Lapinas

Members-

Posts

94 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Lapinas

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

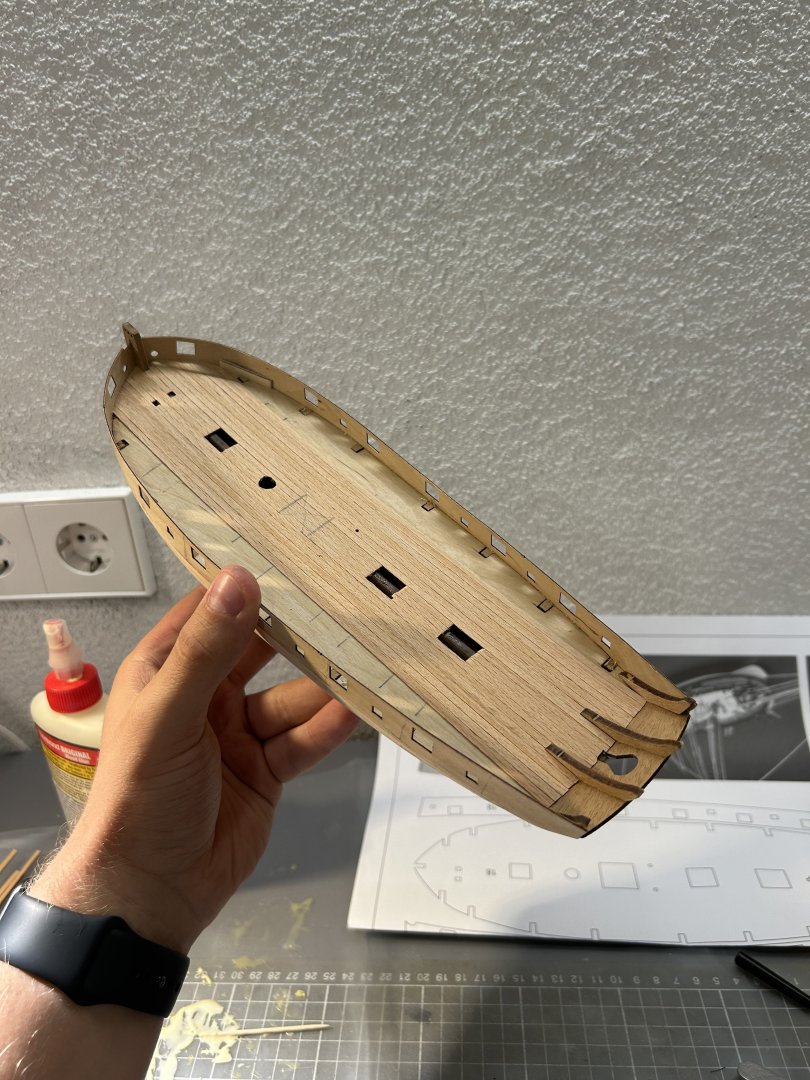

There was not enough deck planks in the kit, to cover whole deck with whole planks only. But not a big deal. I was able to reuse some left overs and do joins below the cannons

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

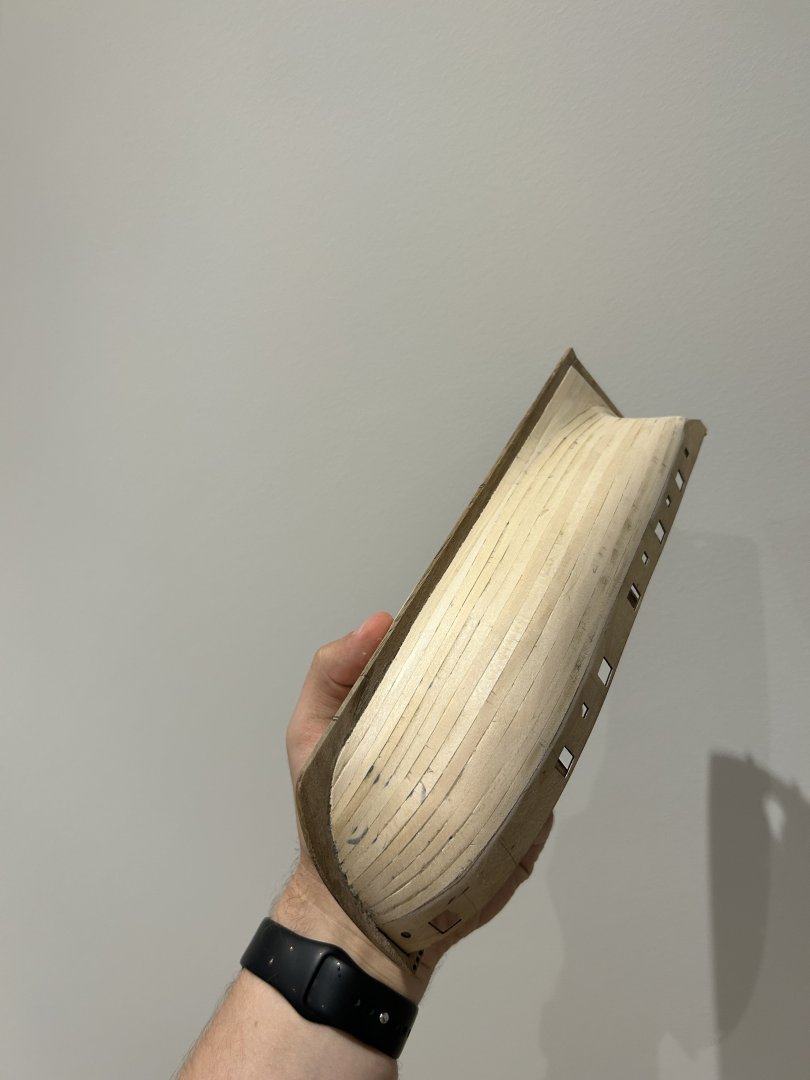

First batch of sanding I think I will do this process one or two times more and then I will be fully happy with the outcome I am not 100% sure yet, but it looks like no wood putty will be required on the hull.

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

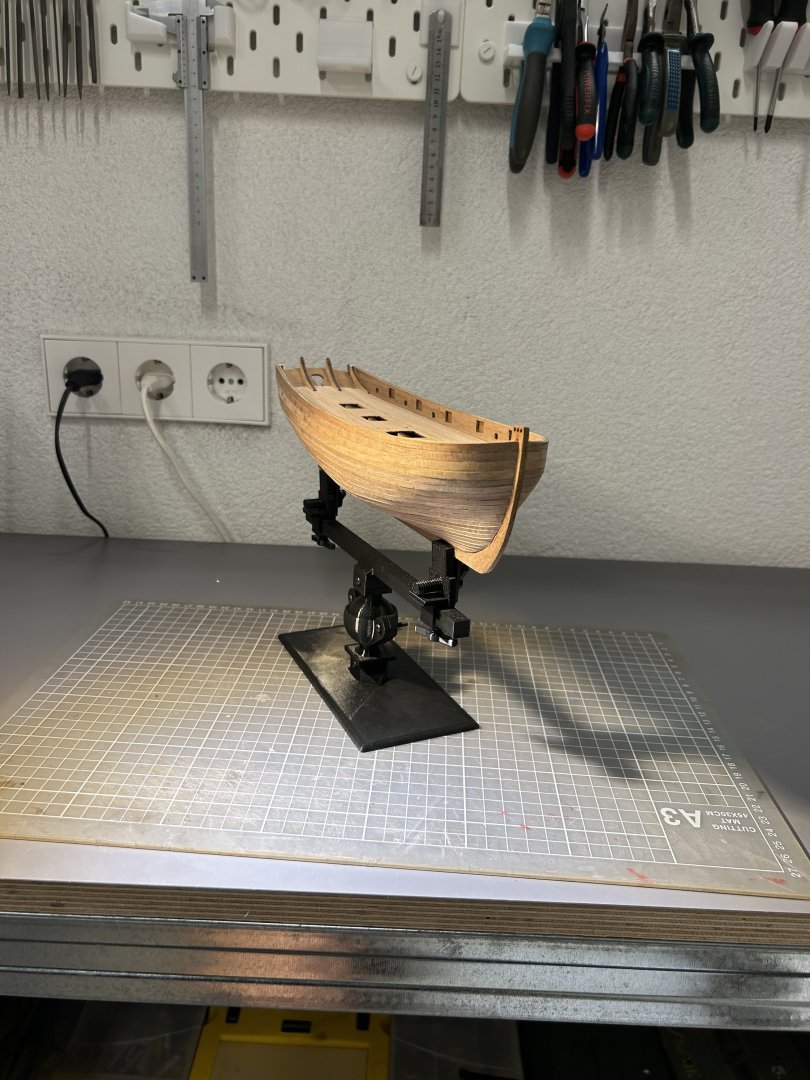

First layer of planks - done. A lot of slow and careful sanding is next. Will add some wood putty as well where it is necessary

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

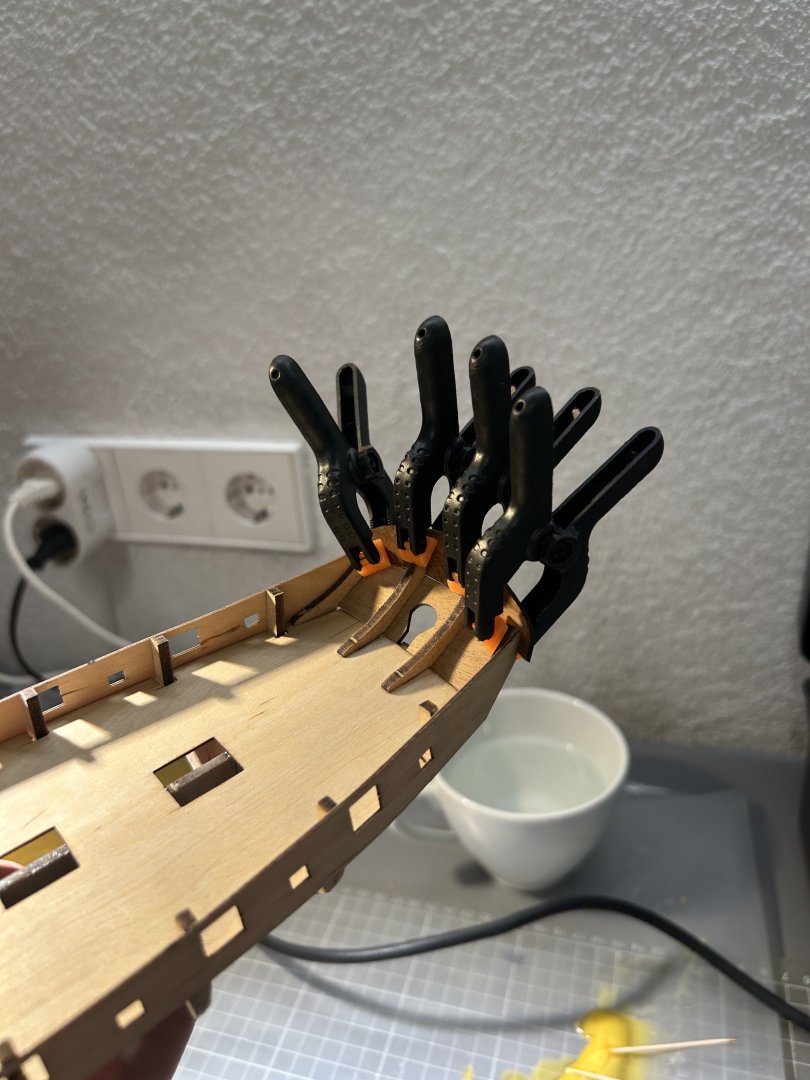

Few more! For every future builder - start using stealers earlier than I did. You will have an easier life 😆 I have realised that I need to use these a bit too late. It is good that it is just a first layer of planks, so I will not repeat the same mistake twice

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Started work on first layer of planks. I have forgotten how slow the process is 😆 4 planks - 2 hours of work.

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

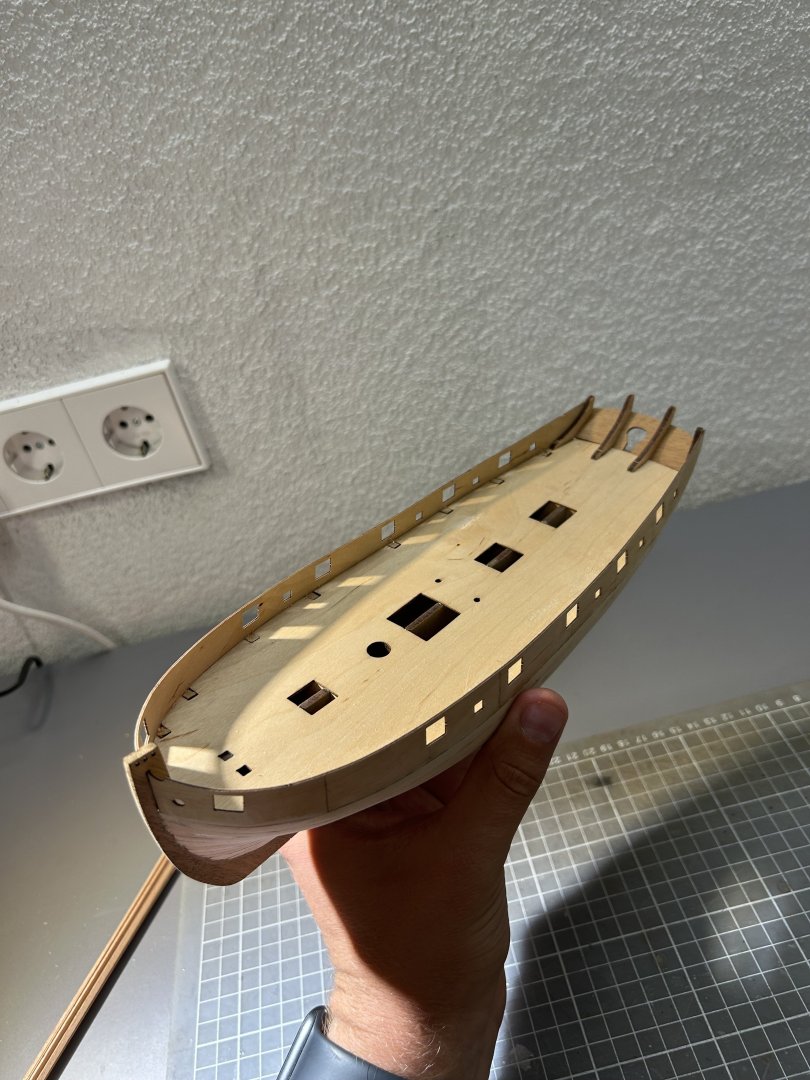

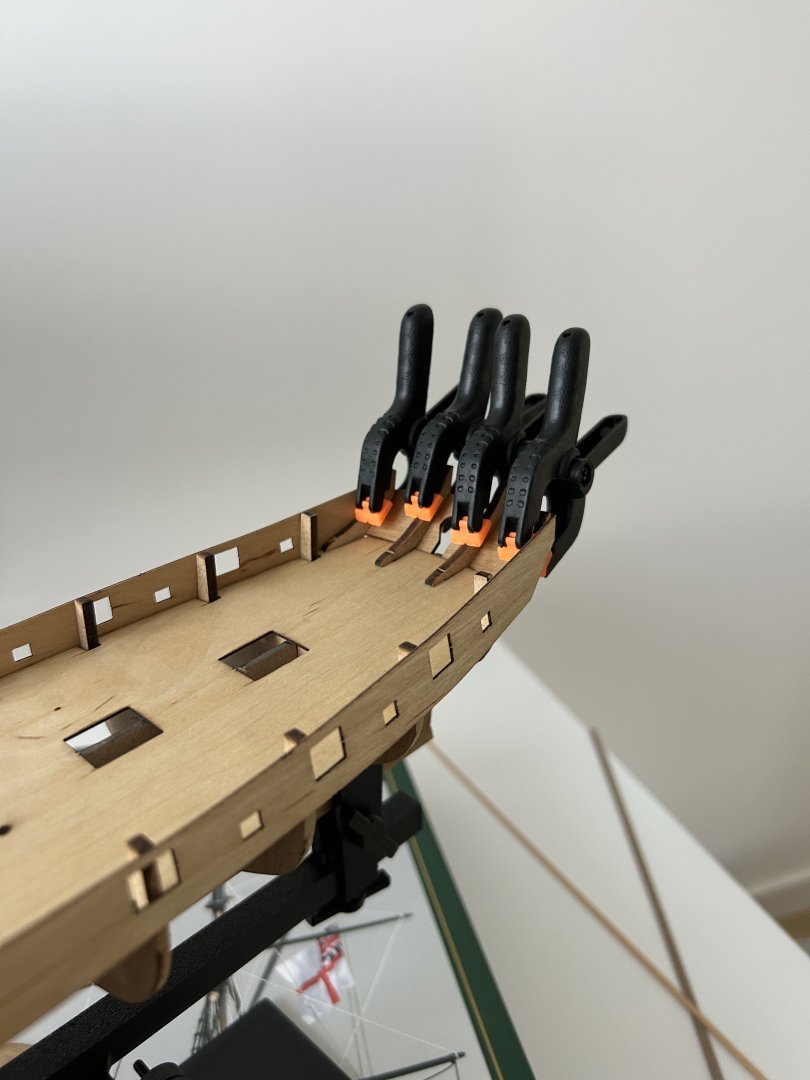

After heat forming and some sanding everything fits perfectly After testing fitting major stern pieces I will be able to proceed with first layer of planks.

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

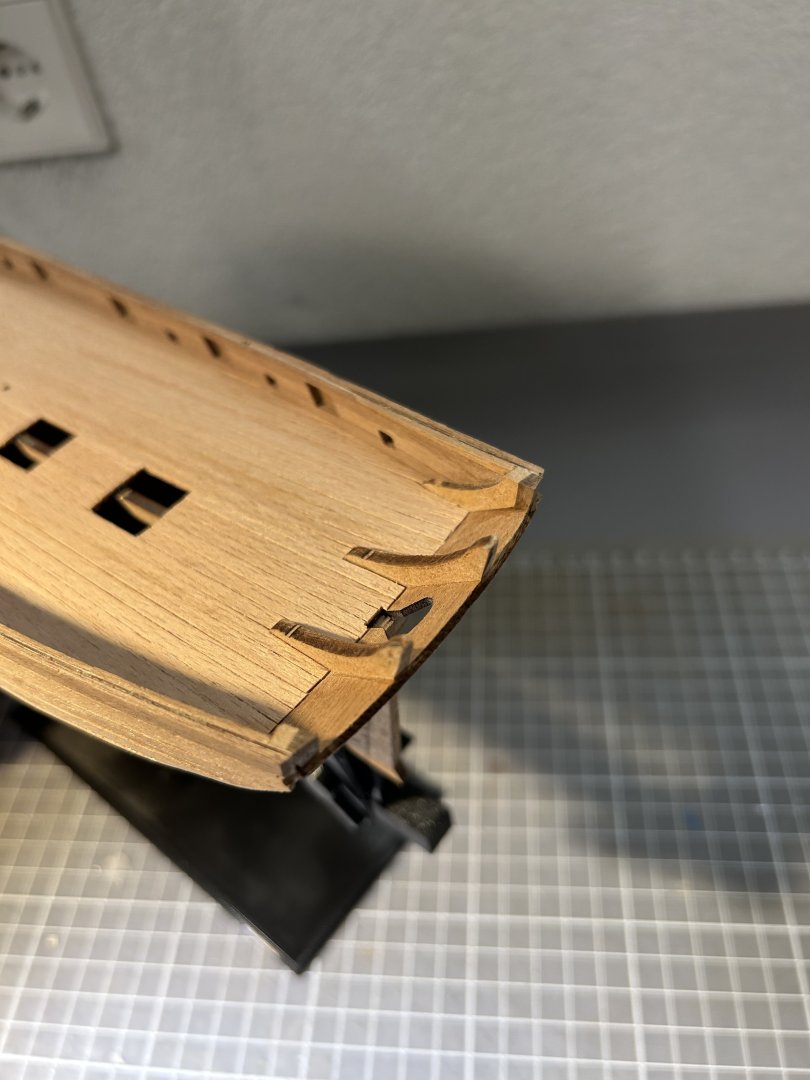

Little more progress. Fitment is medium at best. It will be a good riddle how to bend, sand and form the very end of the ship to achieve a tidy result 😆

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Glue is fully dried now. I went with a simple approach to bend these parts in to the form by soaking them and heat forming using hair curling iron 😅 quick and simple. For all future builders - these two parts are slightly different and the one with the notch at the front goes to the left side of the ship. It is detailed in the instruction manual but I have almost missed it.

- 45 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.