Randy Todd

Members-

Posts

44 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

ERS Rich reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

ERS Rich reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

ERS Rich reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

ERS Rich reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

ERS Rich reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

ERS Rich reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

billocrates reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

billocrates reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

billocrates reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

billocrates reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

billocrates reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

billocrates reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

GuntherMT reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

GuntherMT reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

GuntherMT reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

GuntherMT reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

mtaylor reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

mtaylor reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

Hi Ed, What is a good source for high quality brass, copper bands, etc? I used to think all metals were the same until I got some blades from China that did nothing but fracture. If things go south as I start milling, I want to make sure it is the Indian and not the arrows.... Thanks in advance, Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Michel Bénard reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

Michel Bénard reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

Hi Ed, Sorry to take up the space. Early on we discussed a builder's log and it's not something I'm inclined to sink any time into (best to keep the marriage healthy). I thought you mentioned some interest in seeing my progress. Sorry for the misinterpretation and I'll stop sending photos (hate taking them anyway). I'll confine my correspondence to questions about Volumes 2 and 3- never done any home milling before so I'm sure I'll have plenty. Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

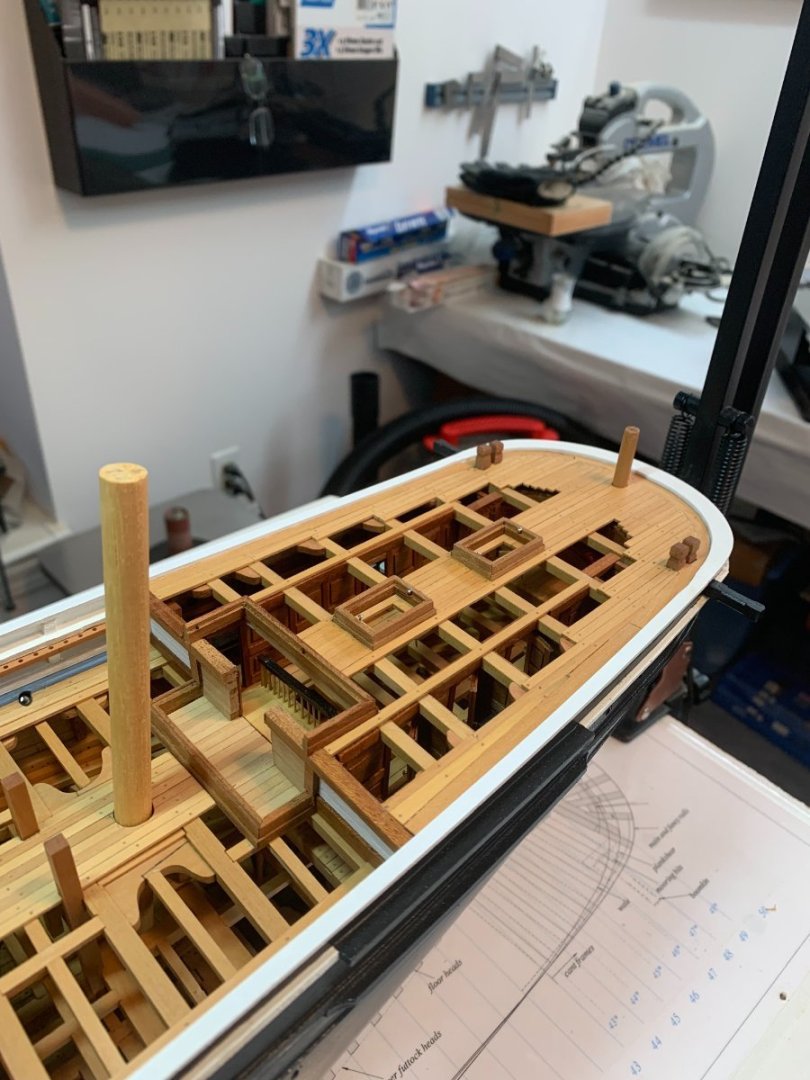

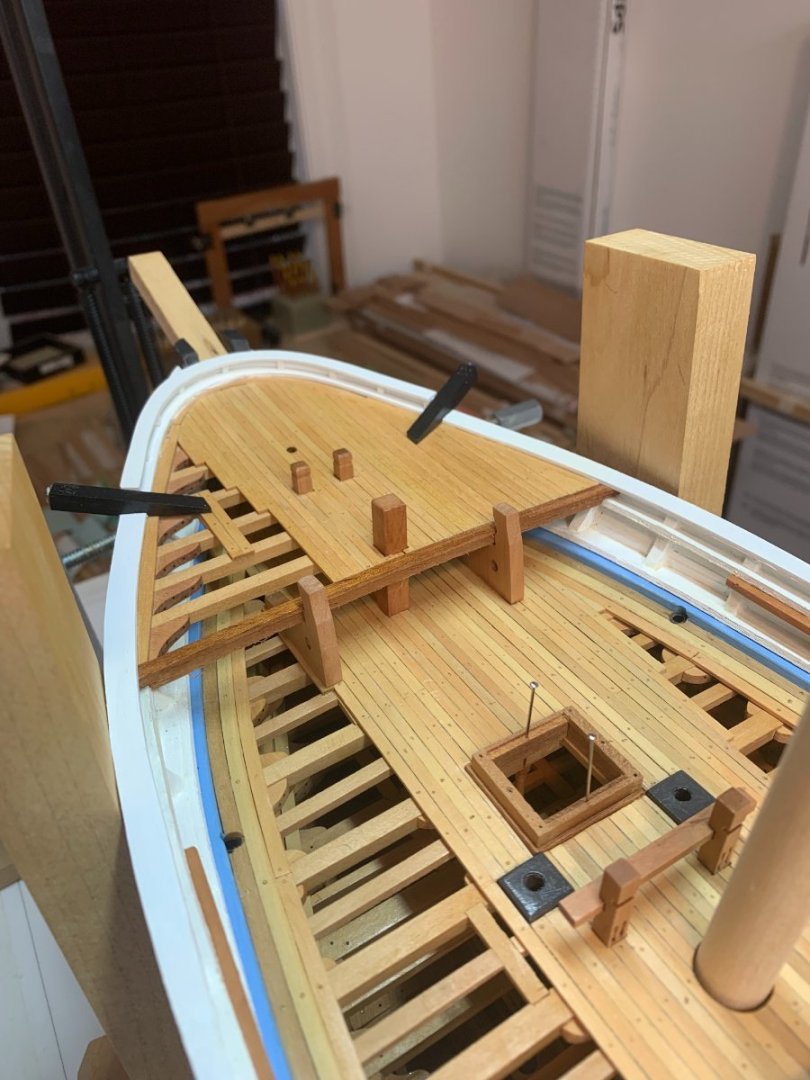

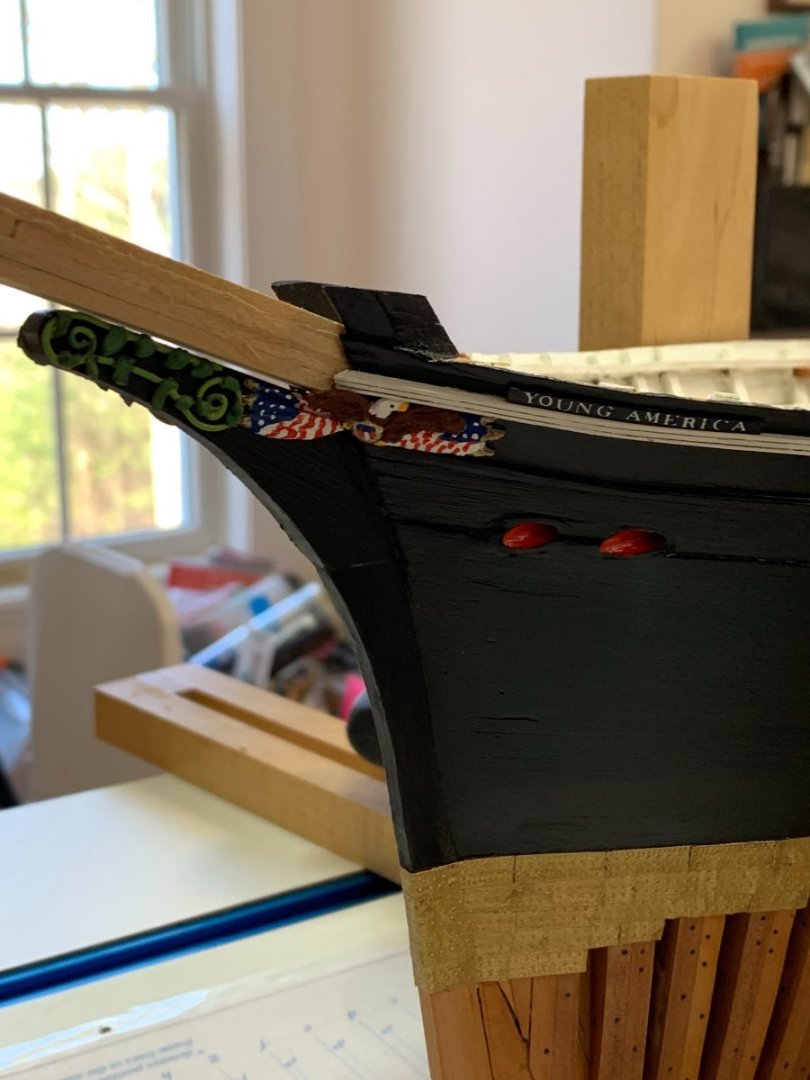

Hi Ed, Here are some progress pictures that you requested. Sorry for the long delayIMG_2345.HEICIMG_2347.HEICIMG_2346.HEICIMG_2351.HEICIMG_2349.HEICIMG_2348.HEIC Let me know what you think, Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Just want to confirm something before I begin. Do you have a reference confirming Young America was sheathed in yellow metal and not copper. On Crowther's table on metal sheathing on era ships, Celestial (1850) and Gazelle (1851) were copper sheathed. Challenge (1851) was sheathed in yellow metal. Crowthers has no reference for either way for Comet (1851), Invincible (1851), Young America (1853) and Flyaway (1853). There is a Remark that Young America was sheathed in yellow metal in November 1879 but it us unclear if this represents a change from copper. Many other builders were using yellow metal, but I'm having difficulty identifying the sheathing material used in 1853. I have material for either approach. Do you remember how you decided which to use? Thanks again! Randy (I have not forgotten the progress pictures but things are a bit of a mess. I'm hoping to remount my hull back on the shipway soon, then I'll send some along for you)

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed- Not to get too fixated on scuppers but looking at Crowthers book, there appear to be four on each side (at the [1] break of the Forecastle; [2] between 1 & 3; [3] low point in the waist; [4] break of the poop deck. He couches this generalization by saying this 'rule' varied by ship design. Do you remember if you found a reference of the number/location of the YA scuppers or made a (very) educated guess? Remembering my hull iron banding fiasco (Admiralty vs Lloyds), I thought I'd check in again before drilling. I know Mystic has a virtual warehouse of models and not all are on display. I trust your YA is viewable by the public-it might be worth the trip. I will definitely share some pix with you. You've been very generous with your time. Let me finish off a couple things before taking some progress photos. It is starting to look like a ship. Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Happy New Year! I am getting close to adding the scuppers. Page 186 mentions the scupper locations are on drawing 1 but I can't seem to find them. Am I missing something? Thanks in advance and hope all is well, Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Thought I'd share something that has been working for me. To prevent debris and parts (and their retrieval), I made two deck-shaped drop clothes (out of a rag) and cut a slit up the middle (to allow placement of the pillars). It not only has saved me from having to fish fallen timbers from the hold, but the surface is easily vacuumed. Deck cover.HEIC

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Replacement motor for Preac saw

Randy Todd replied to Kevin Kenny's topic in Modeling tools and Workshop Equipment

I am having troubles getting to Ship Ahoy's website to get the Pre-ac motor replacement: I get an Asian, unsecure website instead. I have typed http://shipahoymodels.com. Do I have the wrong information? -

Grant (or Ed) I also purchased the Proxxon MicroMill Mf70 37110. I got both because they seemed to have a small footprint (I have little space), looked simple and adequate to complete the YA project. Should I try to return these? If so, what would you recommend I purchase? Thanks in advance for your help/advice, Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Grant- Any ideas how I can set up my lathe to make these turned pillars? I have no experience here. I need some guidance. Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, I am trying to get things set up to fabricate by turned pillars. I just purchased a Proxxon DB250 wood lathe and am very new to this equipment so please have patience with my questions. [1] In figure 9-48, you show a 5/32" diameter brass tube in the tailstock. This is to prevent splitting the wood. However, the tailstock to my lathe comes to a point. I do not believe Proxxon has a similar set up as you show. Is there an alternative way to protect the wood? [2] Is that a clamp on your tool rest that is holding your bit (Figs 9-48 and 53)? My lathe has a simple rest, but no clamp. Do you have any suggestions? [3] What is your bit made out of (Fig 9-50)? These are my questions for now. I'm sure there will be more. Hopefully, I'm being clear. Randy

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Finished the Lower Deck. I learned a lot but am glad my mistakes will be largely buried from view. Middle deck should be better. I ordered my lathe for the pillars- should be an adventure. Your book and log complement each other well and have been a big help so far. Happy New Year, Randy Todd YA2.HEIC Todd YA1.HEIC

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.