Claire7

Members-

Posts

76 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Claire7

-

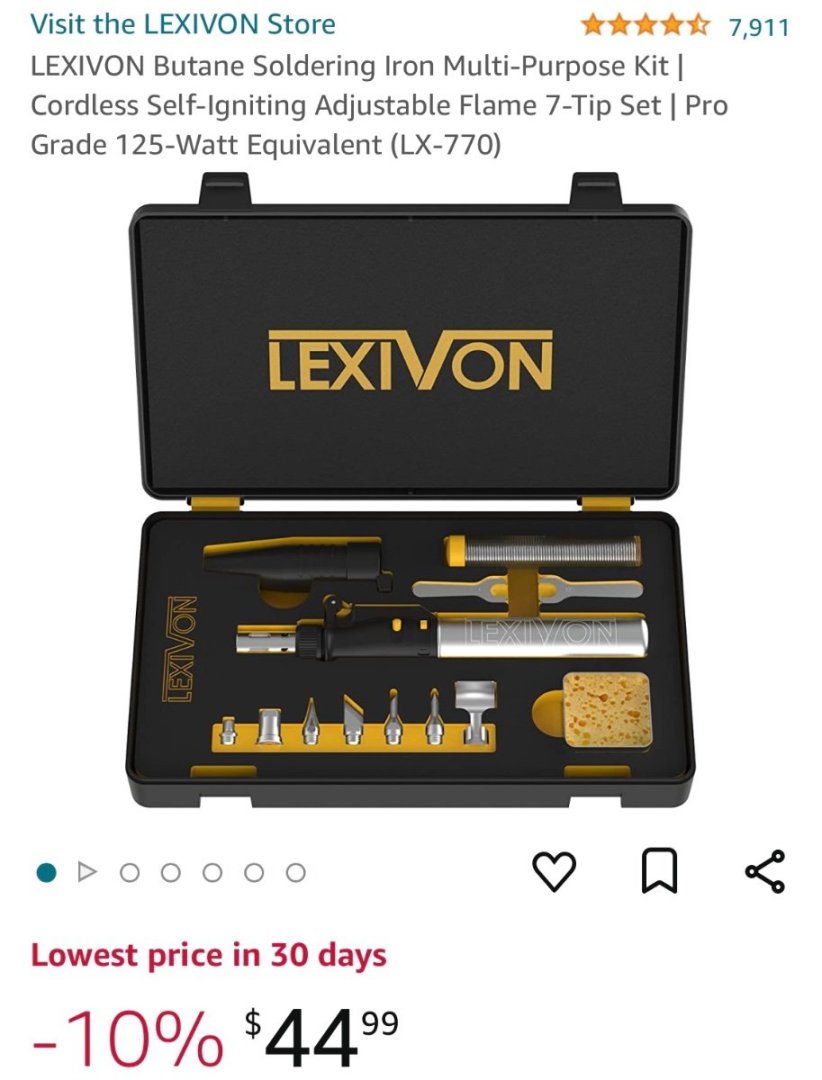

As @druxey suggested I am going to wait for the Brass Black. Consider this tiller a trial run! I wanted to understand how it all goes together. But I realized I want to stain it first before any glue, and I want the darker metal parts. So I will be re-making this, and also preparing the other wooden pieces/mast etc. Then stain everything, then do the metalwork. My ceramic soldering plate was broken in transit so I’m waiting for another as well as some soldering tweezers. I filled the soldering torch yesterday and it works ok, doesn’t always light but I just turn it off and wait a few seconds and try again.

-

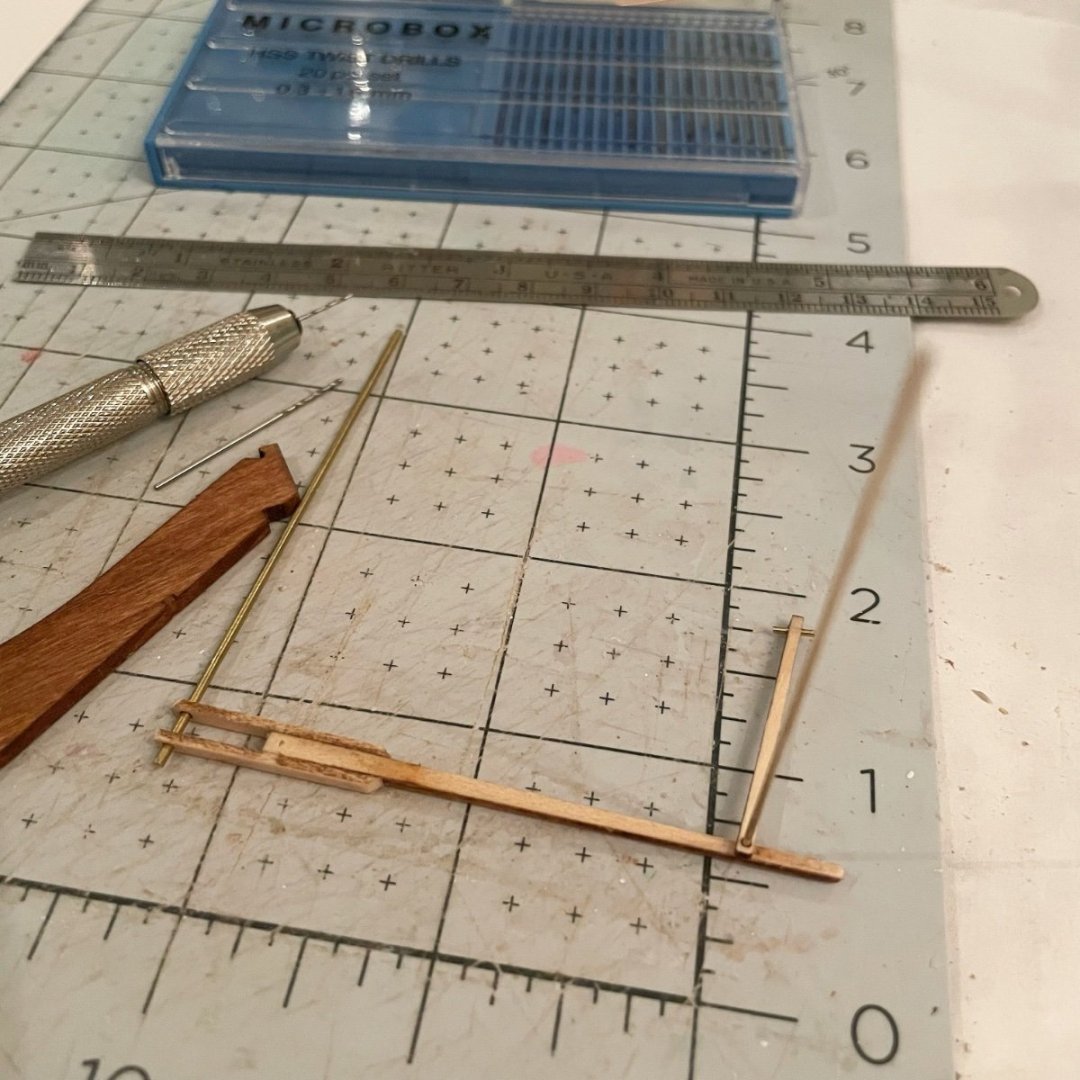

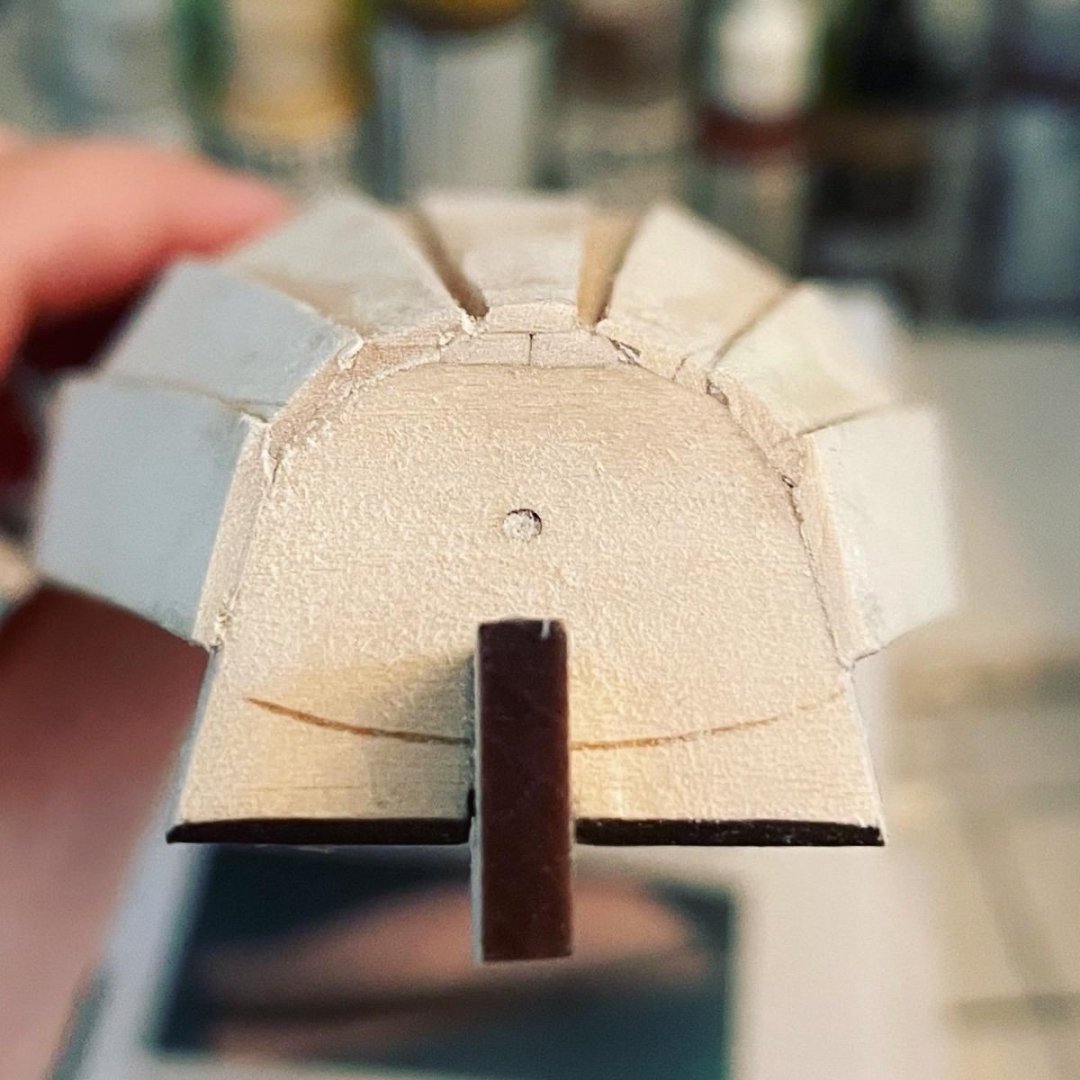

A start on the tiller assembly… I’m not sure I have it the right way around. If I add the supports on the narrow side they are wider which doesn’t seem right. The width matches perfectly if they are glued to the wider sides. But examining the photo it does seem like mine doesn’t quite match. I guess it doesn’t really matter. Also the 1/16” metal rod works for the support ends that join to the rudder. But not the narrower joins. So I will use the 1/32” metal rod supplied. Maybe that’s what is intended and it just wasn’t spelled out. So far I’ve glued the 1/4” long rod in the end of the extension with superglue. And I’ll try the hammering/rivets for the other joins tomorrow.

-

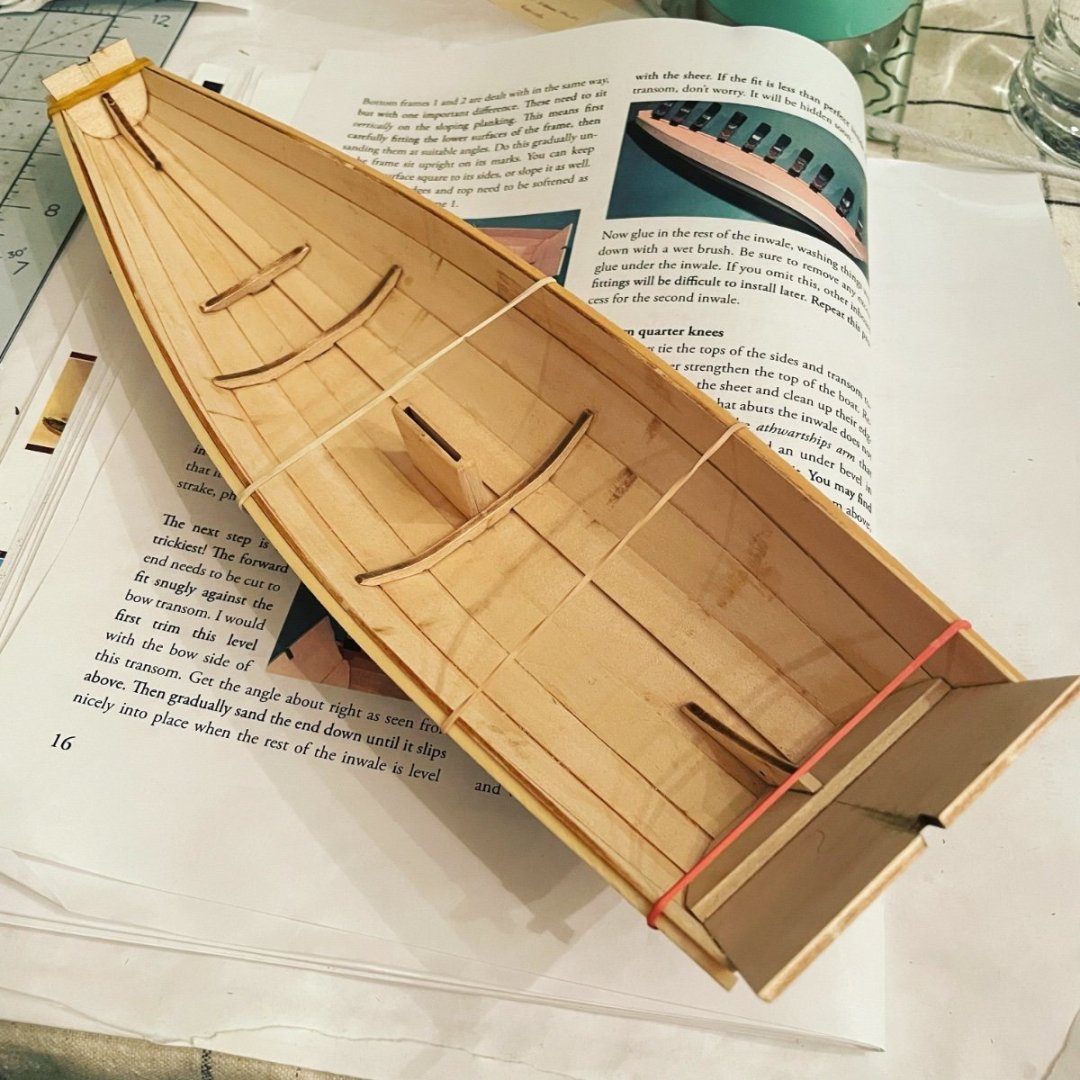

Pram interior painted cream, exterior light turquoise with stained thwarts, rub rails, daggerboard and floor boards. Floor boards and thwarts attached. As before everything needed to be sanded, trimmed and beveled as necessary to fit neatly. I just need to trim the ends of the rub rails. Then up next… the tiller assembly. I wanted to darken all the brass bits and ordered Brass Black but couldn’t find it locally. I didn’t want to pay $30 on Amazon either. So I found some on eBay but it likely won’t arrived for 3 weeks. But the time has come to start the metalwork so I may try painting the pieces.

-

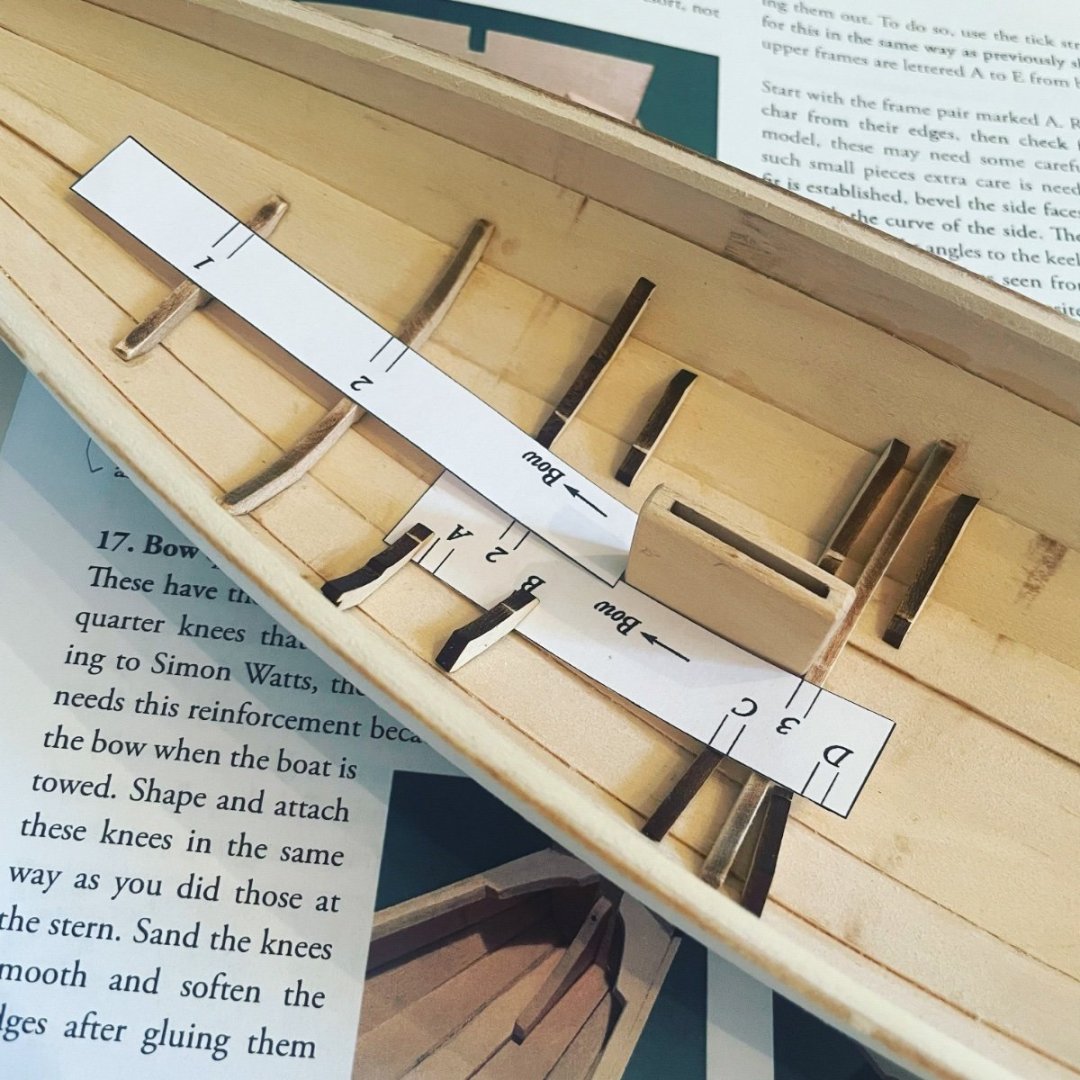

Thank you @Ryland Craze! So far today I have installed lots of tiny bits, inwhales, the stern & bow quarter knees and seat & thwart frames. As others have mentioned it takes a bit of thought to work out exact positions especially vertically which is only indicated with a reference photo for some pieces. One thing that threw me off was the position of the A B and C D pairs of frames. Their position is indicated relative to the 2 and 3 bottom frames (but not to each other on the paper strip). Up next: completing the transoms.

-

I vote we call it the Lobster 😂. I’m thinking I’ll order it to make after the Pram, looks great!

- 39 replies

-

- Model Shipways

- Muscongus Bay Lobster Smack

-

(and 1 more)

Tagged with:

-

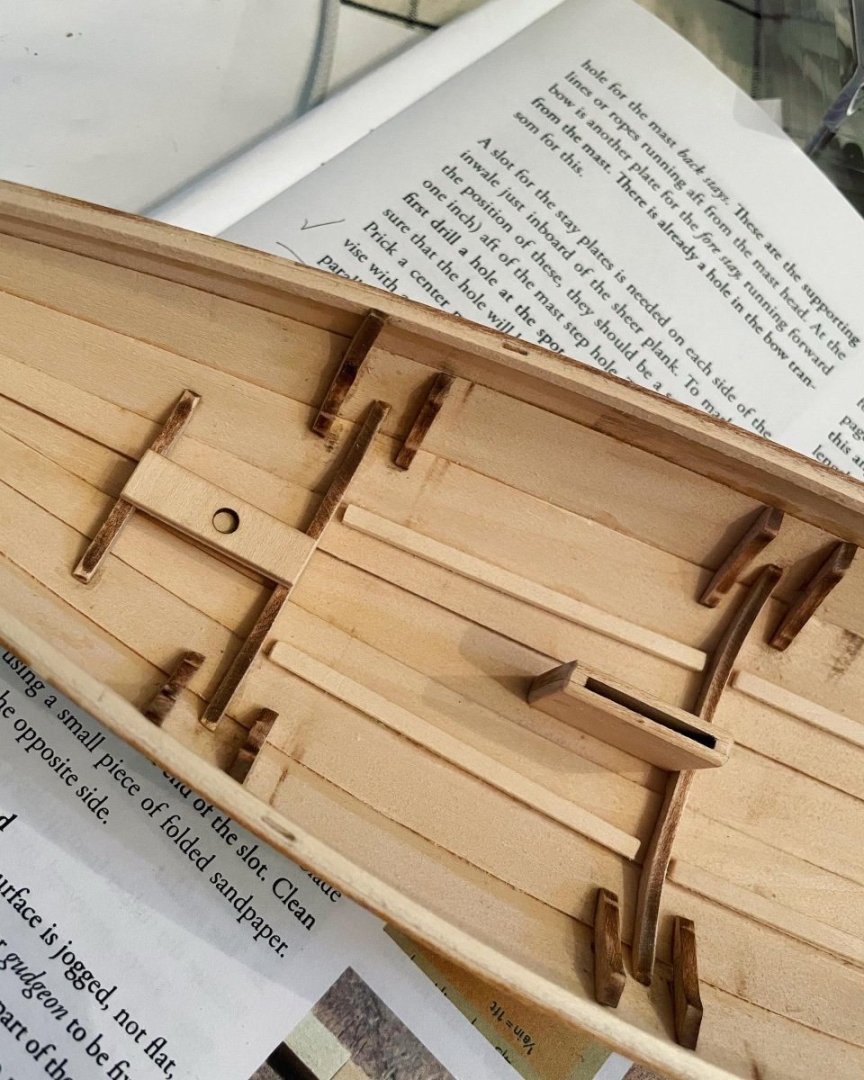

Waiting for the dagger board case to dry before sanding. I came up with a nice way to fill the little extra width of the keel plank slot. When removing the side pieces for the dagger board case a thin strip detaches and I’ve used this to cut a tiny piece to fill the gap. You can cut a few until you get one that’s the right size and as square as possible. I used the tweezers that came with the dory kit and a fine tip glue bottle to help place it. It’s slightly proud of the base so I will sand it smooth. Seems a little overkill as I think it will get covered later… but I like the result. I filled the stern side because that’s the side that gets covered later.

-

Skeg and bilge keels attached. I don’t want to shock anyone but in my opinion they fit snugly enough without the sanding method suggested. Also I don’t have any rubber cement! I calculated the exact position of the bilge keels by measuring the photo then scaling up. My result: the keels overlap the skeg position by 16mm. Hopefully my photo is clearer. The instructions say “sand the outer surfaces vertical as shown”. I sanded a bit but I see the tops still look flat in the photo so I didn’t continue sanding them fully vertical which would result in them having more of a pointy edge.

-

I’m new to this and also annealing. Would you anneal your brass parts before blackening? Maybe annealing would also remove any clear finish.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.