Brian Falke

Members-

Posts

99 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Brian Falke

-

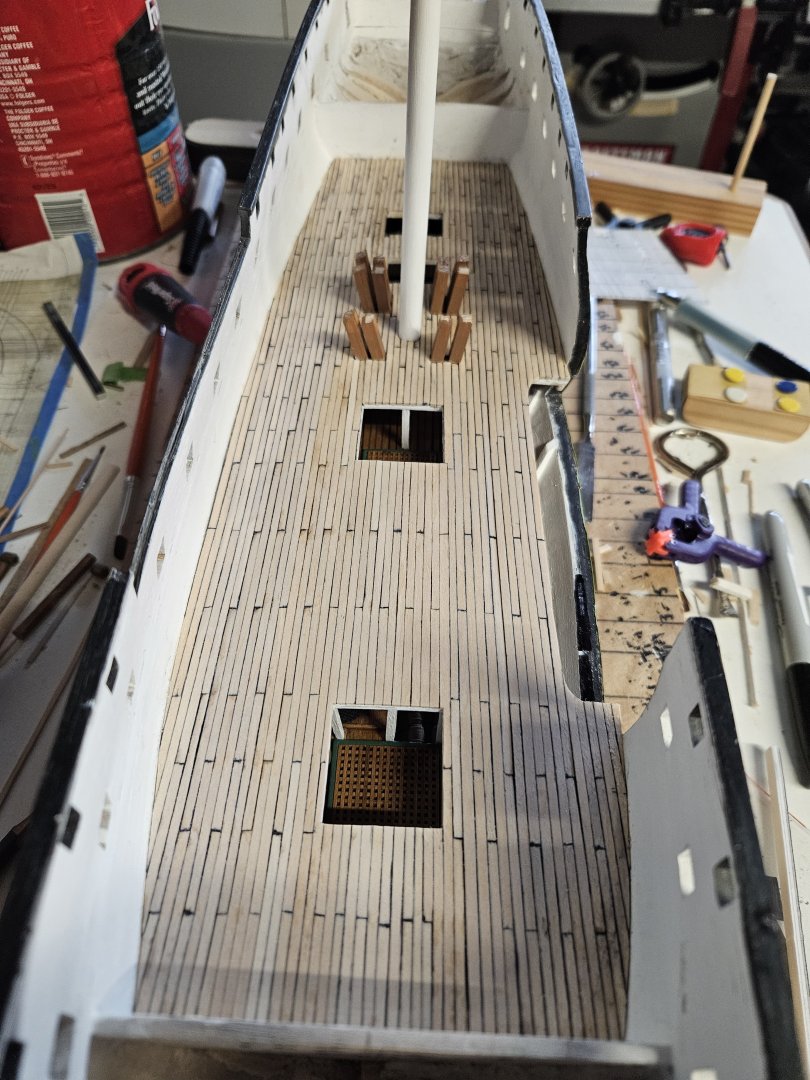

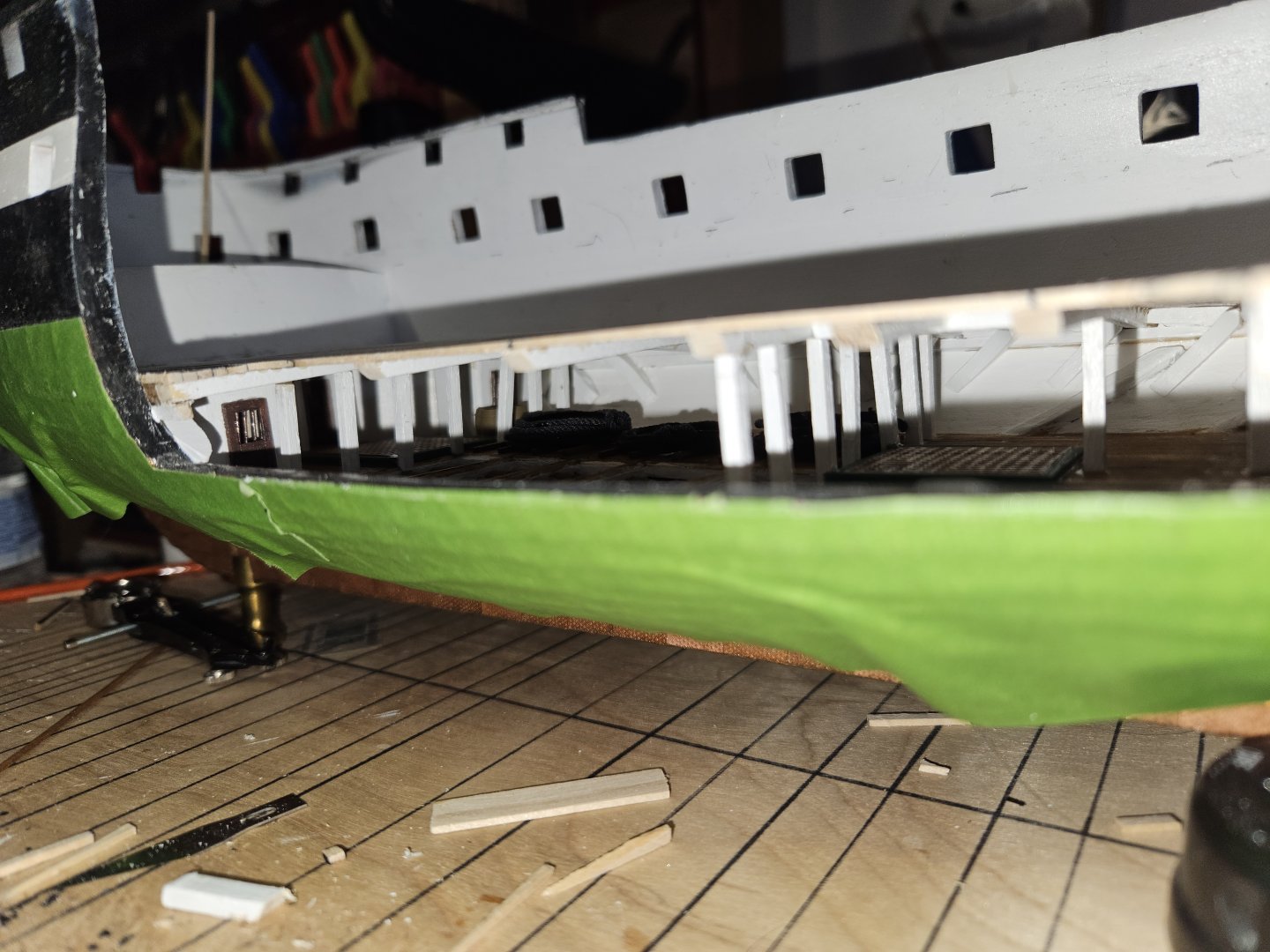

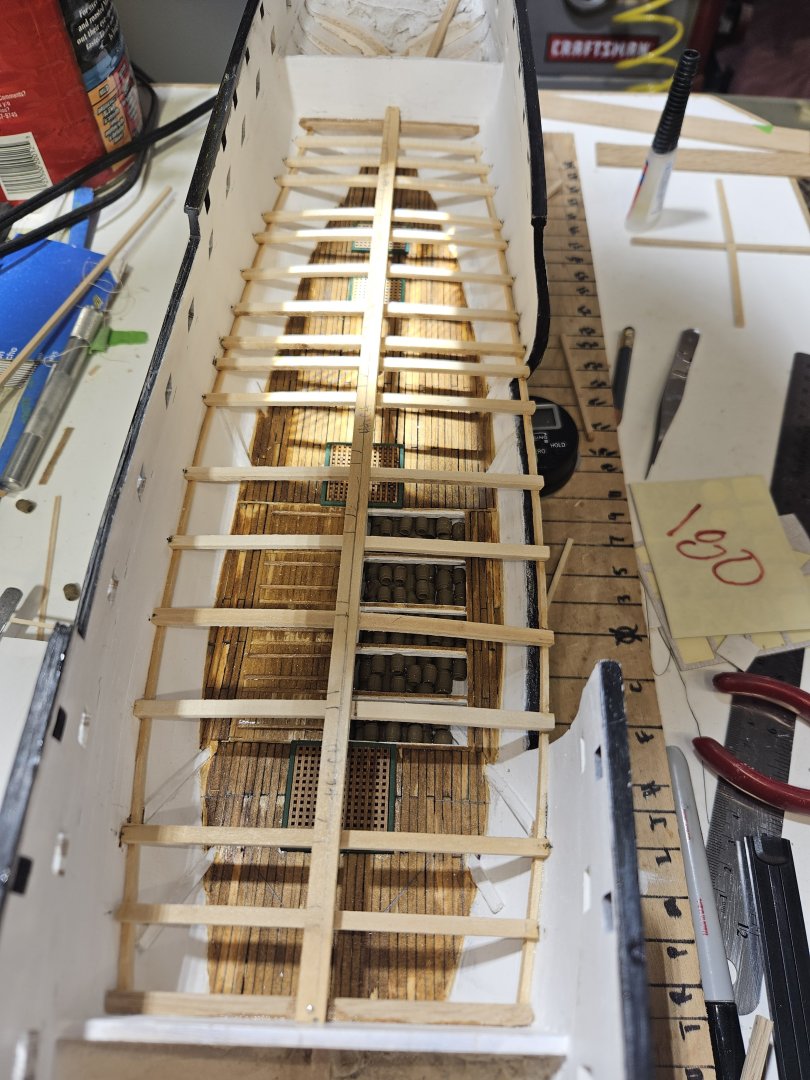

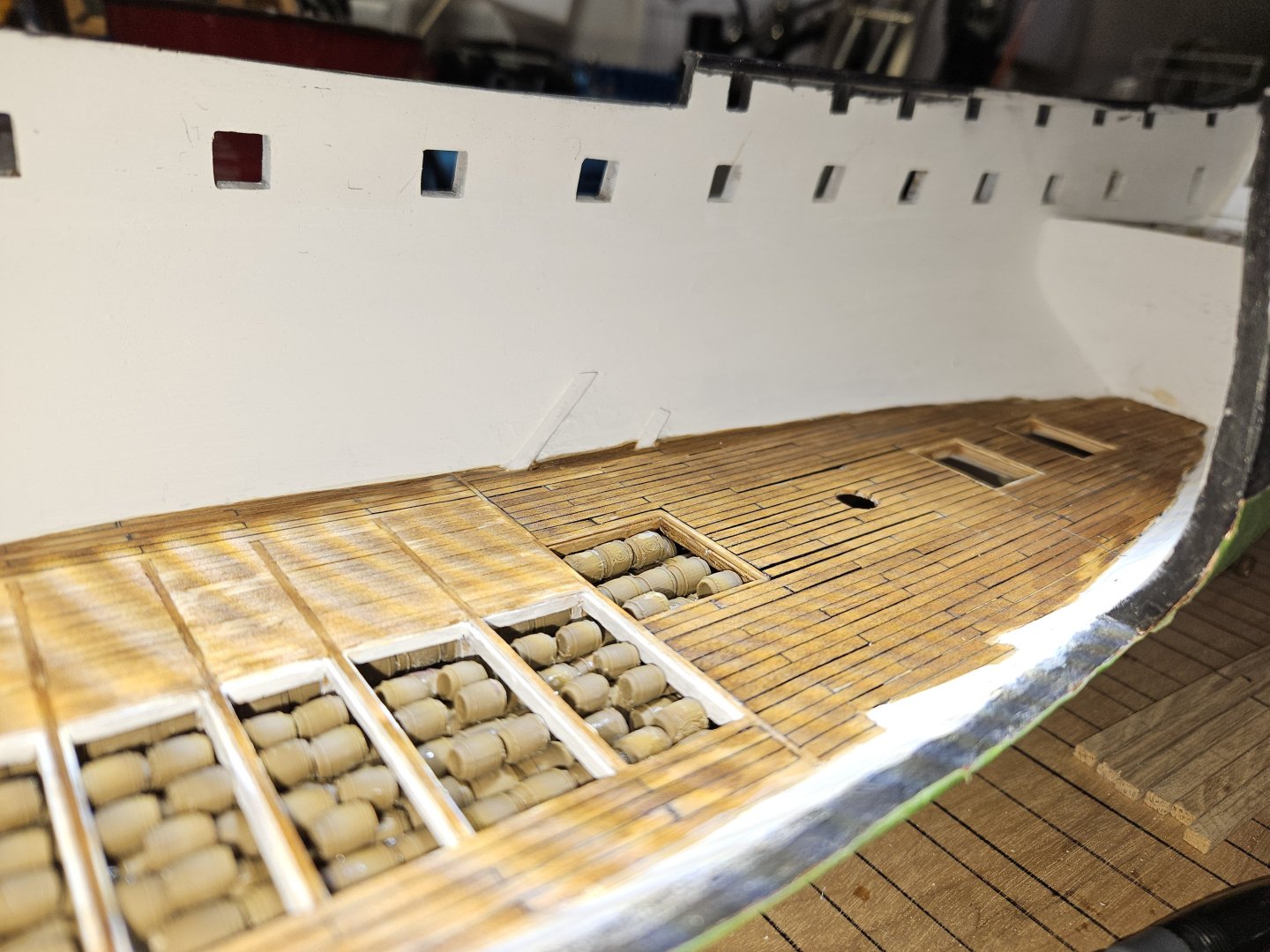

The decking is complete for the Berth Deck. I have started on the Gun Deck. My intention is to start installing the Gun Deck beams from Aft to Forward. Once I get to the green false bulkhead base, I will then have to install the knees with each beam. This is a lot more complex than the knees for the berth deck beams. Also, with the deck beams being about 6' apart, it would be near impossible to install the knees and if it was, they would not come out to my expectations.

-

The Berth Deck decking is installed (still need to stain and varnish). For the port side opening, once I planked to just beyond the cable tier stanchions. Once the glue dried, I cut away the remaining beams and stringer. This opened up the viewing of the Orlop Deck. Next steps are to stain and varnish the deck. After that, move onto the hatch coamings and gratings, then install the ladders to the Orlop deck.

-

Started the decking. Using wood glue instead of superglue. Found that since superglue cured so fast, I could not get the plank tightly against the others thus leaving gaps between them. And, I admit, I am not the neatest when it comes to superglue. I have to sand my finger tips at the end of the day to get the glue off. With the wood glue, soap and water takes care of it. If you look closely, on the port side I made marks where I intend to stop the decking so the Orlop deck can be better seen from the side.

-

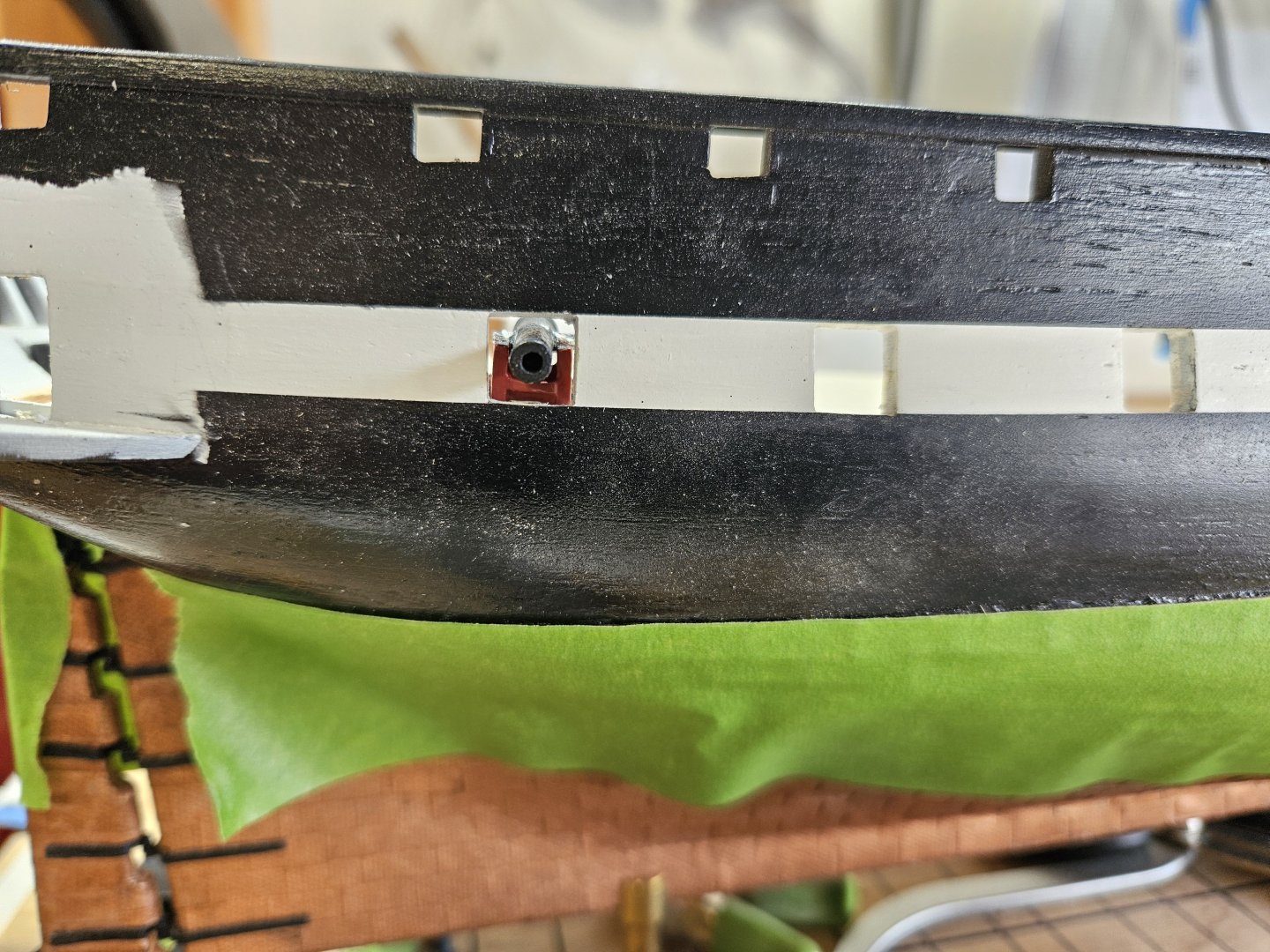

I feel the Orlop Deck is complete. Here are the views from overhead, looking forward and aft. The last pieces to put in were the up and down comers for the bilge pumps. That took a little research as the current CONSTITUTION has pipes. I found that they are square made from wood. This is so after battle, they could be easily repaired and put into use. Next step is to step the Main Mast, but first it would not be appropriate to step the mast without placing the good luck coin at the base. Since a normal coin would not fit, using a leather hole punch, I cut a piece of copper as substitute. Cheers, Brian After stepping the mast, it will be laying the decking for the Berthing Deck.

-

Thank you all for the recommendations and links. I did review them and analyzed the effort it would take to "adjust" the figurine to fit and have action, and it is too much. I would be working on the model until the end of time if I were to do what I feel is appropriate with regards to adding figurines. I am going to keep adding other items. Like in the cockpit, the surgeons table is setup with two casks for...well, limbs, etc. In the forward section of the Orlop, I intend to set up what it would be like for the carpenter. Also, there are a couple of casks by the main hatch ready to be hoisted up to the galley on the gundeck. Thanks again.

-

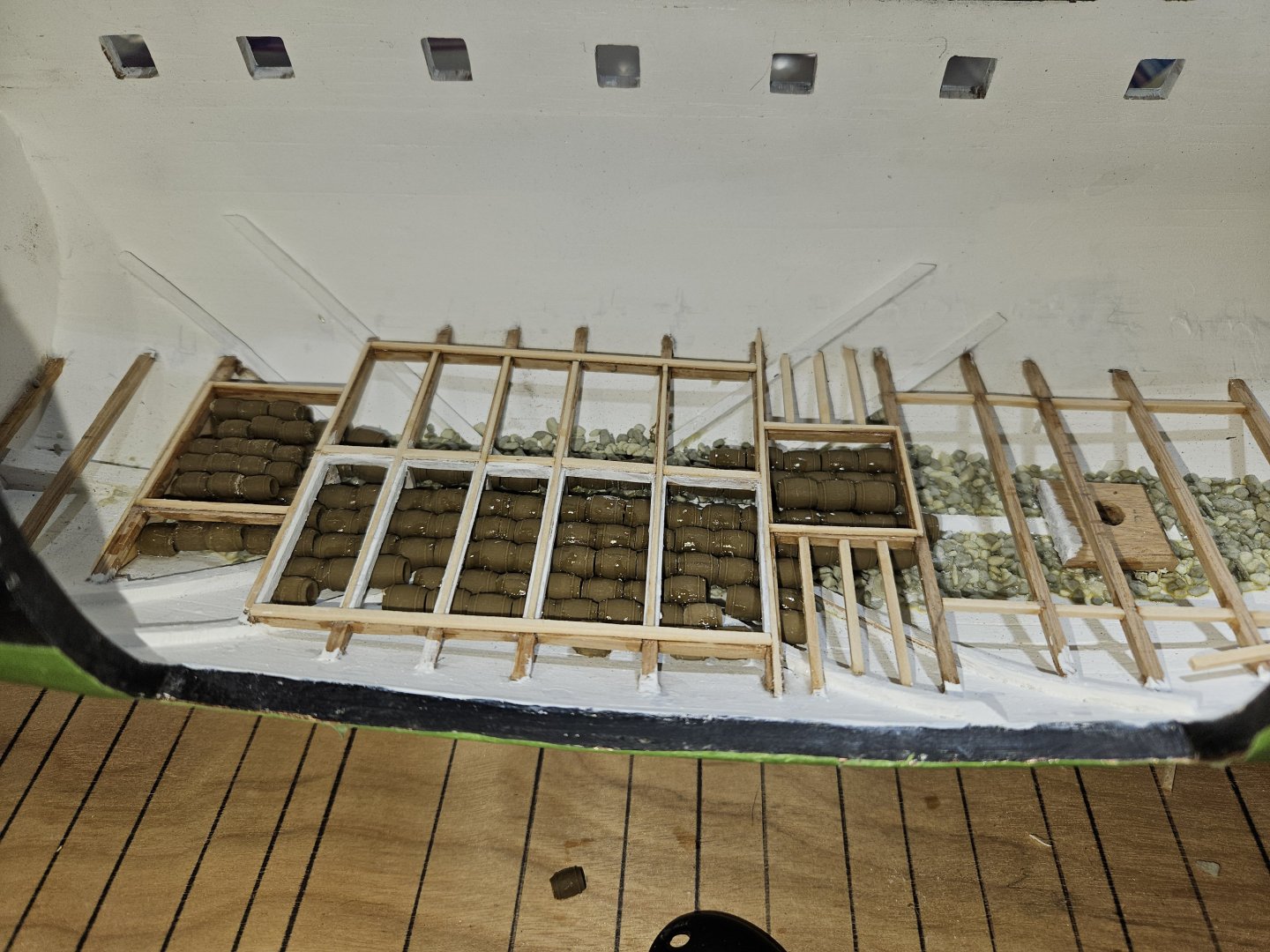

I have come to a decision on the figurines. Not doing it. First, could not find a good quantity of figurines that have some action. For the most part, they are just standing there. Second, could not find any at 1:96 that are US 1812 Sailors. And, felt I could not alter those that I did have into that era. So, instead, I will place those objects that give the observer the opportunity to place themselves in the action. On the Orlop deck I place a table and a couple of small casks in the Cockpit as if the Doctor were back there working on a Sailor (probably amputation). Up forward of the Fwd Hatch, I have placed a couple of larger Casks as if they are being readied to hoist up to the Galley. Amidships, on the Cable Tier, I have coiled line that would be the size used for the Anchor line. I still have to put something (have not researched deep yet) that has the Carpenter working on something forward. Now, will the observer be able to see these once I am finished? I do not know. But, I would rather have them there and not be able to see them than have nothing and be able to see a blank, dead space. Cheers.

-

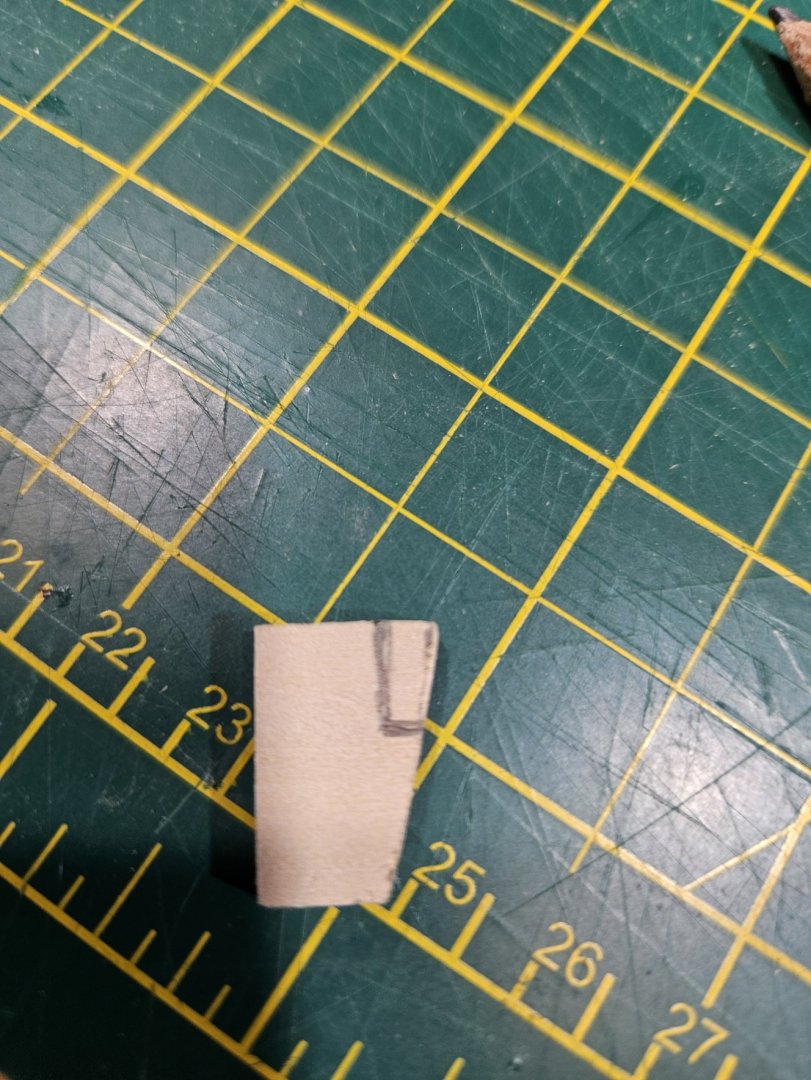

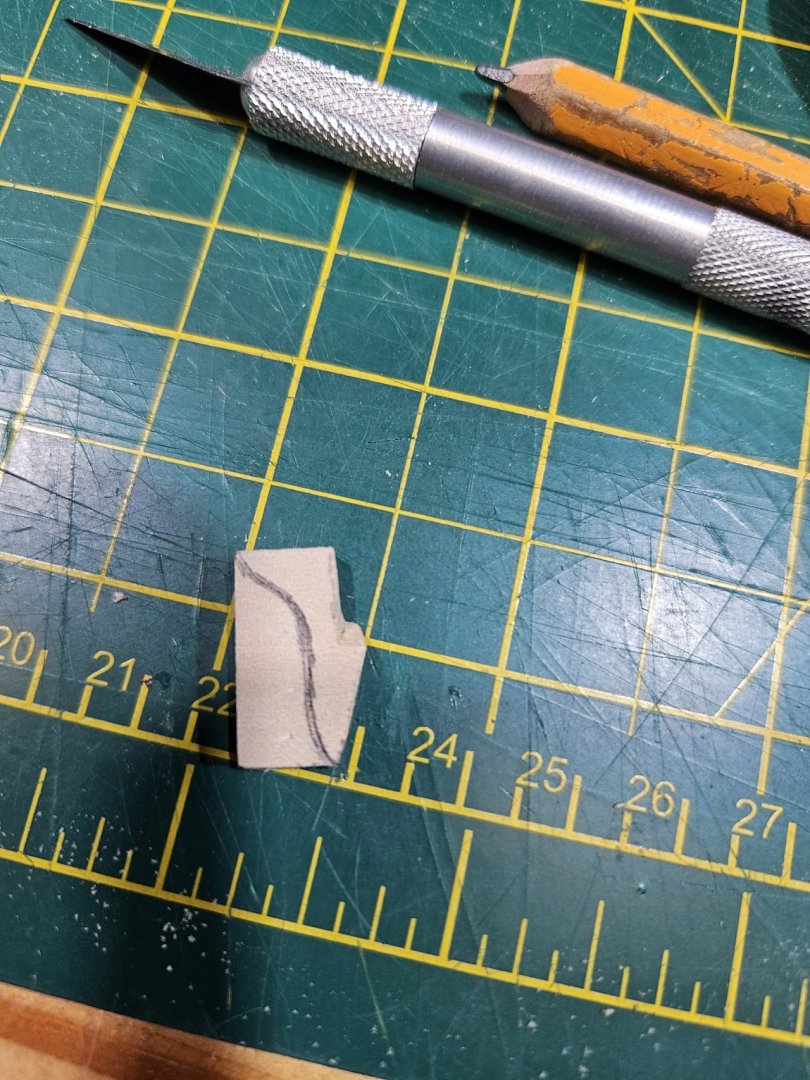

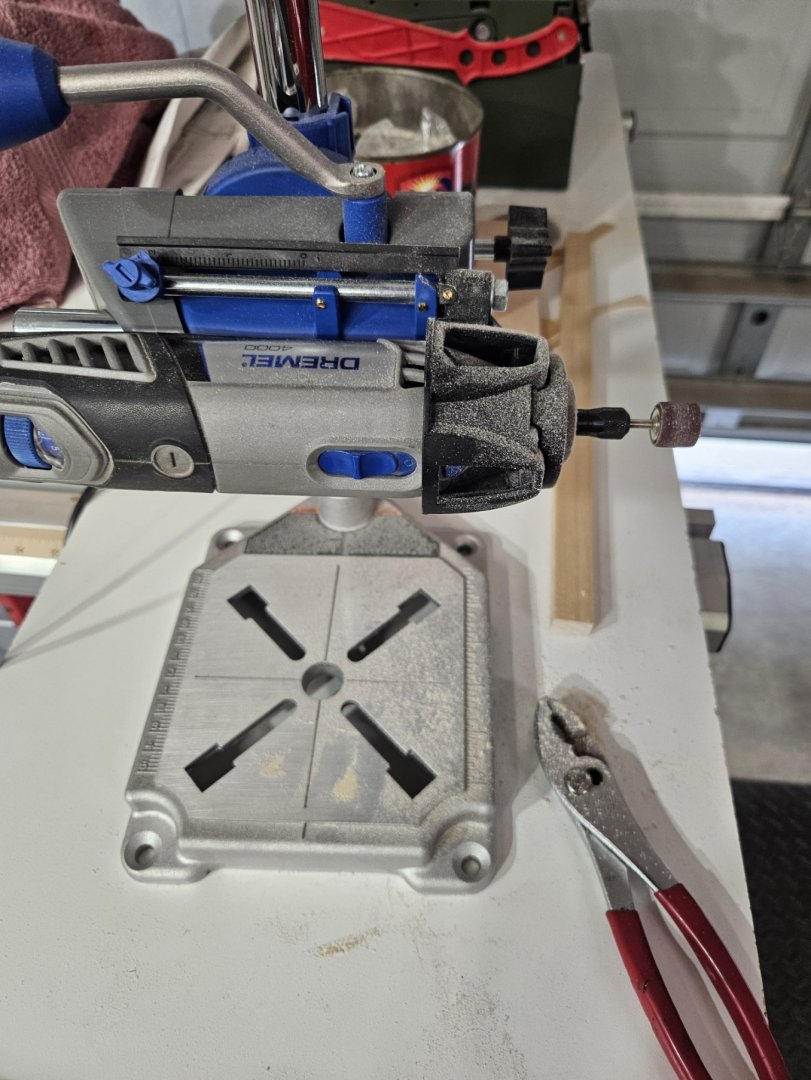

Now I am at the point where I was dreading the most. Making the knees and installing them. I have seen them in real life, seen them in pictures, and seen them in drawings...I just could not see making them with any semblance of accuracy. So, I decided to start at a basic level, just the length and height. They are 4' x 6'. That is what I started with, 1/2" x 3/4" x 3/16" pieces of stock. Here is the start: With this, I placed it against the hull at the 45 degree angle to find how much in do I need to cut given the curvature of the interior hull. Here is how I got that dimension With the square in place, I put a tick mark on the beam. Then took the stock piece, placed it atop the beam and transferred that tick mark onto the bottom of the stock piece. I then free-handed the curve from the top corner to the bottom tick mark as seen in the picture below. After cutting and doing a little sanding on the side against the hull, I then place the piece back into position to define the cutout for the stringer against the hull. After cutting out the notch and again, checking for fit, I then free hand drew the knee. And then cut the corner off in preparation for sanding down to the curve. Using the Dremel sander I ended up with this Then sanded the edge against the beam and the berthing deck to fit into the corner And then the final fit test before painting and glueing in.

-

I have started on the Aft section of the Orlop deck (Cockpit, storage rooms, etc.). For this section, I will be sure to include the Carpenters' Walk. Still debating about figurines. I do have a batch coming in from Dean's Marine. The last batch came from a railroad model store and everyone looks like they are standing around waiting for a train (go figure...), no action to them. I did have another group which looked great around a gun, but the maker only makes like 12 figures which would lead to repetitiveness. This is a trial scene... Guess I just wait and see what Dean's Marine has for me....

-

Finished the compartments in the forward section of the Orlop Deck. A couple of mistakes that probably will not be noticeable. I neglected to leave space between the interior hull and the spaces, the Carpenter's Walk and the Cable Tier stanchions are off a little bit. There should not be one centerline. Other than those two, fairly pleased with how it came out. As for figurines, I have ordered some from Deans Marine. Do not know when they will get here, but for now, I have moved onto the aft section.

-

All major beams for the Berthing Deck are fitted. I initially planned on keeping them in place as I installed the Orlop Deck bulkheads but quickly realized that would be too challenging. So I place a small mark on each side to mark the location of the beam, numbered each beam, 1 being the most forward beam and removed them all, including the centerline stringer (which was temporary anyway). Prior to removing all beams. After removal, I painted them for final installation. But before moving forward with re-installing the beams, I laid base board along the interior of the Orlop Deck bulkheads to glue the bulkheads to. This is the Aft portion of the Orlop Deck: And this is the forward portion of the Orlop Deck with the first beam reinstalled and the first bulkhead fitted. Prior to final installation of the bulkheads, they will be painted and doors installed. My plan is to work from the most forward part aft until the last bulkhead of the forward section is complete, then shift to the most aft bulkhead and work forward until that section is complete. Then I will determine if I want figurines or not (not having much success in that) and lay the cable in coils on the cable deck and place a spare anchor against the starboard hull.

-

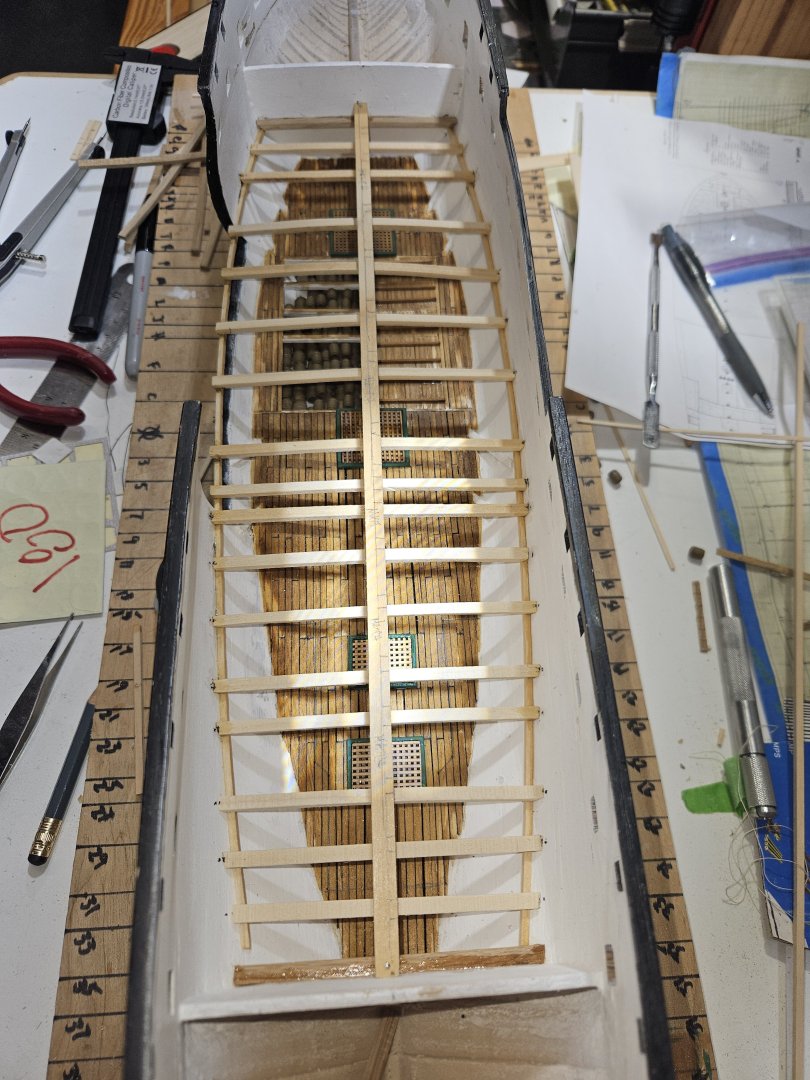

I replace the stringer (?) from the post above to something more substantial and pinned it into the most forward and aft beams. In the below picture, you can see where I marked off each beam and the centerline. This aids in ensuring I get the beams spaced appropriately and centered side-to-side. The first three are in. Once all major beams are in, I will continue finishing up the Orlop deck. If you look on the decking for the Orlop deck you can see the pencil lines for the bulkheads. Cheers.

-

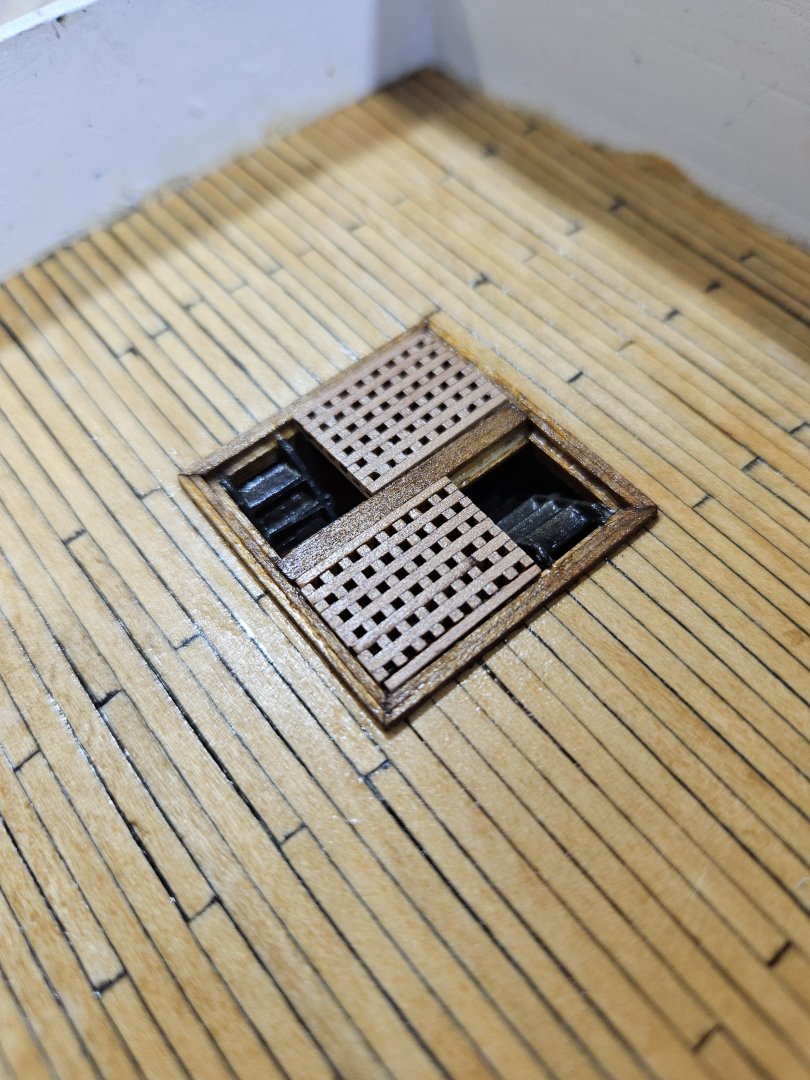

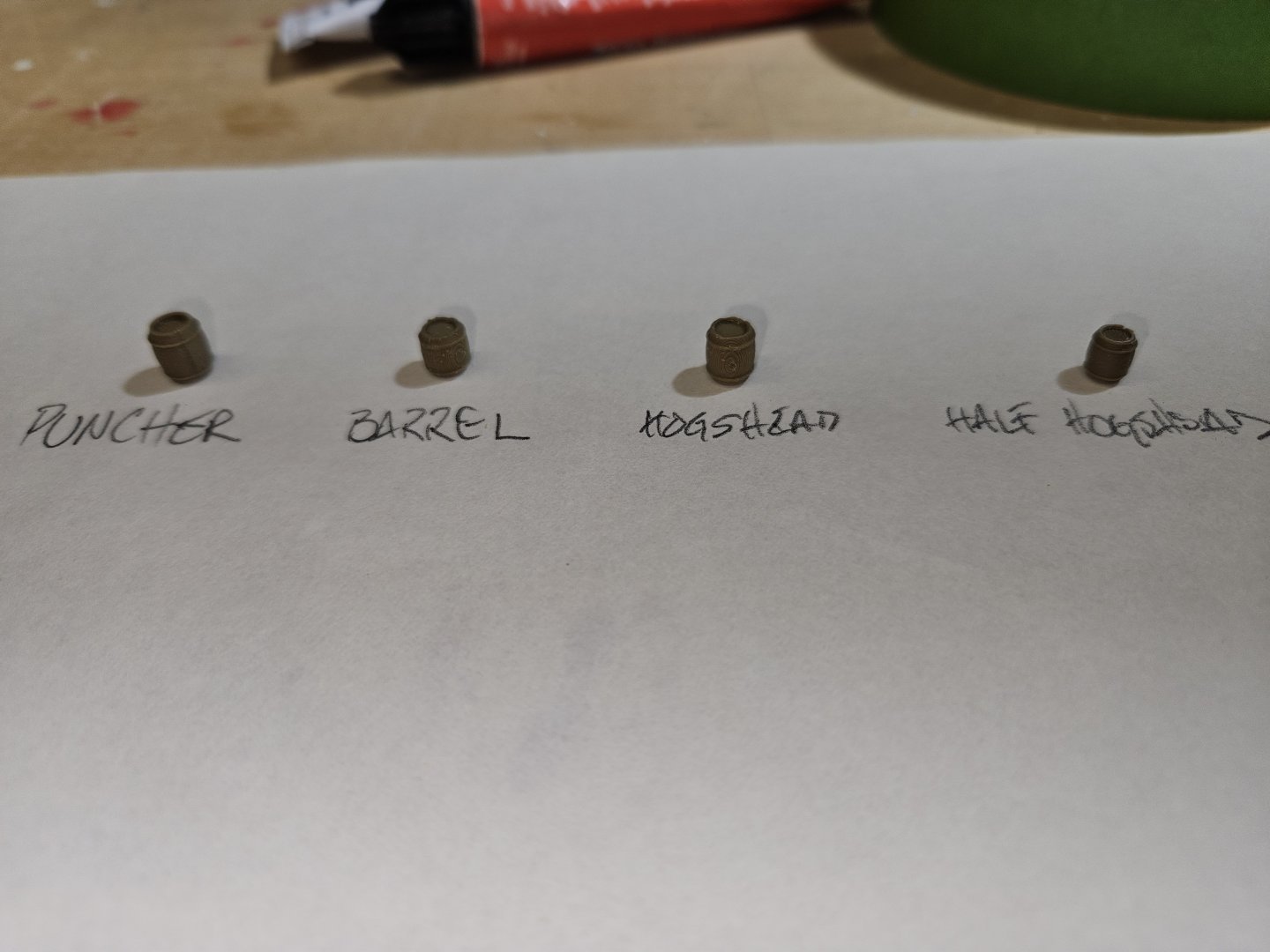

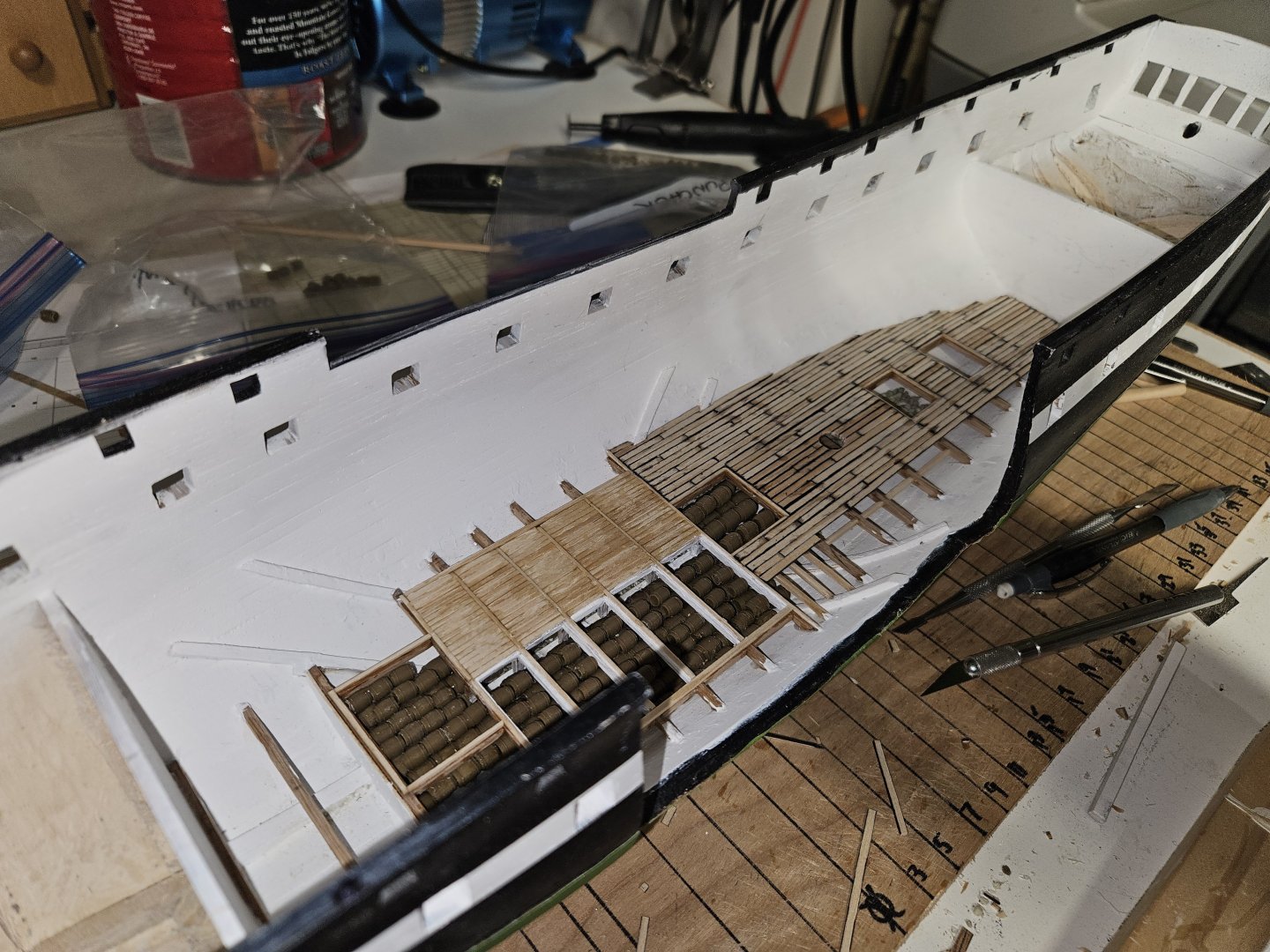

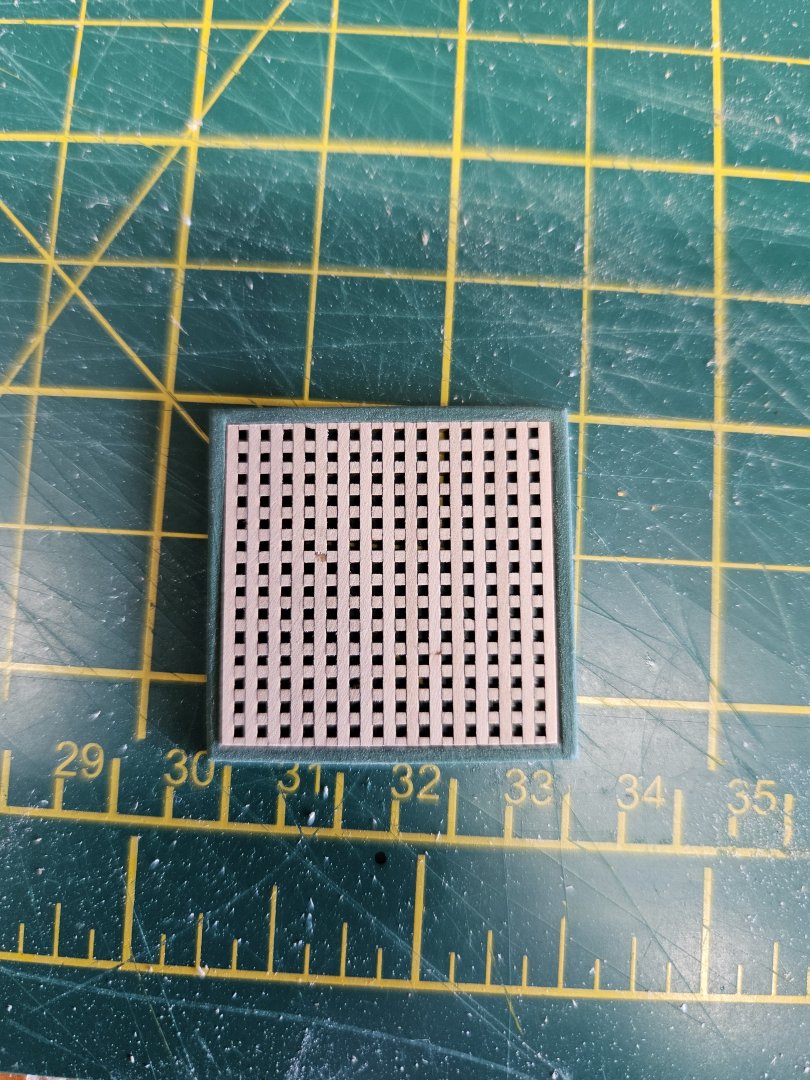

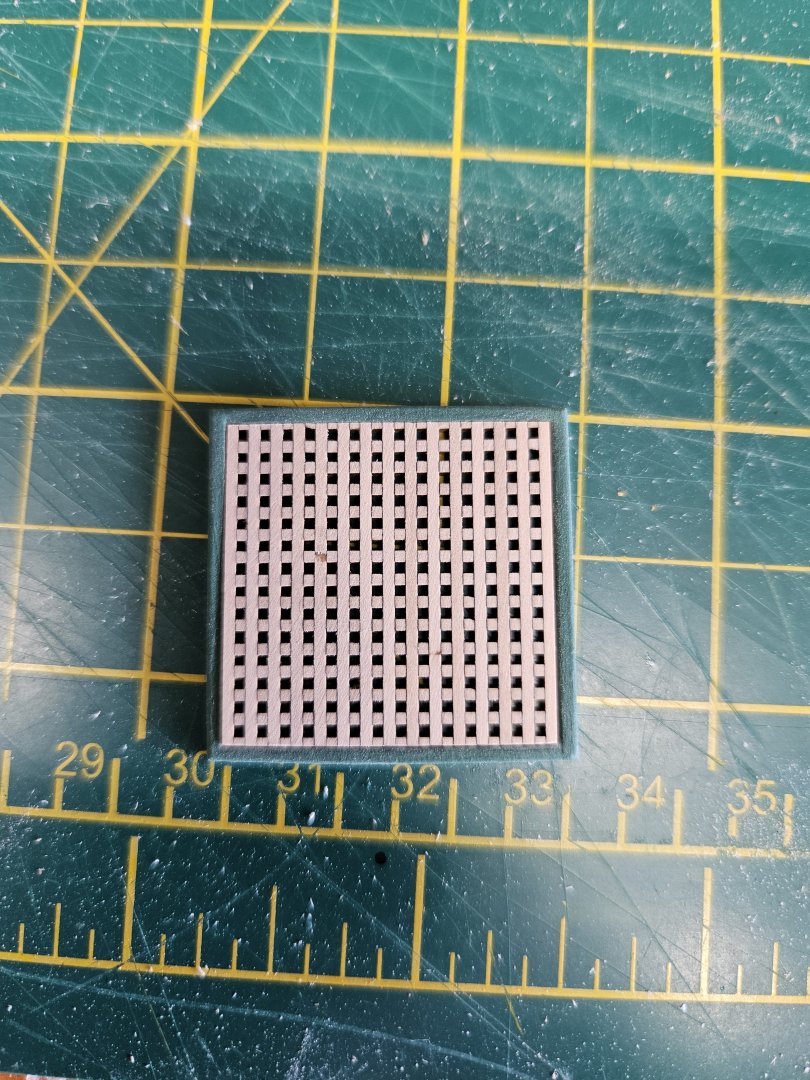

From the last pic to the current, I did make progress - just failed to document here. Using the method I described above (November 28th post), I was able to install all cross beams and hatches. Prior to laying the deck, I outfitted her with a full complement of stores. The casks are 3D printed (could not find the correct sizes) casks. Here is a picture of the different types. And with all beams and casks in place: Using .03in thick by .06in wide white pine, I commenced planking the Orlop deck. The black between the planks is permanent marker. The section amidships is the cable tier. I researched and researched how that was in 1812 and found nothing, or scarcely nothing. So, I suspect that stores were in the hold below the cable tier deck and those sections could be removed for access to the hold. I installed the cable tier deck on the starboard side and left the larboard side open to the hold. The small section against the hull is the carpenters walk, which will be planked as the rest of the deck. And this is the finished Orlop deck looking forward and aft: After completing the deck, the next step was to install the coamings and gratings for the hold access. Because the BJ kit does not include the parts for the Orlop (only Gun and Spar decks), I researched other model parts providers and found 1:72 scale gratings at drydockmodelsandparts.com. Their actual thickness is .03in, which comes to 3 inches at 1:96 scale. I really do not think anyone will be able to see a .01 difference. Here is the forward hold coaming and grating: After installing all coamings and gratings, I am at a decision point. Should I move onto the Berth deck framing, or continue with the Orlop deck knowing that what I install may have to be adjusted due to the Berth deck beams. I moved onto the Berth Deck beams and will install the finishing touches (figurines (still debating this one), bulkheads, doors, anchor cable, spare anchor, etc.). So, moving forward, I installed the aft and forward most beams. Using basically the same method for installing the Orlop beams, I placed a stringer (?) forward to aft to guide me in the installation. Here is where I am today: The cross beams will go on top of the stringers along the starboard and larboard sides and under the centerline stringer. Cheers, Brian

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.