-

Posts

34 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by SWOHammer

-

-

Update on the Willie L. Bennett keelson saga. Model Expo sent me a new set of laser-cut keelson (three-pieces), but they are the EXACT same dimensions as the ones that DON'T match the drawing.

For anyone that has or is building Willie Bennett, does your keelson match the drawings exactly, and if not, what did you do to rectify the situation? Change the sked, or change the keelson?

Negative responses requested.

Cheers,

Rob

-

-

Elijah,

Thank you for the quick response. I've been following your build log; you are doing a fantastic job on the Phantom. I saw on your profile that you are exactly 10 days younger than my son, Andrew. He is more interested in computers than wood, but I'm still working on him!!

If no one wants to give me their card stock templates, I will follow your advice and use the drawings to make my own.

-

Fellow Shipwrights,

I found a fairly old MS Pilot Boat Phantom kit in my dad's basement and I thought I'd work on that after I finished my current build (Willie L. Bennett). He clearly will never build it.

The issue is that he started carving the stern and thinning the bulwarks, but nothing else, and if the meager instructions give any indication (compared to the ones I can download on Model expo's site), I think he bought the kit before it included the templates to measure against the hull.

Does anyone who has built the Phantom still have the card stock hull templates that they are willing to part with? I could always make my own, but wanted to check with the experts first.

Thank you,

Rob

-

Thanks for the tips thus far; I will fabricate some fillers for the keelson using the excess material that the laser-cut parts came from. If they don't seem right and I get the right parts from Model Expo, I will swap them out. In the meantime, I'm working on cutting and fitting ancillary parts that I will need soon after I build the keel assembly (knees, strongbacks, stiffeners, etc.). It seems like so many items are "built to fit" so I don't want to get too far ahead of myself. Maybe I'll work on the pushboat instead since it is an independent build.

See you all soon!!

Rob

-

Hello Fellow Shipwrights,

I bought the Model Shipways' Willie L. Bennett kit about 6 years ago, but have been intimidated to start. Plus I'm active-duty Navy (Surface Warfare), and have been stationed on ships for the past 3 years. Now that I'm on shore duty (and about 18 months from retiring after 29 years of service), I am making the time to start learning this craft.

At any rate, I finally decided to start this thing. I am using the instructions as well as the excellent series of articles written by Kurt Van Dahm (2004, Ships in Scale).

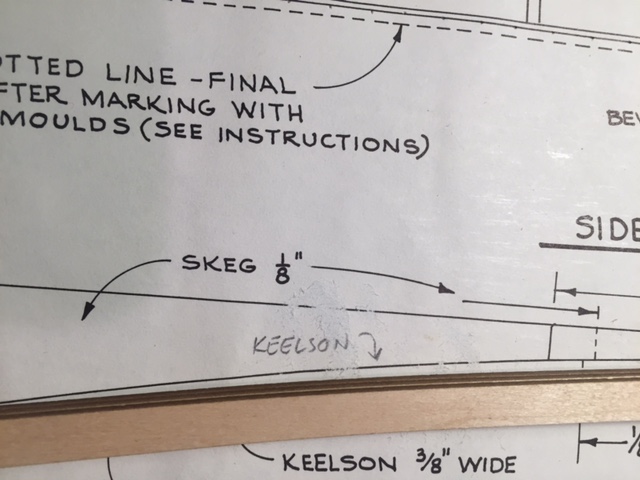

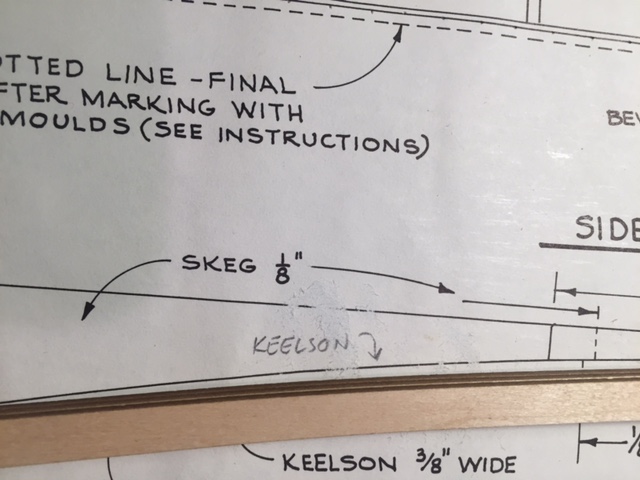

After building the build-board, I started working on the keelson assembly but immediately hit a snag. The dimensions of the keelson pieces (it comes in three that are glued together) don't match the drawing near the aft end. Model Expo is sending a new sheet with the laser-cut keelson on it, I'm just hoping it has the correct dimensions. Worst case, I'll just modify the skeg to account for the missing section of the keelson.

Has anyone else had this issue?

Here is a photo of my build board (I added additional strength members because it felt too flimsy to me, even with the triangle braces on each side).

Last question (for now): What is the best way to create the proper camber on the deck? Do people make a jig, eyeball it, use a template, or some other technique?

- MWerth, Ryland Craze, KevinR and 3 others

-

6

6

-

Has anyone else who is or was building Willie Bennett had this same issue, or is it just me?

-

Hello All,

Just started the Model Shipways Willie L. Bennett over the weekend (though I've had the kit for years...I finally got the courage to start...and a legal separation so the house is empty right now

).

).At any rate, I finished assembling the molds to the building board and was about to start working on keel assembly. When I went to trace the center keelson to determine where to make the cuts for the centerboard, I noticed that the drawings of the keelson do not match the laser-cut parts. Is it better to make the keelson from scratch to the proper dimensions, use fillers to make up the difference, or adjust the difference by extending the skeg? You can see the gap in the attached photo.

Is this just an issue with my kit, or has others who have built this kit found the same thing? (or am I making mountains out of molehills). This is my first build and I really want to make it "right".

Thanks, Rob

Model Shipways Willie L. Bennett Questions

in Wood ship model kits

Posted

Jack,

The addendum just covers how to use the laser-cut keelson assembly to simplify cutting out the centerboard slot.

My parts list is dated 6/12/2009. I wonder if the drawings changed since then that modified the shape of the keel/skeg interface