Frank L.

Members-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Frank L.

-

I wonder if there is a way to attach the photo so viewers can more deeply zoom into it.

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Hi Andrew By eyeballing the bevel line location from the print and running a .7mm mechanical pencil over the wood using my middle finger as a guide at the edge, I was able to make a decent line when it needed to be parallel to the edge. When the line had to start bending away from being parallel. I used a french curve. Next, I chucked a dremel sanding drum into my bench-top drill press and gingerly free-handed the cut with a follow-up of some normal hand sanding. It looks good to me. I am not sure i want to pursue the inboard bevel for this project. For drawing the rabbet lines on the keel, I used translucent sandwich wrap paper, pinpricks and the french curve. Now, I need to practice different methods for carving out that material. Here is a photo of the ECB I took in 2013......

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

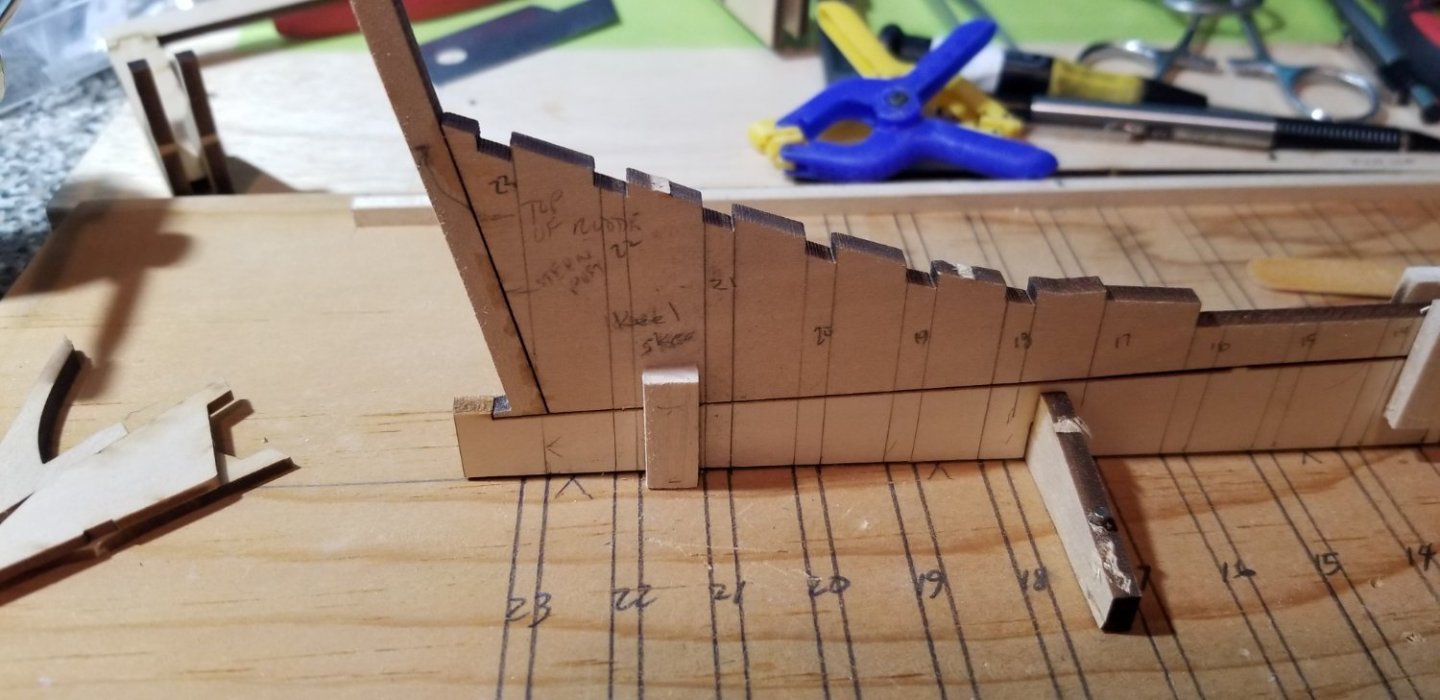

Andrew - How did you transfer the bevel lines from the blueprint onto the bulkhead frames? Did you just eyeball it using a french curve? I think you said you sanded the bevels - as opposed to carving with a knife as the designer suggested. So, did you run the frames against a drill-press-mounted drum sander? Carving / shaving / whittling curved members with a knife seems tricky because sometimes the grain direction works against your effort - or steers your blade in the wrong direction - and there is not much meat for a steady grip. I am also attaching a photo of my completed Greg Davis inspired construction jig that we discussed earlier.

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Hi Andrew Take a look at my revised graphic. Does it capture what you are suggesting? EMMA C. BERRY WATERTITE RUDDER STOCK BOX REV-1.pdf

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Hi Andrew. I want to avoid a horn timber do-over. So I generated a graphic representation. Take a look and tell me if you agree with my assessment. The instruction book mentions 'maintaining alignment'. But they do not make it clear what exactly they mean. EMMA C. BERRY WATERTITE RUDDDER STOCK BOX.pdf

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

I used a 10'' portable table saw to create a V-groove part way thru the edge. I could not run the cut all the way thru due to the tail of the piece protruding into the path. I finished with a small dowel wrapped with sandpaper.

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

I also spotted that address and sent them this note: "Is it recommended that an elevated platform with a cutout for the hull framing be used, as you have done? What is the reason for the timbers laying flat on said platform? Is it because you perhaps slightly overcut the opening and are maneuvering the timbers so their ends are precisely in the proper location for the frames to temporarily abut to? Does the platform obstruct your ability to work on the keel area? Is this a scratch-built or kit POF model?" And, just now, I read your reply to my question. It seems as though we agree on the purpose of the strips. And I agree with you that the platform should be at deck level and i need to revise my cut-out template based on the frame profiles, as you have described. With the nib stuff, I am leaving the keel tight to it, and will shim the prow against the jig to prevent forward slippage. By the way, in my opinion, it seems risky to have a wooden live well, right in the middle of a vessel. So many possible points of leakage. No decent bilge pumps back then - I presume.

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Yes!! I too was confused about the strips extending out from each frame! I was going to ask the builder, but could not find his or her name on that site. Anyway, I scanned the blueprint into my computer and used AutoCAD to trace the hull profile with a reasonably smooth & sharp polyline. The tracing will be printed and used as a template to cut-out the elevated jig. I also saw a builder's comment in your log about using a shim to prevent the sternpost from making contact with the kit's keel support jig's back end. Well, with my sternpost touching the nib/lug/boss of the jig, I had sketched all the frame lines across my 3/4'' pine building board, up the jig and onto the keel before I read that. It would be a hassle to erase all that work and re-pencil it in. Do you know the reason for shimming the keel forward? If it was so important, the kit's instructions should have mentioned it. Although, If I decide to go with the elevated support idea, maybe my pencil lines are unnecessary.

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Hi ahb26 I noticed an interesting rig for supporting the framework of the ECB. See link, below. What are your thoughts about it? I just got started with my ECB. I bought a piece of 1/4'' MDF today so I could cut-out a similar support/alignment board. Julian Nodars of Model Shipways / modelexpo-online suggested that I visit your link for guidance. And so, here I am! https://www.historicshipmodels.com/emma-c-berry/

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Hi anhb26. Can you comment on the elevated platform rig somebody used to erect the frames. Here is the link: https://www.historicshipmodels.com/emma-c-berry/

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.