Avi

Members-

Posts

320 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Those are two good ideas. I thought about a spare piece of plank across the corners. Those are pretty thin, but I think still thick enough that they would make it not flush to the deck. Paper, however, would be great. For those hatches that have gratings, I can make it a little wider, so it also would provide corner support for the gratings. Another alternative is cross supports. I can use spare plank and literally cut across the middle to middle, for those that have gratings. But I like the corner idea. I can do it for all of them. I don’t think I bought wood coloured paint. The blackening is a good idea. So what did you do in the end? Just leave it shiny brass?

-

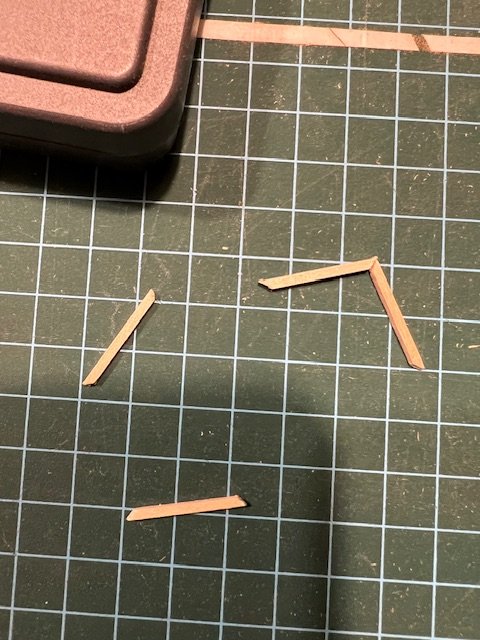

Might as well make the coamings in the meantime. Or try. 😁 The grating is ¾” square, the coaming wood is 1/16”, so the whole thing is 7/8” square. I cut strips 7/8” long, then used the mitre box to cut 45’ angle on each end, and sanded where necessary. the question now is how to connect them. The wood is too narrow for a pin - it probably would split it - so glue is the usual fallback. Unfortunately, the tiny surface of the attachment angles means it doesn’t have a lot to hold onto, and the long relative length of the attached pieces puts too much torque. I suspect, although am unsure, that if I could do all four pieces at once, they would support each other, but I don’t quite know how I would do that. I might try painting the sides white and varnishing the top, and then gluing them together and to the deck. The deck should provide plenty of surface.

-

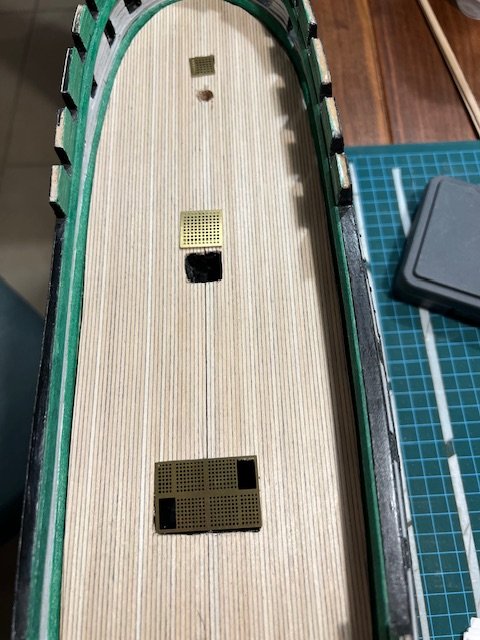

As far as I can tell, 3 of the gratings are intended for the gundeck, 3 for the spardeck, plus the big triangle shaped one for just behind the bowsprit. I’ll attach a picture of them on the deck but not attached (and no coamings yet; that’s next). The painting guide says, “gundeck hatch coamings - white - sides white; tops natural wood.” That’s easy enough once I construct them. But then, “wood gratings - natural wood - valspar varnish.” Needless to say, the gratings are not wood, but are photo etched brass. so do I leave them brass? Paint them something that looks like it might be wood?

-

eatcrow2 reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

eatcrow2 reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

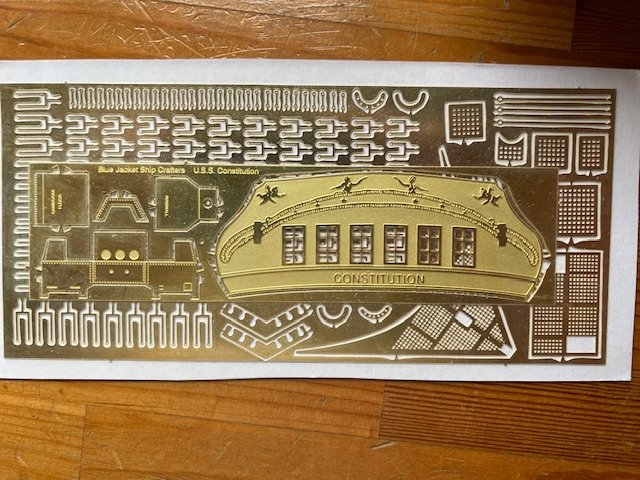

Hi Kurt. That explanation helped. I see what you’re referring to now in your post. I’m not sure I know what the PE gratings are. Are they squares, ready to place? Those strips in the picture I posted, that need to be combined? BJ has two different wooden gratings on their website, this and this. But that’s clearly not what’s in the kit.

-

Avi reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

Avi reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

I cut out the hatches and drilled the holes in the planking for the masts. Some of the planking cut loose in the process, so I glued it back. For the hatches, I marked the outside, felt by tapping where it definitely was hollow on the other side, and drilled small holes in each of the four corners. That made it easier to use a keyhole saw to cut the quadrilateral shapes. It then required some fine trimming with an xacto knife. At the end, the black paint inside the hatches had gotten marked up, so I repainted parts of them. For the masts, I used progressively larger drill bits to ensure I wasn’t veering from the existing holes in the main hull, which had measured correctly. I had to look back at the supplies list to see the diameters of each mast to know what size I was targeting. They all worked out well in the end. Interestingly, despite a relatively short session, this may be the one in which I used the most tools and did the most activities in a long time: drill, keyhole saw, knife, sander, pliers, glue, paint. Usually a session is dedicated to one or two activities, like cutting and gluing, or painting, etc. Next to shape the hatch coamings. It isn’t clear from the guide if there is wood dedicated for this, or if I use spare planks. EDIT: the parts list shows W1370 1/16x1/16x24” for the gundeck hatch coming (along with lots of other things), and W1371 3/32x1/16x24” for spardeck hatch coamings. The other confusing part is the grates. There are 7 hatches on the gundeck (including the very large main hatch), and another 6 on the spardeck. The parts list shows 7 gratings supplied as part of the photo etched brass parts. Is there a plan as to which hatches should get gratings and which should not? The plans show 2 on the gundeck plus the main hatch, and 3 on the spardeck, but hard to tell if that is an actual plan. Or is this more “do what you want”? Also, what exactly are these “photo etched brass gratings”? I don’t see anything that looks like a grating. Is it the pic below?

-

Thanks @schooner I was worried about something similar. I drilled holes into the carriages to have the option, but it didn’t inspire confidence in me. So I took a piece of spare planking, cut it to length, painted it black, glued it between the two trucks. Once on the deck you cannot see it, but it gives a large surface for glue contact. I’m hopeful that will work.

-

ERS Rich reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

ERS Rich reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

Avi reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

Avi reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

KurtH reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

KurtH reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

KurtH reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

KurtH reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

Once it all has a day or two to set, I’ll get to work on the gundeck itself. I need to cut open the hatches and holes for the masts, then build coamings around the hatches. Then comes the various furniture and some rooms, the shot lockers and the knees. I haven’t decided if I’ll do just the hanging knees or lodging knees too. That’s a long way away. I did spend some time reviewing the directions in chapter 9 for the spardeck. As usual, lots of detail, not a lot of explanation or direction. I’m hopeful I’ll figure it out well enough.

-

vossiewulf reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

vossiewulf reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

Coming back to an earlier post, I decided to use satin varnish on the decking. I put on a coat, waited an hour, put on another. Looks great. I found that the wood just didn’t stick well to the “deck surface of the hull”. So I put a coat of sander sealer on it, as well as on the back of the glued up decking. Once it dried, I put a layer of contact cement on the hull deck and on the back of the glued up decking, waited a few minutes for it to dry, and made contact. I got lucky, the last bit in the last tube of contact cement was just enough. It worked quite well. Before gluing it on, I folded the decking in half (since it’s two pieces taped together), marked where all of the various hatch openings are and the three holes for the masts. I then used the jeweler’s saw to cut a small hole in each. I have the template, but this ensures that I get an accurate cut location. It’s always easier to expand a good hole than dig for the right location that _should_ be there. And the gundeck planking is in place. once done, I took a cannon and put it in each gun port, just to see. Fits just right.

-

ccoyle reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

ccoyle reacted to a post in a topic:

USS Constitution by Avi - BlueJacket Shipcrafters - 1:96

-

Finally got around to raising my deck. Actually I just realized. I’m moving homes soon, redoing the new place. Most people put down tiles here, but we really like wood so we are putting down wood planks. If we will be walking on wood planking, can I call it the deck? So we can have the living deck and sleeping deck? Need to see what my wife has to say about that. I took some leftover planking, placed it at the edge, placed the decking, and checked. Rinse wash repeat. Some areas took one run of thicker wales, some took planks, some both, etc. but the heights are right now. Here it is prior to laying down decking. I’m going to varnish it first and then glue it down, then cut the various holes for hatches down to lower decks, masts, etc.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.