-

Posts

2,213 -

Joined

-

Last visited

Profile Information

-

Gender

Not Telling

-

Location

Buckeye, AZ

Recent Profile Visitors

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

ccoyle reacted to a post in a topic:

Indian Girl Canoe by GuntherMT - FINISHED - Midwest Products - Scale 1:12 - SMALL

ccoyle reacted to a post in a topic:

Indian Girl Canoe by GuntherMT - FINISHED - Midwest Products - Scale 1:12 - SMALL

-

a49kid reacted to a post in a topic:

USN Picket Boat #1 by GuntherMT - Model Shipways - scale 1:24

a49kid reacted to a post in a topic:

USN Picket Boat #1 by GuntherMT - Model Shipways - scale 1:24

-

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

GuntherMT reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

GuntherMT reacted to a post in a topic:

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

-

FrankWouts reacted to a post in a topic:

Oseberg by Vivian Galad - Amati - 1:50 - modified kit

FrankWouts reacted to a post in a topic:

Oseberg by Vivian Galad - Amati - 1:50 - modified kit

-

DaveBaxt reacted to a post in a topic:

Air brushing / Spray painting small parts

DaveBaxt reacted to a post in a topic:

Air brushing / Spray painting small parts

-

Obormotov reacted to a post in a topic:

Chuck's planking videos...

Obormotov reacted to a post in a topic:

Chuck's planking videos...

-

Saburo reacted to a post in a topic:

HMS Naiad 1797 by albert - FINISHED - 1/48

Saburo reacted to a post in a topic:

HMS Naiad 1797 by albert - FINISHED - 1/48

-

Obormotov reacted to a post in a topic:

Help for the Noobies

Obormotov reacted to a post in a topic:

Help for the Noobies

-

Obormotov reacted to a post in a topic:

Help for the Noobies

Obormotov reacted to a post in a topic:

Help for the Noobies

-

GuntherMT started following USS Constitution by TomCulb - FINISHED - Model Shipways - 1:76.8 - cross-section , Grecian 1812 by James H - FINISHED - Vanguard Models - 1:64 - protype build of US Baltimore Clipper Privateer Schooner and Lowell Grand Banks Dory by MisterSteele - FINISHED - Model Shipways - 1:24

-

Congratulations Glenn. Very nicely done, and quite rapidly as well!

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Buying that exact same kit direct from Maris Stella is currently priced at $376 USD. Obviously you will pay shipping on top of that. I have no idea why Model Expo is marking it up so much. Even with their frequent 40-50% off sales you might still be better off buying directly from Croatia for this kit. The Maris Stella build logs that I've seen show some really good quality parts and excellent wood, so they should be priced higher than an equivalent sized Model Shipways kit IMO.

-

Congratulations and nicely done Gary. A fine looking ship to display anywhere!

- 162 replies

-

- america

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Joshua Slocum's Spray by HIPEXEC

GuntherMT replied to HIPEXEC's topic in - Build logs for subjects built 1901 - Present Day

Nice work Rich, and agreed the presentation with the drawing is cool. -

Ships vs Boats

GuntherMT replied to Mike from Aus's topic in How to use the MSW forum - **NO MODELING CONTENT**

-

2021 NRG CONFERENCE

GuntherMT replied to kurtvd19's topic in NAUTICAL RESEARCH GUILD - News & Information

An email was sent out to NRG members earlier today, not sure it's not posted here... 2021 CONFERENCE CANCELLED The Board has made the difficult decision to cancel the 2021 Conference. Many of our previous attendees are senior citizens or have high risk factors for contracting COVID-19. Therefore, the Board has concluded that many members will still be reluctant to travel to attend the event this Fall. We have been in contact with the Channel Islands Maritime Museum and are hopeful that we will be able to hold the 2022 Conference there. Our Annual Meeting will be a virtual event later in the year. Details will be announced in the Secretary’s News Letter when the date is determined. -

Looks like you got those pieces in there quite nicely. For applying heat to a large or difficult to get to part in the future, give Chuck's method a try and use a cheap blow-dryer (or heat gun) and just blow hot air over the entire piece!

- 162 replies

-

- Model Shipways

- Constitution

-

(and 2 more)

Tagged with:

-

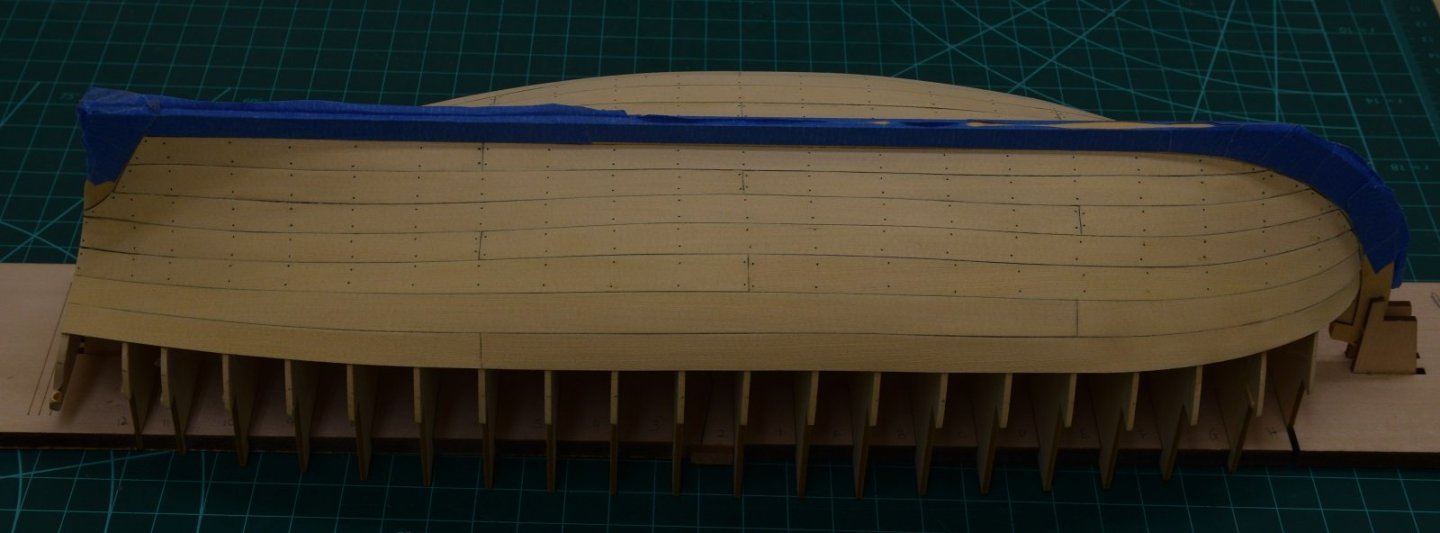

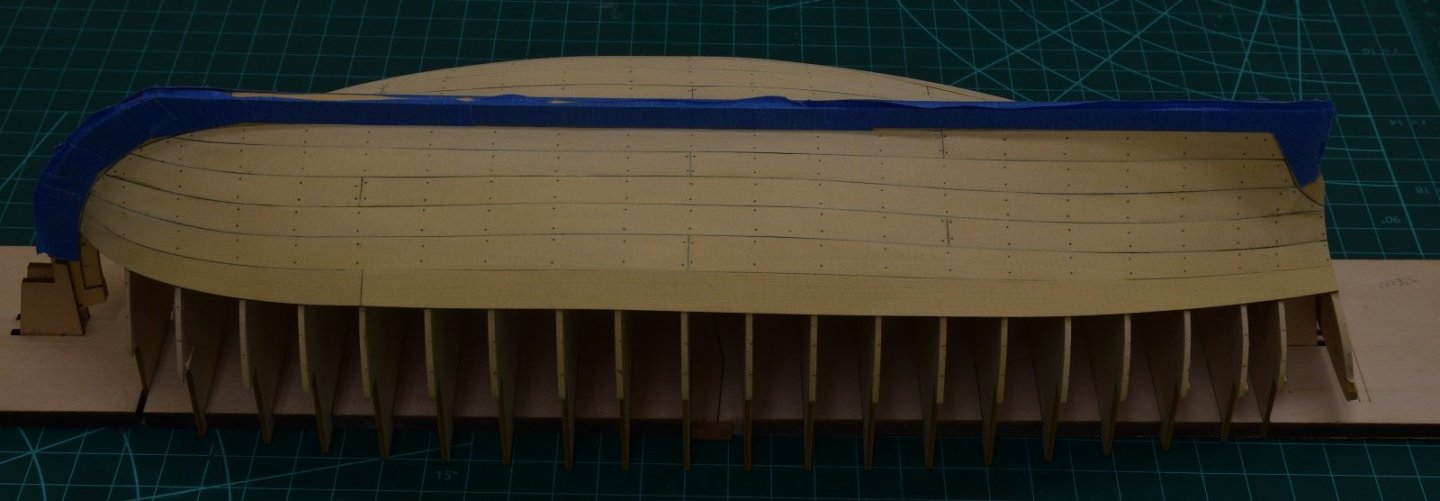

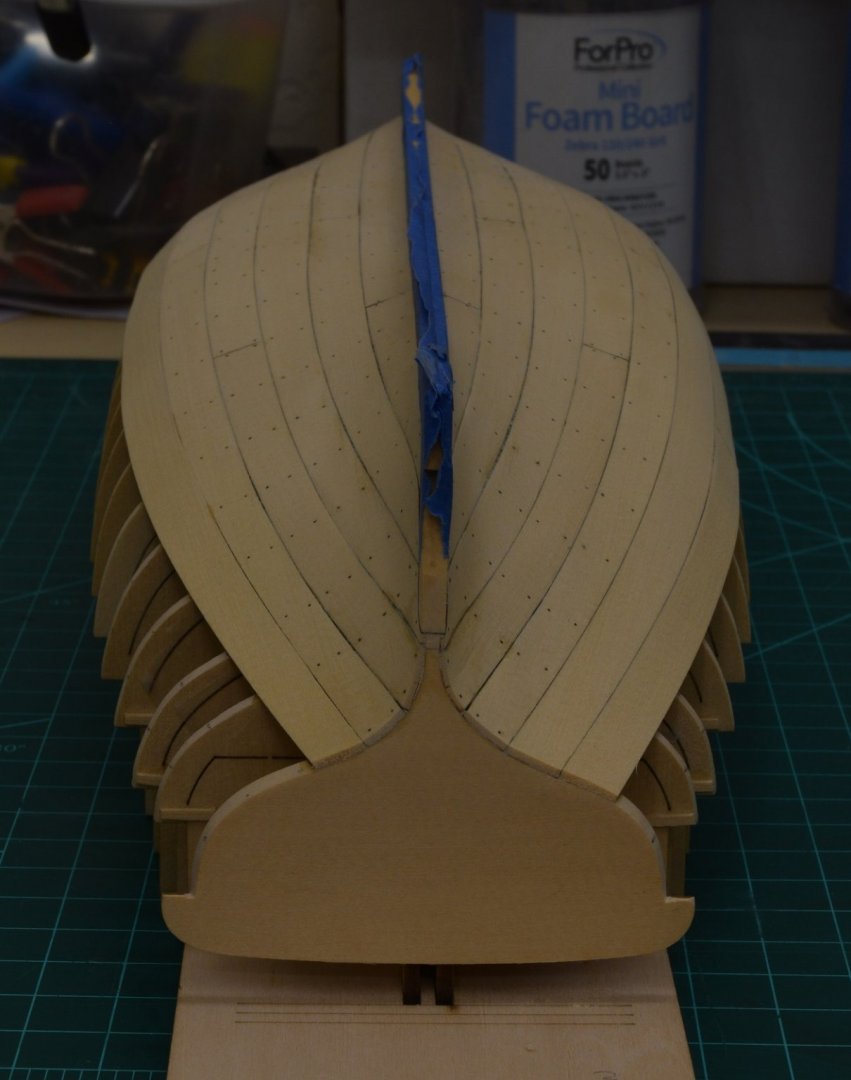

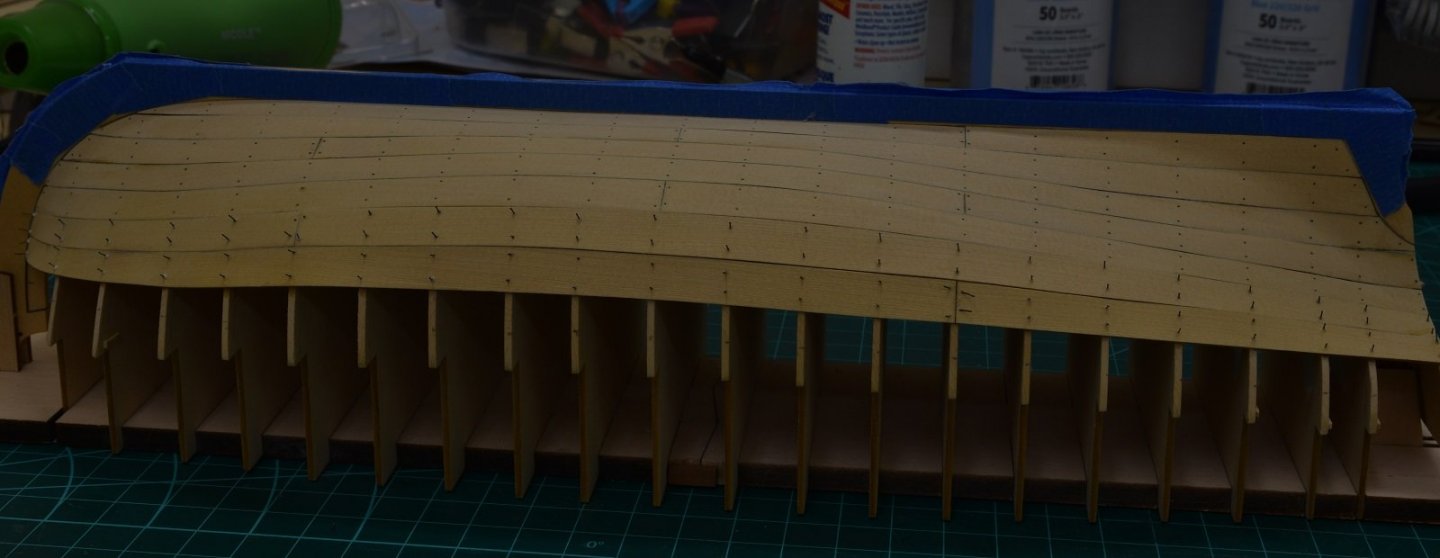

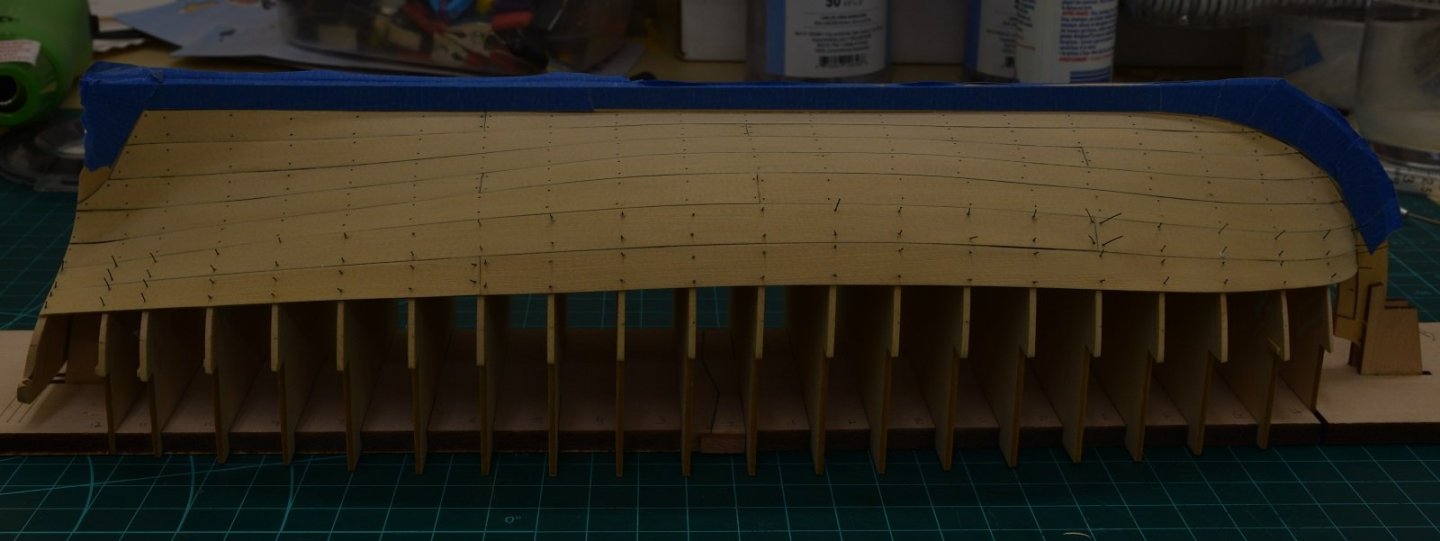

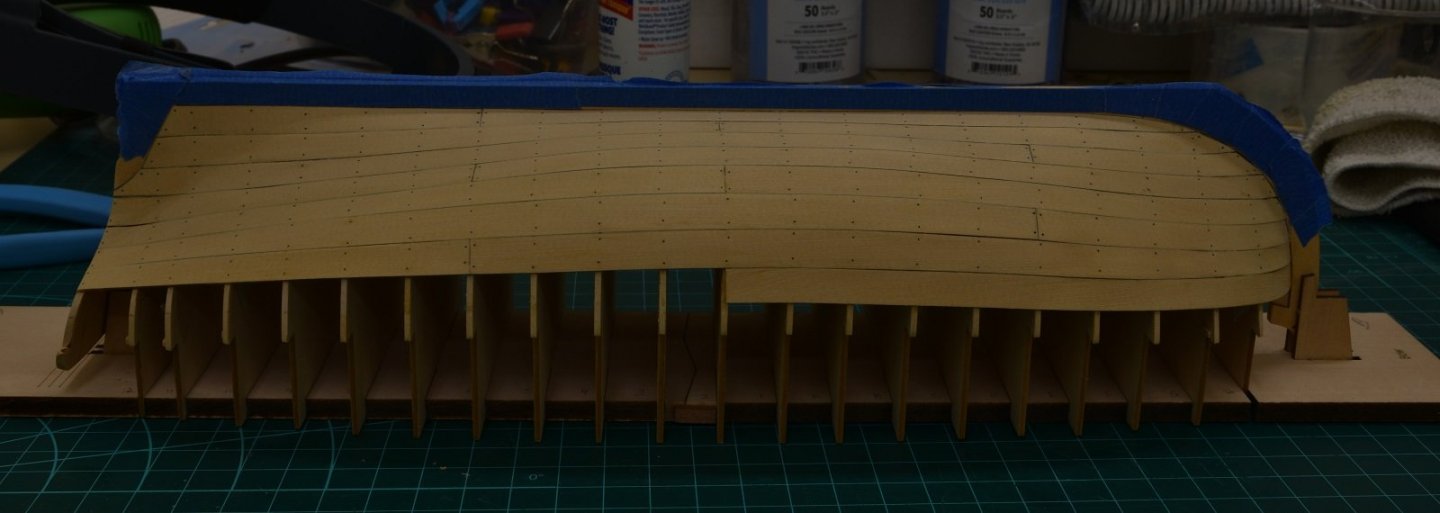

I haven't spent much time in the shop lately as I just got back from being out of the country for a fair amount of time, but before I left I did make some more planking progress which never got posted, because it never got transferred off my camera! Pictures speak better than words, so have some pictures. It's missing that aft plank because I'm an idiot and kept working too late when I was tired. I got it to fit perfectly dry, then started gluing it down and got about half-way back when I realized that I had flipped it and had glued the aft end of the plank midships... I tried to get it off quickly enough but I screwed it up and that plank will need to be remade. I'm honestly not very happy with my planking on this. I think I was using too much force getting the planks into position instead of spending more time pre-bending them, and in the process because the frames are so flimsy, I think I forced some of them out of alignment as there are some dips and rises in the planking that I don't think are fixable, but we shall see when I get some more time to get back into this build.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.