Lapinas

Members-

Posts

126 -

Joined

-

Last visited

-

Scott Crouse reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

Scott Crouse reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

Lapinas reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

Lapinas reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

-

Lapinas reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

Lapinas reacted to a post in a topic:

Lady Nelson by Danstream - Amati/Victory Models - 1:64 scale

-

Knocklouder reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

Knocklouder reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Knocklouder reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

Knocklouder reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

Scott Crouse reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

Scott Crouse reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

Scott Crouse reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

Scott Crouse reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

brunnels reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

brunnels reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

brunnels reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

brunnels reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

brunnels reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

brunnels reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

JacquesCousteau reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

JacquesCousteau reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

JacquesCousteau reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

JacquesCousteau reacted to a post in a topic:

Lady Nelson by Lapinas - Amati/Victory Models - 1:64

-

I have tried using precut stairs from Amati too, but they I think also does not look according to scale 😬

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Hm this wooden pump was used in build that is advertised in their website, but I am not sure about the scale. This wooden pump is much bigger than the metal counterpart 🤔

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

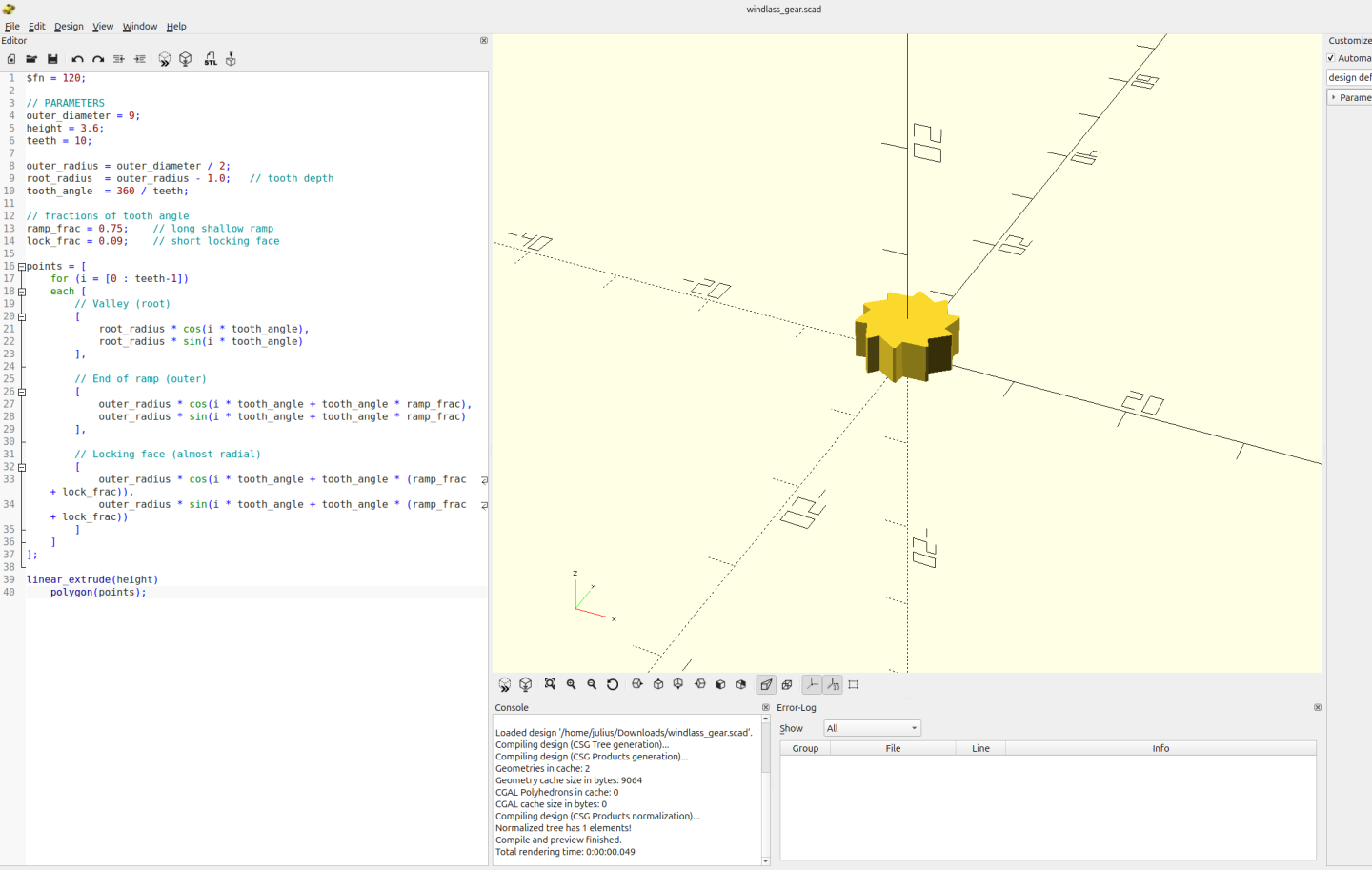

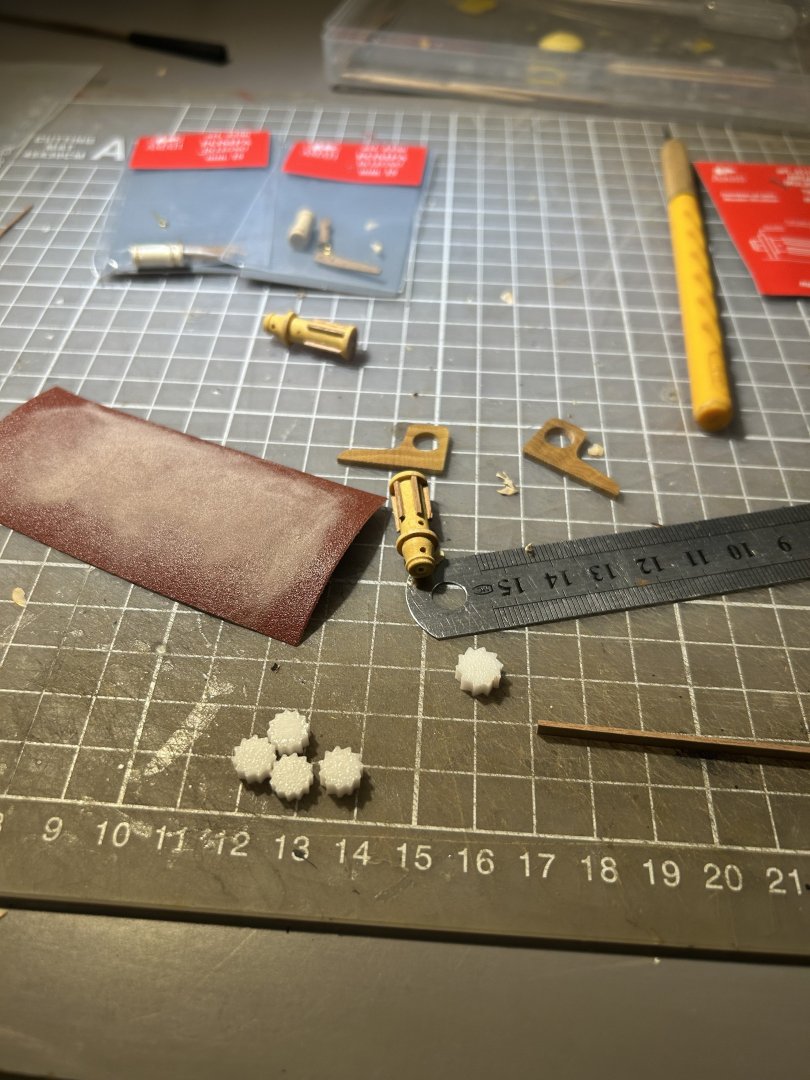

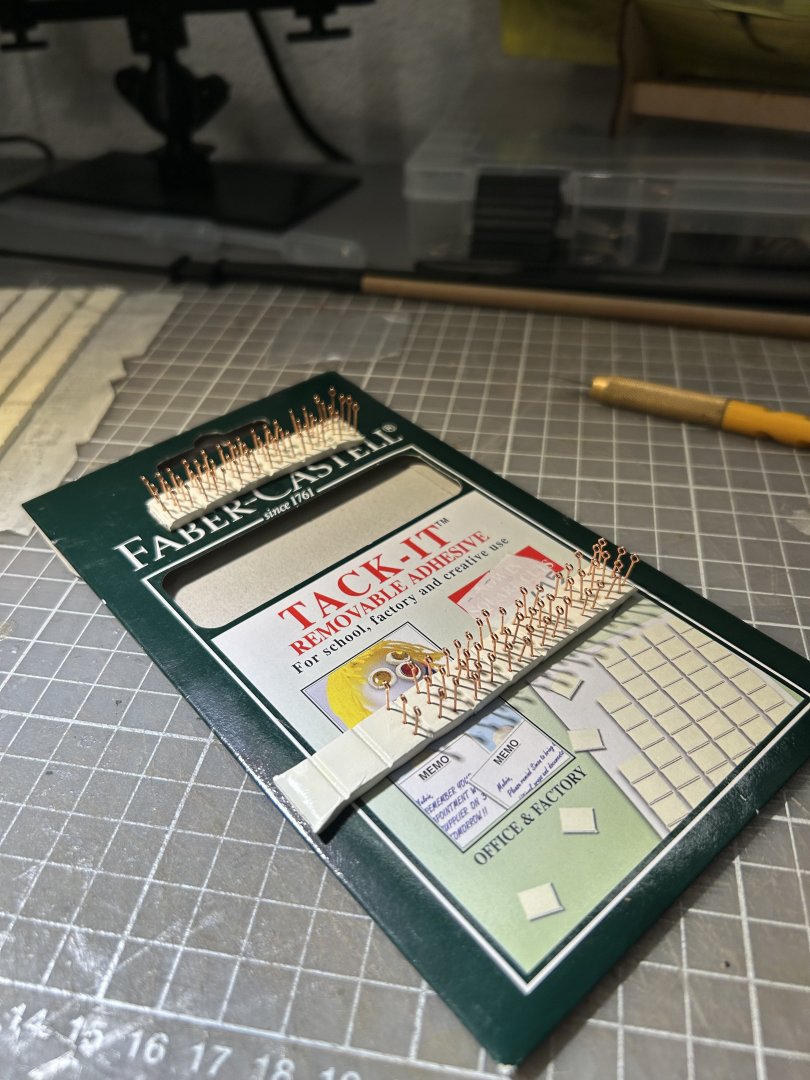

It looks like the consensus for this kit is that the windlass included - is not really suitable for this ship. I have noticed that a lot of people are repurposing this wooden windlass from amati: https://www.amatimodel.com/en/small-parts-and-accessories-for-model-making/product-wooden-windlass-type-h-mm55-b411505.html So I did that as well. Also I have noticed that the middle part of this windlass is replaced with ratchet gear. I could not find anything suitable in my stash, so I have designed one with Openscad and 3D printed it. After a few iterations I was satisfied and replaced the middle part of the windlass. Final result. You can also see that I have decided to use different kind of water pumps (https://www.amatimodel.com/en/small-parts-and-accessories-for-model-making/product-wooden-pumps-mm-15-b4356.html) instead of the metal ones that were included in the kit Windlass will be painted red together with "ratchet stopper". To help fellow modelers, I am also sharing an STL file so you can 3D print this gear at home. Additionally, I am including the SCAD code for the part in case any modifications are needed. windlass_gear.stl windlass_gear.scad

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

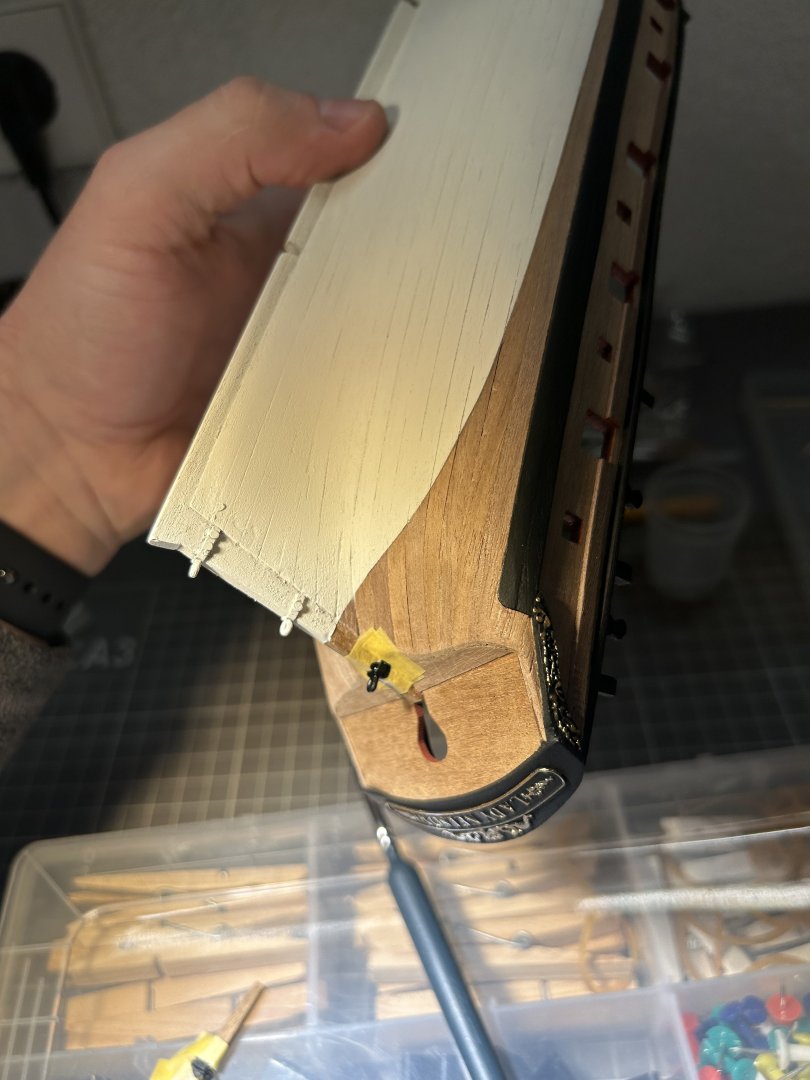

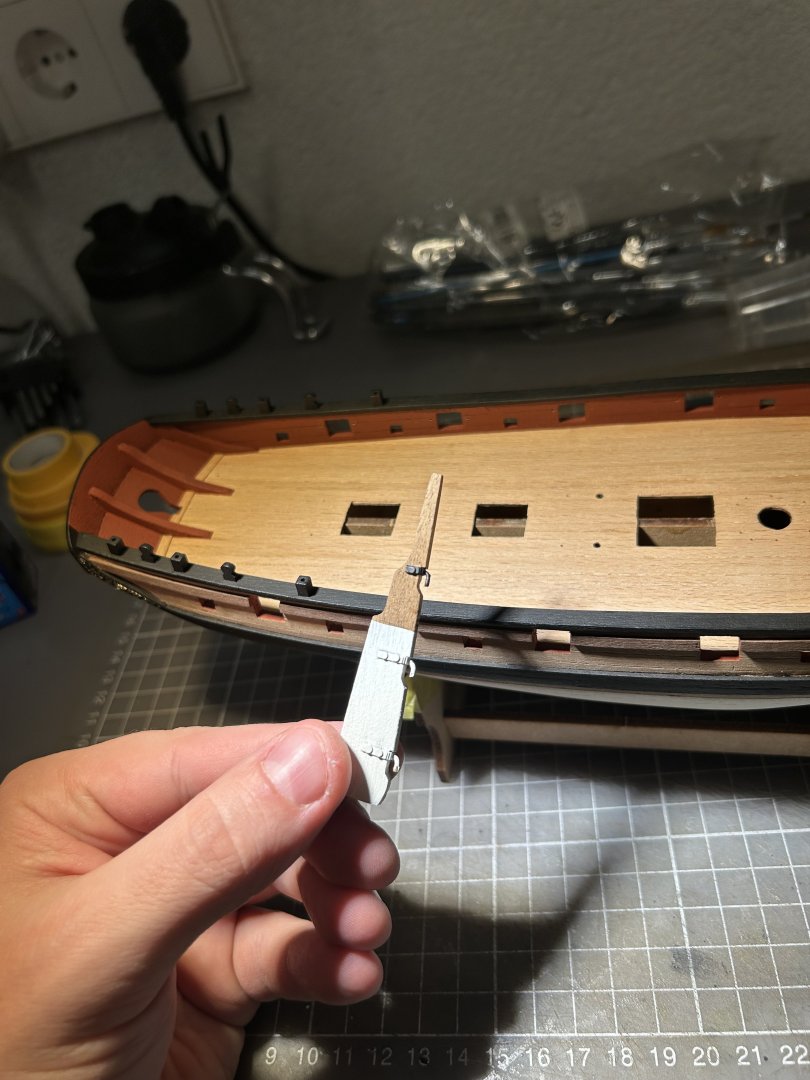

I have finished drilling all holes for eyelets. Painted brass rudder holders black. I have also made a custom rudder part based on some other build logs. Custom one looks way way better.

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

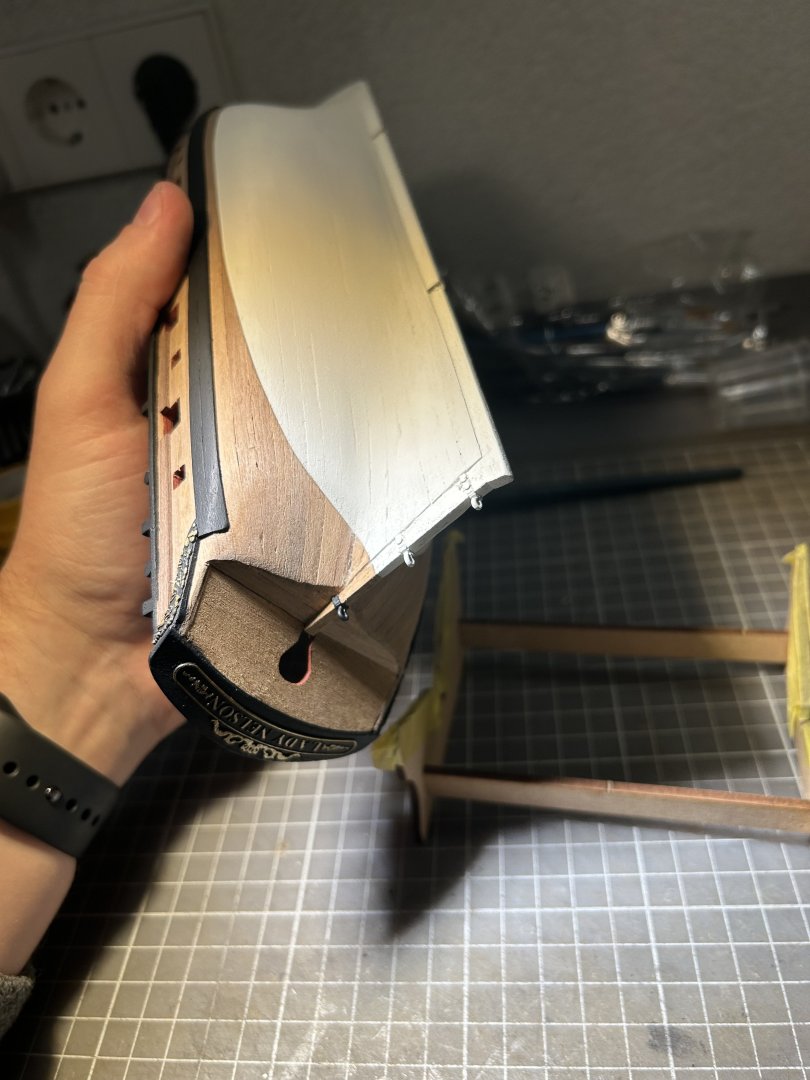

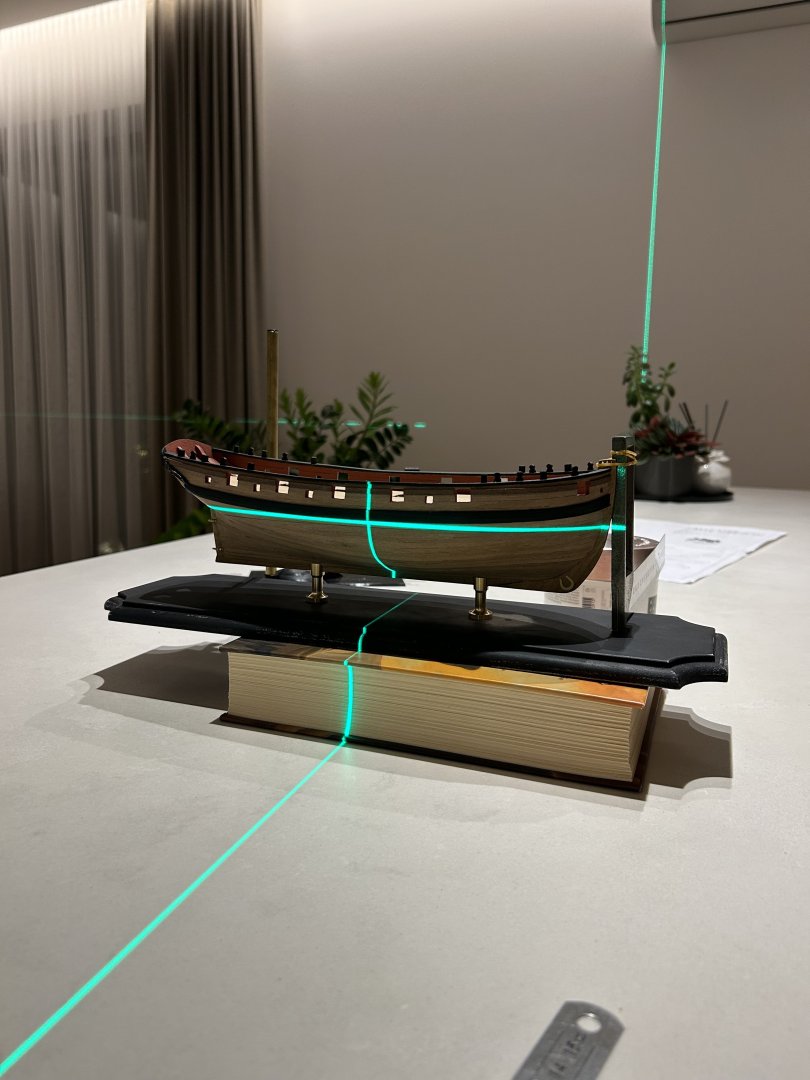

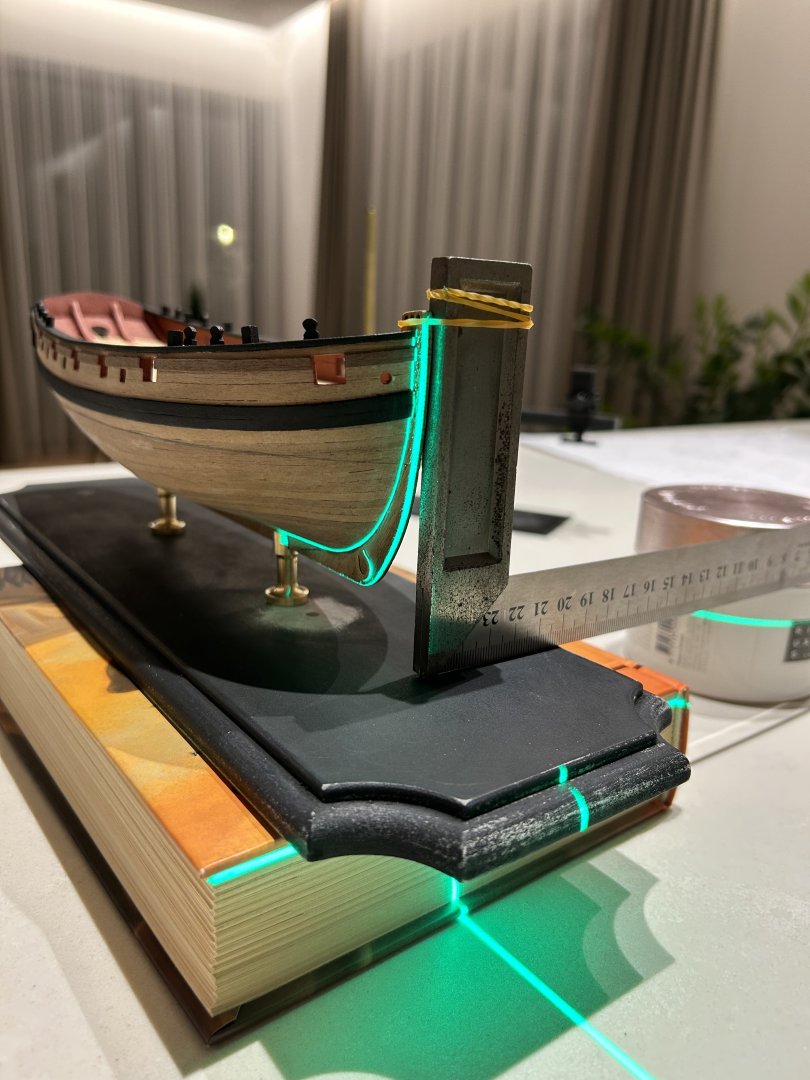

Hull was painted white. Base board was sanded and repainted in black I will eye into buying / making small drill press. It is very hard to manually drill straight holes with very high accuracy:

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

I have drilled holes for M4 screws in the keel and in the base board. I have also sanded the base board. Will paint it the second time. One reason would be to try to get a nicer finish, another reason would be because I drilled the second hole in the wrong place 😆 to fix that I have filled the hole with a wood dowel, added some wood putty.

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

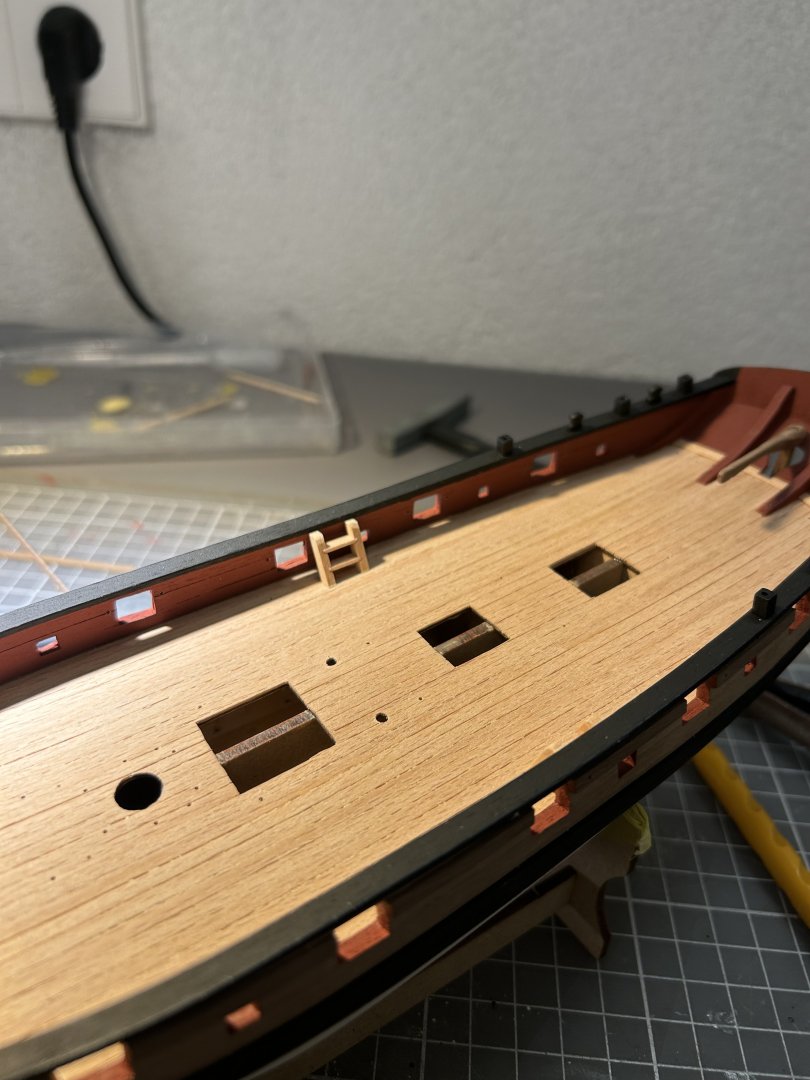

I have drilled some holes on the deck and bulwarks. Scanned plans has really helped to mark the precise location of the holes with awl. Also I have painted some buckets. I think I will be staining these later to tone it down.

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Add some horizontal planks on the deck towards the stern. It will mask nicely a slightly chopped deck planks line where it meets the vertical surface painted red.

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Had a little bit of time, so I have finished painting canon carriages. I also did some paint touch ups with brush on the ship itself to make it perfect

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

I have finally found a color that I like for painting bulwarks it is revell aqua color 37. Paint job still requires some finishing touches, but it turned out extremely well! Really happy with it.

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Still trying to decide If I want to keep it that way 😅

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

In the meantime I have airbrushed some small parts in black. Unfortunately I have some difficulties painting MDF in black. For some reason it is very hard for me to get the finish I desire with this mdf base plate. I will try sanding it and painting again, maybe will try some wood putty too. Just very hard to get even finish with it.

- 81 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.