Thanks for the tip on mast diameters. I do not think I have MM drill bits, but I have the fractional equivalents. Worst case I have a lathe so trimming the dowels and shaping them will not be a problem.

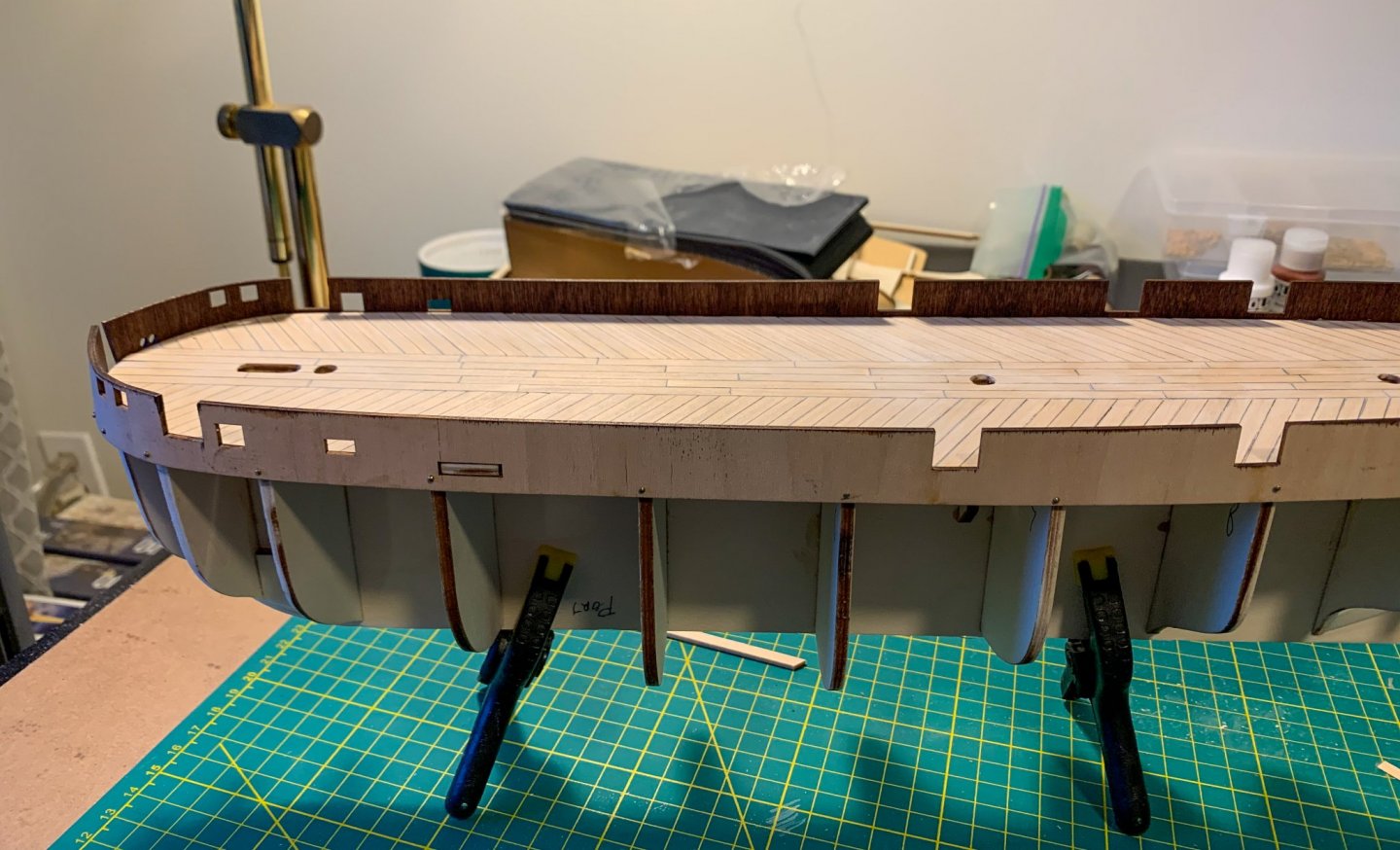

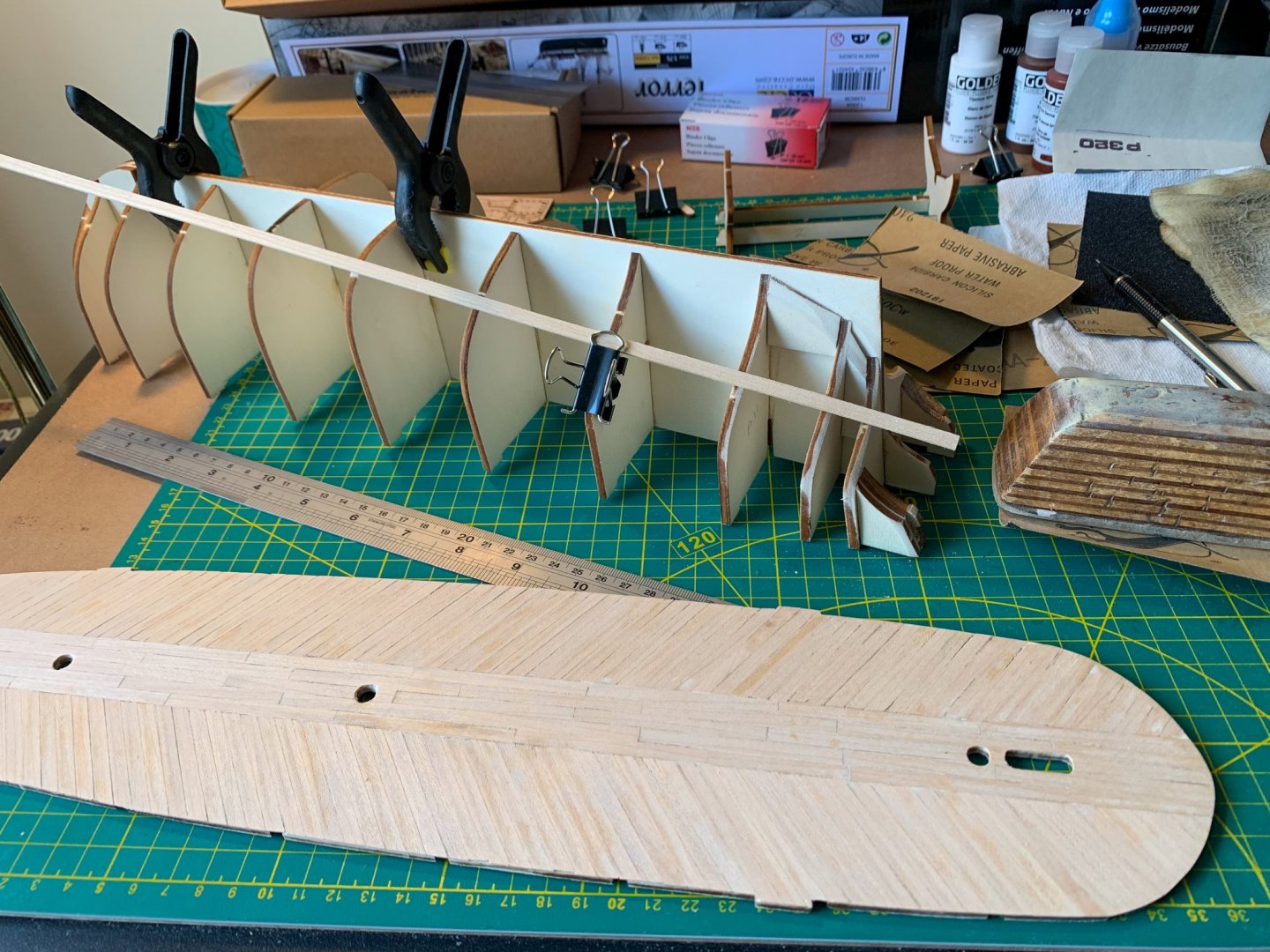

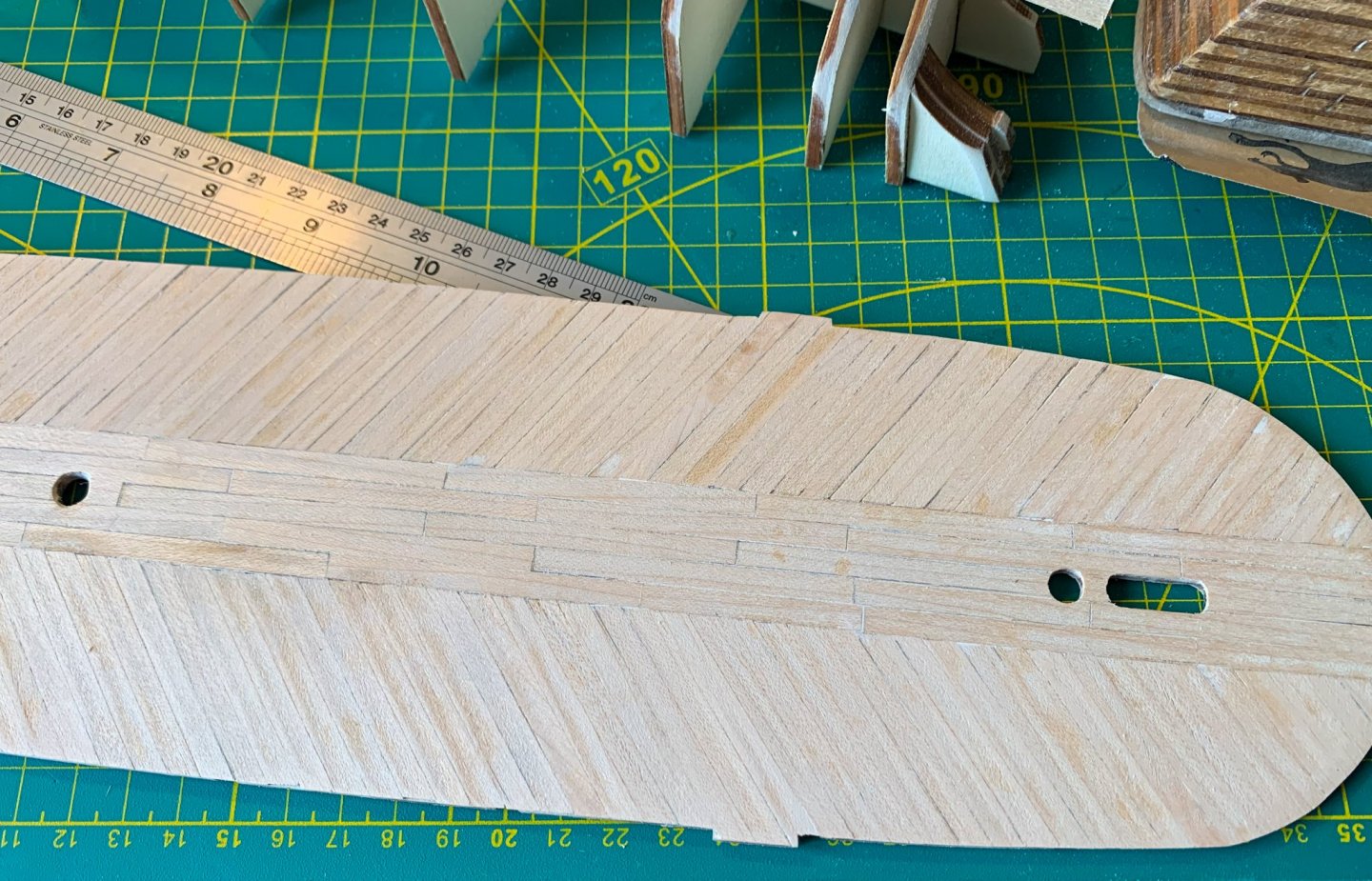

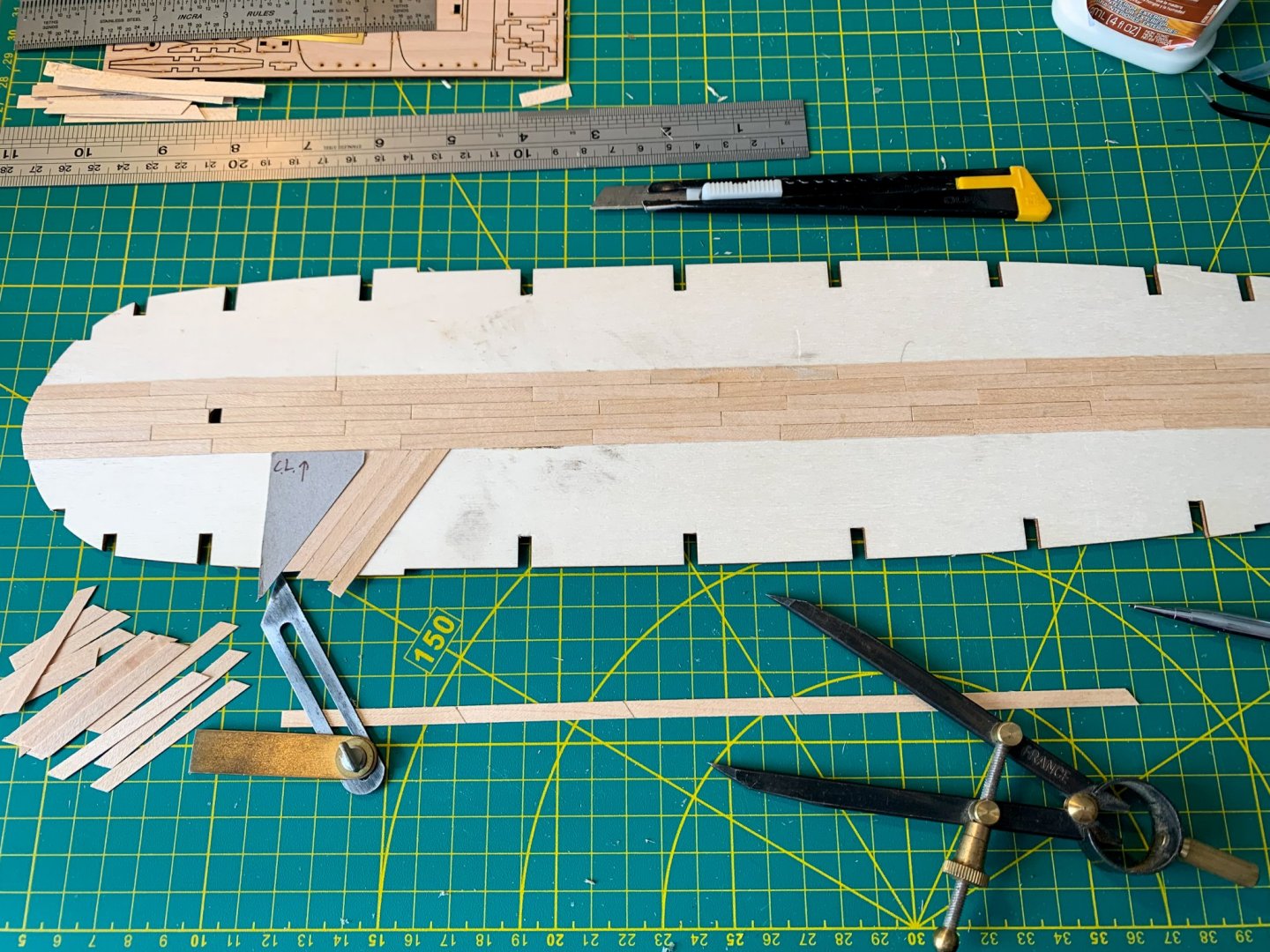

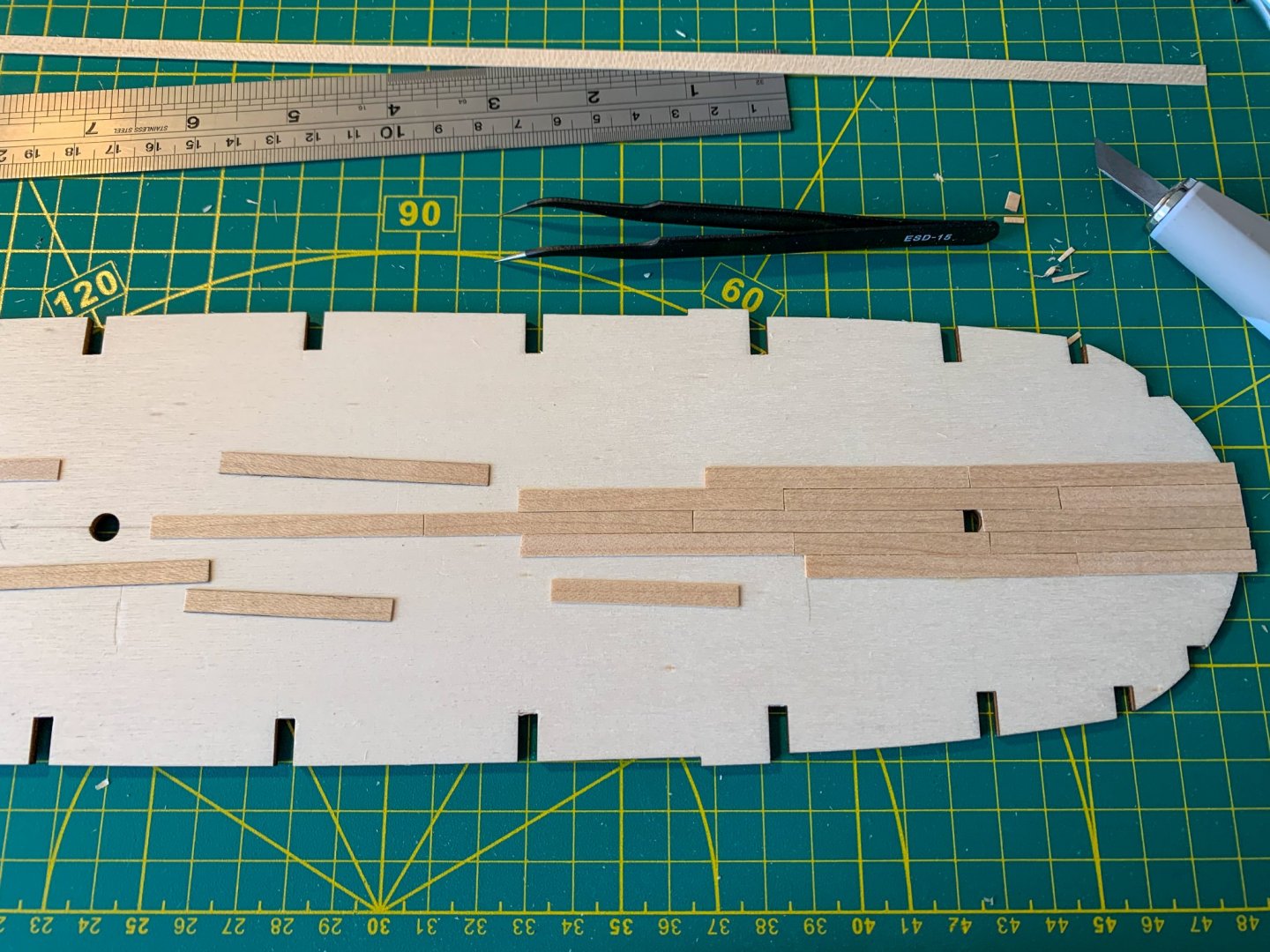

I figured out how I screwed up the deck planking. A close review of the instructions revealed that the center planks should be part A-21 described as 0,6x5x400, Qty 10, herringbone planking as A-22 described as 0,6x5x47, qty 75. In my kit I have many strips of 0.5x5x600 and maybe 5 strips of 0.5x6x600. So my deck has 5 center runs of 0.5x5x60 planking and herring bone layout of the same width and thickness.

By the way it looks fine to my eye.

I'm sure these variants were included to confuse old north American woodworkers, who are sure that if God wanted us to use the metric system there would have been 10 disciples.

DB