KurtH

Members-

Posts

364 -

Joined

-

Last visited

-

KurtH reacted to a post in a topic:

HMS Speedy by usedtosail - Vanguard Models - Scale 1:64

KurtH reacted to a post in a topic:

HMS Speedy by usedtosail - Vanguard Models - Scale 1:64

-

allanyed reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

allanyed reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

mugje reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

mugje reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

mugje reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

mugje reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

Mr Whippy reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

Mr Whippy reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

KurtH reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

KurtH reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

-

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

-

KurtH reacted to a post in a topic:

HMS Flirt by wvdhee - Vanguard Models - 1:64

KurtH reacted to a post in a topic:

HMS Flirt by wvdhee - Vanguard Models - 1:64

-

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

KurtH reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

KurtH reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

KurtH reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

rcweir reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

rcweir reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

mugje reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

mugje reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

DonSangria reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

DonSangria reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

JacquesCousteau reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

JacquesCousteau reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

chris watton reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

chris watton reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

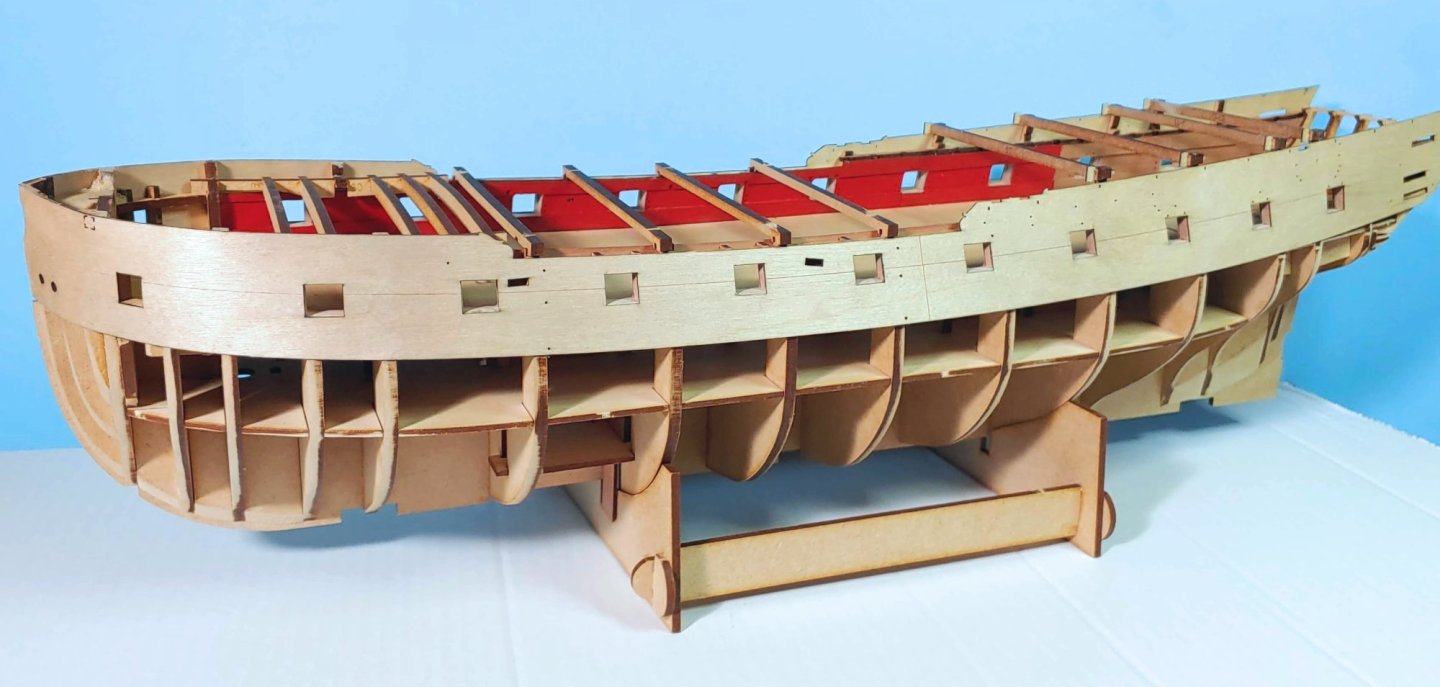

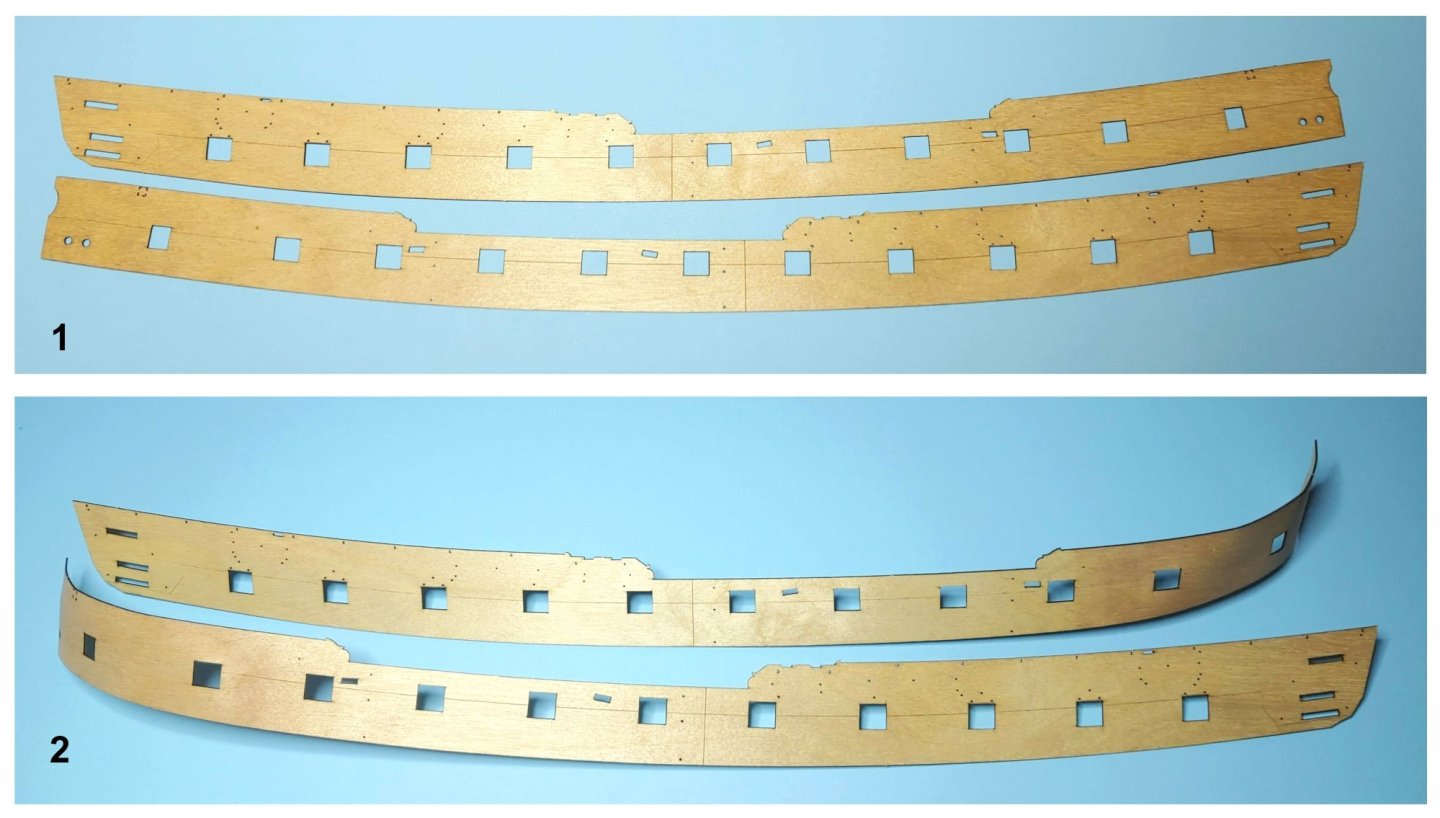

The next step is to install the ply upper hull side patterns: 1. Upper hull side patterns 2. Upper hull side patterns after having been soaked in hot water for 90 minutes and clamped to the hull. Upper hull side patterns installed: Next comes the first hull planking. I did hull planking down to the waterline in my BJ Connie build, but this will be my first foray into planking below the waterline. There are many methods and philosophies as to how this should be done, but I am inclined to go with what is described in the manual. I would like to proceed as if this were the final planking to get the practice of exacting tapering and bending so that when I actually do the second layer, I will have learned some lessons and will be in a position to do my best. I anticipate using filler to fill in dips and hollows but not the small gaps between strakes, as the final layer will hide these.

-

KurtH reacted to a post in a topic:

1921 Bluenose by John Ruy - Model Shipways Kit No. MS2130 - 1/64 scale - Canadian Fishing Schooner

KurtH reacted to a post in a topic:

1921 Bluenose by John Ruy - Model Shipways Kit No. MS2130 - 1/64 scale - Canadian Fishing Schooner

-

SUBaron reacted to a post in a topic:

USS Constitution by KurtH - FINISHED - BlueJacket Shipcrafters - 1/96 - First wood model kit

SUBaron reacted to a post in a topic:

USS Constitution by KurtH - FINISHED - BlueJacket Shipcrafters - 1/96 - First wood model kit

-

Thank you Geoff. I greatly appreciate the compliment! I have just looked at your build. Wow!!!

- 110 replies

-

- Bluejacket Shipcrafters

- Constitution

-

(and 2 more)

Tagged with:

-

I have only just now checked on my build log and found some new and most rewarding comments! Thank you Dom Fischli for your kind words. I have found that debonder does a good job of diluting the CA although I have not tried it in quite the same situation that you describe. Thank you Blue Ensign for your compliments. I have spent a great deal of time looking at your builds and have the greatest admiration for your work as do many other modelers. Your comments mean a great deal to me! Incidentally, I plan to add lodging knees to the quarter deck scantlings in much the same way that you did. I can only aspire to do as well.

- 110 replies

-

- Bluejacket Shipcrafters

- Constitution

-

(and 2 more)

Tagged with:

-

Thanks Rich! I appreciate the info. I also have a couple of books on the subject - one by Donald Dressel, and one by Kieth Julier. An alternative to measuring and dividing is described by Chris Watton and James Hatch in the instruction book. It is good to have a variety of techniques available to consider. I will take my time and think carefully before I proceed. As there are two layers of planking, I can try one way on the first one, and, if that does not produce a good result, I can try another way on the second.

-

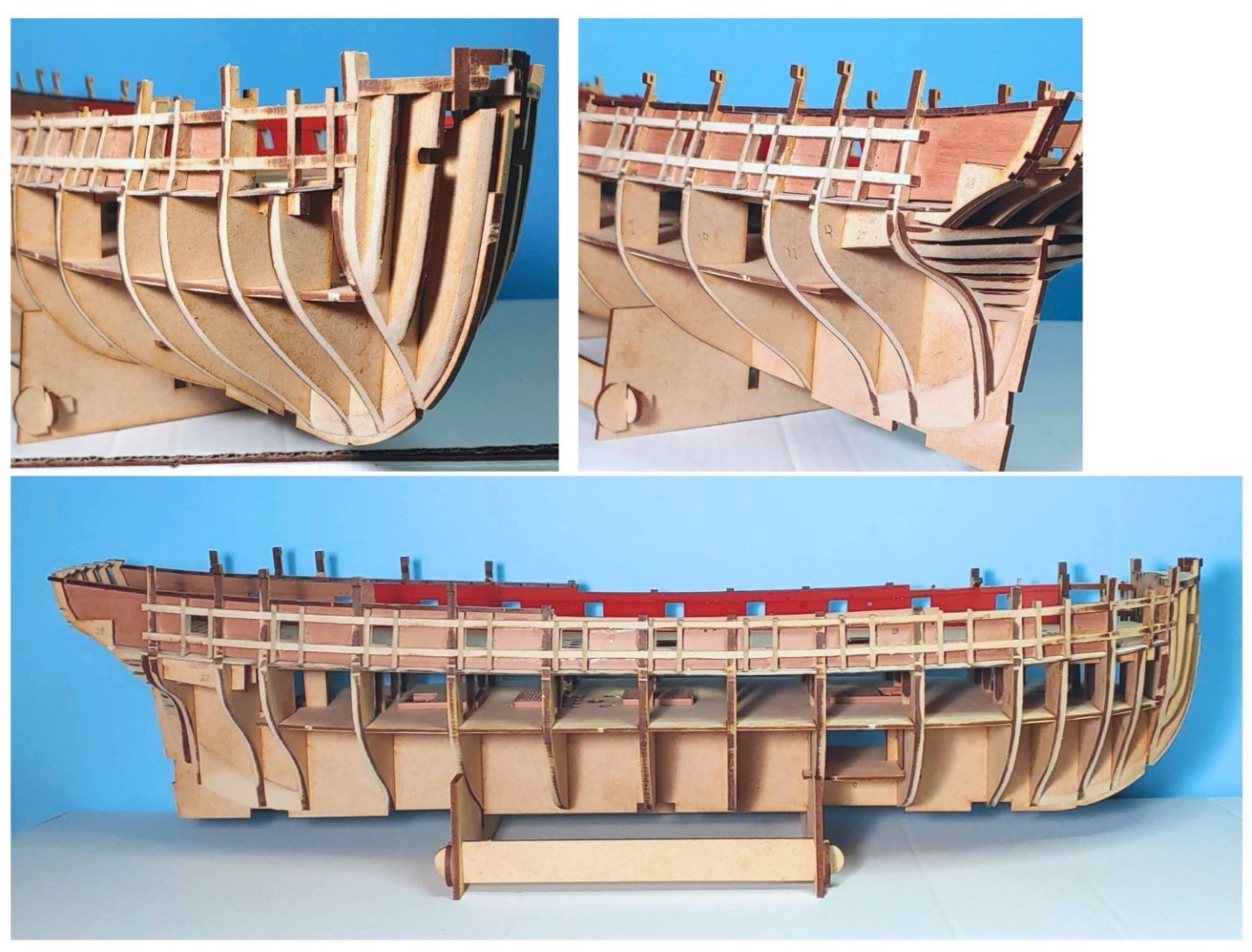

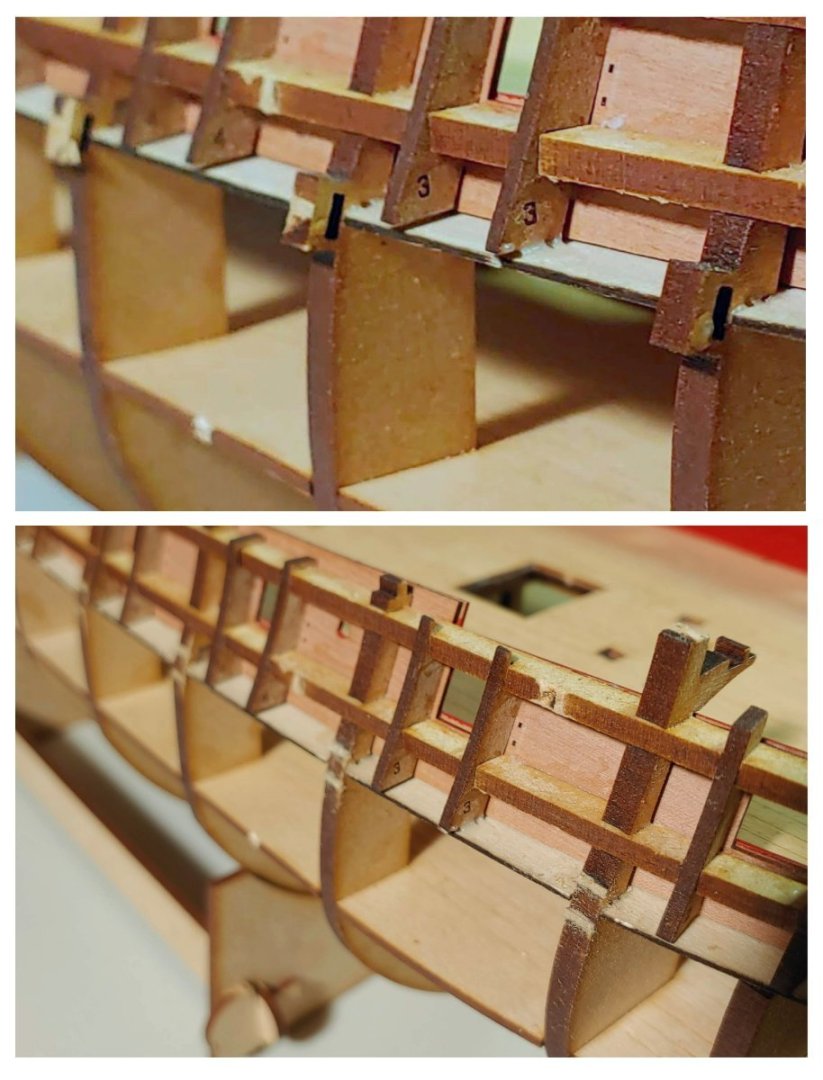

This is my idea of the fairing of the hull. It is my first attempt, so I will not know for sure how well I did until planking commences. Based on what I could determine using card stock strips, I should be OK, but we'll see. The advantage that I see of a plank on bulkhead arrangement as apposed to a solid hull kit is that accuracy of the hull shape is assured as long as the shape of the bulkheads is not altered. To begin with, I sanded the components making up the bulwarks flush with the bulkhead ears. To avoid taking off too much material below the deck level, I left a thin line of char on the aft edge of the forward bulkheads and on the forward edge of the aft bulkheads. This may reduce the bearing surface somewhat when the planks are glued in place, but I think it should still be sufficient given how strong the bonds have proven to be using PVA on MDF and pear. I used my own technique for getting the angles right on each part of each bulkhead, which I am reluctant to describe until I am sure that it worked. It is time consuming, and I am sure that experienced modelers could do just as well much faster. I just did not trust myself to get it right doing it quickly. The process did not take three weeks however. There were other delaying factors which I need not go into. At any rate, here are shots of what I have done:

-

Hi Gary. I varnished that deck with the recommended Vallejo Matt Acrylic Varnish to protect it. The fact that little of it will be seen was an advantage for me, as I am inexperienced when it comes to finishing, and I wanted to see what the result would be. I do not see why WOP would not do as well if not better, but what do I know? Fortunately there are many modelers who are expert finishers who would be glad to give you good advice.

-

Gary - I have seen several other builds in which the boats were done first (I forget which). In most other boat builds, the frames serve as the ribs of the boat, and you break out a center piece. In the Sphinx boats the whole piece except the bottom comes out and ribs are added subsequently. I am guessing that you glue the planks to the stem and stern post and to each other edge to edge, avoiding gluing them to the frames. Am I right? Your boats look really good! I can only aspire to do as well.

-

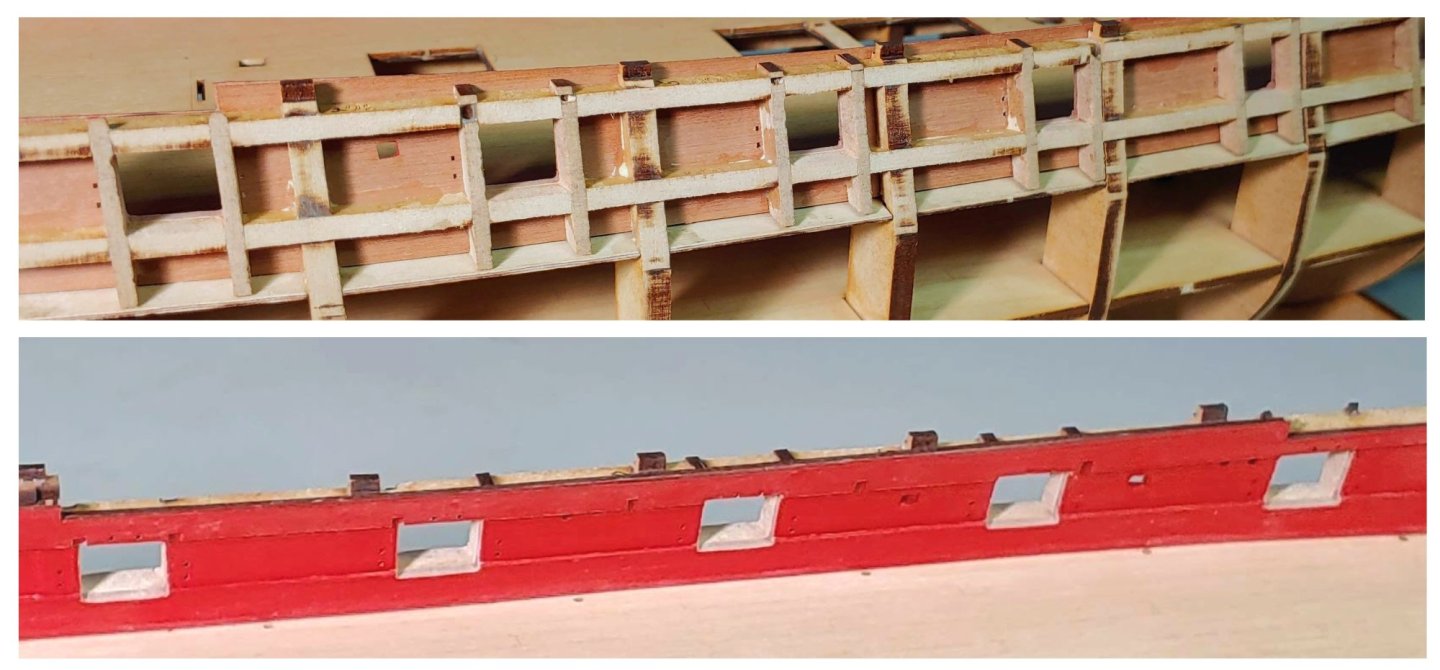

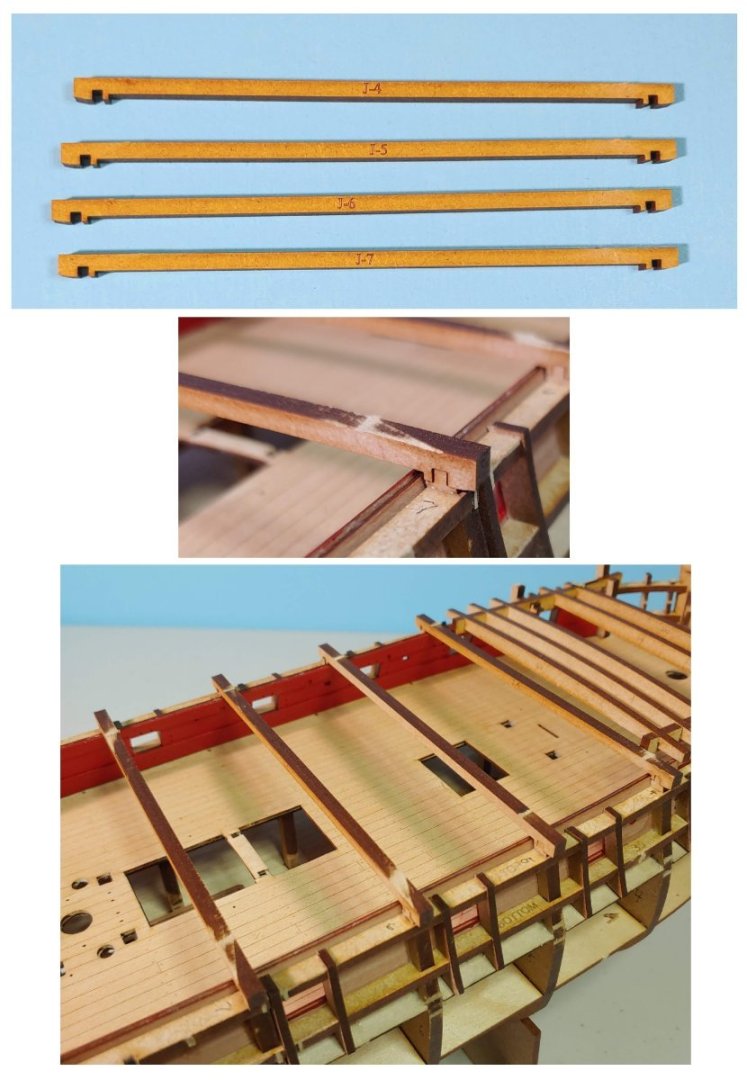

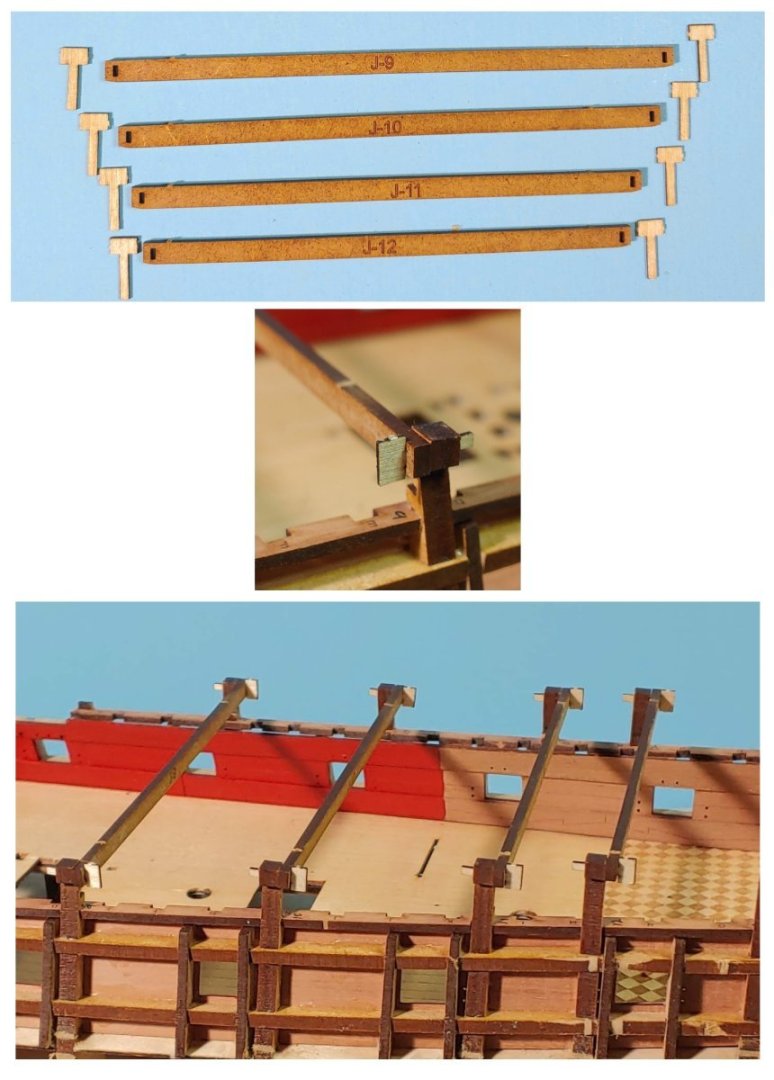

The next step is to remove the gates which strengthened the bulkhead ears because they are no longer needed, and because they will obstruct installation of the upper hull side patterns. Here is a before and an after pic: Time to construct and fit the jigs which will keep the bulwarks properly aligned as work on the upper hull planking details progresses. This composite photo shows the component pieces of the forecastle jig unit, and how the assembled structure looks when slotted into position. As you can see, the parts are all engraved with letters which guide you when assembling the unit. This parts fit together easily and precisely. but, as I was dry fitting the beams into the side pieces (#30) to check the fit, the port unit gave way at the "U" notch. It seems that these pieces are vulnerable at that point, so caution is needed there. I glued the joint back together with PVA, and reinforced it with one of the extra keys provided in the kit. The jig beams at the waist have notches which fit over tabs in the longitudinal gun port frames. The numbers engraved on the beams match the bulkhead numbers. The J stands for jig. Again, the fit is precise. The jig beams at the quarter deck are secured to the bulkhead ears with the afore mentioned ply keys. A number of extras are thoughtfully provided in the kit. I glued these into the beams to keep them from getting lost when the jigs are not in use. I was, of course, very careful not to let any glue get to the tongue which engages the bulkhead ears. The glue was allowed to set and dry with these tongues partially inserted into the ear slots to ensure exact alignment. It works. I checked. The numbers engraved on the beams match the numbers on the bulkheads the ears to which these beams attach. Here is the current state of play: No deck planking detail is visible in the photo but, as I have previously demonstrated, it is there. Like the Nazca Lines of Peru, these details look a lot better when viewed from above. Now to begin fairing the hull. I have no experience at this, so I intend to proceed slowly and carefully. It may be some time before I post again.

-

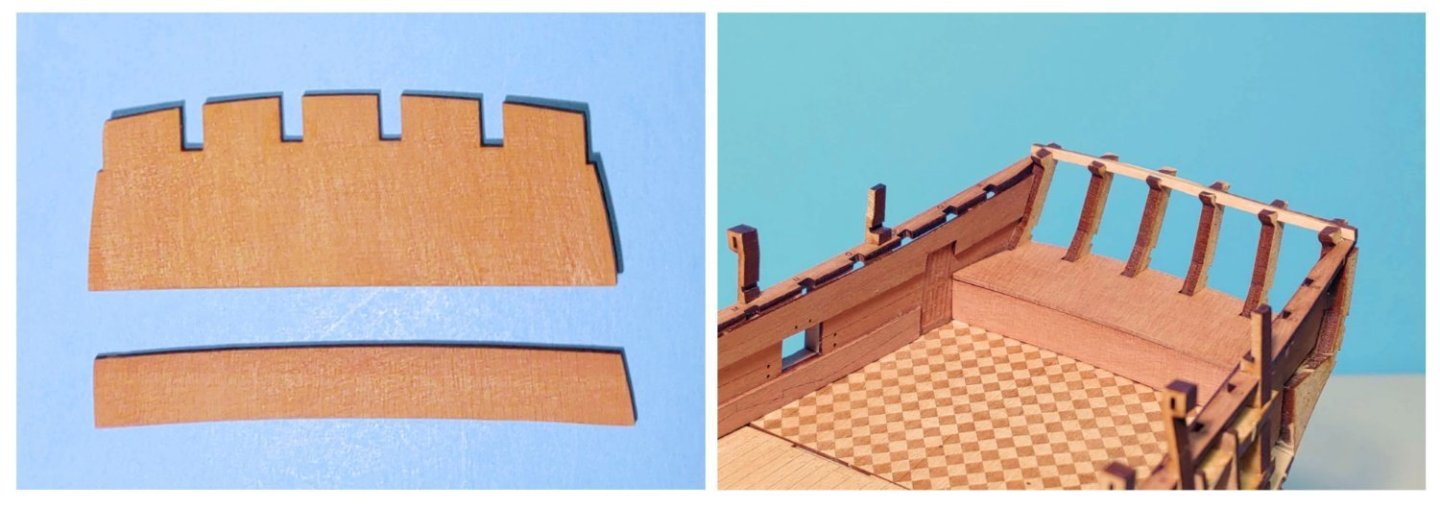

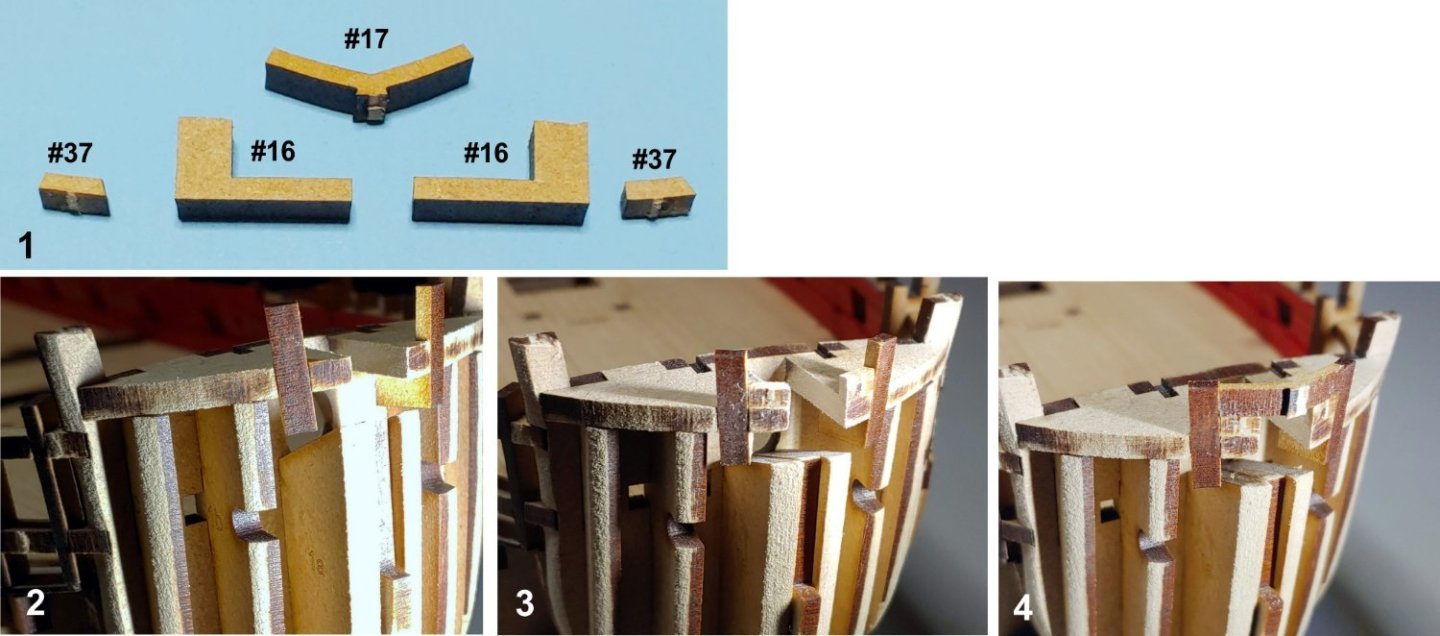

The stern cabin bulkhead pattern and the stern cabin seat pattern are removed from their sheet, varnished, then glued into place: 1. The forecastle bulwark bulkhead patterns removed from their sheet. 2. Parts #16 are glued into notches in the bow curve pattern. 3. Parts #37 are glued into place. 4. Part #17 glued into place. Thinking ahead, I tried fitting the dowel which will be the bowsprit stub into the slot before adding all those little delicate parts. The dowel was a bit too big, so I widened the slot slightly to accommodate it. I dry fit the bowsprit step and fettled a bit until the dowel fit nicely. I figured that doing this now would be easier then doing it when the time came.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.