aaronc

Members-

Posts

83 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aaronc

-

Thanks, it's gonna sound a little more complicated than it is but the stain is called aqua fortis/ferric nitrate. There are different ways to make it at home or it can be bought. It is iron dissolved in acid, the historical stain used in the 17th and 18th centuries for Kentucky Longrifles. I'm not a rifle builder but have made powder horns and use maple regularly on various projects. I was staining other projects last week and just included the oars. I like the antique color it brings and it's also lightfast.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Your doing a much better job than I did on initial alignment, it's a major area of improvement I'll be focusing on for my next build. I've also got lego blocks on my get list.

- 27 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

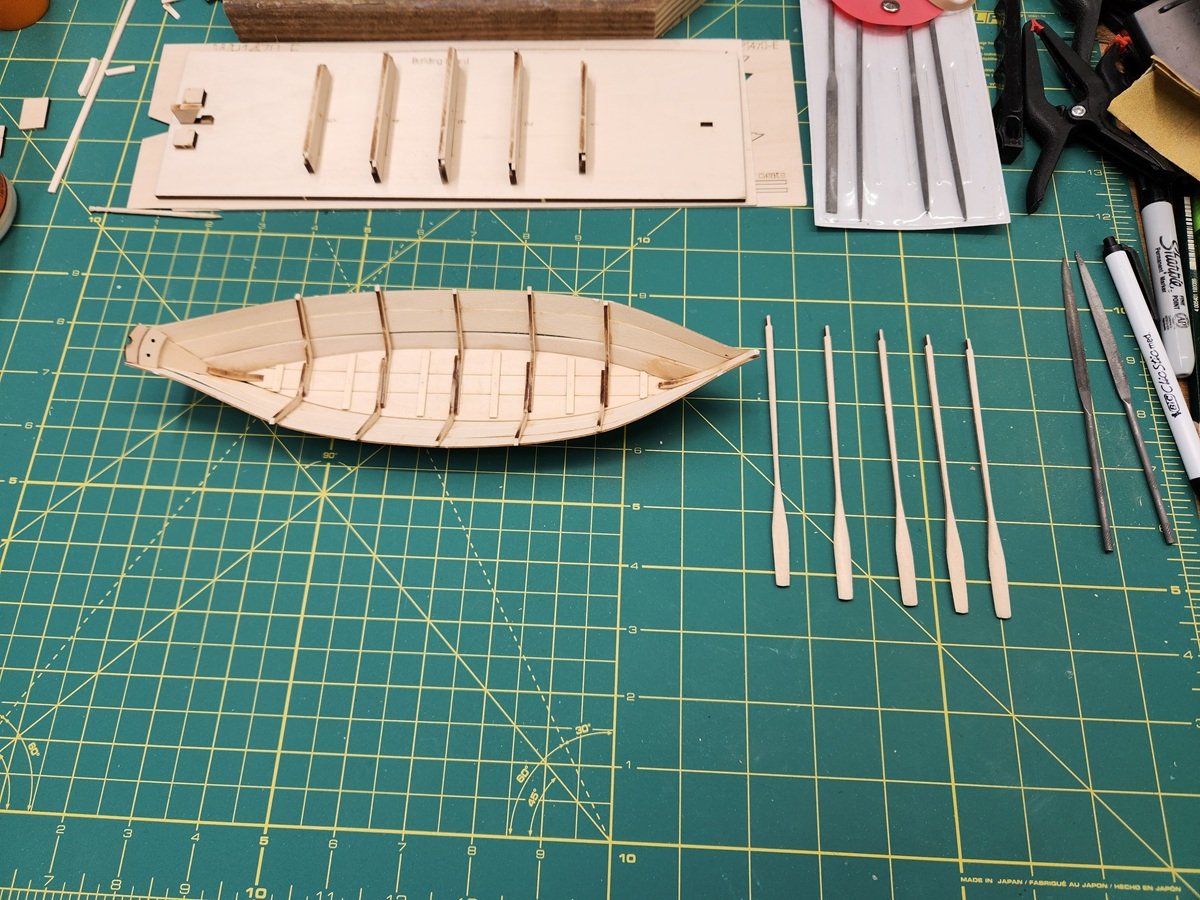

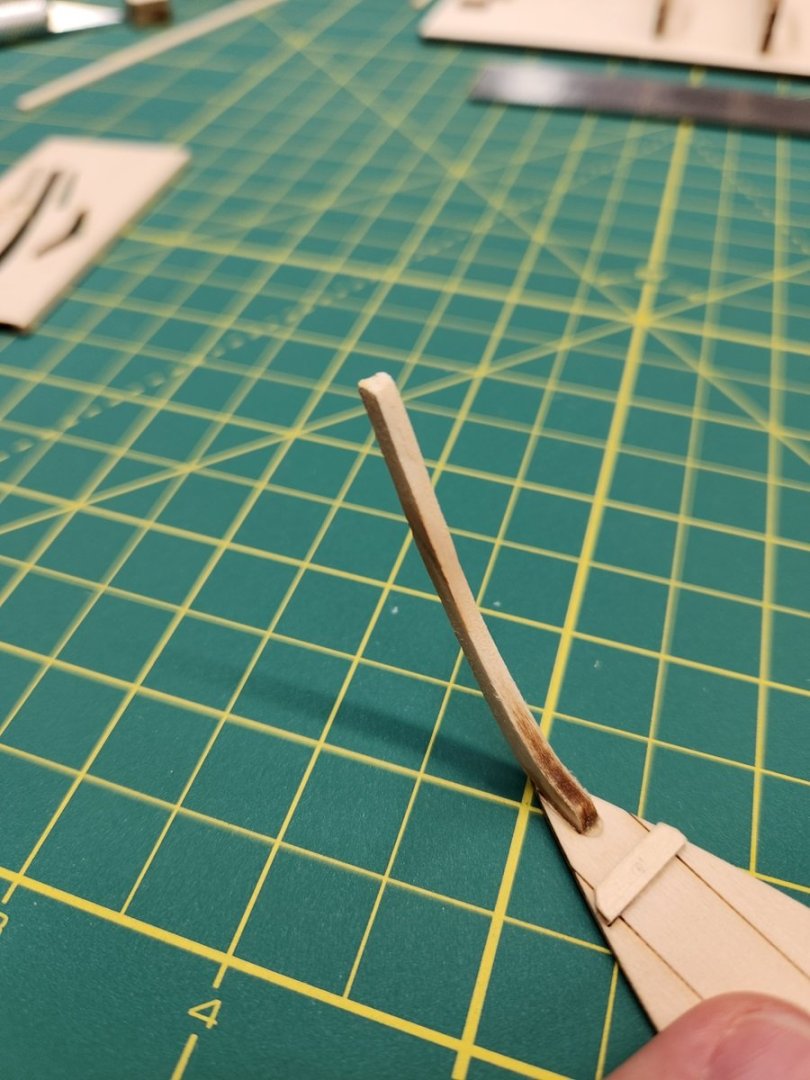

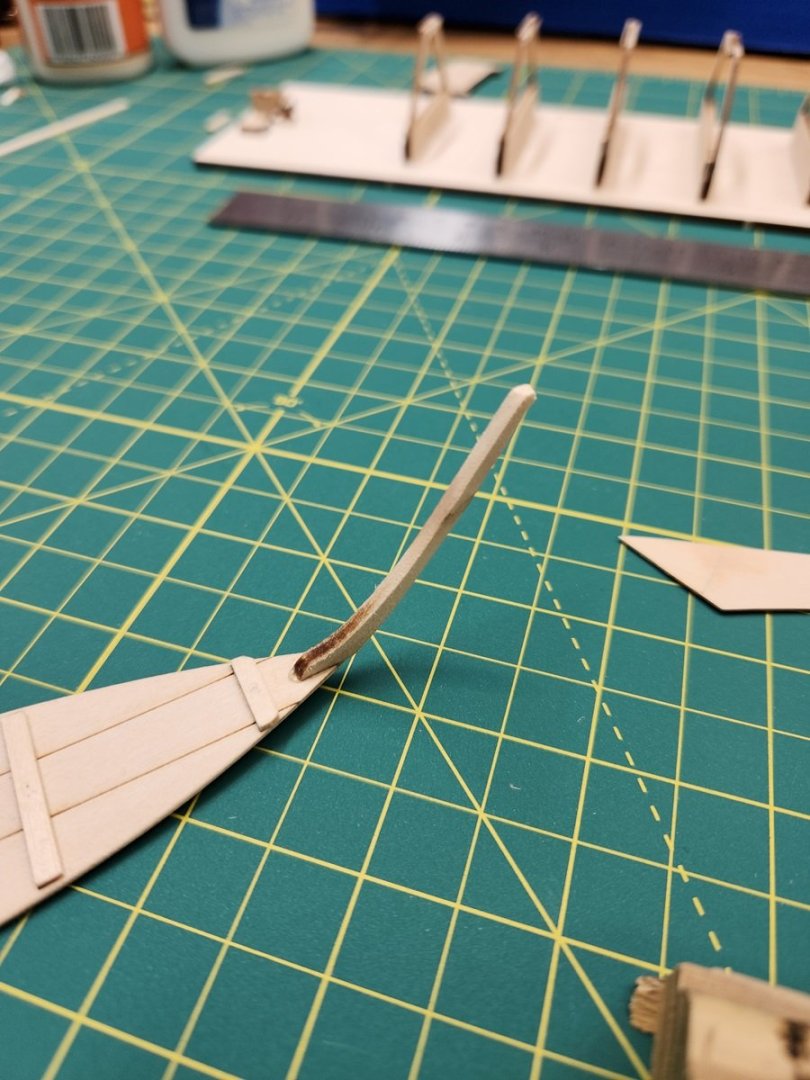

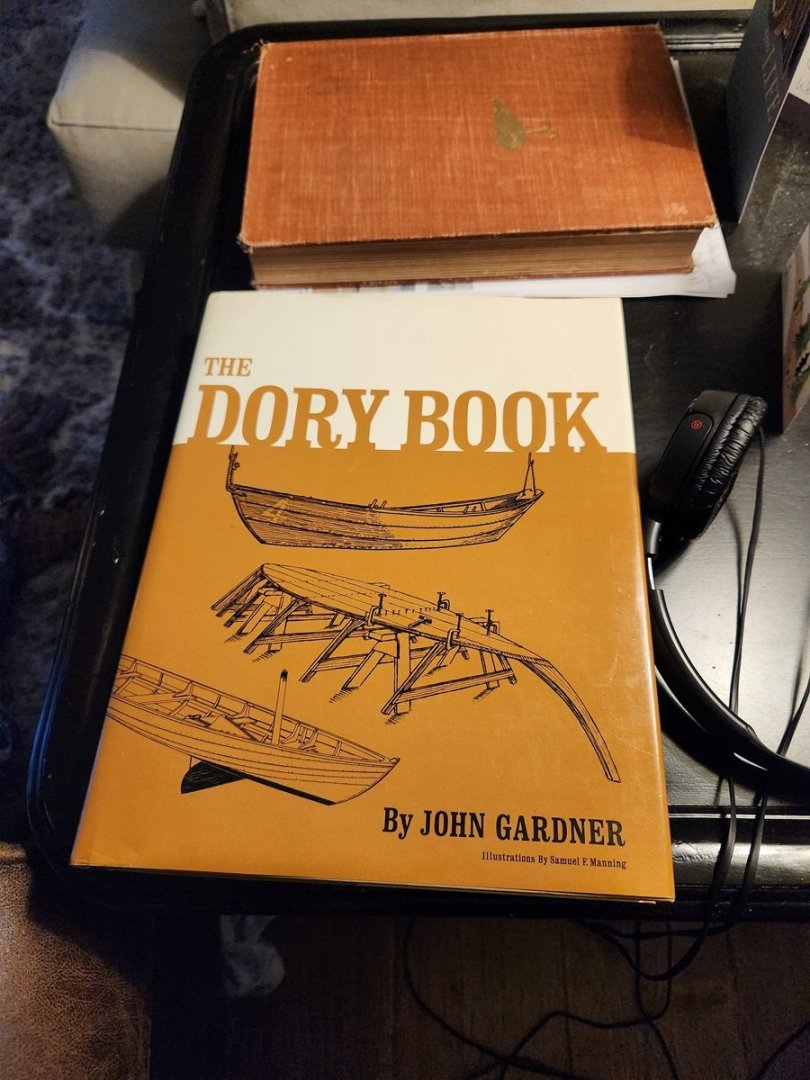

While I had some staining going this evening on other projects I hit my oars for some color. I had rounded out the handle end a little yesterday with a needle file for final shaping. Topped them off with some home brew finish. Don't have a definite plan yet on color but leaning heavy toward an off white with grey trim for my paint. I'll be using oils. I received that Peterboro canoe from Santa per my request thats posted in the "what did you receive today" thread. I'm excited about that build but sticking to my plan. Given the mistakes I've made on this build I ordered the 1:12 Dory today. It will be my next ship model and I also plan to work in some different materials on the build. Looking forward to that aspect as well.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

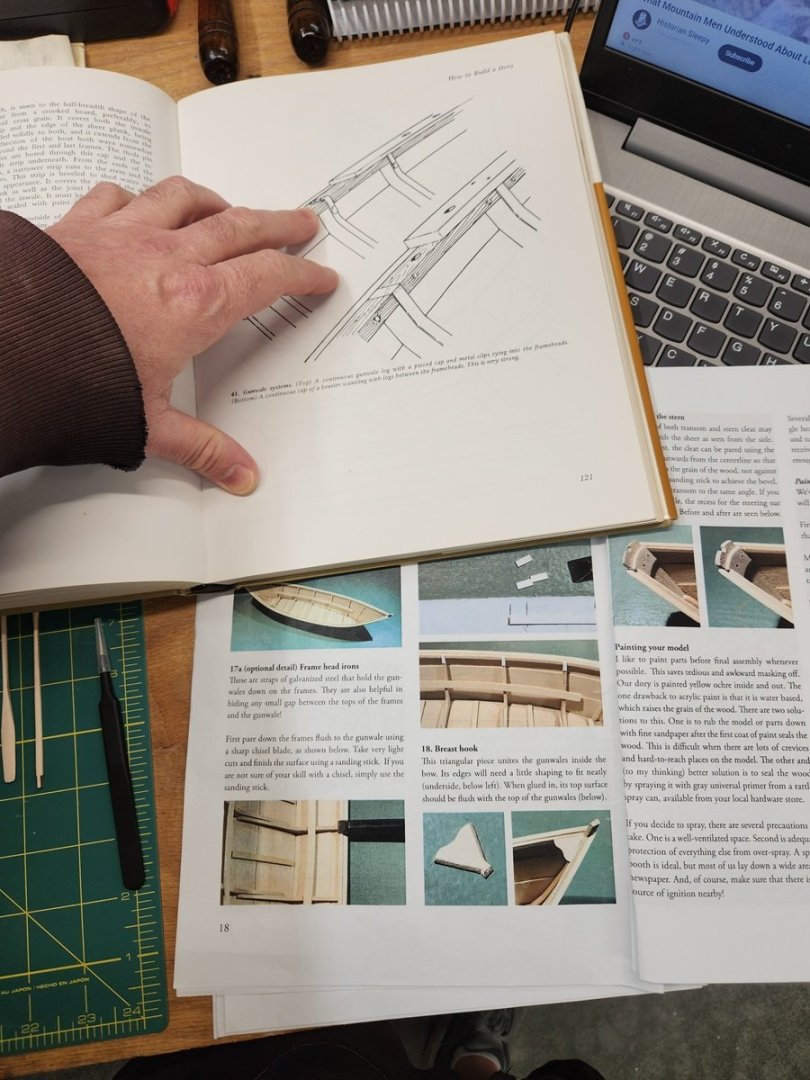

Notched out the top of the frames for frame head irons. Not sure what I will use yet for material, but I'll find something. Some decent reference was found in the Dory book. I thought it was a good time to apply a thin coat of primer.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

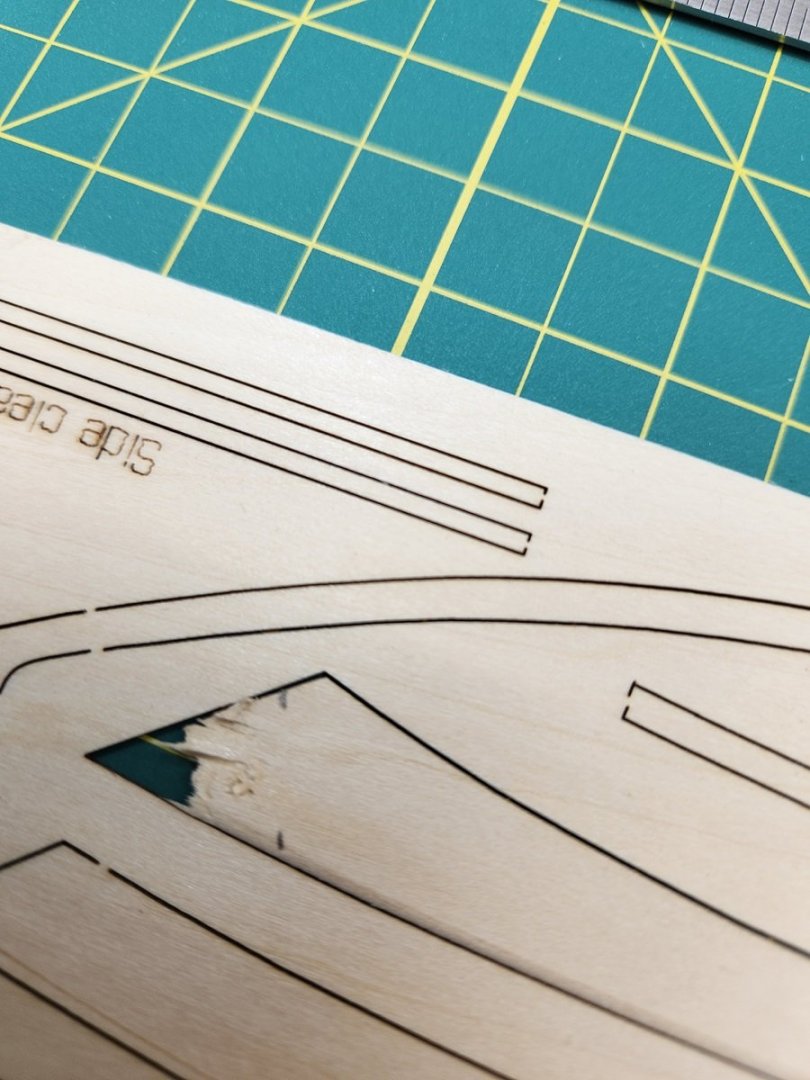

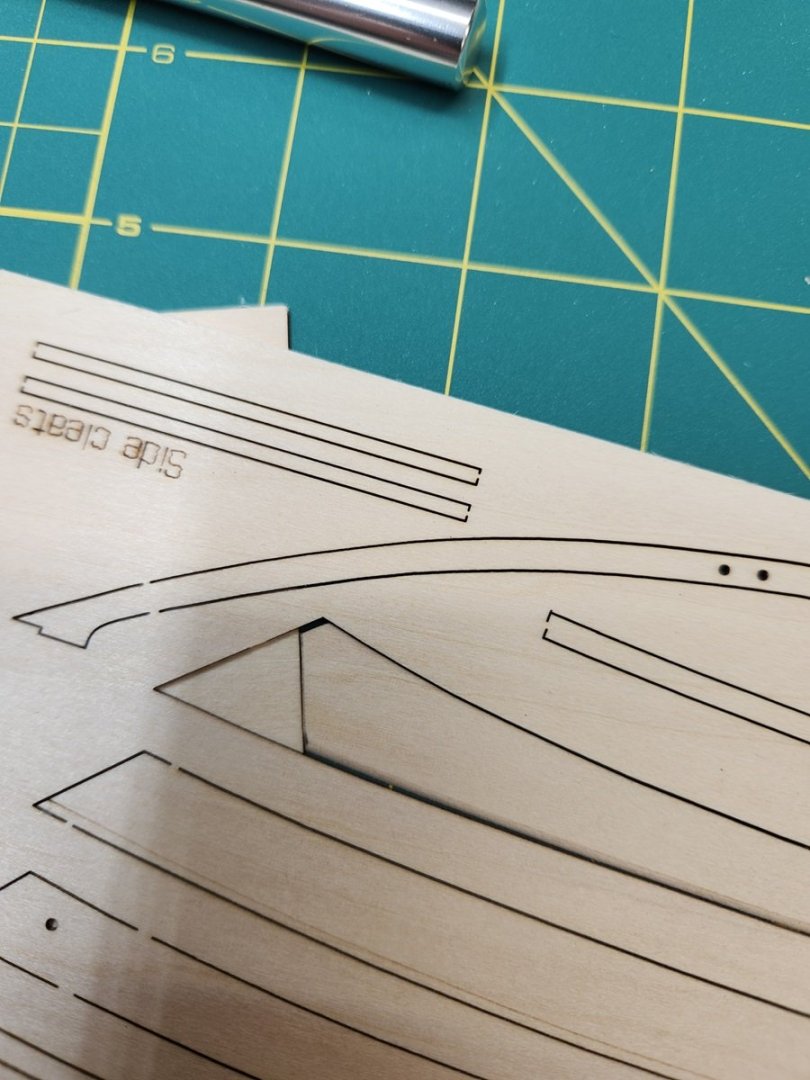

Those marks were already there, at least on my model. Good luck with your build.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

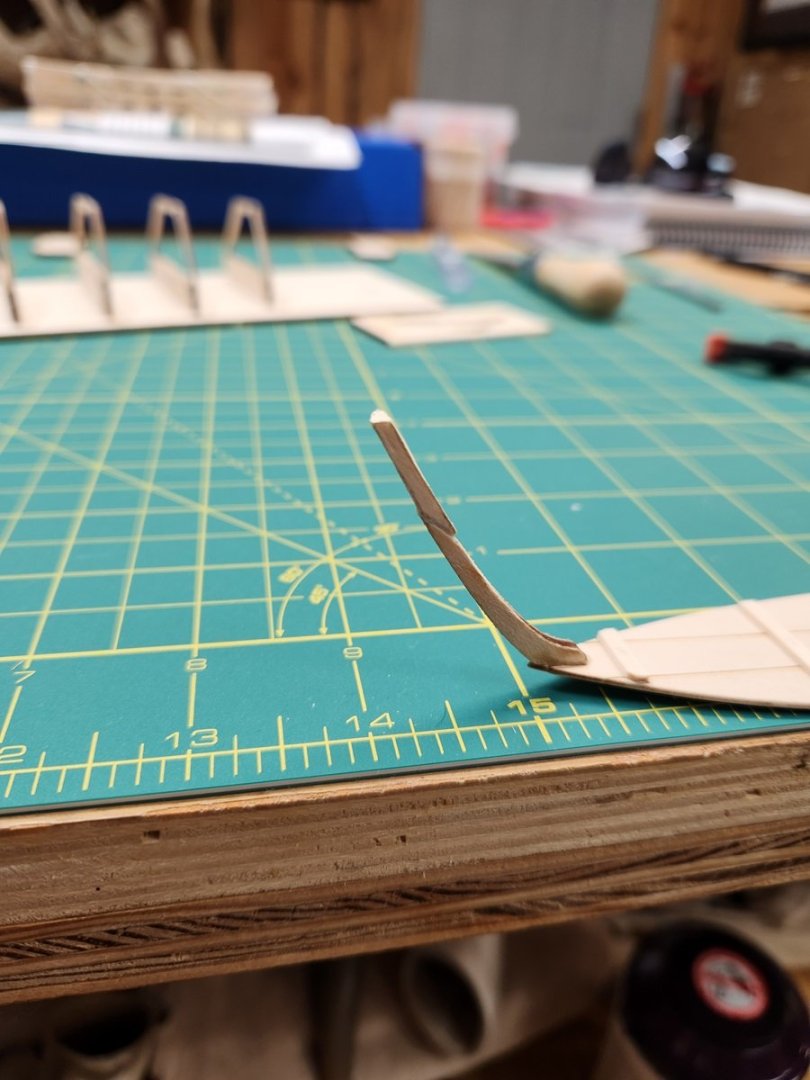

I'll do some final profiling before I call it good but I have me a false stem fashioned and attached. I used some apoxie sculpt to get a nice fit and also wood glue for securement. I think its a bit bulky but I'll take it, My breast hook wasn't fitting great so I used the original for a pattern and just enlarged the size. I finished shaping it this evening.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

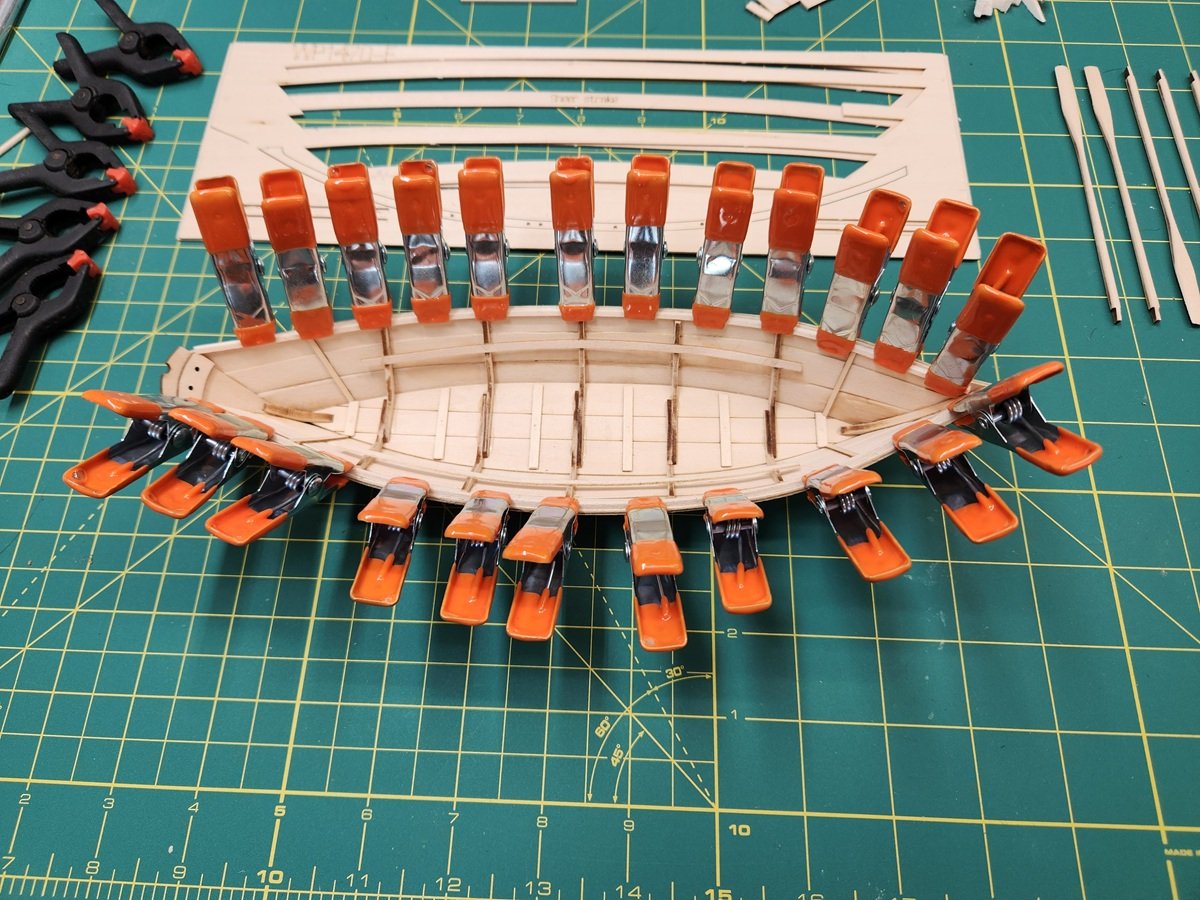

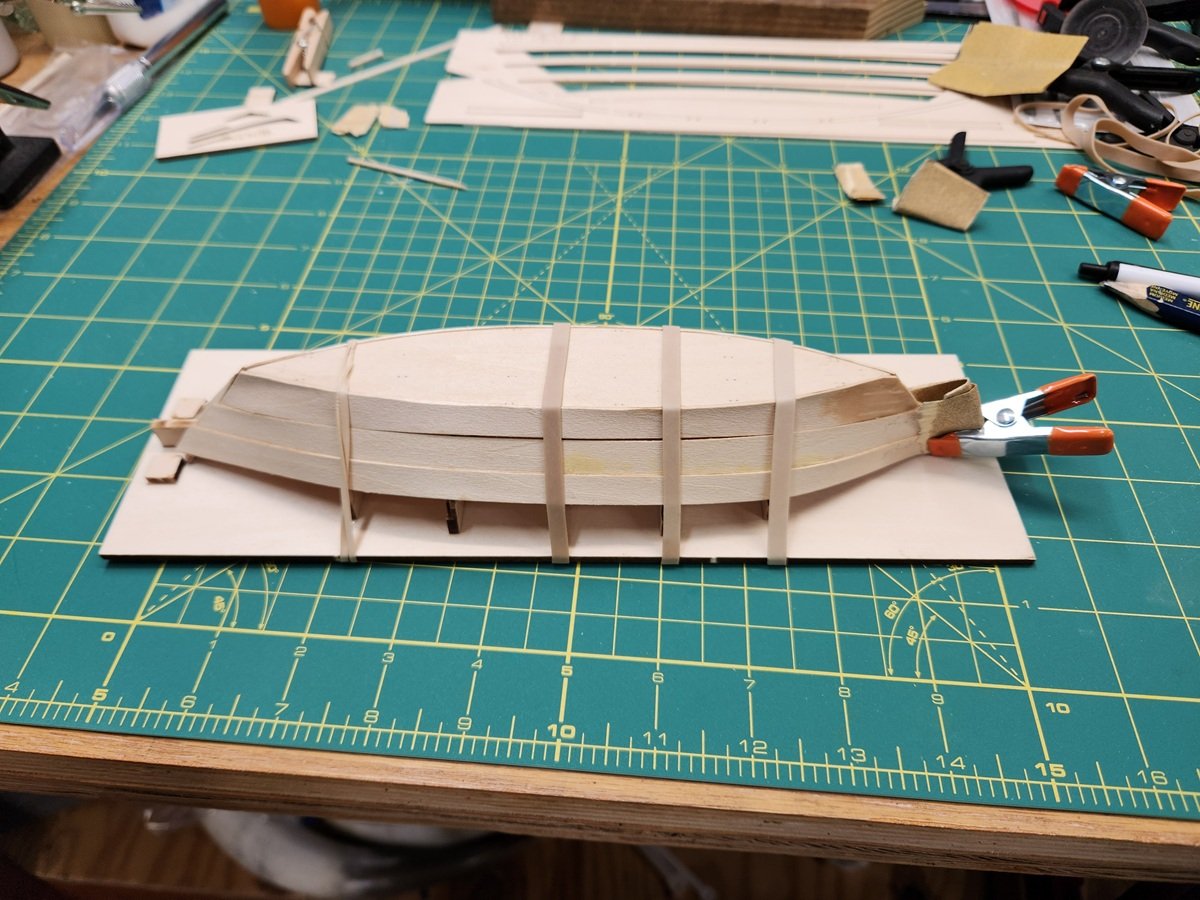

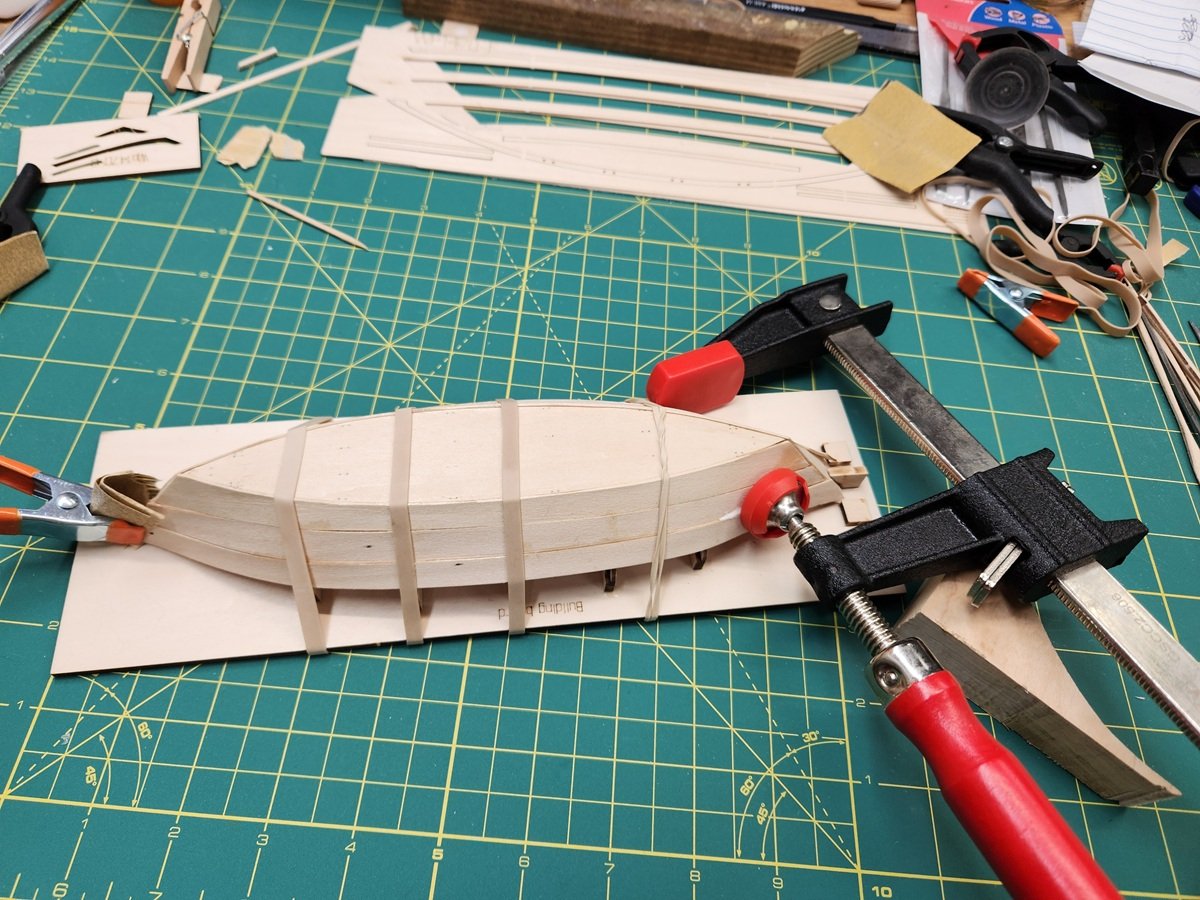

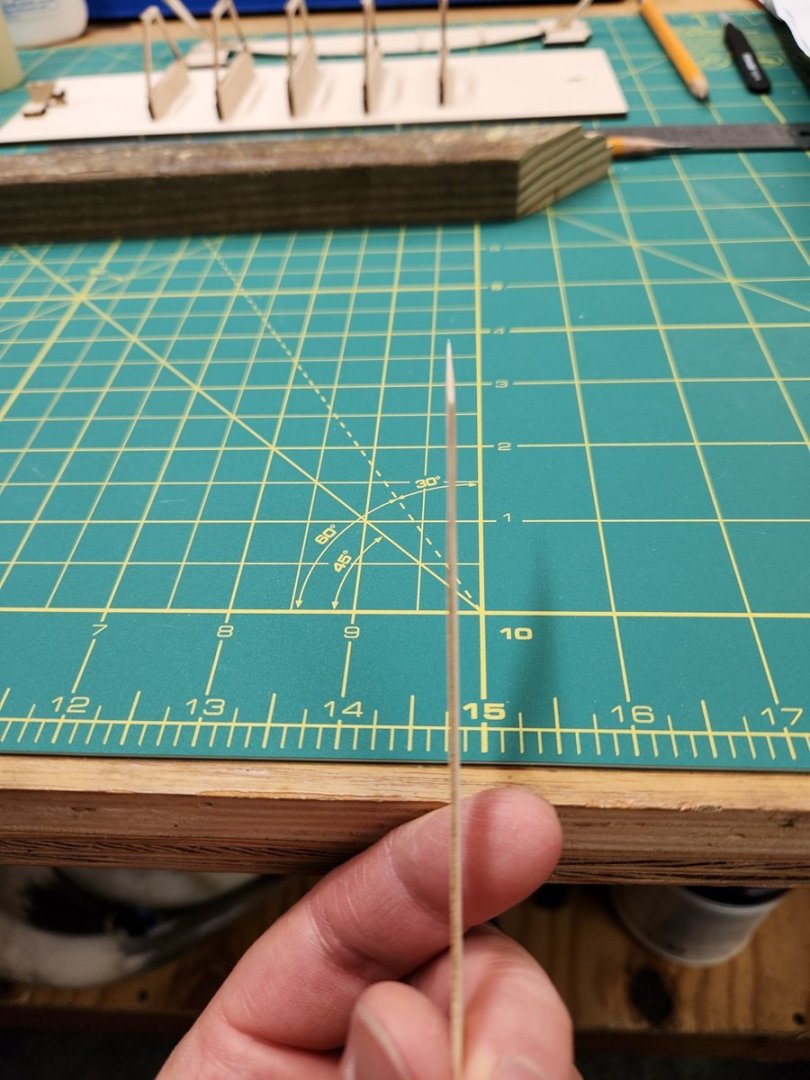

Been moving along here and there since cooler weather has set in and yard work has slowed down. Currently the gunwales are dampened and clamped. I'll do final sizing and glue next week. I've had a couple of misfires on the false stem but hopefully will get it lined out next week as well.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks for the response 👍

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Is there a specific height or landmark that the risers are set to or are pics just used for reference?

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

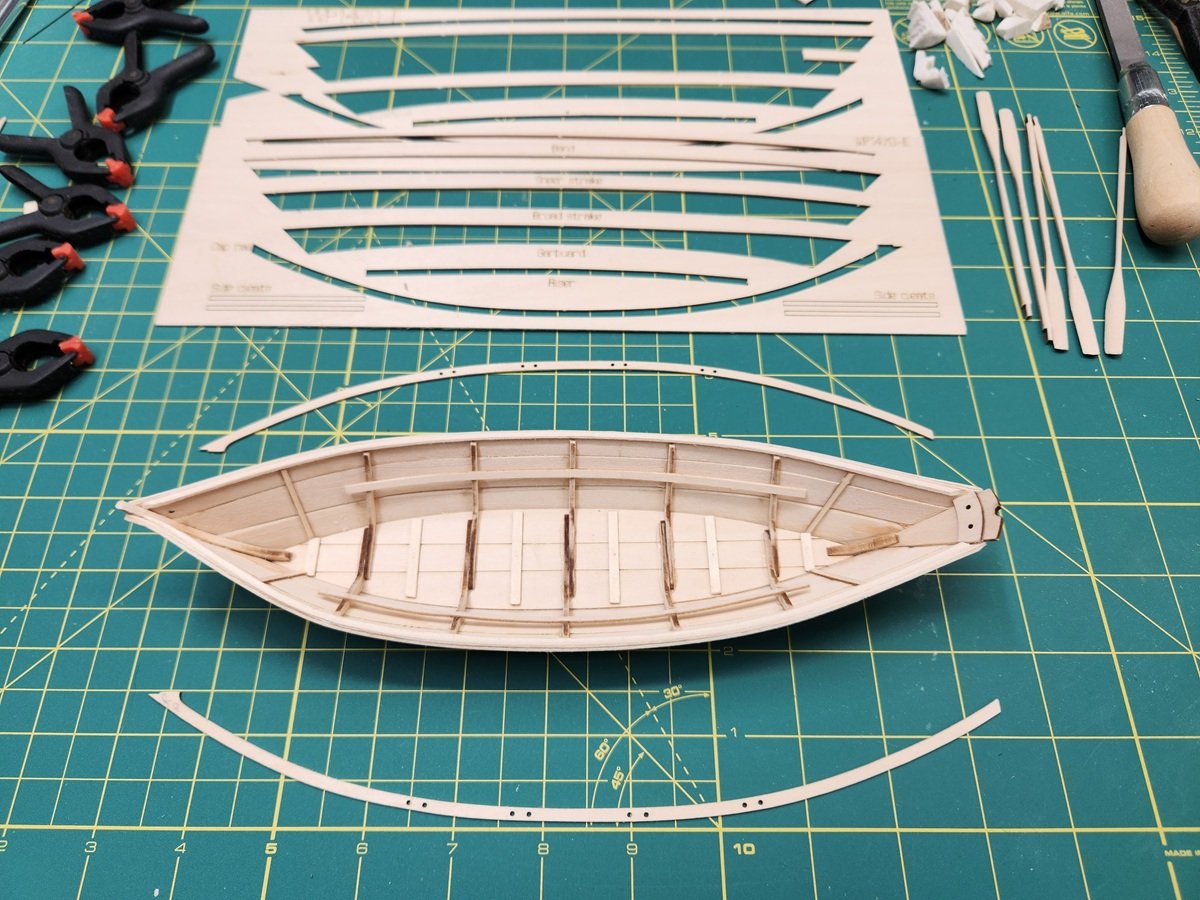

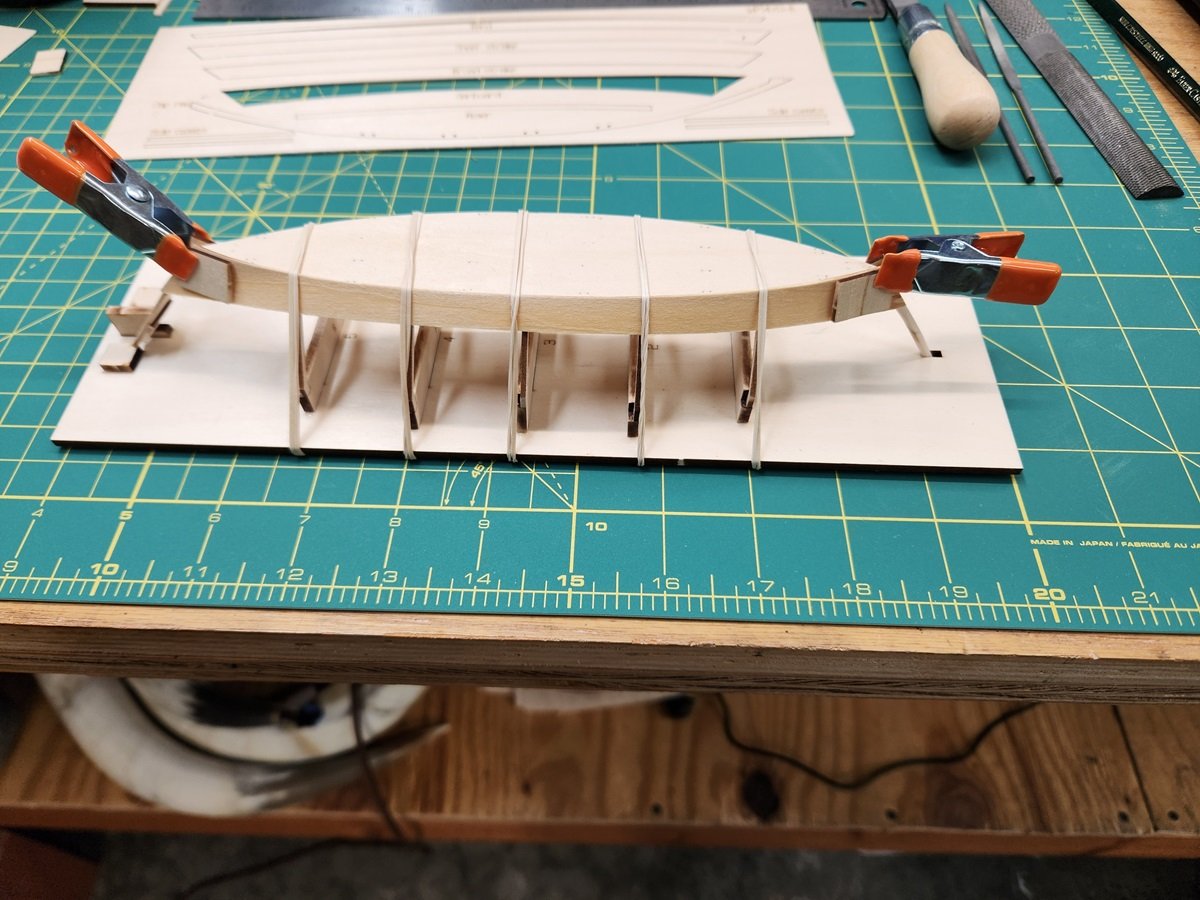

Looking more like a boat. Framework cut off and considering a rustic shelf to set it on when complete, the specifics are still in play. Wood for shelf found at my favorite supplier 😉 Side note: Of my hammer selection my Collins Legitimus is my favorite to clean nails out

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Well done Sir. I enjoyed looking through your build log. Very nice work.

- 56 replies

-

- grand banks dory

- Midwest Products

-

(and 2 more)

Tagged with:

-

Plenty of mistakes goin on here but I'm moving forward with her. I have some gaps present, I'll cheat and hide those best I can. Bout have her planked up though. She's probably looking more like a "boat wreck" than a boat 😅

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Strong work on the build,..I plan to stain my base as well. Well done Sir.

- 69 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thanks, that was my goal,...we'll see what happens.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

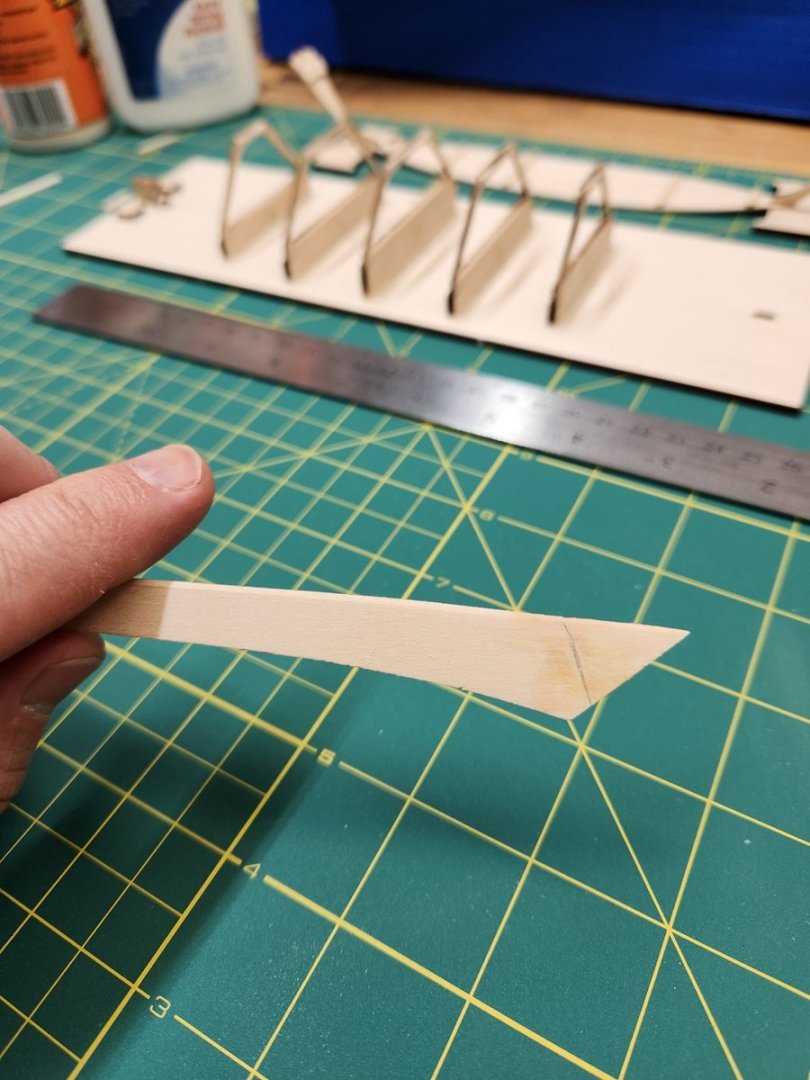

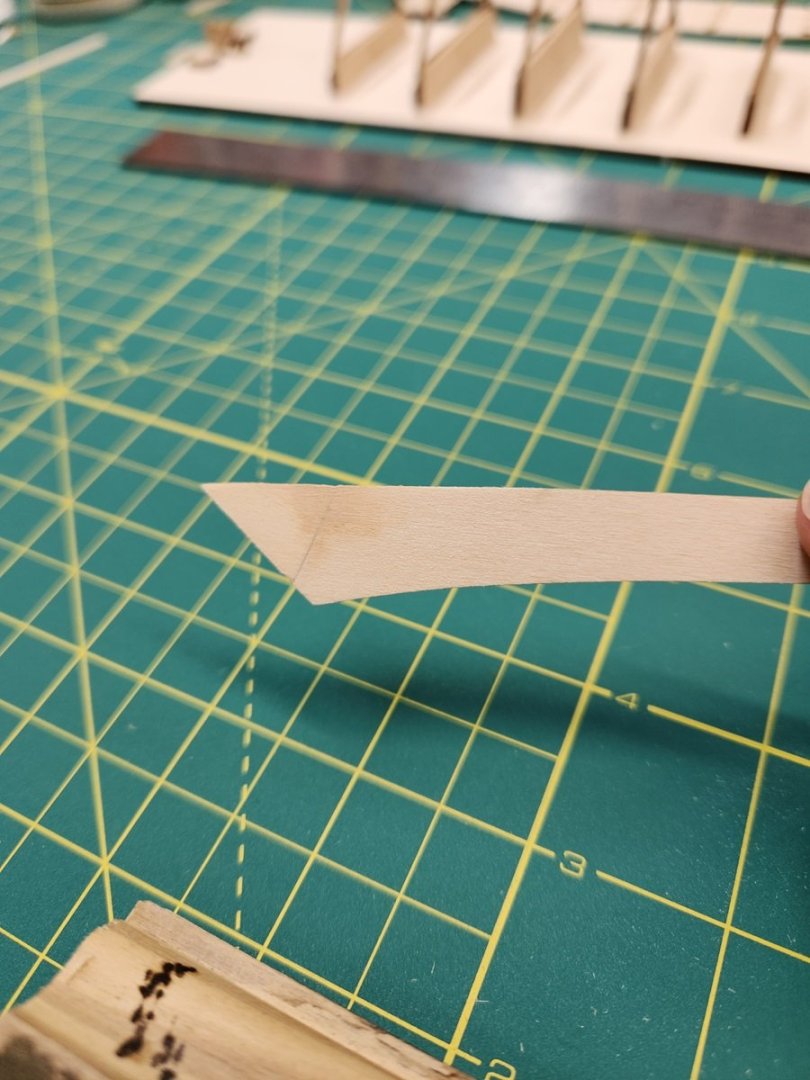

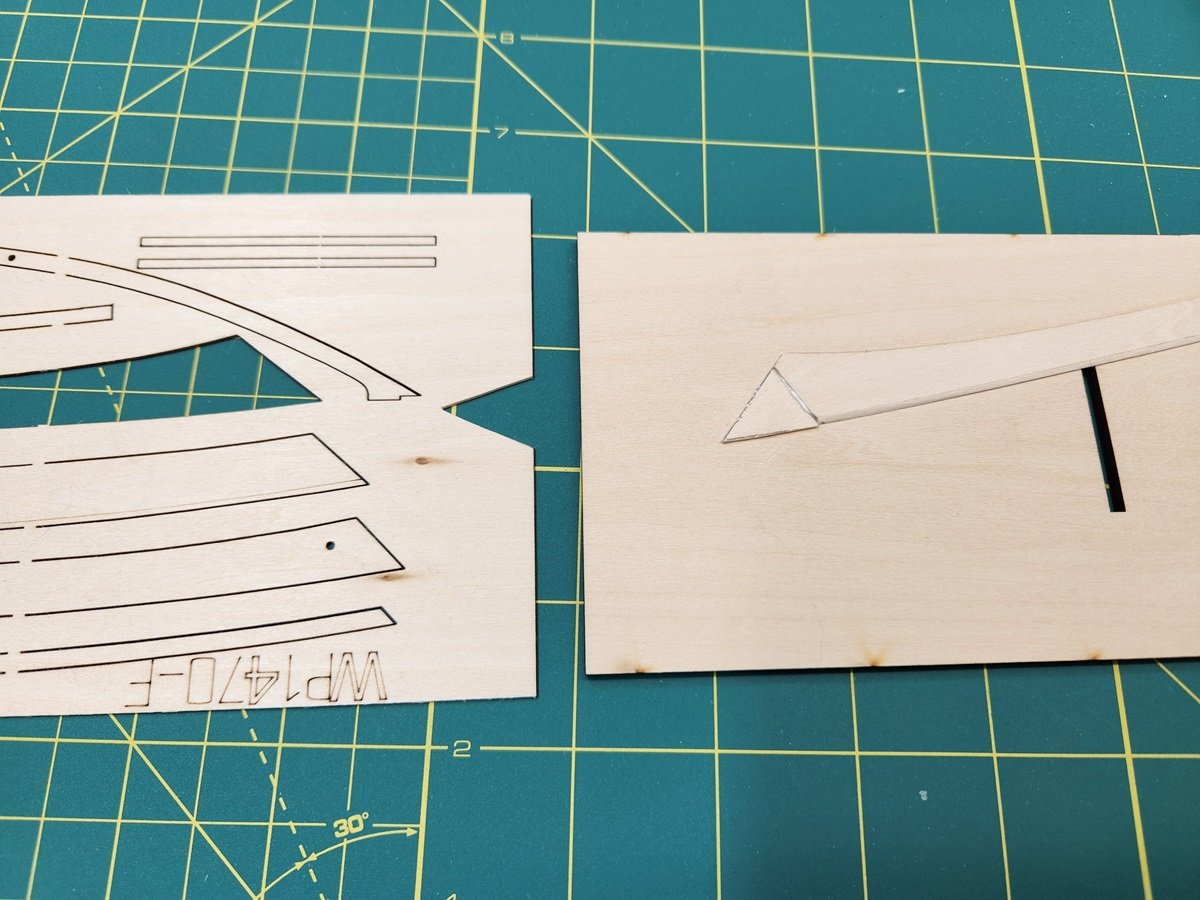

I went with some strips of basswood, filled in spaces in between and then sanded smooth for repair on the plank. Stern knee bevel filed,..then finished with sandpaper..and we're glued to the frame. Thats it for today....may look into the oars later tonight.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

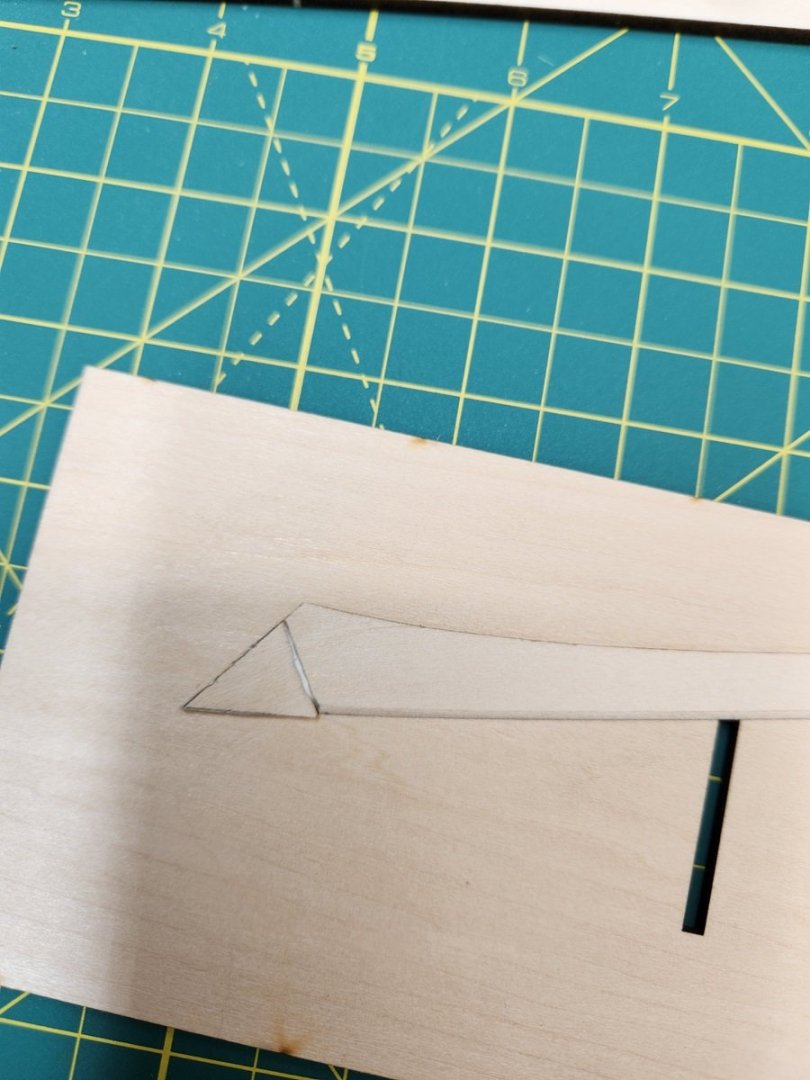

A little repair update...I'm still gonna piddle with some sort of patch for the plank...I don't think the joint will hold for any length of time when mounted to the frame.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

They've been adopted, I wish them well.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Not sure if the plank repair will hold,..may have to reinforce that a little somehow hidden best I can on the inside of the boat...We'll see what happens.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Been a bit delayed in progress. Had a little lightning strike a few weeks back and was busy lining out repairs here around the house. No real damage but it takes up time meeting with the contractors. So my wife adopted a stray cat not long ago...I have no problem with that but she then turned into 4 more cats 😏 long story short they had some time in my shop unsupervised and did some chewing on my Dory. Finally had time this evening to begin repairs. I'll fill in and sand out seams next week and we'll hopefully be back on track. Good news is I did score a Dory book for fathers day,...it's a keeper 👍 BTW the lightning strike holes are 24 and 30 inches deep respectively.

- 31 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Not sure what that is...lobster trap? Or something else..but it looks great. I've noticed several making their own "extras" to accompany their Dory builds.

- 69 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.