-

Posts

45 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Sundt

-

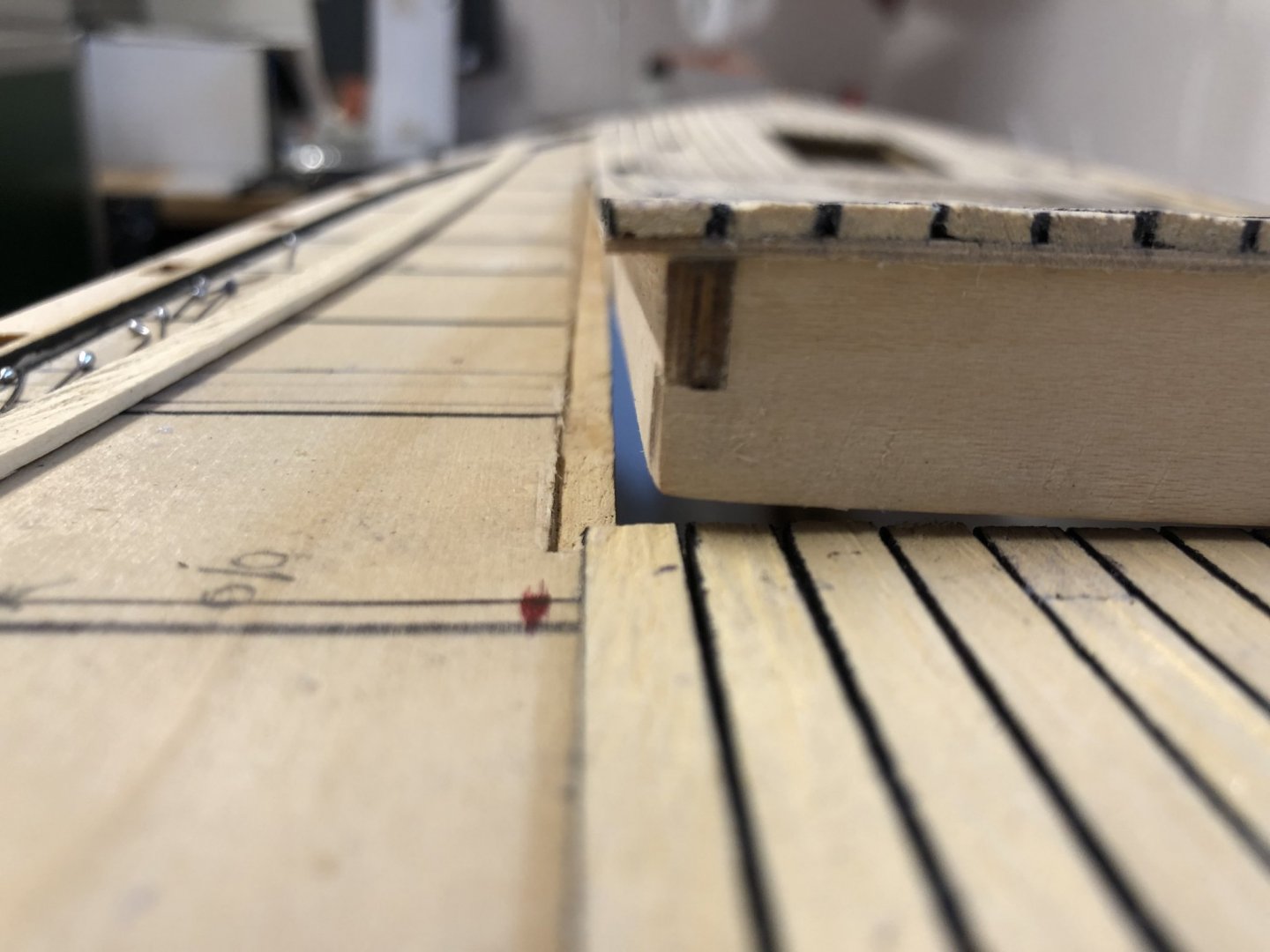

The access hatch is finished, all planks glued on middel part of boat. I adjusted the hatch plywood to match the planks glued on, see pictures with pencil pointing on cap. I will try to add some rubber later for waterproofing? Only 8,33 planks both side of hatch left 😉

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

Ship ahoy. I glued the center plank first, need more research on the web, watching pictures and youtube. To get a idea of the layout. No need to be 100% My boat will have around 48 deck planking, the original colin archer have 45. Two evenings work made 5 of 48. I hope the idea of permanent marker on the edge of wood planking looks good then finished 😉

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

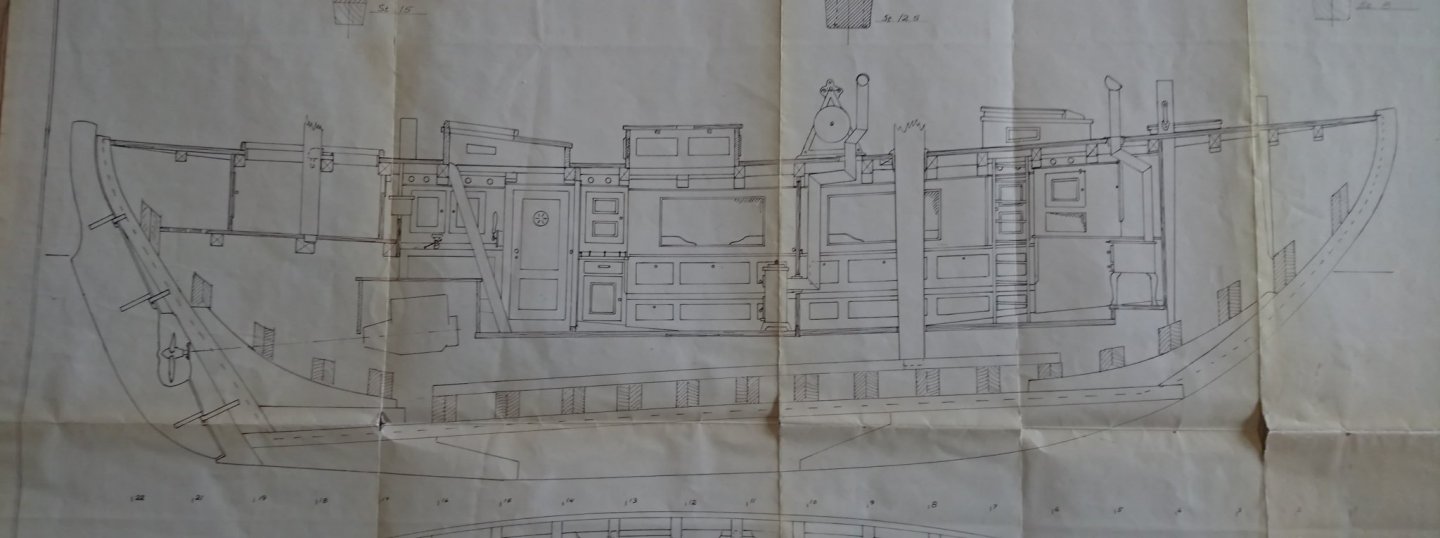

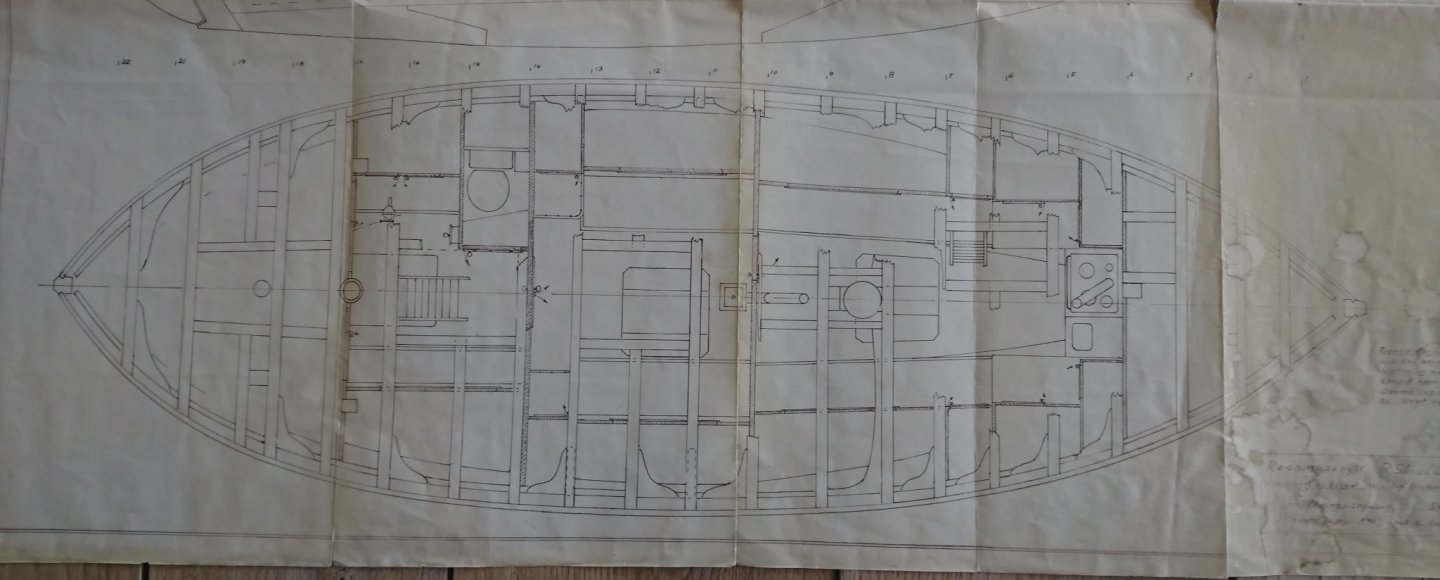

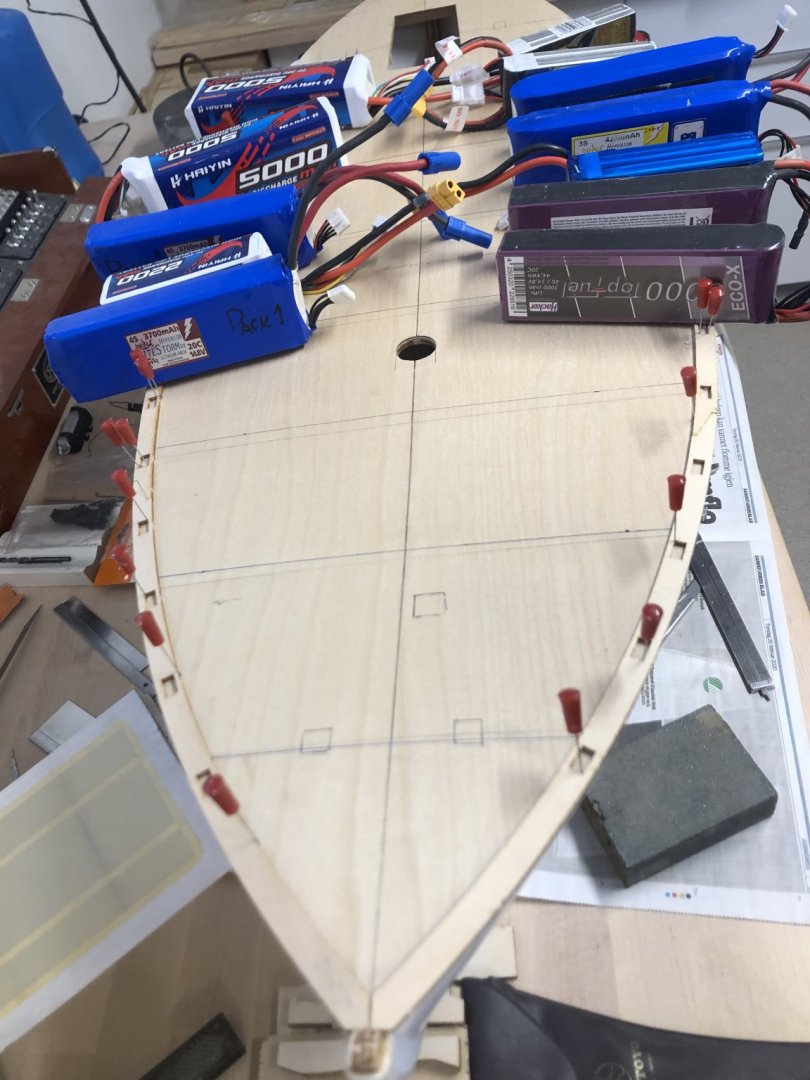

Startet with som pictures of RS1, discovered that drawing wasn't correct according to deck- beam ? new black lines with permanent marker where it must be acc to the designer drawing. New layout on planking. Permanent marker on edge of planking, to ilustrate caulking.

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

My next question is making the deck planking including 0,6mm caulking1:15(8-9mm), deck layouts is important when planking. The outer dollbord is oak i think. Have to collect som information before installing reiling? I think its nice to finish the deck including outboard Dollbord, sanded and some oak/ mahagoni stain where needed. Outboard dollbord glued on, it was a bit difficult, but after some test fit, its installed 🙂 Happy easter from Norway

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

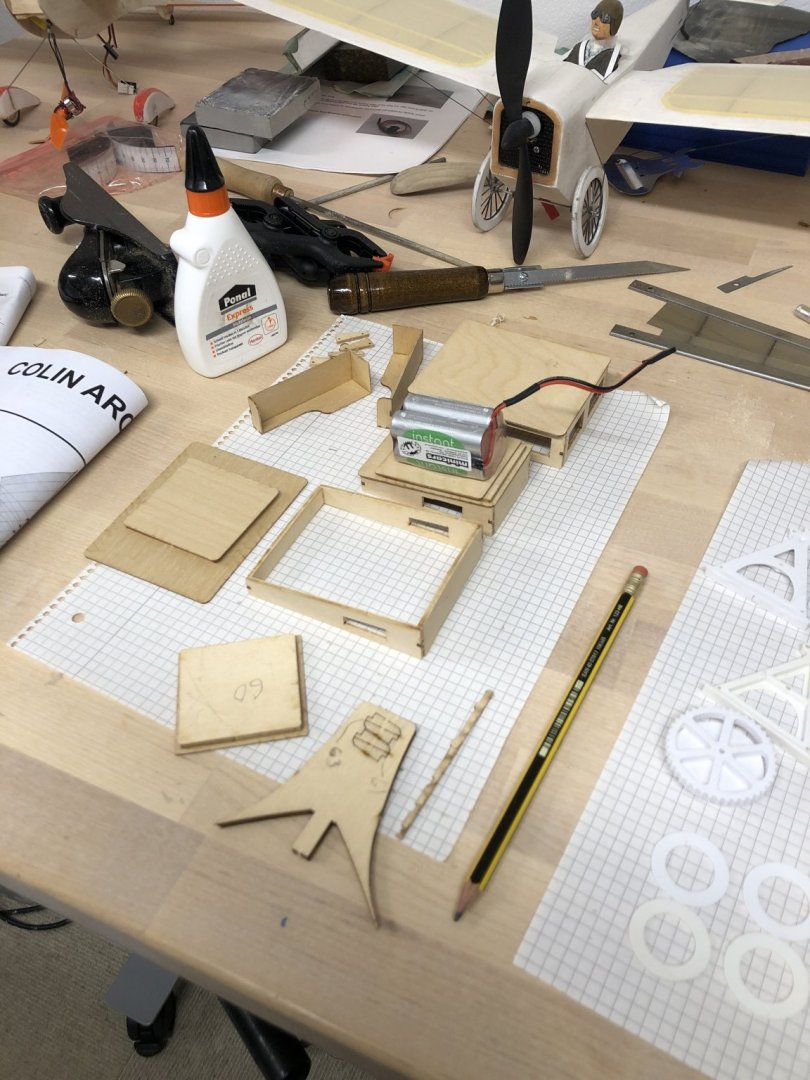

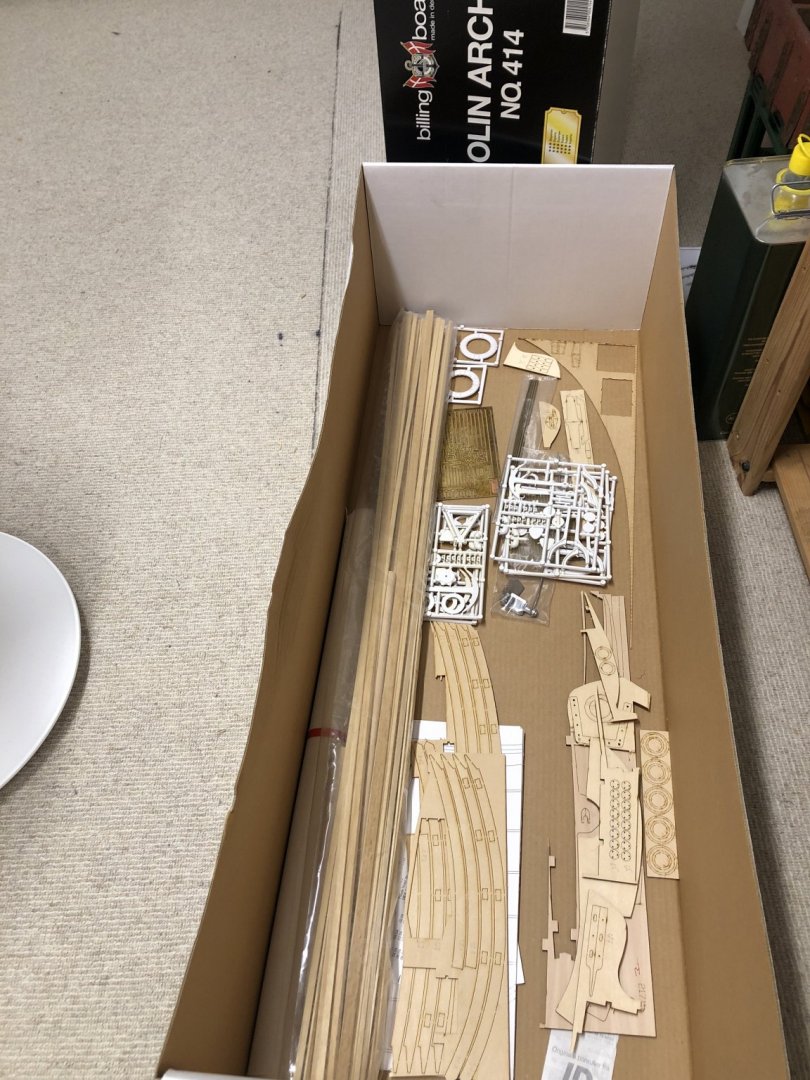

thanks, I needed some inspiration, grabbed some sticks in the box, she will be lovely 🙂 IMG_0375.HEIC Colin Archer.HEIC

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

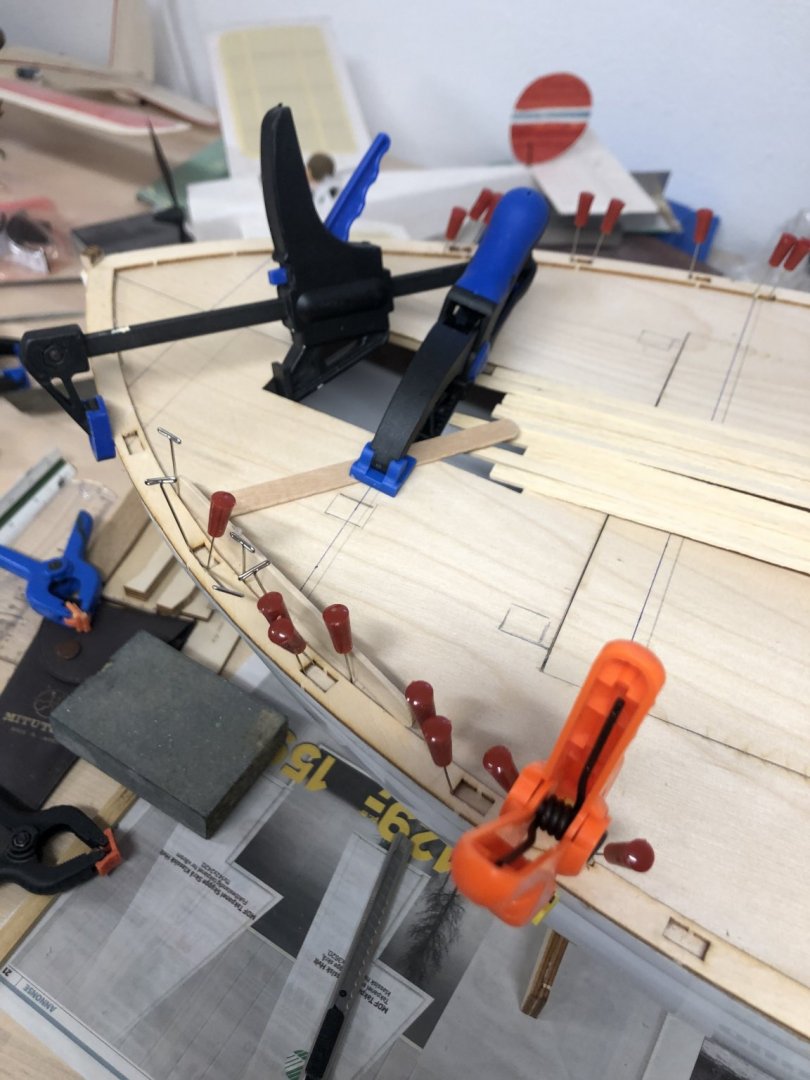

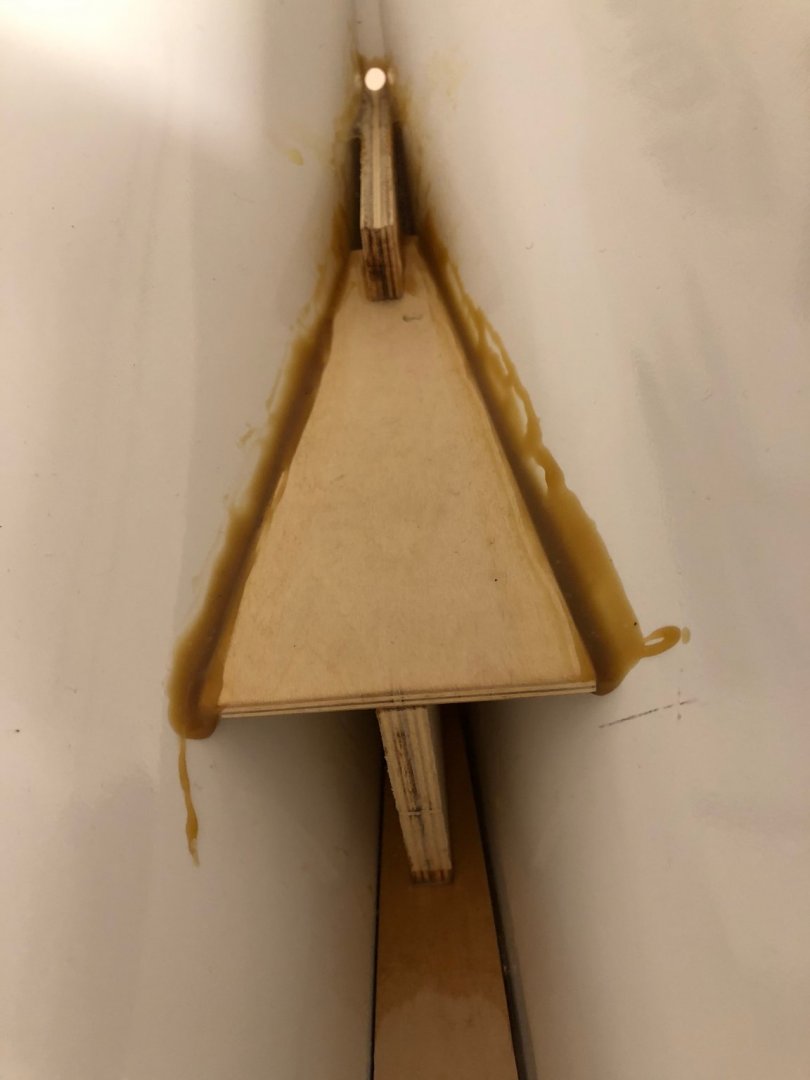

Glued some more tonight. Deck installed. Tomorrow i will see the result 🙂 Before gluing, i made a clamp and installed weights 2- times. 10 min first time, 7 min second time 😉 Then applied glue, clamp in mast hole and around opening in deck. Weights , and tape on edges around the boat

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

Stabilit express glued in a wooden stick for reinforcement. Just in case, some of the rigging rope to be attatched.

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

i see that kit on the marked 🙂 Thanks, i will post my progress, from glue, stain, photos from a real Collin Archer or changes i do, haven't find any photo or video of the rigging. I want som details, so hopefully a got som nice pictures in the end. Just ask if more information is needed , i then changes the text bellow the pictures 🙂

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

Some smal part glued. Tomorrow the hull need to be sanded so the ply-deck can be glued on. Still some part in the box😄

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

I love the smell of wood. have built some modelaeroplane from stevensaero (off topic) . the bottle will be opened then the hull is close to finished, or i feel it's finished 🙂 I will follow your built if it´s in here. Thanks for following !

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

Plastic hull, i needed Stabilit Exspress. I wanted a RC sailing scala boat from Norway 🙂 More gluing with white glue "ponal exspress"

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

Upper side beam in ply was to stiff to bend. some hot water and soldering iron to make a curved beam work well. Video: how to bend wood and plywood. You can practice on som leftover from earlyer builds. Glue: Stabilit Exspress (PS hull to wood) IMG_9244.mov

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

A bit tricky to glue aft and front plywood to the PS hull. Strapping tape made my day. Next time i will preinstall the tape on the hull, not on the ply( glue then get dragged outboard on the hull) I do that on the bow, the stern get nicer, the tape was applied to the hull first. 🙂

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

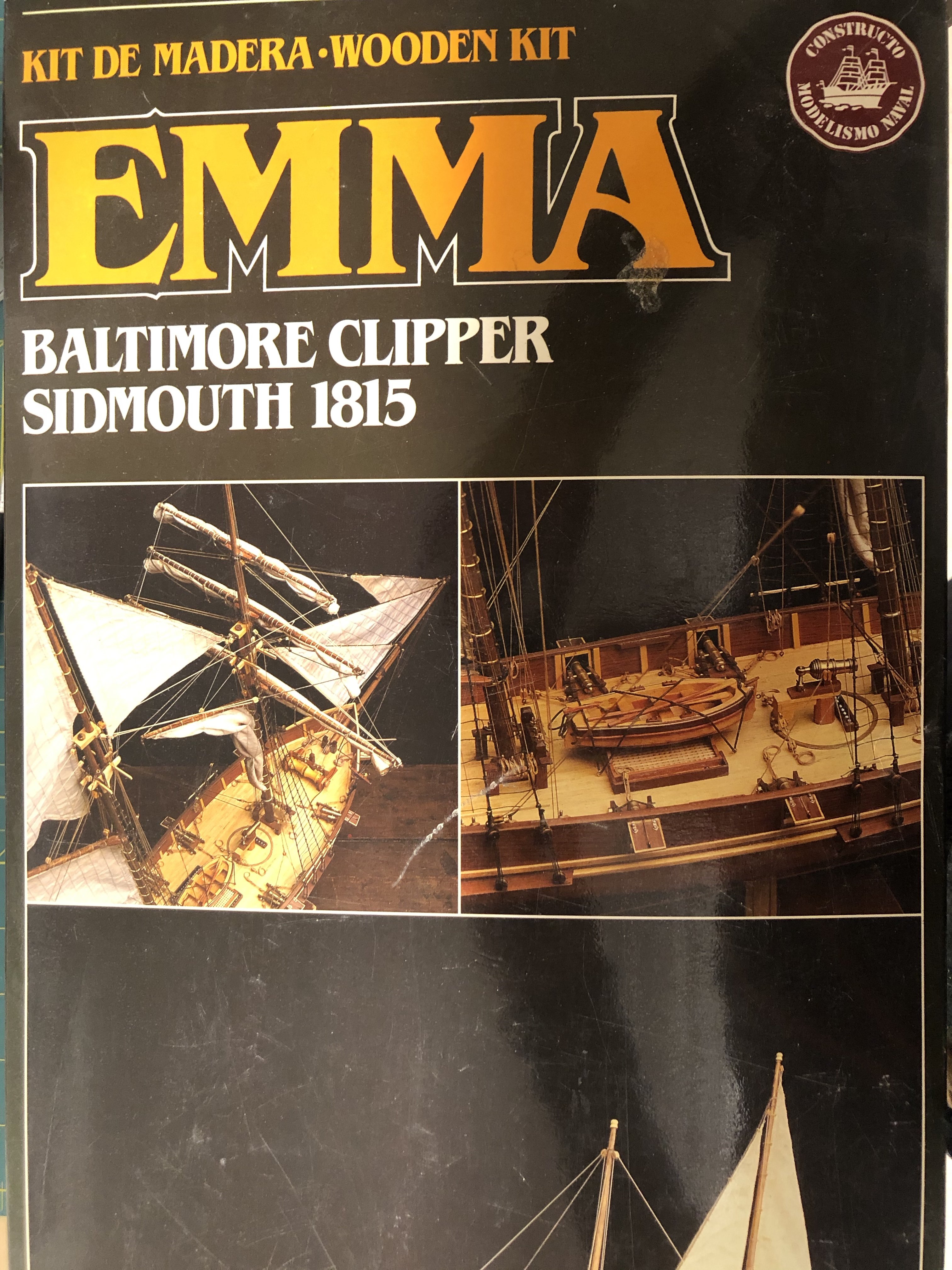

Thanks a lot, this kit hopefully prepare my skill to finish a Constructor's kit named Emma Baltimore clipper. Brgds Andreas

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

Thanks, Will be sailing. i hopefully finishing next year. 2020 hull work, 2021 rigg and remote control. In my house i start planing for storing fully rigged and easy access to bring the boat to the water 🙂 Cross my fingers. Then doing som house rehab, the time is 3 times my planned. Have made some internet search for the kit. haven't found to much, so now i will bring it on the net 🙂 brgds Andreas

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

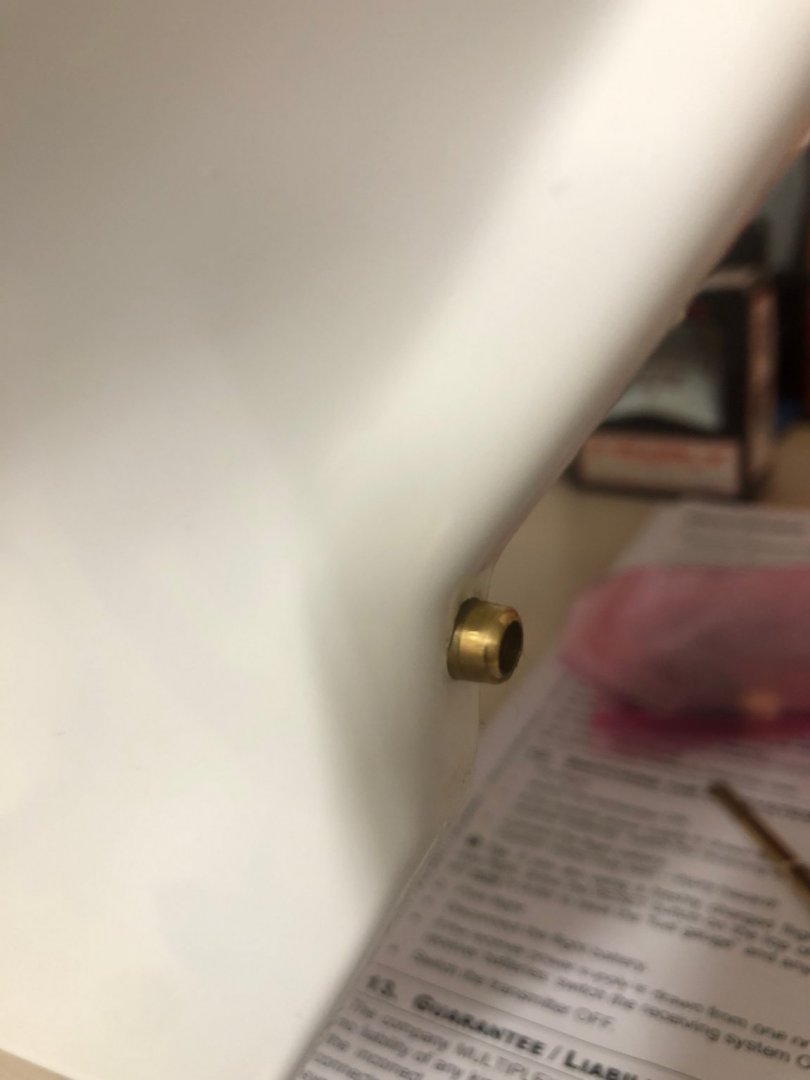

Brass tube with fittings to be installed. The boat will be used in saltwater. fitting is to be inserted in the tube with some pressure. Is it clever to just add some thread locker, or glue?

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

-

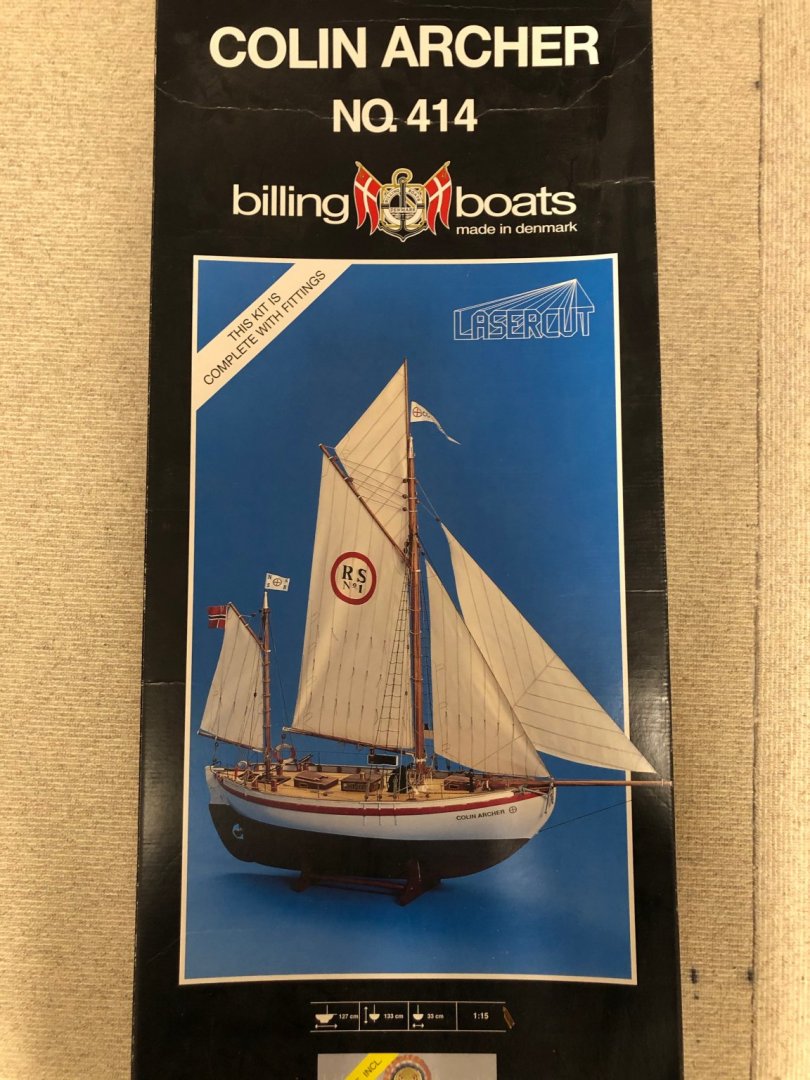

Started building a old Billing Boats kit. PS hull was told to be the last kit, they started a new production in wood some years later, available today. some tip about glue will be asked for 🙂

- 90 replies

-

- billing boats

- colin archer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.ee4d205046163acd786c8b7e92026d43.jpeg)