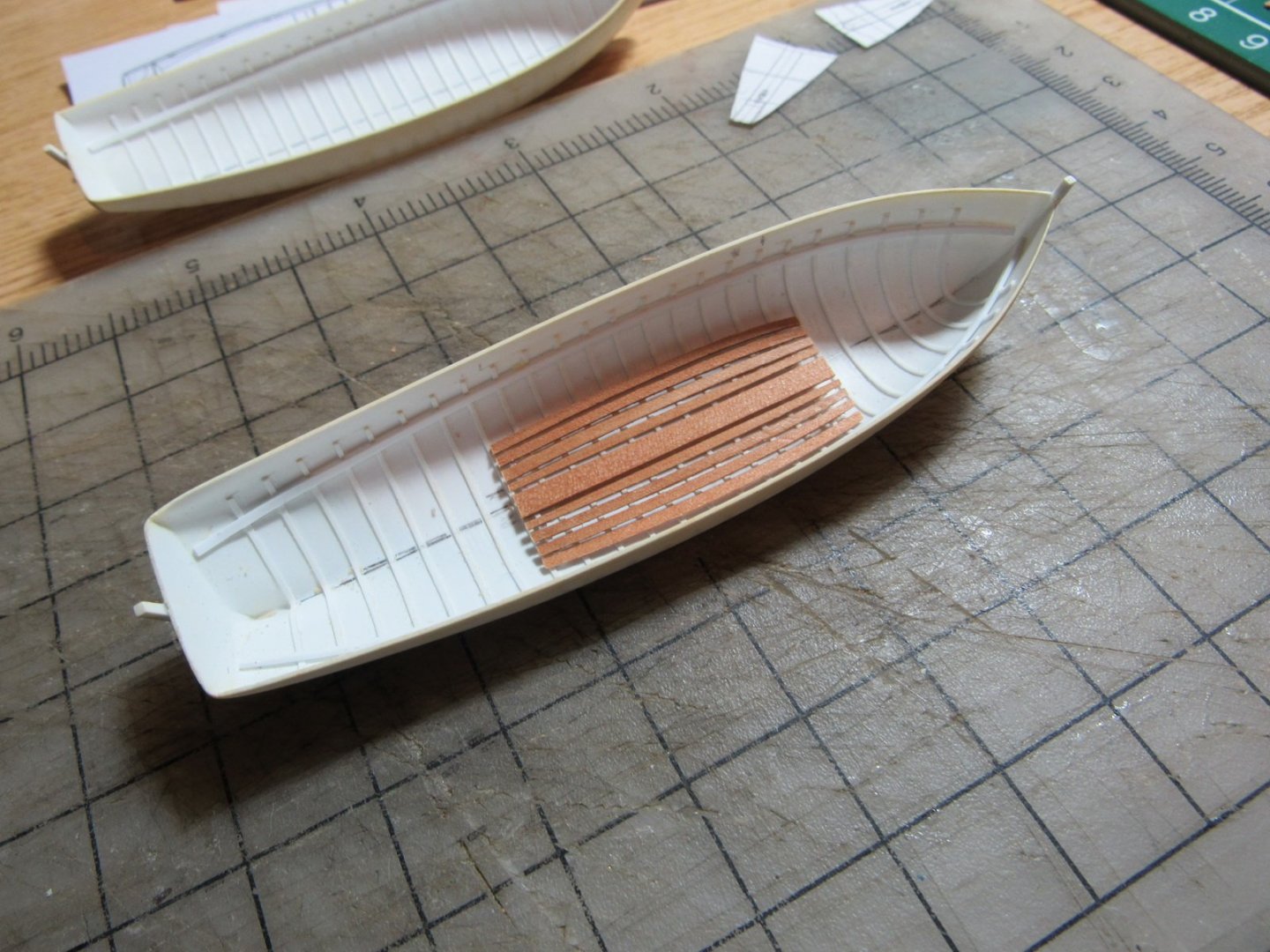

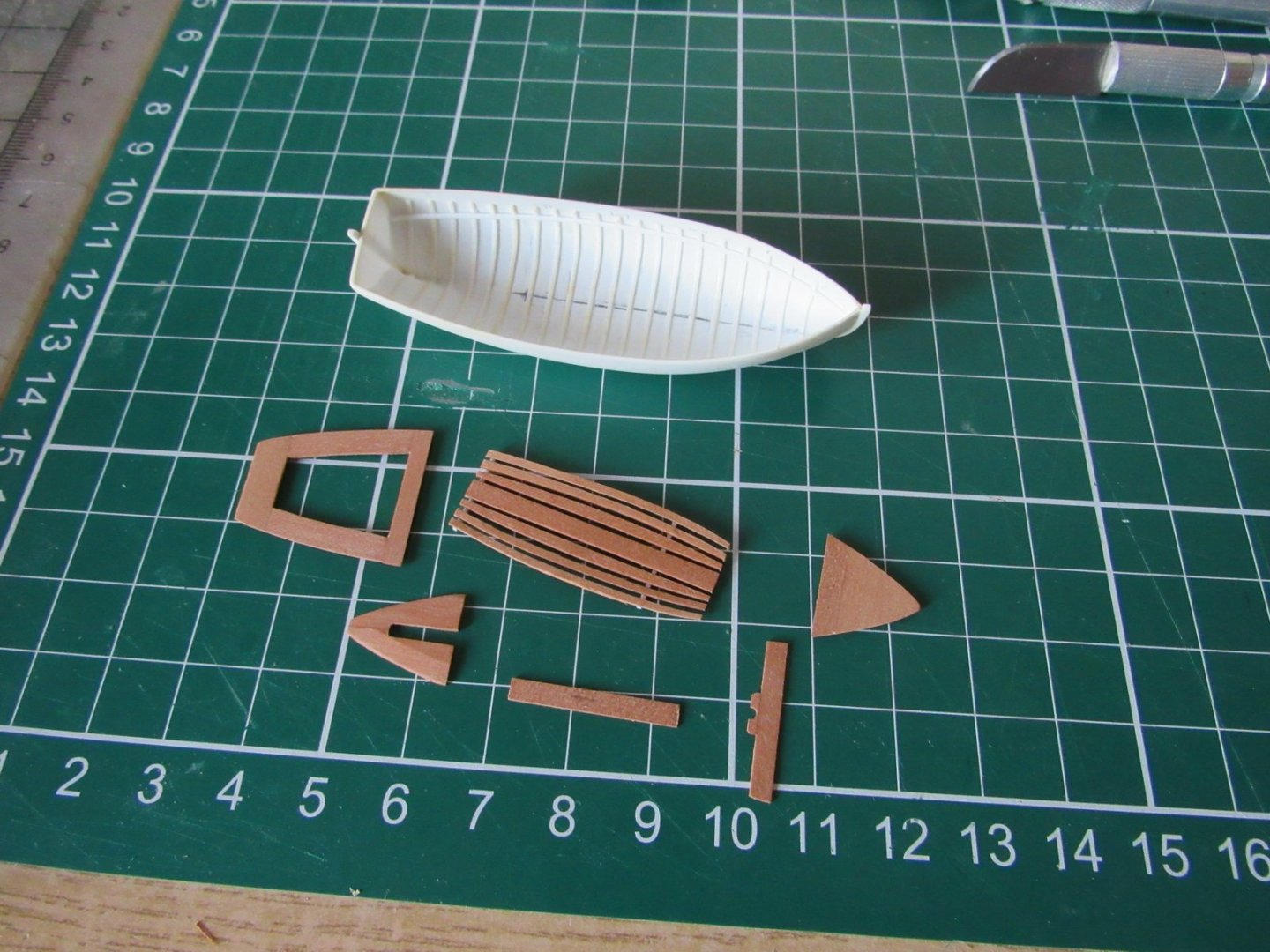

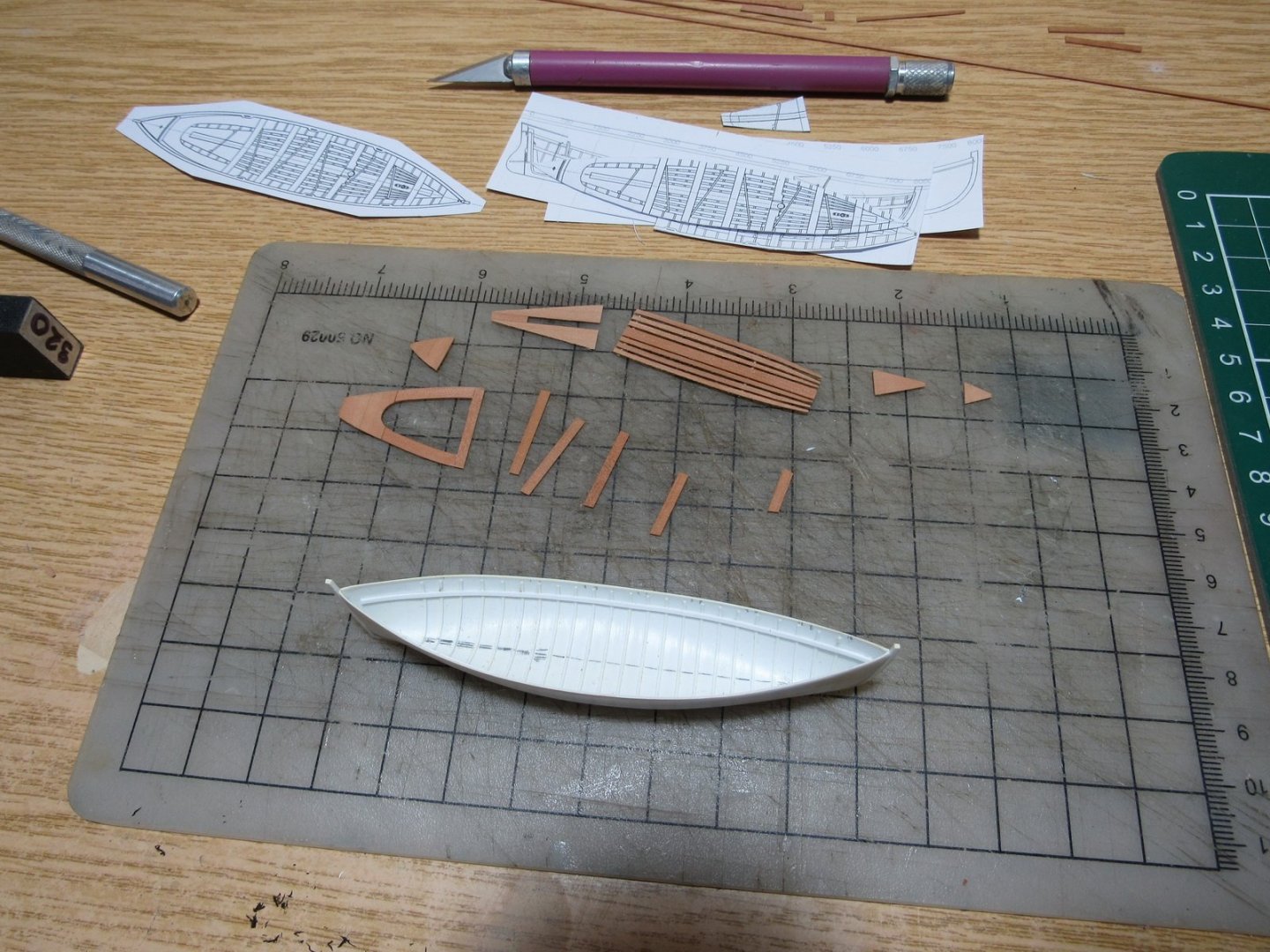

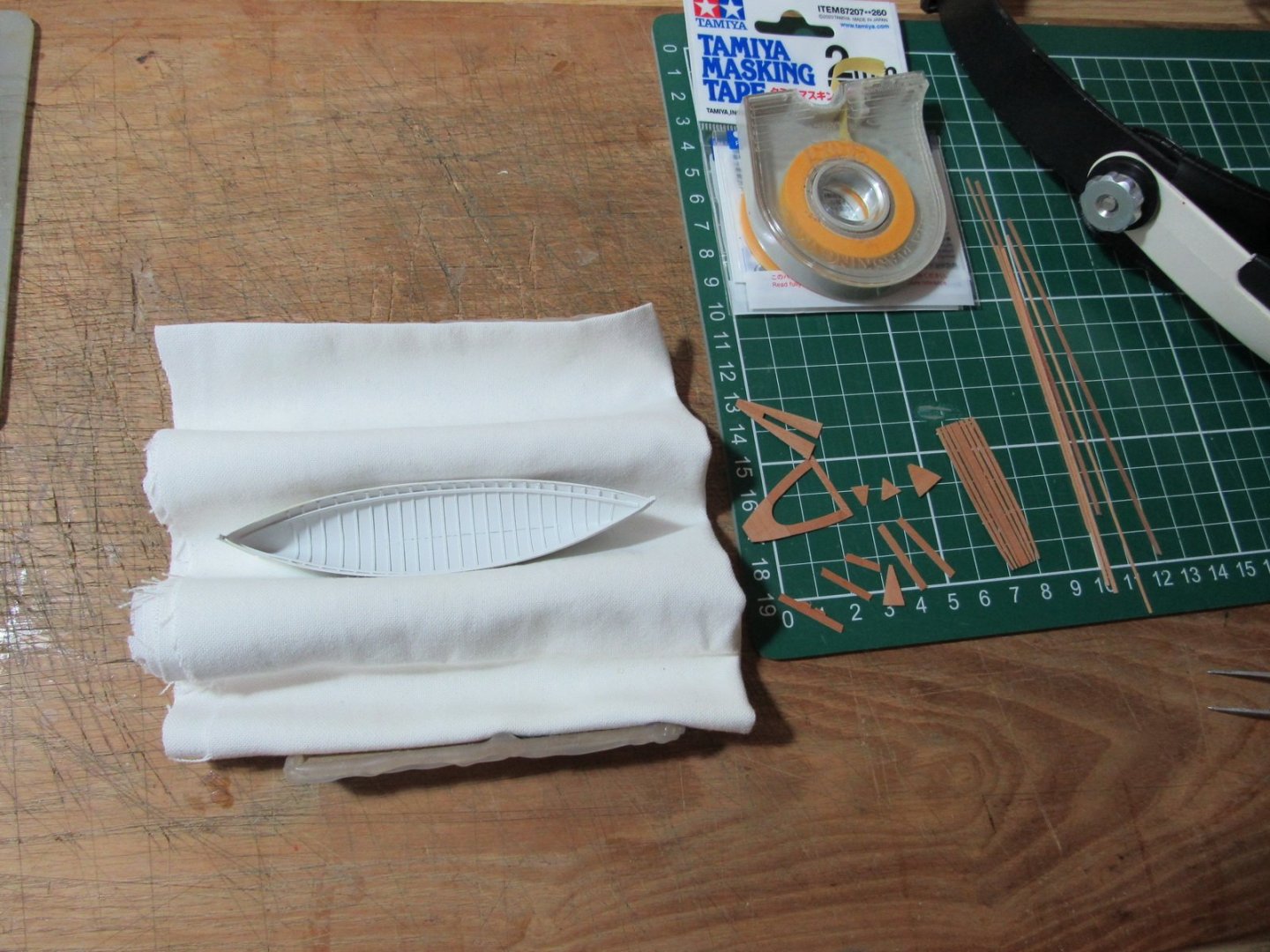

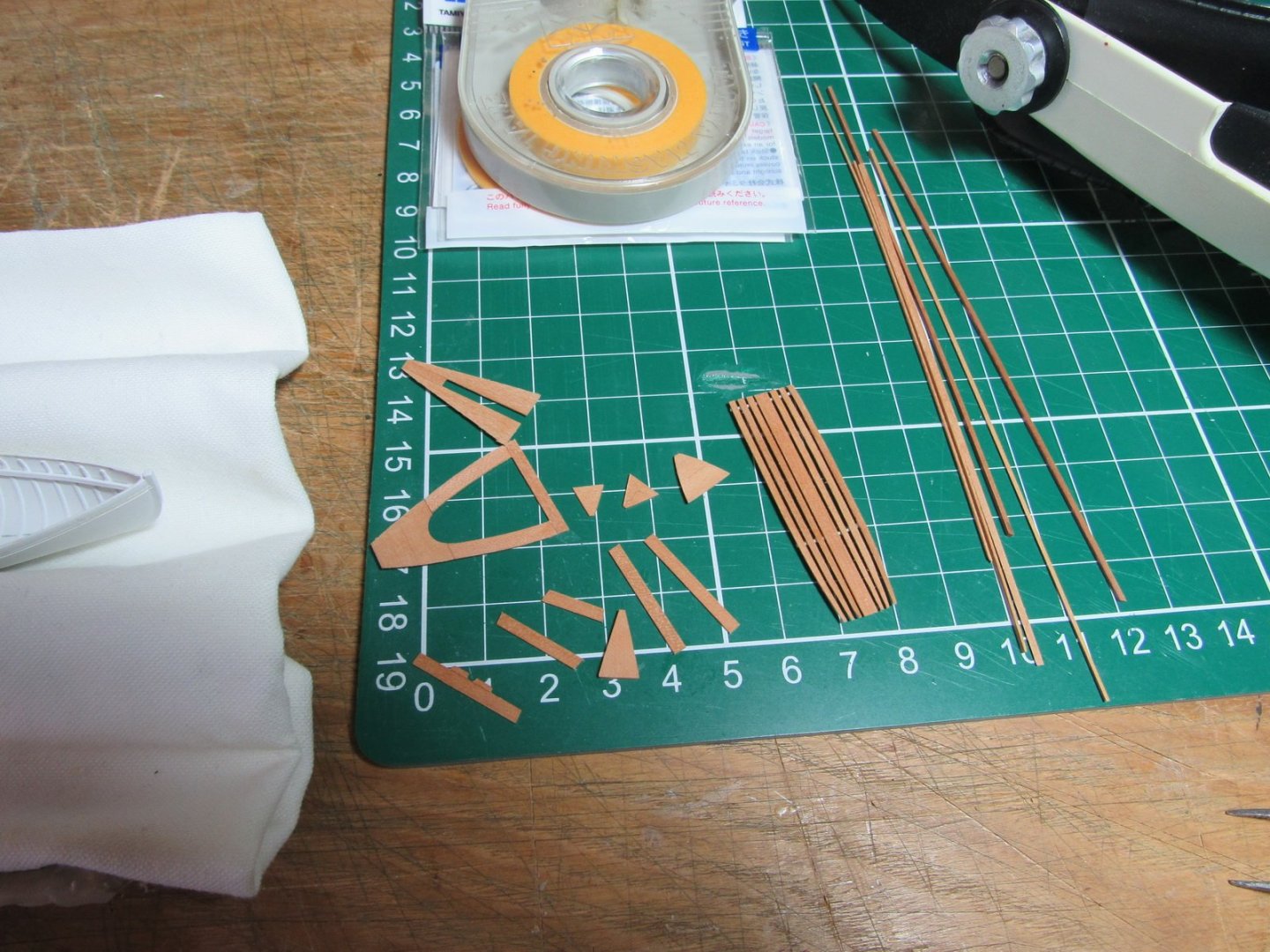

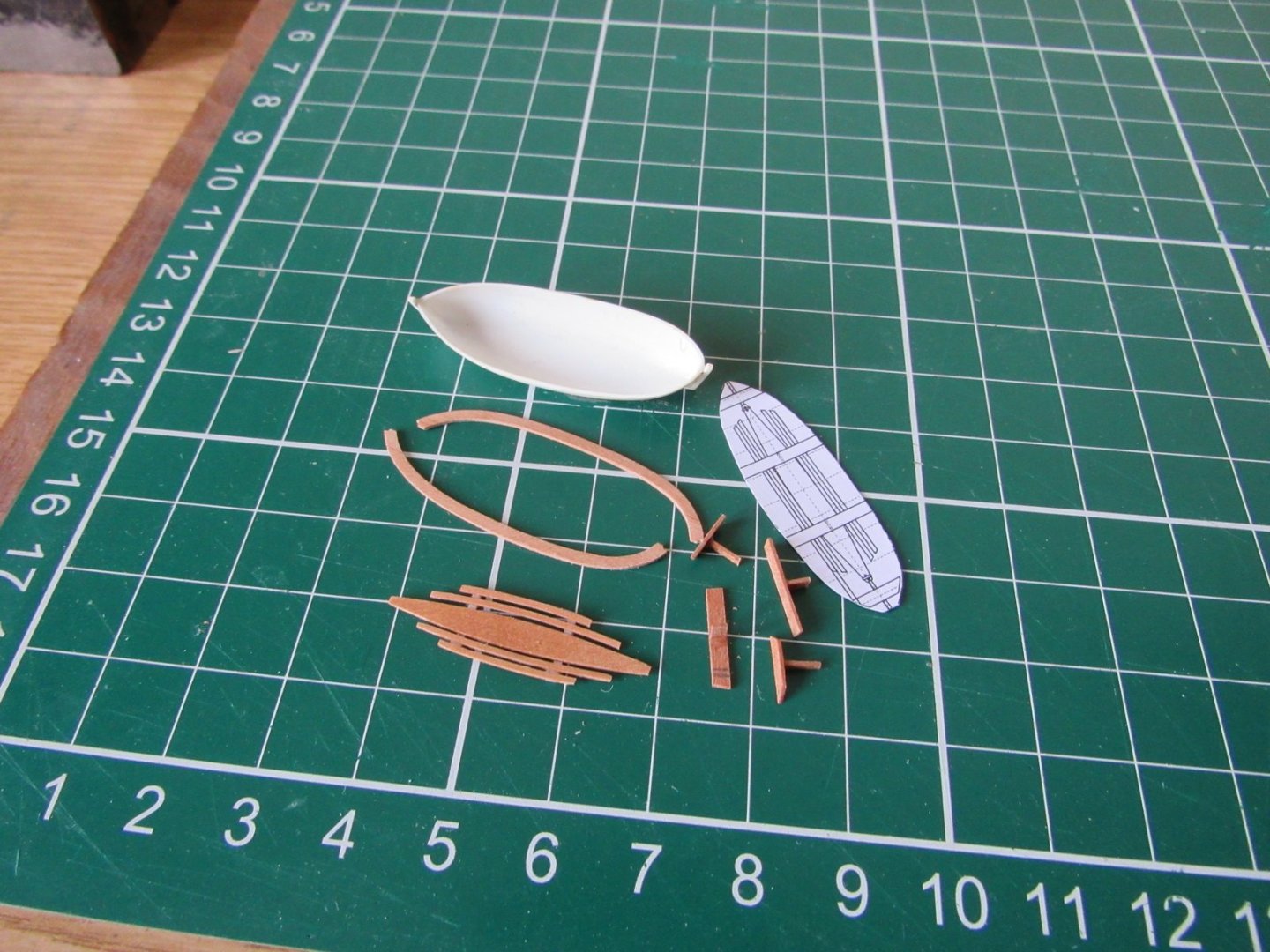

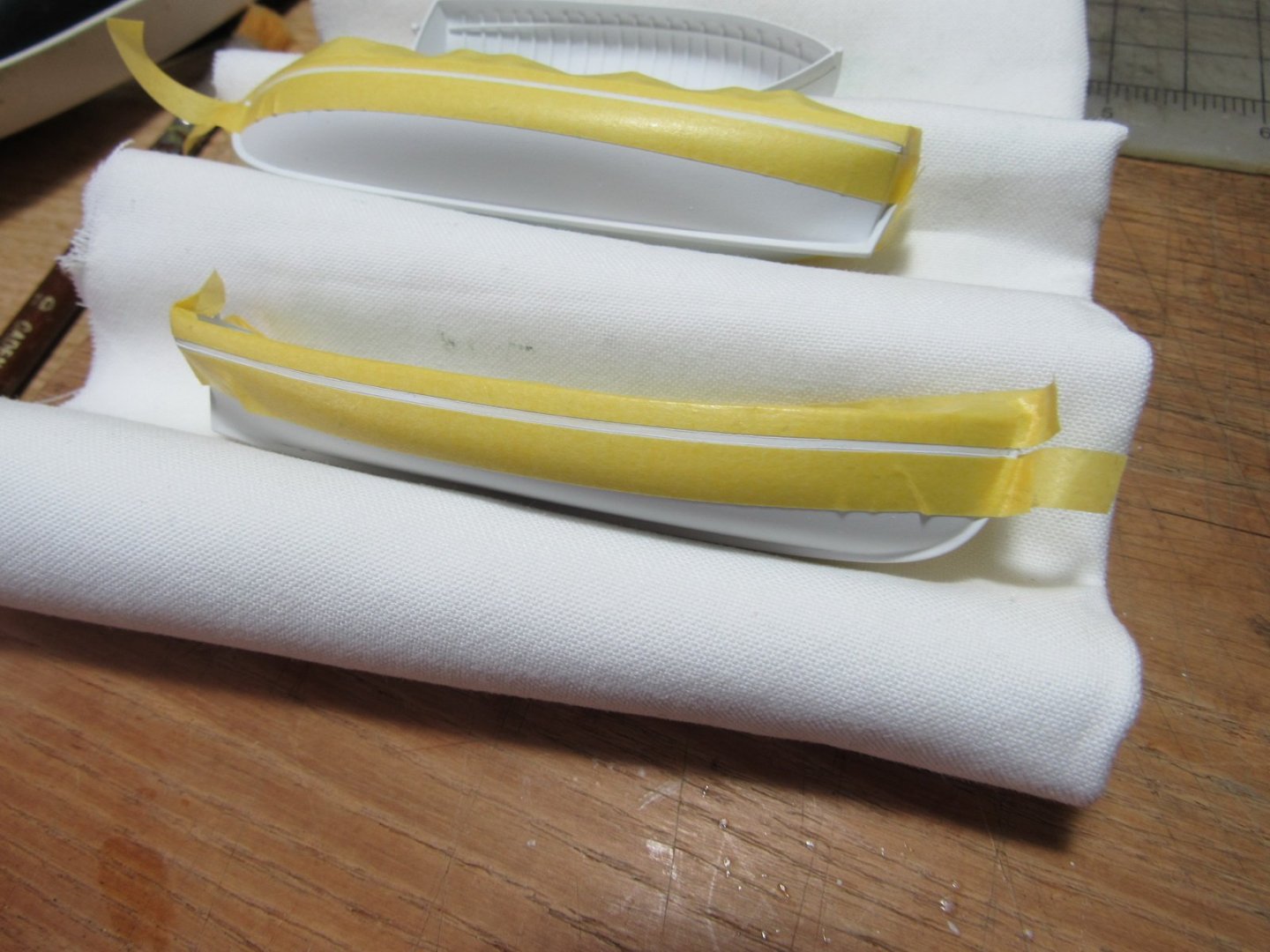

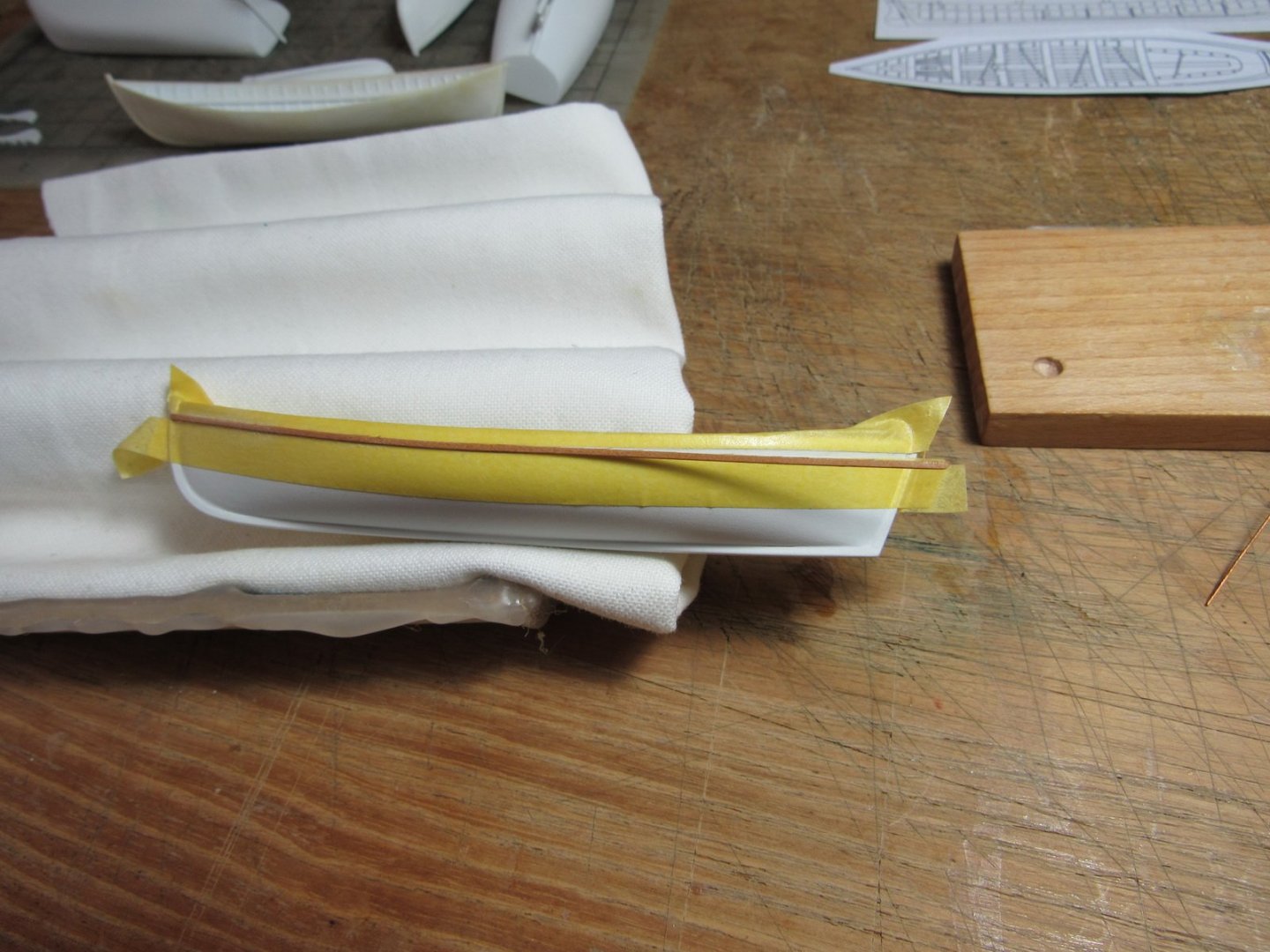

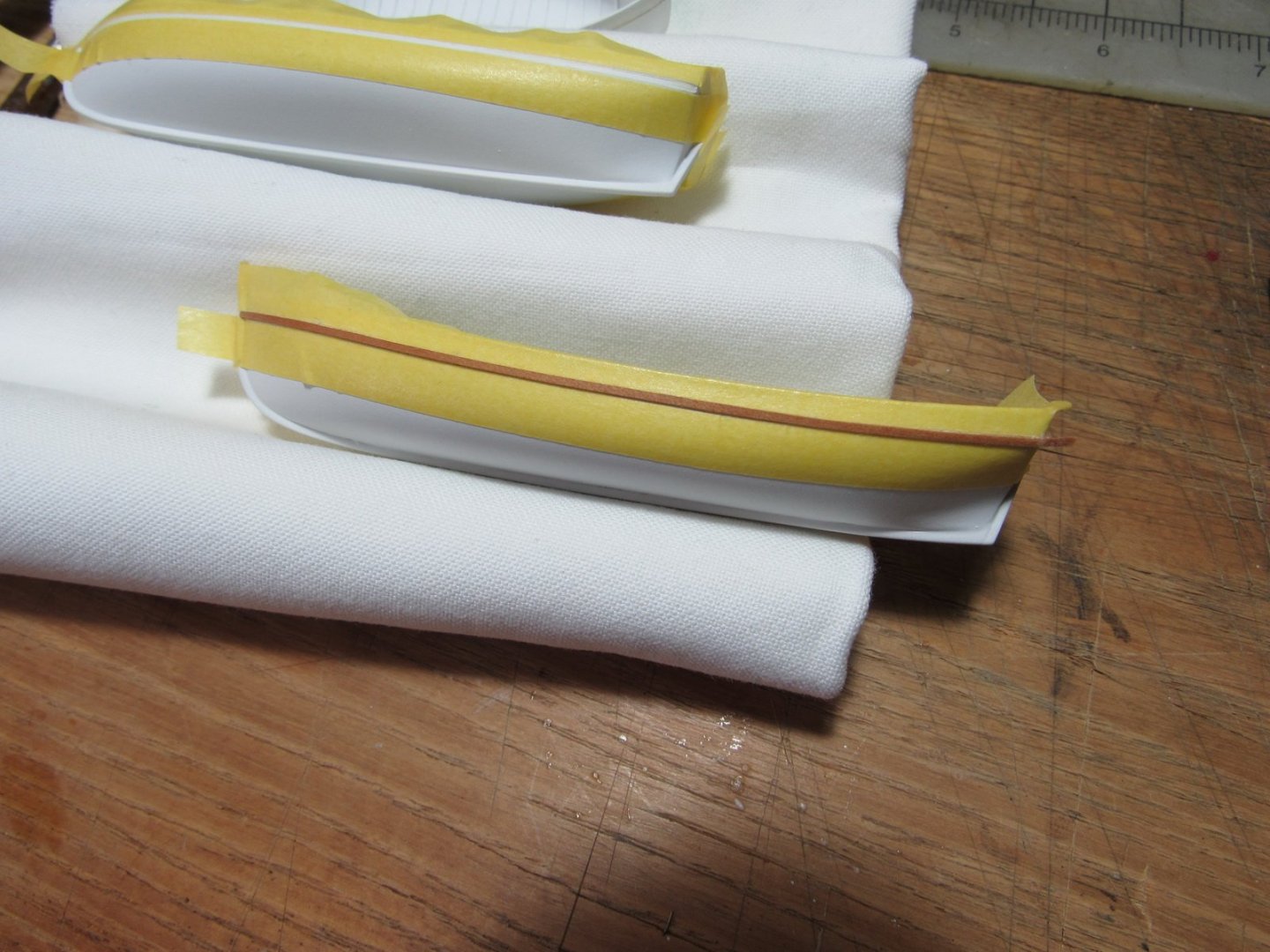

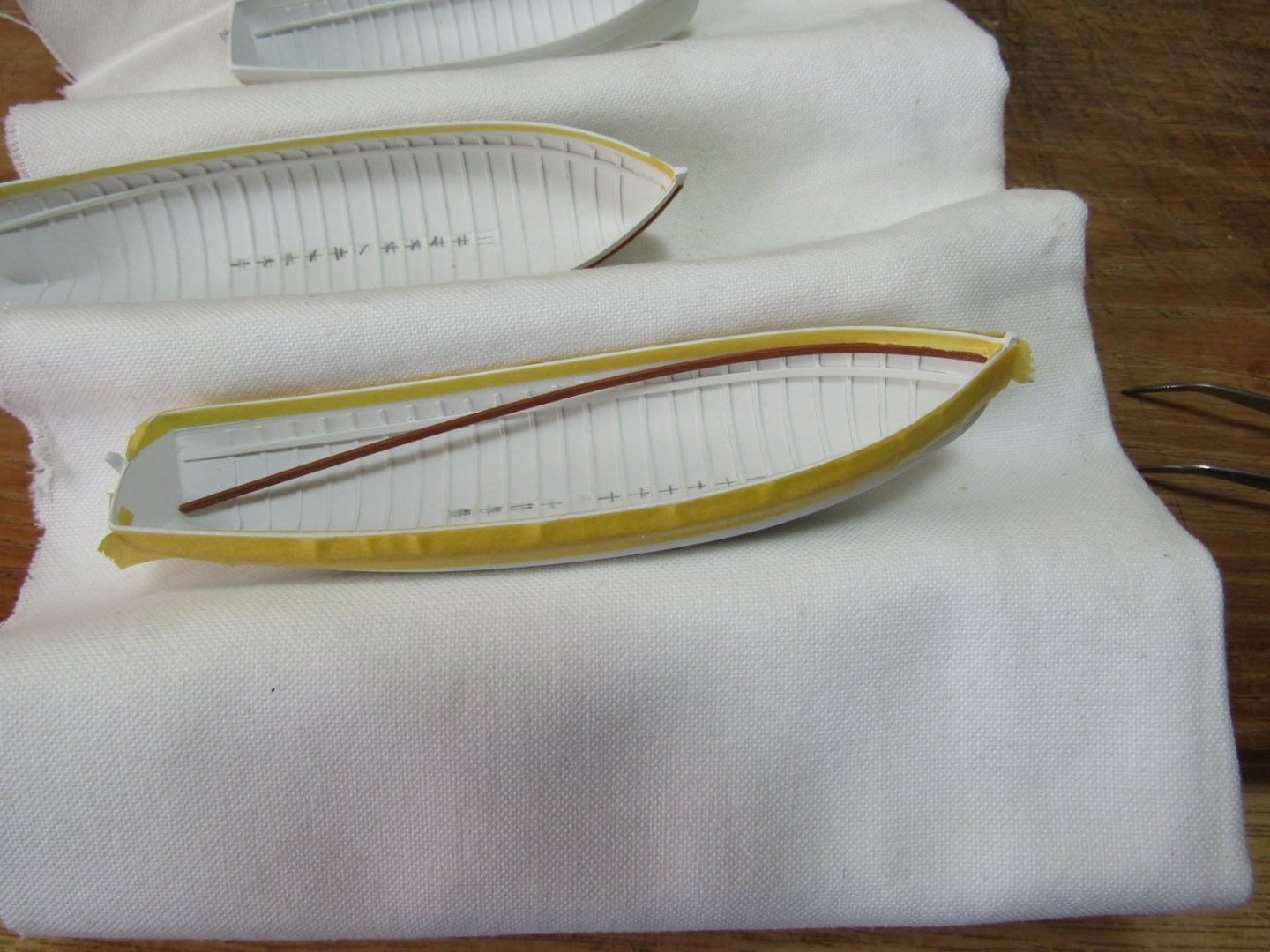

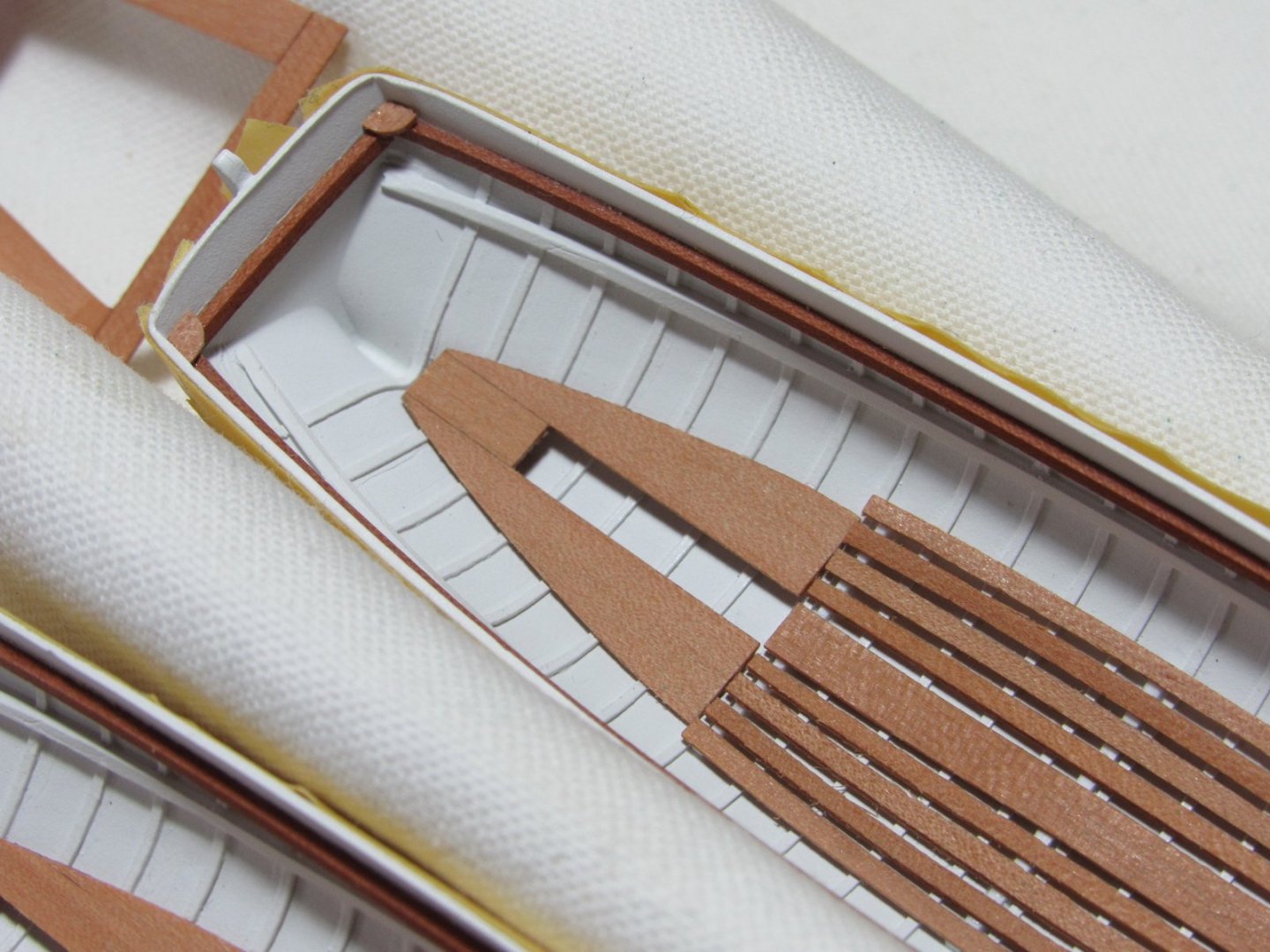

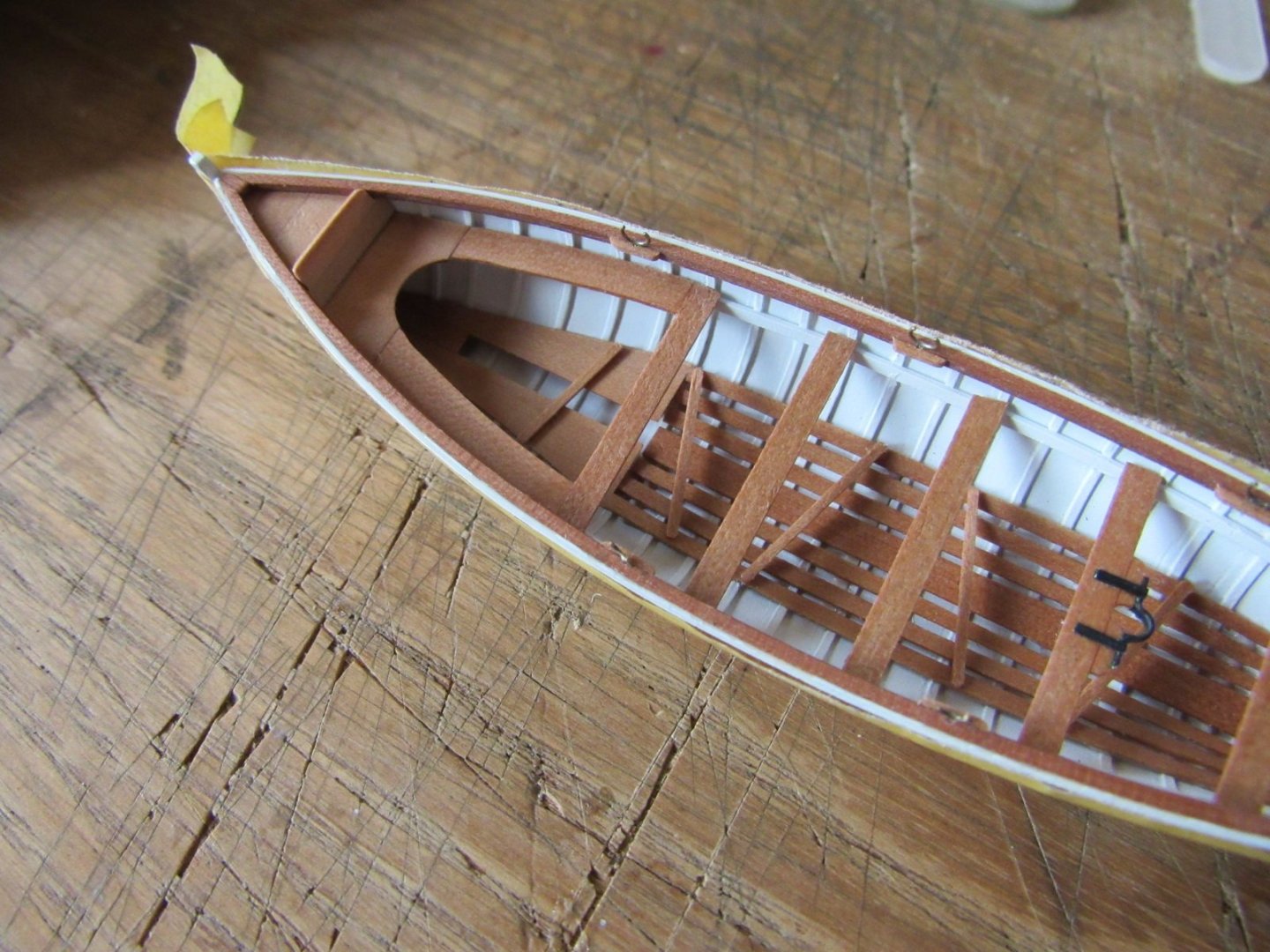

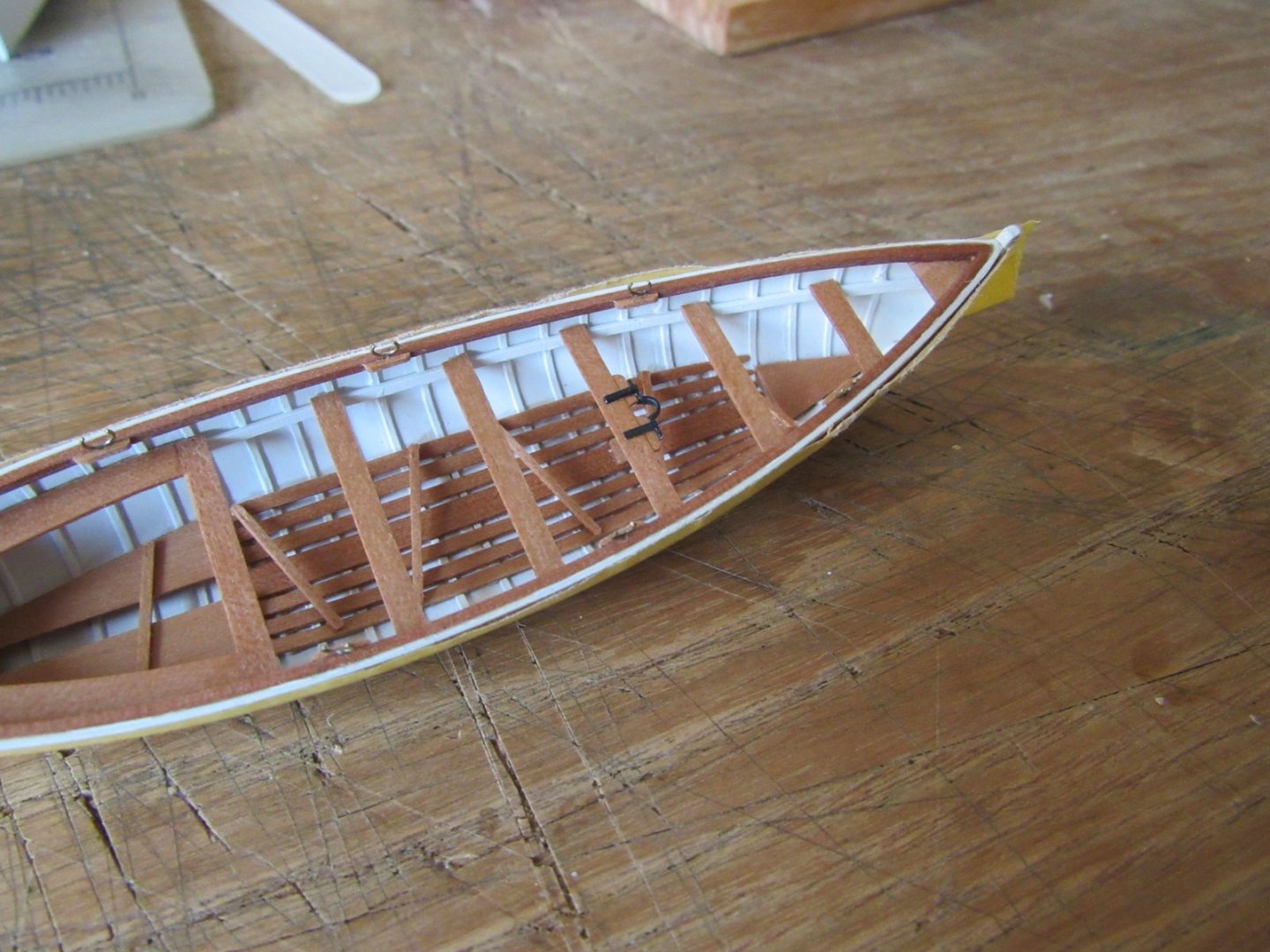

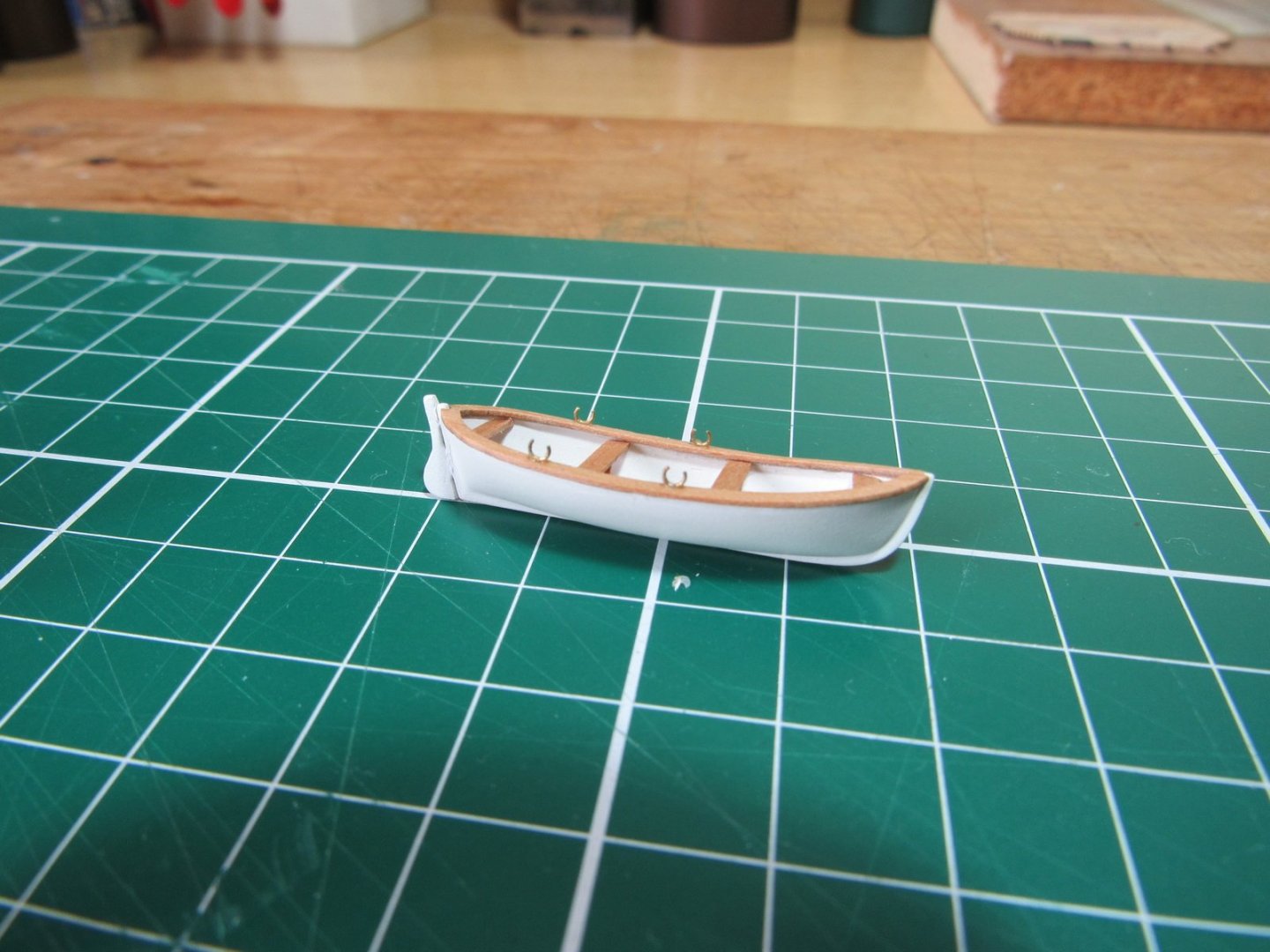

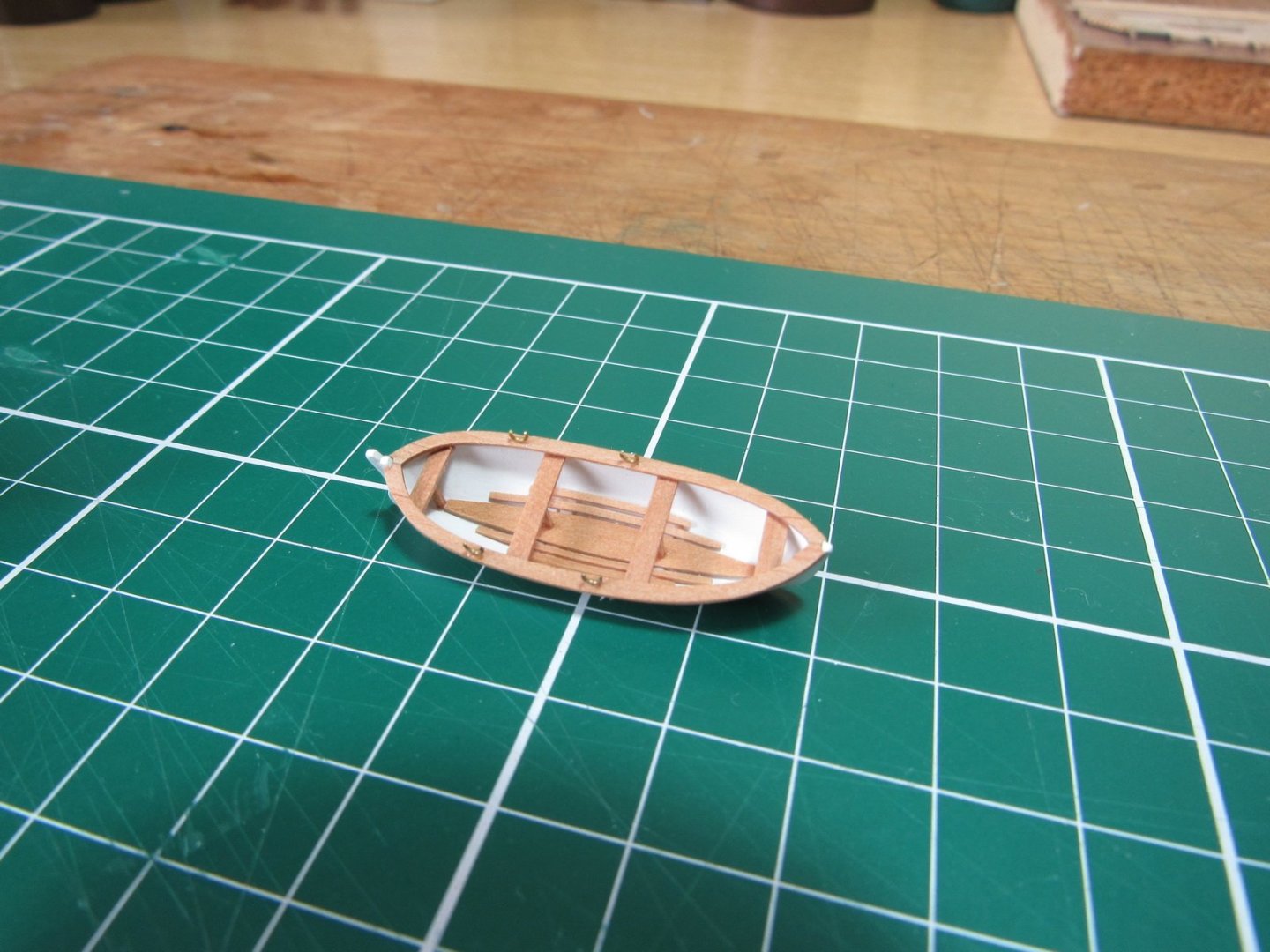

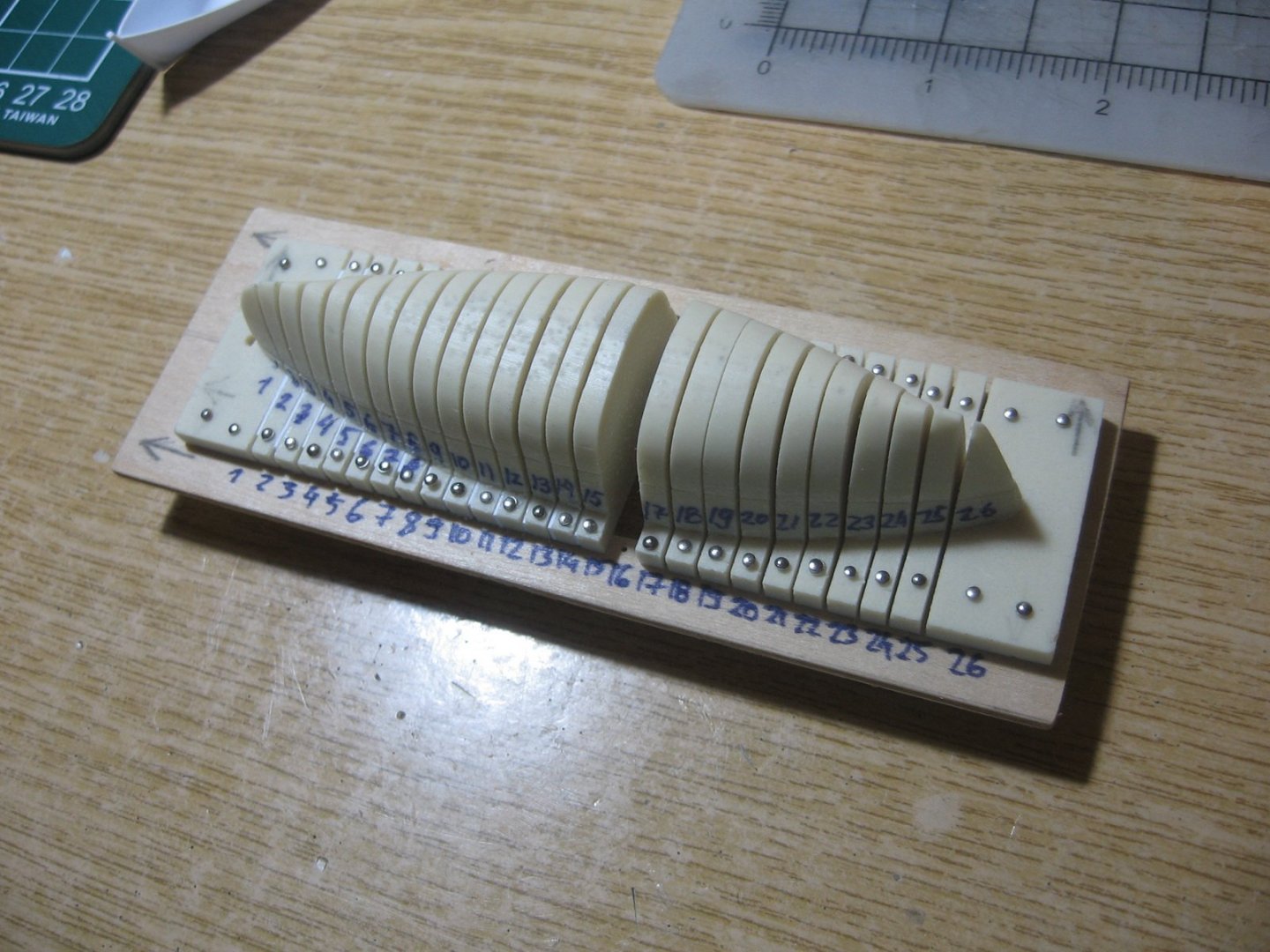

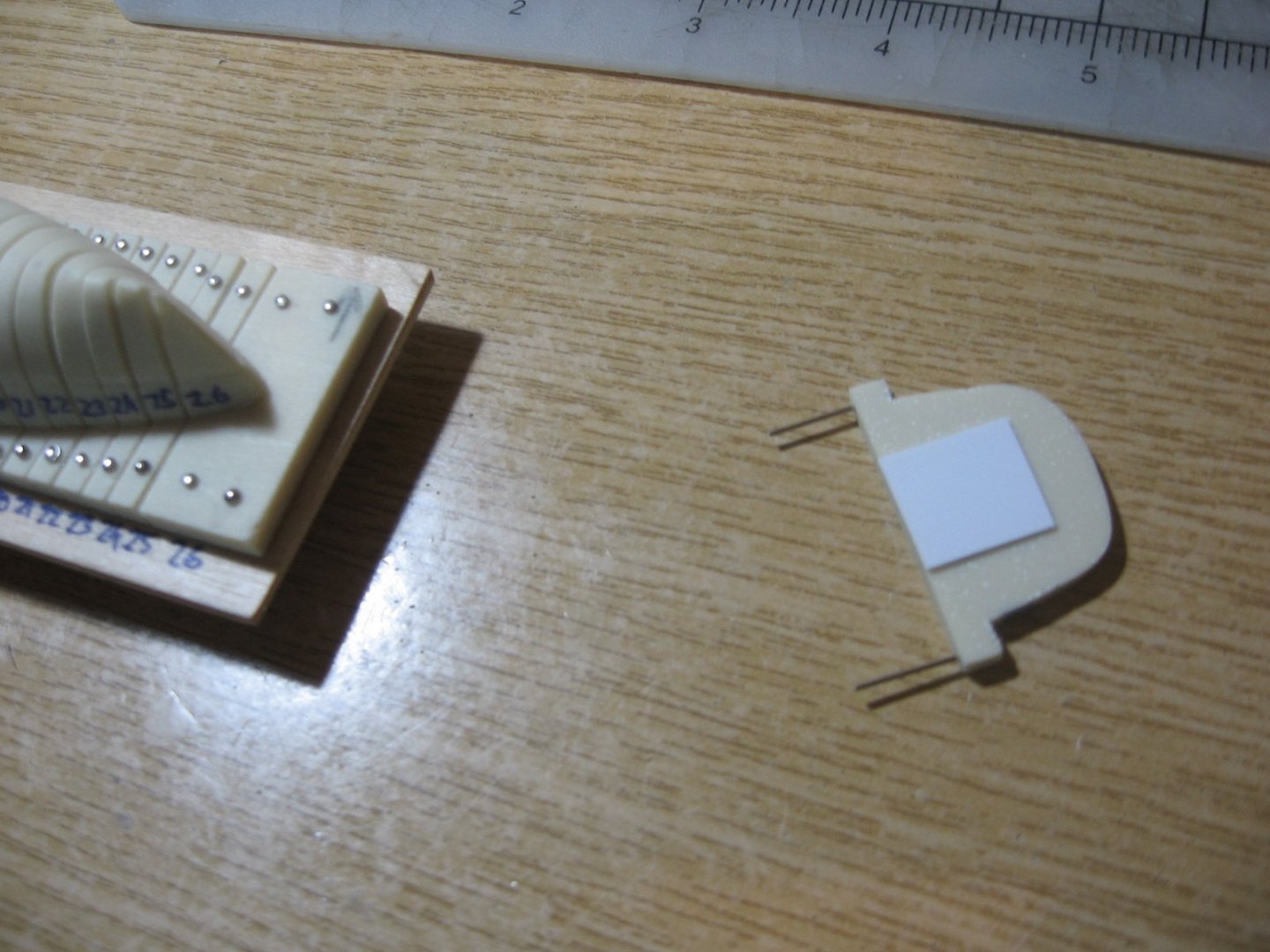

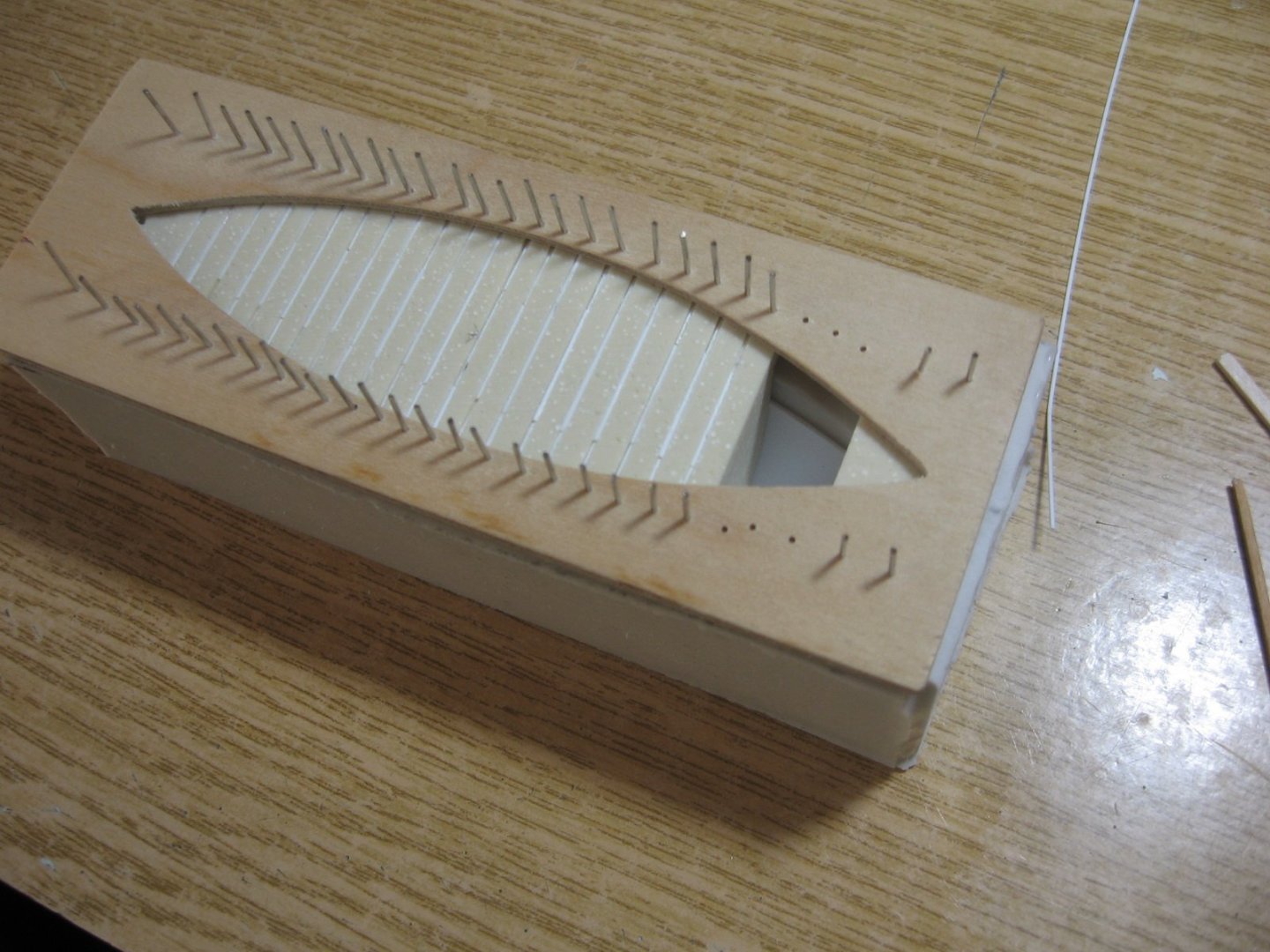

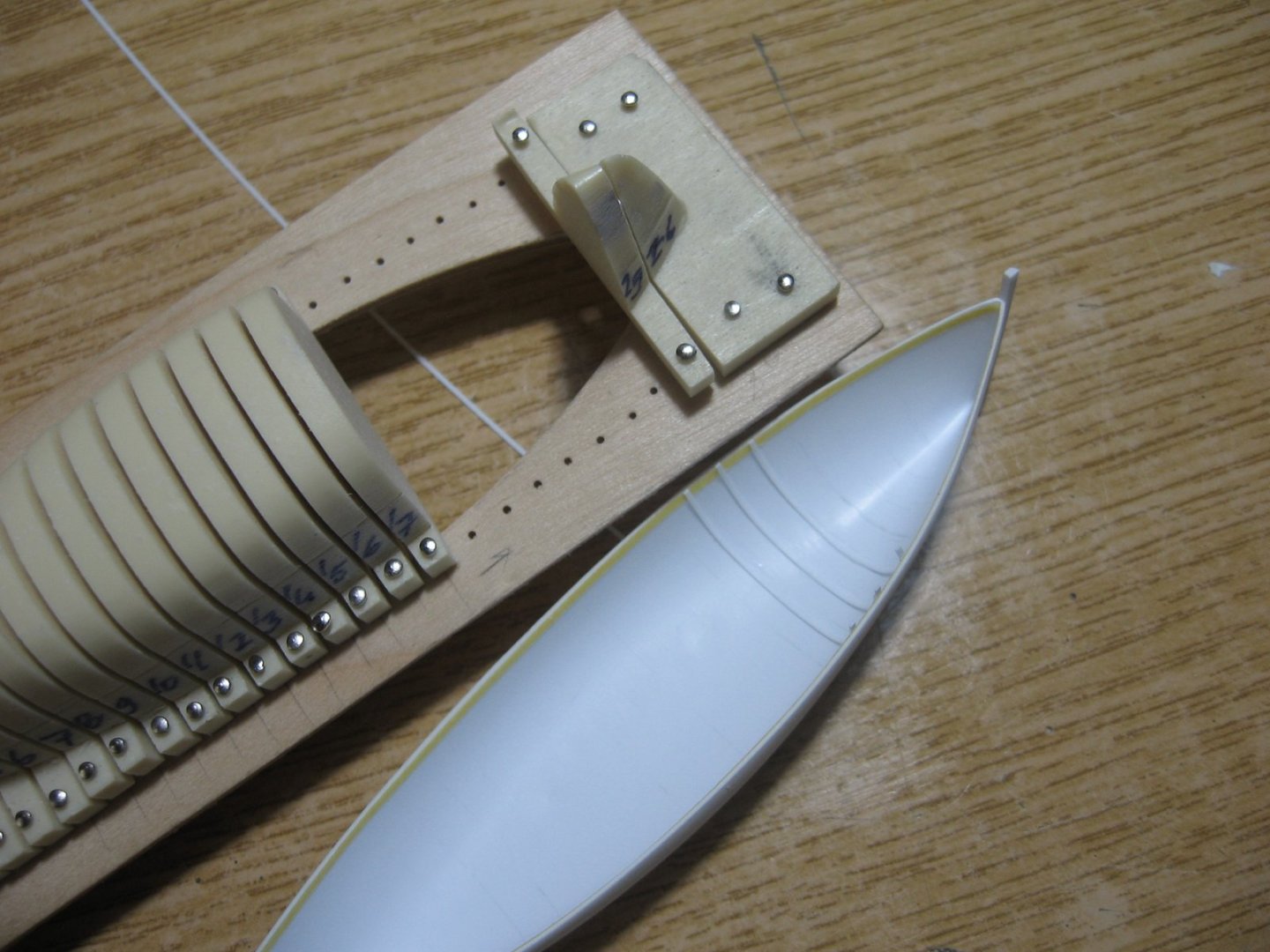

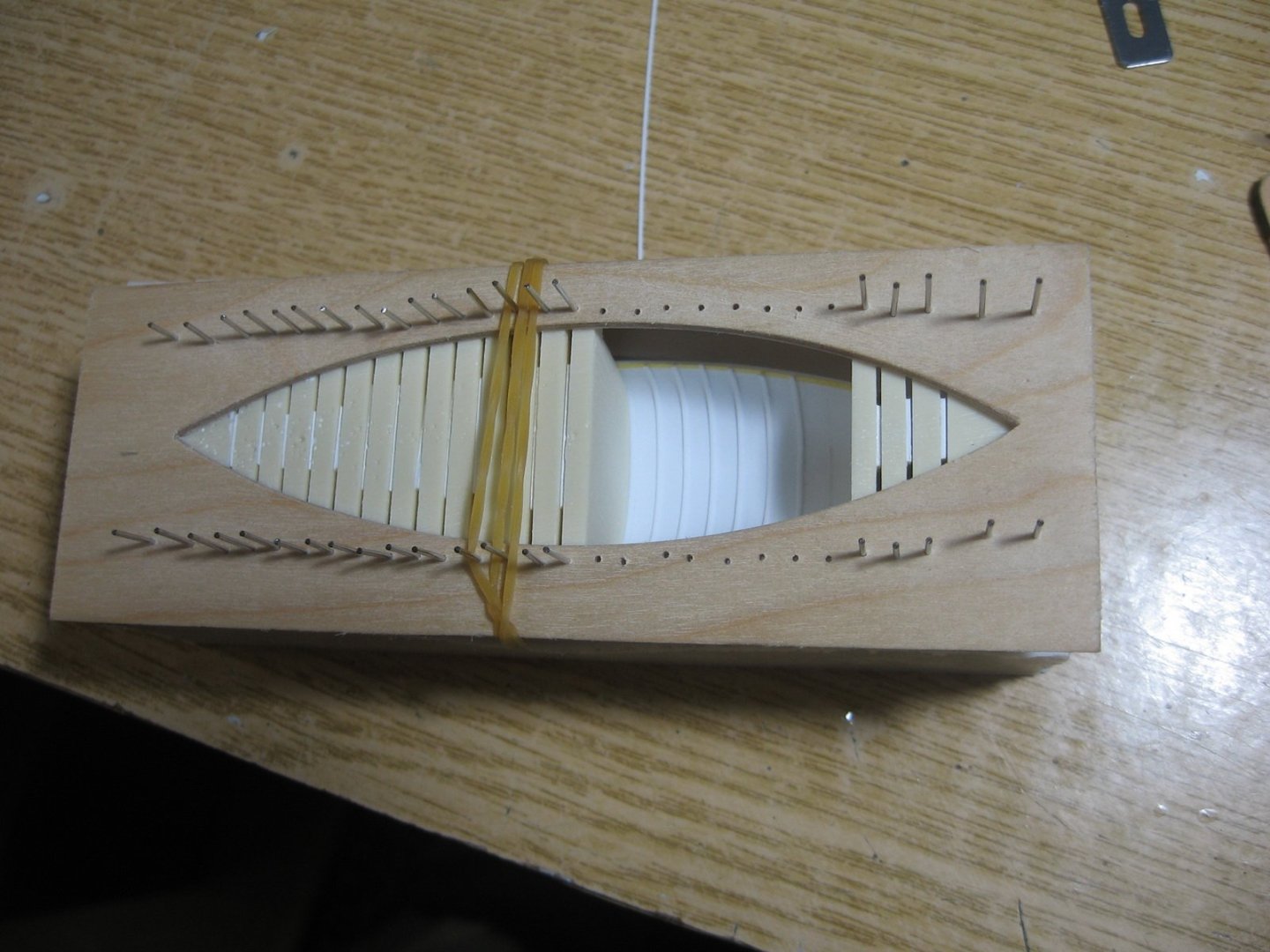

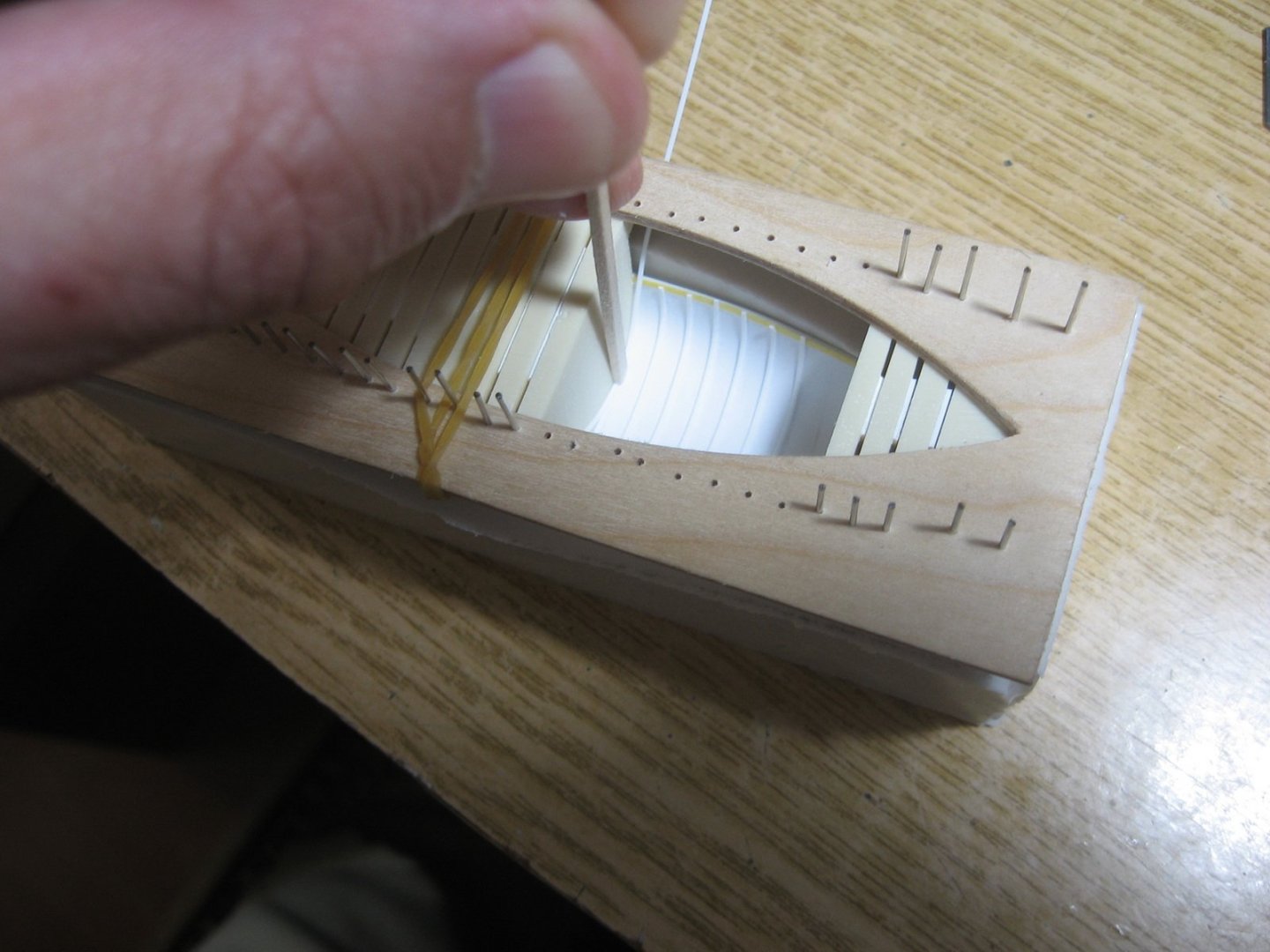

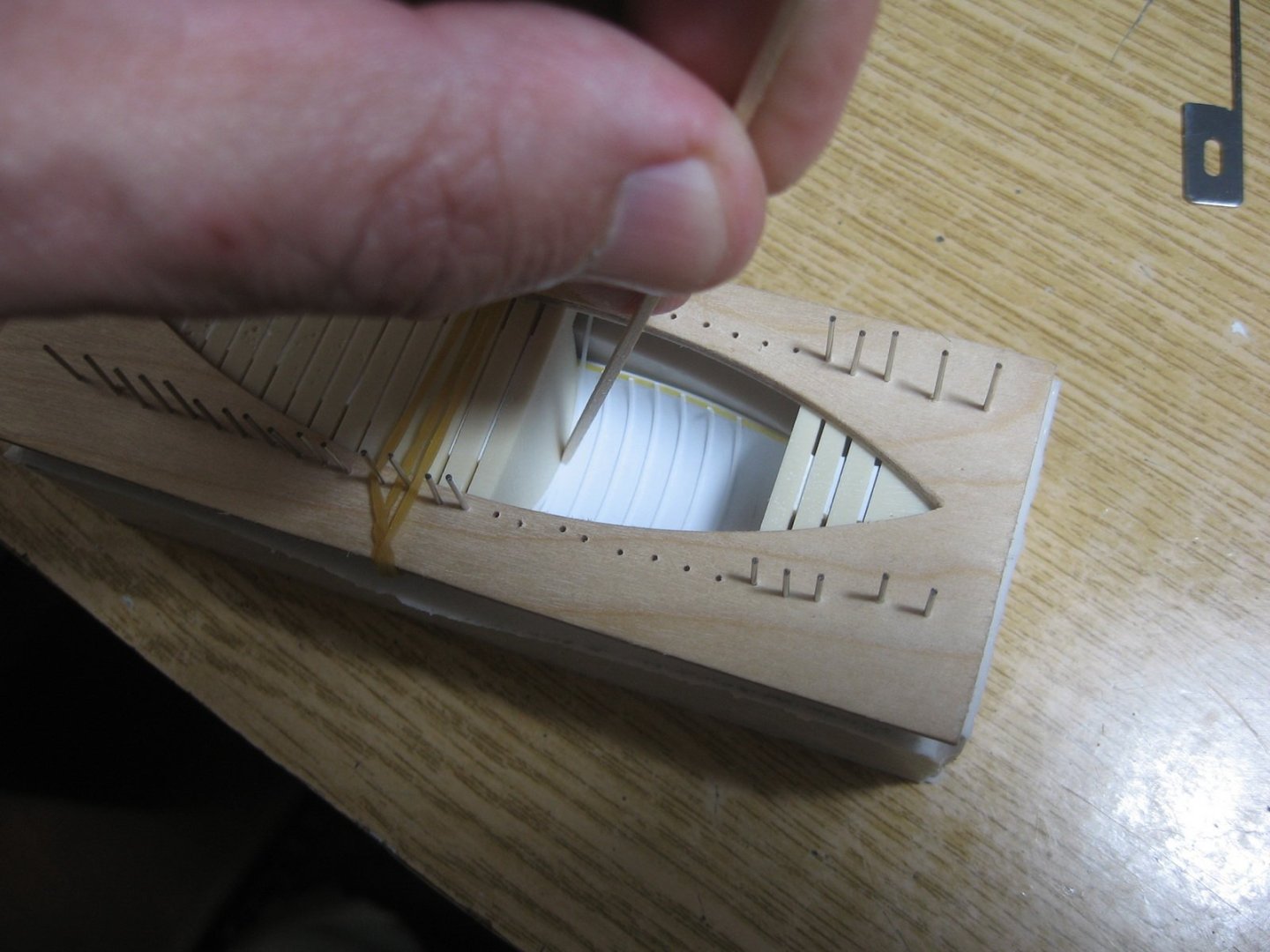

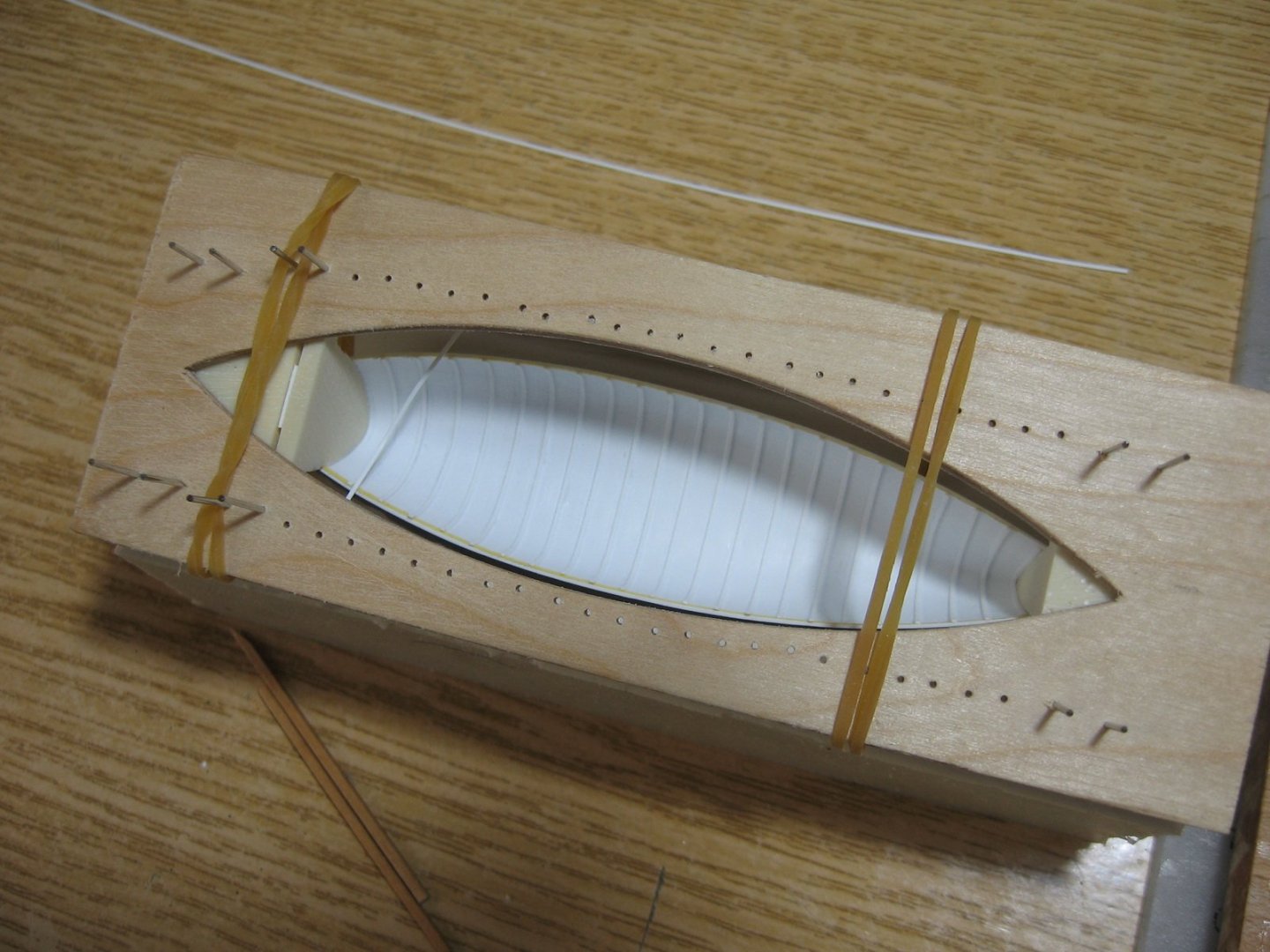

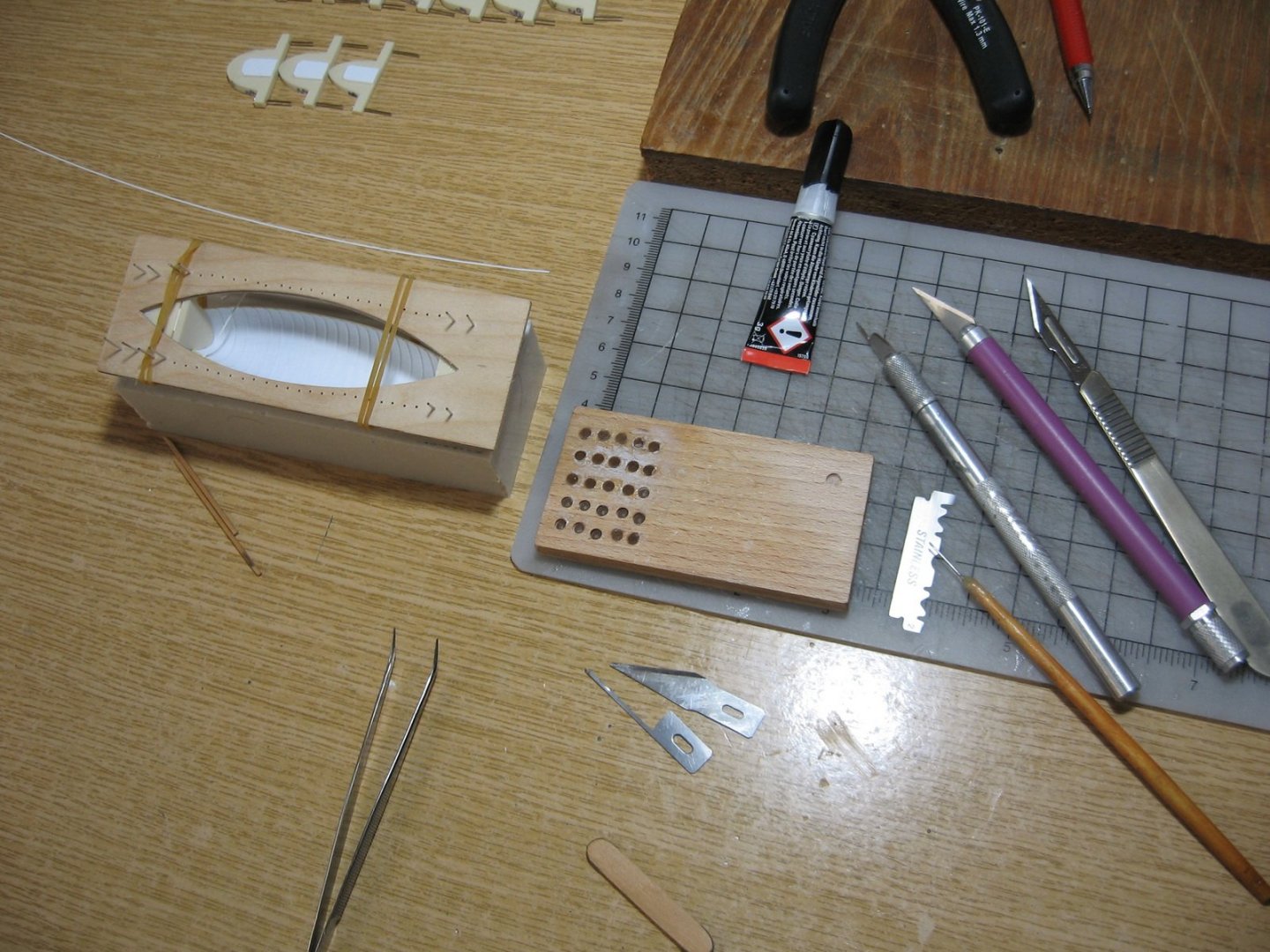

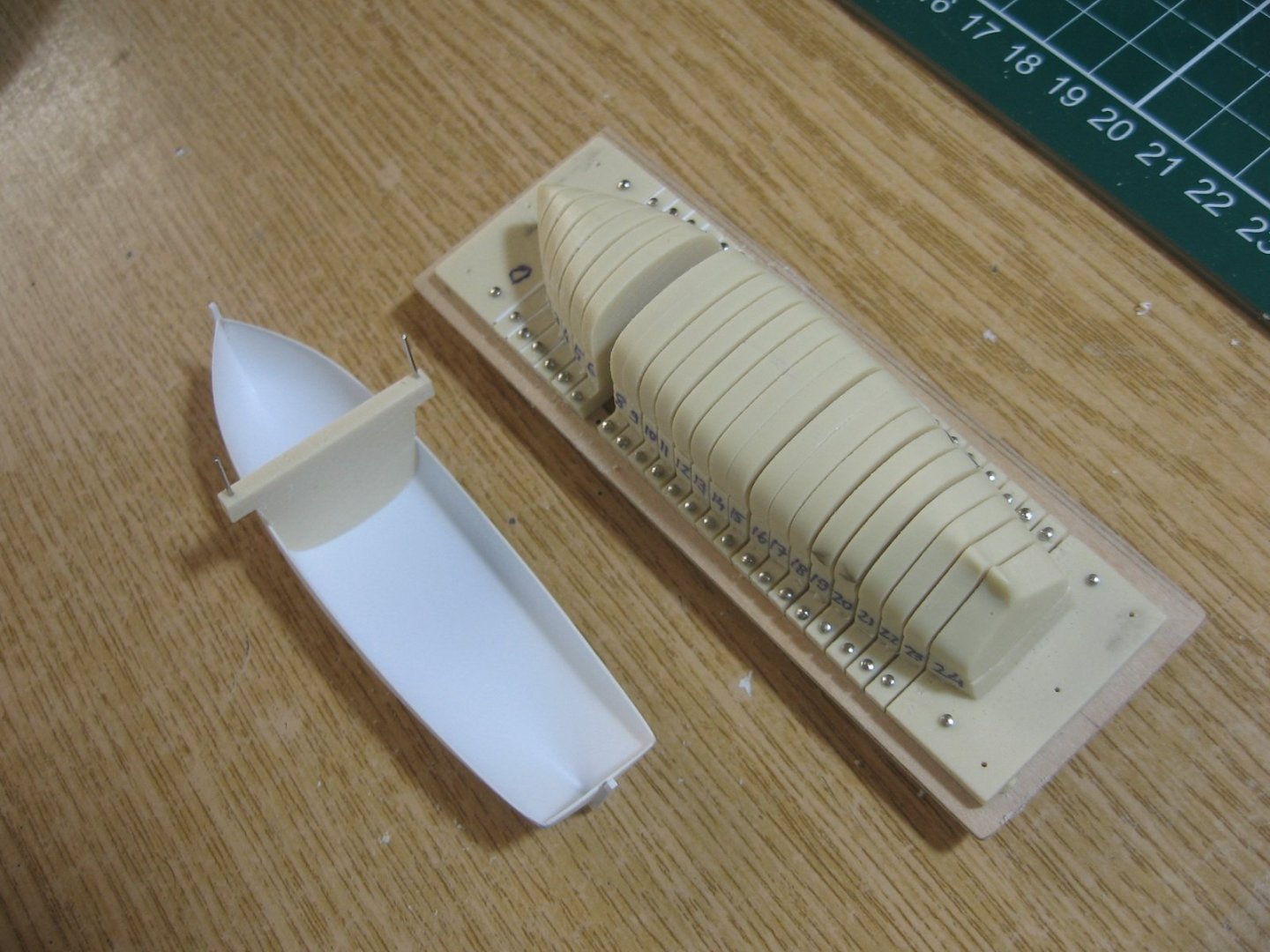

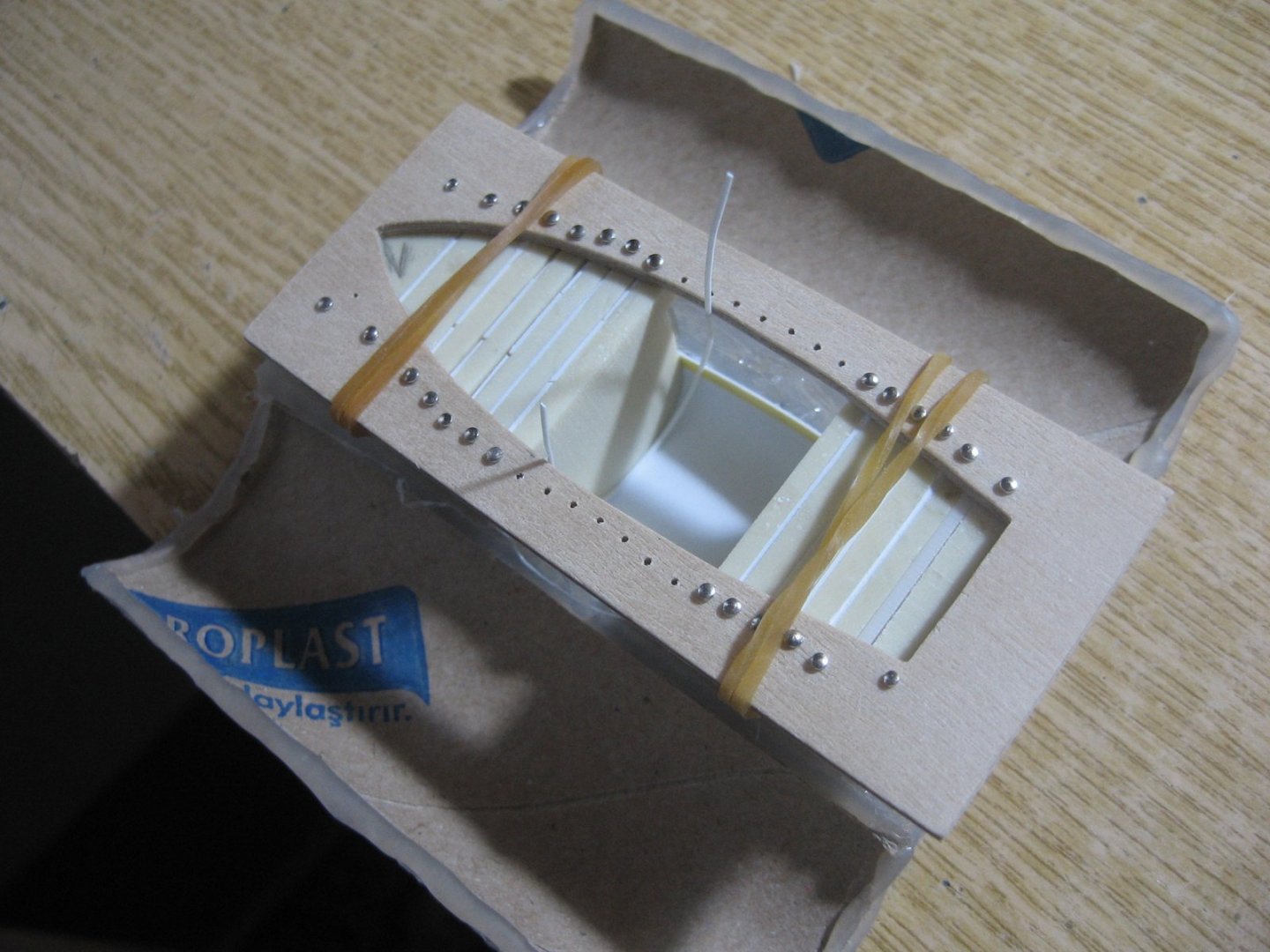

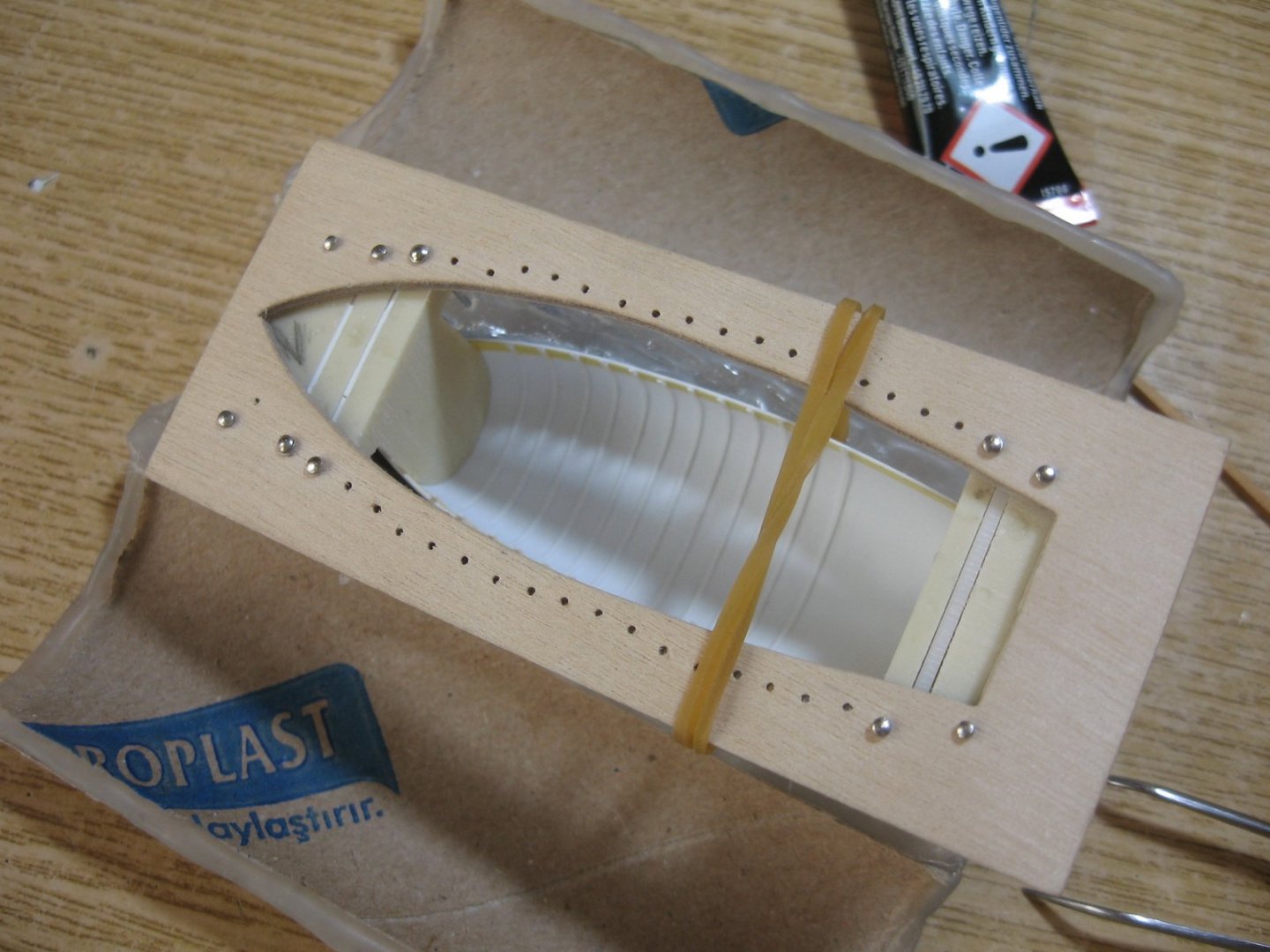

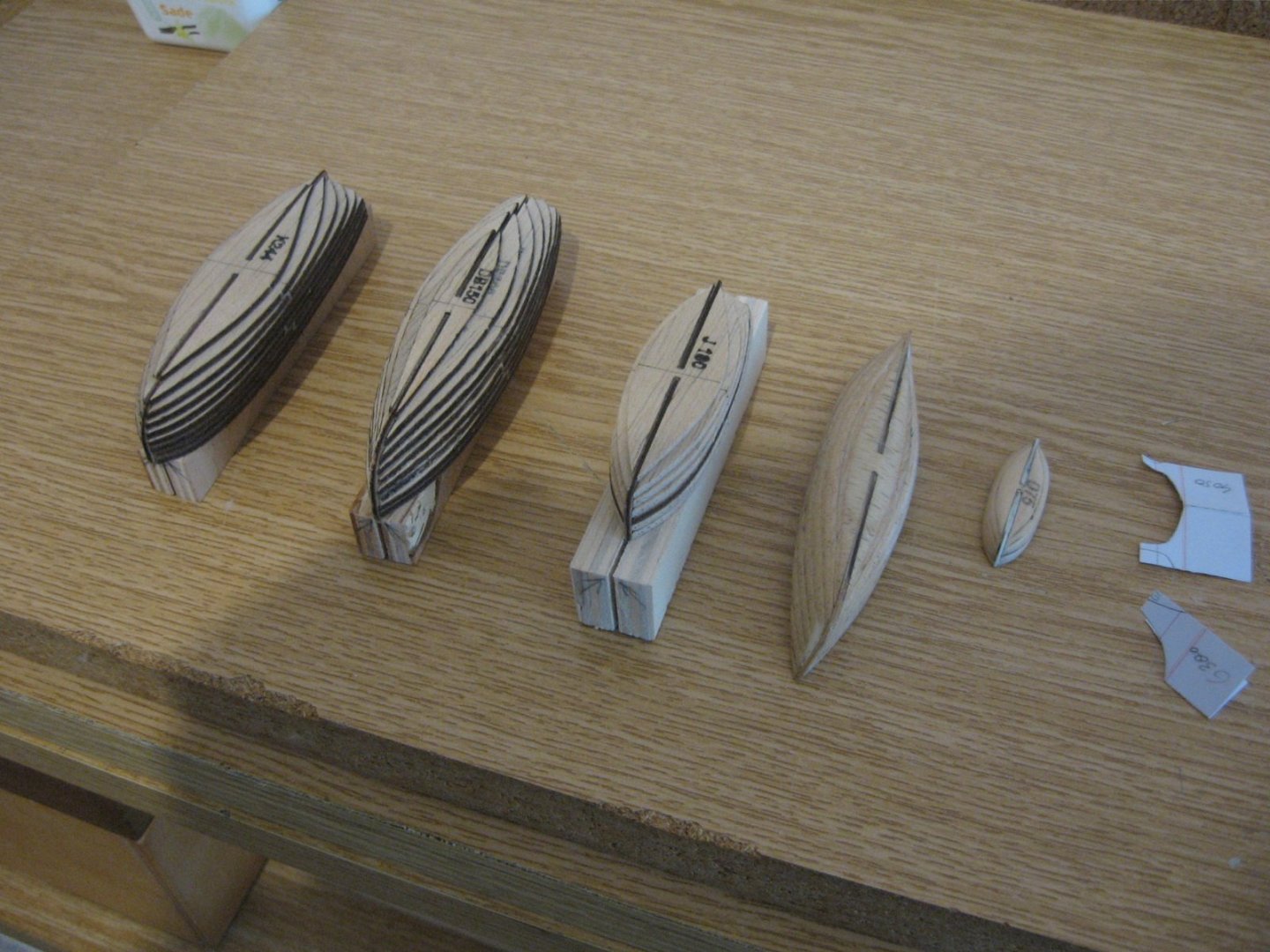

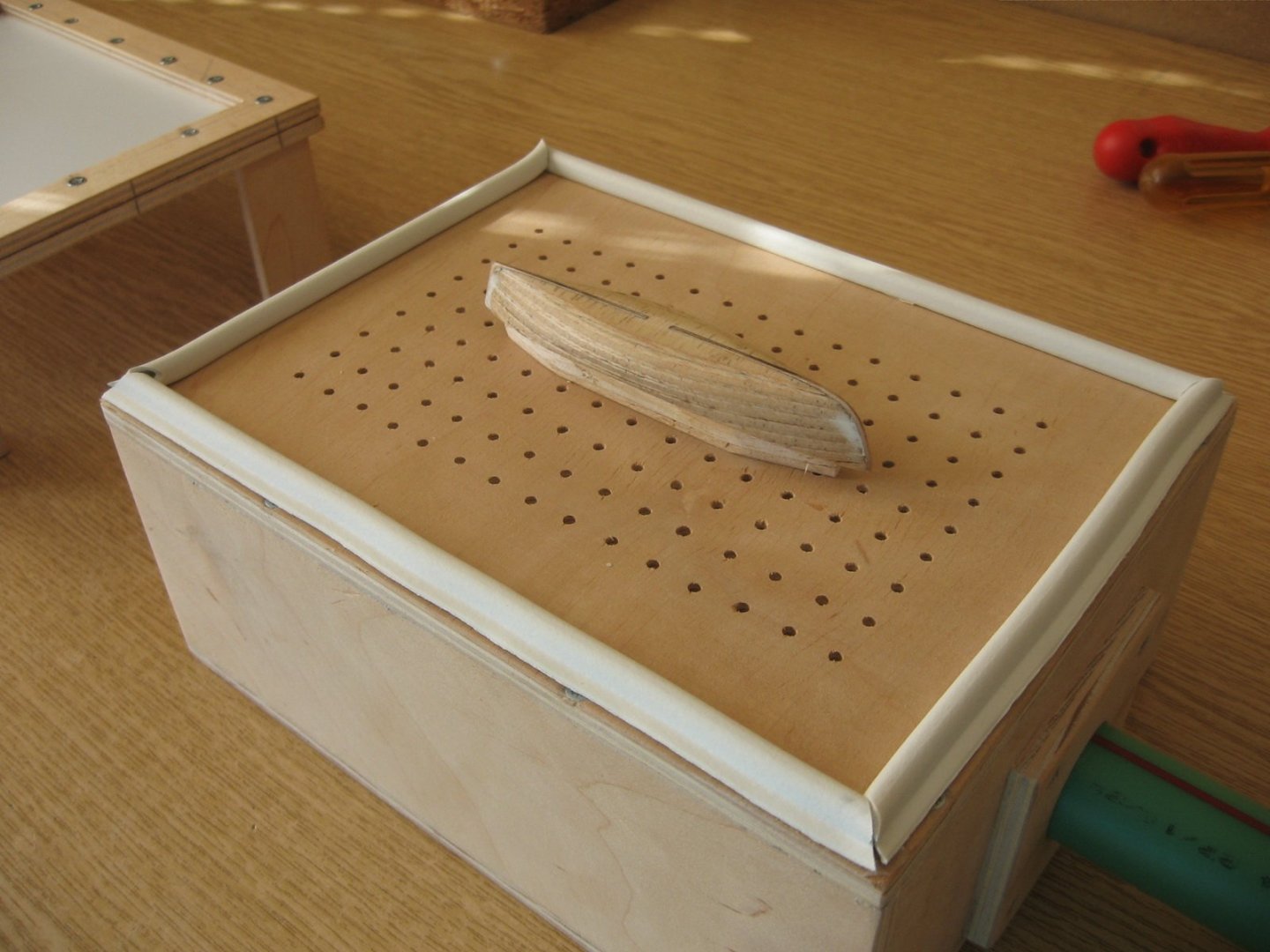

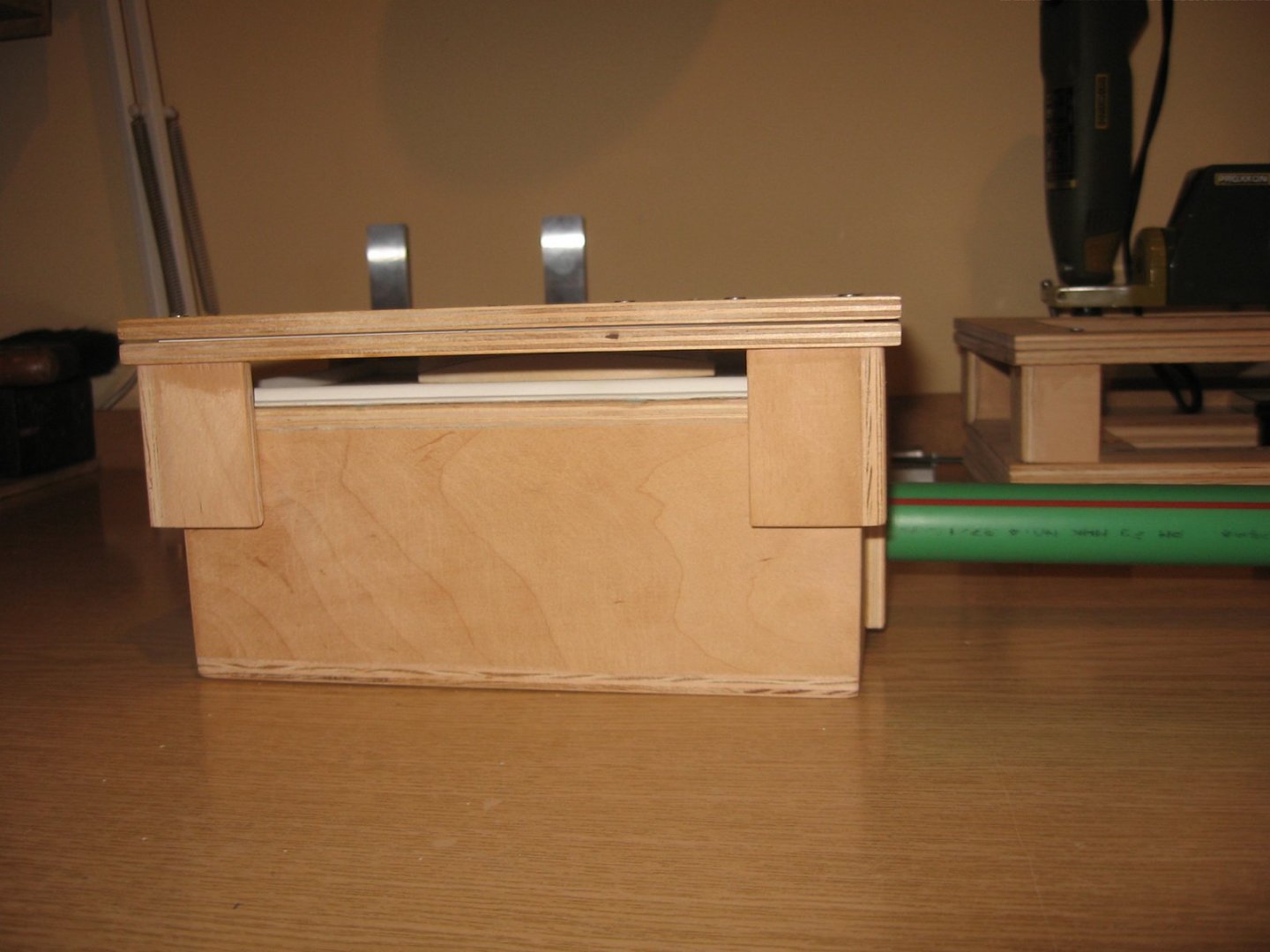

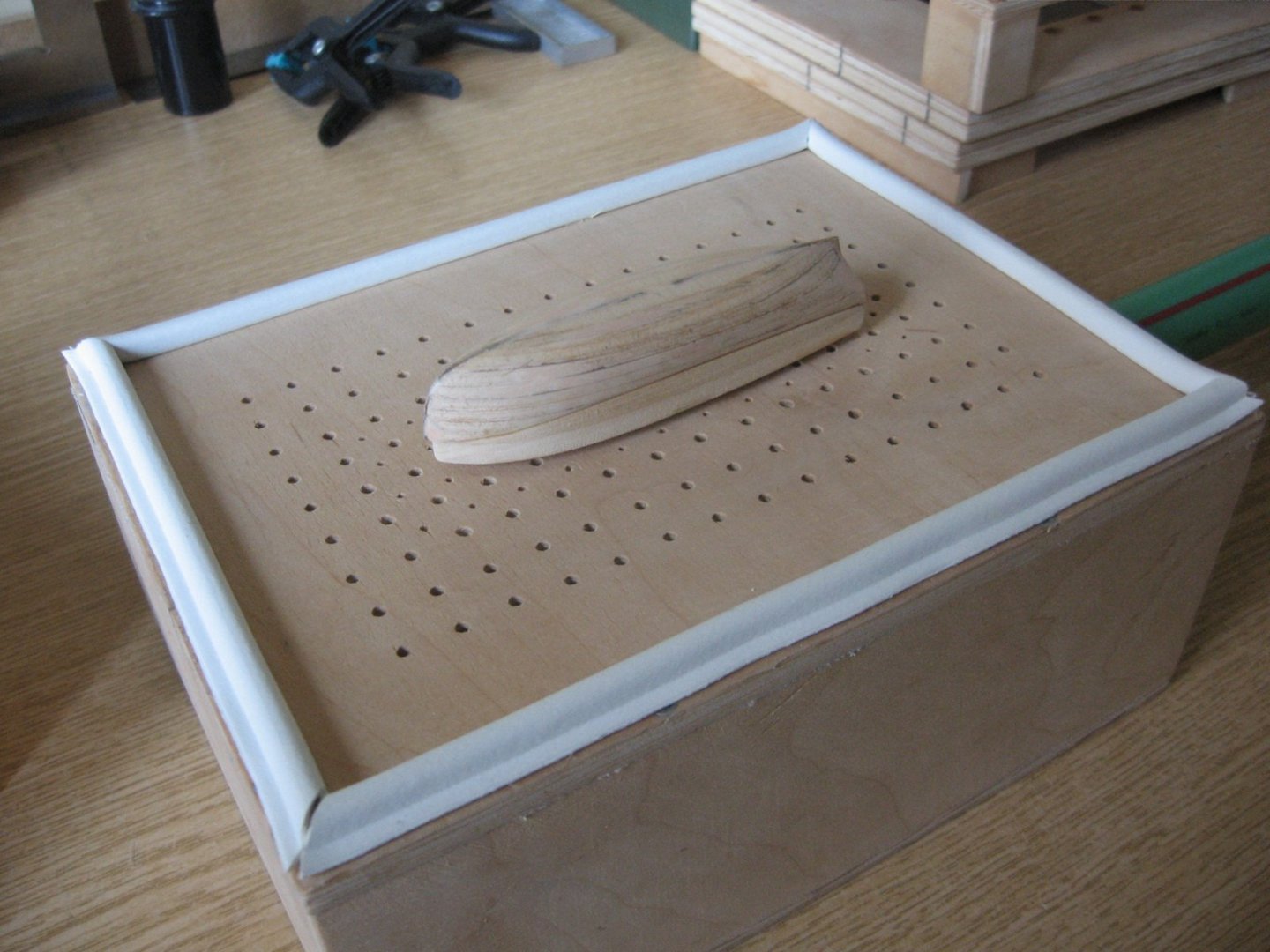

To get the keel (0,75x0,75mm plastic strip) straight I made a straight edge and glued the strip with polistyren glue. I have most problems with the frames and getting them aligned. After several failed attempts I made a plug/core of the boot and cut it at the intervals of the frames. So using these mould parts as a template I managed to fix the frames exactly aligned and square to the keel. I press the plastic strip (0.25x0.75mm) to the mould and let tiny drops of CA to penetrate at the side. One by one and step by step.

-

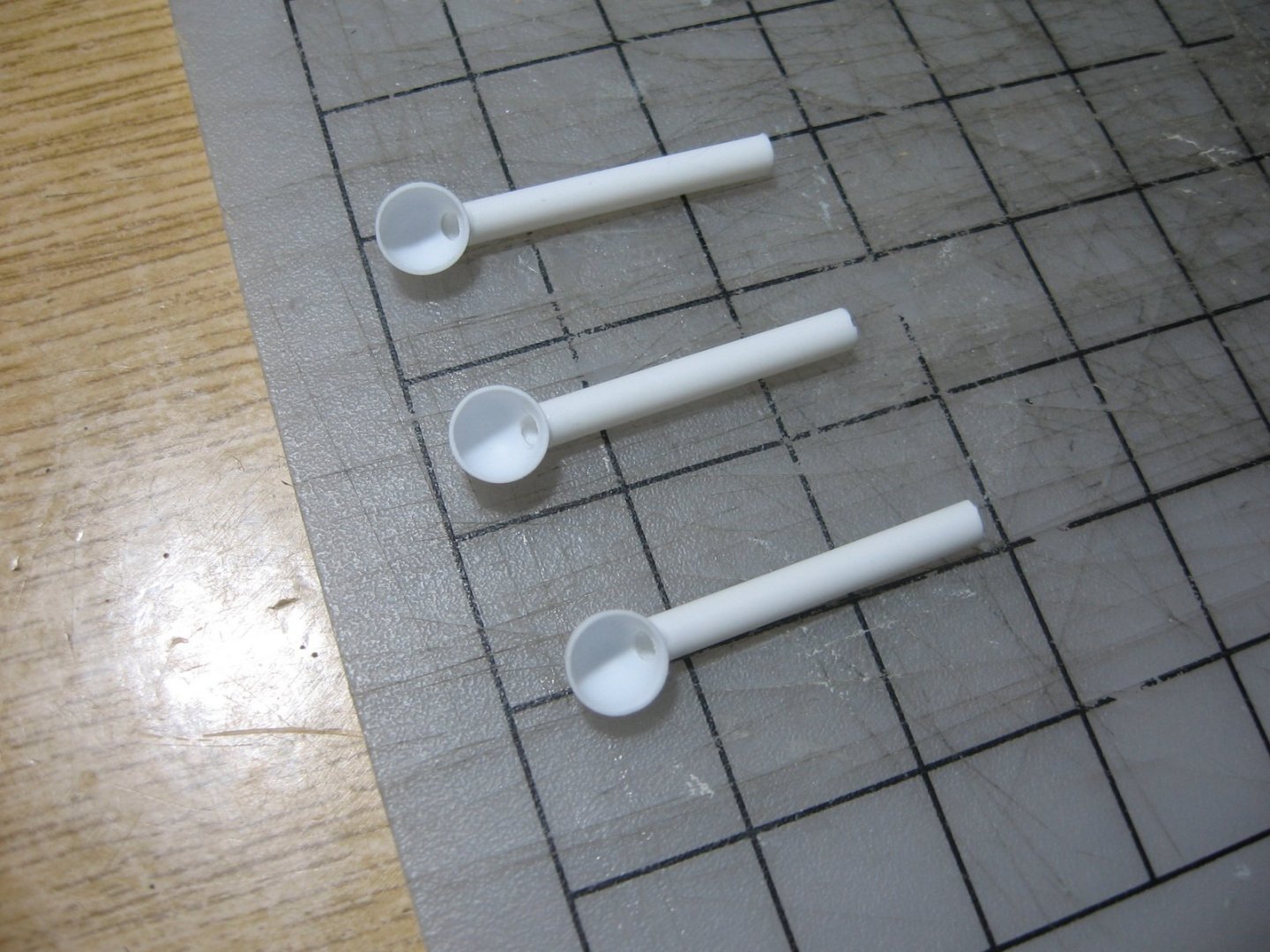

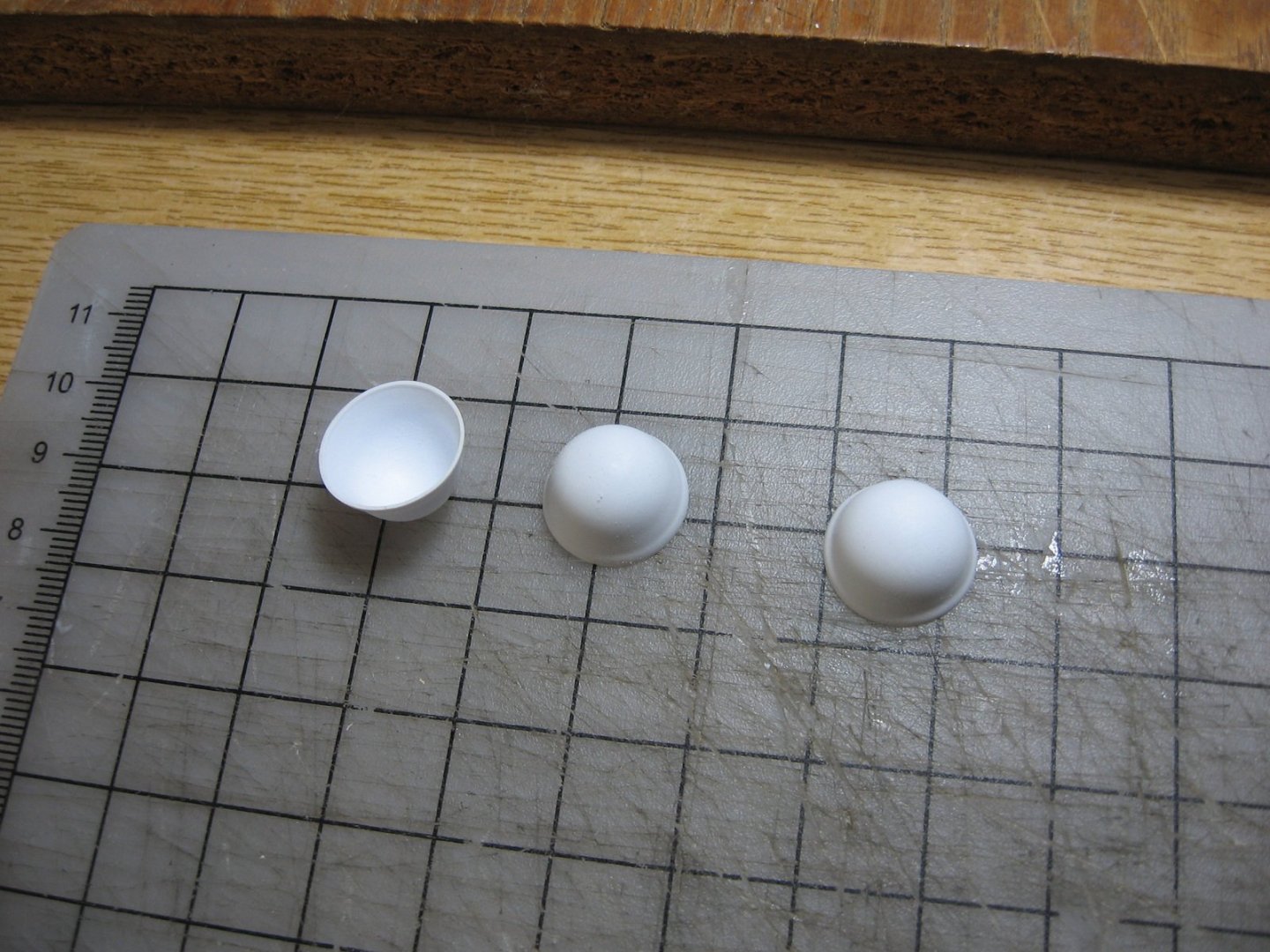

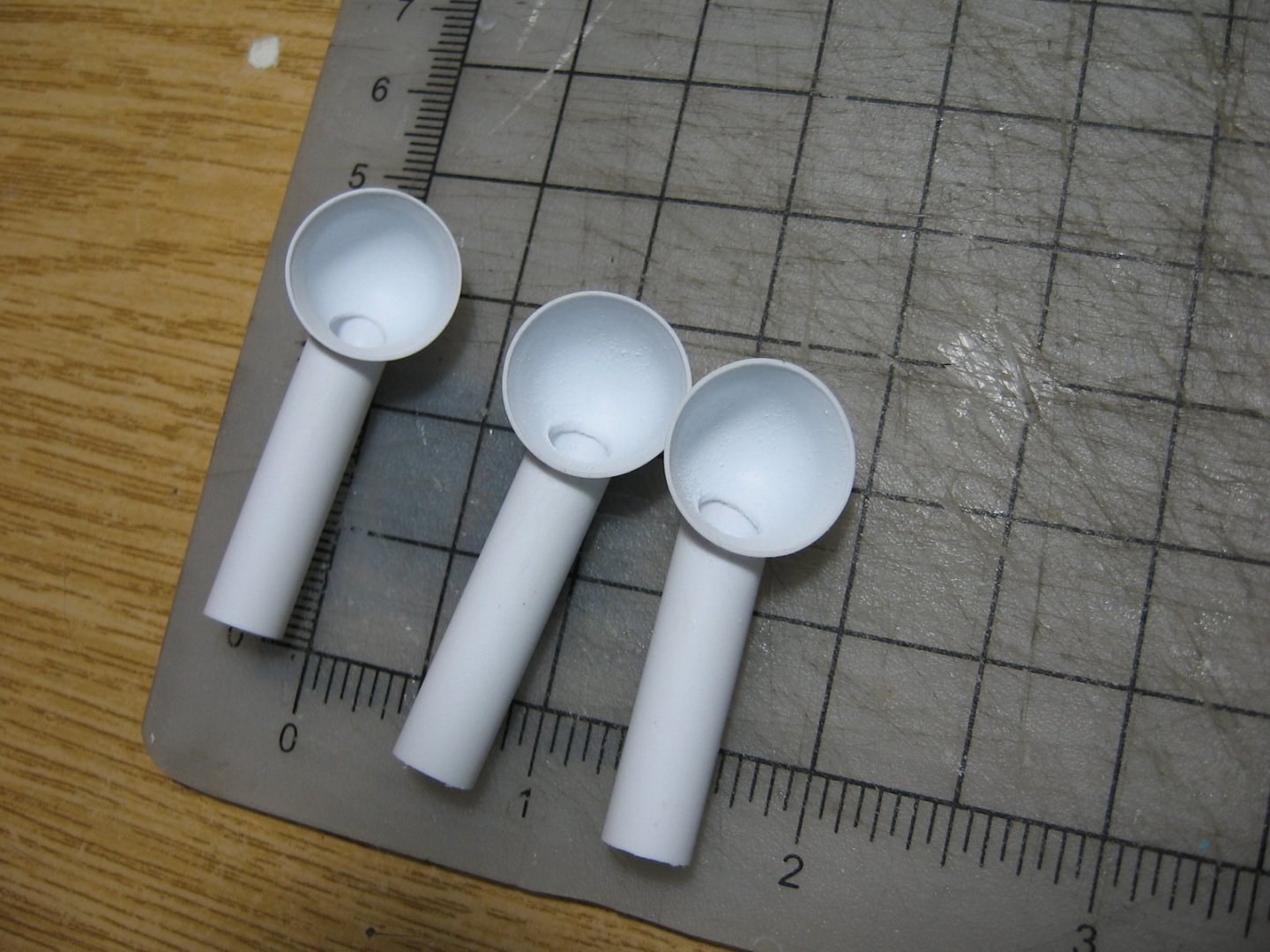

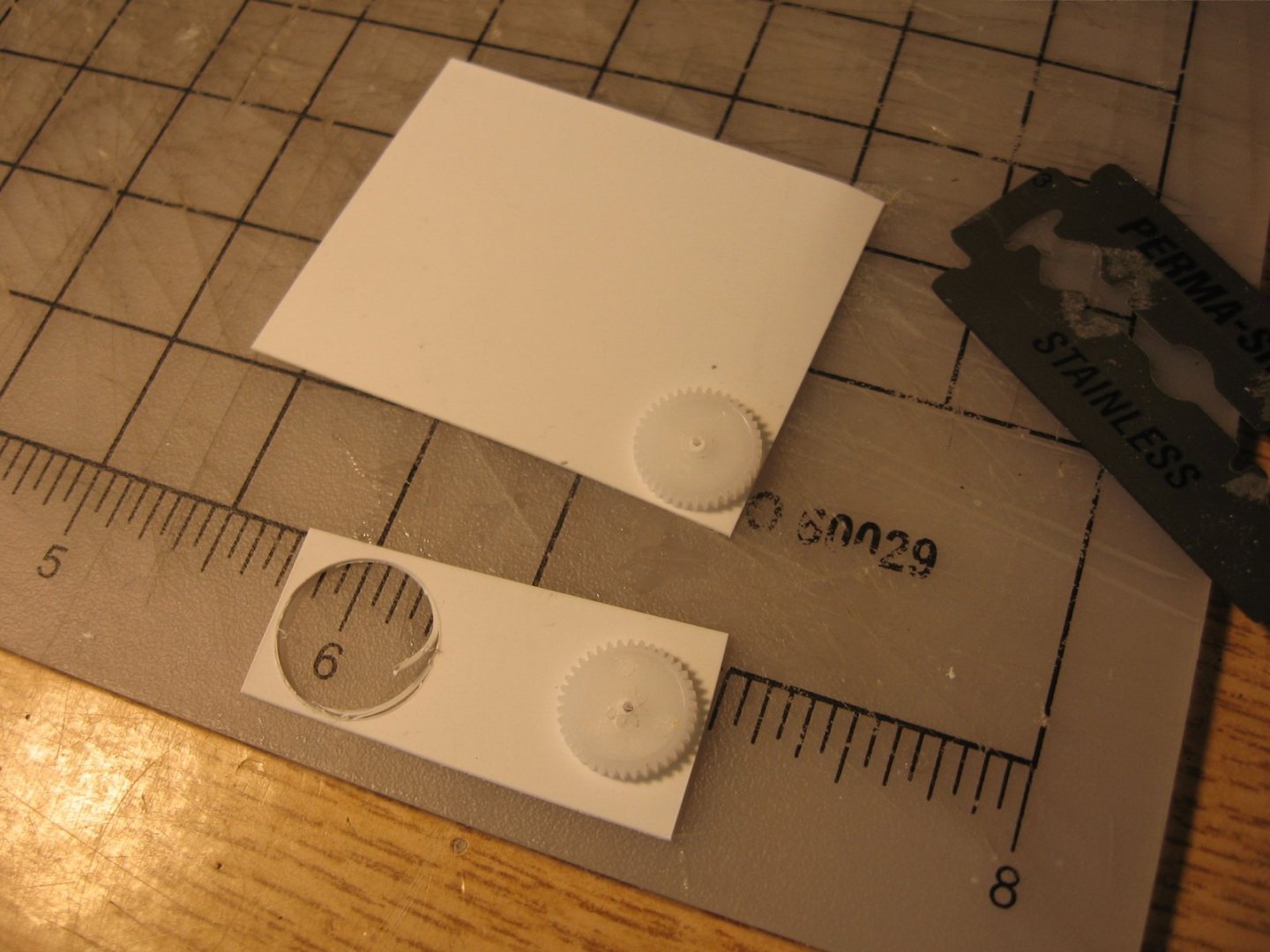

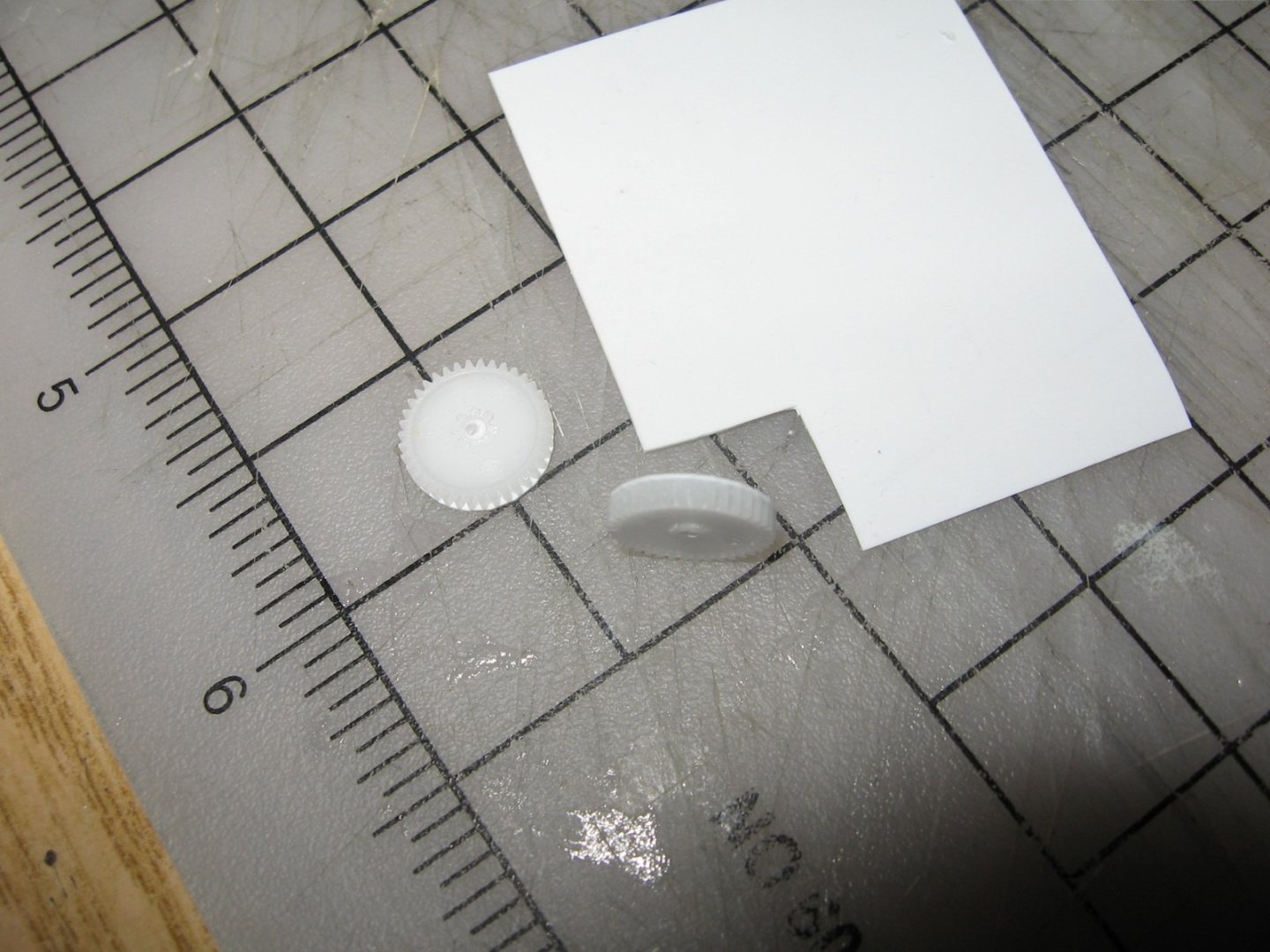

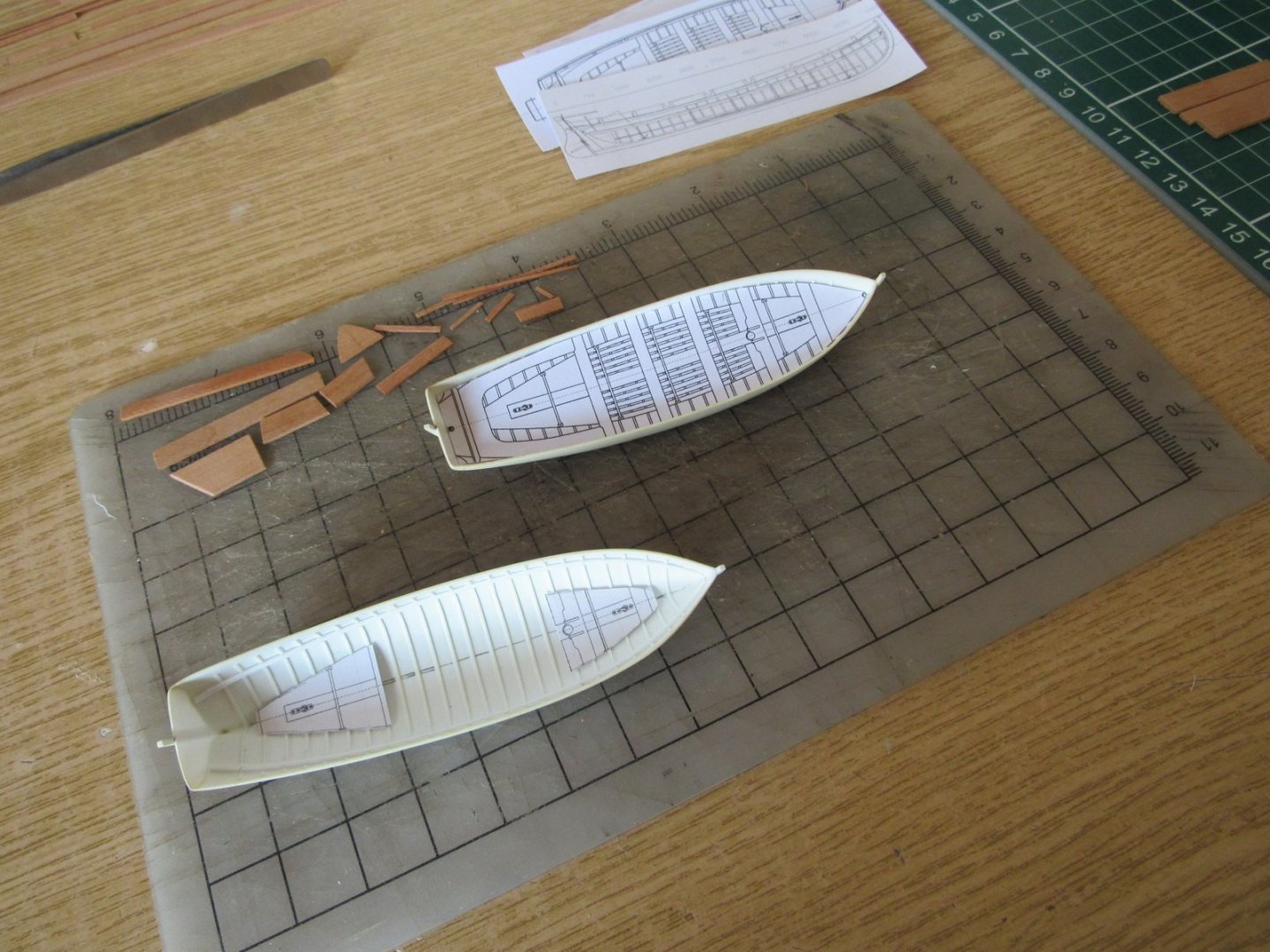

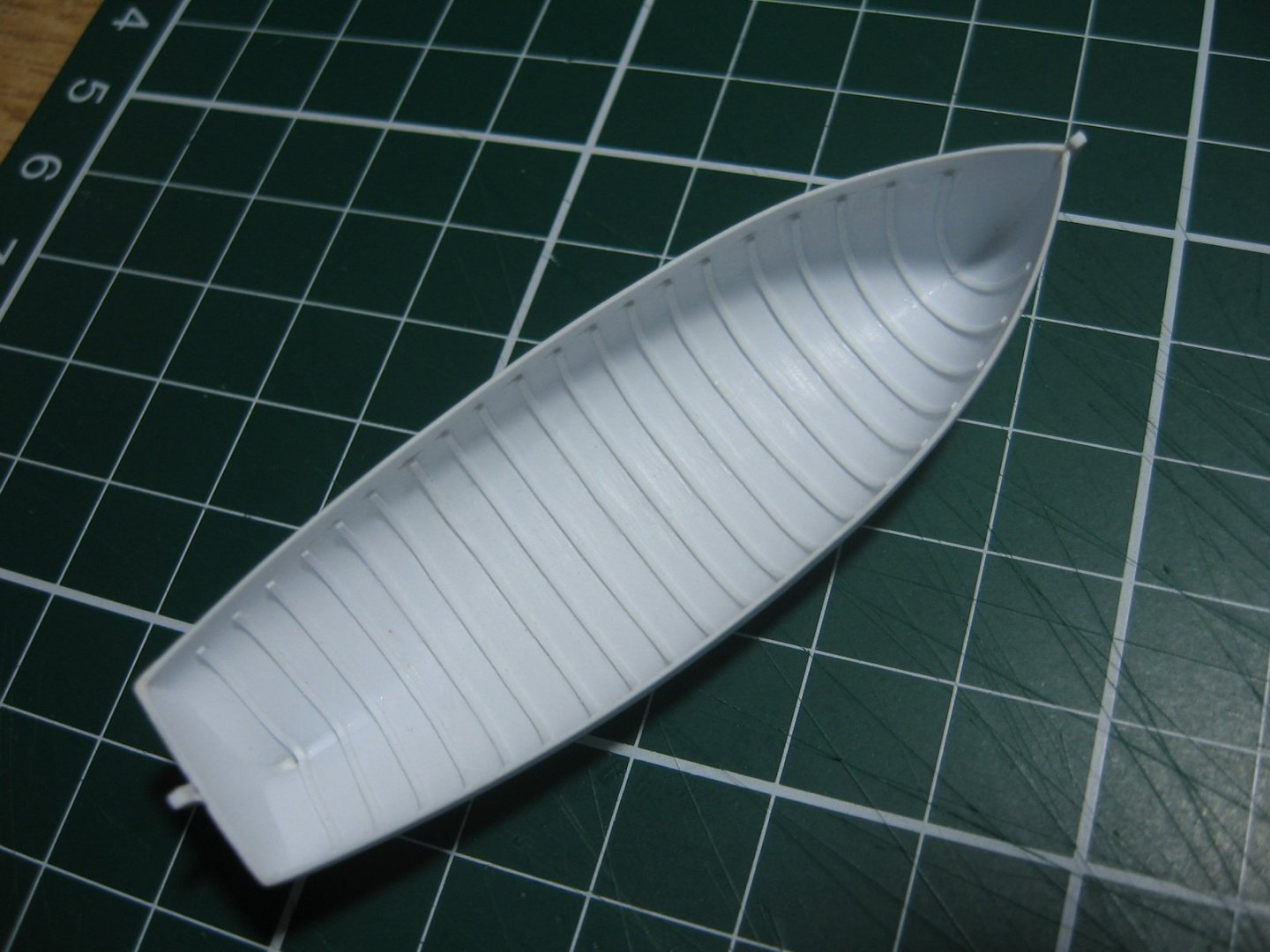

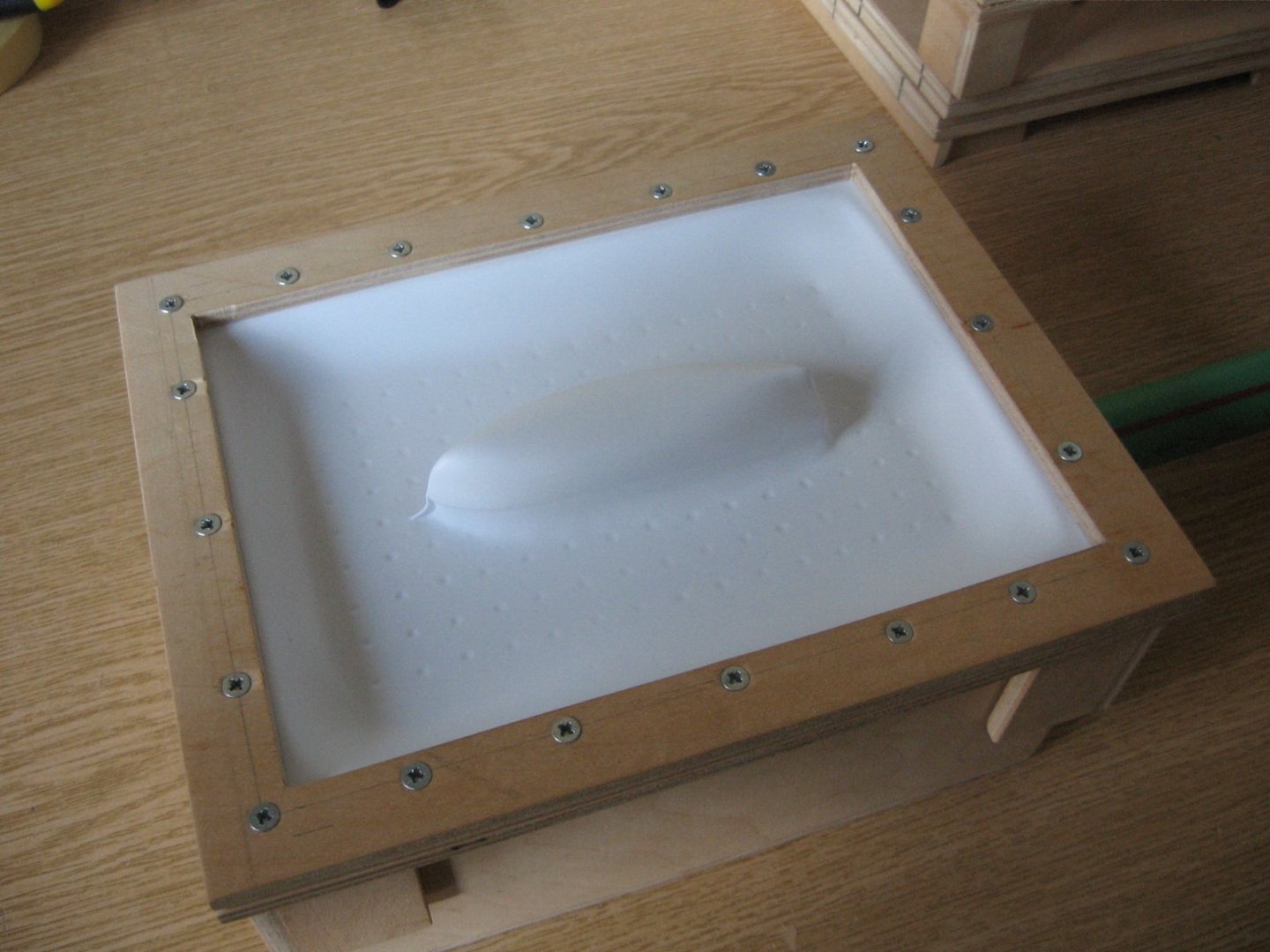

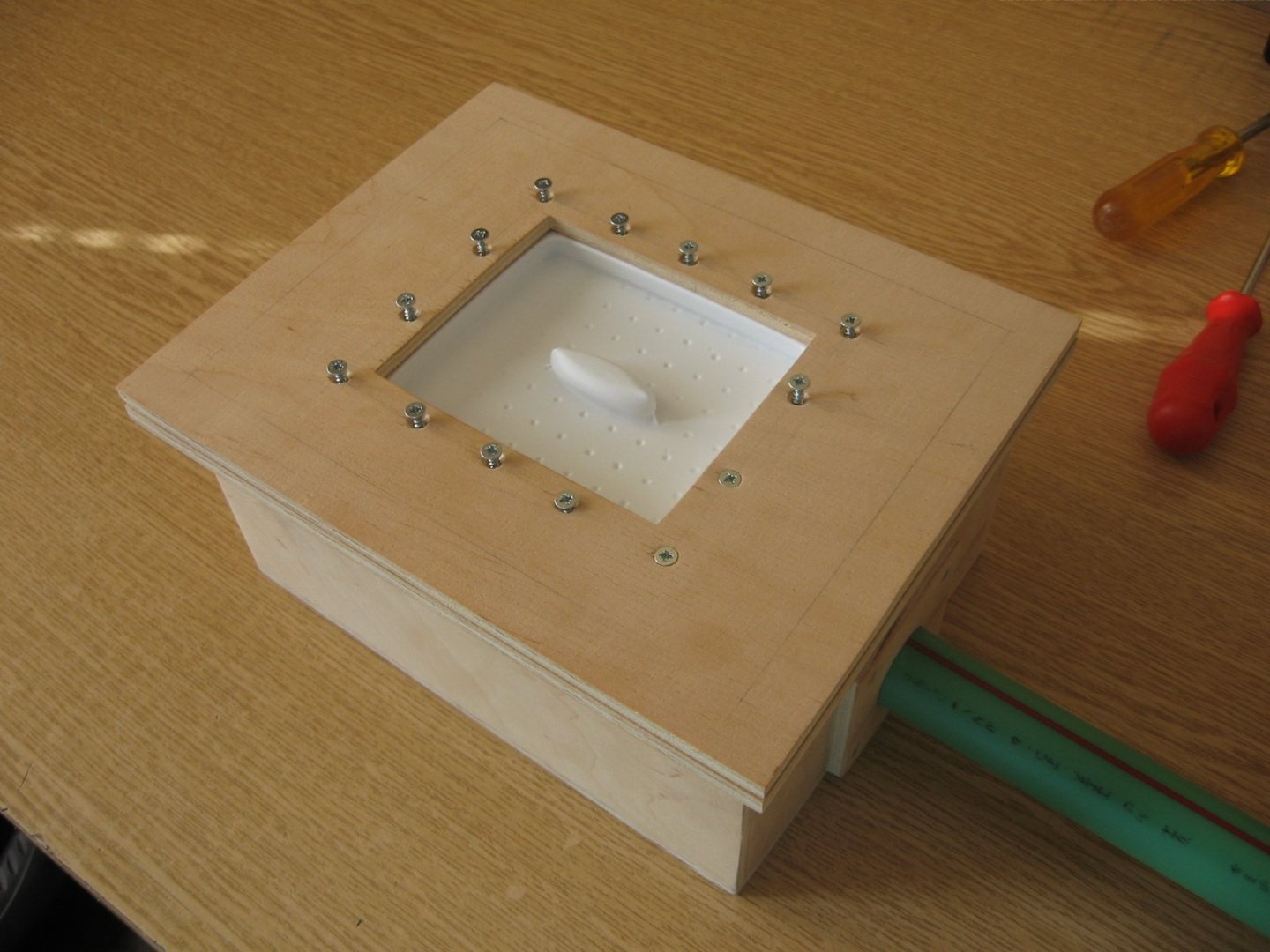

Thanks shipman. It's polystyren sheet initially 0,75 mm thick. After forming it reduces appr. to 0,5 mm's.

-

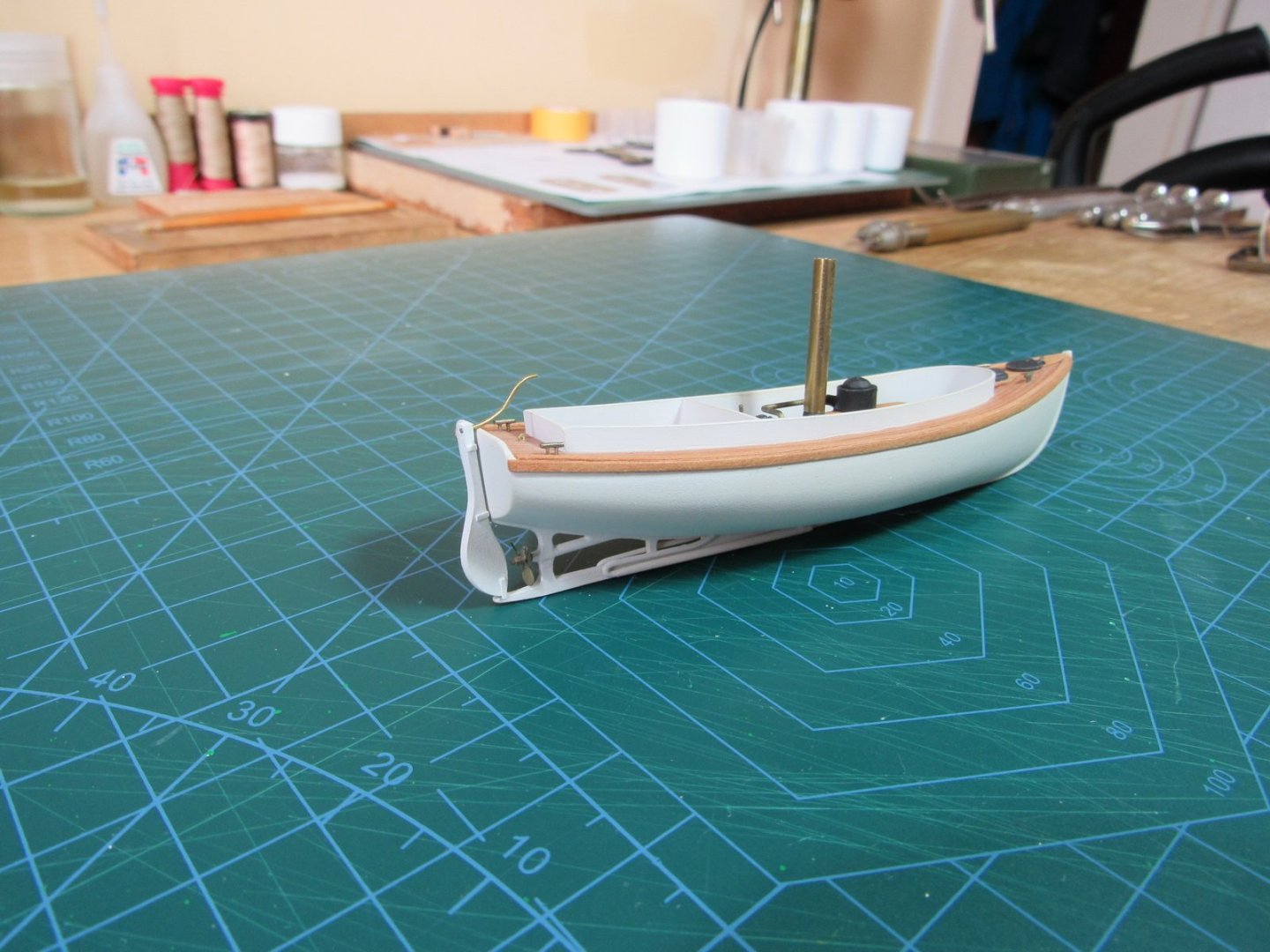

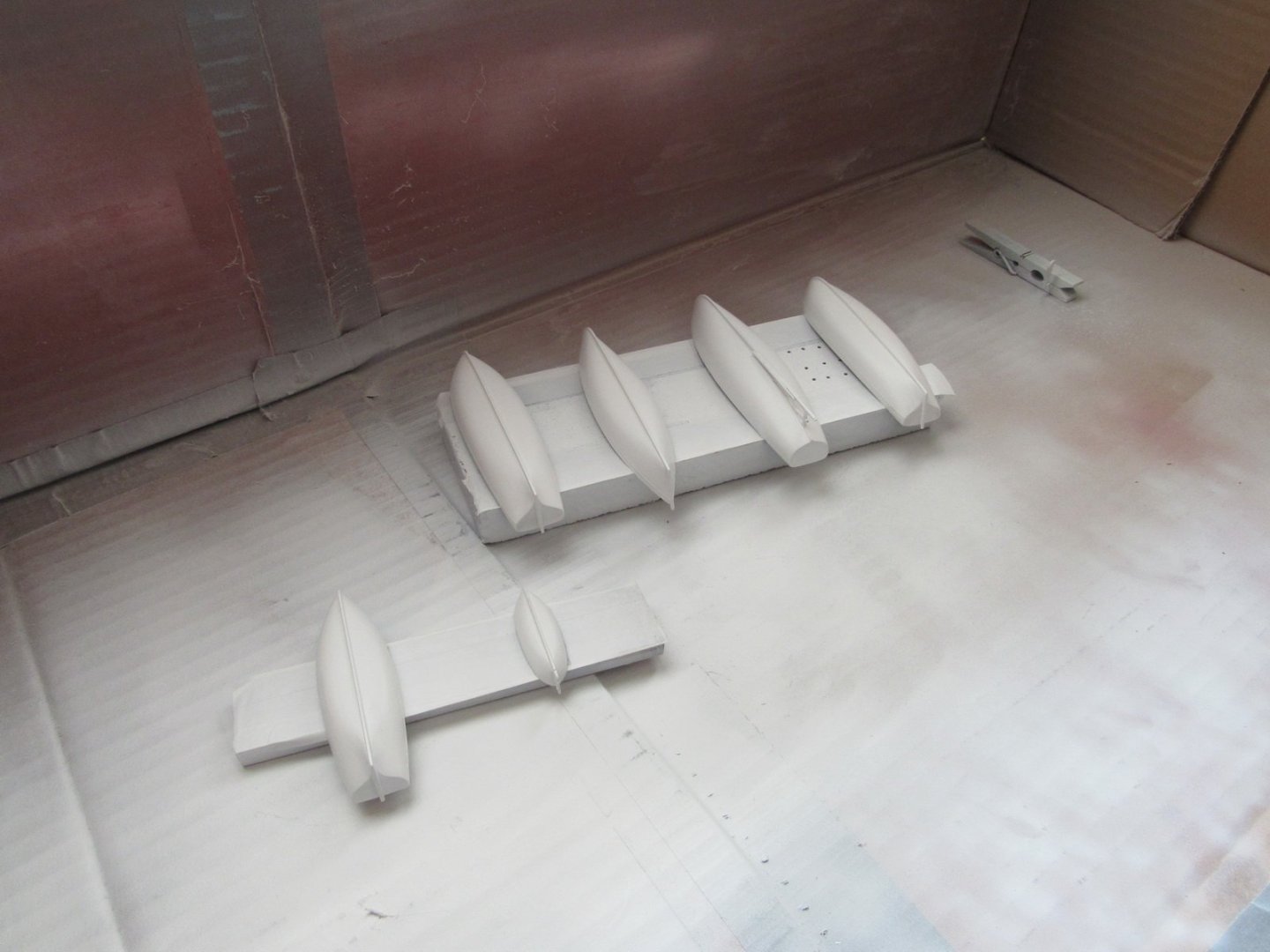

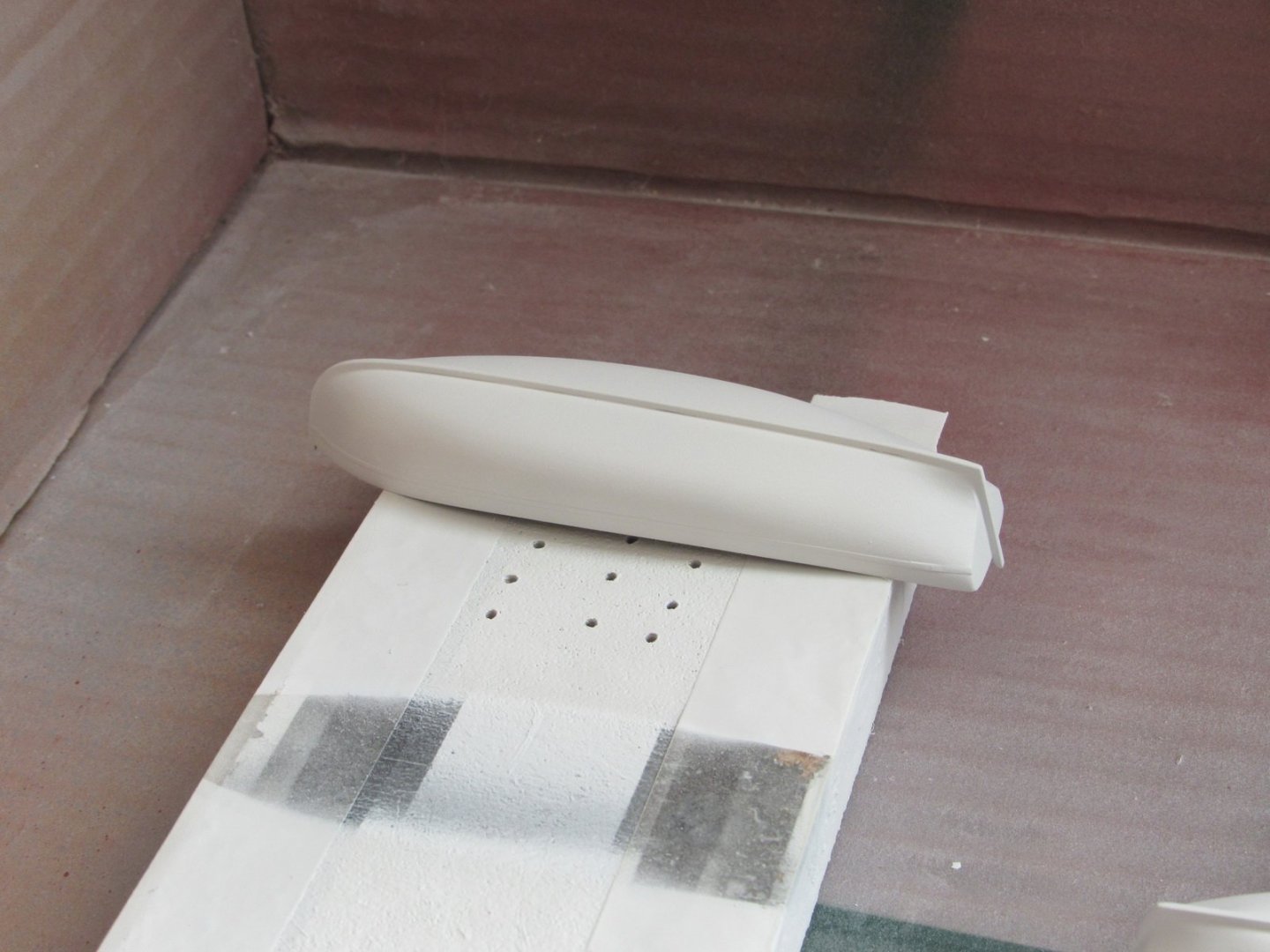

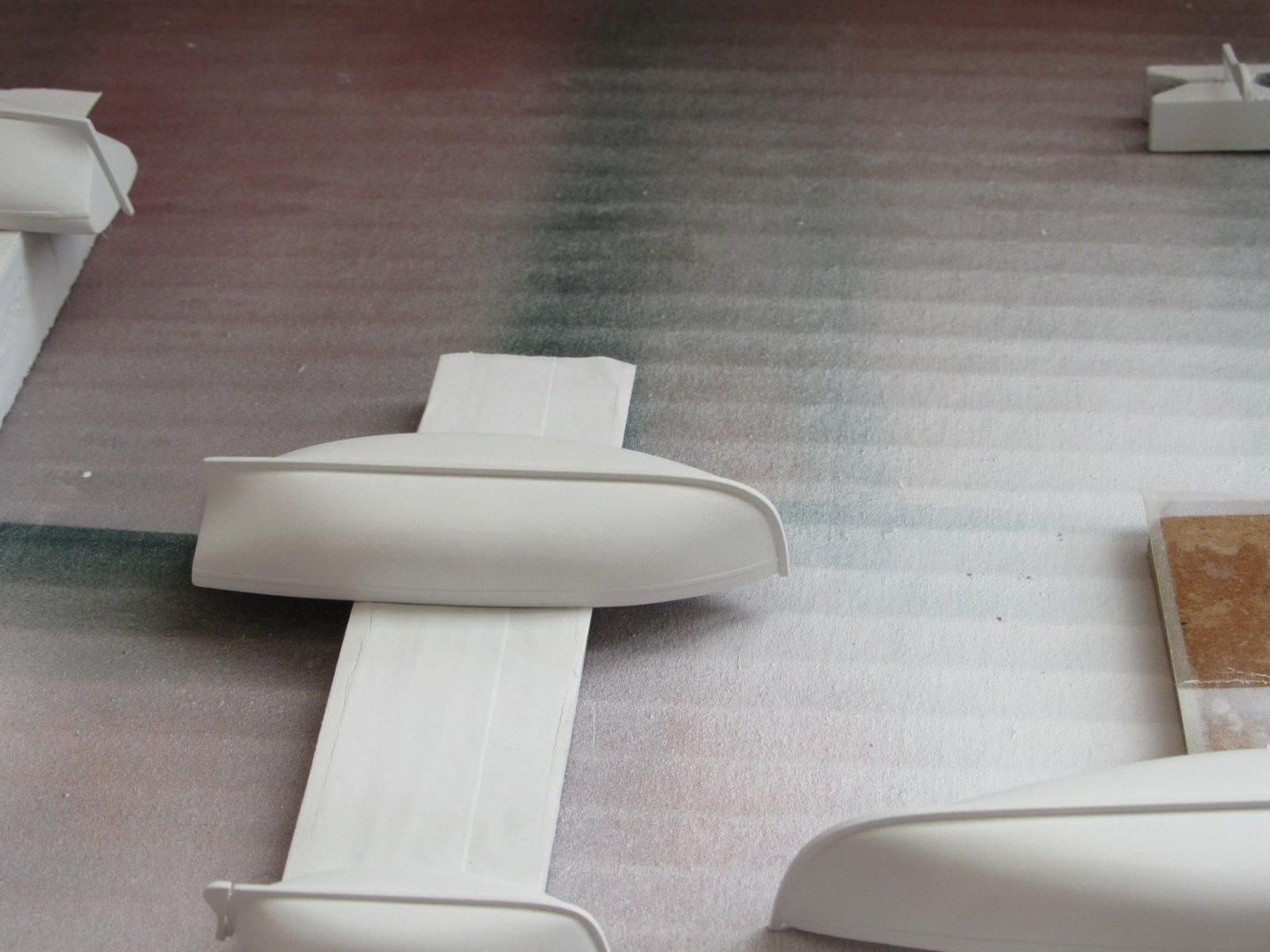

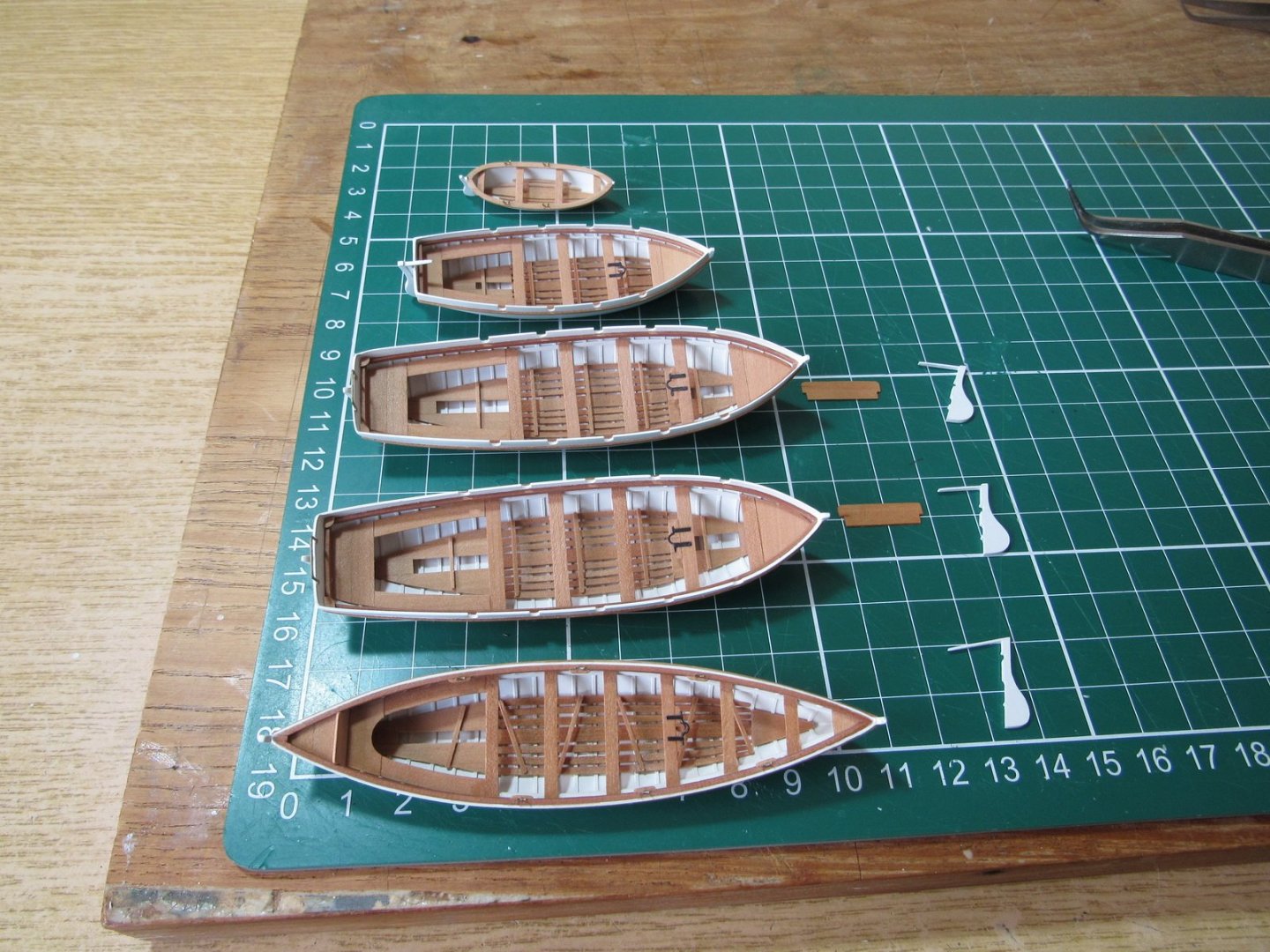

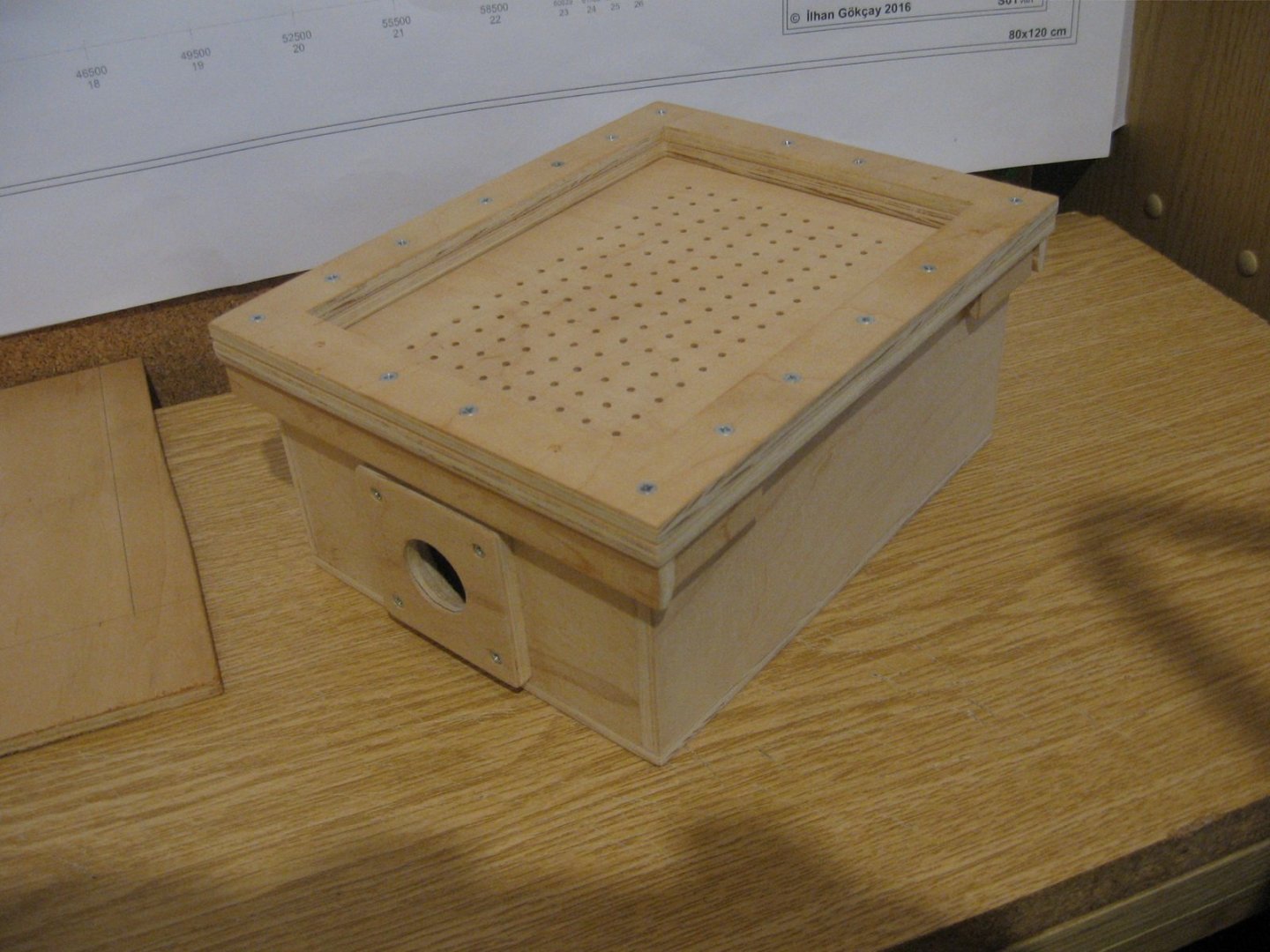

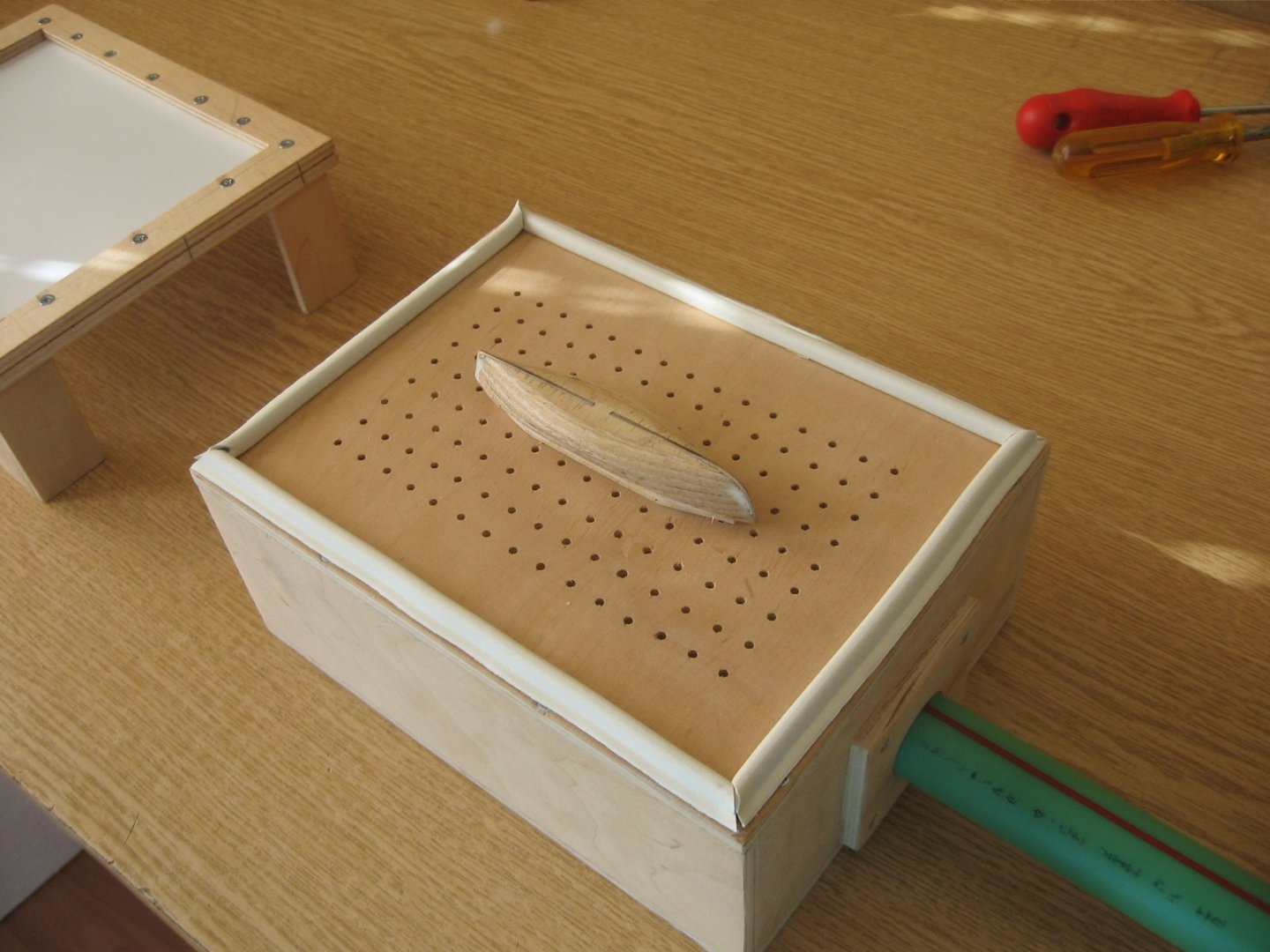

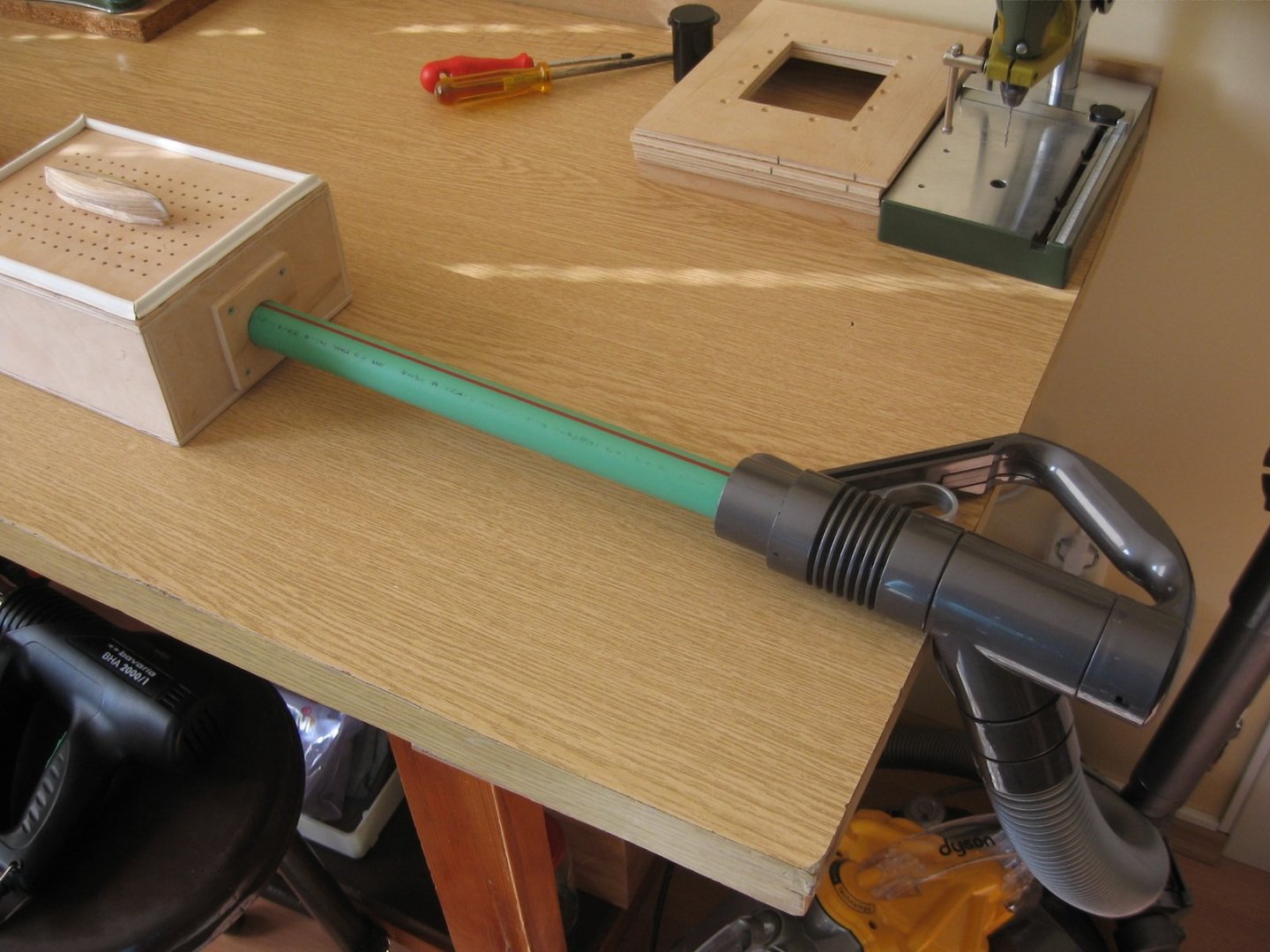

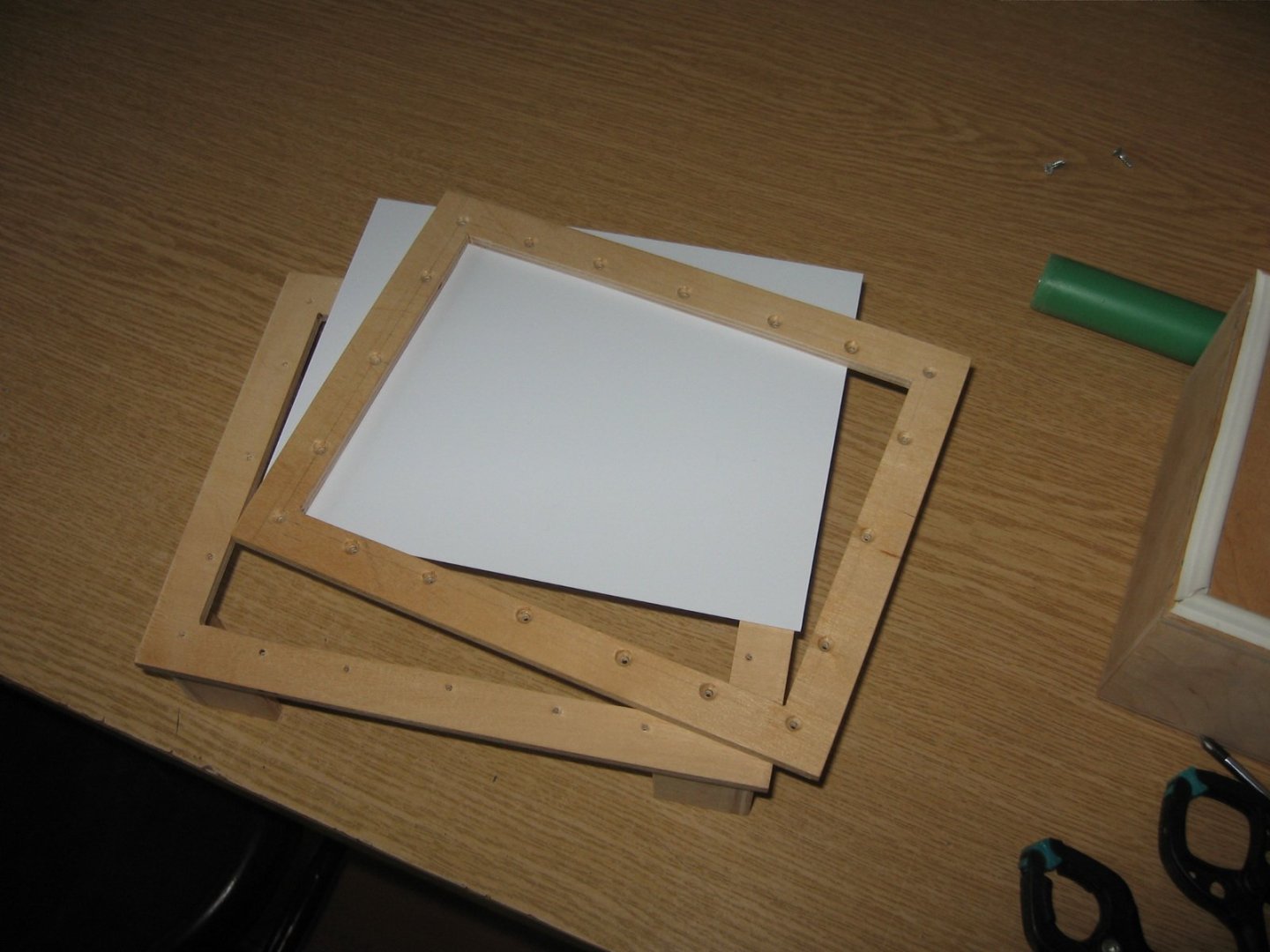

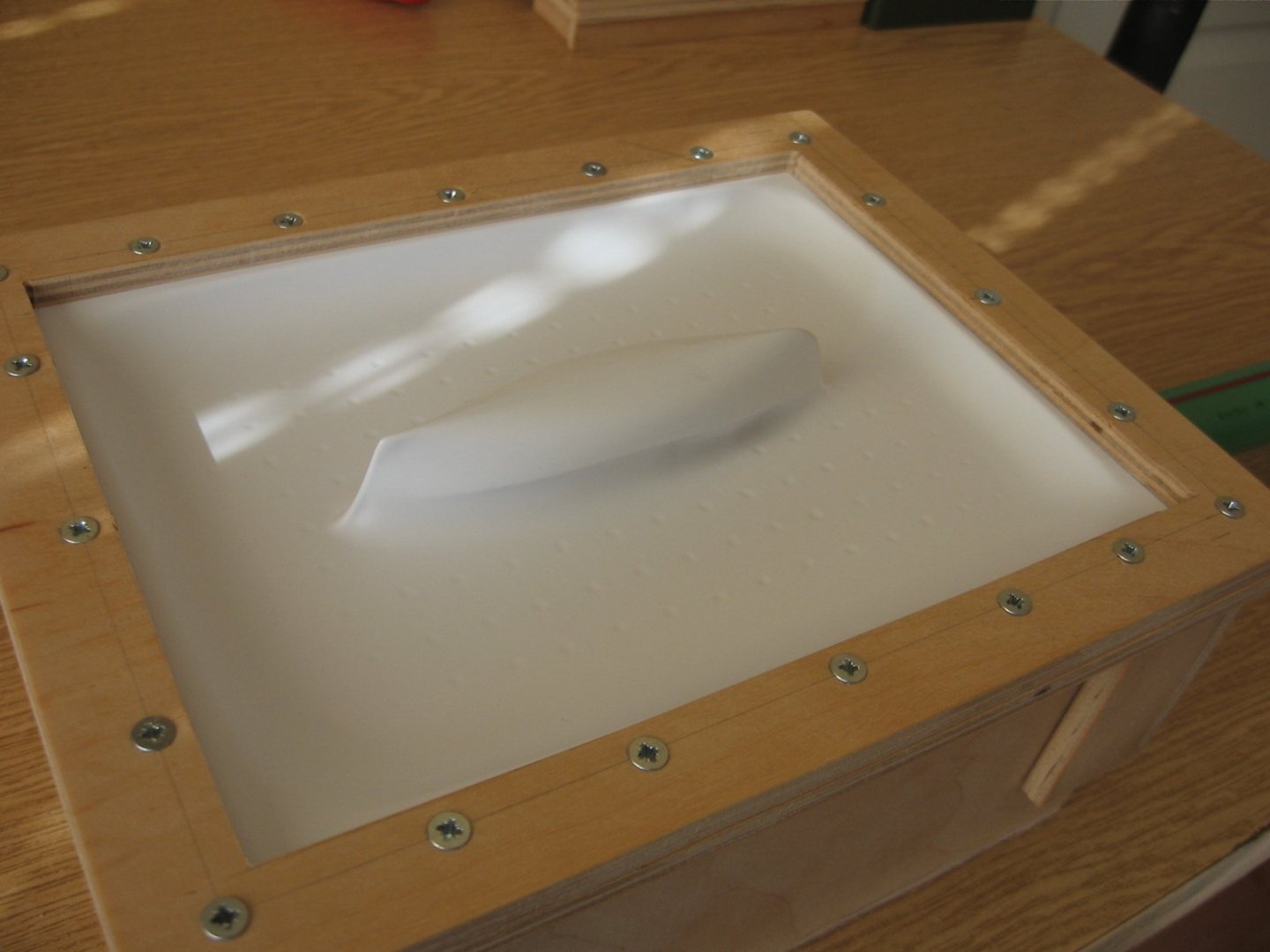

I've started to build the boats. There are 6 boats and they are all made of polystyren sheets with vacuum thermoforming.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.