-

Posts

176 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Loomis, CA, USA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Sail feedback request, Mondfeld method

travis replied to travis's topic in Masting, rigging and sails

Anyone have a recommended US vendor (besides SIG if their product is possibly not durable enough)? -

Sail feedback request, Mondfeld method

travis replied to travis's topic in Masting, rigging and sails

@Y.T. I was wondering about the durability. I wonder if it can be layered/laminated for strength? That batiste fabric sounds interesting though too. Going to look that up. -

Sail feedback request, Mondfeld method

travis replied to travis's topic in Masting, rigging and sails

Thank all, I keep reading about silkspan but hadn't gotten the initiative to give it a try yet, in part becuase it's not a available at the local hobby shop and there seems to be a lot of "fake named" products online? Just trying to find a good supplier thats in the US (darn tarrifs!) thats not overcharging or excesive shipping. I did try an interesting aproach on my first build (a schooner). On that one i used a light fabric and carefully "pulled" a single thread out where each seam would be. Still of course out of scale but a pretty cool look for a larger scale build (1:40 I think?). Can't get it to work on a tighter weave fabric though. I think i will make a try for sourcing the silkspan/modelspan first and if that doesn't work out I'll go for the penciled fabric. -

Sail feedback request, Mondfeld method

travis replied to travis's topic in Masting, rigging and sails

-

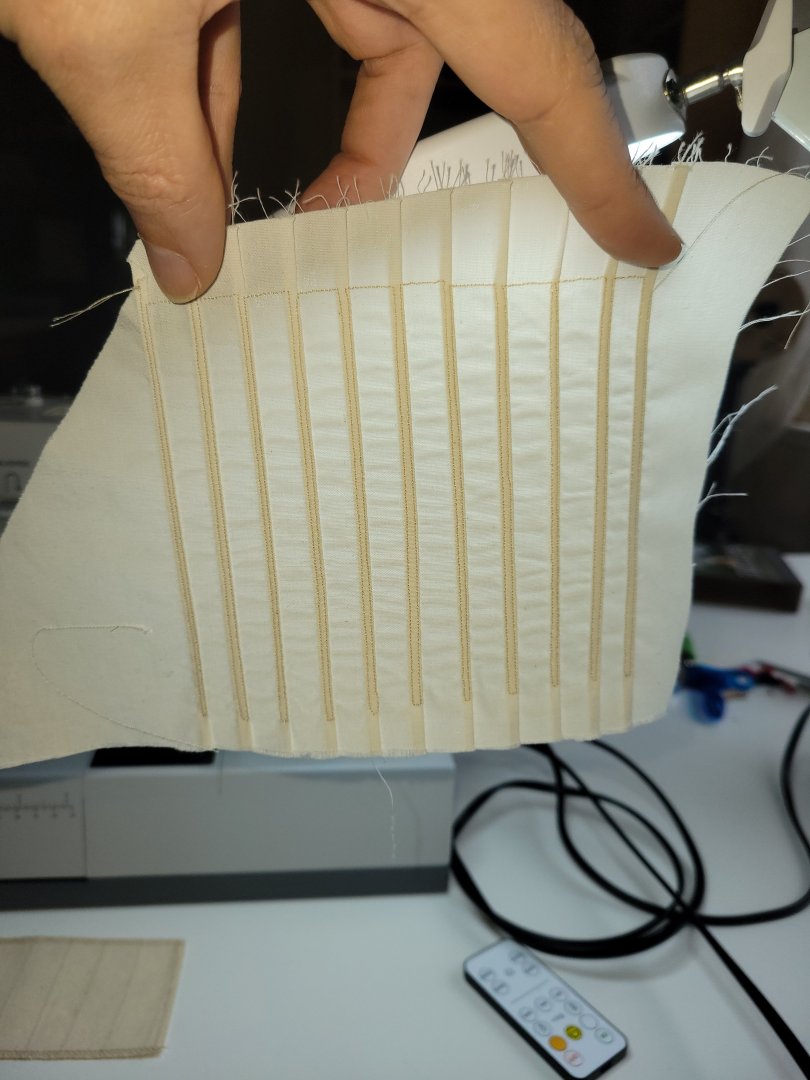

Looking for some community feedback. I'm starting sails for my third build, Occre Apostle Felipe. So approx 17th century spanish galleon from the silver fleet (mexico). Each build I've tried a different sail strategy. This time, I've used a lot of reference on this build from Wolfram Mondfeld's book, historic ship models. I noticed he has a unique sail making approach that i don't think I've seen on any posts here. His approach is press/steam a seam for each panel of the sail and then straight stich those seams. So a bit more than just using the stitch to create the panels but an actual hem. It's a lot of work. Also quite hard to steam the small seams at a consistent width and sew the seams. In my attempt, I have a 3mm overlap of fabric which results in about 12mm panels (model scale is 1:60). Interested in everyone's feedback before I commit to all the sails. This one is a spritsail. First image is the sample before hemming the edges. Second image is the sail supplied by occre which is of course to heavy a fabric. Constructive criticism acceptable!

-

LoydB reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

LoydB reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

Lind Mihály reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

Lind Mihály reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

kgstakes reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

GrandpaPhil reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

GrandpaPhil reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

DavidG reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

DavidG reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

vvvjames reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

vvvjames reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

Lind Mihály reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

Lind Mihály reacted to a post in a topic:

Apostol Felipe by travis - OcCre - 1/60

-

These are a great find! Well produced and fairly well detailed. Especially great resource for anyone new to the craft/

-

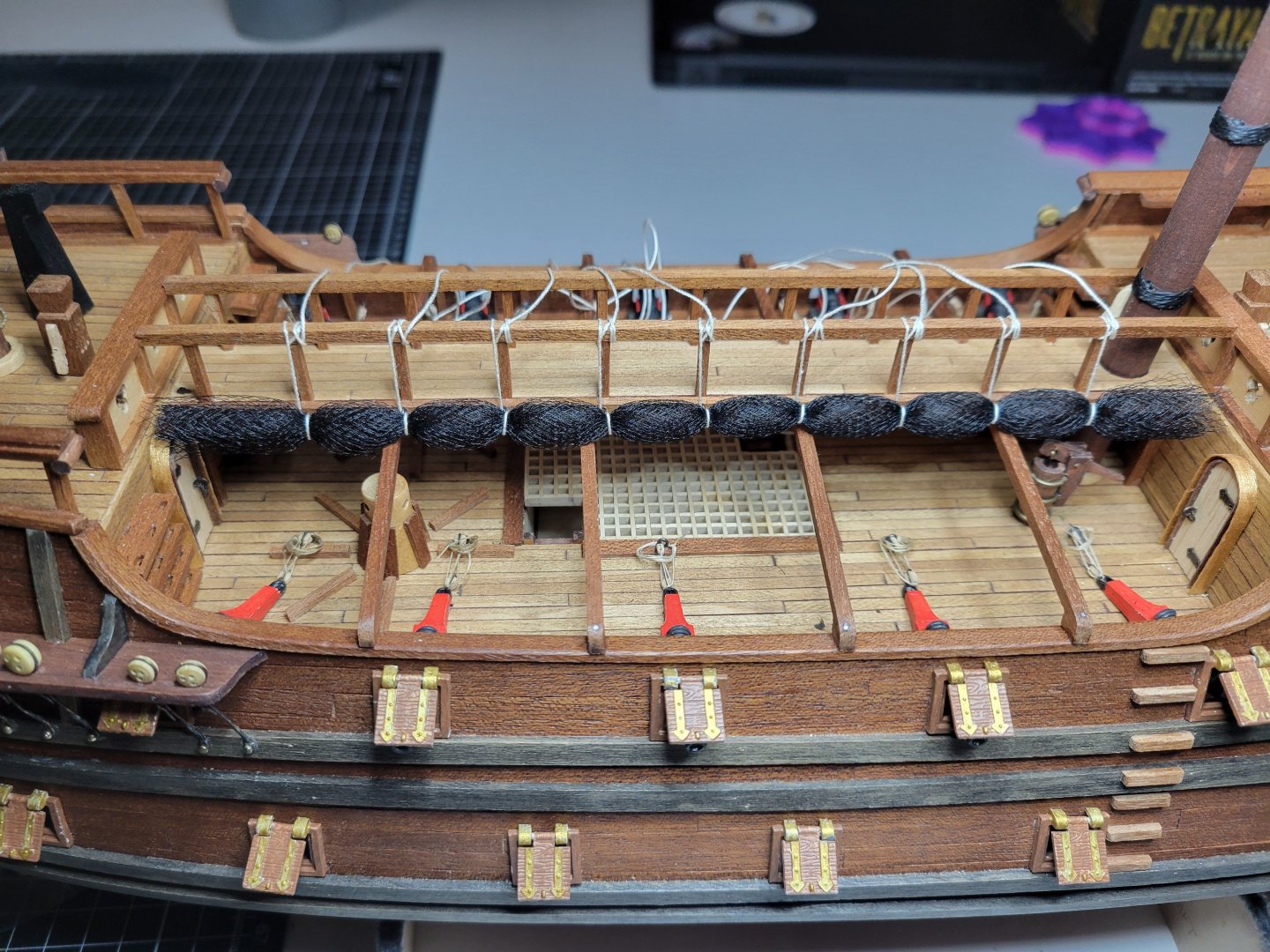

Ot much available on these nettings/grattings over the gun deck so I'm just going with what makes sense from my own time handling the lines in the navy (granted a modern destroyer is a bit different than a 17th century spanish galleon!). I figured there would be people "rolling/gathering" the netting from the gun deck and a second team on the walkway above hauling in on the lines. Once in place they would probably just lash those lines right to the rail with a good ole clove hitch and then coiled on/near the rail. The mesh netting from Occre was not properly sized (not long enough) and a bit rigid so I replaced with tule fabric which has a smaller grid which fits the scale better and just looks more natural.

-

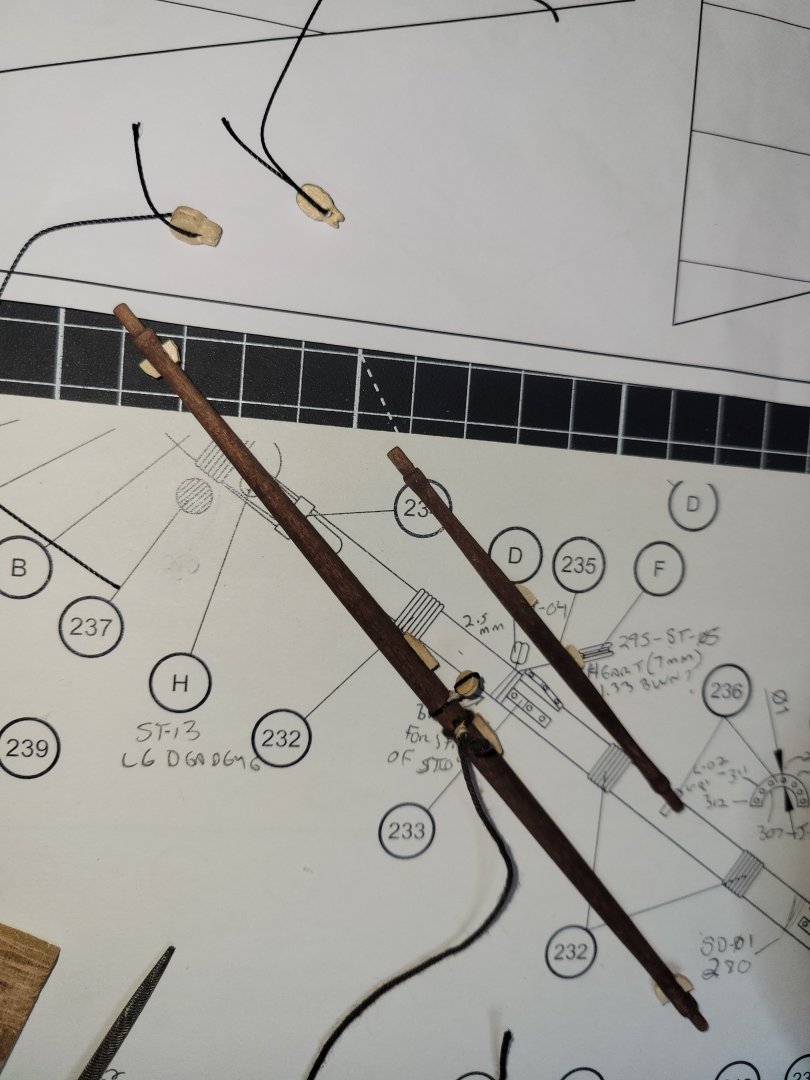

Just a note on ropemaking. I have a thread with some variation in its color. Made a small rope from it and at first figured i couldn't use it because of the variation. Realizes that this would actually perfect for any rigging lines that I want to "accentuate artistically" so that they stand out from others on purpose. For example, using it on the cathead/anchor tackle. I know thats not "accurate" but I like the look anyways so now I just need to think through anywhere else I want that done intentionally!

-

Thanks. I was worried about creating "perfect rope" but quickly realized, my simple lego machine paired with a couple practice runs and my so-so inexperienced rope is already so much better than kit rope. Certainly not at the quality and consistency of chuck's syren rope or ropes of scale (shout out to both for not only fantastic rope products bit lots of content to help the rest of us make our own!) but definately good enough for me. When I lay up the next rope I'll take more pics if anyone wants to see it in action to build their own. Next trip to a hobby shop I'll probably pick up gears and other parts to make a more permanent version.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.