-

Posts

121 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JLong

-

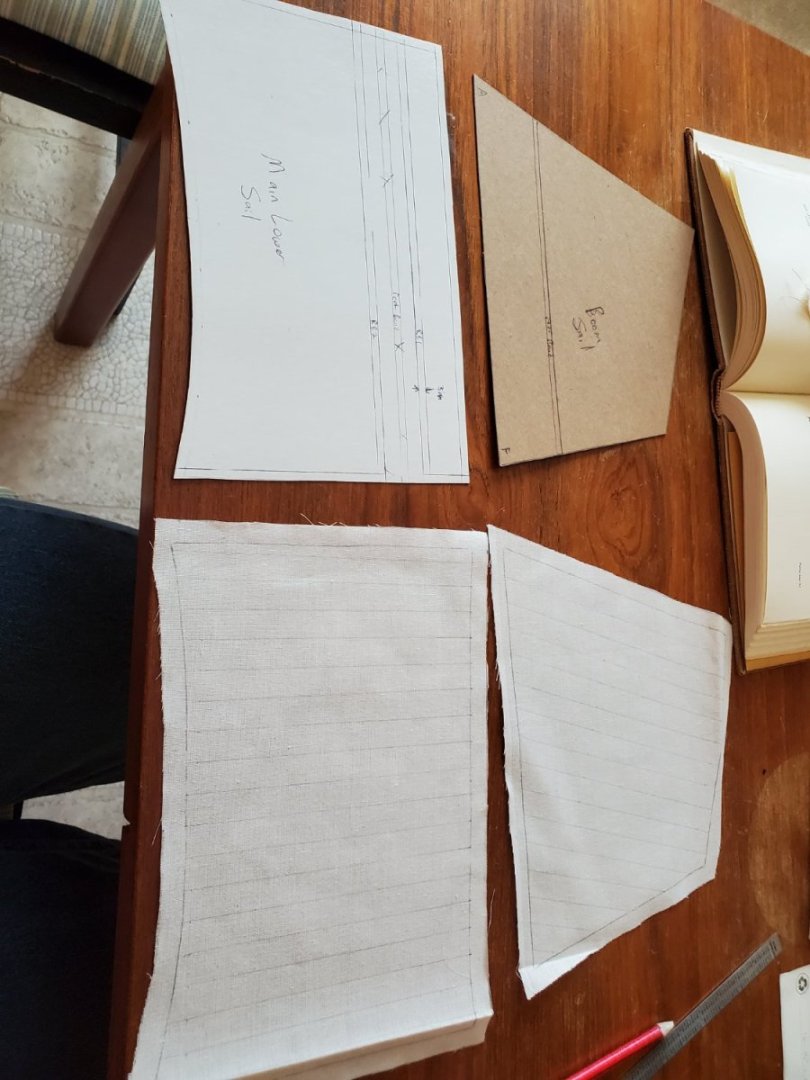

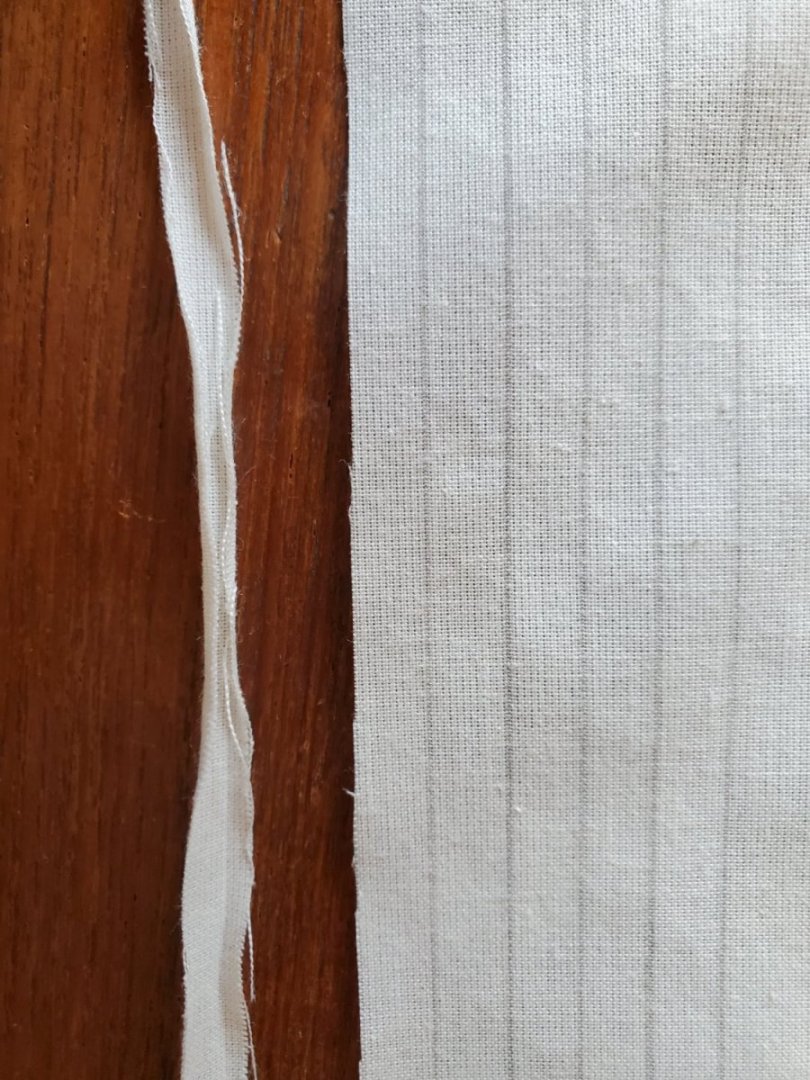

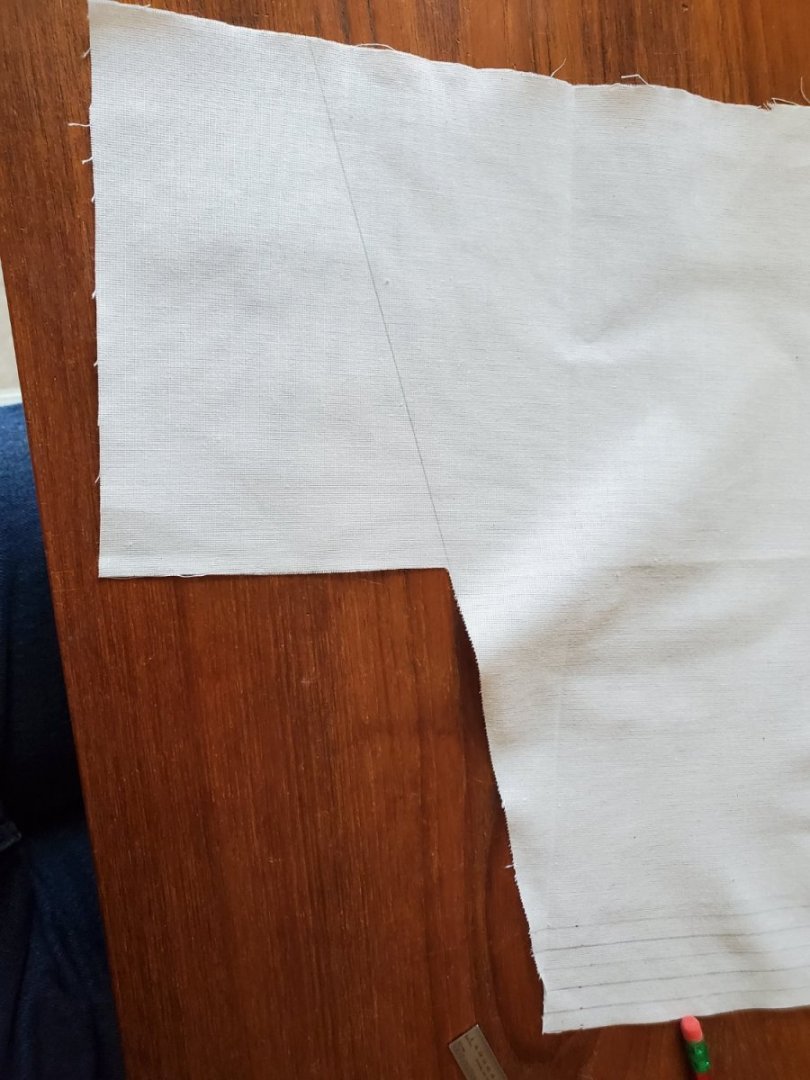

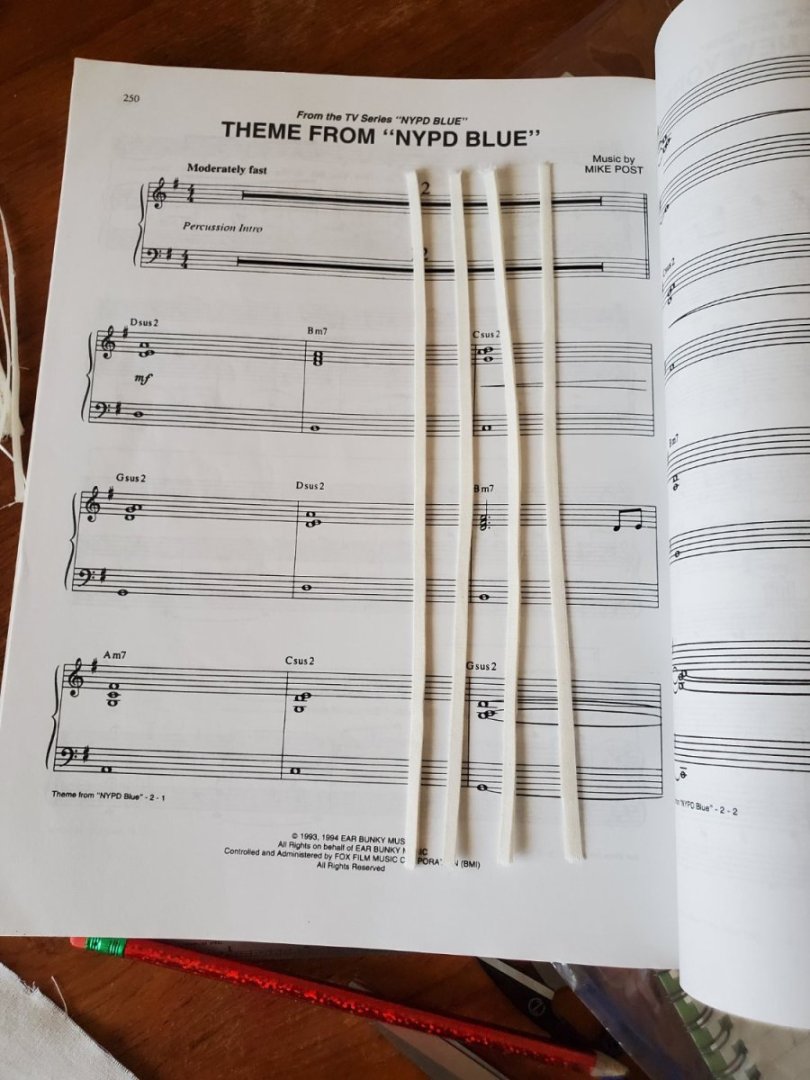

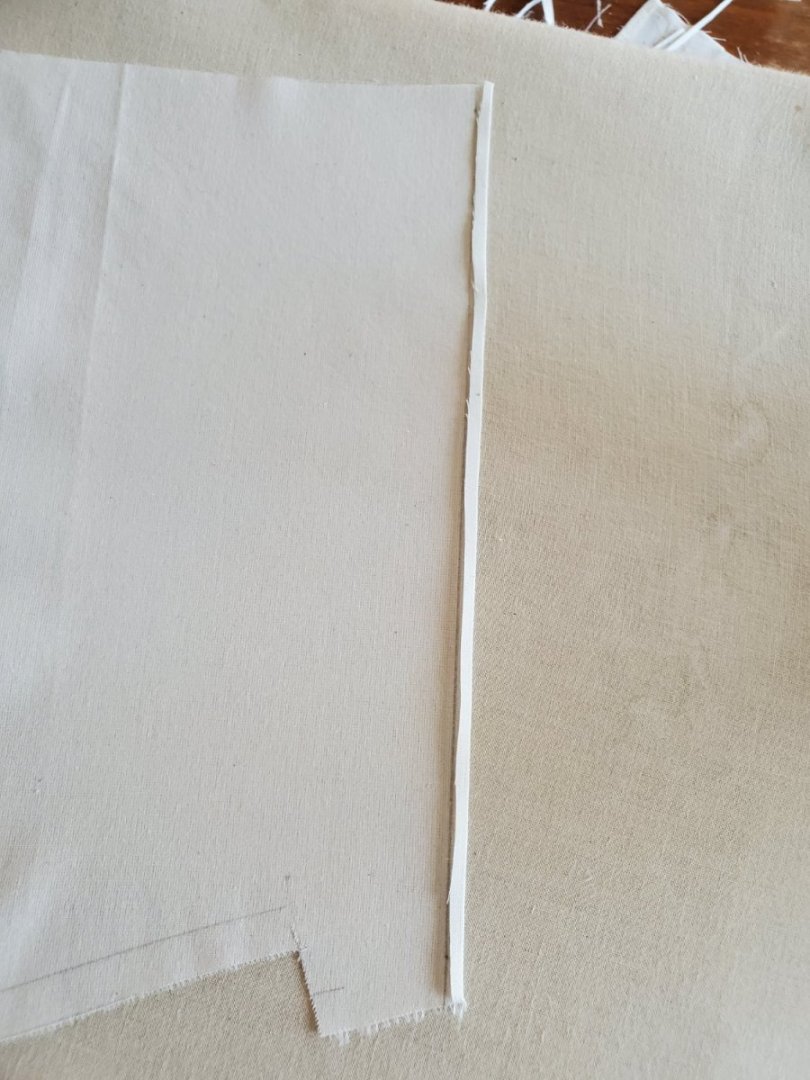

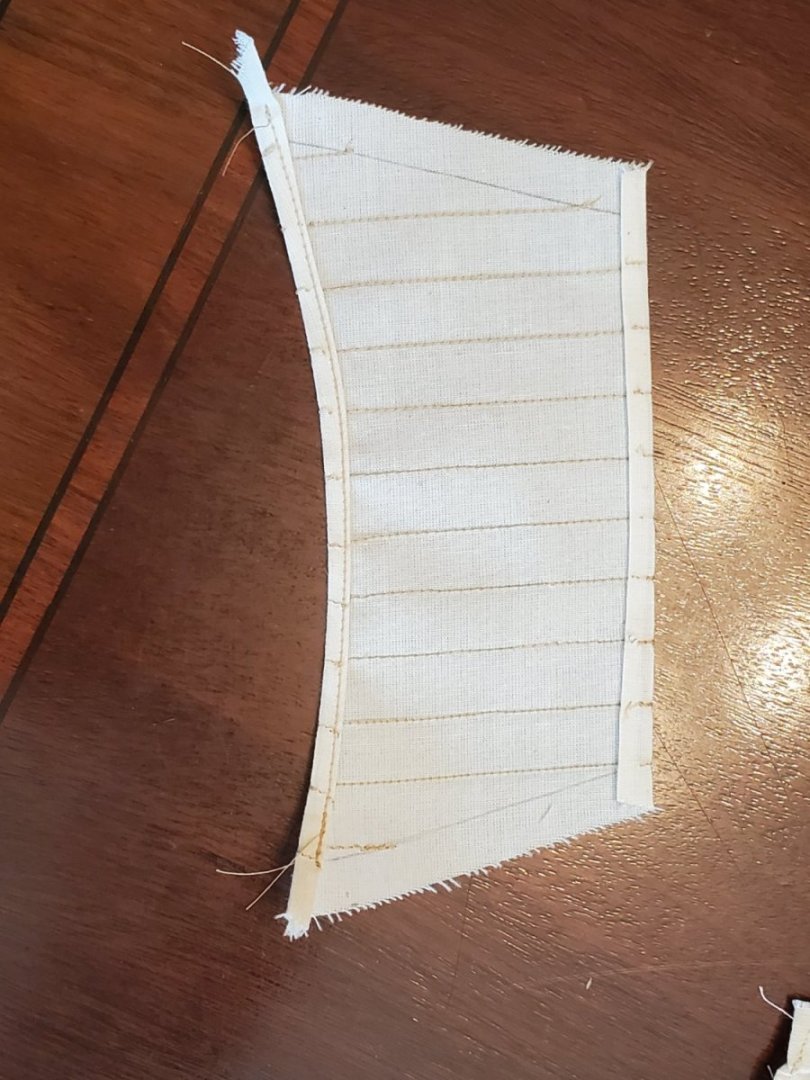

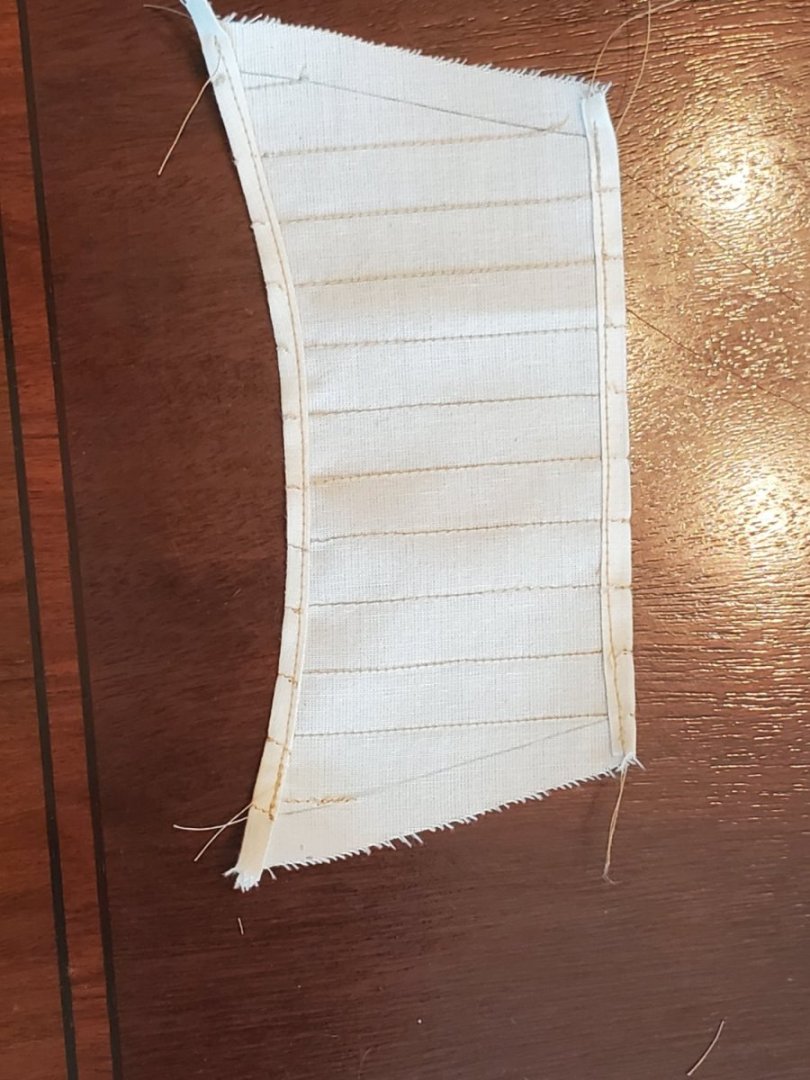

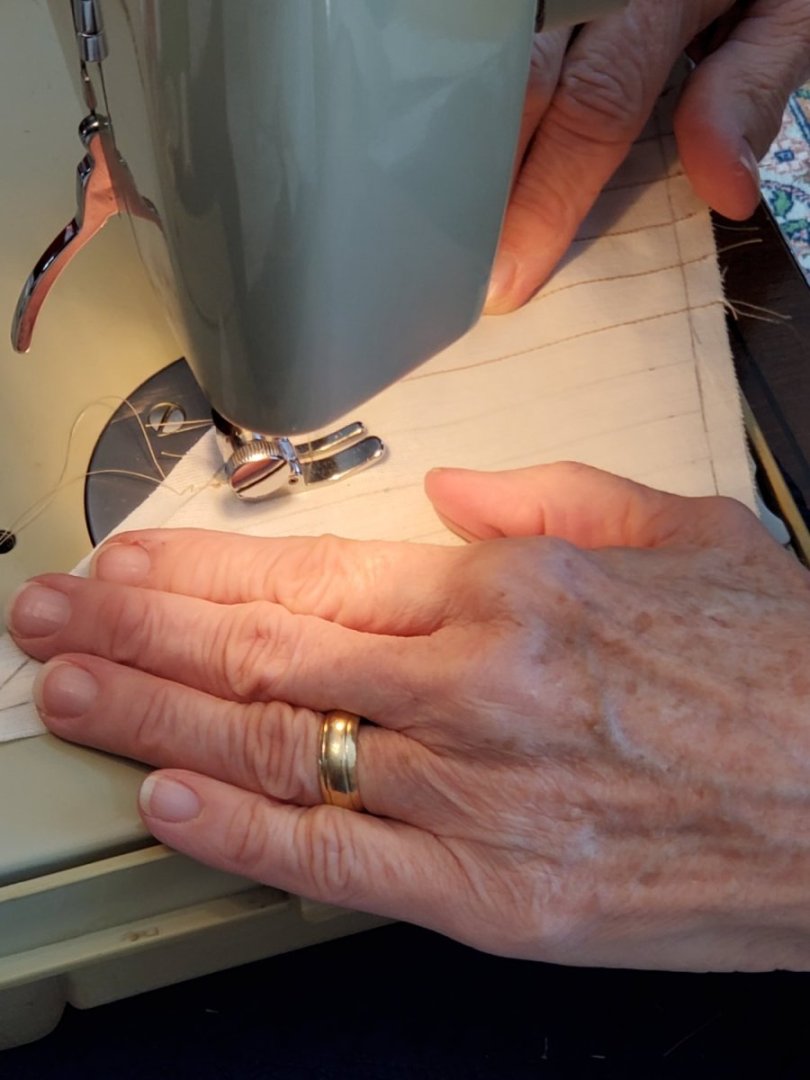

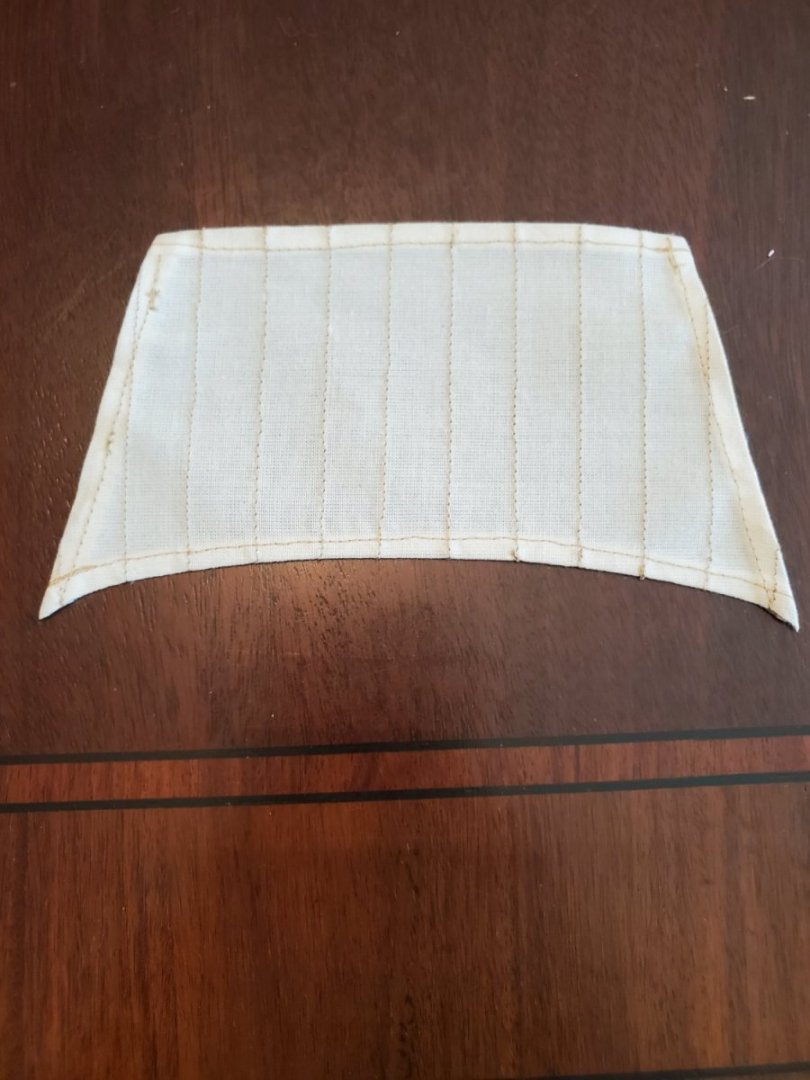

Some sail making progress on the Fair American: After last time, sewing sails was postponed 2 weeks, as my (retired) mother in law was busy. It was worth the wait. With each sail cut out, I made light pencil marks showing where to sew the seams. These were spaced apart 0.5in, which is scaled 2ft, as dictated in Steel's Sail making section. The thread will cover up the pencil marks, so I'm not too worried about it showing up. Bottom and Top sails have reef bands. Acccording to Steel's, they are to be 1/3 width of canvas. For practical/folding ability, I targeted 3/16" wide. This fabric is NOT easy to use, and folding them over 2x to prevent unraveling was a nightmare. It got all twisted and rolled, instead of folded. I was going to use the Iron to flatten, but I couldn't even get to that point. I thought that folding along the weave direction wasn't going to work, so I tried cutting them out from an angle, so the weave would stay more intact (see the angled line I cut). It didn't help. the pieces are just too narrow to handle. Very frustrating. So then I thought, well I need more 'substantial' material to fold with. So I didn't cut the strip free, just folded over 1x.... Then ironed it. Then folded again, ironed again. THIS WORKED! Afterwards, I just cut along the second fold - worked great. I just needed something to 'hold onto'. I took the cut reef bands, and placed them in between the pages of a big music book. I play piano, so this is apparently the page I turned too. They'll stay flat and protected until I'm ready for them. Now for the more fun stuff. Please note: I have no idea what I'm doing - really just trial and error and ''yeah that'll work''. Bob Hunt's practicum on Sail Making is helpful, but I really wish there were more pictures. Anyway after careful consideration, I decided on a medium tan thread, as the sewing thread for the sails. In hindsight, I probably should have gone with the next lighter shade, but I'll live with it - No turning back now! My mother-in-law started with the vertical seams first, following my pencil lines as a guide. We played with the settings for the tension, stitch, and 'that spool up on top' (12, 7, 2, respectively) You can see the master at work tabling the ends This first Main Topsail had a generous curve on the foot. Folding and ironing this tabling was a challenge. We discussed folding/ironing all 4 tabling ends was not easy to sew - to many layers at once. So we did the head and foot first, then I folded and ironed the leeches afterwards. Note - Nowhere in my research, or in Steel's, did I find which way the tabling should face: fore or aft. My brain says aft, but I wish I could know for sure. The Rogers model LOOKS LIKE the tabling is aft, but I really can't tell. The reef bands do go on the fore side, so those will be sewn last. Here's the 'fore' side of the sail, with tabling facing aft. Here's the head tabling sewn - it looks pretty good. It was hard for her to stay close to the edge of the seam without the stitch walking over the edge. Thus, it's not perfectly straight. Beginning and ending the stitch was very difficult. The material likes to snag in the sewing machine. We had to make adjustments for start/end to get it right, with a couple reverse stitches to keep the thread from unraveling. After the head and foot were sewn, the leeches were next. I left the folds long, so she had something to grab onto, then trimmed later. The final sewn sail ended up being slightly smaller than the carboard stencil at-scale. There's some material puckering and my folding wasn't perfect. When the sail is rigged, it will be bent to the yard anyway, so thank God it didn't end up bigger! I think it looks pretty good, considering first sail, first time, first material, first ship. Most of the credit goes to Jane, but we made a good team. We worked on one of the Jib Sails next - This was about as far as we got yesterday.... We spent ~1hr deciding on the plan, 1hr with a practice sail/seam, and 1hr of real sail sewing. I'm going to go back later in the week to make more progress. She sews, I fold and iron, she sews some more. We haven't sewn on the bolt rope yet - that'll be at the end once they're all tabled, and the reef bands are on. Hopefully more progress in the coming weeks. Enjoy your week - Jason -

-

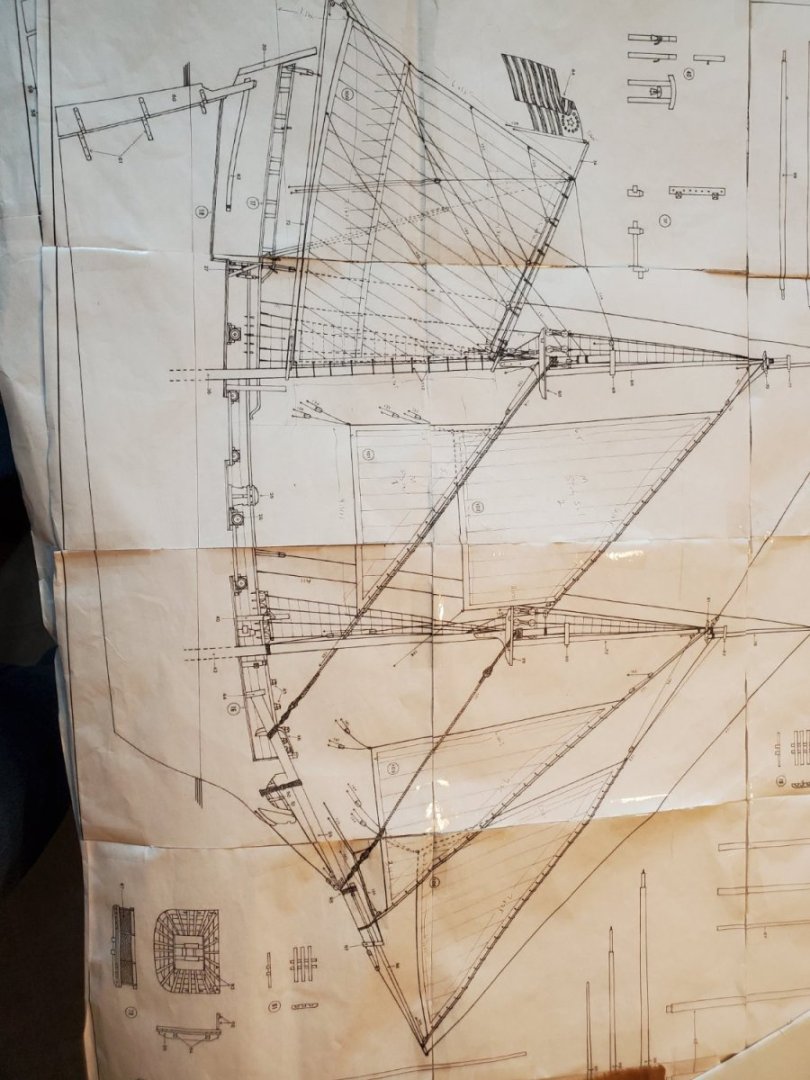

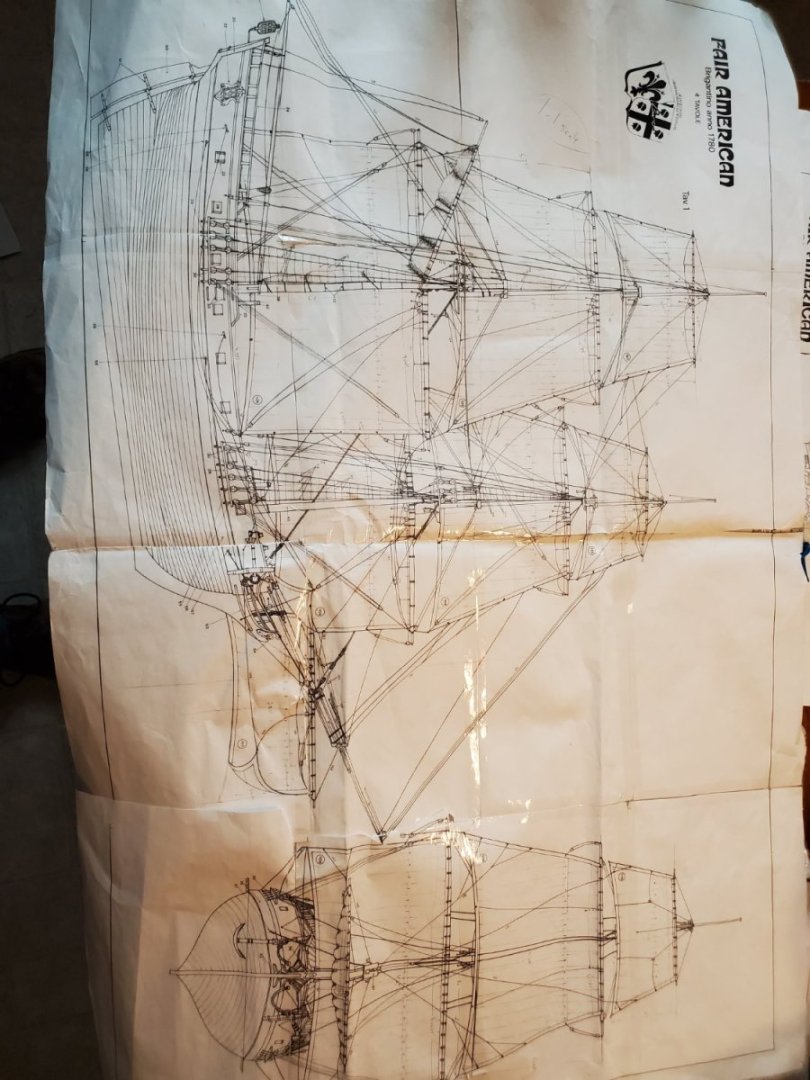

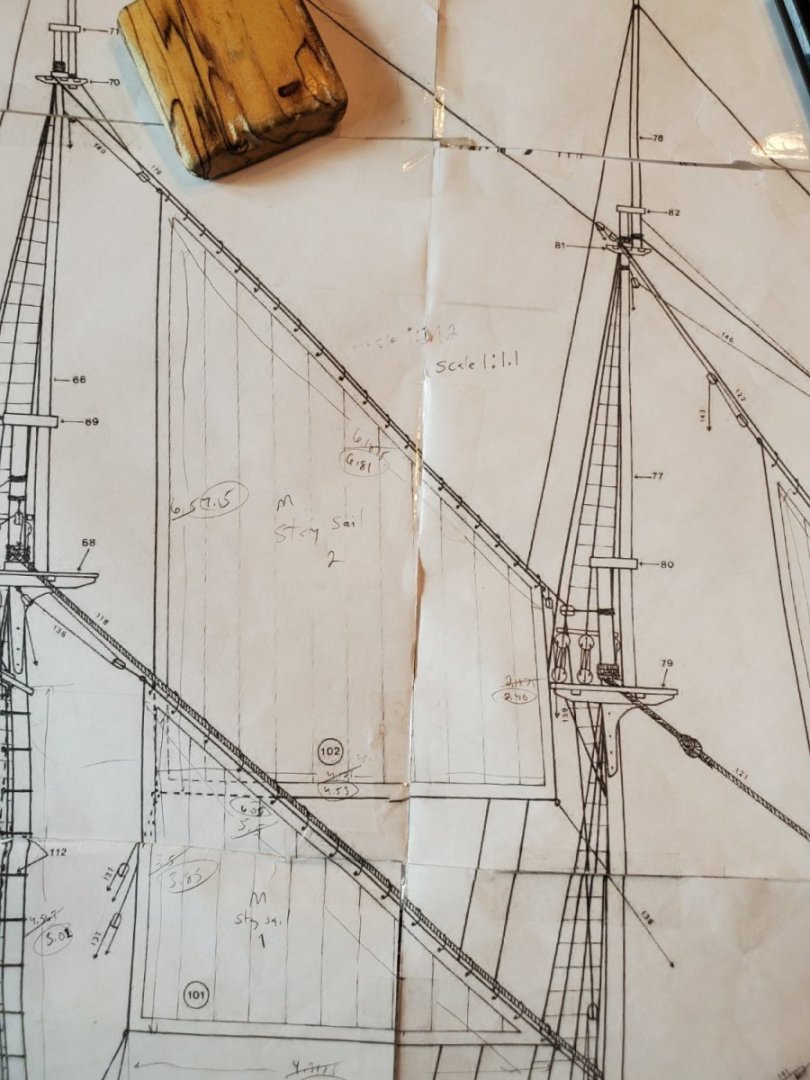

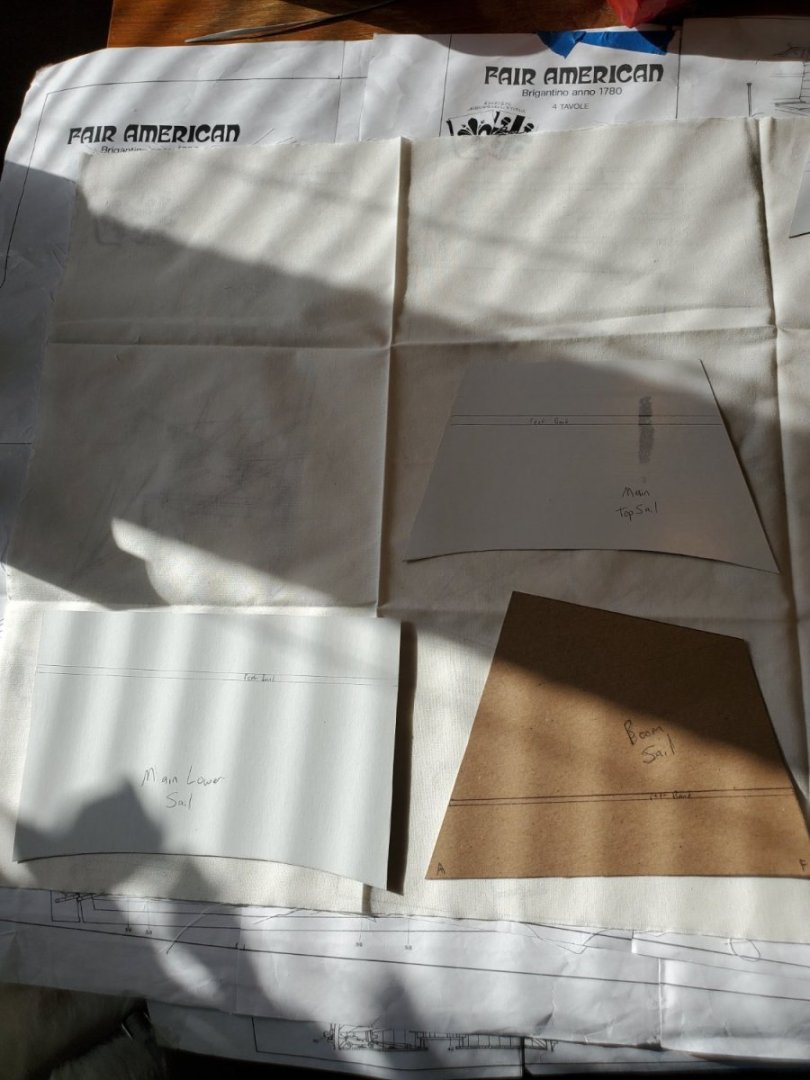

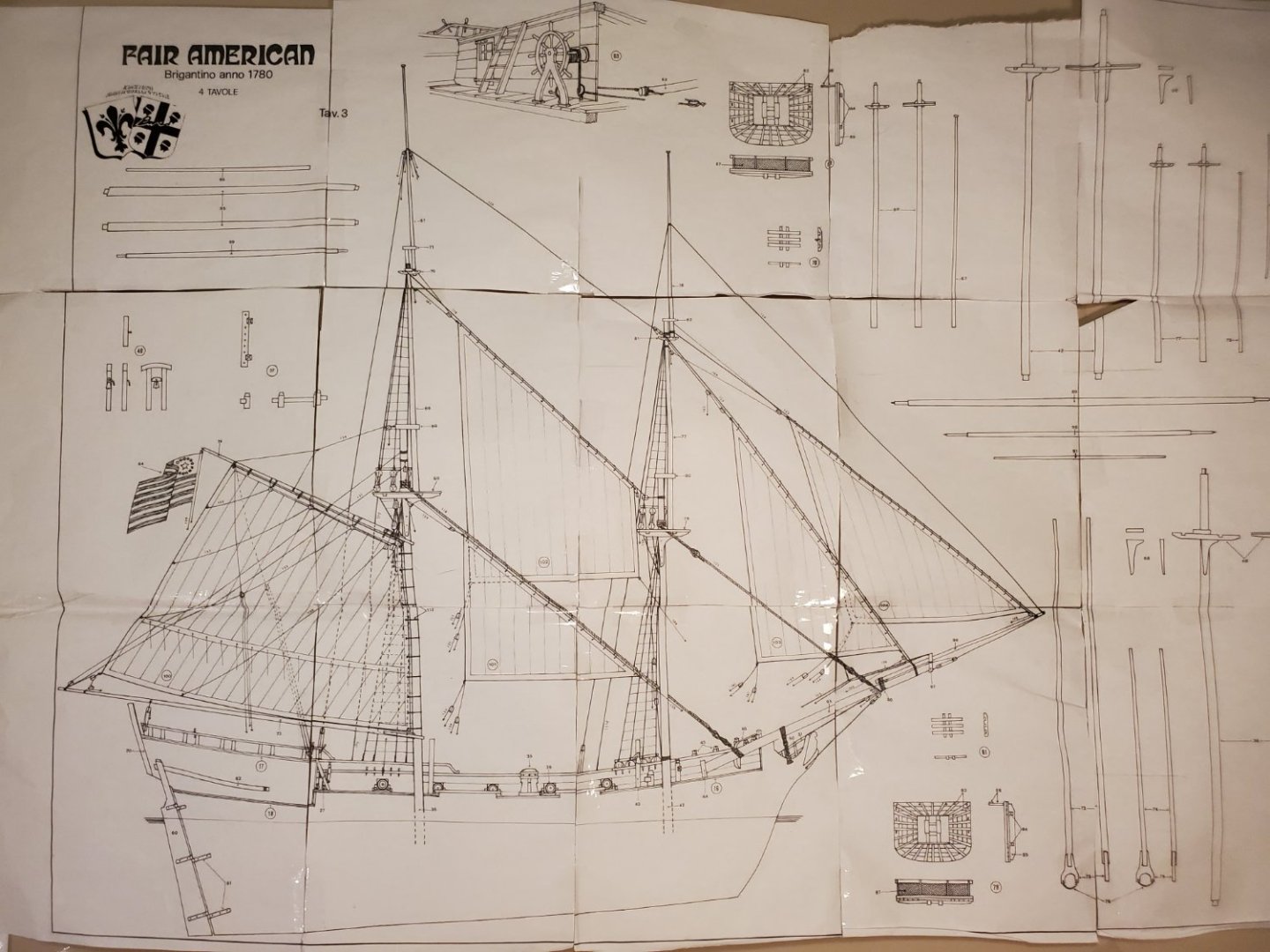

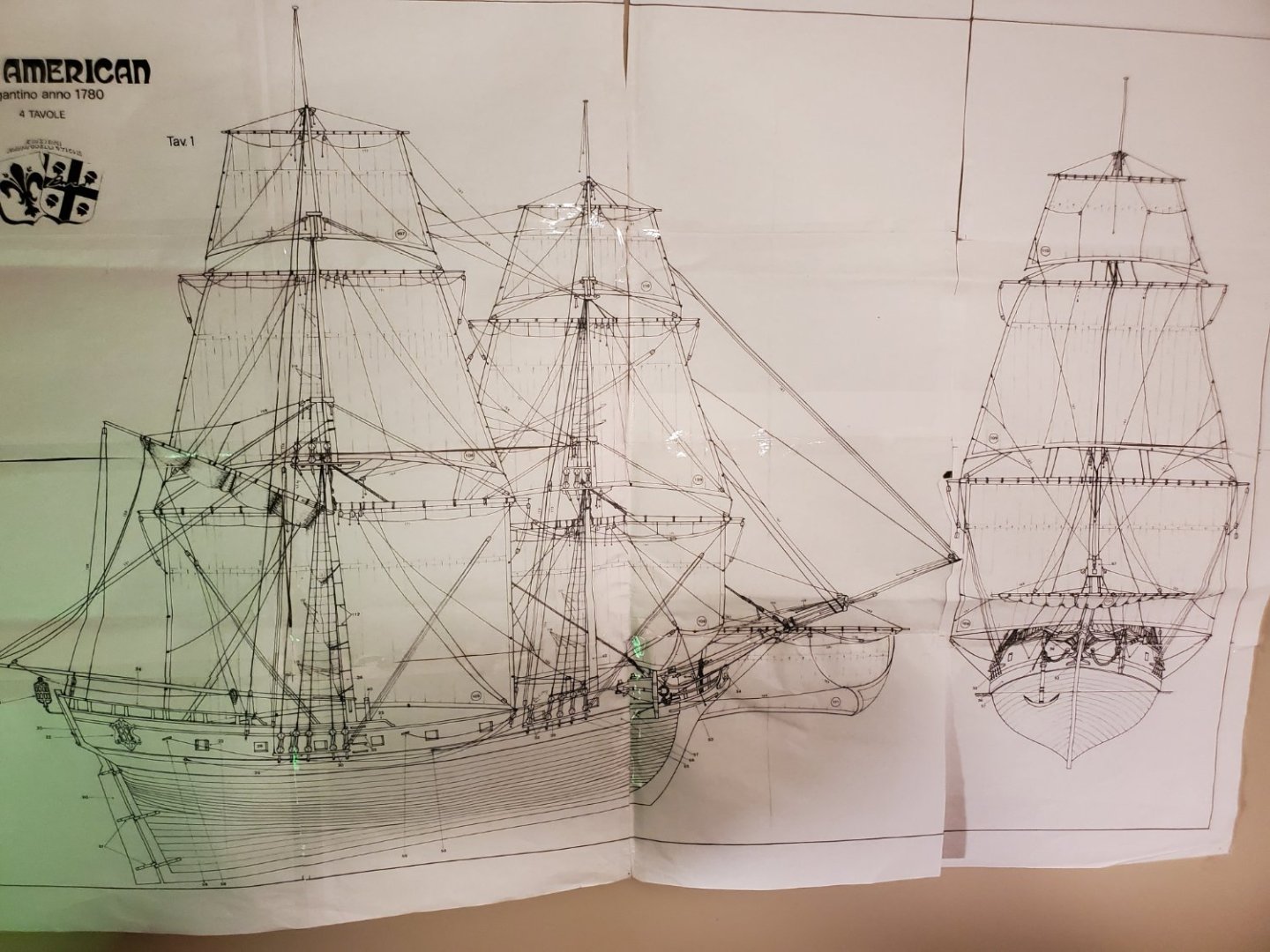

Progress on the Sails for Fair American... After putting this off for a while now, I decided I needed to bite the bullet and finally work on the sails. I can't do much progress with rigging without them, so it's time. My mother-in-law graciously offered to help with the sewing machine and stitching expertise, which I'll go into more next post. First, I took all the rigged plans I downloaded and taped together from https://www.shipmodell.com/index_files/0PLAN1C.html, to see if they were even close to scale to the actual yards. Some were, some weren't. This pages' sails were really close to my model (1:48), at least lining up the yards to the page. So I took the measurements from here, to start... But this view, (stay sails, and gaff/boom sails), were not in scale, for some reason. They were 1:1.12, so I measured, then calculated the 1:1 size, and circled that number. From there, I laid out the sail cloth I purchased from ModelShipways on the dinning room table. Its a big piece of fabric. With the measurements in hand, I made cardboard stencils to scale. It was a sunny day, so shadows were abundant, sorry. After all the stencils were made and cut, I arranged them on the sheet so they all fit. I made sure to allow extra material in between for tabling (seams). Here's all of them laid out. There's extra material in the top corner for reef bands, middle bands, and linings, as necessary. After studying Steel's for a while, and looking at Bob Hunt's practicum from Lauck Street Shipyard on Sail making, I came to the decision to make 3/16" wide tabling. Any smaller than this is going to be really hard to handle and fold. The Fair American in the Annapolis Naval museum is 1:32 scale, so those sails' tabling was probably more manageable, I would imagine. For this smaller scale model I have, I'm happy with 3/16" as a first attempt. It'll do nicely for Jason's personal museum quality workmanship. Note, the offset for tabling is actually 3/8", since I'll be folding over the edges before sewing, so they look large. now I traced the edges of the stiff stencil with pencil. I tried to erase a mistake, but that started to leave eraser debris in the fabric, and picking it out started to fray, so I have to be really careful not to shred it or get it dirty. Pictures are lacking from here on out. At my mother-in-laws, I wasn't focused on taking quality pictures, but more on her sewing skill which was impressive. This first 'tan' thread was a little too dark for my taste, and it's supposed to match the rigging line color (picture absent). #2 tan was pretty darn close to the right shade. (bad picture again). But I wanted to see #3 the lightest shade too.... #3, the lightest tan was a little too light. It blended very well, much like the Naval Museum model sails' does, but just a little too light. Also, I measured out 9/16" spaced seams for this stitch, to get an idea of how it looks seamed. It's too wide; not sure how I came up with 9/16". Later seams were 1/2" apart which looked better. And since Steels mentioned ~2ft wide canvas used on sails, my model is 1ft = 1/4", that makes 1/2" between seams. All these are just test/practice pieces so far. Only trying to get an idea of how the stitching/color/sizing looks and feels before the real thing. Also practiced ironing the material after stitching to see if it helped the wrinkles. I might keep them in, for a more authentic look. I'll spend this week planning out order of operations (seams 1st, then reef bands, then leech tabling, then head/foot tabling). Then I can draw some faint pencil marks to guide my wonderfully helpful seamstress to where the stitching goes. I might have some actual sails ready next weekend, if things go to plan!!! More progress soon. Thanks for reading - Jason -

-

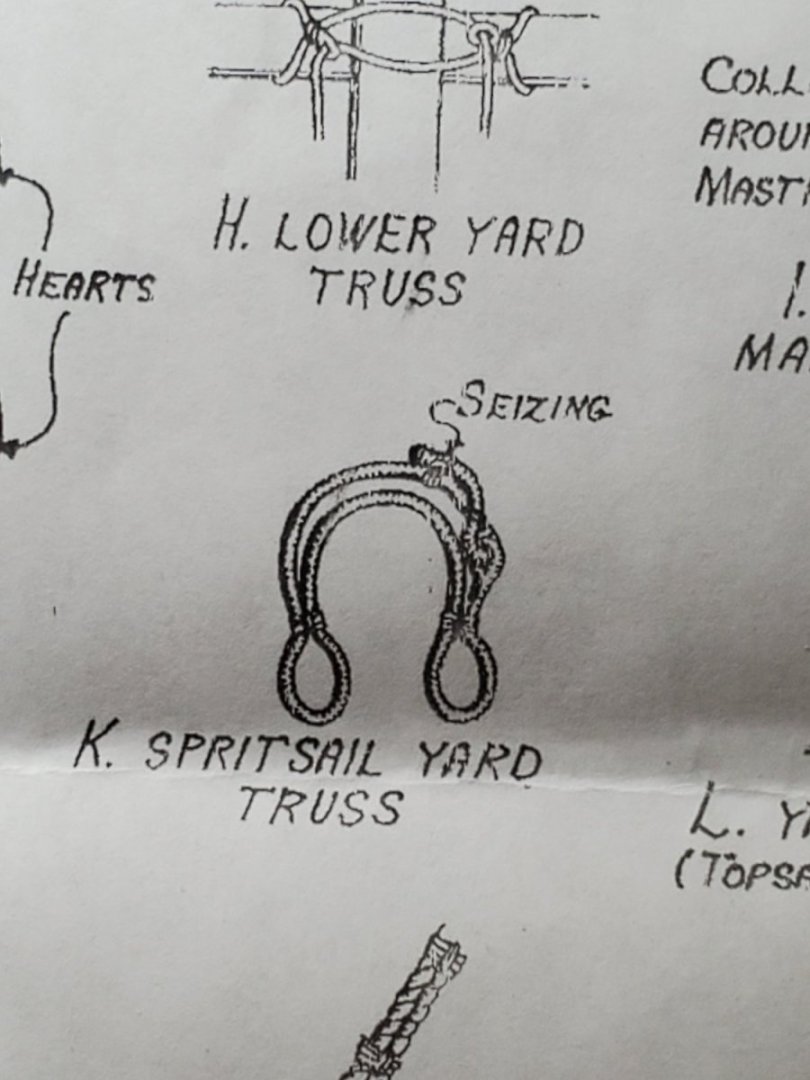

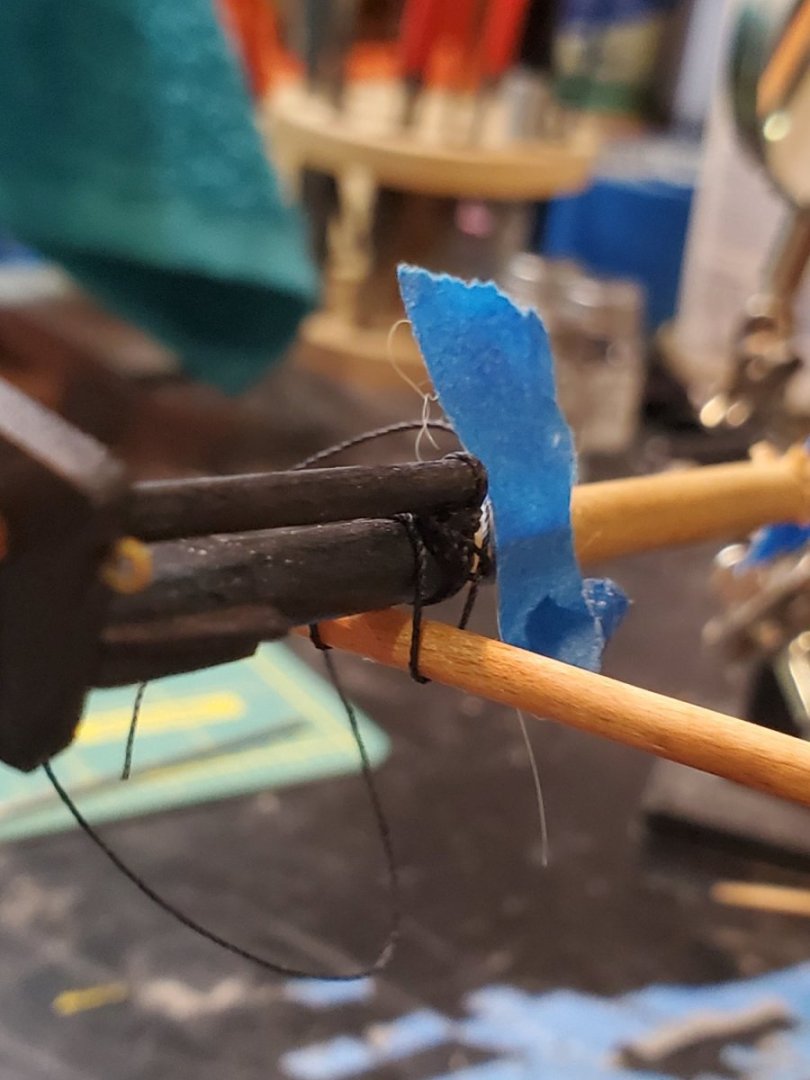

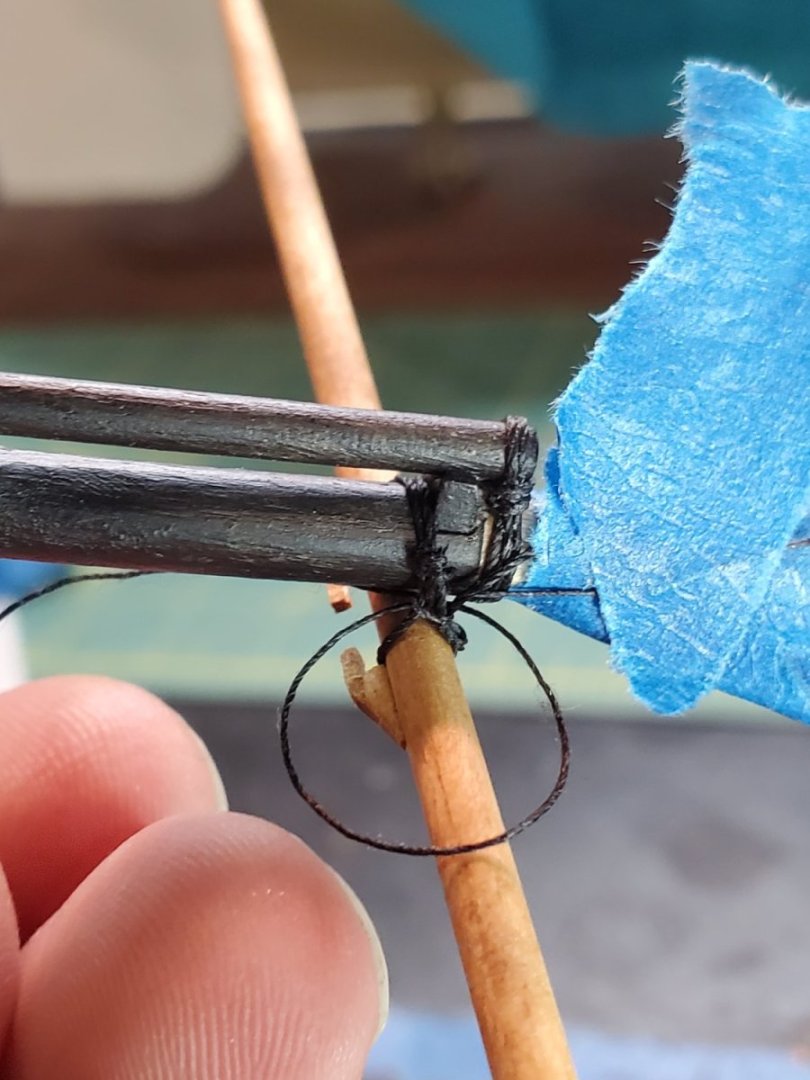

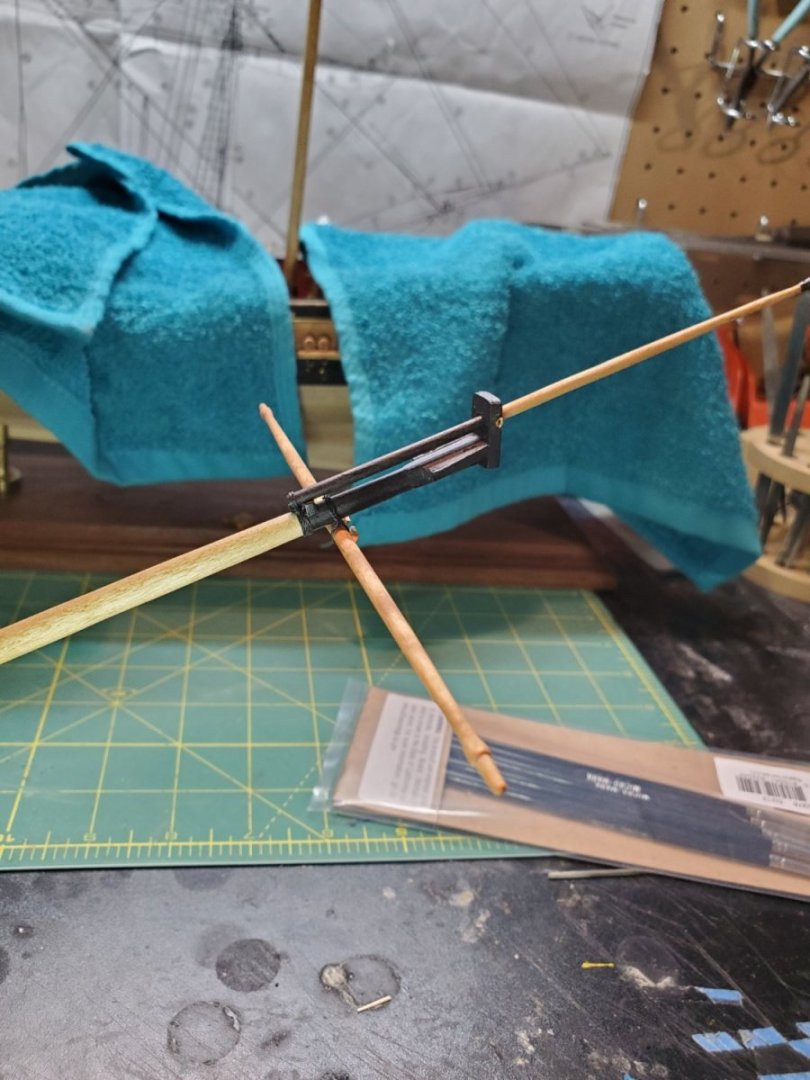

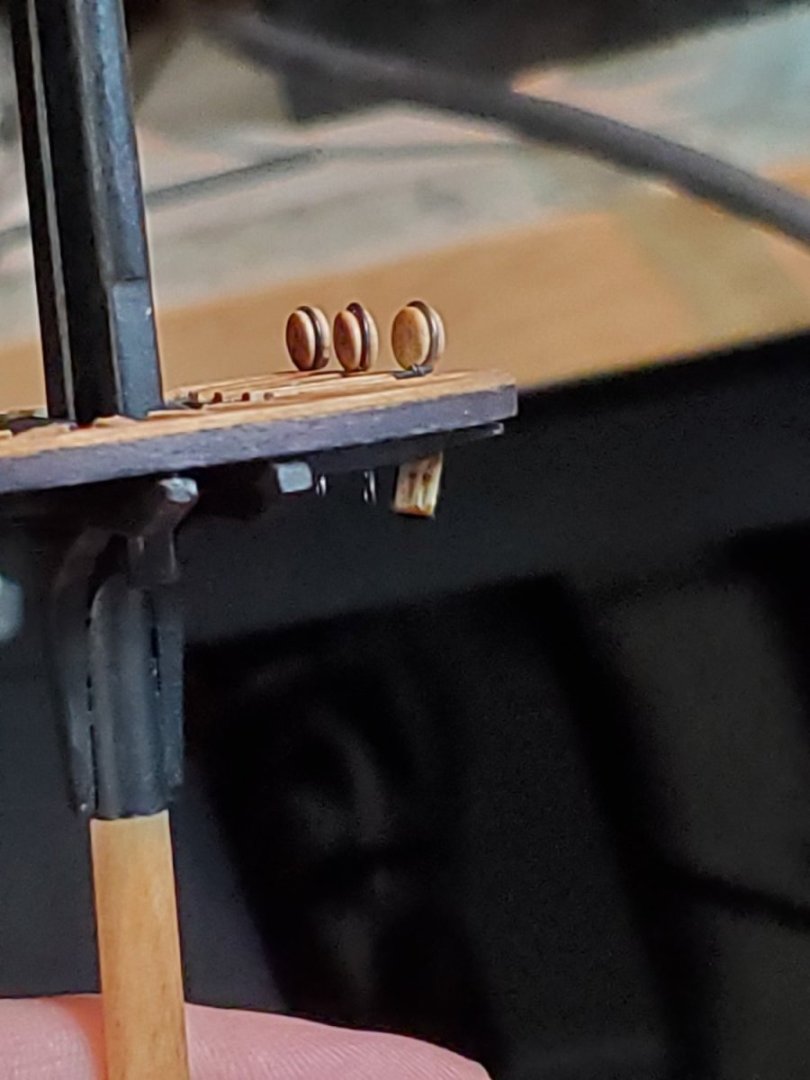

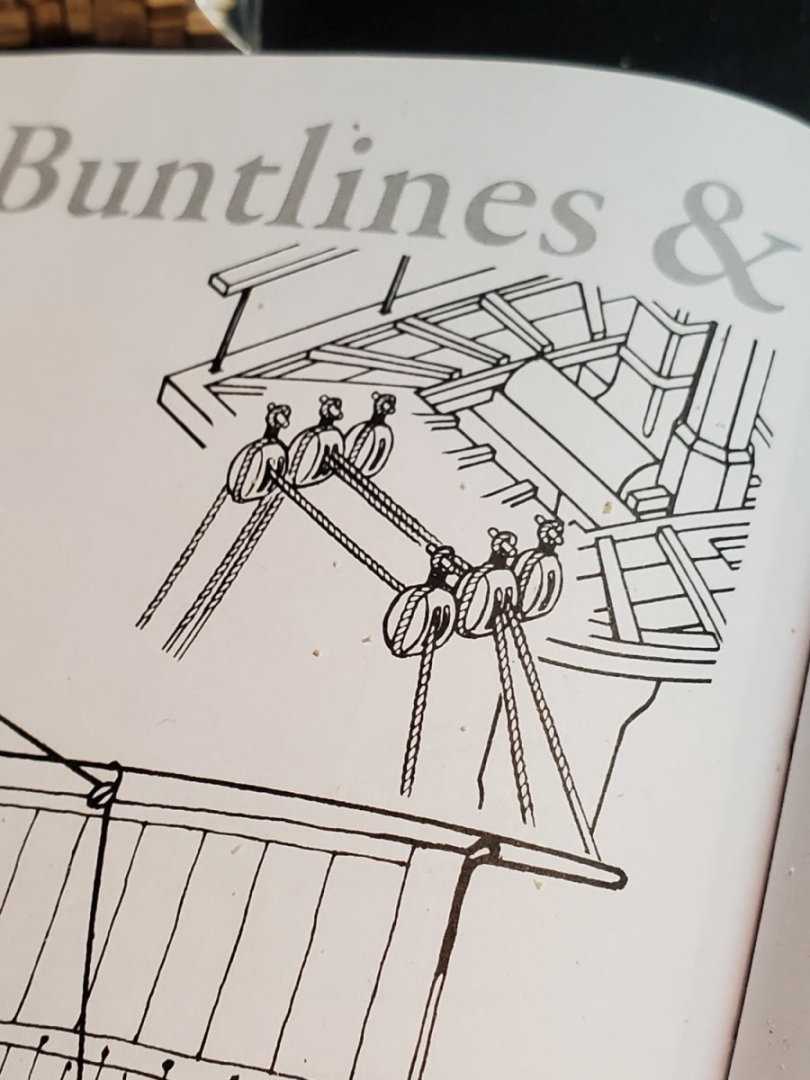

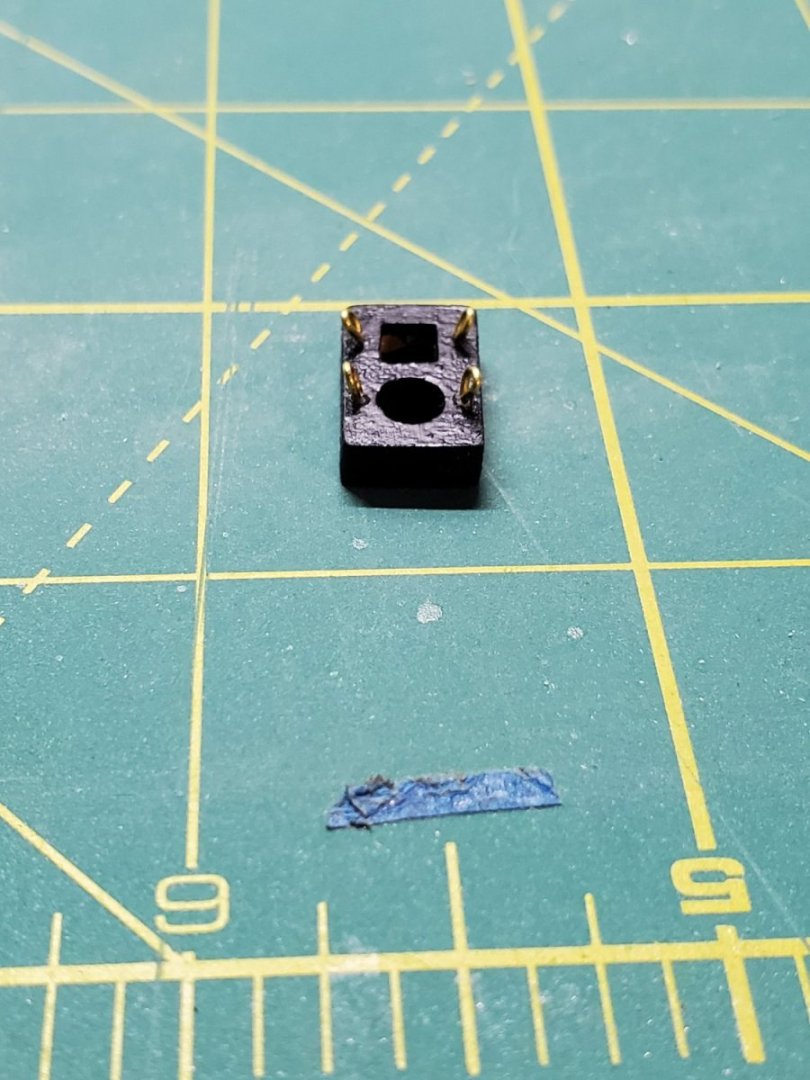

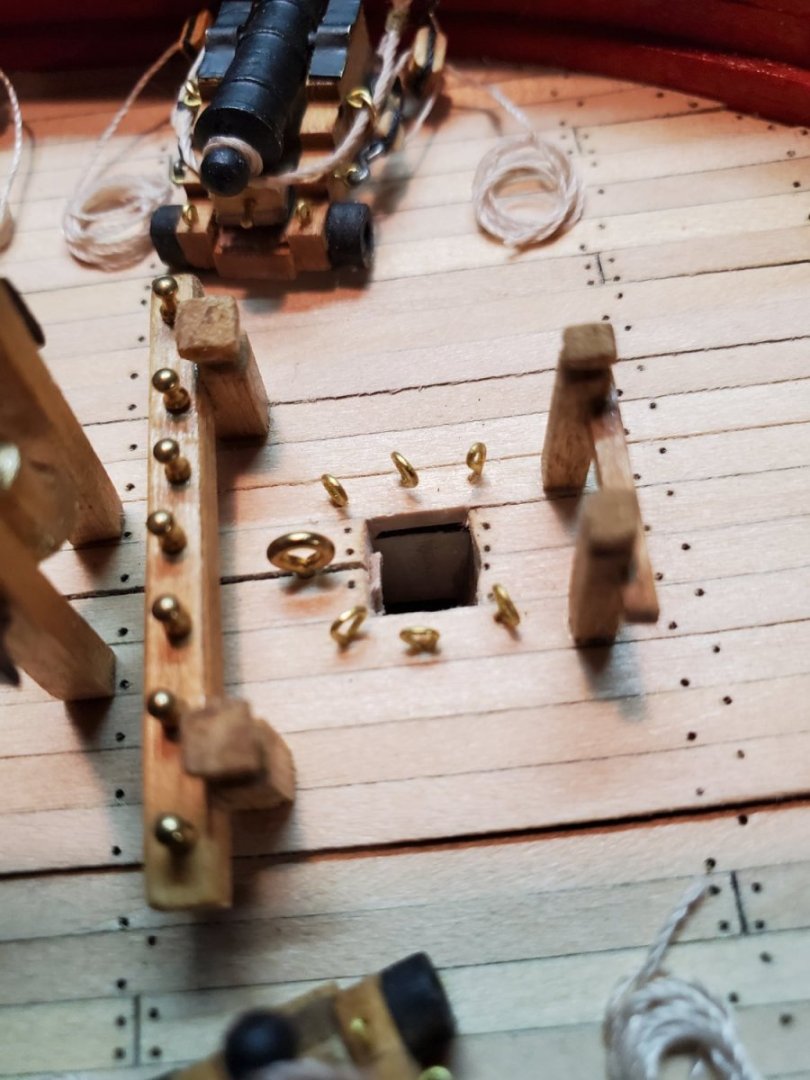

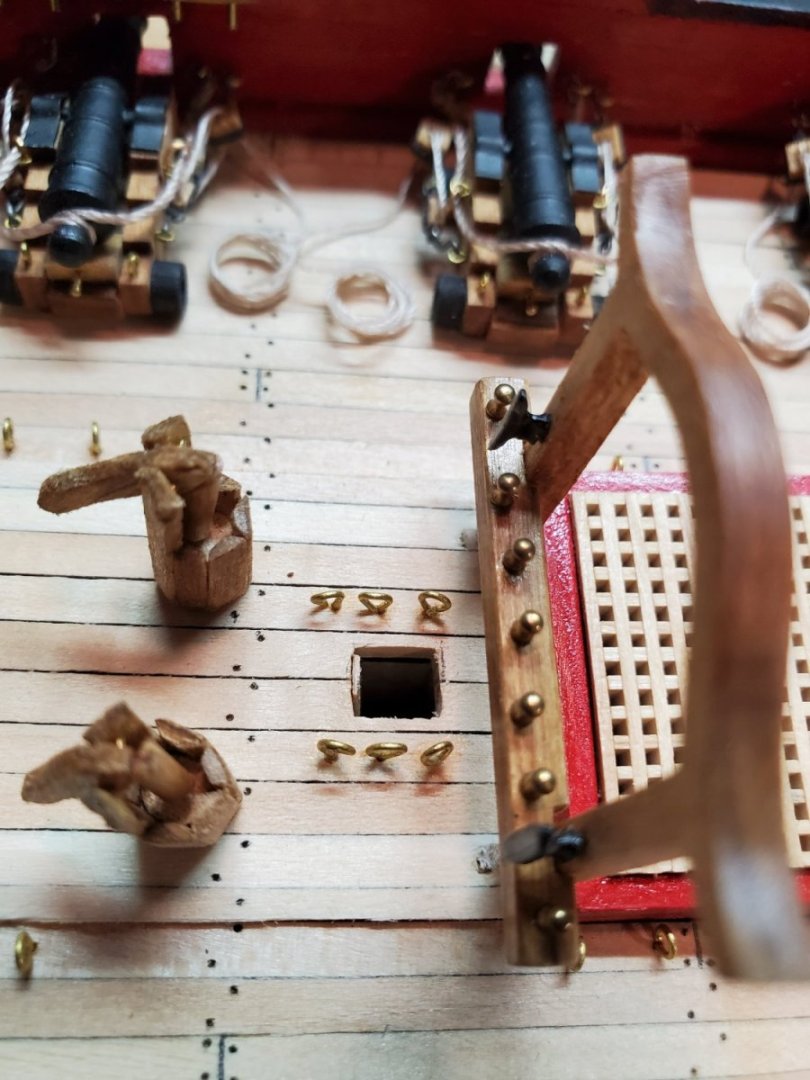

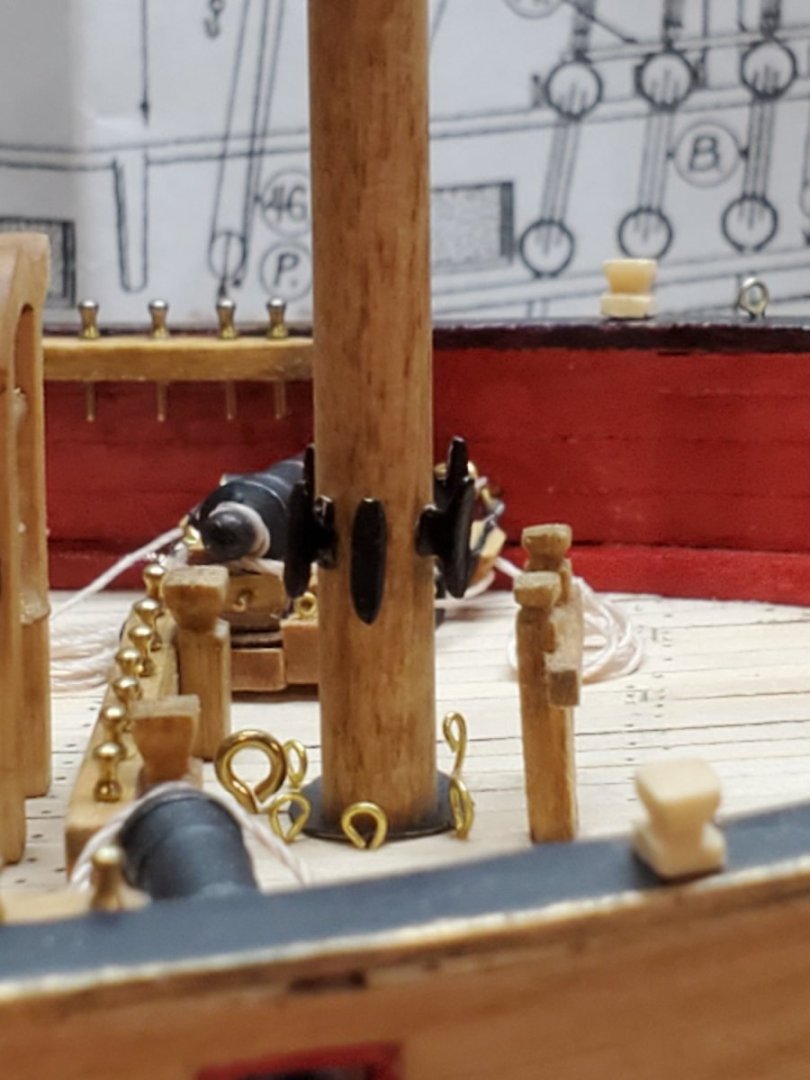

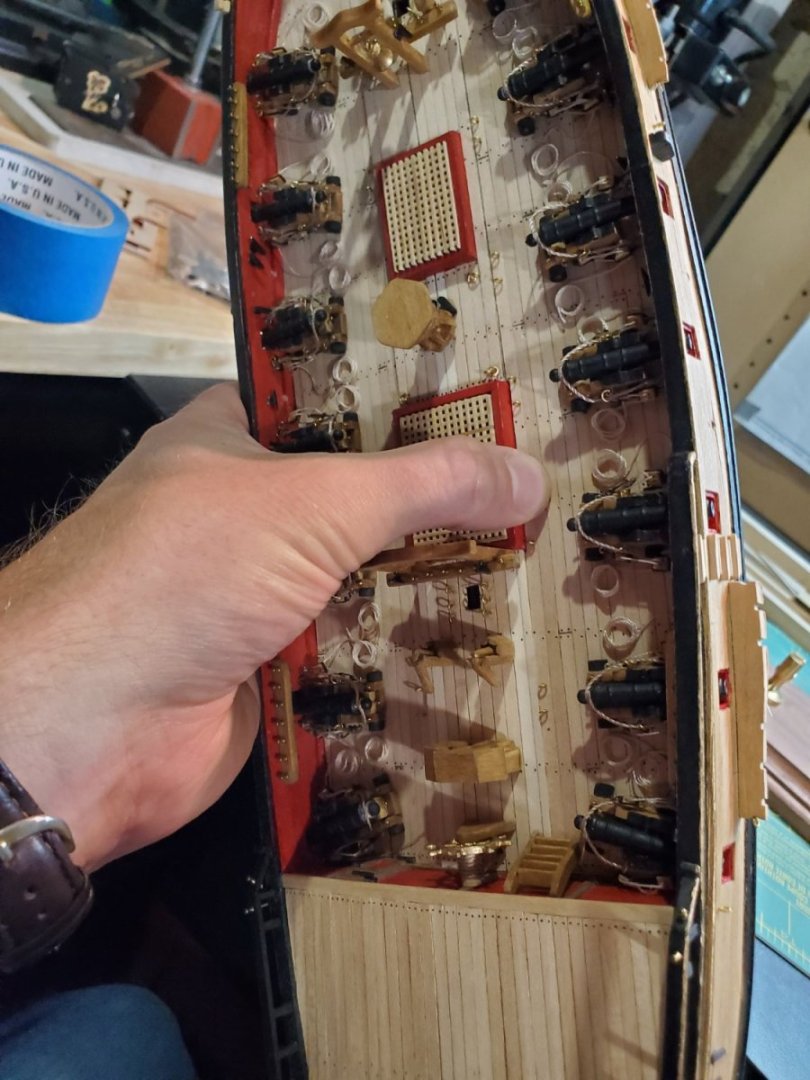

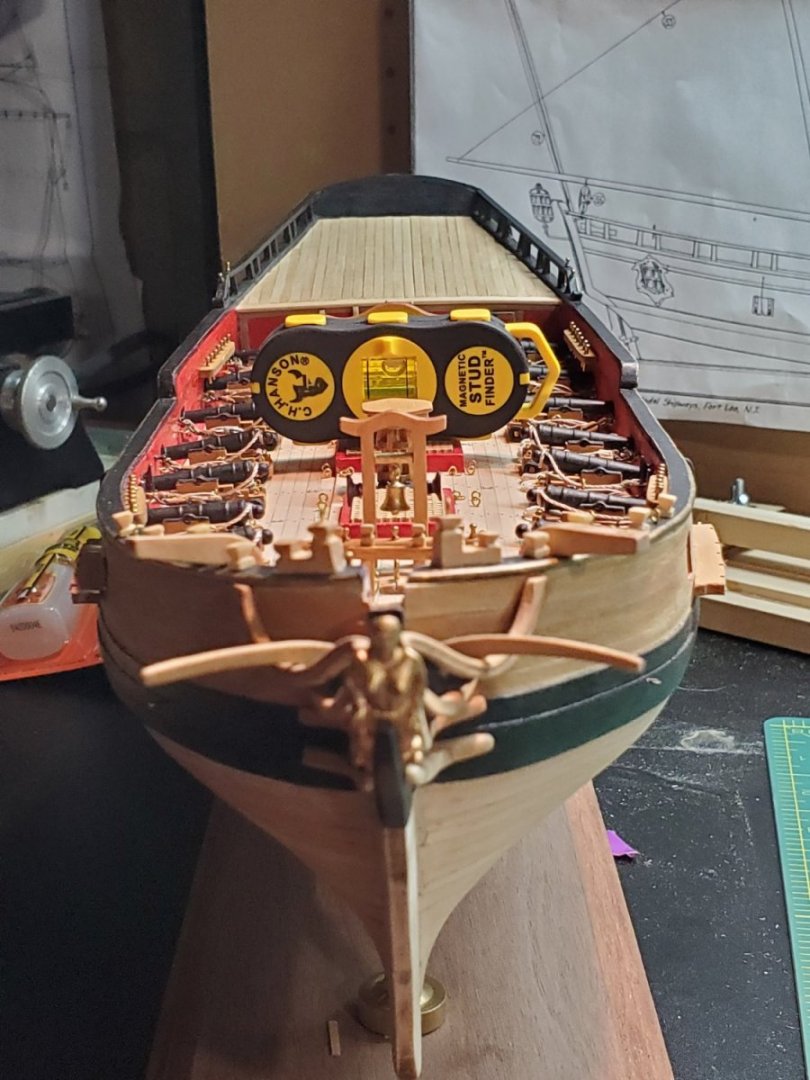

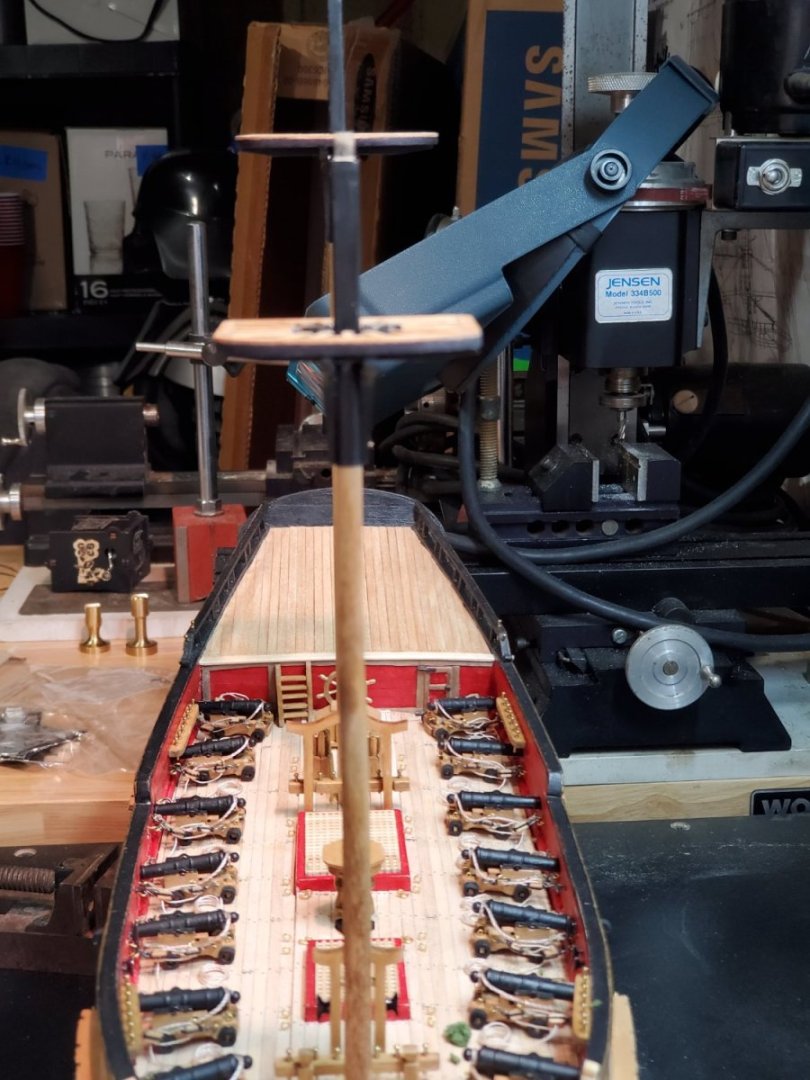

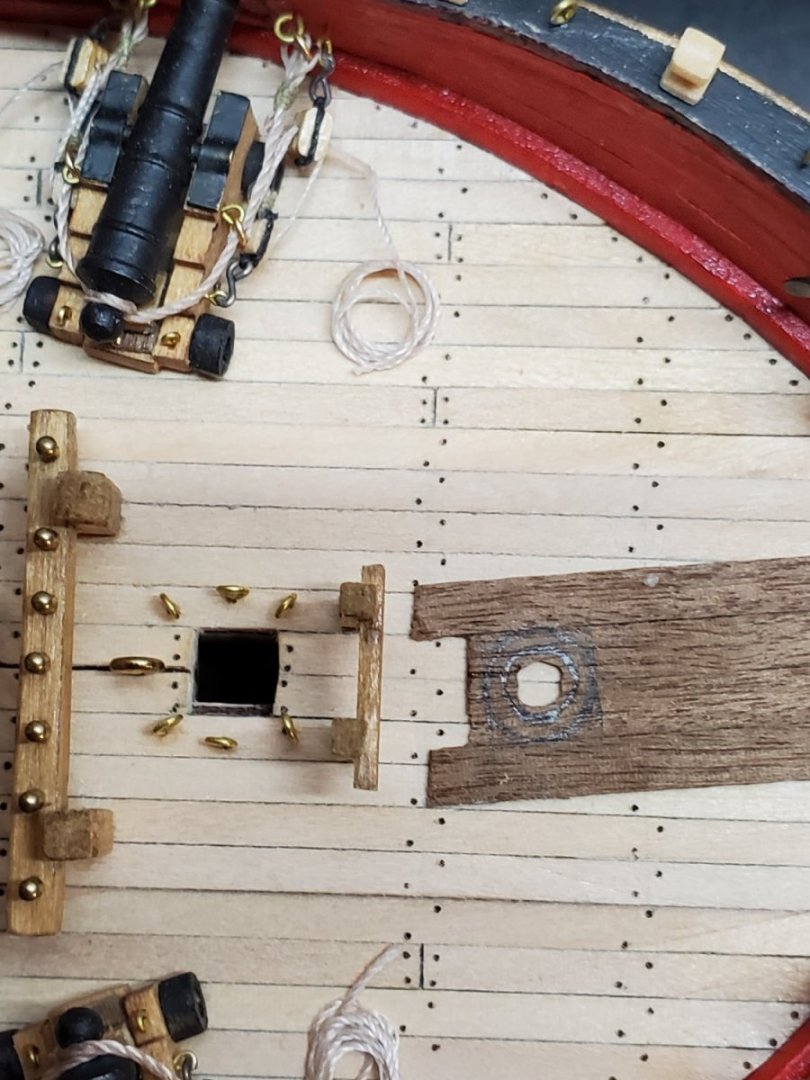

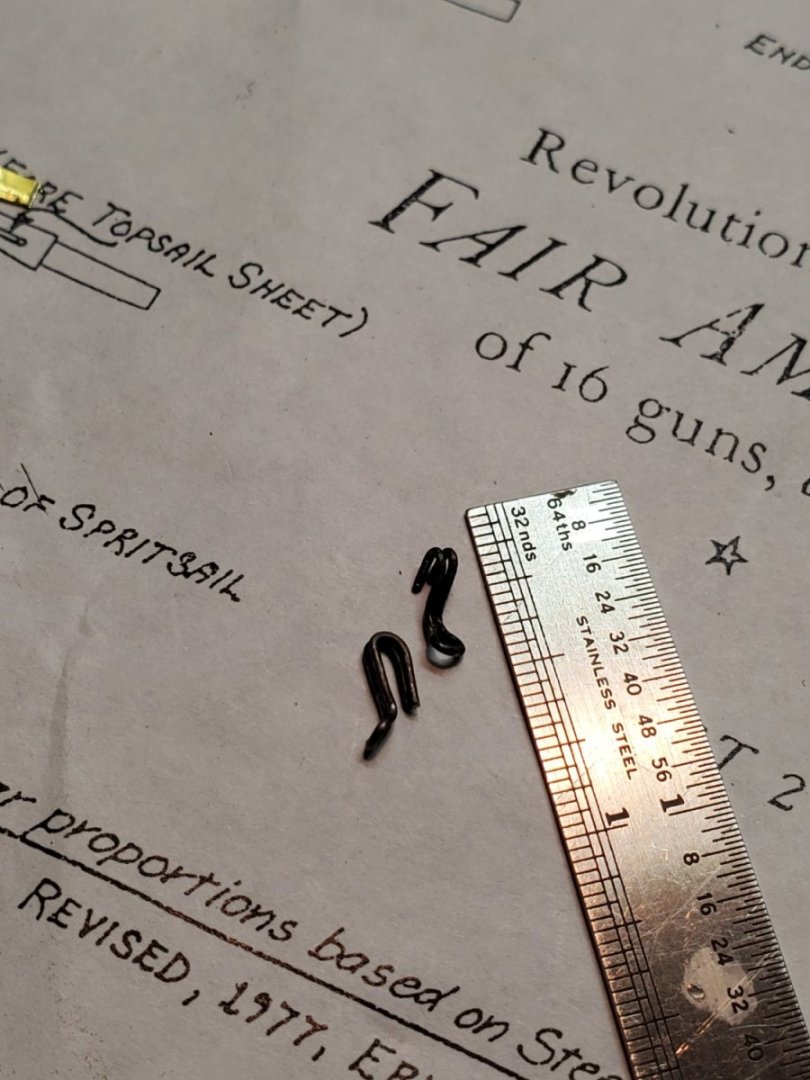

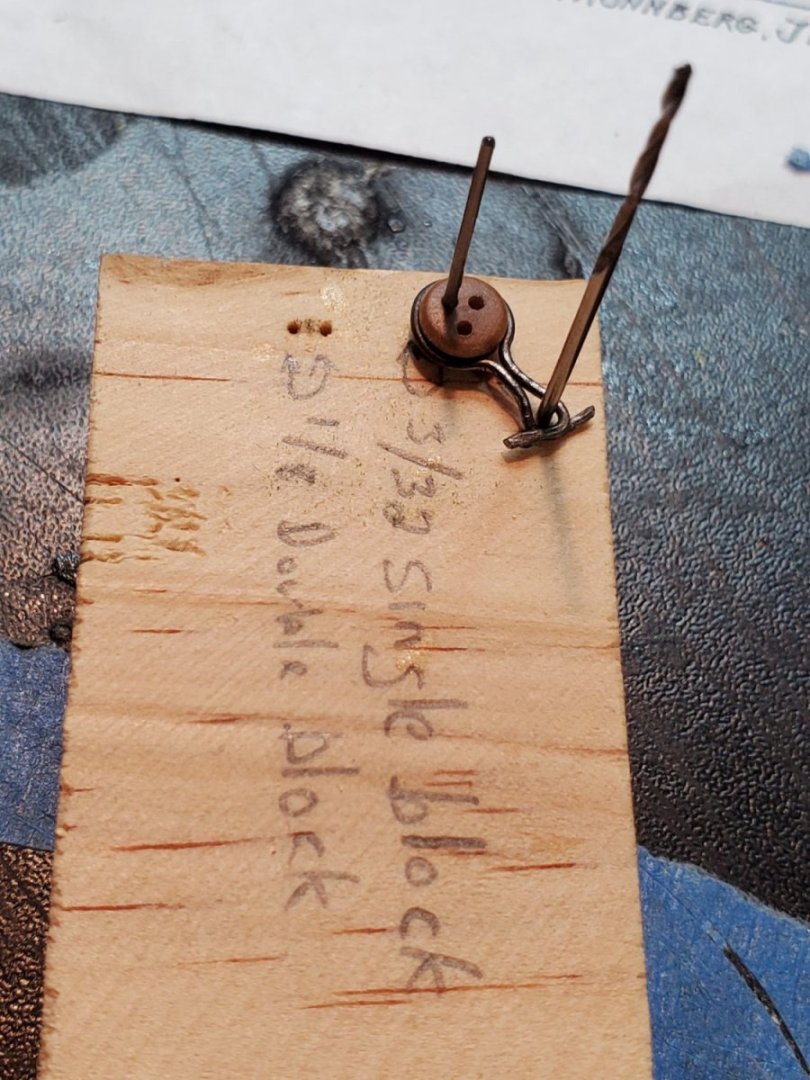

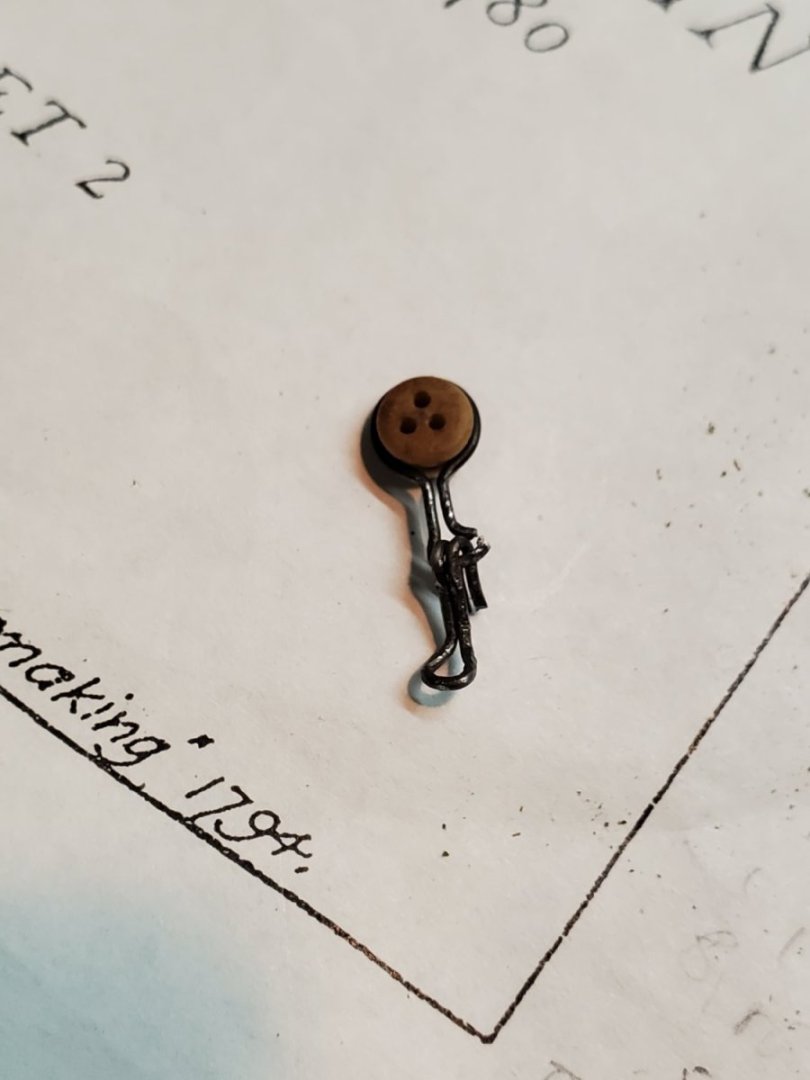

Progress on the Fair American Model Ship: Again, very overdue, but progress nonetheless... I got all the deadeyes and chain plates mounted. Got them as straight as possible and raked with the masts. I made sure to line up each deadeye as parallel as possible, before gluing the channel cap. There was a lot of re-working and re-bending chain plates to get them all to look right. While this was happening, I rigged up a little ''stain-sling'' to help hold the yard while I stained them. It was just two rope loops hung from two helping hands, with the yard in the middle. The Roger's model has the yards black, and the studding yards stained, but I'm staining the main yards in my model. Now was time to do some actual rigging, starting with the Spritsail Yard Truss. No instruction on how to start/stop this thing, so I made up my own method. I wrapped rope around the Sprit sail yard P&S, then blue taped it to the Bowsprit. Tied a knot on one end as a makeshift ''loop'', and fed under Jib boom. Then I semi-seized the loops tight on P&S sides with fine thread Then pulled it tight, and snipped the ends close. The final knot/seizing on the opposite side was just a hidden square knot. I didn't know how else to terminate it. That's about as neat as I can make it. After the Spritsail Yard Truss, I moved onto making double blocks for the leechline, buntlines, and Spritsail yard braces. I took some .012in black rope and made a tight loop around an old drill bit and taped the ends back. Then I could tie two knots to form an upper loop that will feed in the mast top later on. I did not feel confident in my ability to splice a loop on itself with this size rope. A knotted loop is more my style right now. And snipped close. I glue/tacked the knot to the top of a 5/32in double block, and then knotted the bottom with an overhand. I did this with cannon blocks too, and it worked well, but tedious. the 1/8in blocks were just too small to ''hang'' from the top well enough to access, so I used 5/32in. Glued and snipped close again, and it looks alright to me. According to Petersson, this is how these blocks will attach to the top. My instructions were useless, as well as the rigging plan. I'm following this approach. I'm going to reeve ropes for leech, bunt and stays similarly, but make educated guesses for my own model as I get there. I was hoping the Roger's model would make it more clear, but again - difficult to see exact pin assignments through glass. Petersson also shows blocks fore and aft, so that lines come up and over the yard, then down to their pins without getting tangled. The Rogers model also showed this detail, so I'm doing the same thing here. Drilled some block-loop-holes in the top, and snipped some .012 annealed wire, and glued in place. The block hangs pretty well - just accessible. I now have two blocks fore and aft, and port and starboard. I'm doing all of this with the mast detached from the deck. I haven't stepped it yet. Once it's permanently fastened to the deck, I'll never be able to access the underside again. I'm trying to do everything I can before I can't 'reach' anymore. I'm sure I'm doing the rigging wrong, but without any help from the instruction manual, I'm doing what I can. If other modelers have recommendations for HOW they learned to do blocks, or start rigging, I would be eager to learn. I'll keep plugging away at the main mast blocks next, the same as the fore mast ones. More progress soon. - Jason -

-

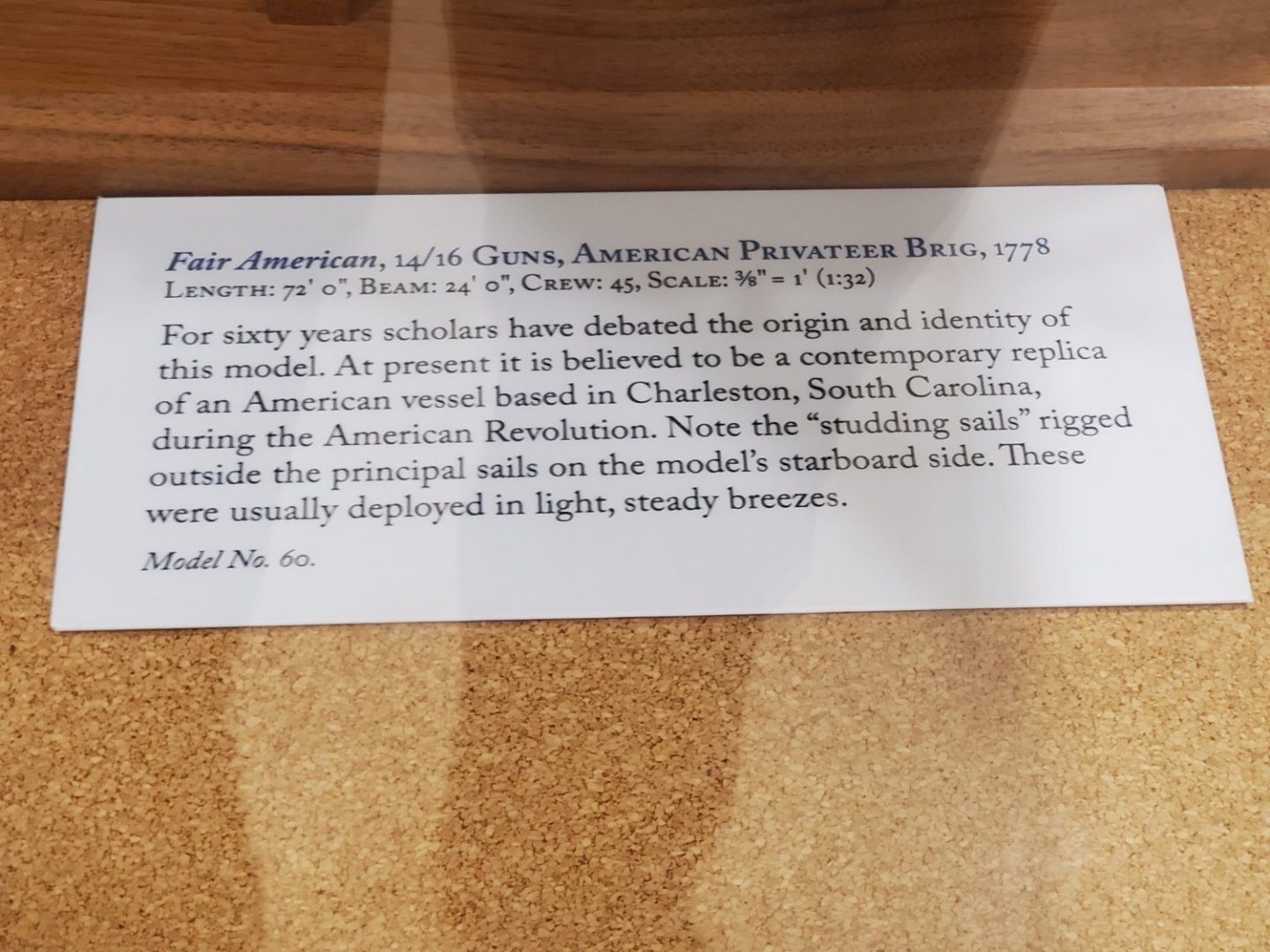

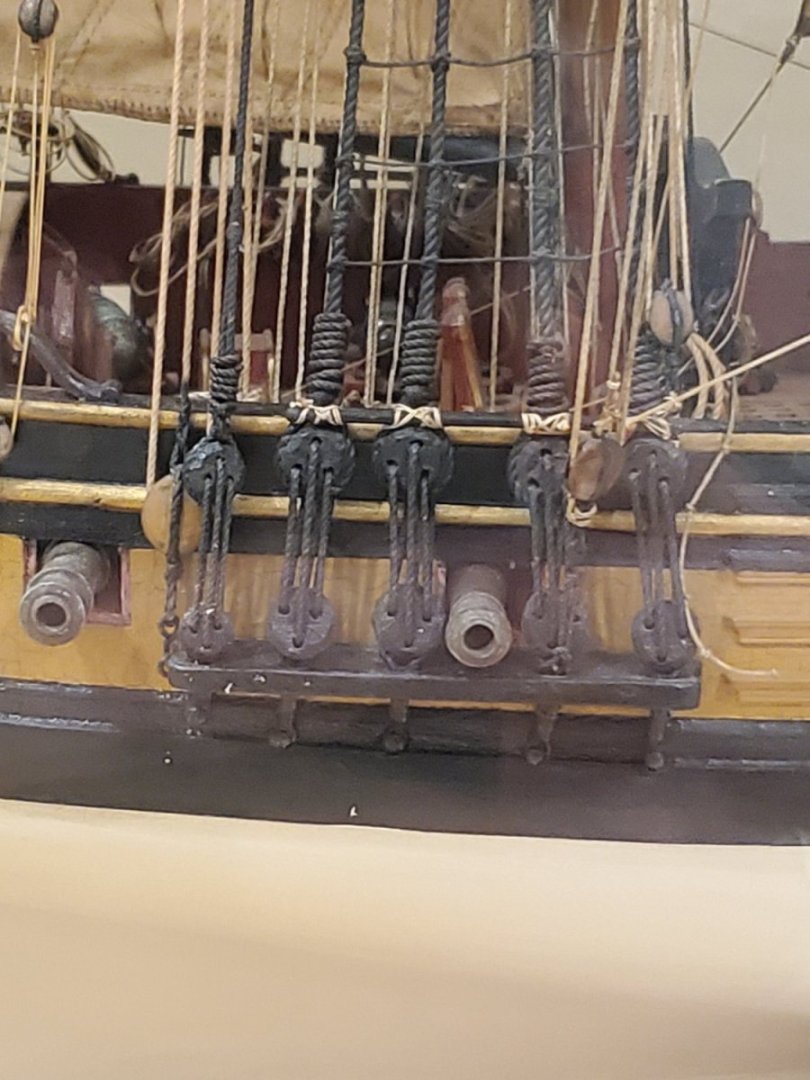

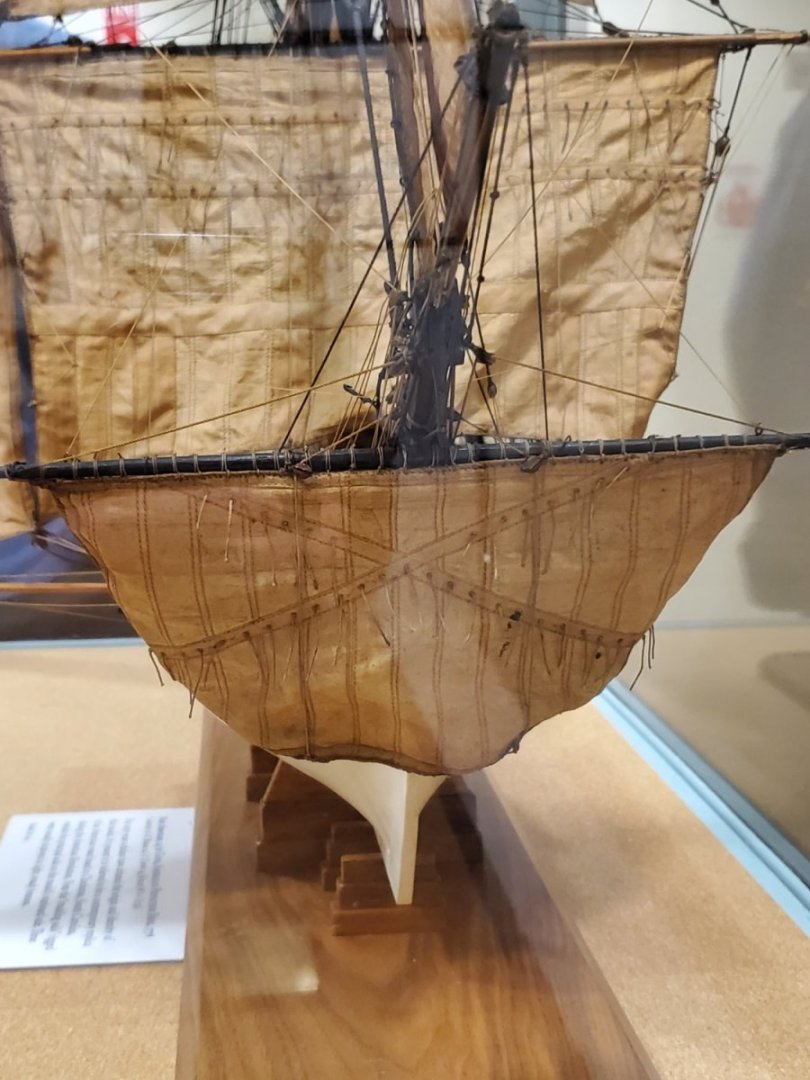

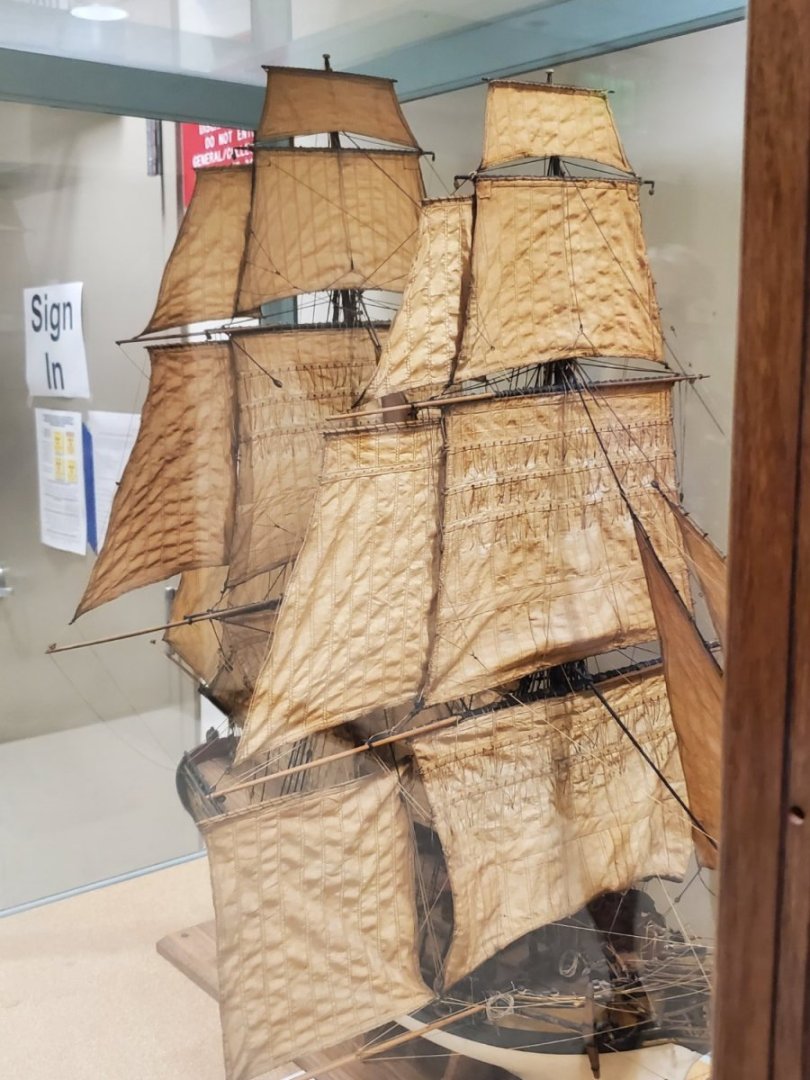

Very long overdue update on Fair American Few months ago, fellow model ship buddy CiscoH and I went to the Annapolis Naval Ship Museum. The Fair American from the Rogers collection was supposedly located there. First 40min looking around, no Fair American. After asking one of the workers there, she mentioned it was not on display, but up in the Restoration Room. She kindly took us up the private elevator to see it. It was an amazing model. Fully rigged with sails, including studding sails. The only draw back was that it was in a poorly lit area, and inside a glass case - reflections prevented good shots with my phone. This was a 1:32 scale model, so much larger than the kit I'm building from Model Shipways My primary goal was to document the rigging, to use on my own model. I didn't take many overall pictures, sorry. The folllowing pictures are NOT my model. They are of the Rogers Collection Model only The detail on the sails was incredible with amazing stitch work. There was a lot of black on the model - hard to see exactly where things were rigged, especially with the glare. I wish I had taken more wider pictures, but this is what I got with Cisco and her waiting patiently for me to snap pictures. I didn't want to impose too long. There were several other pictures I took, but not included here. I won't be putting studding sails on my model, but seeing how/where some things were rigged and attached gave me a lot of insight for my own model. I'll be updating my own Fair American tomorrow, hopefully. I have made progress, but with holidays, birthdays, anniversaries and weddings, it was hard to find time to do much. Thanks for reading - Jason -

-

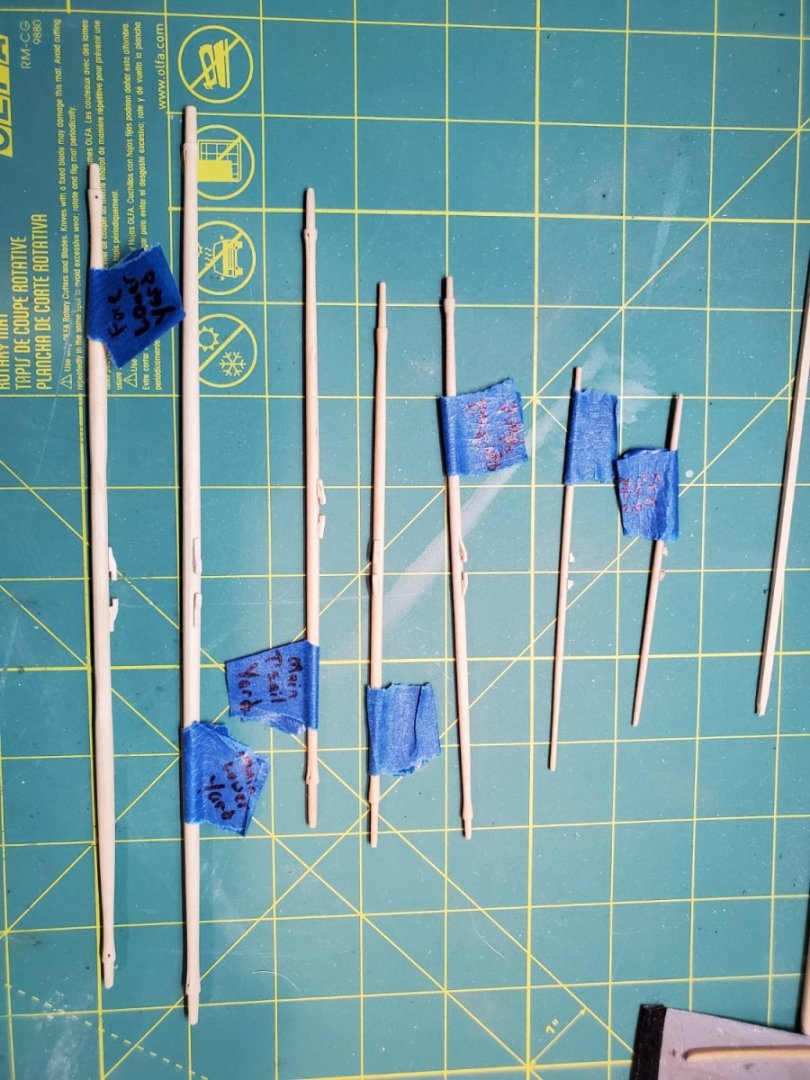

Fair American progress update: Lot has happened in September - turned 40, got Covid, missed the Admiralty workshop, brother's bachelor party and still had time to do some work on the ship! For the mast tops, started adding eyebolts in place. Also started making plans/drawings for where various blocks will go to (not shown). Had to bend the eyes out slightly, so they could be accessed near the mast. Almost done all the yards too. I like the fine details of the yard shapes - they've been fun to turn on the lathe. The yards are supposed to be black, via the plans. I'm debating whether I want to stain them instead. I think that black will hide all the great detail, but I'm still not decided. I'm moving onto setting the rake angle for the chain plates/deadeyes next. Before that, I need the rake of the masts to be correct. I needed to add little shims in the deck hole to offset the heel of the mast correctly. You can see the little piece on the left side. According to the plans, I can use taut string to approximate the angle needed for the chain plates. I'm drilling a hole at the bottom of the black strake where the plate will be pinned. After the pin hole, I can place the deadeye in. About as aligned as I can do. I made mine a little differently, as you can see. The instructions call for a metal strip that isn't available anymore. I pre-measured dimensions from the channel to the black strake, to come up with my hook and loop design for the chain plates. I did have to make some adjustments, but they fit pretty darn nice. I'm really happy with how they turned out! I also got the top mast and tops glued to the masts. I needed a reverse grip tweezer to hold it straight while the glue dried. The fit was just a little loose. Of course nothing is perfect - especially for me. The Fore and Main tops are NOT the same size. And obviously I grabbed the black one, instead of the black one and now the Fore top is glued to the Main mast. The one in my fingers is the Main Mast top, its just slightly wider than the Fore. I'm going to live with it, but now everyone knows - always label things - like I did for the yards in blue painters tape. Another learning moment. So that's all for now. I'm going to keep chugging away at the chain plates and maybe I'll have the masts glued/stepped next time!!!! Have a great week, - Jason -

-

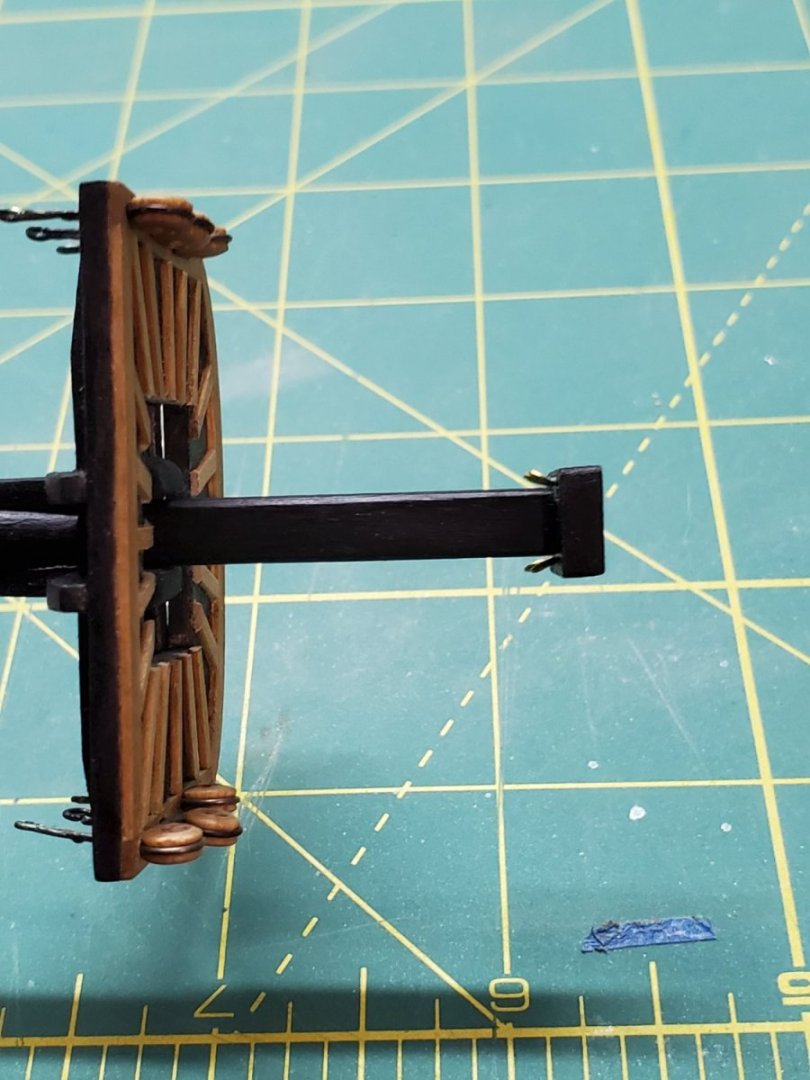

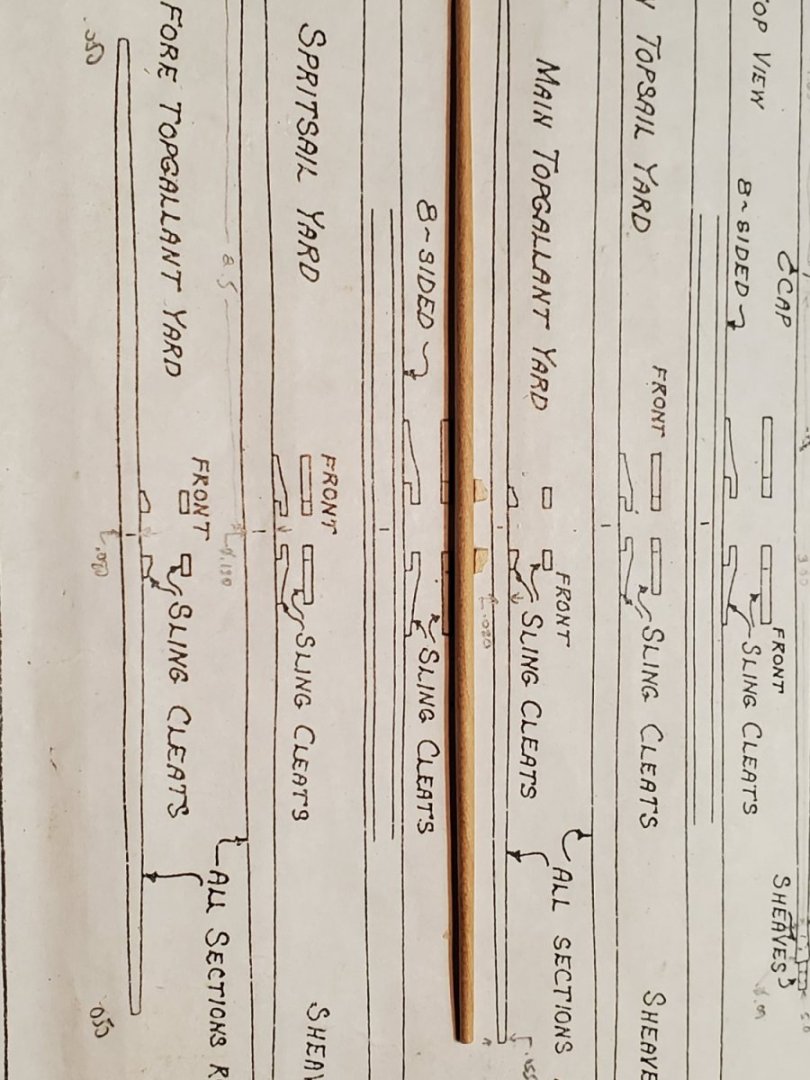

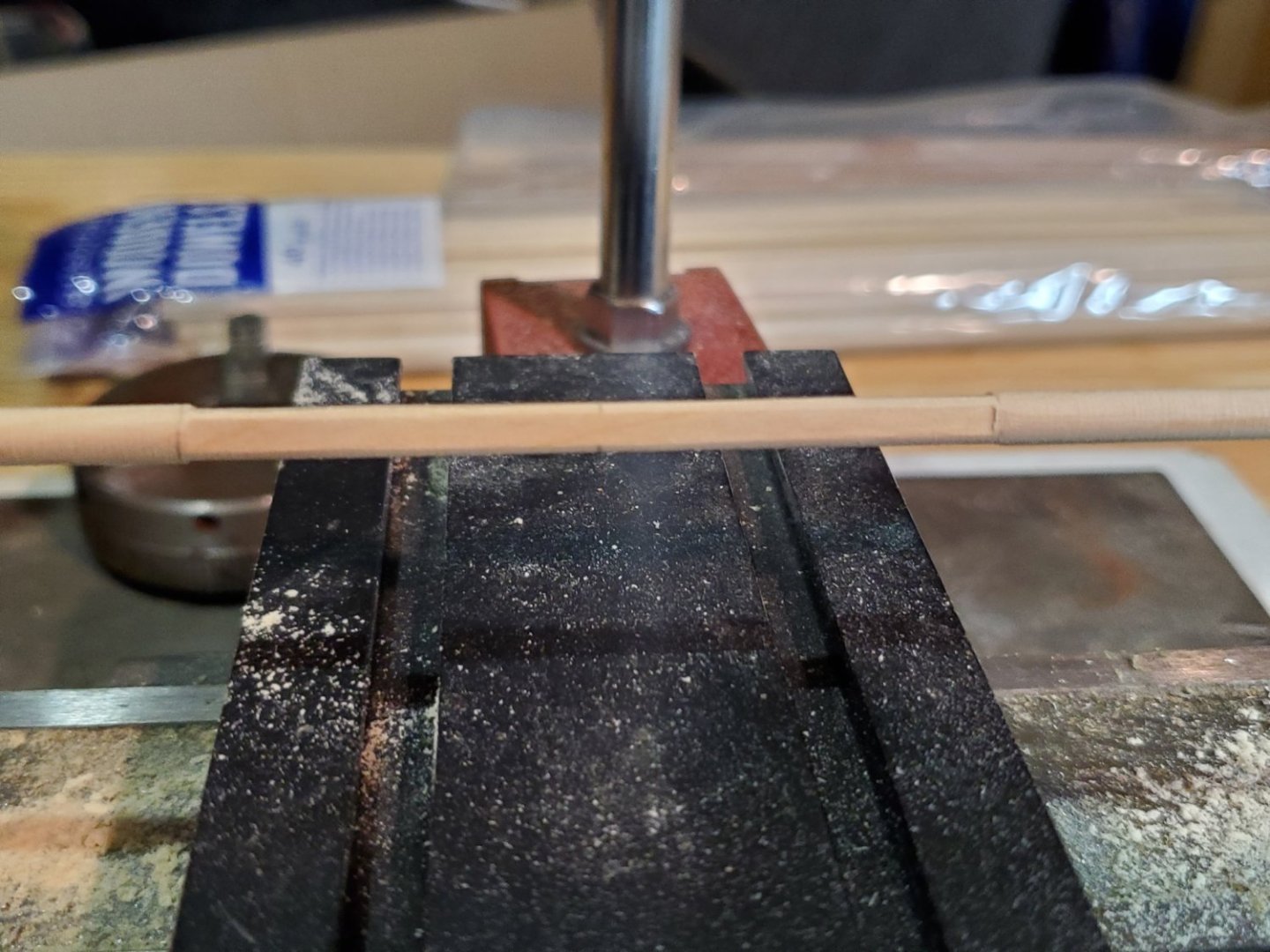

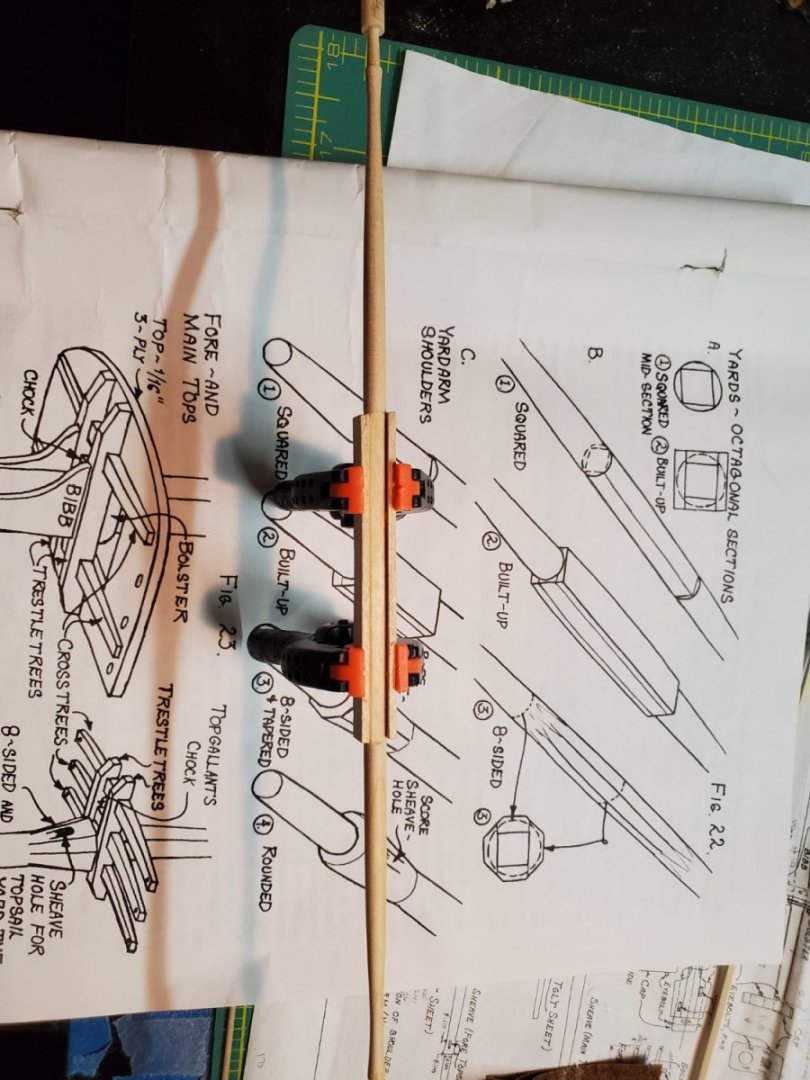

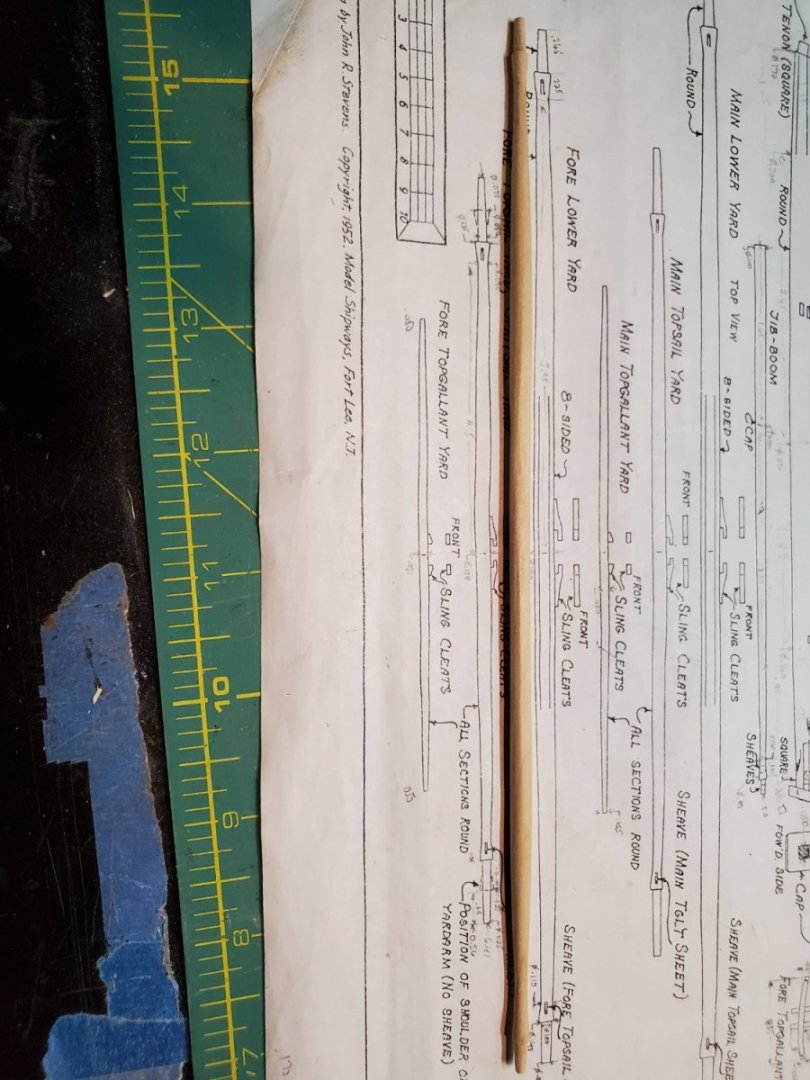

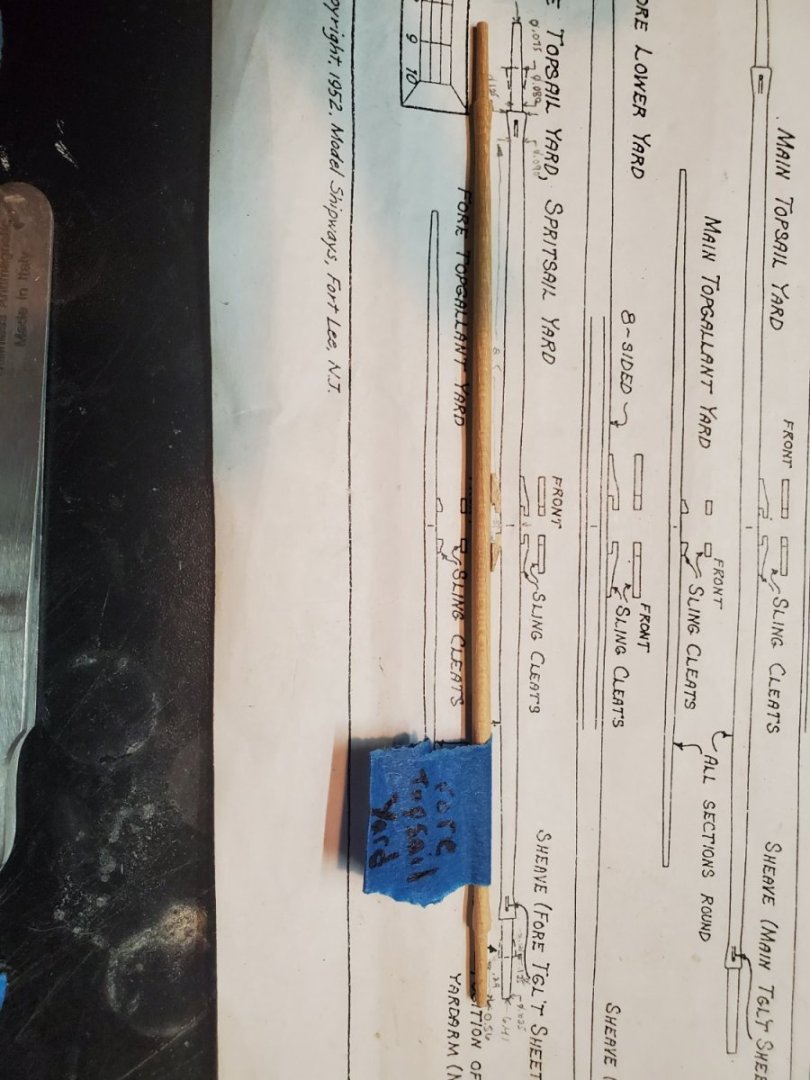

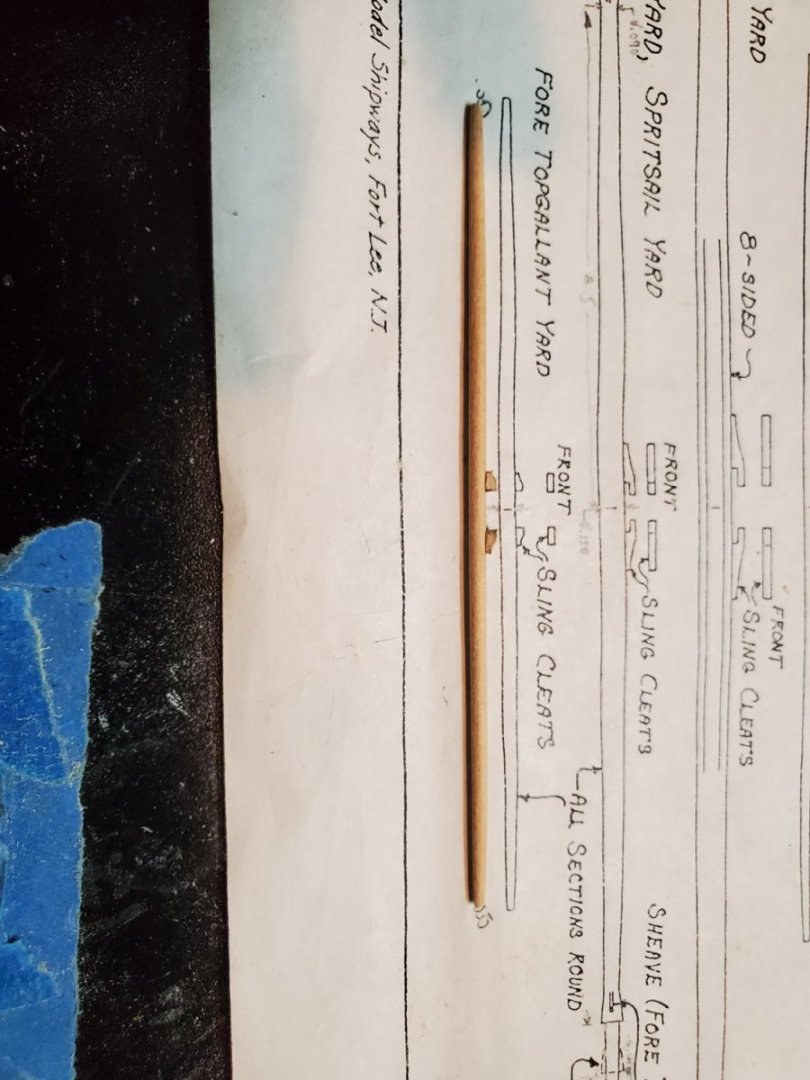

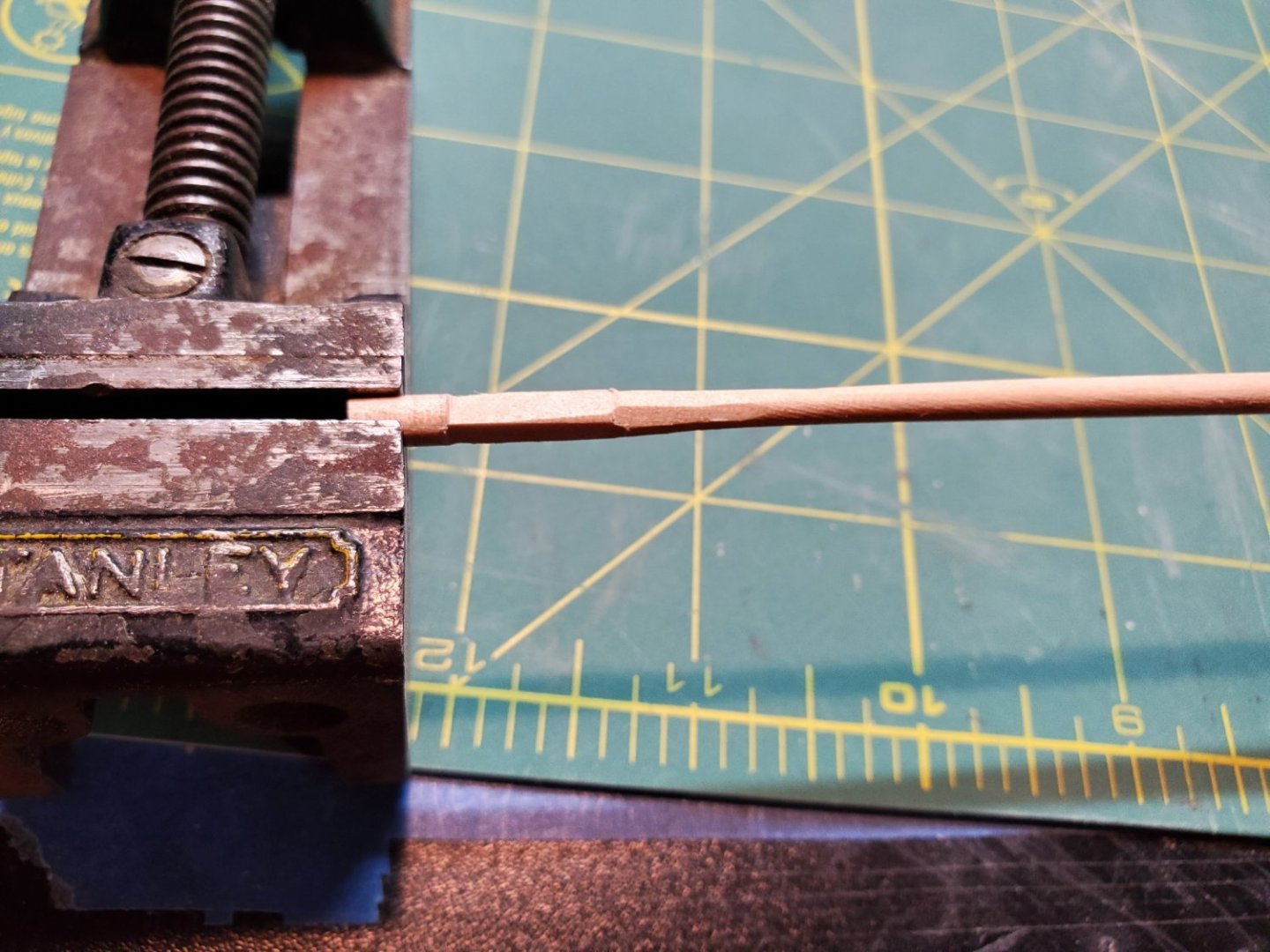

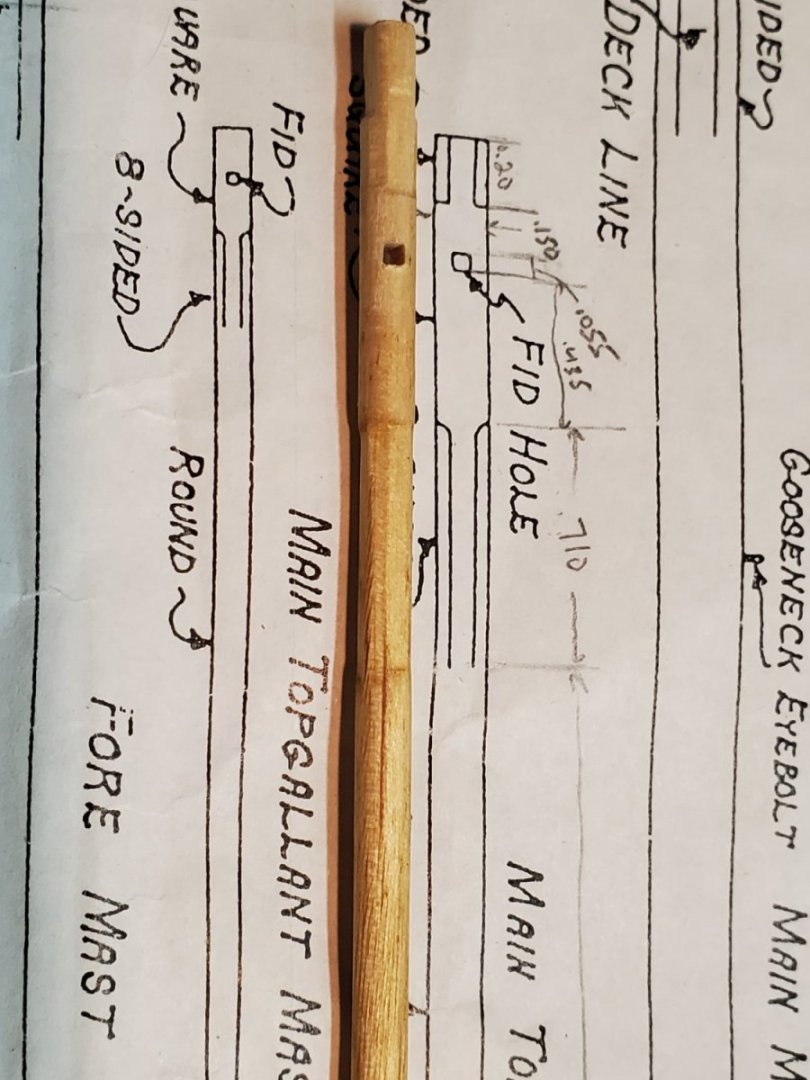

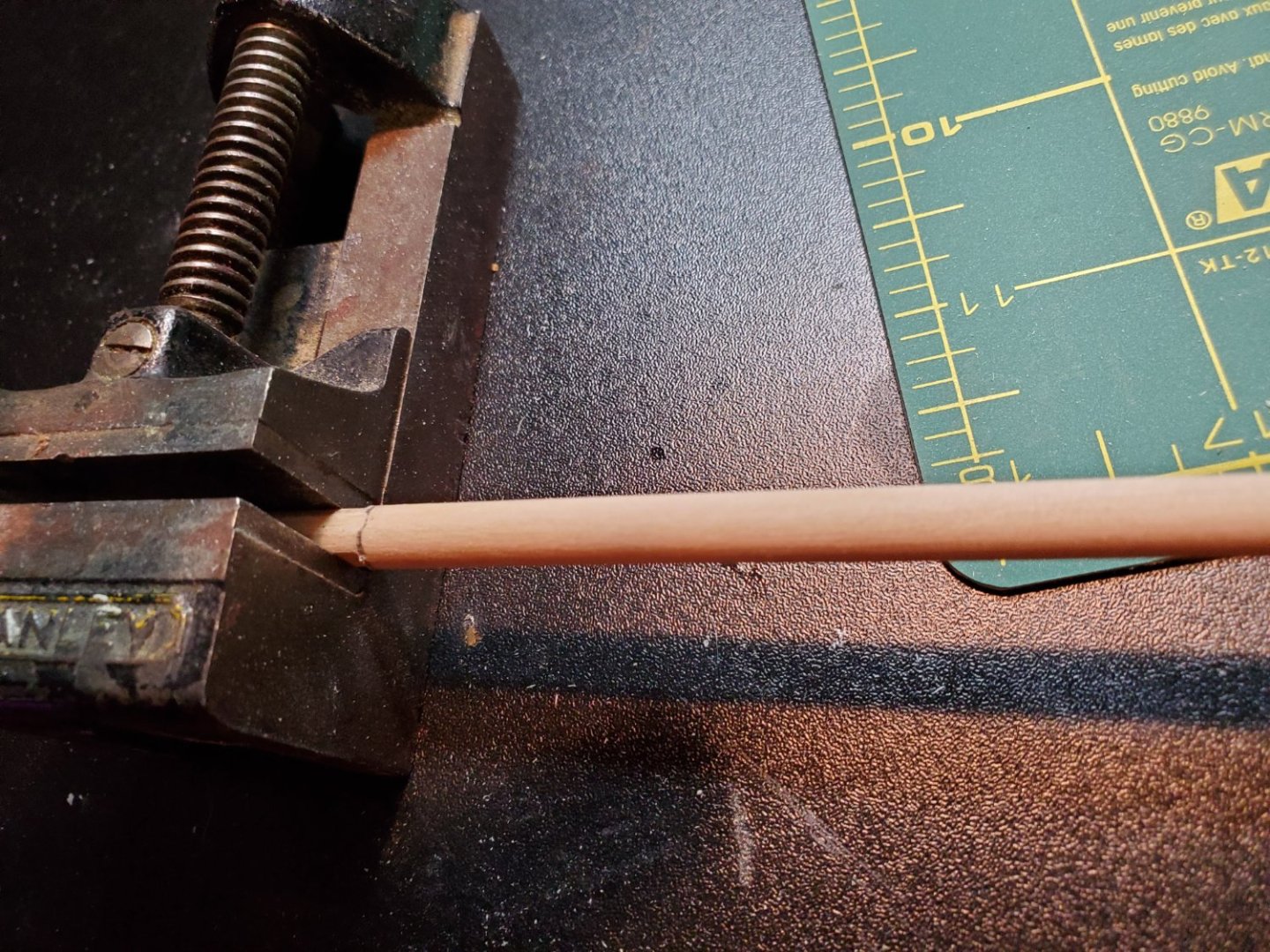

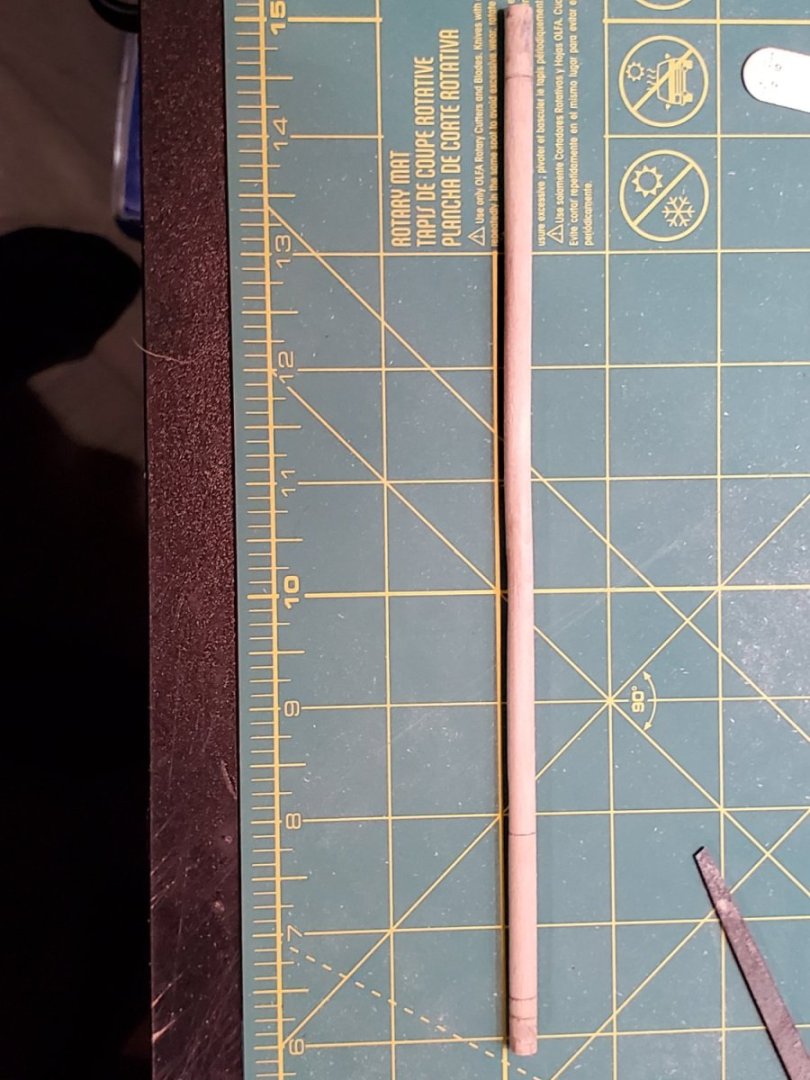

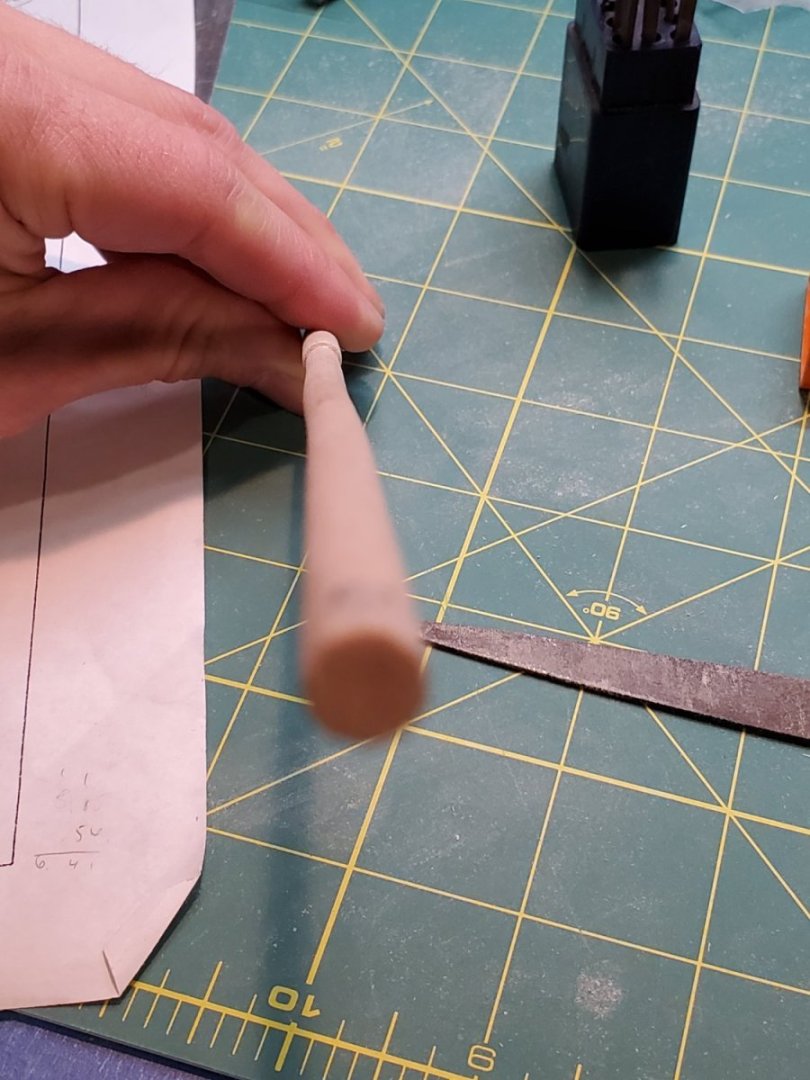

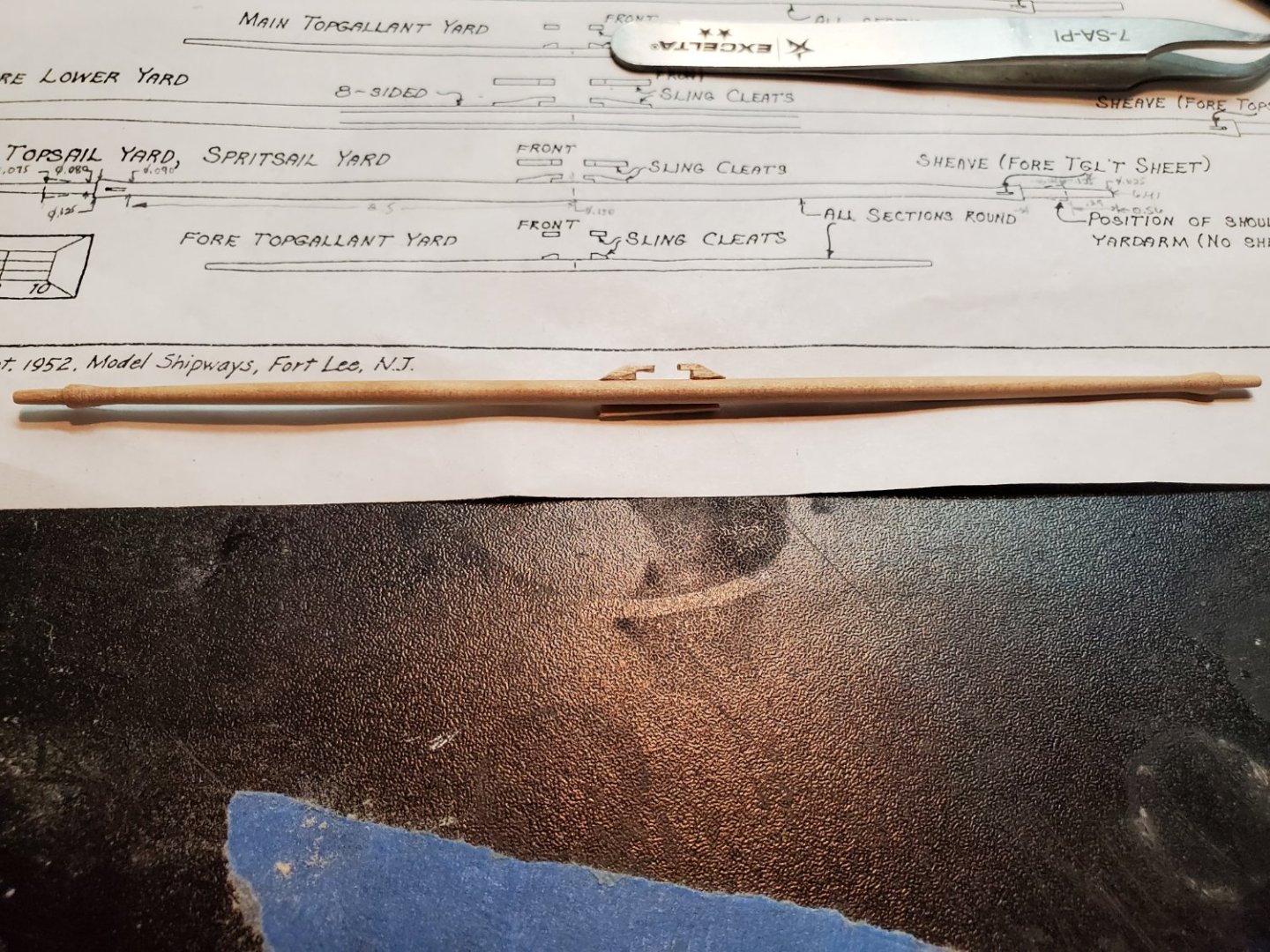

Time for an update on Fair American Model ship. Back in July, I ordered a selection of rope from Syrenshipmodelcompany.com, as well as the Serv-o-matic. I'm excited to start serving ropes soon. One first bit of rigging I did, was the tiny gammoning wrap for the Spritsail. Neither the plans nor instructions describe HOW to do this, just a picture of it having been done. So I wrapped some .012in black rope around the Bowsprit and tacked with glue, I guess... Then taped one end with painters tape, and made a few more loops. I hadn't left much Spritsail overhanging the saddle, so I really had to wedge it in there. Then made a few wraps, as you can see... Added one clove hitch tucked inside, then trimmed the edges tight. Dab of CA glue here and there to secure it. I didn't want it ever unraveling... Looks pretty 'neat' to me. After battling with the hand drill for 5min at a time to shape the yards, I went back to the lathe. I know I don't have a spindle on the opposite end to keep the yard straight, but I minimize the wobbling as best I can during chucking and using low speeds. Most of the time I'm using low grit sand paper to shape it, which is taking a while. I'm reluctant to use the turning tools, because I don't want to go too deep and ruin it. So, slow and steady as she goes.... I've managed to complete a few yards now, such as the Main Topgallant Yard below, and Main Topsail Yards Working on the Fore Lower Yard, the instructions say to add blocks to the middle, then shape to 8-sided geometry from there. This was because the diameter in the middle is just under spec. So I started with filing flats for the blocks to go in: Then glue the blocks as per the instructions... But I didn't file the center down far enough, and so the blocks have a small gap. Right where the 8-side corners are going. Not good. When I tried to file it down, the blocks shredded, since they're so close to size and the notches weren't deep enough. Really not good. So, I decided not to remake the entire spar, and I simply filed the middle 8-sided section a little undersized. I'll live with it. The ends turned out a little short, but the overall length was correct. I think I was too conservative during the shaping, not wanting to cut off too much too soon, and risk the whole shaft wobbling in the lathe. I'm now moving on to the Main Lower Yard, and I won't attempt the same 8-sided build up again. I'll just make it a little undersized. I should be done the rest of the yards soon too. The lathe surprising goes much faster than 5min spurts on the hand drill. Who knew? I also had a week off last week, so I was able to dedicate more time to the build Have a good week, all! - Jason -

-

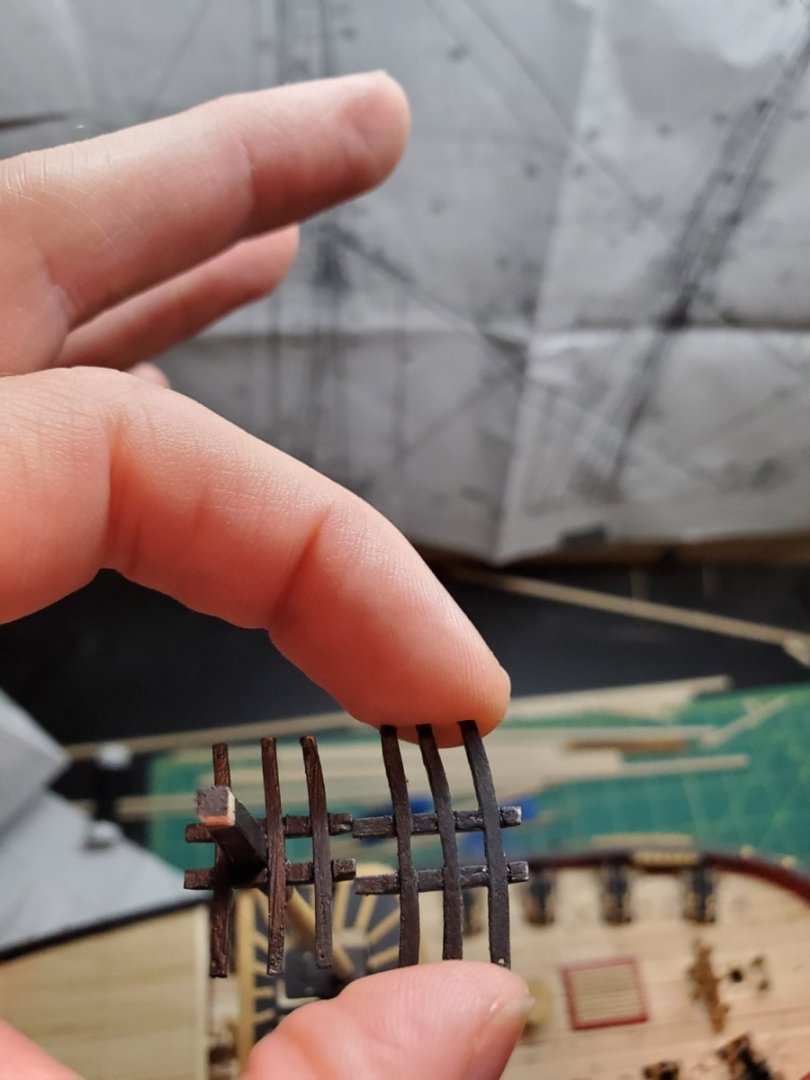

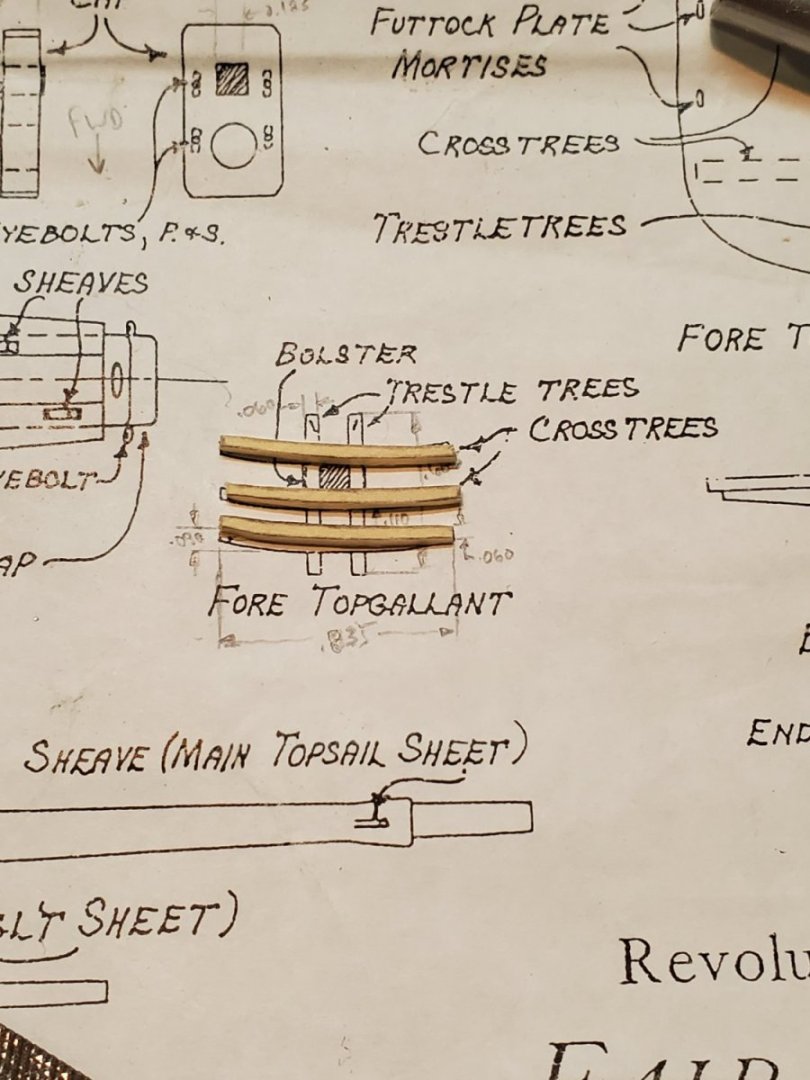

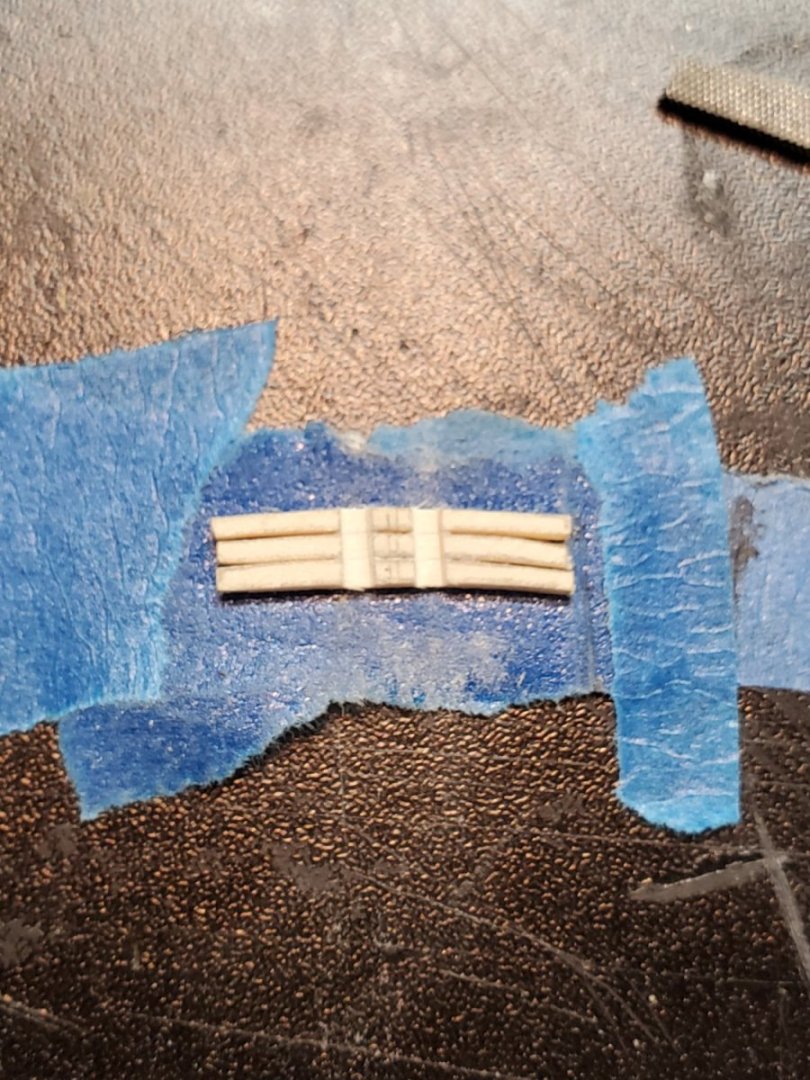

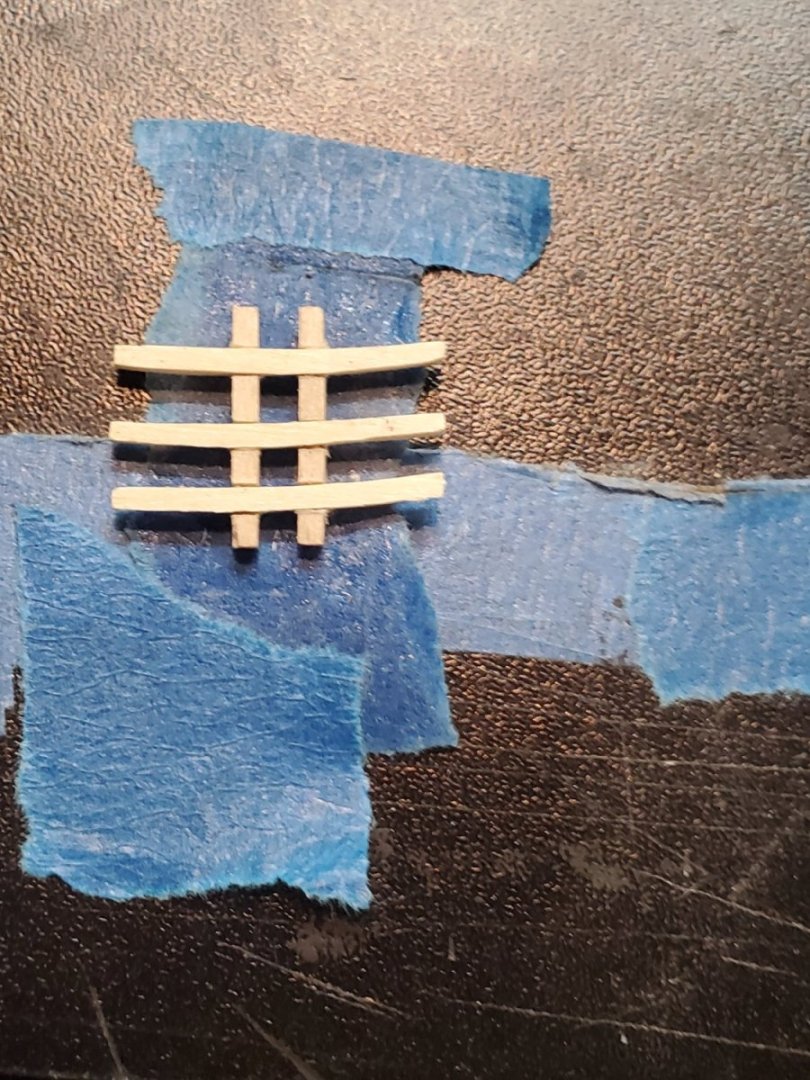

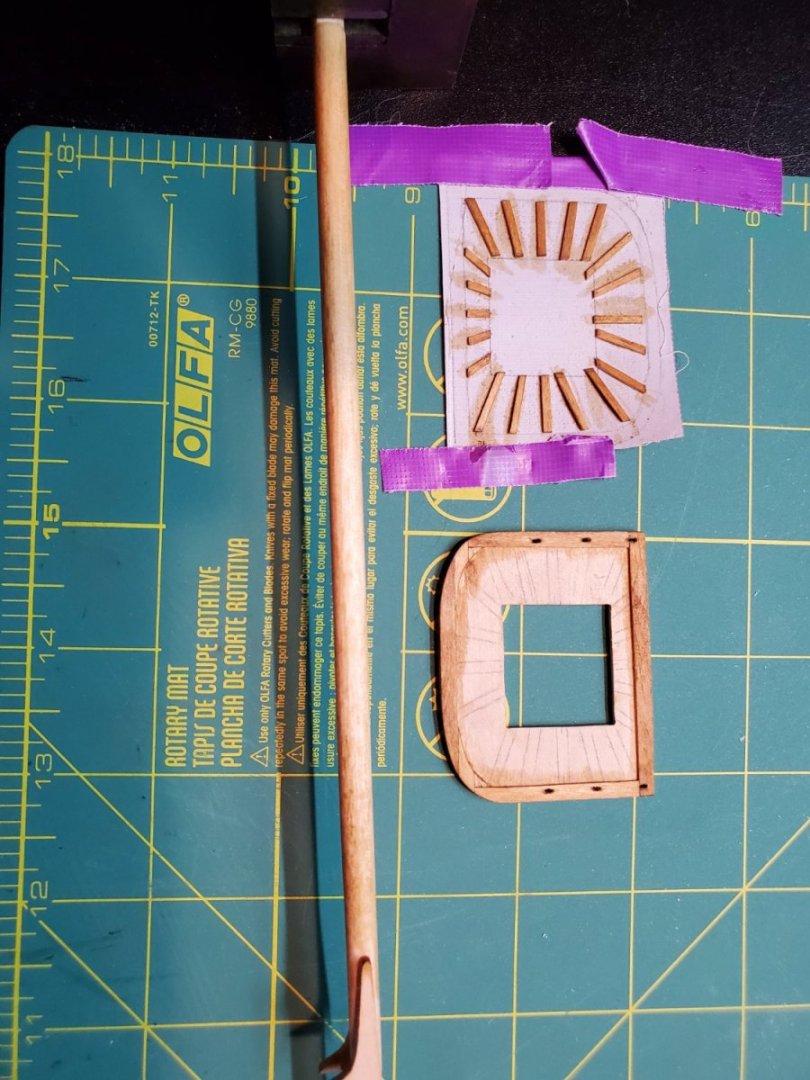

Making slow headway on the Fair American Model Ship The summer has been full of activity, and my progress has been on/off. I wish I had posted a little sooner. I did, however have a great time making beer and hanging out at Cisco's house, recently. Trying not to drown in the pool by his kids was tough - I could have brought the Fair American and rigged up a few mini-cannons to fire, but I'm not sure it would actually float, which wouldn't have fought any kid-armada off at all. 'Kidding'' aside, I was able to stain the base with MinWax Puritan Pine. It almost looks professional - almost! I went back to work on all the chain plates and futtock plates for the deadeyes. As with a much earlier post, I made a jig to hold the deadeye in place, then used fine tip needle nose pliers to pinch the wire-plate to shape, and wrapped around the pin. Afterwards I could trim the excess to leave a satisfactory chain/futtock plate. This was similar to the method described in the instructions, but I'm still deciding whether to solder and file the flat. I might just leave it. I had to file the cutouts for the deadeyes in the tops to make the plates fit. That was tedious, but I got it done. In between that work, I would intermittently work on the yards. The lathe I have is really small, so i couldn't chuck both sides the way I wanted to. I resorted to the hand drill. It took a lot of chuck-centering, but it wasn't too bad. Using files takes a really long time before the battery goes. Coarse sand paper sometimes turns faster, but burns my fingers just as fast. It also doesn't help that I'm a perfectionist, trying to get within 0.005in diameters. I wonder why it takes so long?!?! I got the Fore Topsail Yard and Fore Topgallant Yards done this way. I also worked on the Fore and Main Topgallant trestletrees and cross trees. These were simply sawn to shape, to get the curves. Notches cut in both Trestletrees and Crosstrees done on the vice, which provided a nice edge to file down to. Nothing perfect, but they're done. Upside down painters tape works really nice for lining things up for sanding/filing/gluing. I continue to work on the rest of the yards, as time allows. Hopefully I won't burn out the drill, trying to turn them all down, but we'll see. Have a great week! - Jason -

-

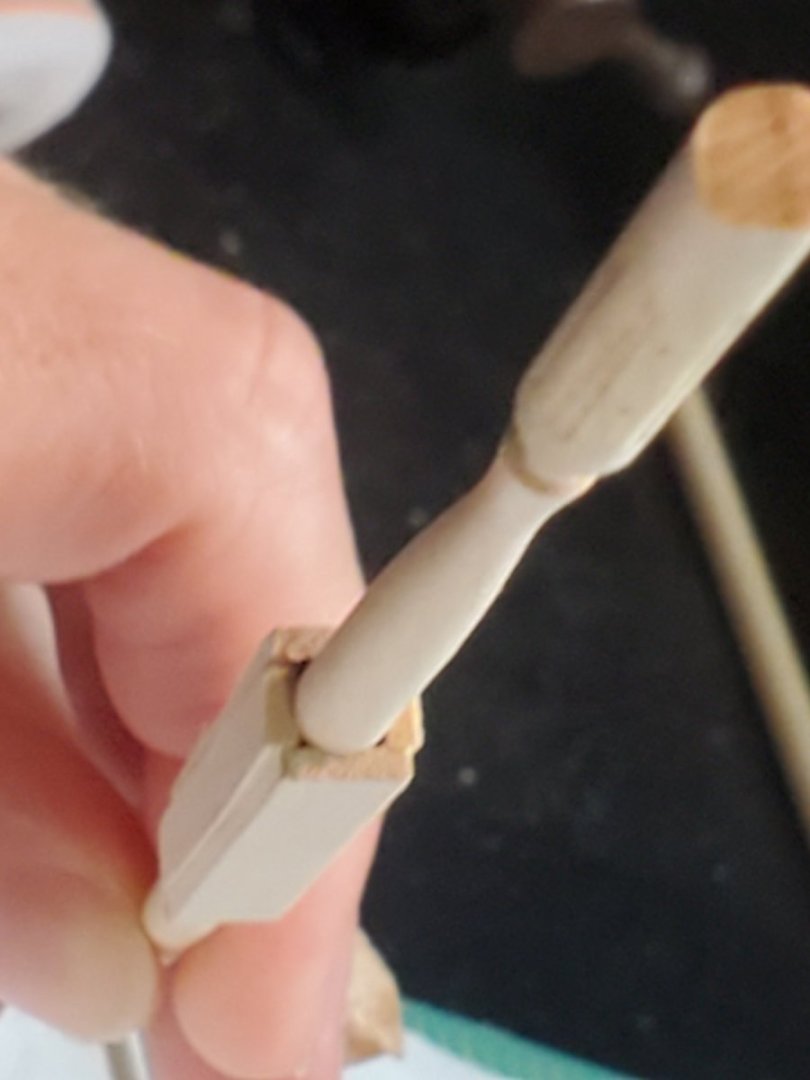

Progress on the Fair American model ship: Yet again, long time blogging progress. This month (May) has been sluggish. Primarily because the new Legend of Zelda: Tears of the Kingdom video game came out, and I've been playing non-stop for weeks. But anyhow, I found out I was 2 cleats short in my kit, and I needed them for the masts. First I tried shaping them from scrap wood, and because they're so small, they basically shredded in my hands. Fortunately I had some leftover casting, that I never used, since I made my deck furniture in wood pieces. So I cut a piece from the binnacle, and used my jewelers files to shape it. The top cleat is the real cast one, and the bottom two are the ones I made by hand. They were fun, and I'm proud they turned out even close to shape! They got painted black then installed on the masts. Masts are not glued yet. I decided it was time to mount the model (extremely late, I know). With all the progress I've made, I had nowhere to grab, except like this. I'd hold in one hand, and flip the entire model over. Then use pin vise to drill the holes, smallest to largest, hoping they were straight. I'd made pencil marks on either side of the stand-off so I'd know where to drill. Keeping the drill straight was really difficult, obviously. I didn't want the screw to split the keel, so I went with a 6-32x2in machine screw. After the tap drill was used, I took the screw and drove it into the keel a little ways, to pre-start the threads. I also counterbored the hole in the bottom so the head would be just a little under-flush. Marked the front of the stand-off with a pencil ''F'' to indicate the orientation. I had already pre-chamfered the corners so it wouldn't gouge the wood when it finally mounted. The screw is just a little proud, so it won't bury in the keel too far. I carefully placed the model in the stand-offs and hung one end of the baseboard over the edge of the bench. Then I could reach the screw from underneath. I got both screws in with little problem. Then I got into trouble, BIG trouble. The model was WAY WAY tilted. I was careful with drilling everything. But it wasn't enough. I think any small off axis drilling, causes larger effects when you mount it. I did everything I could think off to counteract the tilt, to no avail. I stepped away for 2 days for Zelda to cool my nerves, and not wreck my ship in frustration. The only idea I had was to shim under the stand-offs with scrap wood. I didn't have any washers thin enough to use. This is not what I wanted to do, but I needed to move on, and I felt good about the sturdiness of the screws to the baseboard and keel. You can see the little shim underneath. Fortunately it worked. As close as I am willing to accept. I don't want to ruin the model, or worse risk dropping it to try more fixes. Its ''within'' level, and I can sleep again. Again, I'm using the Capstan as the middle reference point. It may not be dead level to the model, but it's what I can use as a check. It's about mid-ship anyway. So there she is - mounted! Finally. I'll be working on the deadeyes for the tops next, getting them installed with other block before finally mounting the masts. What a month for me. Zelda and near-miss shipwrecks. Probably more progress next month! - Jason -

-

Thanks for the kind words, Chuck. I plan on doing full rigging, with sails. Its ambitious for a first build, but I like a challenge. The rigging ''plans'' are already a challenge to understand. I like your suggestion of the shroud cleats; its also why I added pins to the bitts, to provide appropriate belaying points. I'll keep rigging along....

-

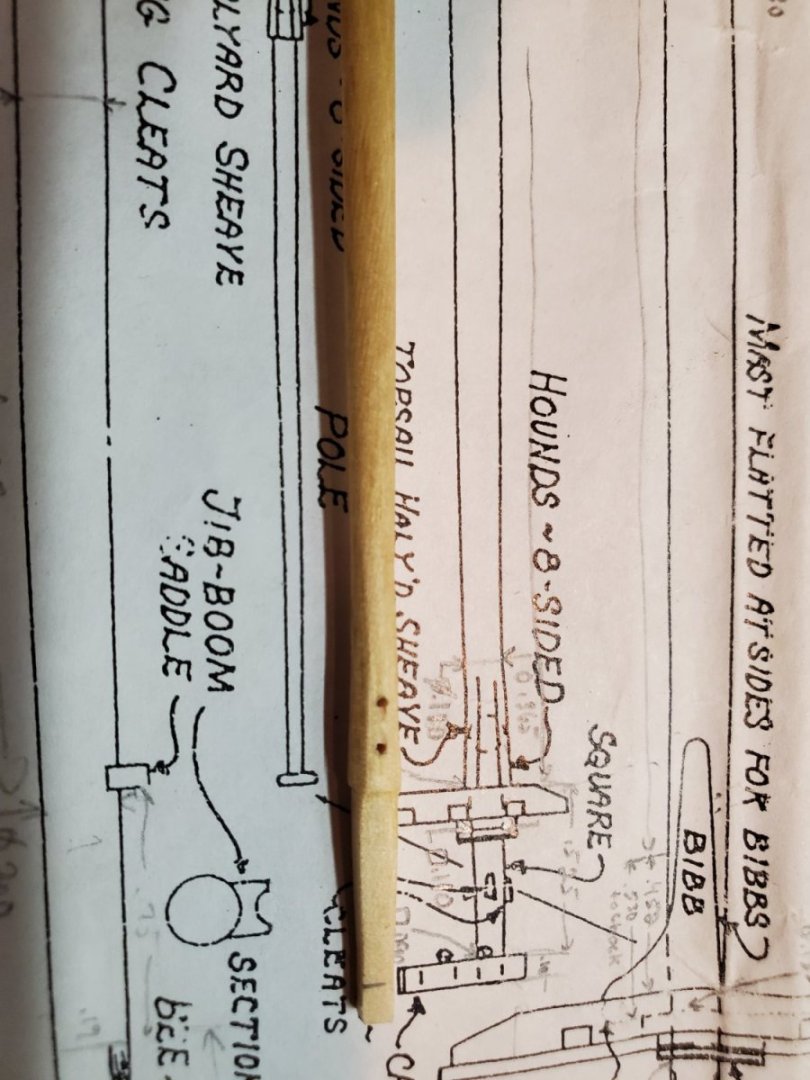

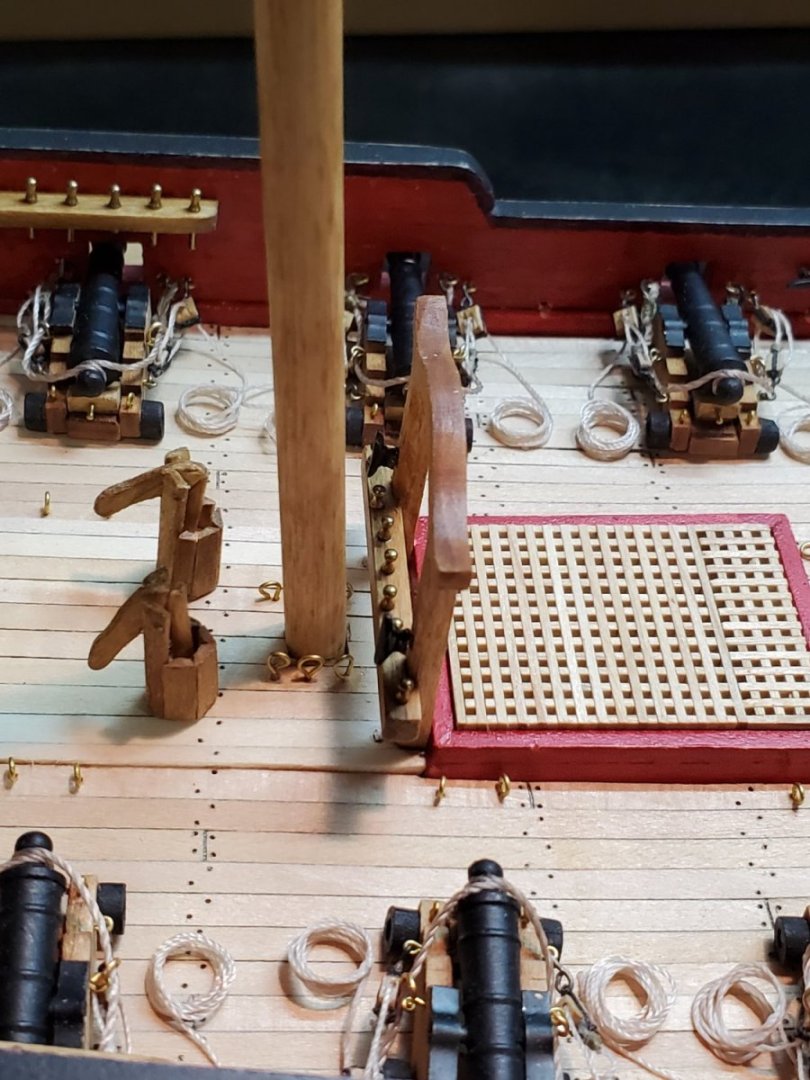

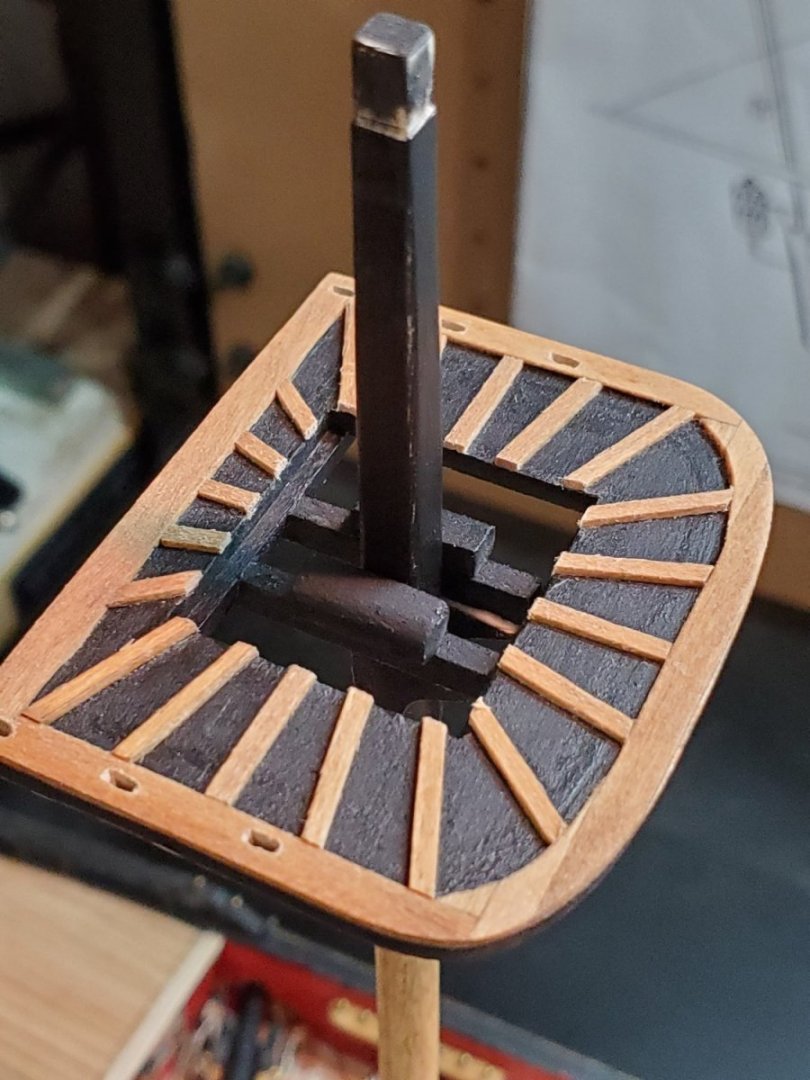

Overdue progress on the Fair American Model Ship: As always, my progress is slow, but steady. I'm determined to finish this year. Most of the work has been on the masts, both Main and Fore. I'm committed to shaping the spars as close to the plans as I can manage. It's slow going, of course to shape the masts: tapering down, then blending to 8-sided, then square tapered towards the top, etc. Using the vice and clamping a sacrificial end, filing, then rotating 90deg to index the sides has been working well. This is the Main Topmast, in progress. As you can see, I use the calipers to measure the feature sizes, then do my best to make the mast to shape, accordingly. You won't see the detail as much once the ship is fully rigged, but I like the detail. I was pretty proud of this work. The upper end of the top mast, again I make lots of measurements. I wasn't going to attempt to put a small wheel in there for the sheave, so I just drilled 2 holes to simulate it, and carve out rounded edges. Once everything is finely sanded to 1500grit, it gets stained with MinWax Golden Oak and painted flat black. I try to do everything in batches, while the paint brush is out. According to the instructions, most everything is supposed to be black. The color scheme I'm using is from other modelers like Rafine, who's craftsmanship is incredible. Another thing I was able to do, was move the Bitts farther away from the main mast hole. If you remember a while back, I mounted the Bitts too close, and the mast was basically going to be touching. I took my time to work the glue loose, and re-drilled the pin holes on the deck. If you look closely you can see the previous holes just peeking out. Very happy I was able to move this without incident. The Main Top turned out really nice. You can see all the jigsaw pieces of trim I had to use to build the rounded end. The Bibbs on the Main Mast weren't perfectly perpendicular to the square bottom that goes in the deck. So in order to glue it straight, I temporarily wedged the Mast in the deck, and looked down from the top to align it. A little of the top/port Bibb can be seen under the trestle tree. I'll live with it. I have yet to put the chock in, I need to stare at the plans some more to get it right. Both Fore and Main tops look pretty straight to each other, looking from the bow. So this is where I'm at now. No masts are glued in, only placed for appearances. Its really starting to look good I still need to mount this on its final base board, instead of clamped in my ''dry dock''. I have been putting off this part, because I don't want to mess it up. The ship is really coming together well now. I'm excited to start rigging this thing. Hope you enjoy reading my progress - Jason -

-

Chuck, that's a beautiful model. I like that you used white on a section below the whales, and left the remainder stained wood. Looks sharp! I'm currently working on the tops. (AKA picking at, as time allows). Trying to determine if the Fid rests on the chocks, or the bottom of the top mast rests on the chock(s) - the instructions are not super clear. Hope to have another update and pics soon. Thanks for sharing the pictures of your FA - its gorgeous

-

Nice work on the planning, Cisco! I spent a similar amount of time preparing mine. From that yellow planking book from MS, it can get complicated with rules, lengths, size, etc. I think each modeler's approach to planking is interesting and unique. I like how you penciled the layout on hull, before laying any planks. Smart! Jason

-

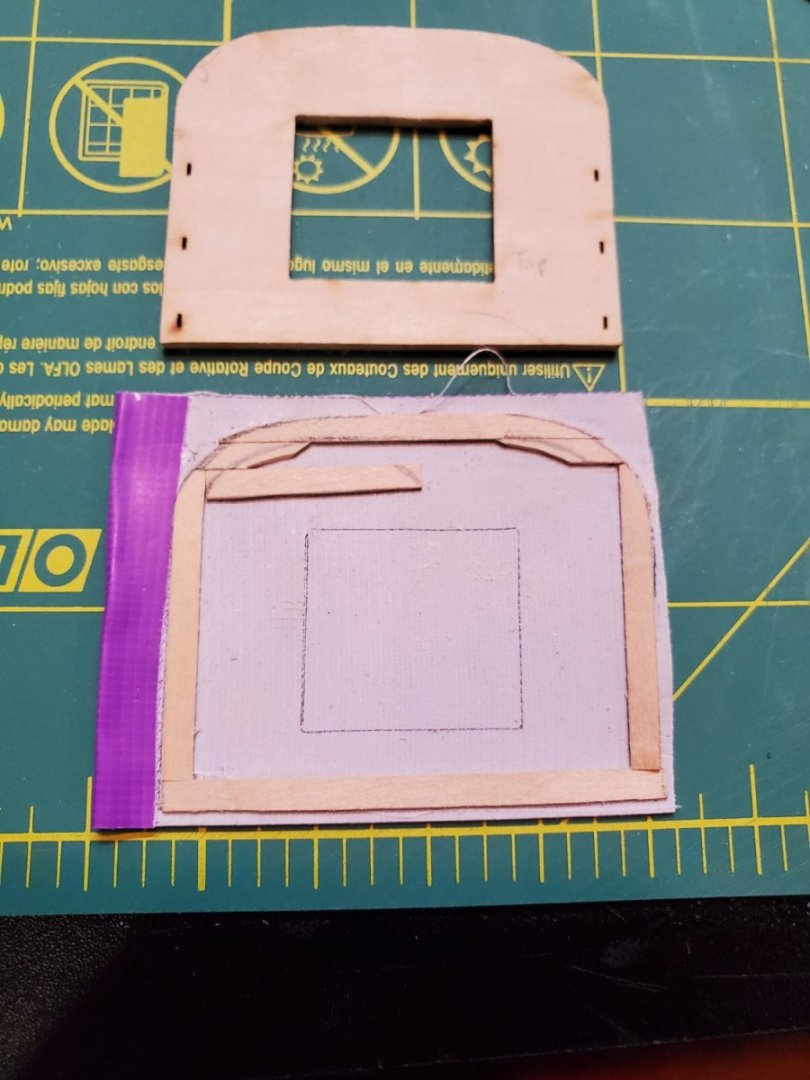

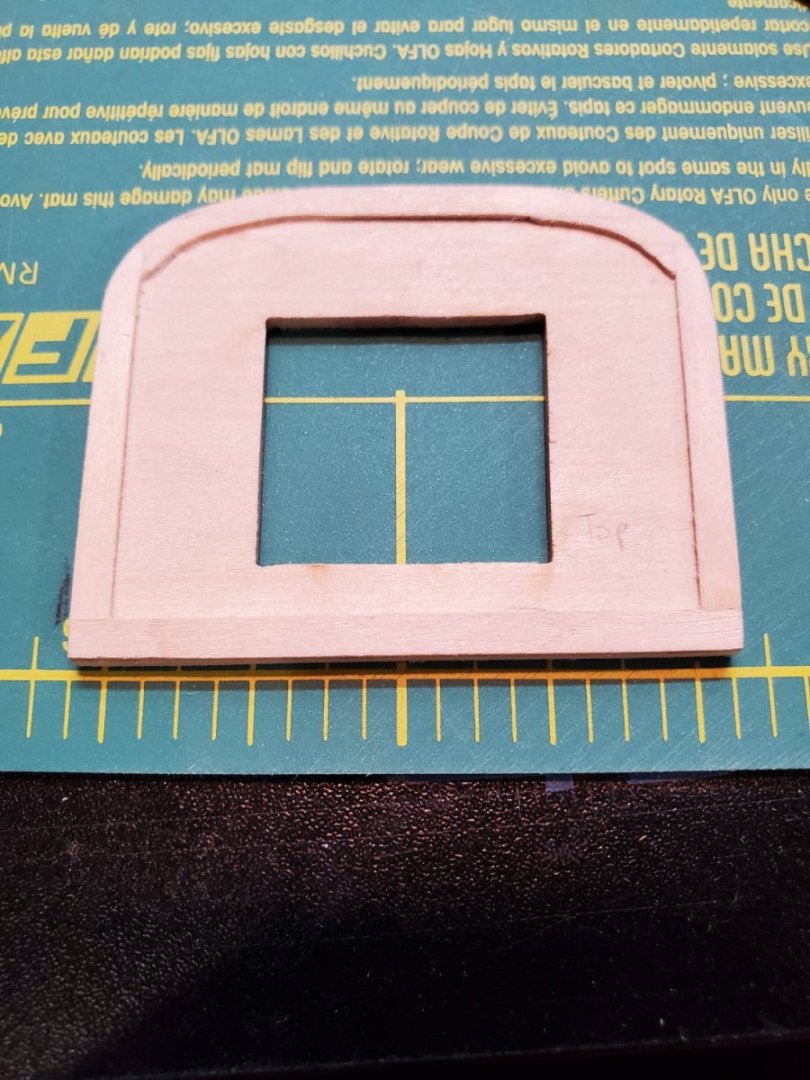

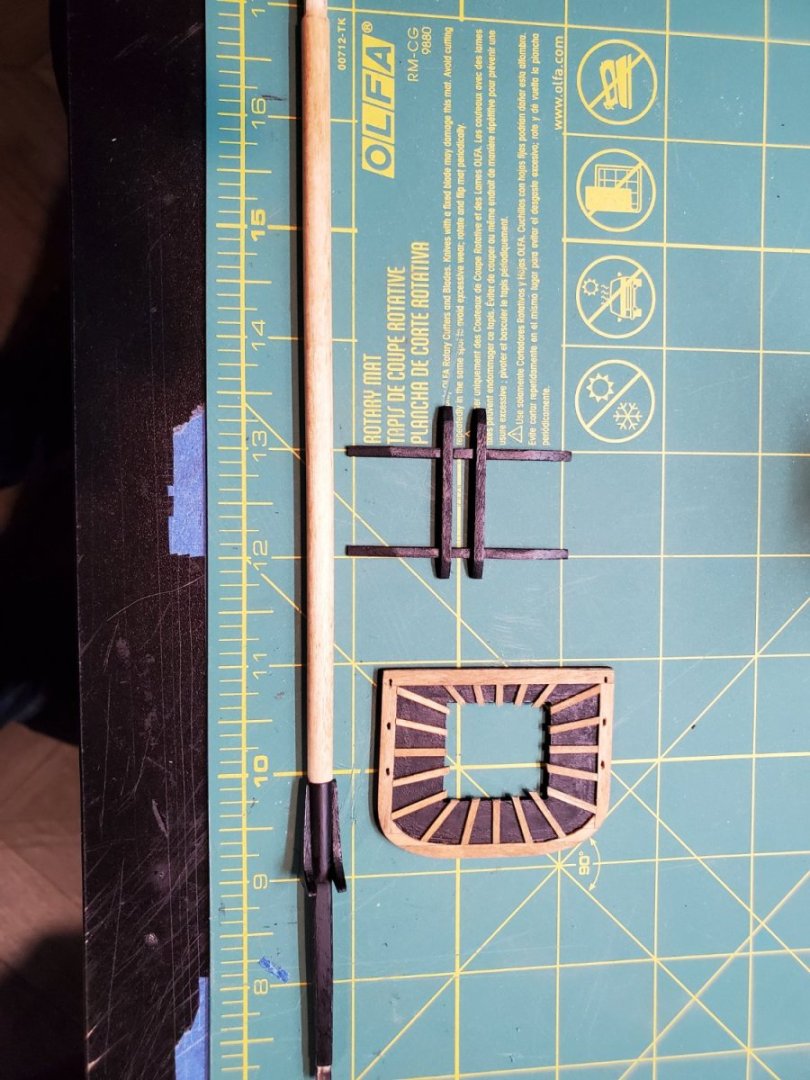

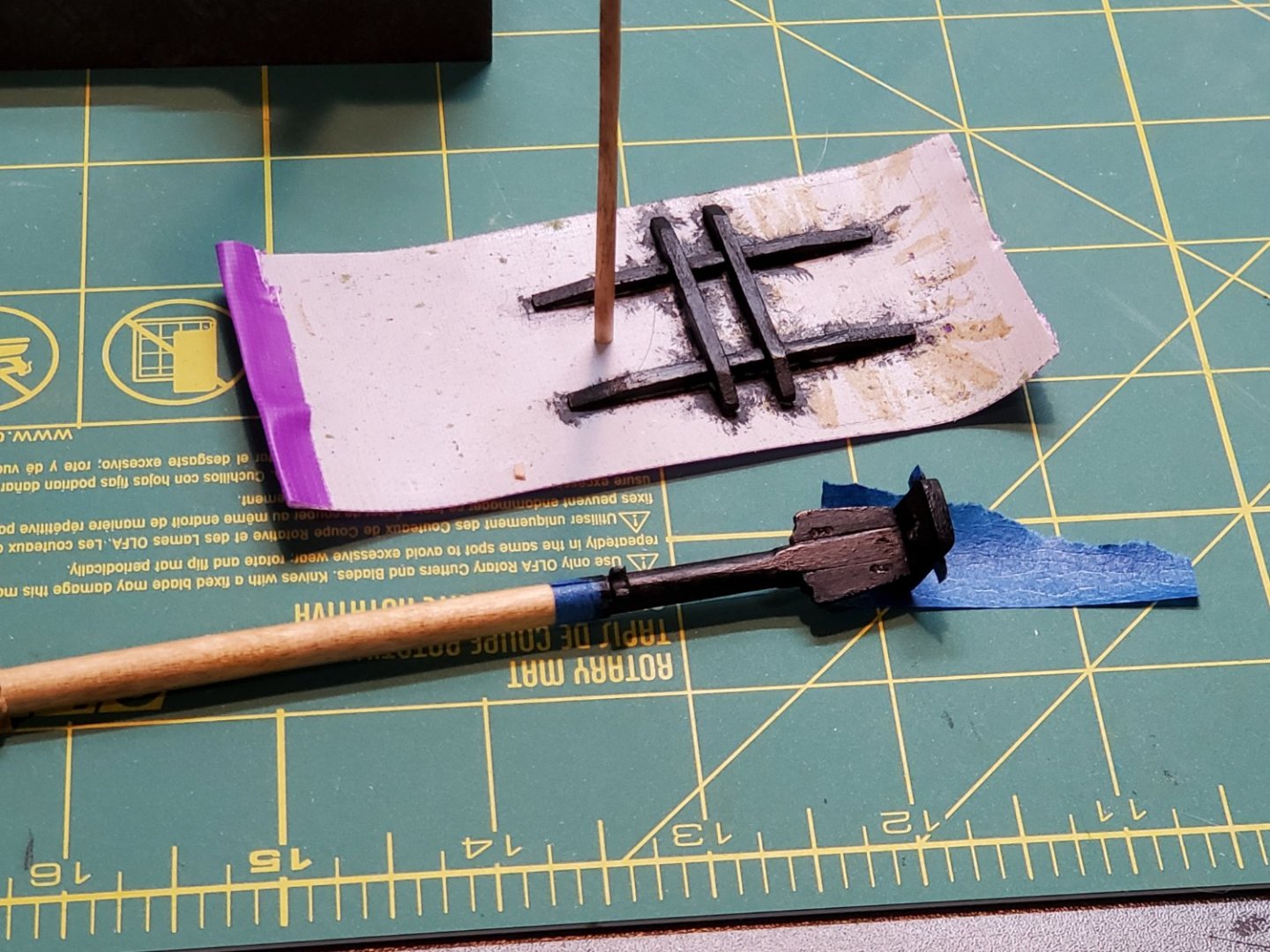

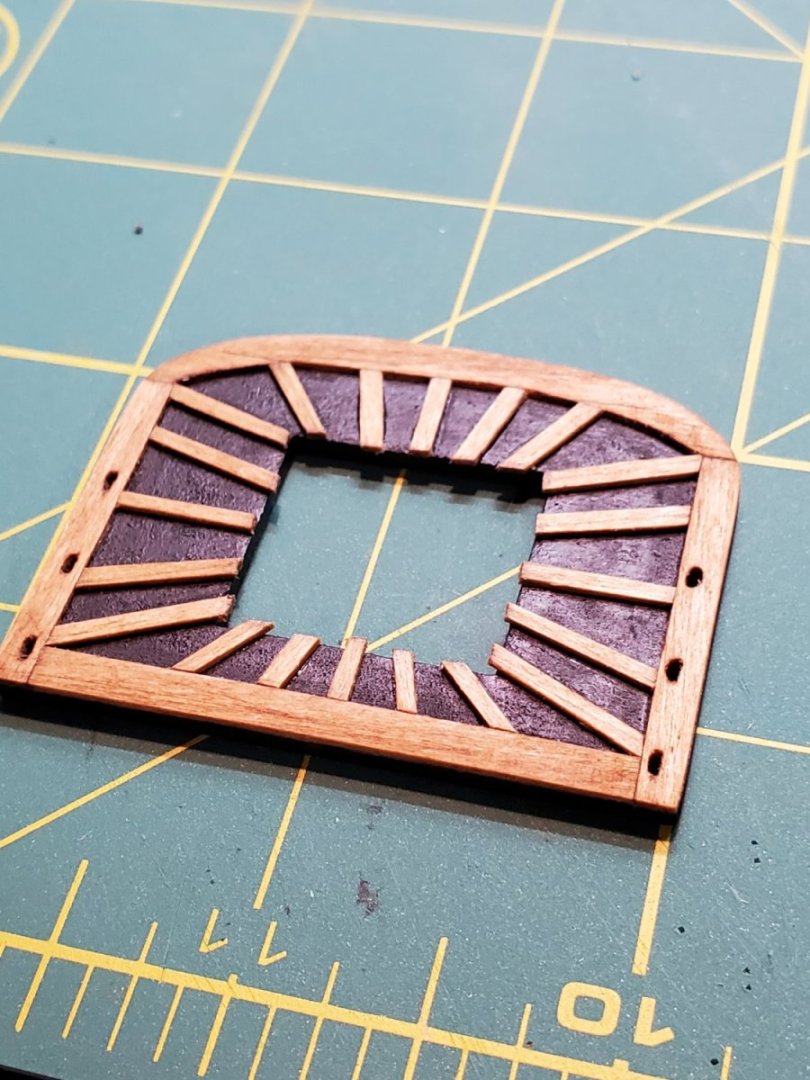

Finally making more headway on the Fair American model ship. After so much time sitting waiting for the masts to be finished, the model has been gathering dust like crazy. I've been blowing it around as I'm working - that didn't help. I bought a keyboard duster can, and got what dust I could off the model, then covered it with a cloth until I'm ready to progress. Working on the main mast now, I think I've come up with a pretty good method of shaping it. I start with filing the flats on the bottom of the mast, to sit in the deck. I keep that section long. Then I can clamp it in the vice, and I now have a way to orient the spar as I'm shaping it. I can tilt the vice 90deg to form the square sections, and rotate my flats 180deg to get all sides. Now that it's oriented, I support the end with my fingers and file the flats to shape. It's slow going, but I want it to be even and symmetrical, so it's worth the time. However, my hand cramps after a short while, so I take breaks. I was lucky I had a week off on vacation, I could dedicate blocks of time to finish the whole mast and top in a week. The main top was larger than the fore top, so for the ''trim'' I had to use several 1/32" pieces to make the shape. It would have been better to have a sheet to work from, but I'm doing things the hard way, apparently. This isn't what is shown on the plans, but I like the look, so I'm doing it. The upside down duct tape works nice to hold things in position for tracing. Hard to see, but the finished product looks good. Lot of sanding to get the blended curve just right. After staining, it'll look like I knew what I was doing! Almost. Next came the cross and trestle trees. These were fun. I made sure they didn't overhang the top, like it had on the fore top. I drew a little F on the front so I knew which way was which. I made that mistake once, I wasn't about to do it again. I got the Bibbs glued on next. You can see on the end of the mast I drew an F --> to indicate which was front facing. That was the mistake I mentioned from the fore mast. The ribs for the top came next. Again, the tape worked well for orienting and locating everything. I stained the top, mast and ribs all at once. You can see the individual 1/32" pieces used to build the trim on the top - tricky little pieces, but turned out nice. Once I got a few coats of flat black paint on there, it's looking pretty sweet! Again, I've left the ribs long on the inside of the top. I'll sand them flush later. I'm starting on the top masts next. Its much of the same process of flatting, and sanding I've done so far. We'll see how long that takes me. Hope you find this FAIR'ly interesting to read ;-) - Jason -

-

Cisco, this is where the fun begins. I tried to use the lumber provided from MSW to build the planking bands, but they didn't lay well as described in the yellow book for me. I like your tape method, actually. The garboard strake is just ''wider'', typically 1.5x a regular plank. The rest above the garboard can be regular width. Your approach of using one long plank, wetting it and clamping it to shape, then cutting the butts in after it's glued for the appearance is exactly what I did too. Just don't cut all the way through, or the plank may pop out. How are you going to determine the plank butt separation? The yellow book has a nice set of rules to go by, but I had to modify a lot to make them ''work''. You've got a fine model going. keep up the great work - it'll be in ship-shape in no time 😉 - Jason -

-

Long overdue progress on the Fair American Model Ship: January was another busy month for me, so not a ton of progress this time. I got the Foremast completed, though I'm not 100% happy with it. The square cross section at the top was undersized, so there wasn't much flattening to do for the Bibbs. I also filed a flat for the bottom of the mast to seat into the square hole in the deck - this will keep it straight and aligned. I was finally ready to stain it, before any painting. I used 800, then 1500 grit sanding pads to get it smooth as I could, rubbing in the direction of the grain. I blotted and wiped MinWax Golden Oak stain, just one coat. The knot in the mast was pretty dark - I should have used the pre-stain first. But hey, it's character! The camera on my phone wouldn't focus on the mast, so it's blurry. After constructing and gluing the cross and trestle trees, they got painted. Along with the fore end of the Bowsprit. Painters tape worked nicely to get a clean line for painting. The Bowsprit stained really nicely. After all the flat black paint was dry, the result so far looks sharp! For the eyebolts surrounding the fore mast hole, they're way too close. I made them to scale as per the plans - I should have spaced them farther apart. Not sure why the plans don't show it, but I've seen most modelers put some round, black mast ''seat'' on the deck - what is that called? Anyways, There's no room for it on my model. I thought I'd get clever, and make a really thin one out of glued planks of 1/32" Walnut. I thought I could slip it in there - it's not going to fit. It's too flimsy and keeps splitting. I'm not sure what to do. What I tried, was to rip out the eyebolts and move them out - bad idea. I had a grip on one with needle nose pliers, and it let go and I dropped the point on the deck - now there's a dent. I'm lucky nothing else broke too, but I can't erase it. It isn't visible unless you're looking for it - but I know its there (no picture). I'm going to leave the eyebolts where they are - its safer that way. I had the chance a few weeks back to visit Cisco at his home - he's got a ton of modeling books and sundries and Legos! I had the pleasure of seeing his work space, along with a gorgeous cabinet he made himself to hold all the fine chisels - really beautiful work! I hope to get back again soon. Thanks for the pack of dowels too, already picking through them for the Main Mast. Hope to have more progress soon. Thanks for reading - Jason -

-

You're probably right about the re-warp potential - I hadn't considered that. Being that this is my first model, I'm not familiar enough with different woods and how/when to use them. I hear Boxwood is a good material. I may take you up on the offer to steal dowels when I come visit - looking forward to meeting up again.

-

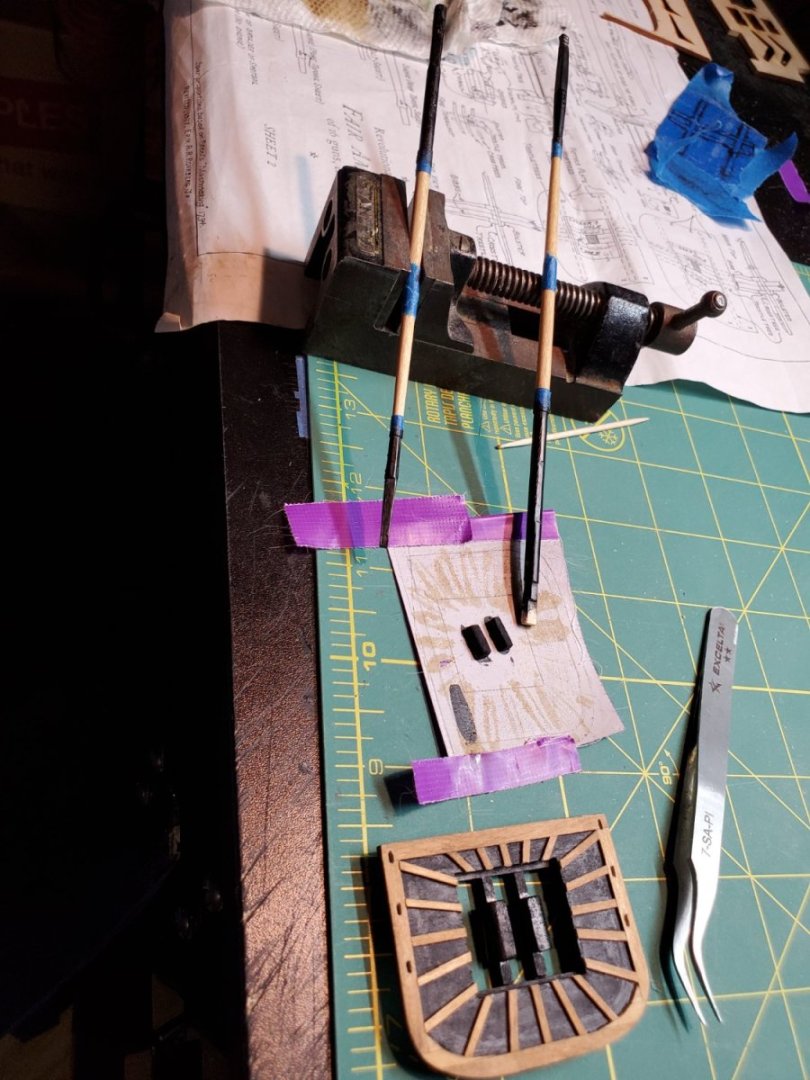

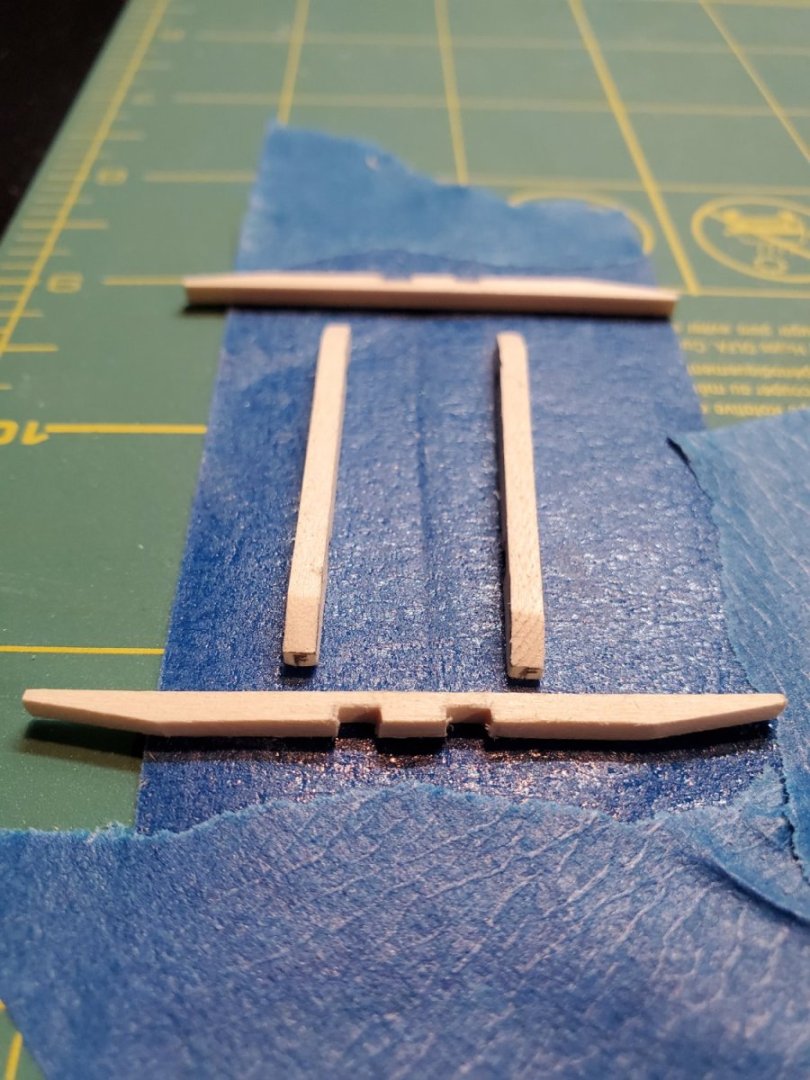

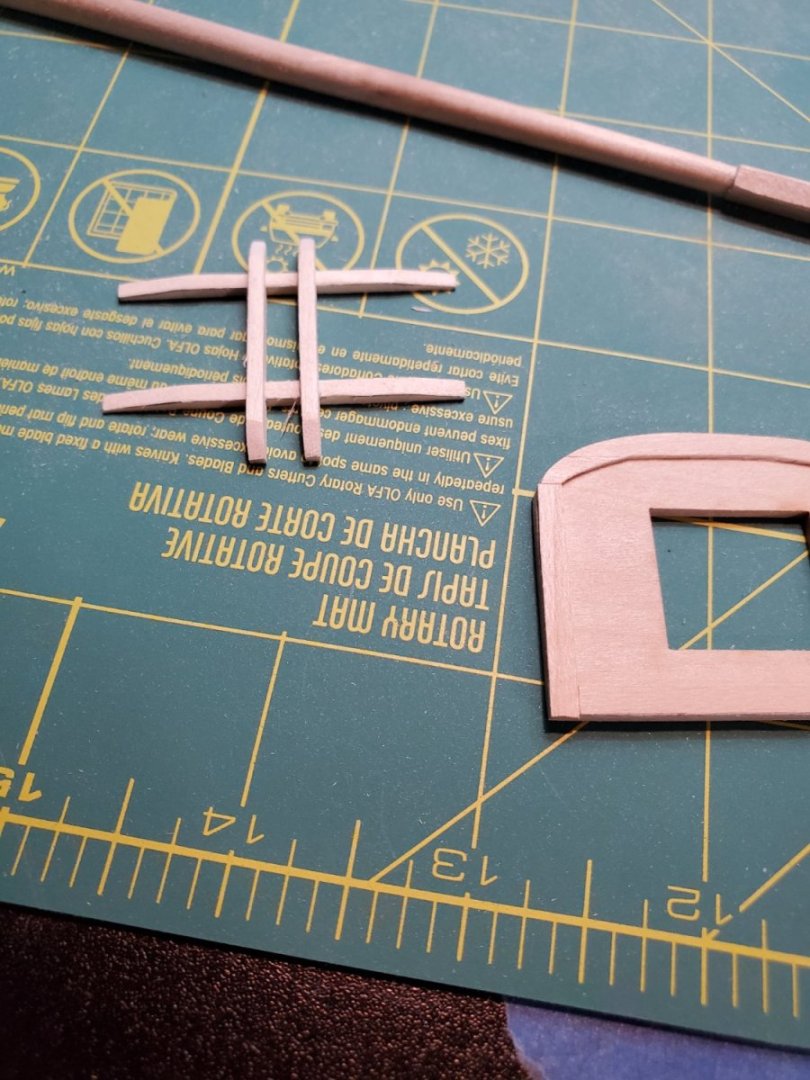

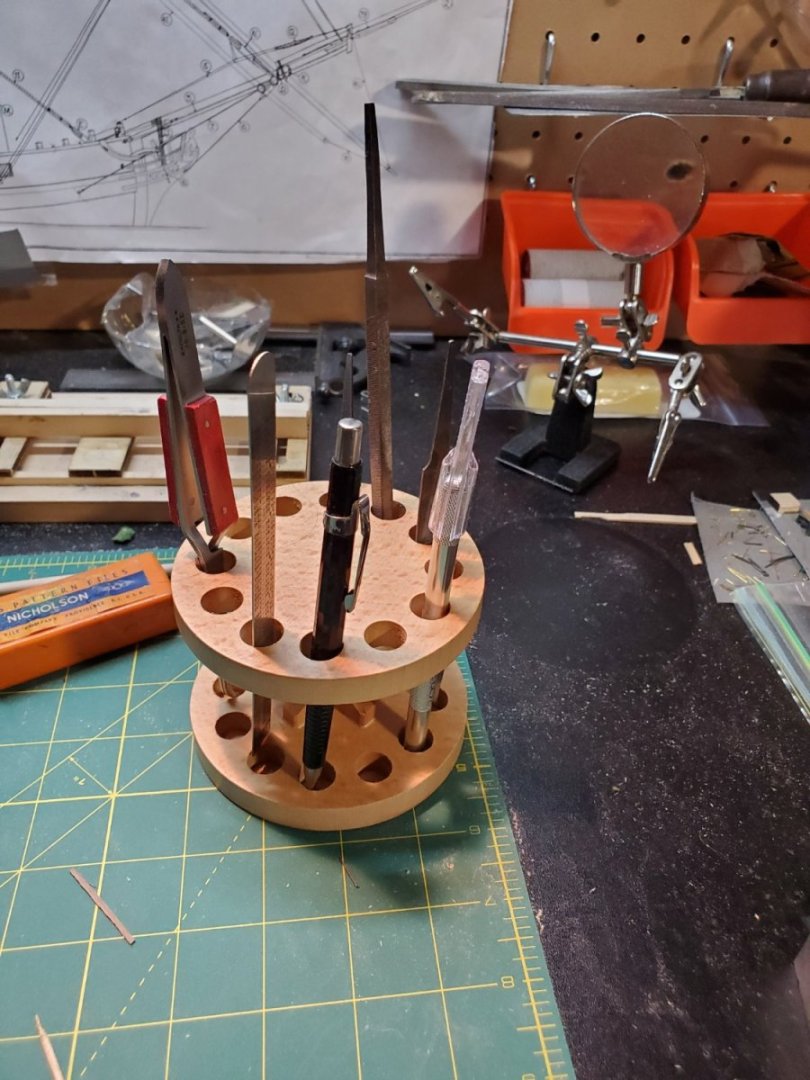

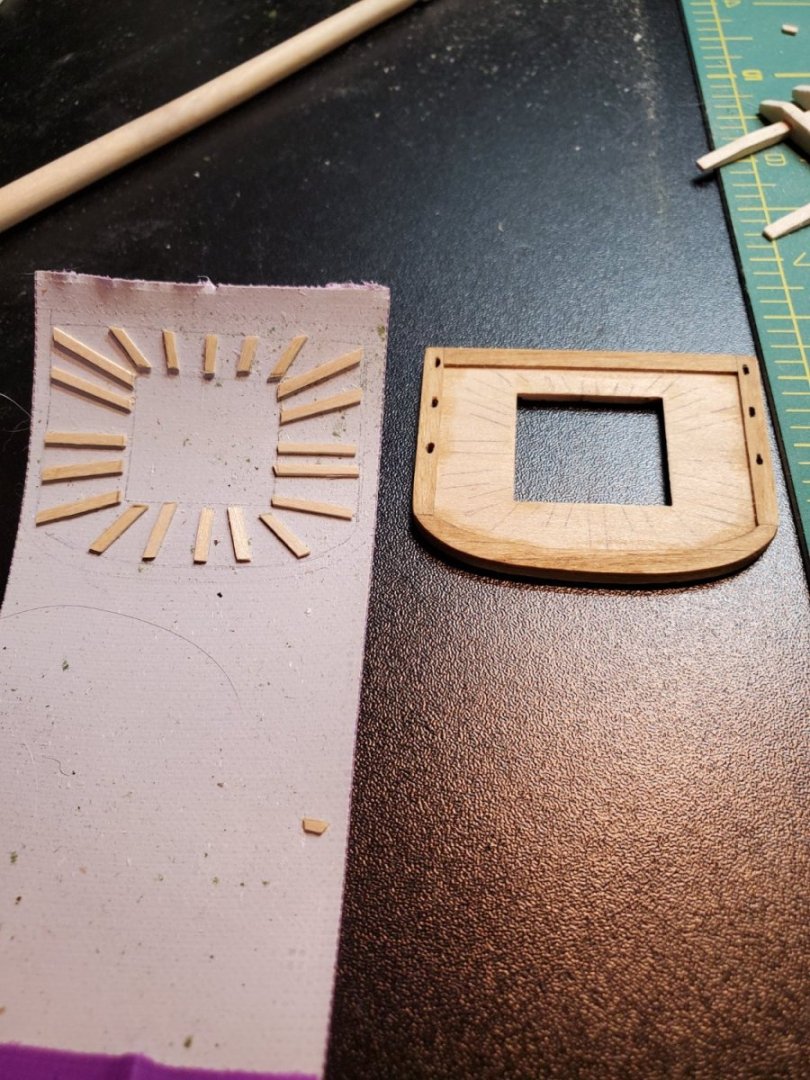

Continuing to progress on the Fair American Model Ship: I set to work on the Foremast next. The first attempt at shaping this went well to start, then got worse and worse. The rod of 1/4" basswood was slightly warped to begin with. I tried to compensate by roll-sanding the high spots, in an attempt to round it out. This did NOT work. The end tapered too short and too narrow, and it created an oval cross section, instead of circular. Irrevocable! So I tried again with a new piece. However, I only had so much in stock, and what was left, was warped too - Badly. I needed to save the rest for the Main Mast. I spent 2 weeks trying to straighten it. I soaked it and weighted it - nope. I hung it off the edge of the workbench, and hung weights to counteract the bend - nope. I soaked it and clamped it in the high spots - nope. It...would...not...straighten. If I couldn't get this warp out, I'd have the same issue as before - a wobble as I sanded the mast down, creating an oval shape. I gave it one last attempt. I soaked and triple clamped it to the bench, and had one end suspended off the bench. Then I hung some weights until all the daylight I could see underneath disappeared. Left it there for 2days. This was as straight as I could get it. It isn't close to perfect, but manageable. There's still a 'stitch' at ~10in mark. Has anyone else experienced this with the masts, and if so, how did you rectify the warp? After setting that straight, I finished shaping it as close to the plans as I could. I messed up the square end near the top. I thought it was square, but under close inspection of the plans, it's rectangular. I need to slow down and take my time again, and not hurry to make up lost time. Next was the top. I've seen other models with the tops having slats and a rim, and not just a flat board. I also completed the cross and trestle trees. I measured each of the slats and spaced them as evenly as I could. Then I traced the pattern onto a piece of detacked duct tape, and placed them each where they belong, for staining. I stained the slats and the rim with golden oak stain, then CAREFULLY panted the top flat black. I wanted the rim to stand out, so I used a fine tip black sharpie to 'paint' the edge without ruining the stain. It worked! I left the slats long on the inside so I can sand them flush later. I know its not in the plans, but I love the look. One cool little Christmas gift I got from my aunt was a ''small tool rolodex'' - it spins! Love this thing. So that's where I'm at now. I need to glue the top, and start on the next piece. I feel I'm back in the swing of things of modeling again - I'm having fun. More progress soon - Jason -

-

Finally back to work on the Fair American Model Ship. Yeah, it has been many months since I posted. I underestimated how much time a new house takes up. Then holidays, then work, and house stuff, and work. After 3yrs in, I sort of used the new house as an indication I needed a little break from the model. So after a little hiatus, here's what I've managed to work on.... The Spritsail yard wasn't too bad. I am still using my "roll the rod on the desk, and file in the other direction to shape'' method - The lathe I have isn't long enough to spindle the end, so this is the long way. After that I decided I needed a break from masts, and would focus on the deadeyes and chain plates for a change. I went through several methods - shape the chain plate from brass strips - too tedious; twist wire around, then bend it to shape - too flimsy. Finally I ended up on using fine needle nose pliers and bend by eye. I made one to scale, then the others to match. They don't look to bad. Next came the dead eyes. I measured the approximate spacing between the loop and the dead eye, and used the old block rigging-block,with some drill bit-pins to bend wire around. This ''looks'' similar to how the instructions show, so I went with it. After wrapping the loop, I can slide the whole thing off the pins... Then trim the ends as close as possible... The finished product isn't bad. That's one! Now the chain plate and deadeye hook to each other well. I need to wait until the masts are up to line up the deadeyes at the proper angles, as per the instructions. The foremast is foremost, obviously. That's next up, and since the lathe I have is small, I'll need to shape by hand. I don't want to mess this up. More progress pictures soon. Happy New Year! - Jason -

-

Had a good time hanging out, talking ship with you as well, Cisco. The longboat you brought was a very pretty model. The waterway on the Fair American was a pain too. I didn't feel skilled enough to scarf the waterway, plus mine didn't come with one at all. Yours looks really nice! I especially like the clamped-down wedge approach - I wish I thought of that. I ended up soaking mine for few hours, and then clamping it to bulkheads, while still wet. Kinked horribly at the bow. With the sanded down bulkheads, attaching the main cap rail later might cause you some trouble. Are you planning on pinning it, or simple glue? Keep up the good work - Jason -

-

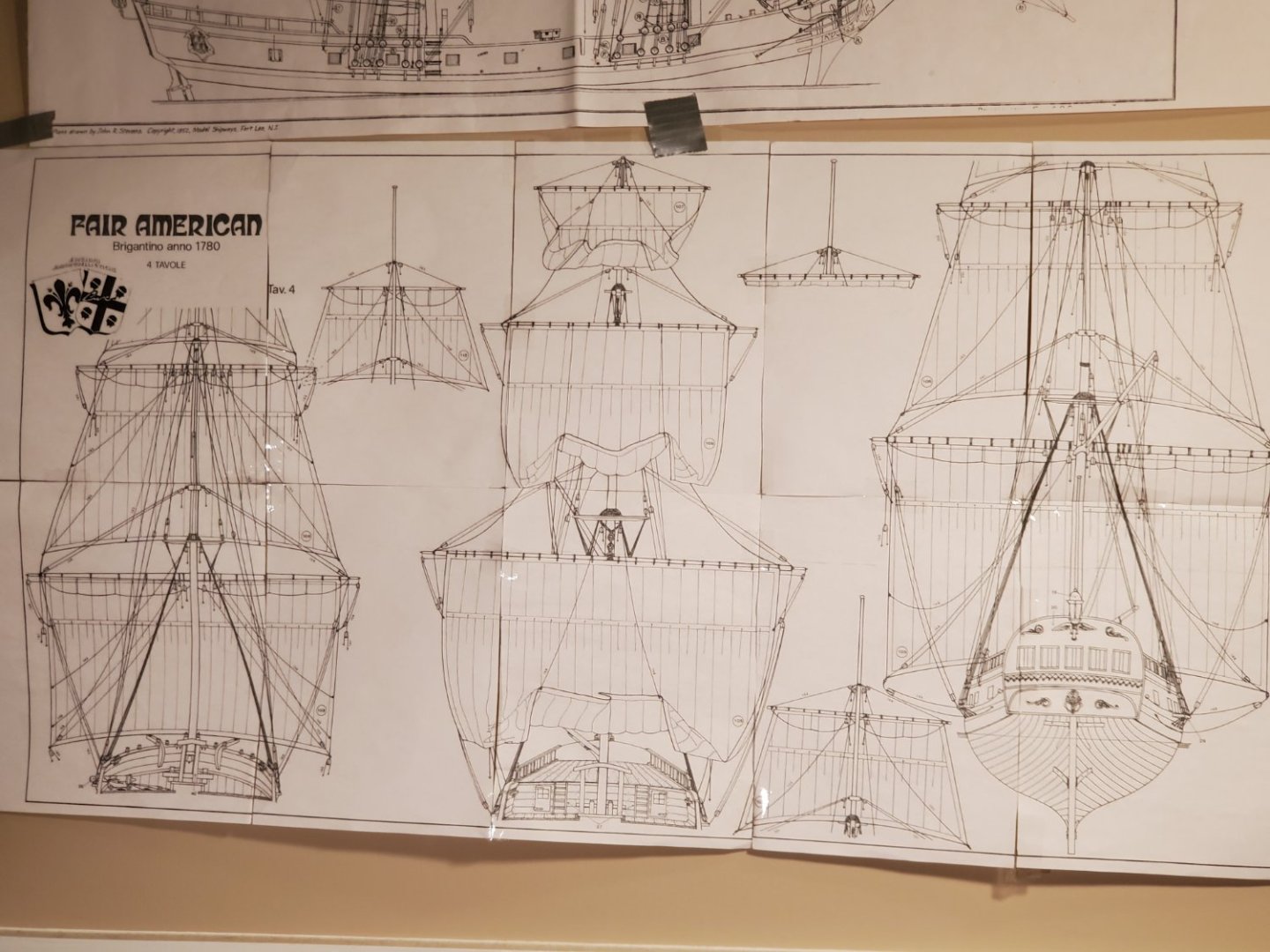

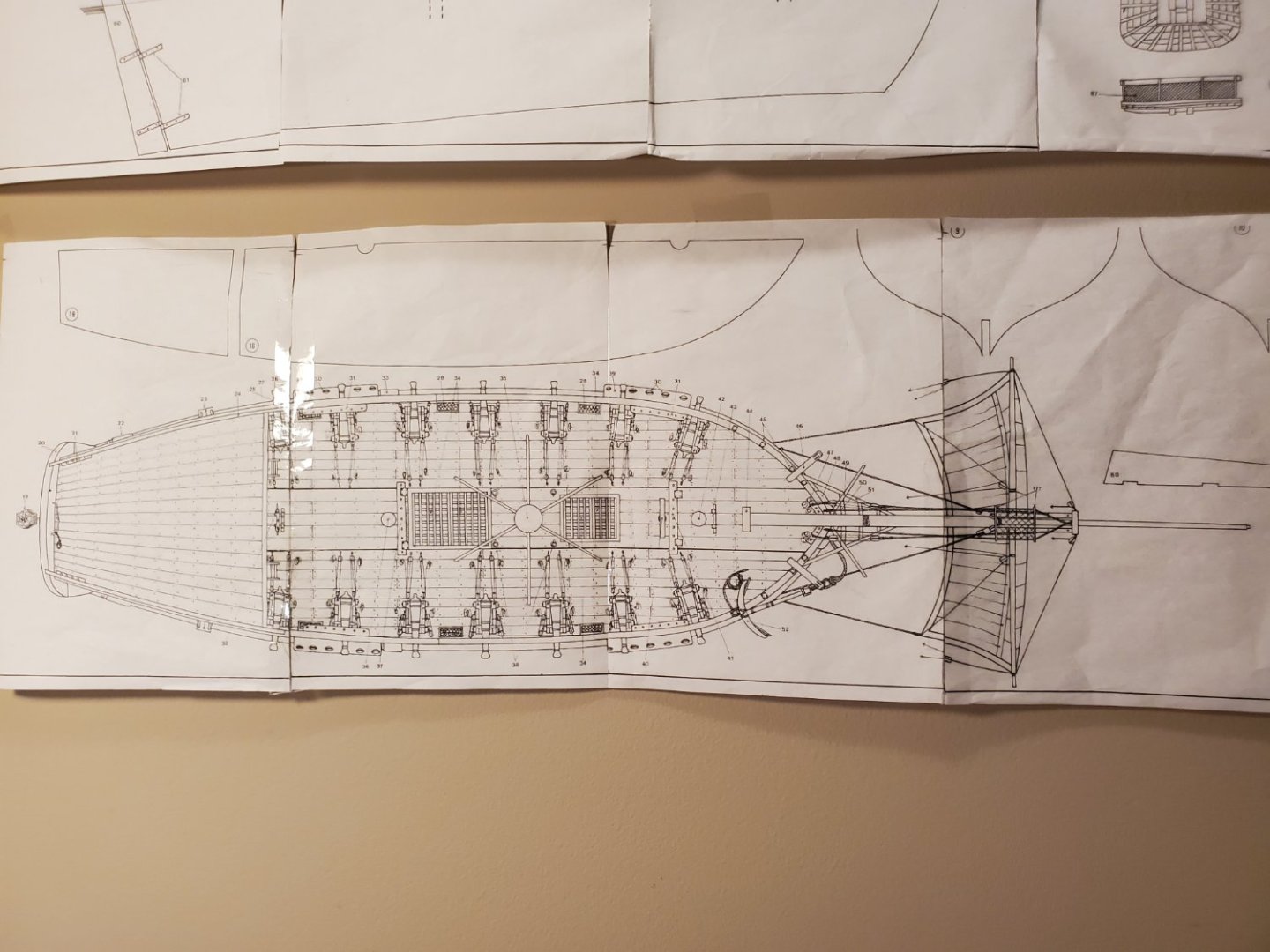

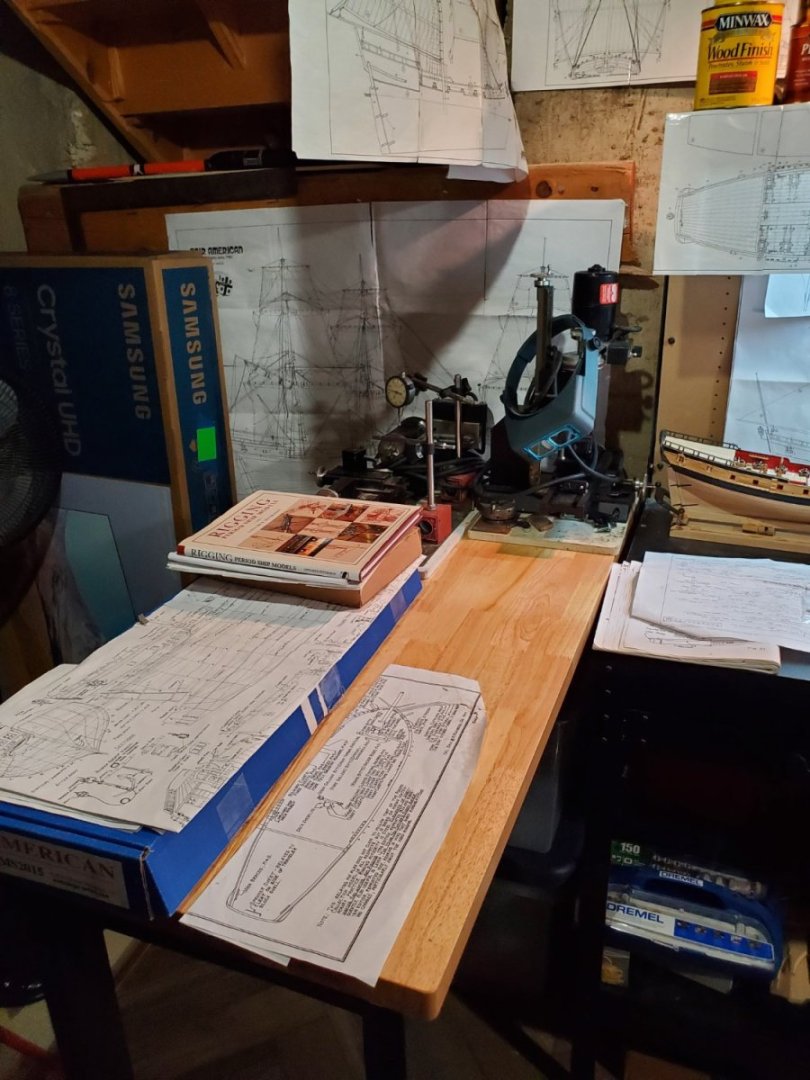

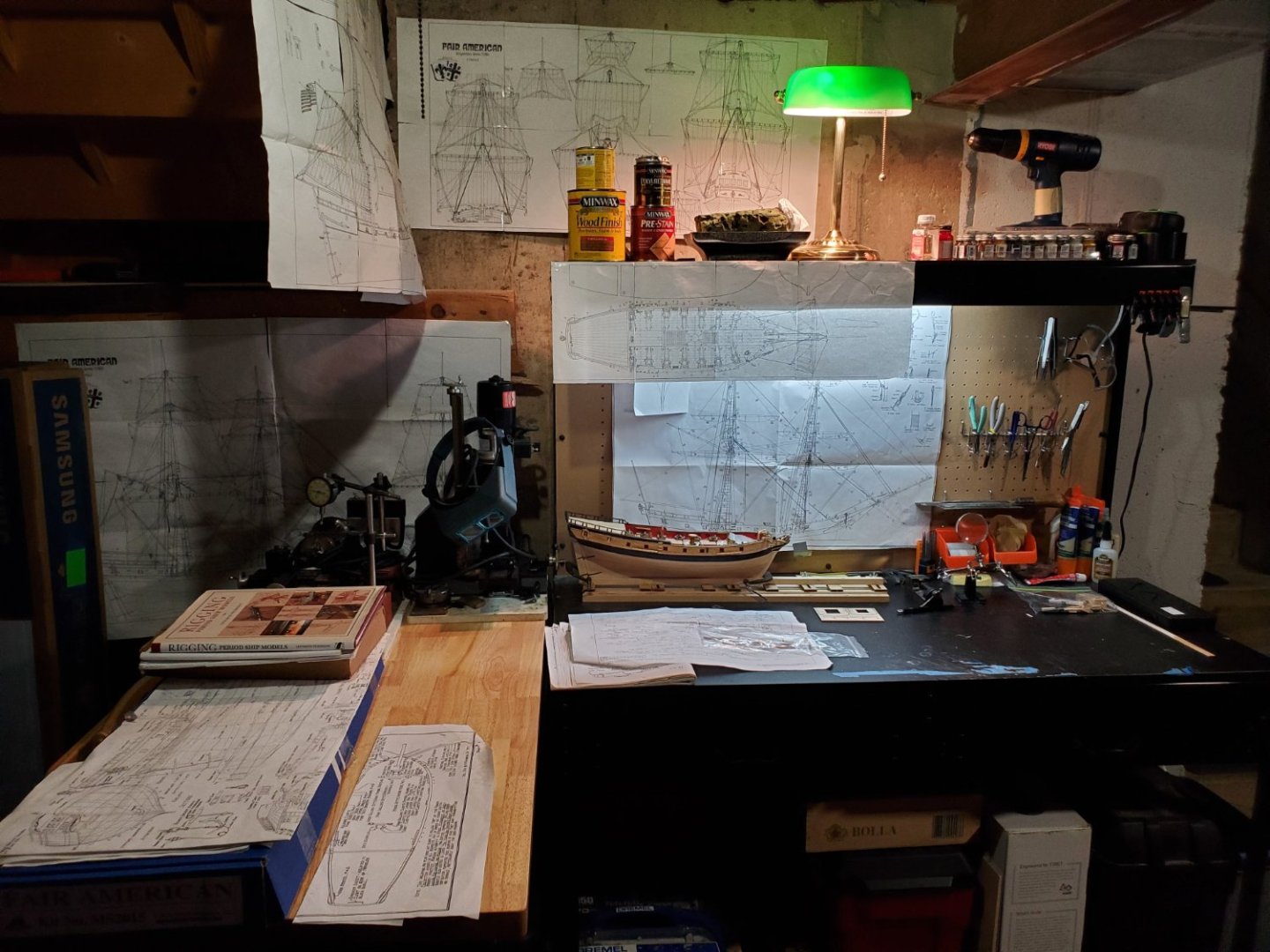

Set up shop in the new house - ready for more work on Fair American Model Ship: Moved into the new house pretty smoothly. Only 9,997 boxes to go! The ship survived the move intact!!! I placed it on my wife's lap as we drove to settlement - I couldn't prevent her from breathing on it, but hey. Finally got the basement set-up for ship modeling - bought a new wood top work bench, which gave me some elbow room. My grandfather's small lathe and milling machine DO take up a lot of space, even in the back corner. I still may move some things around, but this is a good working area for now. The peg board has helped, gets many of the tools off the table top, so I'm not constantly pushing them on the floor, accidentally. A year ago, or so - during Google searching, I came across some Fair American plans, showing the sails. http://www.shipmodell.com/index_files/0PLAN1C.html I am planning on adding sails to my model, so this will be a great ''overview'' of size and shape, and rigging. The plans, once downloaded, are in several tiny sections, which I printed and taped together as closely as I could. These are what are hanging around the workbenches now. I'll be soon working on the Bowsprit and other masts - finally. I'm looking forward to meeting up with @CiscoH this weekend, to sharing shipbuilding tips and stories! More updates in coming month, I hope. - Jason -

-

Nice job on the planking. Can't believe you're going to do a second planking - one was painful enough for me! I like your approach of planking the transom heavy, then trimming back to a clean line, as you described. I started at the transom, and worked forward; Stern planks weren't as tight/clean as yours. How did you bend them so neatly? One suggestion - after you finish sanding, you should consider sanding. Definitely have to hang out and swap savvy sanding stories sometime soon. Jason

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.