Lapinas

Members-

Posts

126 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Lapinas

-

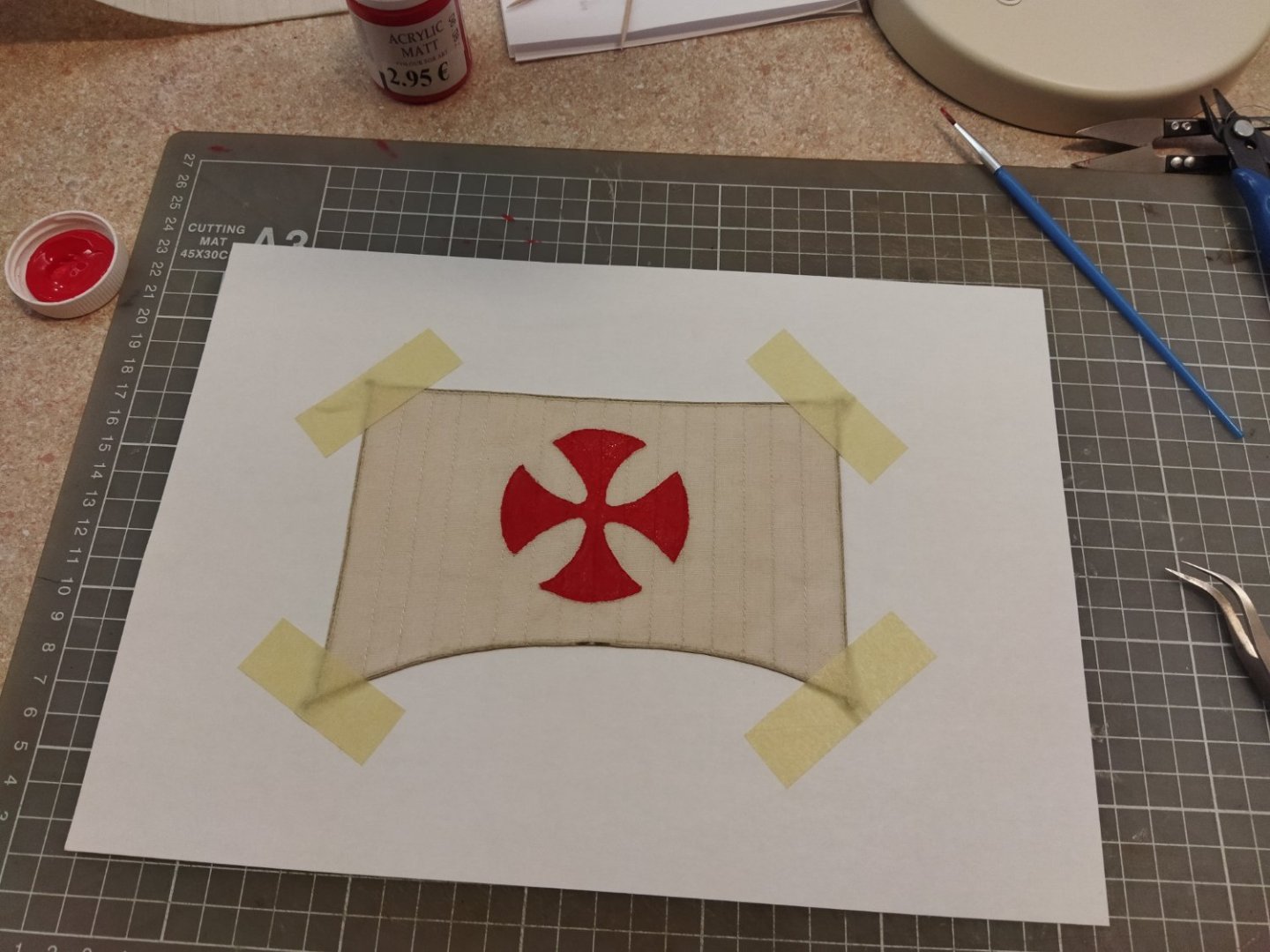

I have painted sails today with acrylic paint. I am quite happy with the result. I had to paint from both sides of the sail. Not sure if it is accurate, but pain has seeped to the other side after painting it on one side, so I was basically forced to do it this way

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

I redid the main sail, but got the same result... So I have tried ironing it and it helped. Thanks! 😃 Not sure yet. I was eyeing more recent sail ships recently used in sport

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

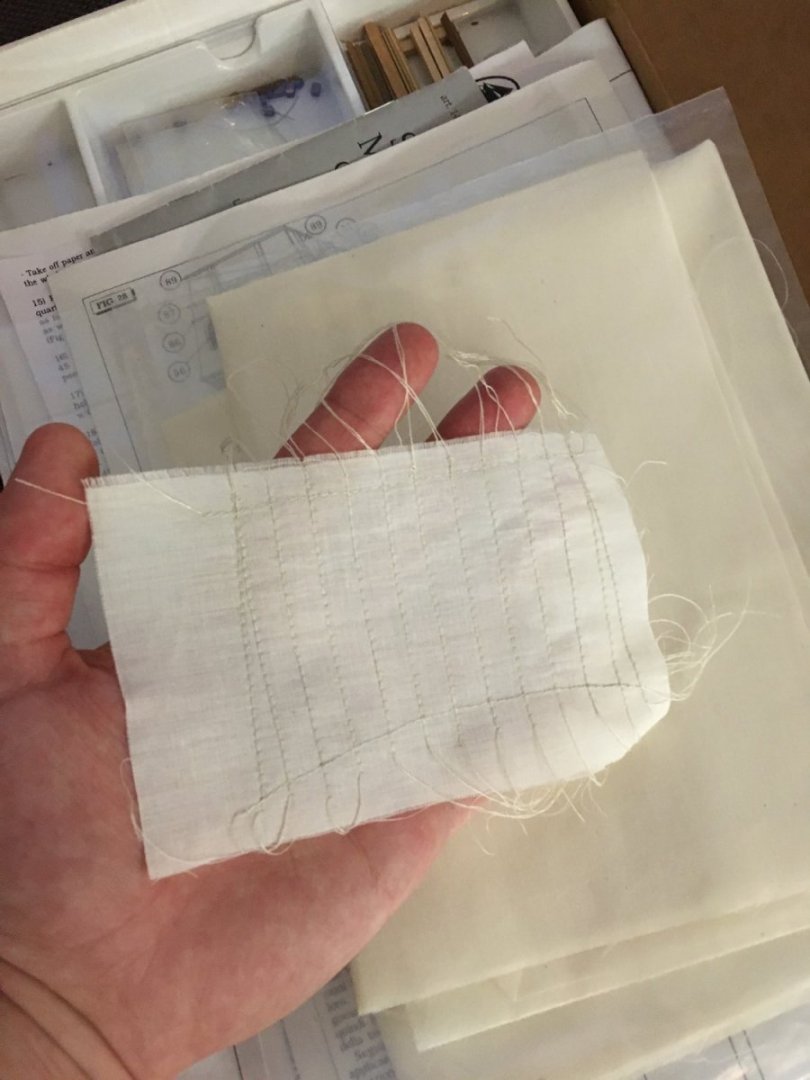

I have finished the sails. I have ordered 4 different batches of bitumen, but when mixed with turpentine it was not giving be a nice color... So after last failure I gave up and went to my local grocery store and bought some black tea 😄 When I was joining the main sail top and bottom parts it looks like the thread got too tight and most likely I am going to redo it.

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

Ratlines are done I have made guides for each side. It helped me to maintain parallel lines while rigging.

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

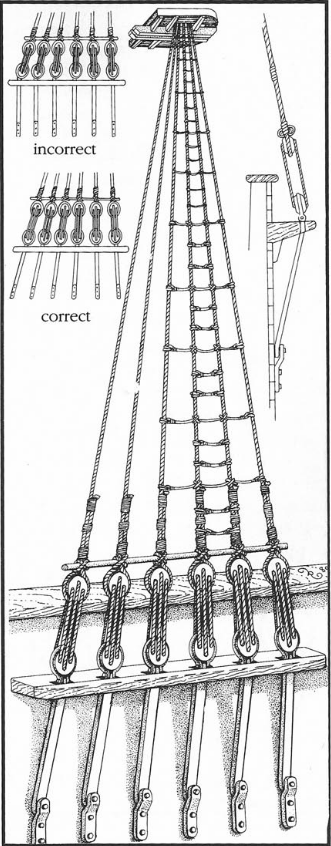

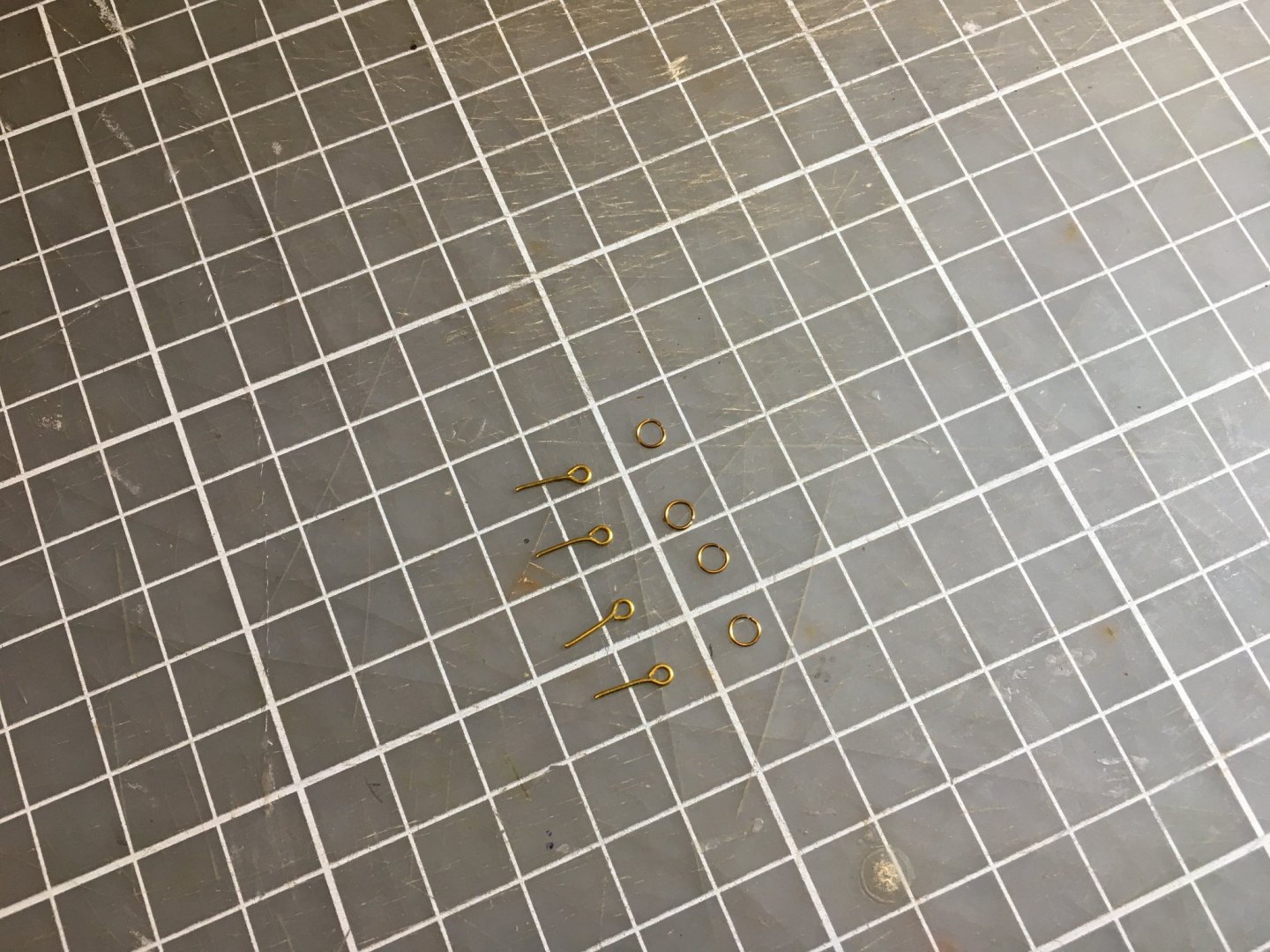

Added shrouds with deadeyes. Could be better.. but to fix bottom deadeye "holders" alignment is a bit too late What I mean for future builders: This is going to bother me forever This is a great page about making shrouds: https://suburbanshipmodeler.com/2017/10/07/shrouds/ I have tried to maintain spaces between deadeyes consistent by using these hand made tools:

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

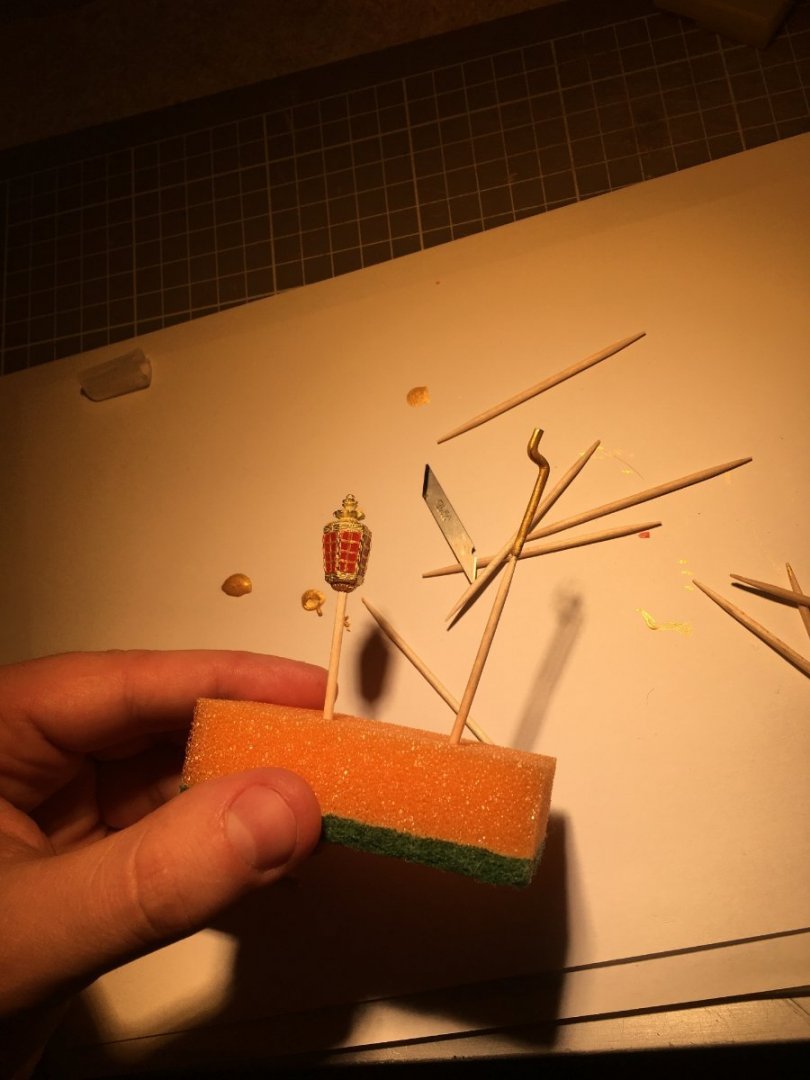

Small progress update Did a bunch of ropes: This tool is very convenient to cut threads, can recommend:

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

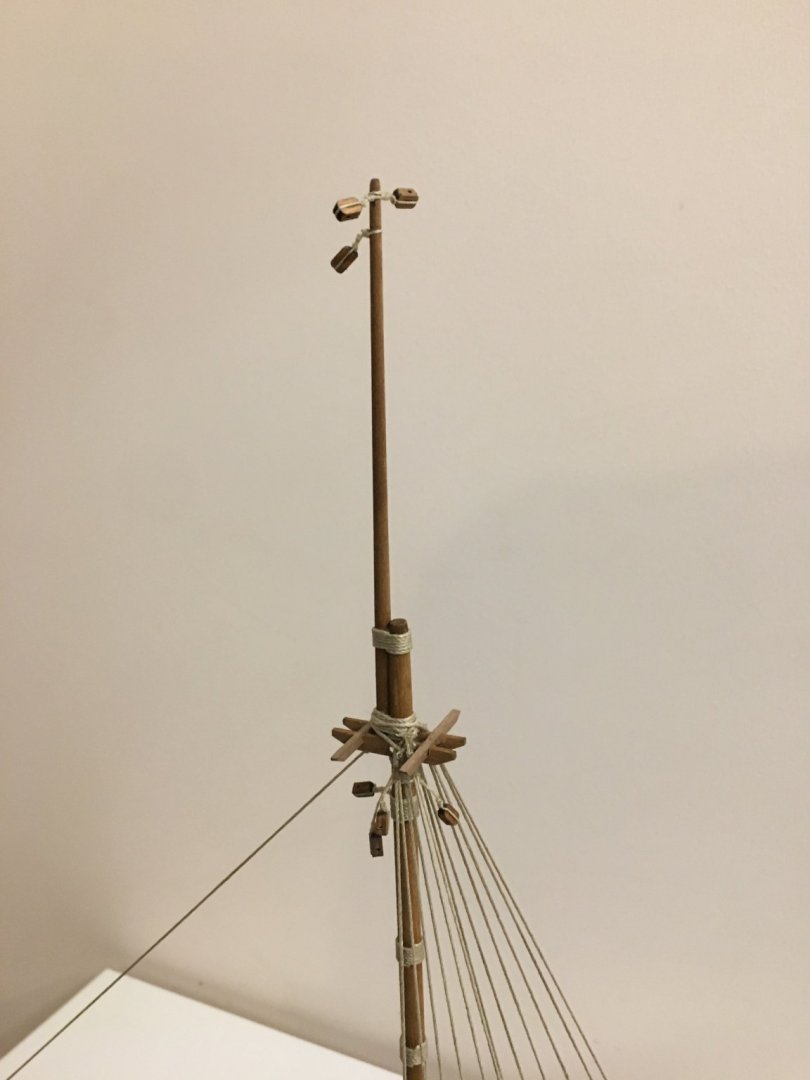

In a few hours I have managed to glue front-most mast and tie it down... It was way harder than I expected, everything was so tight and I had to try multiple times until I get it right.. I was not able to figure out what I am doing wrong until I found redhawk Santa Maria build on modelissmo.net (https://www.modellismo.net/forum/modelli-terminati/61121-wip-santa-maria-2.html). It included this blueprint: After I saw it everything clicked in my head finally and I was able to achieve the desired result. I hope this helps for future builders. I would love to have a better instructions for this ship, but maybe it is more fun to work this way. I have spent countless hours studying other people work on this kit.

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

Pinta by Andyrew - Amati - 1:65 Scale

Lapinas replied to Andyrew's topic in - Kit subjects built Up to and including 1500 AD

Keep up the good work! -

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

I just ordered metal pedestals from Amati and I am waiting for oak baseboard It will take a while... Can't really do anything because, I want to glue masts when ship is fixed in place...

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

I have received this baseboard from Amati and the quality just isn't there for using it without fully painting it. The wood is very orange and there are two distinct colors of it... I have tried staining it, but no stain I have or I am able to buy is able to cover the orange shade. I am going to put this model on hold until I am able to source the baseboard locally. Want to fix it in place before gluing on the masts..

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

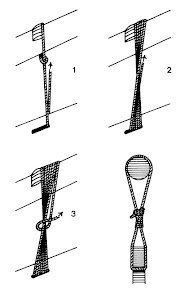

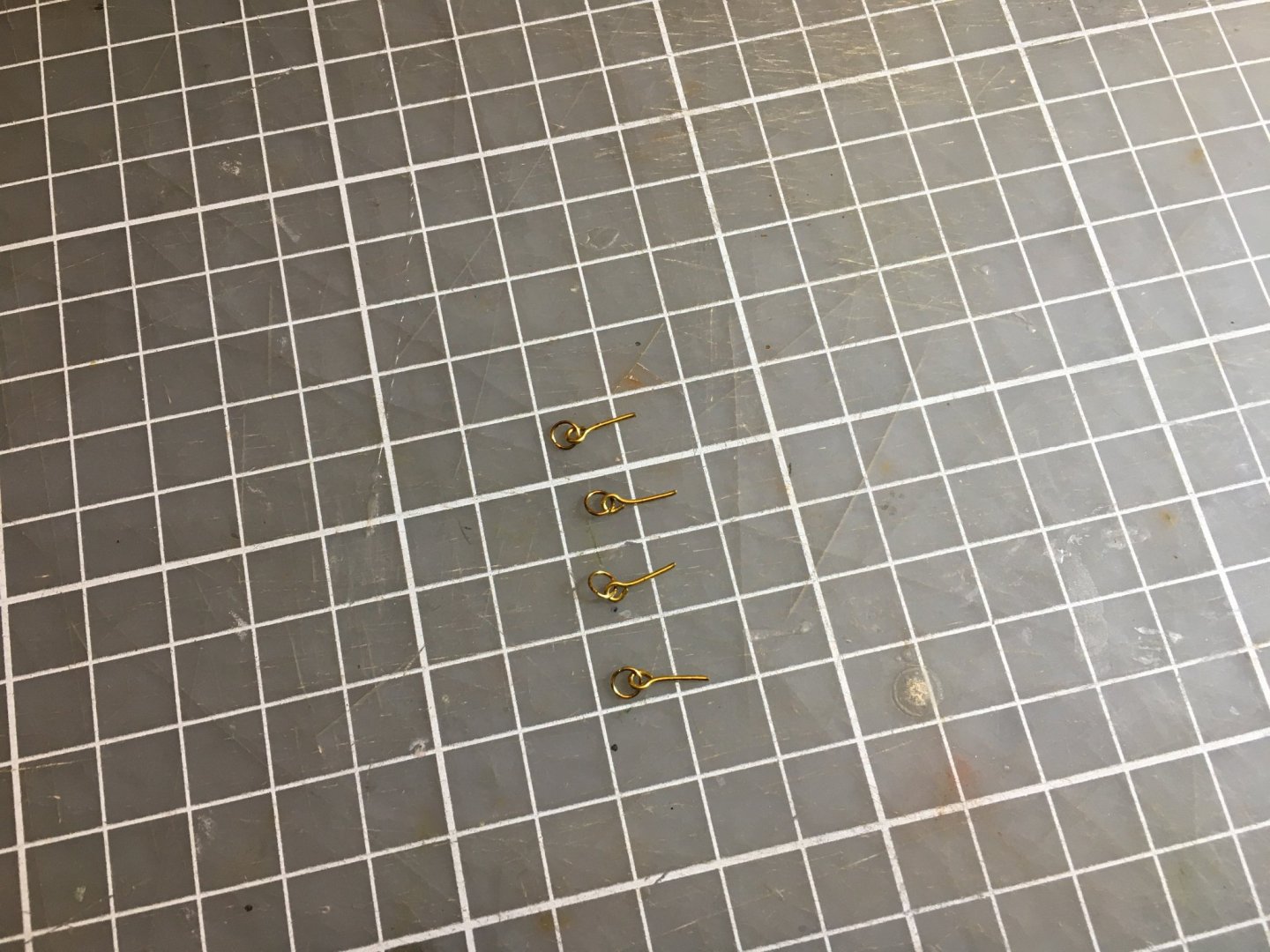

A little update here. Finished rudder by adding a loop: Made some loops for fixing the boat rope: Glued the boat in place: Added boat rope attachment loops: Added ropes to fix the boat in place: Glued the stairs in their appropriate places:

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

Really stunning work! Can't wait to see how it will look finished. For next build I suggest buying silicone wires (if not using it already, can't really tell from the video). They are much more flexible and also head resistant! Soldering iron will not melt the isolation. I use these wires when working on my electronic projects and I like them a lot. Also, I would like to thank you for making all these videos. They are a huge help for a beginner like me.

- 156 replies

-

- marisstella

- marisstella model ship kits

- (and 4 more)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.096fd2458554758bb0fcaf721271972f.jpeg)

.thumb.jpeg.0f5959d6a4b491d2f934b1d94024e481.jpeg)

.thumb.jpeg.a1844c78c13e48ef33c99a17be91c0f3.jpeg)

.thumb.jpeg.a9b9e104adee469101f20dedb9448e5b.jpeg)