Fentone

-

Posts

47 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Fentone

-

-

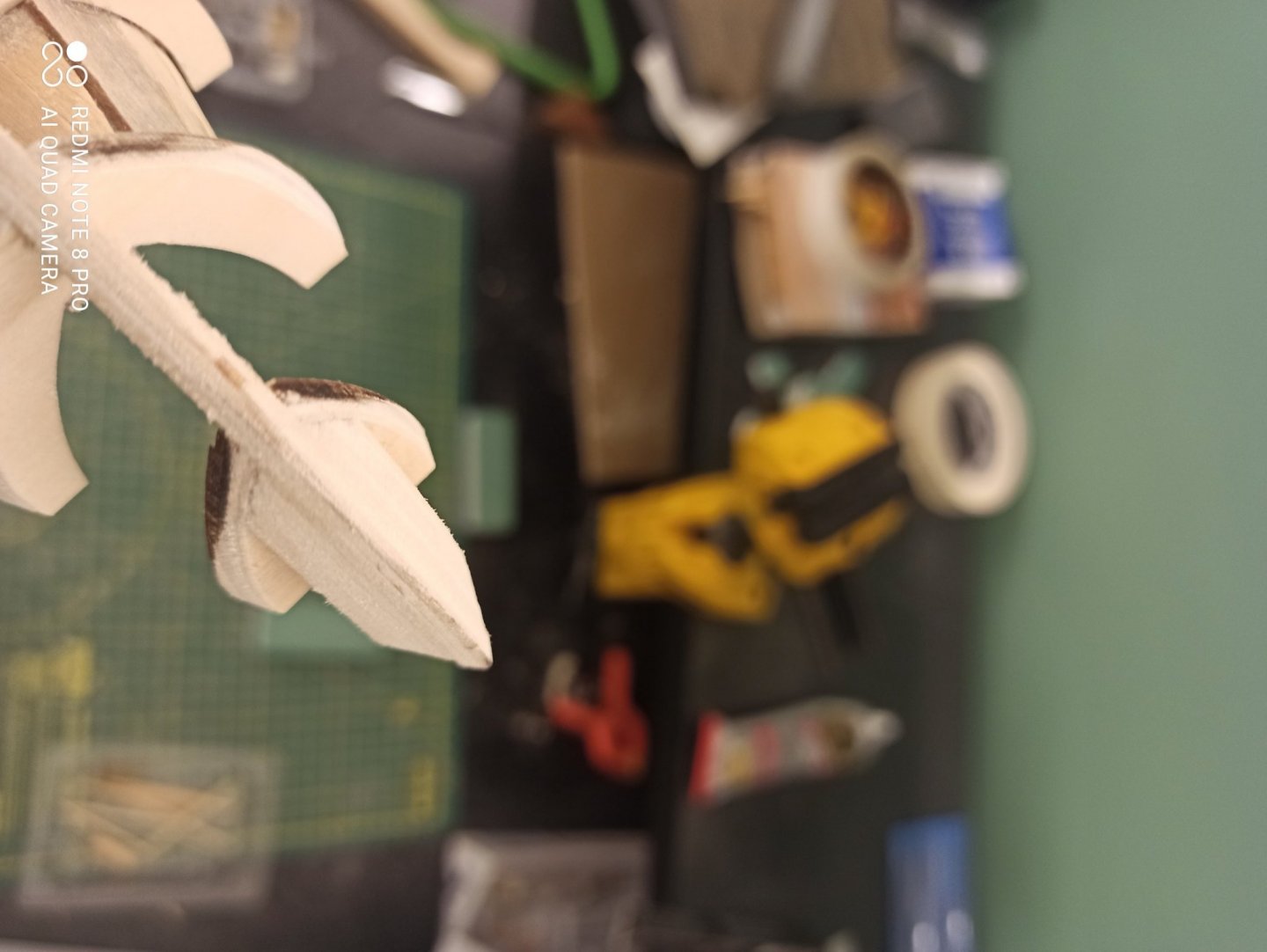

Cutting with scalpel was easy, however sanding cleaned it up somewhat. Overall result not great, not terrible. Bow/stern taper end in slightly different places, however I'm reluctant to take any more off as I'm happy with the port/starboard symmetry, and I'm happy for the boat not to be perfectly symmetrical end to end.

-

-

-

Thanks for the help Mike, I will read those resources before continuing.

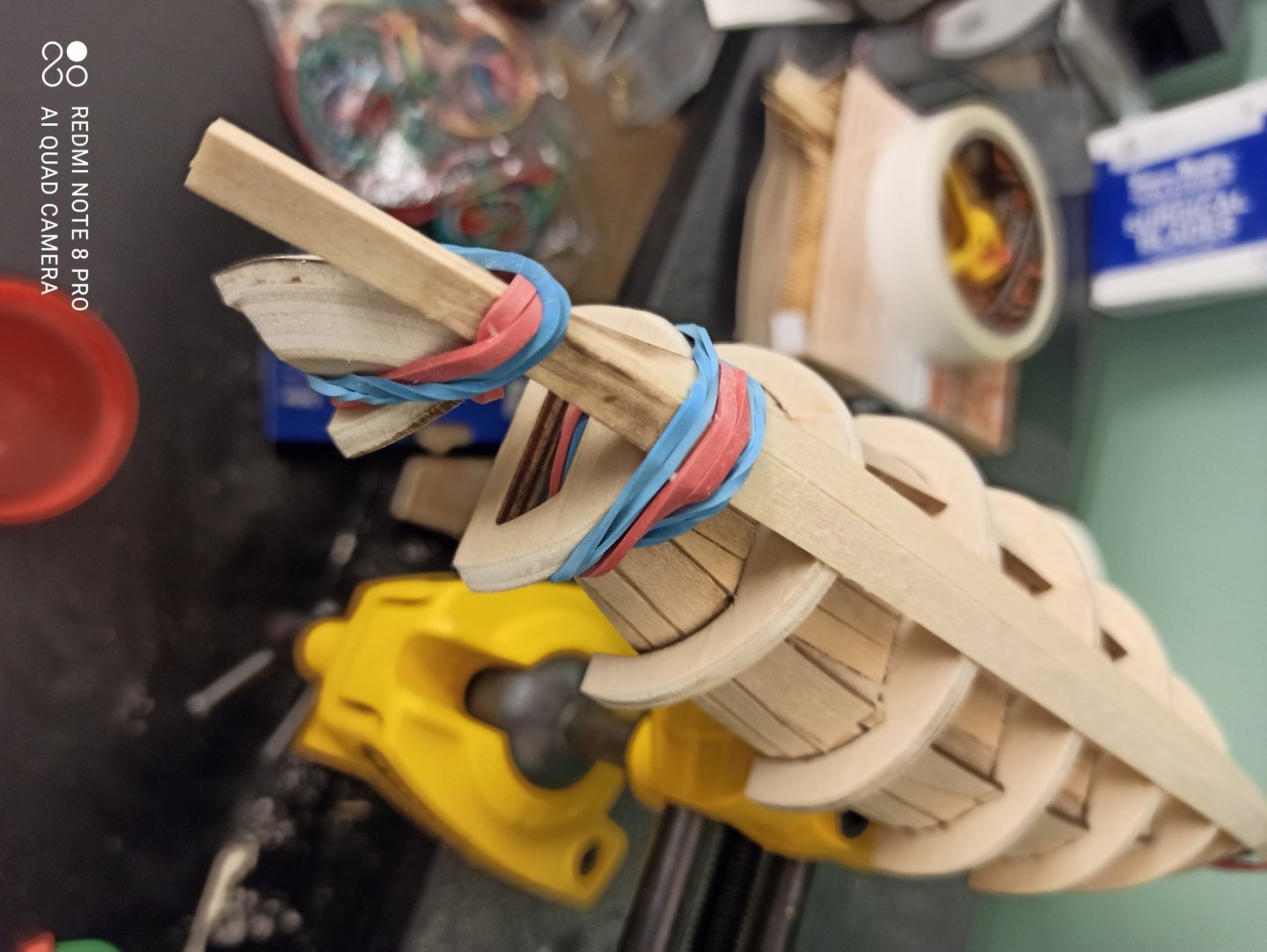

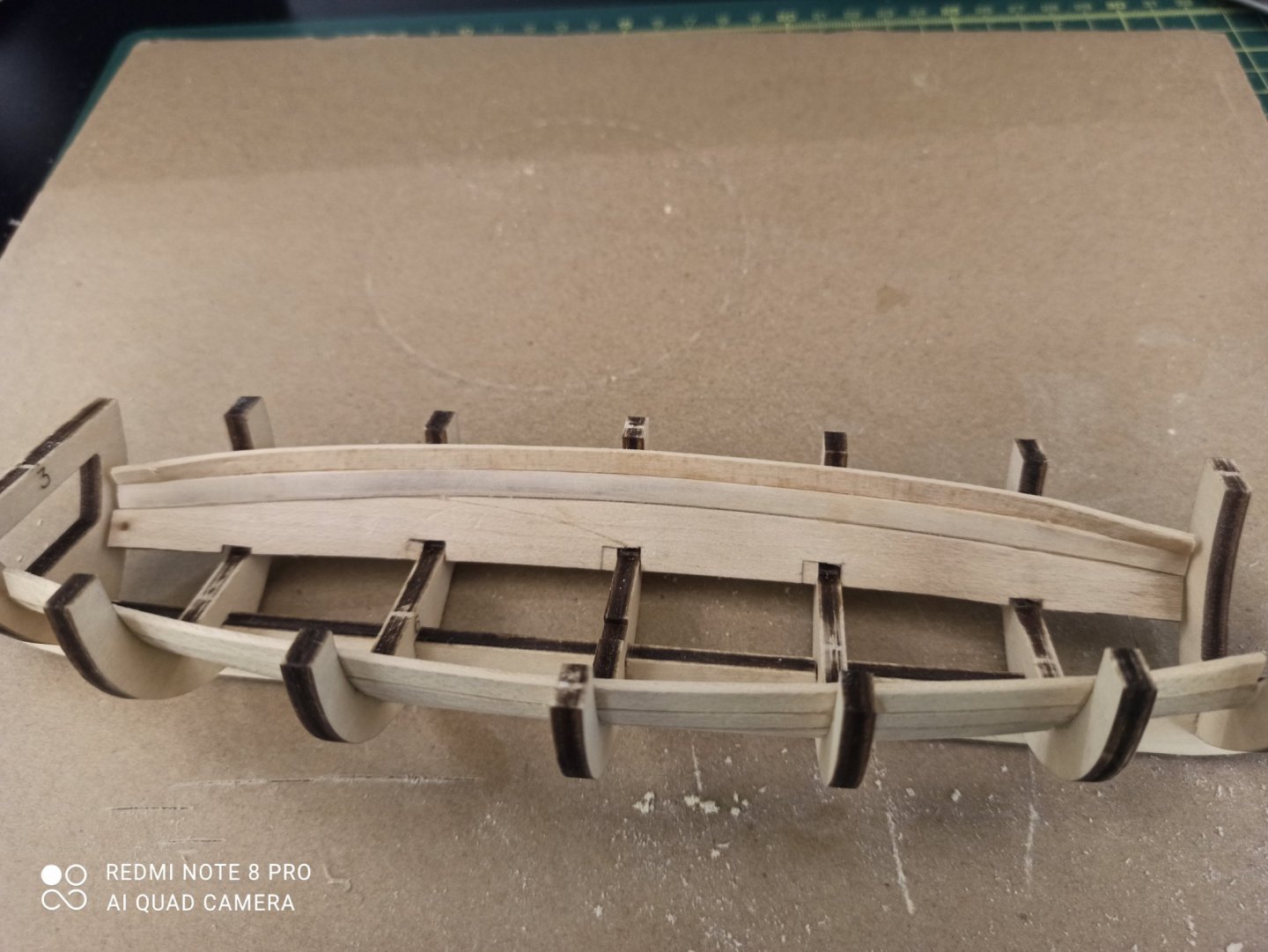

However I have run into a mistake - I should have bent and cut the ends of these two planks before gluing. Somehow I misinterpreted the photo in modeller_massa's build to think he was doing what I've just done. So I'm going to attempt bending these planks in situ, maybe after soaking the tips in water so they draw it up through capillary action. This may be a terrible idea. But I want to find out. I am less worried about cutting, as I think patience and a million cuts of the scalpel will do the job. However before this can happen I need to repair a couple of fractures I accidentally made to the keel at both ends in the previous step, hence the two rubber bands.

- G.L. and Keithbrad80

-

2

2

-

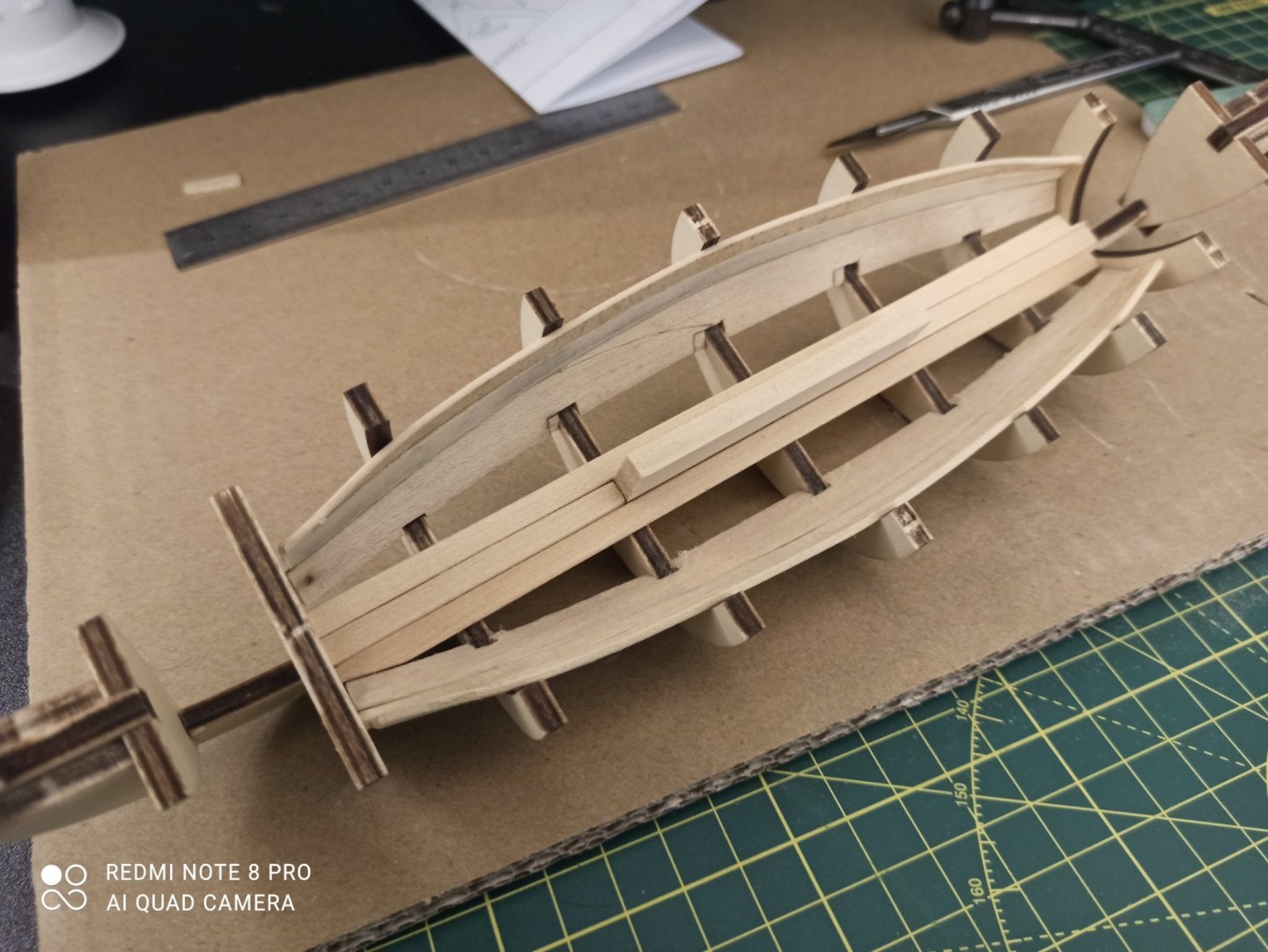

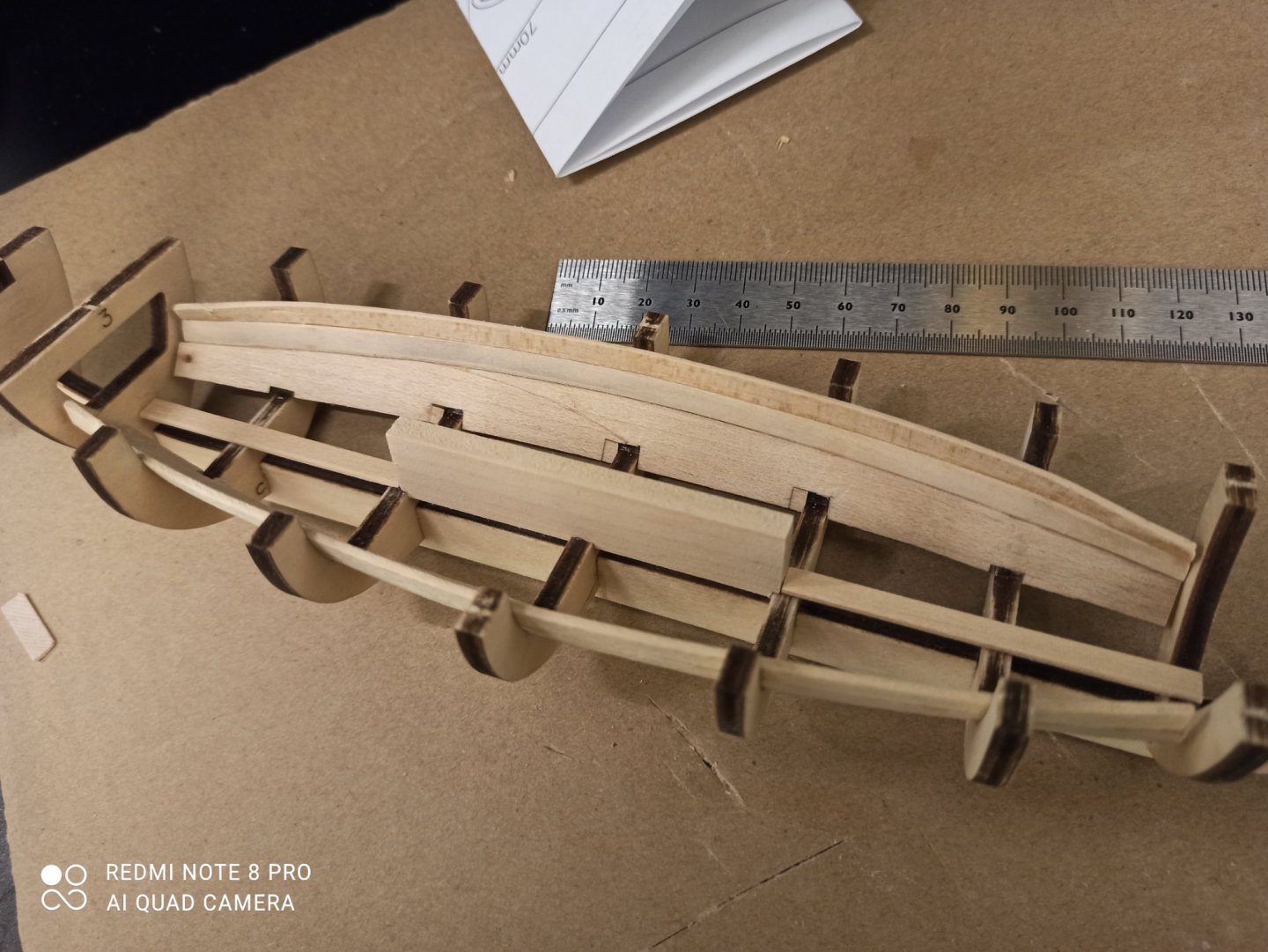

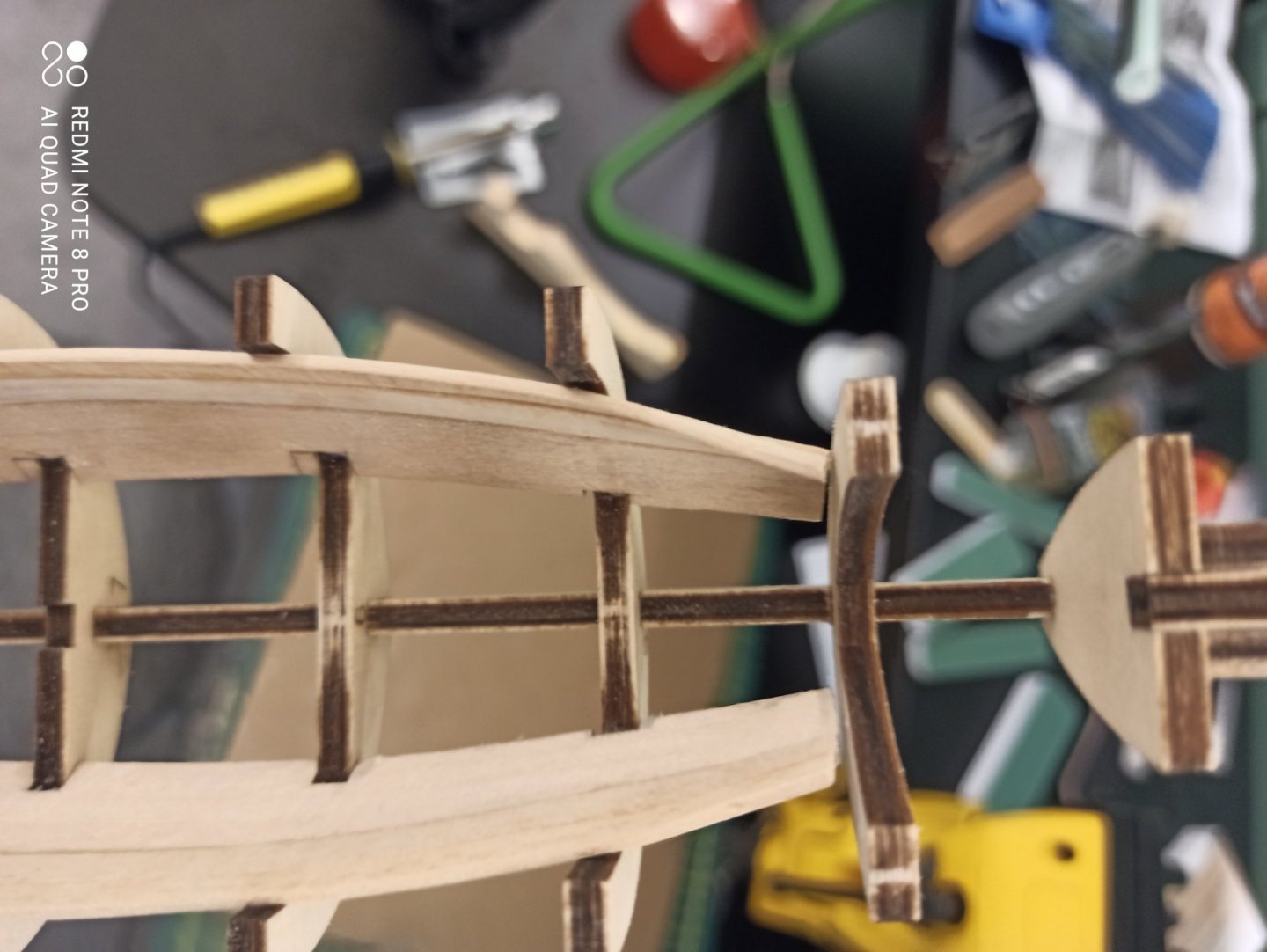

I had a setback. It was time to glue the first two external planks on. I couldn't find a clamp large enough for holding these two planks. They need to be clamped all the way through the depth of the entire boat, and sort of pushed together at the same time. So I decided to use contact adhesive for the quick drying properties and hold them with my fingers, not having enough hands I had to go through each bulkhead in turn and give it a squeeze. After 20 minutes of this I squeezed a little too tight and they fell right off, and I realised they had barely adhered at all. But now the glue had set into its feeble rubbery bond and needed reapplying. I went through the whole process again for the same thing to happen. So I had a look at modeller_massa's build log for inspiration. He used rubber bands for this step. I ordered a big bag from Amazon. The next day I sanded all the CA off both surfaces and tried again using my beloved Gorilla Wood Glue and the rubber bands. Great success! P.s. I wasn't sure whether these external planks needed bevelling. There is NO mention of doing so in the instructions, and as modeller_massa appeared not to, I didn't either.

-

- Keithbrad80, bruce d and G.L.

-

3

3

-

- bruce d, Keithbrad80, G.L. and 1 other

-

4

4

-

- Keithbrad80 and G.L.

-

2

2

-

Not shelved at all! The next step was sanding the sort of overall curve shape to the bulkheads. It took ages! I would pick it up, do a little sanding, put it down again. There was a lot of material to take off. And that every slow unfocused approach took basically two weeks. I'm about to apply the first two outer planks, and a little confused by the instructions. Will seek out some other build logs and return.

-

I have issues. Started the side planks too high so now have these ugly holes. The Admiral says "That's alright, those are holes to drain the water". I don't like them. But can live with them if necessary. Any solution ideas? Putty of some kind? P.s. note to self in the future: could have easily prevented this at floor planking stage by some strips on the bulkheads to raise the floor.

-

-

-

An staggering attention to detail, Mike. The 'nails' look terrific, and I really like the color scheme.

-

That hull looks delicious, Bradley.

-

18 hours ago, Mike_In_RI said:

I've read that you have tried different glues. What glue are you using for general use? Some wood glues set up pretty quickly by just applying finger pressure for a minute or so as long as the bends are mild. One can use the time to think about the next piece.

Gorilla wood glue (PVA) where possible. For the interior planks I'm using Gorilla Contact Adhesive as the clamps don't reach that far.

-

-

-

-

-

-

Thanks once again for such help and encouragement. I will look into the dividers, I can see the big problem with my build so far is symmetry. I've seen the point of CA now, it's useful for places where it's near impossible to clamp. It does build up and leave a solid bump though. Used it for these two floor planks today:

-

-

Step 2 complete. On this last plank I had to compensate for height difference with the opposite side of the boat by sanding it right down along its length. Also for some reason, the clamps decided to crush/fold the tips right over this time. Either because I made this plank thinner, or because I didn't soak it quite as long, not sure. Hopefully invisible later.

-

I've just realised the obvious answer. Should bend them, THEN cut them. DOH!

Providence by Fentone - Artesania Latina - 1:25 - New England whaleboat

in - Kit build logs for subjects built from 1851 - 1900

Posted

One end got a bit gnarlier than the other. Notice the slight difference in length. Could have gone a lot worse given the method.