Cpt_Haddock

Members-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Cpt_Haddock

-

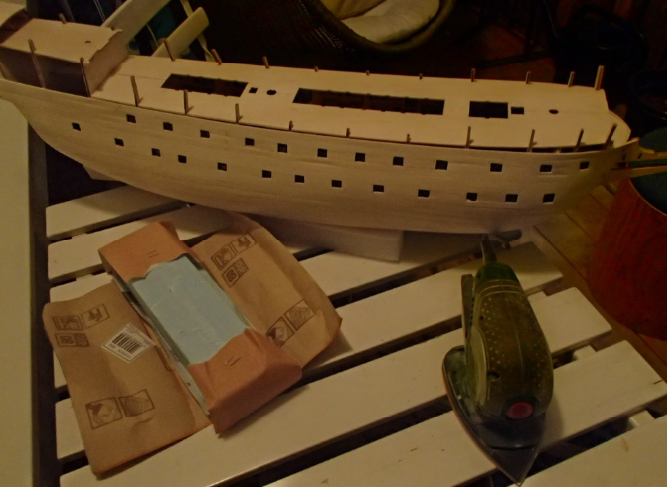

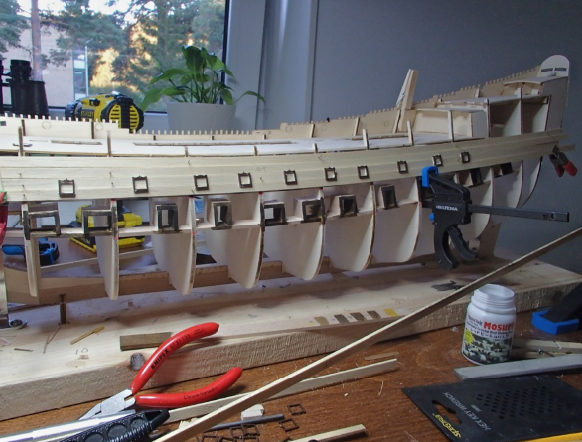

Some more pictures from planking the first layer: The lower part of the front got really tricky: One side done but one extra hole.. The non-symmetric placement of the cannon port can be seen here from the wreck: And then the same on the other side. The windows were soldered and the result was not perfect, maybe I should have gone with the kit plastic, below picture from the model at the museum: And the final board before sanding - I still have not attached the top sides. Some parts of the lower front came really thin after sanding it even. Progress bar (calendar time elapsed, roughly hours put in):

-

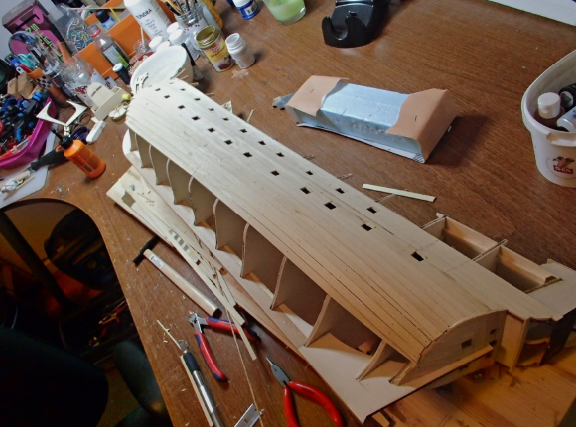

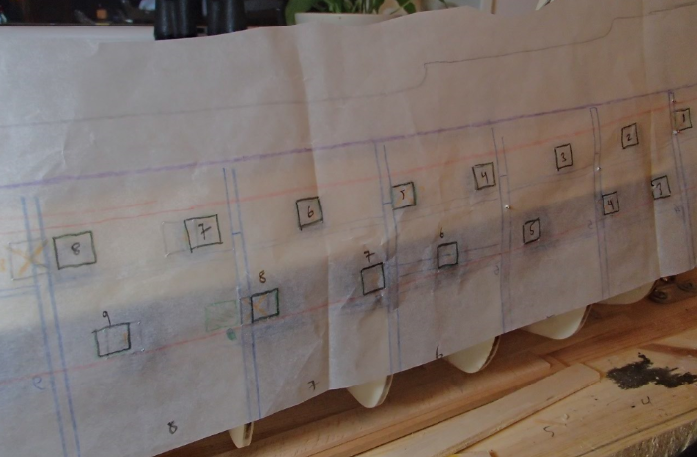

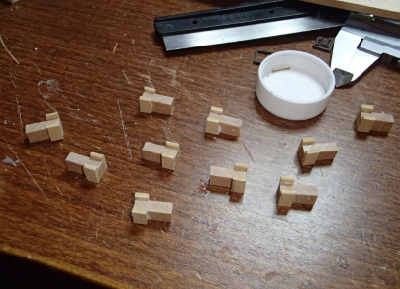

Thanks for your comments, yes I have been to the Museum and seen the amount of work they put in all the figures. The ship itself is kept in twilight (to protect the wood) and quite creepy - more like an old pirate ship. It is a sad story - building a ship with all that timber and then to sink on its first try on water. Figuring out the position of the ports: and making the "wagons" for the cannons. then continue planking: Among all the tools . I used this 1 1/2 inch Stanley (single) razer blade put in between a couple pieces of wood and found it very useful: And then cutting the holes:

-

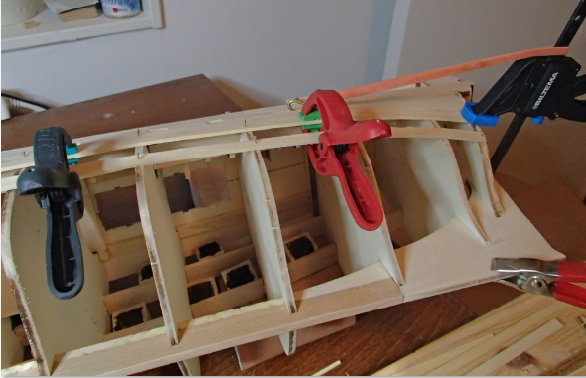

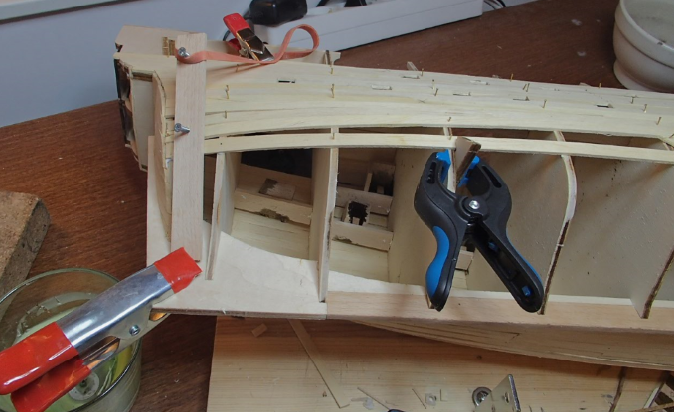

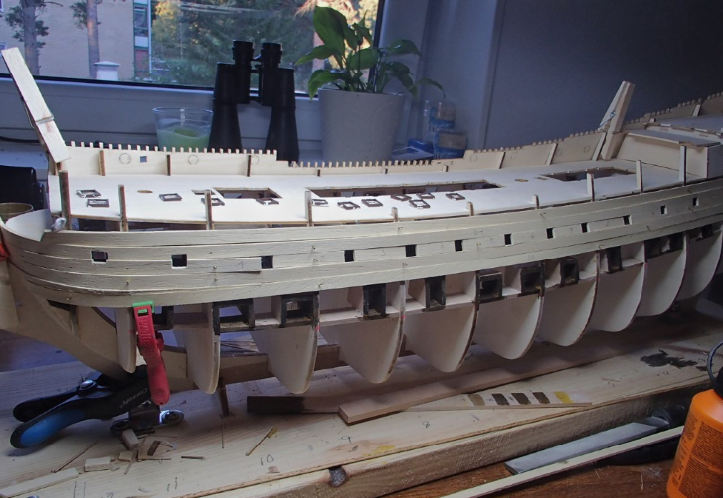

I put all the metal stuff in a bowl and mixed with vinegar to get the oxides. I notices that the canon holes on the lower level was "fake". I saw someone who made "real" holes and tried that. I made a mistake choosing some hard wood (beech) as building material. Later when i tried to drill though the planking the drill got stuck in this wood pieces. Some of these fell inside the ship. I then began the planking, starting from the top.

-

Some pictures, quite straight forward in the beginning. Bending the stern piece. The BB490 has the Blue color theme unlike the Stockholm museum ship model that has the red theme. I went along with the blue. It is blue in the book but with red fancy pansy "curtains" From "The Royal Warship VASA" From the model at the WASA museum I also decided to go with the gold instead of painting the small statues though not historically correct.

-

I am very happy to have found MSW and to get the energy and inspiration to build this ship. Thanks to fmodajr and md1400cs. The WASA ship section below (unknown fabricator - prob. Billing boats) - was built in the early 90s and I mostly remember the tedious work cutting all pieces by hand (not laser cut) from wood panels. It took two years to build the main part and then another 4-5 years until the rigging was finished. Most of the time the build was put away waiting for me building up confidence to finish the model. This time I had the opportunity to have a dedicated work space, were the model could rest when no work was being done, and laser cut pieces. I though replaced the keel with a solid wood bit due to poor quality plywood. I had read that the foundation was a key to get the hull planking go easy. I tried to follow the instructions but later I found the book by Björn Landström "The Royal Warship VASA" from 1980 (ISBN 91-86448-12-9) and I ended up with some "creative" planking pattern compared with the images in this book. I was very close to mix two of the mid pieces before cluing them on the keel.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.