-

Posts

102 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Caferacer

-

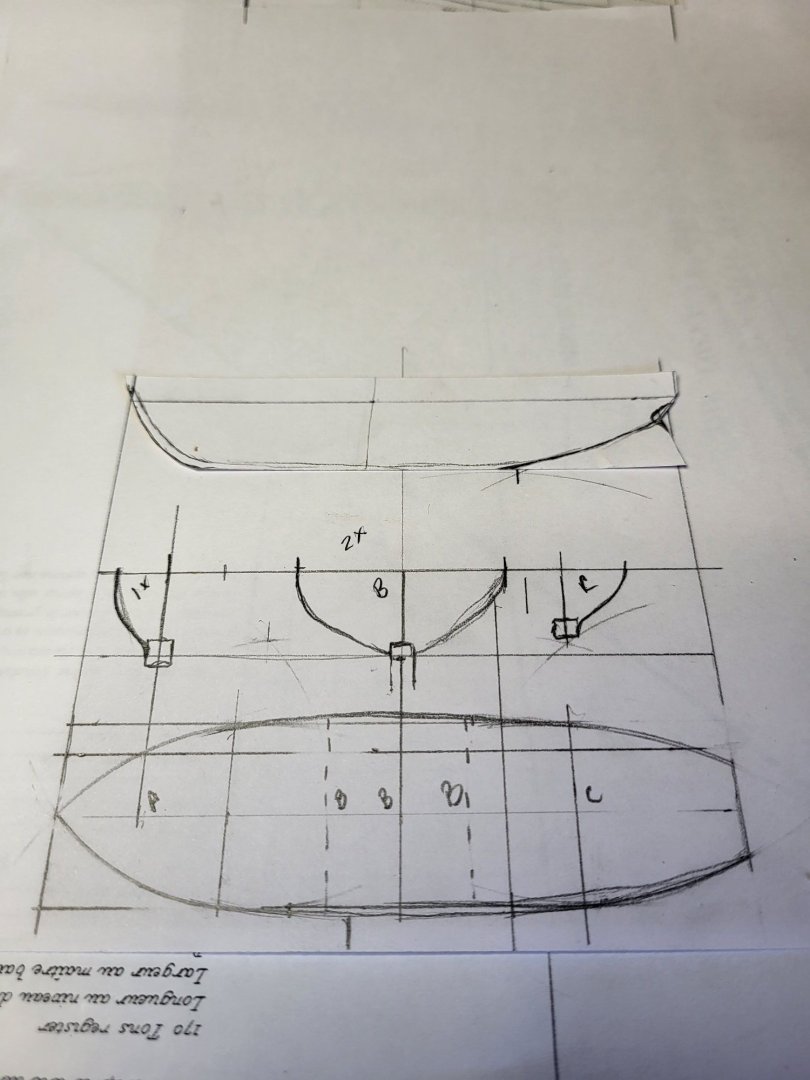

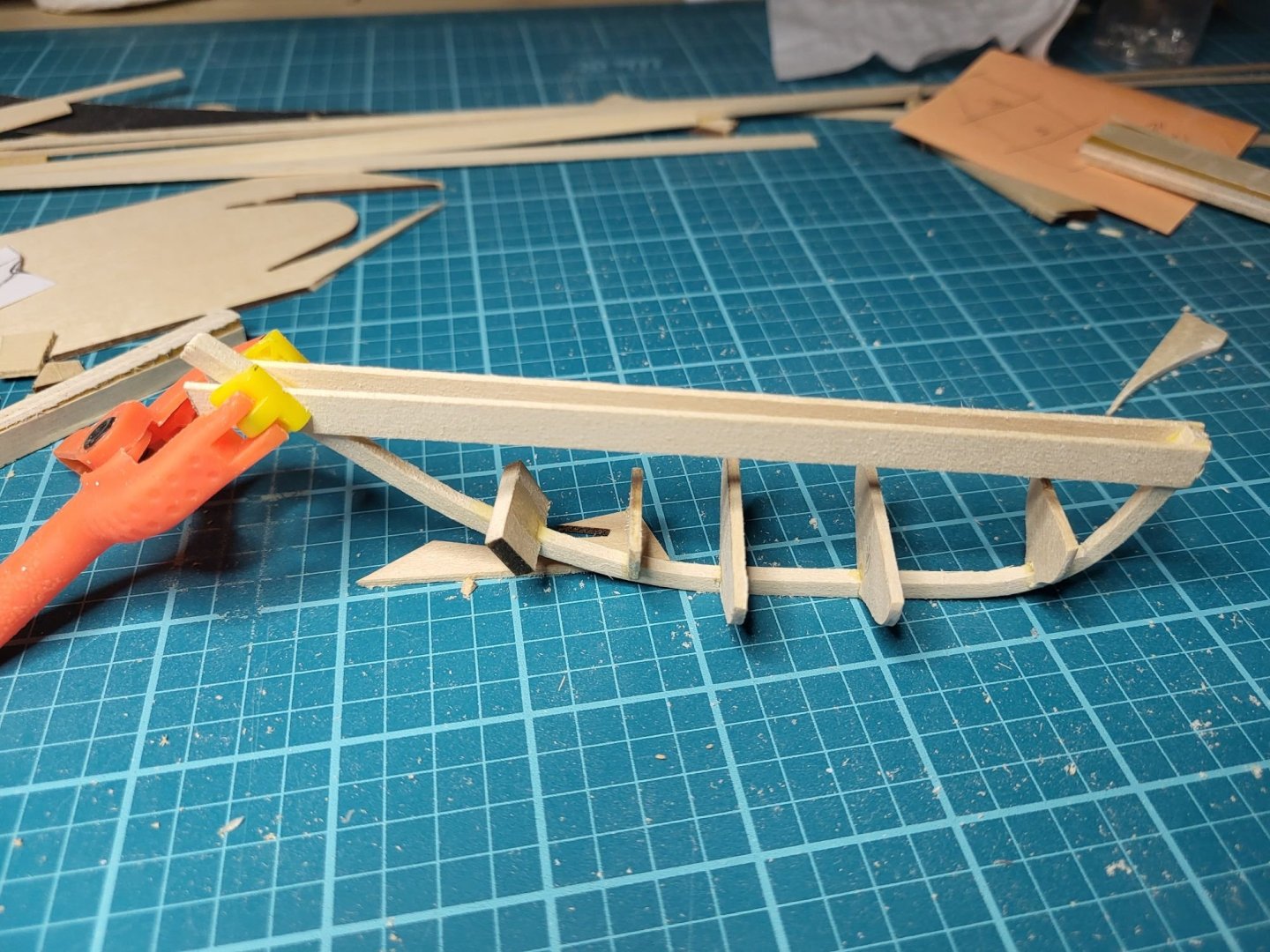

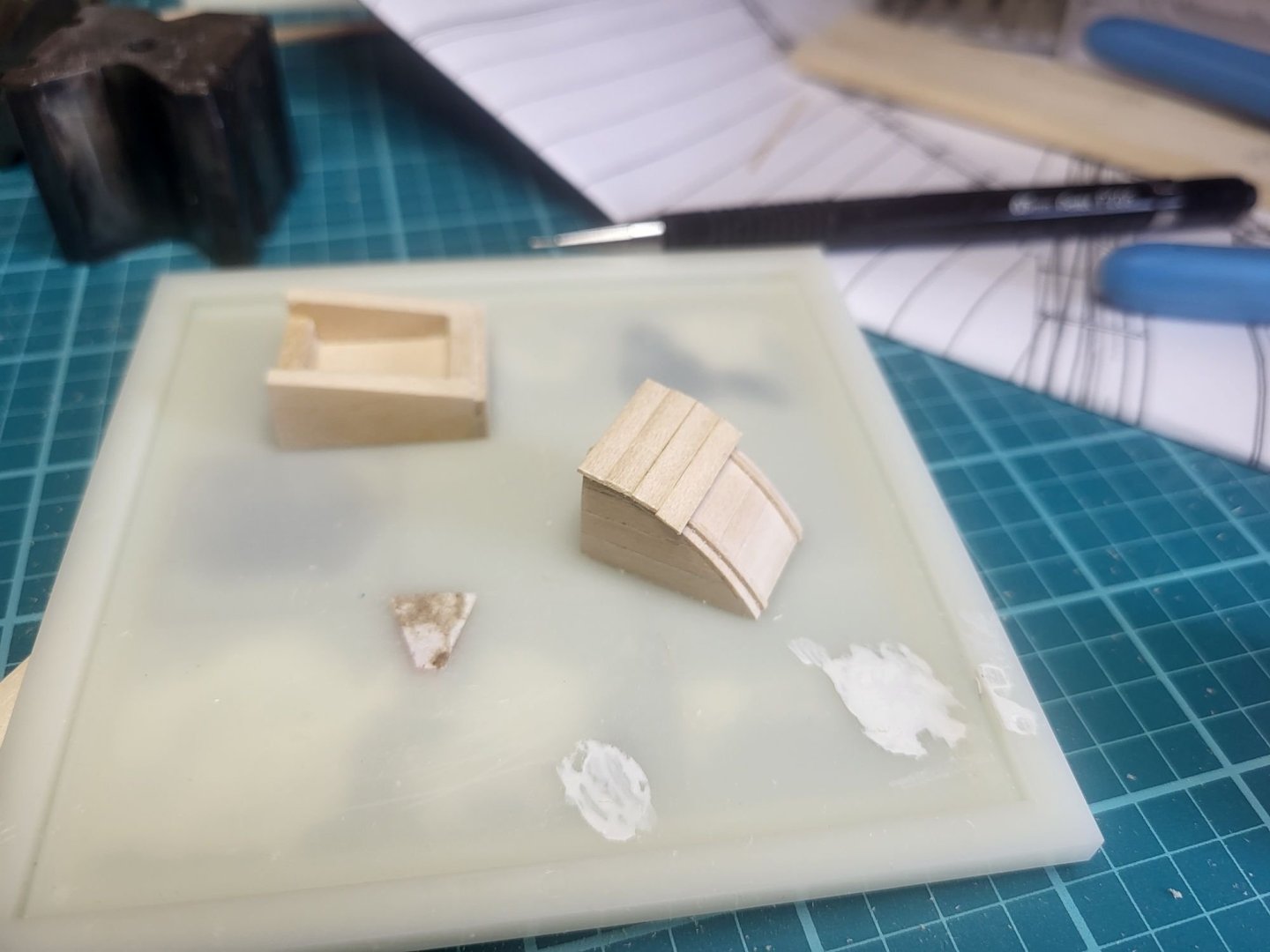

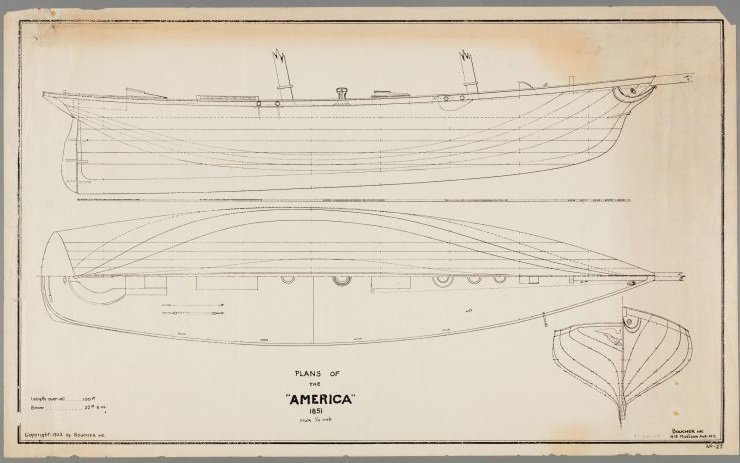

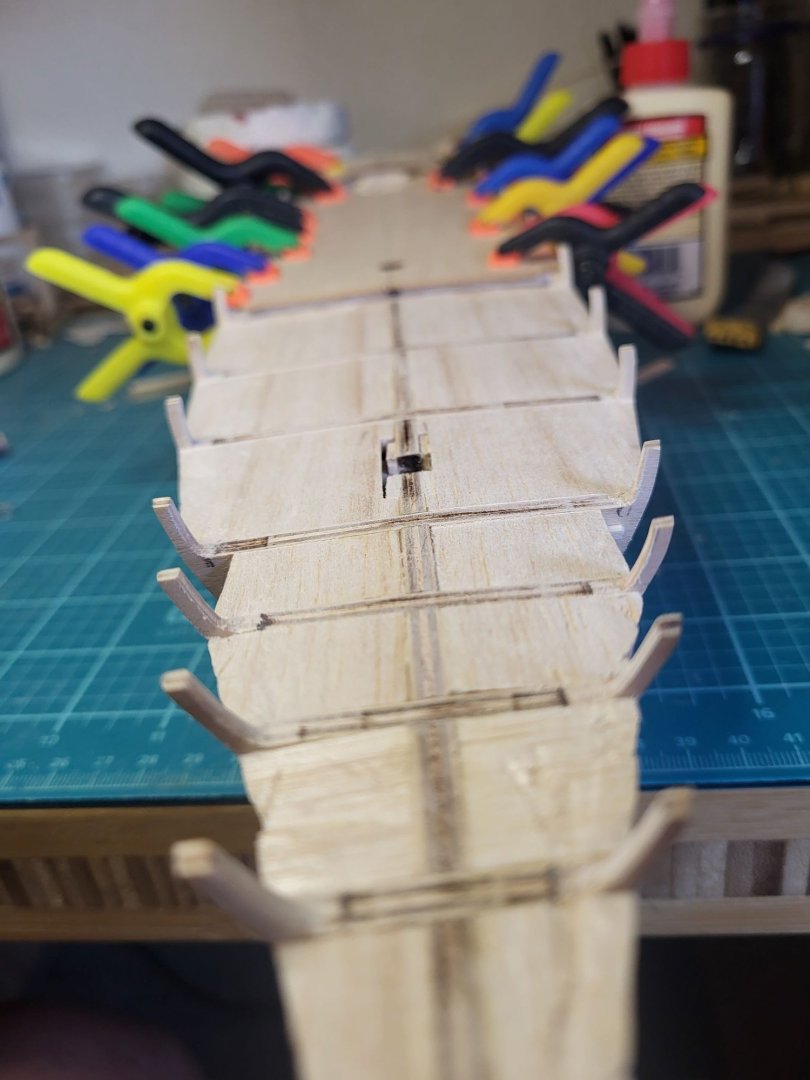

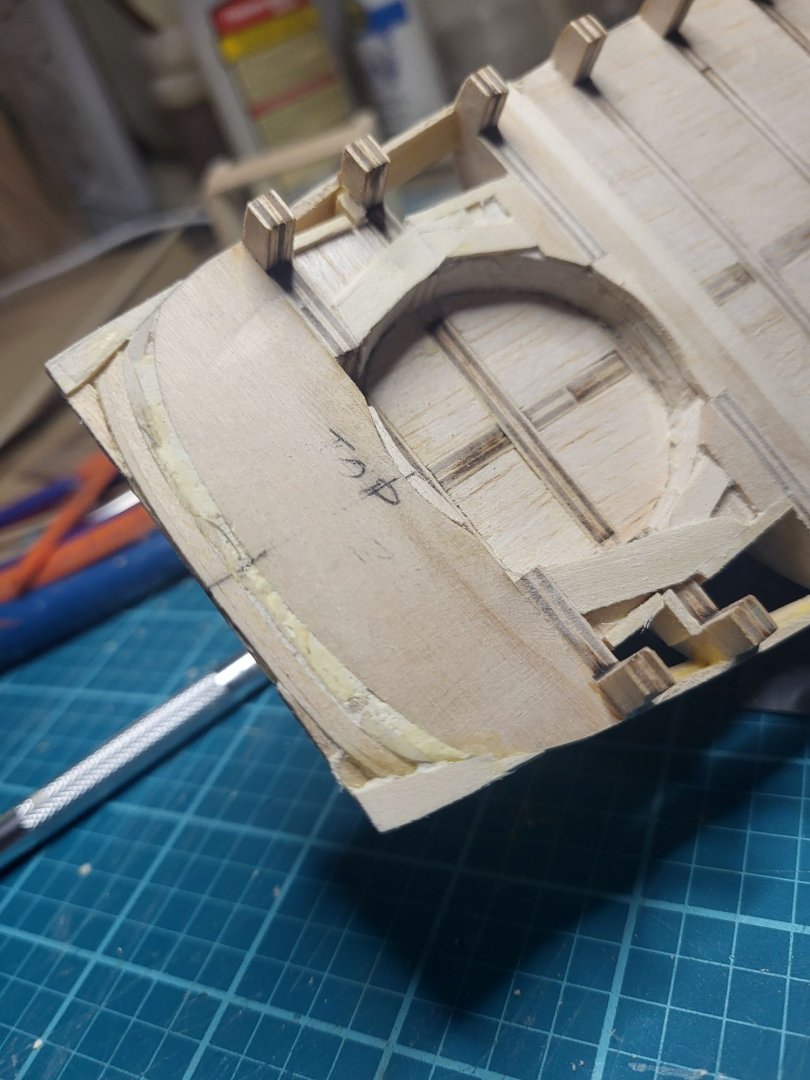

Again we're at "what America are we building" and I think I have settled on the reported state, after spending time in France. Reports say the copper was removed, and above the waterline was a "dove grey". To that point the yacht would have a jolly boat or some dinghy. It's unlikely (thought period paintings show it this way) it was on deck while racing. I'm using a similar technique as I did for the Benjamin Latham dory, this keel seems large, and it is, but a lot of it will be cut away once it's planked. I used some period paintings for the profile, then guessed at the top view.

-

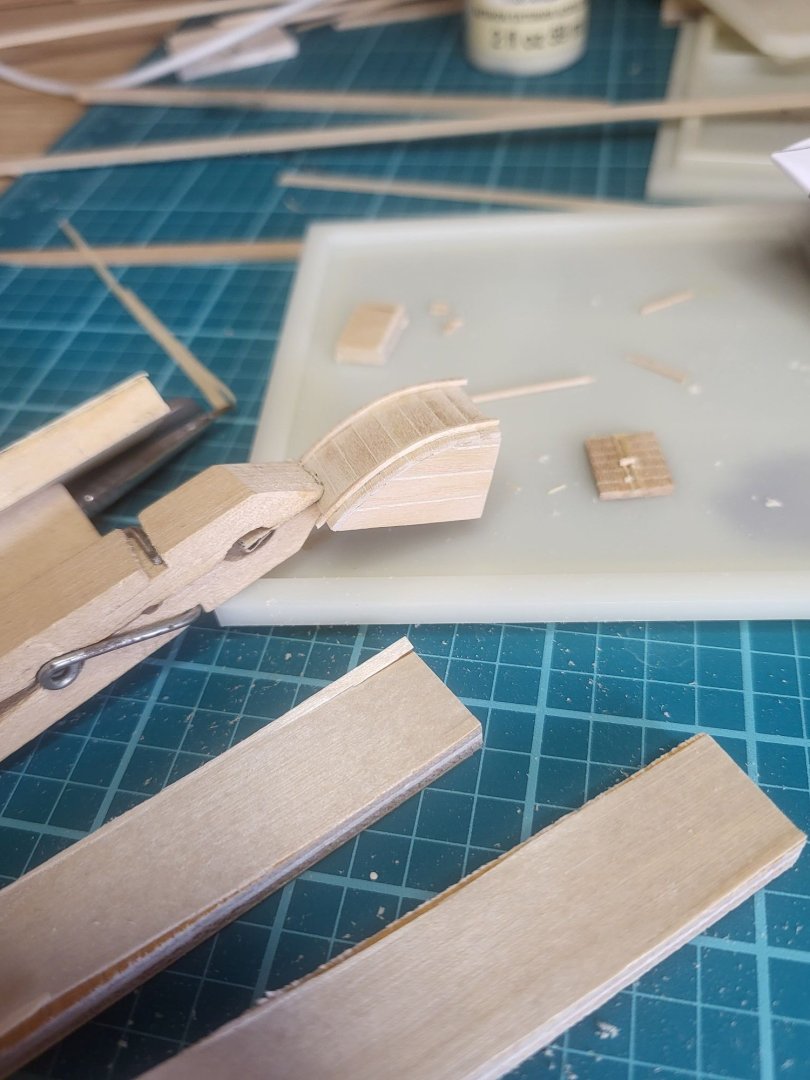

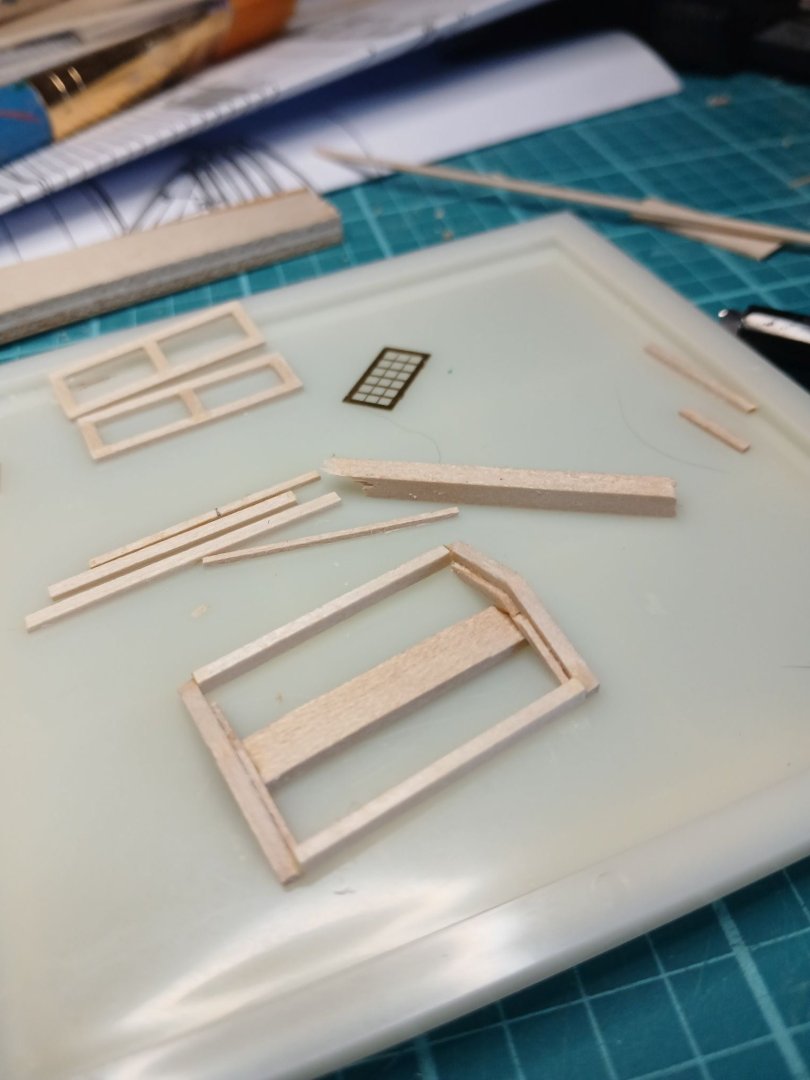

Bouncing around a little, while forming some of the top planks around the stern, I planked the fore deck. Old t-shirt material works well for clamping, much better than rubber bands in my opinion, especially since you can easily control the tension and get a lot of coverage. Seen in the back the material is not just holding the plank flush with its lower neighbor, but holding it to the curve.

-

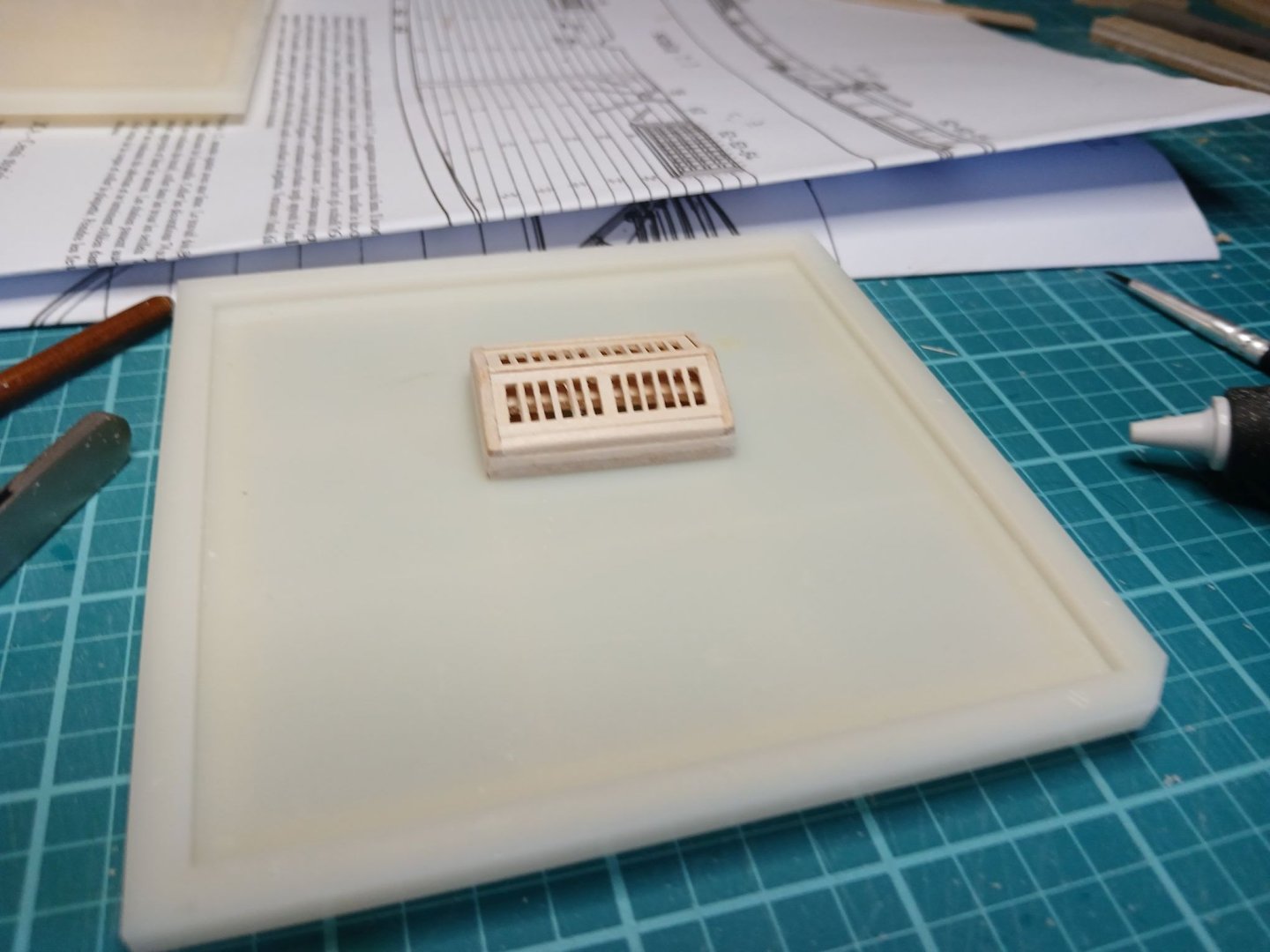

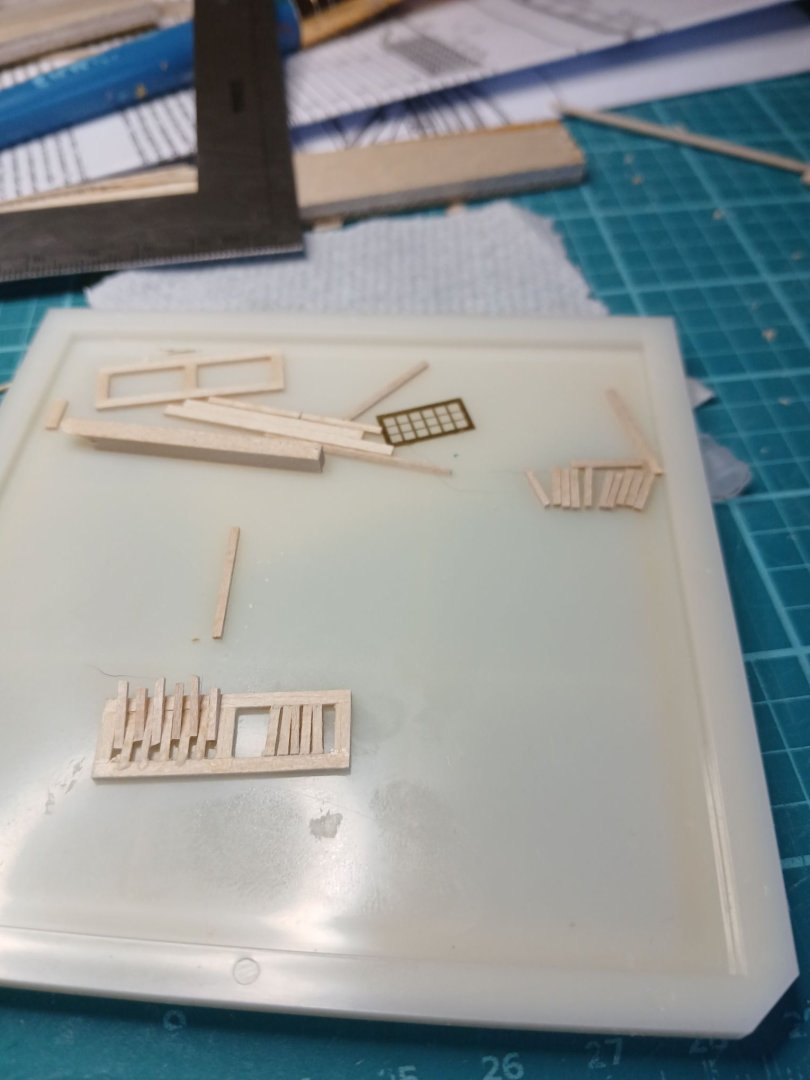

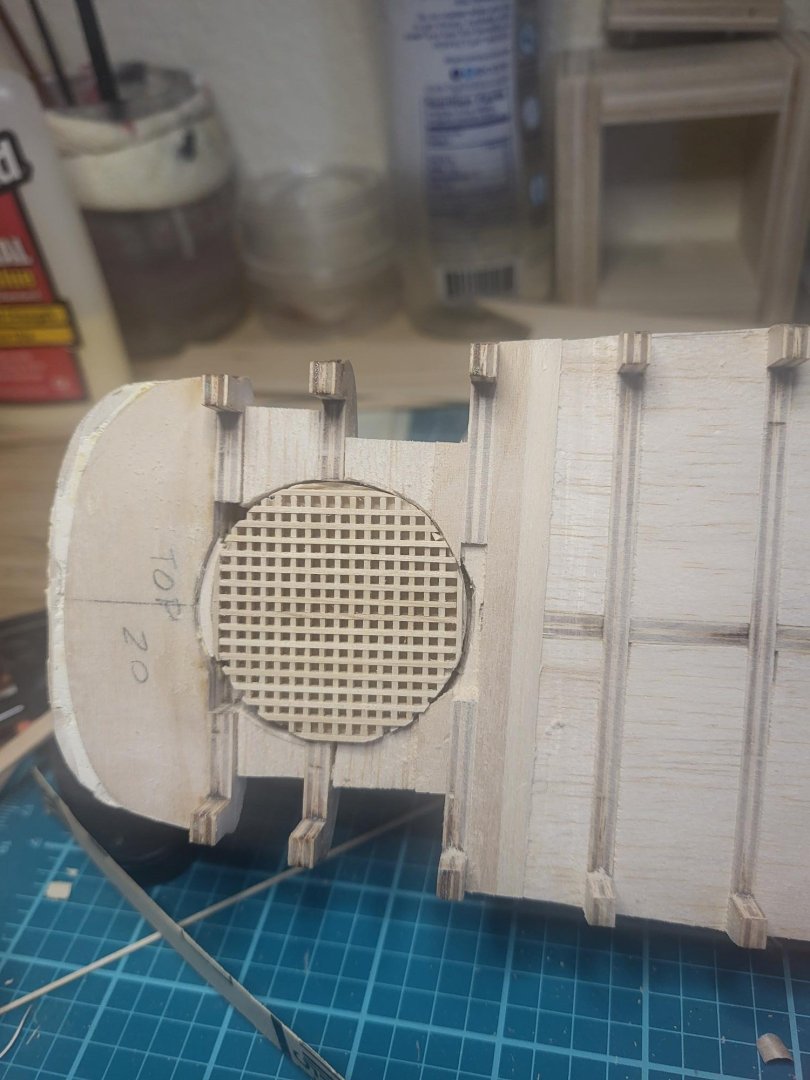

Pictures from the when the America was at the Naval Yard clearly show the large skylight was rectangular panes, not tiny windows as the etched parts have. In fact the skylight from the America is in the Mariner's Museum in Newport News. This is the great thing about this build, so much historical data available. So while the brass guards on the panes might be hard in this scale, I'm at least going to match the 5 pane design, just not sure how yet.

-

Thanks! The lines are "interesting" anyone else might say "ok it's an old boat" but the lines are really interesting and very different than other ships I've done. Foolishly trying to "dry" bend the first planks. On past builds I dislike the distortion that can occur with wet wood. I haven't tried steaming, speak up if it creates the flexibility to bend the planks without the dips or bulges I'm seeing between frame ribs. This actually went fine until making the next joint after this one, then the previous three popped, I was on the last three joints... ugg

-

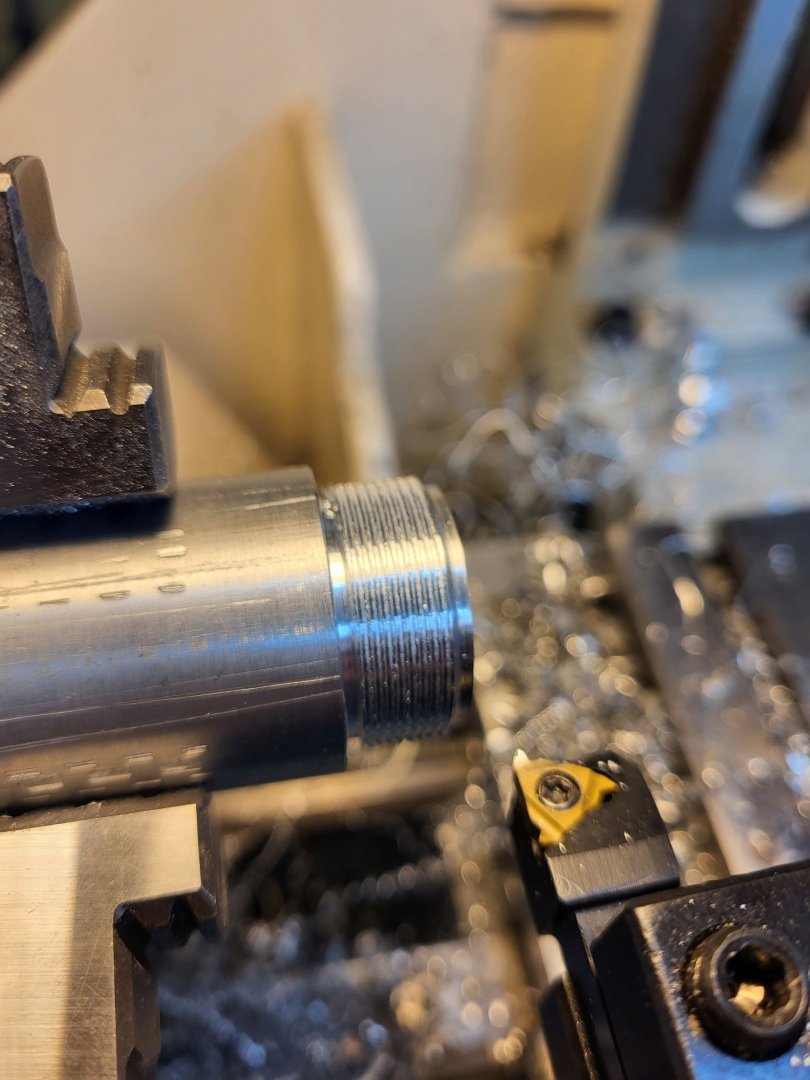

Hey! I'm back, all is well, I live in Mesa Arizona, so from about October to well, not usually now, it's been a fairly cool "spring", normally April or May, I spend time in the garage. I've done a fair bit of machining on the hobby lathe/mill, a few 1:1 scale wood projects. Oh and putting together a "housewarming" tool kit for my hopefully daughter-in-law. She's a very handy young woman, meanwhile my son is.. well, more brain active? lol Good tools aren't cheap and cheap tools are not always good, so leveraging some of the vendors I use in my day job, I've collected the best (based on my experience) tools someone would need starting out.

-

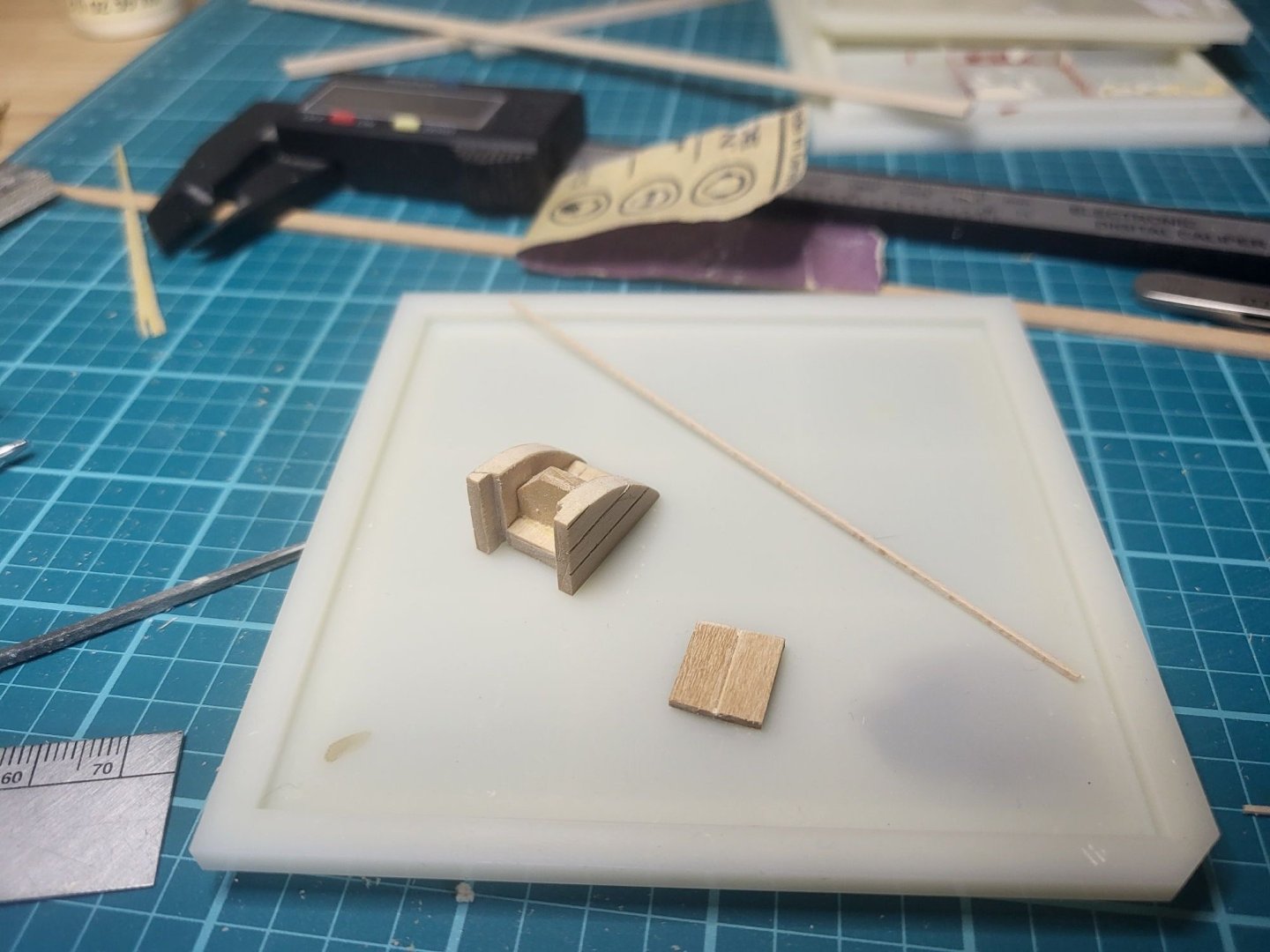

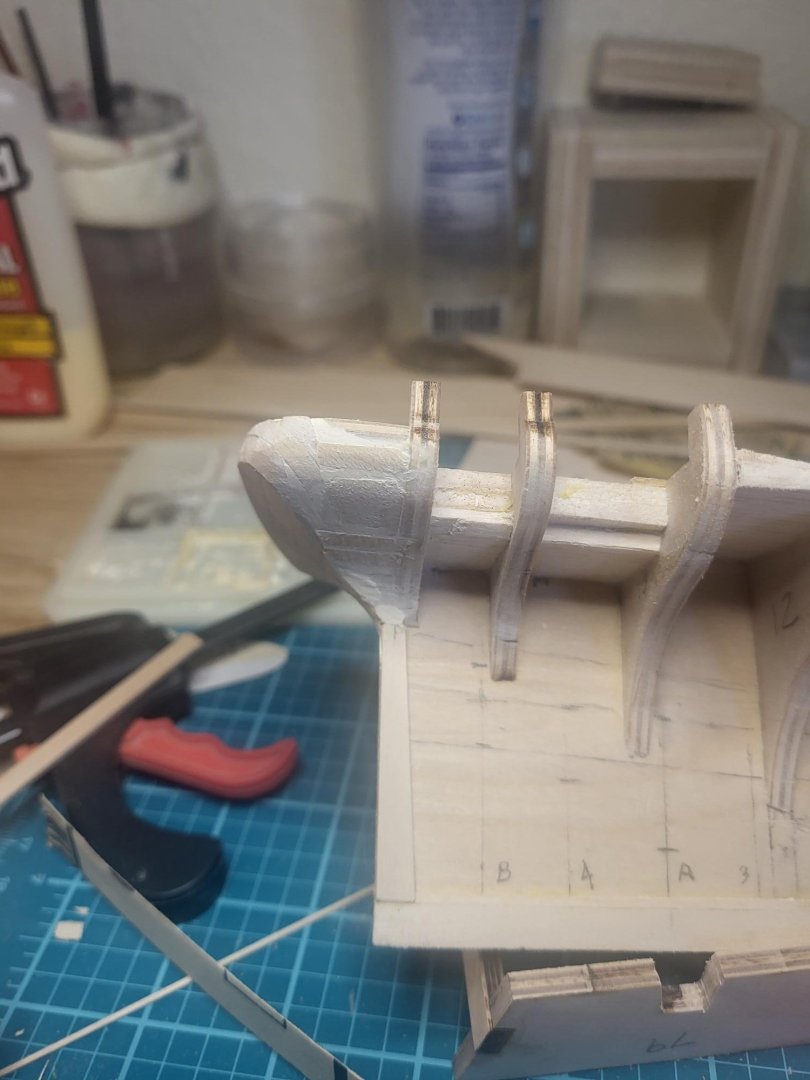

Figured out what to do with the timbers.. duh.. Thinning them out on two sides, brings them close to the size, rather than cutting them off. I'm not jazzed about pre-bending the bulwark then attaching them later, after all I want to plank the deck first, so the bent bulwark sits around for a few weeks? So once the deck is done, I'll shape them to the final size contour, and I can bend the bulwark and attach it to the timbers, and then add false timbers.

-

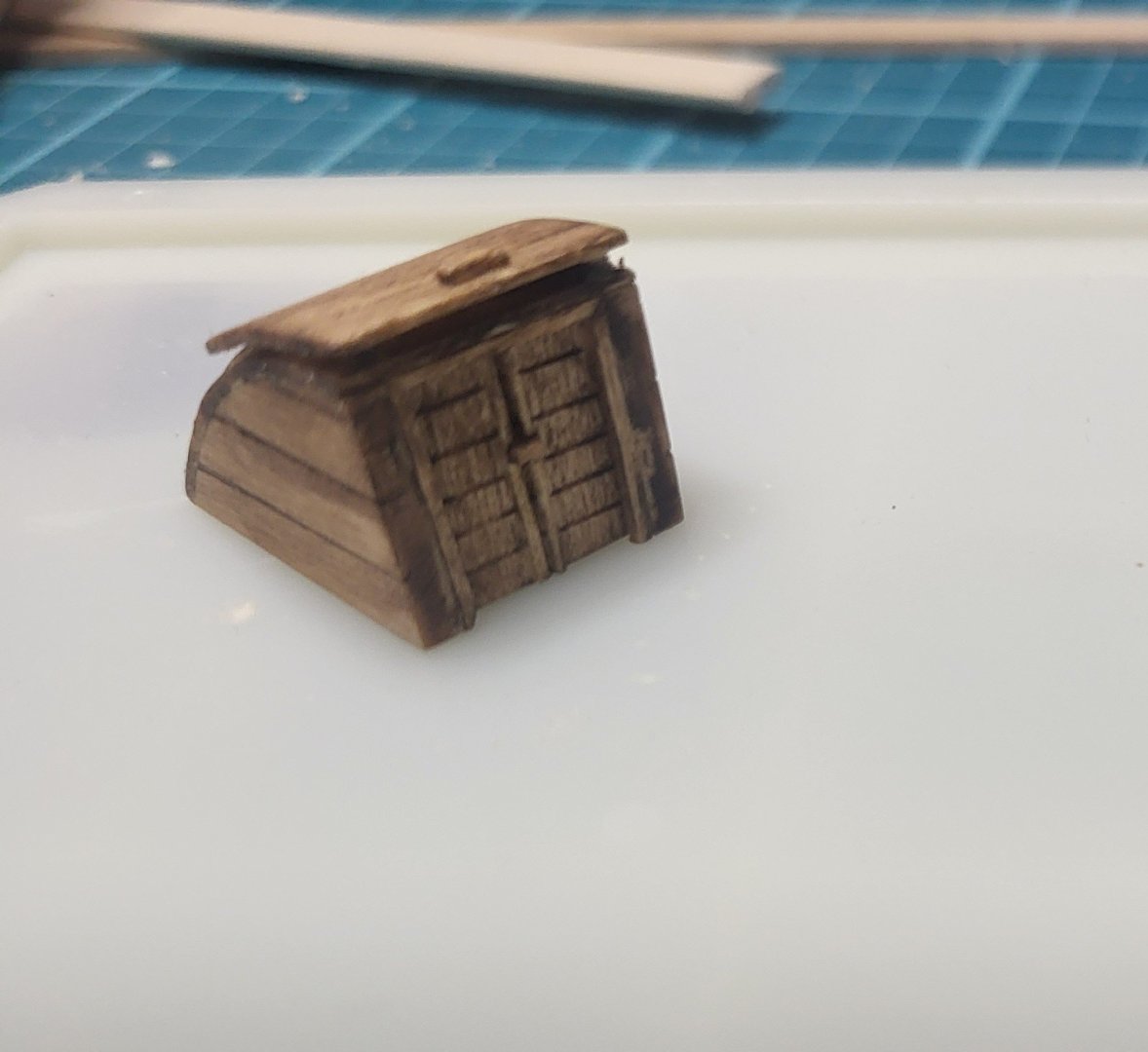

The tale of the transom. The shape and proportions of the kit are far away from the photos and period drawings, it's sharper and at more of an acute angle. I have been building up and shaping for a couple of weekends now. Pausing to create the cockpit grating, and to build up the transitions of the deck. I know the companionway is going in here somewhere, so now is the time to be sure the frame isn't going to foul good placement of it. In the back of my mind I'm also figuring out the plan for the bulkhead tabs. Obviously I won't cut them until the bulwarks are bent, but exactly how and when? This material, unlike basswood, can't be easily chiseled away after installing the bulwarks and false heads. I don't want to get painted into a corner.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.