-

Posts

83 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MisterMeester

-

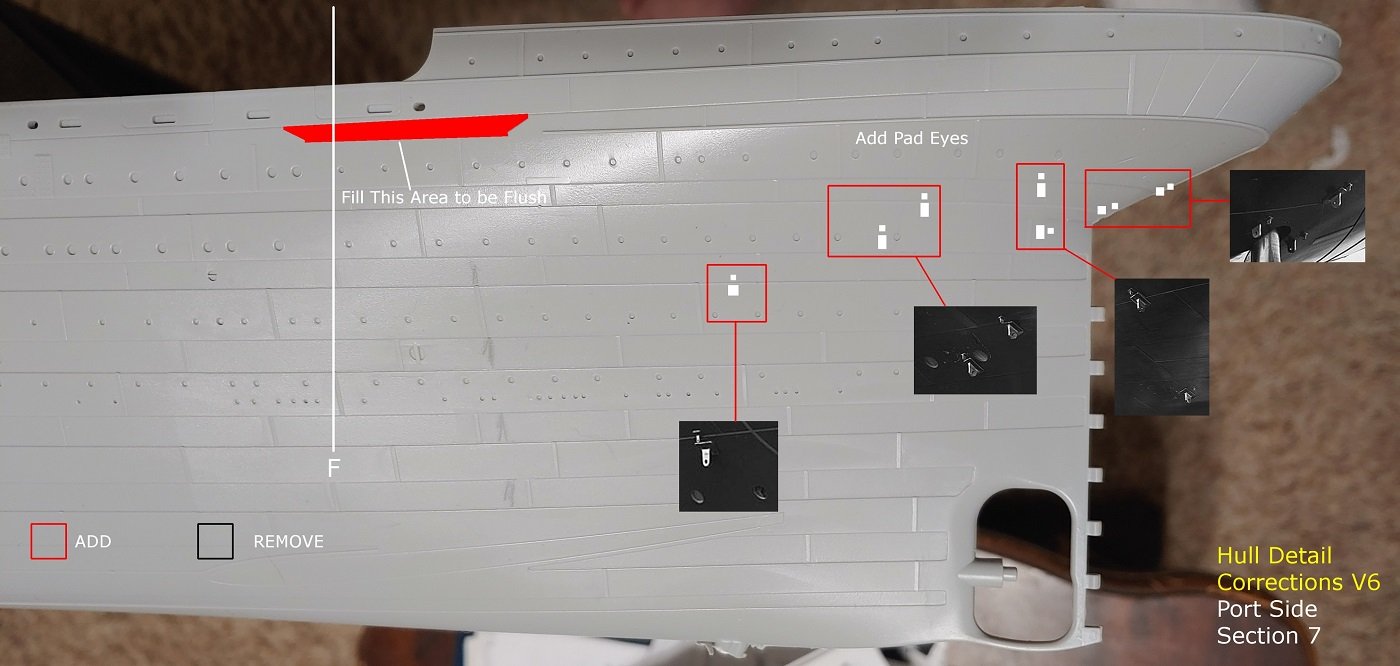

Changed my mind on getting to the propeller shaft wings and bilge keels next. Will get to those later. I need to address something else so I can get back to content sleeps at night. I did a dry fit of the Mini Brass Hull Profiles PE kit, port side. Ugh. As one can see by the photos, alignment is perfect in some parts (circled in green), but grossly not in other spots (circled in red). In hindsight I suppose more research on others experiences with this aftermarket kit would have been prudent. Apparently, turns out the kit hull has even more inaccuracies and, in this regard, the Mini Brass PE is correct. Who knew? If I had known that, I likely would NOT have purchased the kit. One of the reasons I was sold on it was that I expected no major surgery required. There is no mention of major surgery in the instructions, which I perused online prior to taking the leap. Having said all that, and given the amount of time and money already invested in this PE, I think I can make it work. Unfortunately, I have already drilled out the portholes. Less surgery would be required if they were still intact. First step is to remove the raised detail for a flush surface. Then more dry fitting for a better understanding of where I need to cut. Thanks for looking. Cheers, Mark

-

Doubling plates (all 180 of them) attached. Used CA glue for these. Parts A - D now complete. I found Part CU-2 backplate to be the most difficult. Particularly on the Stbd side (circled in red). It popped off under stress from handling. Re-attached with epoxy. Unfortunately I re-attached it without paying attention to alignment. Thus, it is slightly off by about 1-2mm longitudinally. Shouldn't be a big deal and hardly noticeable. Up next, as per instructions, with this PE kit is to prepare the hull. However, before engaging in that surgery, I want to do somewhat of a dry fit first. As well, there are other hull features still to be attached. For attaching the bilge keels and propeller/shaft wings I expect I'm going to want to flip the hull upside down. I'm quite certain that would not be a good idea with this PE in place. Further, kit parts N1 & N2 and P1 & P2 (for A, B, and C decks) come into play with this PE. Having said that, it's time to install the internal frame aftermarket kit. Original plan was to install the frame kit after painting the hull, as it would be much easier to install the porthole "glass" without the frames in place. But that plan was before I decided on this PE kit, and plans change. Glueing one frame at a time. I did not have a bar clamp large enough for this, so went out and bought one. At $18.99 CDN each (on sale, down from $29.99) it made more sense to get just one, instead of four. In the meantime, prior to starting on the internal framing, I was pondering the lowest row of molded indentations on the hull, which represent through hull fittings. Common advice regarding these is to DON'T DRILL THESE OUT(!). But wait.....I'm not lighting my model, and therefore, there would be no light leakage through these if they were drilled. I decided the overall look will be better with them drilled. Left undrilled, some of them will end up painted over with antifouling red. Done. Second frame glued in this morning. Two more to go. Should have that completed within a couple of days. After that will be the bilge keels and propeller/shaft wings. Thanks for looking. Cheers, Mark

-

Parts CU1 and CU2. For the Port side, I treated these parts same as the previous back plates. Worked them from the back side. Measured for fit and applied epoxy. Then flipped the sheet over for fine tune positioning. As soon as I flipped the sheet over both pieces fell off. I wasn't able to apply enough glue for the parts to remain attached during the flip. Bit of a gong show, from that point, but I managed to position the parts while working them from the topside and using CA glue in conjunction with capillary action. Different approach for the Starboard side, which was way easier. Worked them from the topside from the get go and simply positioned the pieces dry and then taped them in place, followed by applying CA glue at each ends, allowing capillary action to do it's thing. Then, once secure, flipped the sheet over and applied more CA from the backside. On to the Doubling Plates... Thanks for looking. Cheers, Mark

-

Back Plates of Sheets 1 and 2 done. I've been working on another project, which delayed me for a while, but that's completed now. As well, I found I had to provide weight to the PE to flatten the bends resulting from the shipping damage. Not sure if this would have been required regardless, but me thinks not. At any rate, because of this, I chose to do each of the larger back plates one at a time. I wanted to minimize the possibility of the back plates slipping as much as possible. Thus, this slowed the process down. I chose a BIG HEAVY book for the weight. Further, I switched to a slower curing epoxy. Working out well. On to Sheet #3, and more Back Plates. Four back plates for each side (Port and Starboard) on this sheet. I'm hoping to get all eight done in two applications. We'll see. Thanks for looking. Cheers, Mark

-

Hello Evan! Thank you for your post. Honestly, removing the well deck bulwarks had never entered my mind. I’ll take a look at that when the time comes, however preliminary thought on that is….leaving the delicate PE without any backing support in that area makes me nervous. I neglected to mention….I found working on the hull, prior to acquiring and employing the cradle I’m using for her, to be awkward and cumbersome. Prior to the cradle, I managed to inadvertently erode away a fair amount of the rivet detail. The main reason I got this MiniBrass kit was to rectify the lost rivet detail. My initial plan was to use 3D rivet decals (I even went as far as purchasing some), but decided the PE was the way to go instead. Cheers, Mark

-

Ahoy Harald! Thanks for your post. The E6000 packaging says it's good for metals, so I suppose it would work. I considered it, but for the sole reason that the instructions do not mention it, I decided on epoxy. I'll be touching up the edges with CA. Speaking of glue....the Gorilla two part epoxy I've been using is 5 minute quick setting. I'm finding it to be not very user friendly for the larger back plates. My method of application involves mixing a puddle of the stuff onto an old CD and transferring it to the PE by way of dabbing a round toothpick in it and applying small drops onto the PE. This is somewhat time consuming. Longer than 5 minutes for the larger plates. The epoxy begins to set before I'm done, resulting in it becoming globby and stringy. Bob Smith Industries makes a "Mid-Cure" (15 minute) and "Slow-Cure" (30 minute) epoxy. Segue to the Saskatoon hobby shop you likely visited. Express Hobbies. Couple of blocks North of 33rd St. It's essentially the one and only here. They have both epoxies in stock. I think I'll get the Slow-Cure and give that a go. Back to the hobby shop....I moved here in 2016. Didn't actually step through their door until 2022. Not sure what else might have been here before then. There's one other store here that I've never been to as they are pretty much all about RC. Cheers, Mark

-

Argh. Didn't take long to have a couple of issues. I take full accountability for my mistakes, but some clearer and more comprehensive instructions would be nice. But that's part of scale model building, isn't it? The first issue. Fitting Back Plate A, for the Port Side of the kit. As one can see of the port holes within the blue oval, I did not get the back plate lined up properly. The way the instructions are written suggests that the back plate can, and ought to, be fitted in place with Plate A upside down. No. This is not the best way. Don't do what I did. Upon gluing Back Plate C to Plate C (haven't done B yet), I found that what's better is to flip it back over to topside up and work the underneath back plate from above, with a scriber tool. The "Utley" aspect of said portholes, as well as the inside portion of the window frames, are visible and the back plate can be manipulated into position this way. The second issue. Completely got the placement of Back Plate DP wrong. The end in the blue circle needs to be at the end of the green circle. I was wondering why there was no port hole in Plate A for this end of the back plate. Further, I trimmed the end as it was slightly covering the adjacent smaller port hole by ~1mm. I had just assumed this was a manufacturing flaw. Nope. Modeler flaw. Having said that, the instructions could be better. I'm a visual guy and a better diagram would have gone a long way. The contrasting color of blue (the back plates) to grey (the fret, etc.) is not very evident in this particular spot. Further, all the port holes of this back plate are indicated in white....except for the one port hole at the left end, where the red arrow points. Yes, turns out it is indicated, but in extremely hard to see, and easy to miss, grey. Just a poor visual representation. Had it been indicated in white, like all the others, it would have been obvious. Great. What to do? Am I going to have to order another sheet and go through another three months of waiting for it to ship? Thankfully, no. I managed to separate the back plates from Plate A with a straight razor. (Gorilla two part epoxy glue used.) And cleaned up with a sanding stick. Ready for attempt #2. I'm happy, and relieved, to announce that attempt #2 was a success. Back Plates A and DP are now glued on Plate A correctly. Thanks for looking. Cheers, Mark

-

Small update. Got the starboard side anchor guard bars and porthole guard bars glued on a couple weeks ago. In so doing, I discovered a mistake in the instructions. The location of the non-existent porthole indicated (starboard side only) is not where the instructions say, but rather ~20mm further aft. But it's a moot point anyway, as Trumpeter did not even mold this porthole into the hull, and therefore, it's obvious. Golf season is officially over for me (as of 10 days ago). I've been busy with chores around the house, transitioning from summer to winter. Getting back to the bench just now. Next step will be starting work on the MiniBrass Hull Profiles PE set. This set is quite extensive and will transform the hull significantly. The set arrived (last May) damaged. All three sheets bent. I assume this occurred during shipping. I emailed the proprietor advising him of this. I mentioned I thought I could make the damaged product work, but suggested he might want to re-address choice of packaging for future orders. He replied that this is the first time he had a report of damage and assured me that he'd replace any parts that won't work. Fingers crossed. Intro to the instructions... General information page.... First three pages, describing the first steps... Expecting to get started this afternoon. Should be fun. Thanks for looking and cheers, Mark

-

Ya, they’re quite tiny. And such a huge project overall. I’m figuring two to three more years at least. Probably more. Found your build log and following. Happy modeling and cheers, Mark

-

MiniBrass Pad Eyes P2, P3, P5, and finally P4 attached. Pad Eyes complete. Not perfect by any means. A few are slightly crooked and there is excess CA glue here and there. Probably goes without saying that the P4 Pad Eyes (the smallest) were the hardest. The white object in the tray on the left in the first pic is a cat whisker. I used that for applying a tiny drop of CA glue to each P4 base before attaching the P4 eye to the base. I forget where I heard about using that as a tool for small amounts of CA as it was quite awhile ago. Perhaps a member of Model Shipwrights of Niagra, but I'm not sure. This is the first time I've employed a cat whisker for that purpose and it worked out quite well. I used a glue looper for all the other gluing. Having said that, one lesson learned with this aspect of my build is I think I underestimate the power of CA glue, and tend to use too much. Looking forward to working with it more. I need to find something to practice on with it. As for fret nubs, I did not bother sanding/filing any nubs off the remaining PE beyond P1. I figured it's so tiny and hardly noticeable that it wasn't worth the bother and risk of losing some of the parts. I considered cleaning them up (fret nubs and excess glue) once attached to the hull, but upon closer inspection with my Vision Aid magnifiers, I'm going to leave well enough alone. Another lesson learned is my eyes aren't what they used to be. Despite using the magnifiers, this PE (especially the P4 eyes) was somewhat difficult to see and work with, but I managed. Hoping I will never have to work with such small PE ever again. I suppose now, the hardest trick of all will be making sure they stay intact. (Read: not get careless and bump them off). One final thought on the Pad Eyes regarding mention of mine upthread of the hole of the eyes getting CA glue in them. How did that happen? Well, in working with the subsequent eyes, it became apparent. It is quite difficult to attach an eye to a base while maintaining a vertical aspect of the eye. Often they wanted to just flop on their side once they came into contact with the drop of glue. Hence, once on their side and in the glue, that glue gets into the hole. Just a heads up for anyone else who might be using this aftermarket kit on their model. Thanks for looking and cheers, Mark

-

Despite golf season still being in full swing, I've found some bench time lately. Before continuing with the PE for the hull sides, I've decided to do the Pad Eyes at and near the stern next. This is tiny PE. Did the larger P1 Pad Eyes first. As evident in the pictures, this PE has two parts. The eye itself, and the base. I figured it would be easiest to attach the eyes to the bases with the latter still attached to the fret. I filed the fret nubs off the eye parts with an 800 grit sanding stick while holding the part with square jawed flat pliers. Tricky. Then using the Mini Brass instructions, as well as Graham Boyd's document, I placed the positions of each Pad Eye, by eyeball, on the Port side with an Ultra Fine Sharpie. For the Starboard side placements, I measured the Port side placements from various references points and placed accordingly to make both sides symmetrical. And a couple of pics showing the P1 Pad Eyes in place. Unfortunately, I somehow managed to get CA glue within the eye hole of most of them. At least, it looks that way. Despite using Vision Aid magnifiers, I found it quite hard to actually tell. I tried cleaning them out while they were still on the fret, but after breaking two of them off, I gave up. I suppose, in hindsight I could have burnt the CA off with a lighter, but that heat would most likely have caused each eye to become removed from each base. Thus, having to start all over. Anyway, not sure how that might have happened. As they are so small, I'm happy with how they turned out. I think the ultimate tell will be when I get paint on them. As for fret nubs on the base parts, I cut as close as possible to the base edge. Consequently, I manage to avoid any nubs on the bases. If there are any there, I couldn't see them. And finally, as far as I could tell from instructions and reference photos, the two aftermost Pad Eyes were on the centerline (which makes sense to me). As a consequence of that, there is one extra P1 and one extra P4 provided. Hoping the smaller ones will go as well as these ones did. Thanks for looking and cheers, Mark

-

Small update. Got the MiniBrass anchor guard bars PE installed on the Port side. As well as the single and double porthole guard bars on the Port side. Dime added in photo for scale reference. This is tiny PE. Thanks for looking. Cheers, Mark

-

Update: After much thought, consternation and reluctance, the sole reason I started a build log for this model on Model Ship World was because one+ year ago the FineScale Modeler Forum (of which I was a newbie) was proving to be a $%&*#@-Show. I had started a build log there, but gave up after only one week. They have since (about 7-9 months ago) done a 180 with a new platform and it's waaaaay better. (I'm on there every day now). Not having come anywhere close to completing this build once they had fixed things, I decided to start a build log on there again. I also started a build log (later) on another forum. Modelers Social Club. With the other two build logs for this model, I decided to not bother updating this log here. I recently put my 1/200 Trumpeter Titanic on hold for a few months to get this model finished. Having said that, for the purpose of closure here, I'm posting one final pic of this build. This model is complete. If anyone is interested in the progress of how this build went, they can find it on FineScale Modeler Forums. Figure category. Same username as here. MisterMeester. Sorry to have used up bandwidth with this log. If admins wish to delete this thread entirely, I'm okay with that. Cheers, Mark

-

The Prow Hawse Port. Used for the center anchor as well as being towed from ahead. It did not look as Trumpeter molded it. I began with filing down Trumpeter’s version. Not sure if that was necessary. It might have helped keep the saw in line. I used a #13 Excel saw blade for the cut. I cut down 25mm. This was conservative, making sure I didn’t cut too far, and fined tuned later. The gap here, on the Starboard side, came away pretty much on its own. For the Port side I had to do some additional cutting. The first additional cut was easy. For the second additional cut I decided to drill holes to make the turn easier. I suppose, in hindsight, I could have made that cut coming up from the bottom instead. I measured the gap required to be ~0.75mm wide. Using a file to accomplish that width. Cutting complete. No turning back now. I put the Fo’c’sle deck in place to ensure no fit issues down the road. The new Hawse Port CA glued in place. I used a straight edge to ensure proper alignment with the stem. The next step was puttying. I first taped the exterior of the gaps, to act as a backstop, because….. …. I applied putty from the interior first. I let this set for 24 hours. I used Milliput Superfine. As expected, some putty was pushed through to the exterior. Port side as well. Milliput Superfine putty applied to the Port side. Let to cure 24 hours. The red arrow indicates a piece of styrene strip I taped in place. I neglected to take a picture of this prior to puttying. Purpose of this was to let the putty create the forward edge of the recessed strake here, as opposed to me trying to sculpt it later. Post sanding, Port side. Starboard side. Blue arrow in this image better explains the intent of the styrene strip. Red arrow indicates the Mainmast Forestay fitting. Note that it is intact. I flipped the hull upside down to work on the Starboard side. I’m right-handed and wanted to sand from aft to forward, for the most part. My main concern with this was that I hoped the different perspective wouldn’t cause a different result. Starboard side putty in place. Let to cure 24 hours. Starboard side sanding complete (for the most part). Note the red arrow indicating the now missing Forestay fitting. While the hull was still upside down in the cradle, I decided to do some clean up and clipped it with the hand vac. Downside to many resin parts. Very brittle. Spent about 20 minutes looking for it. Next task was to fill these gaps (within the red circles). And filled. For the top ridge I used 0.75mm x 1.0mm styrene strip, sanded down to ~ 0.55mm² prior to gluing in place. For the bottom gap I used 0.25mm x 0.5mm strip. The ridge gaps on the Starboard side were not as bad and did not require styrene. The camera shows me they still need attention, however, so I’ll take another look at those. New forestay fitting manufactured from 0.75mm x 1.5mm styrene strip. The hole is 0.7mm. Larger than the original hole, but it’s the smallest drill bit I have. Probably should have left this well enough alone until much later. No doubt it will get broken off again. Note to self: Be careful. Some final shots. The last was one shows the cover in place. It’s not perfect, but disaster averted. This could have gone so wrong. I'm very pleased with how it turned out. Thanks for looking. Suggestions are welcome. Cheers, Mark

-

Me too! Aiming for late Spring, early Summer. It has to be painted outside. In the garage at the very least, but it’s not heated and not the best lighting. Cheers, Mark

-

Progress update: Not much. I decided to scribe the panel lines after all, for the remaining Double Strakes that were missing, but already flush. So, now there is at least representation of them. Turns out that will be moot anyway. To be explained later. Continuing with the Coaling Doors, I have those all applied now. Prep for adding the indentation for one of the two doors missing the indentation. And removal of the molded door itself in advance of attaching the PE replacement. Starboard side Coaling Doors complete. Proceeding onward, I was puzzled over where the Cleats, on the same PE sheet as the Coaling Doors, go. I had no clue. So, upon researching this it finally became apparent that the instructions for the MiniBrass Coaling Doors and Cleats PE sheet is buried in the MiniBrass Stern Plating Instructions pdf document. Sheesh! Not only that, but the instructions for the MiniBrass 1:200 Titanic Hull Details PE sheet are buried in the same document. Sheesh x2! Absolutely no mention of this in the title of the document. Just “Stern Plating Instructions”. Ridiculous. Rant over. So, it turns out the Cleats are actually associated with the Coaling Doors. A pair of them are to be attached above each door. I’ll be leaving that for another day. I was also curious why the MiniBrass Hull Details sheet has only five so called “Gangway Doors”, when there are 16 total molded doors on the hull (8 each side). This research led to discombobulated thoughts on what the heck is accurate and what isn’t, strategy, and a potential change of plans on which direction to go with some aspects of the hull build. I learned that the five doors provided are optional doors for E deck, and are to be used to compliment the MiniBrass 200 HULL PLATING PE sheets. I also learned that the KA Detail Kit has PE hull doors for the model. I missed that the first time I looked through the kit. So, at this point, I decided to go with the KA doors. I began with Port Forward. The KA instructions indicate a door goes here (red circle). It is also “implied” (my term) from the Starboard profile hull plating diagram in a particular reference book, that there should be a door here (again, red circle) so I attached a KA door here. As well, it appeared to me that some other modifications were required. The raised feature within the blue circle is not in said diagram and needed removal. Further, the lower portion of the raised feature within the black circle needed to be trimmed. Here’s an image of the work done. But wait! The KA instructions are wrong, and the hull plating profile perused is that of the Starboard side, not the Port side! I forget the sequences of events moving forward from here, but upon researching the doors more I discovered the following: - There are instructions for MiniBrass’ Hull Plating PE sheets (who knew?). I was previously aware that MiniBrass has these sheets available, however I had assumed that using them requires major plastic cutting surgery. After reading through the instructions (that I just discovered), it looks to me that the application of these is not as hard as I originally thought. - Also discovered in said instructions, apparently, there is no such door on the Port side, such as what I just applied. - Unfortunately, there is no Port profile hull plating diagram in the (to remain nameless) reference book to point this out. - However, perusing a photograph in another reference book confirms this. No door here (red circle). Looks like I got the other modifications wrong as well (blue and black circles). Also, while working on this door application I couldn’t help but notice (for the umpteenth time) the rivet damage I’ve incurred to the hull prior to having the cradle I have it in now. Prior to the cradle, I just had the hull on two boards with hand towels as protection. It didn’t always work out. Not to mention some of the rivets were inadvertently chiseled away by carelessness while chiseling something adjacent. Sometime a go, I purchased an HO scale 3D rivet decals sheet to help rectify this, but they just aren’t the same. Taking into consideration…. - the rivet damage…. - that the Trumpeter hull rivet detail is actually quite lacking overall and that the MiniBrass PE kit captures the actual rivet detail…. - that the MiniBrass kit looks to be not that difficult to apply….. - and the MiniBrass kit should take out further guesswork of what goes where…. I’ve decided to order the MiniBrass 200 Hull Plating Kit. Oh, and the scribed panel lines to indicate the missing Double Strakes…. those will be replaced correctly by this PE. In the meantime, I’ve applied the Trumpeter provided PE parts 48, 49, 50, and 51. Condenser Intake screens. Next work will be on the Prow Hawser Port. This piece was purchased from Shapeways. This will require some plastic surgery and putty/sculpting application. Intending major patience on this. Even if the first cut takes me an hour, it takes me an hour. Hoping it goes well. Hopefully what I’ve described makes sense. Believe me, to achieve an accurate representation of the Titanic with this kit is a major challenge and I’m often lost myself. I can only image the experience of what others just reading about it is. Thanks for looking. Suggestions are welcome. Cheers, Mark

-

Looks great, Evan. Will probably follow your lead on the keels. I have a set purchased from Shapeways, but they are very brittle and no doubt will break at some point. Leaning toward scratch building them also. Cheers, Mark

-

@Jim Lad Yes, thanks. I was thinking silver or aluminum, but perhaps there’s a color available that’s closer to zinc. If you know of a brand and color code off hand, please share. @king derelict Thanks for the ideas. I happen to have beeswax. Will give it a try. Cheers, Mark

-

Progress has slowed somewhat. Wife had hip surgery three days ago and most of my time has been devoted to that lately. Continuing with the Mini Brass Hull Details PE sheet.... I applied the zinc anodes and reinforcement plates in the vicinity of the stern frame. Zinc anodes are the smaller squares, the reinforcement plates are the larger. Not too happy with how the zinc anodes turned out. I did the Port side first..... I have a $15 CDN manufactured pick up tool, but it proved to be useless, so I crafted a homemade pick up tool made from a round toothpick and blue tack (as seen in the next image). I suppose the ball of blue tack is too large for these applications as, upon placing the zinc anode, I could not actually see the photo etch piece. I figured I'd just get it on there (CA glue already applied) and then shift it into position accordingly. However, the CA glue set up immediately and it is what it is. The zinc anode should be butted right up to the plating below it. The Starboard side..... The placement of the pieces here are what I intended to achieve, however, the zinc anode and the adjacent plating below clearly do not align exactly, indicating that I did not quite get the angle of the upper end on that stern frame plating correct. Bottom line is, the placement of the zinc anodes, one side to the other, don't match and the Port side zinc anode placement is inaccurate (too high; should be right up against the plating). I considered trimming the styrene on the Starboard side, to match the Port side, but that plating matches now as it is, so that would just change one problem into another. I also considered trying to pop off the Port zinc and reposition it, but I had visions of the piece flying off into the carpet monster's gaping mouth if I tried that. In the end, it is what it is. This model will not be displayed in the middle of a room with both sides in view. One side will be up against a wall. Not sure which side that will be yet. Depends on which side has more mistakes. Chalking this up as a learning experience. One of my next tasks will be to make another pick up tool with a much smaller ball of blue tack. Further, technically the reinforcement plates should be flush with the plating around it. Having said that, I'm okay with how I placed those. I proceeded to then move on to the so called "Safety Bars". Some of the Sidelights (aka Portholes) on the Titanic had bars over them to protect them from the Anchor Cables. Nine on the Starboard side, (five double and four single), and ten on the Port side (five each). I got as far as cutting them from the fret. Here's a picture with a dime for scale reference to indicate just how tiny this PE is. Four single bars are in the left container, five double bars in the right. As I cut these from the fret, they bent from the knife pressure. That's how delicate they are. Another hurdle I have with these, besides just trying to get them glued on, is that most, if not all, still have an attachment nub remaining on them from the fret. I'm interested in advice on how I can file and/or sand these nubs off, seeing as they are so tiny. I'm thinking glue them in place first and then try dealing with the nubs once they are secured in place. Any suggestions on this would be greatly appreciated. In the meantime, I've decided to move on from these, for now. Instead, moving on to the second MiniBrass PE sheet I purchased, Coaling Doors and Cleats. Beginning this sheet with the Coaling Doors. The only reason I purchased this sheet is because there are two molded Coaling Doors missing from the Trumpeter hull. But seeing as I now have the sheet, I figure I might as well do all 44. There are 22 Coaling Doors on each side. I'm not even sure where the Cleats go. Haven't researched that yet. (Instructions are lacking). The black circle represents a Coaling Door as molded by Trumpeter. The red circle represents a molded door already chiseled off by me. Happy to see the indentation remains. Will aid in positioning. The blue circle represents one of the two missing coaling doors. A porthole was here in its place, which I had previously drilled out. Hence, the putty fill. Thanks for looking. Suggestions are welcome. Cheers, Mark

-

@yvesvidal I’m very much looking forward to seeing how it will all look painted up. Thanks for the like. @Force9 Thanks. I may still at least scribe panel lines for the one double strake I passed on. Haven’t decided yet but leaning that way. Thanks for the like. Cheers, Mark

-

Looking good, Evan. Excellent sleuthing on the gangway doors. Excited to see what you come up with for bilge keels. Cheers, Mark

-

First ever experience with PE went well. Very pleased with the results. Started with the Condenser Discharge Ports. I did the Starboard side first.... And the Port side. For this side I decided to give the provided template a try. I think it helped a bit, but not essential. Looking forward to working with the rest of the PE and getting on the hull. Thanks for looking. Suggestions are welcome. Cheers, Mark

-

Continuing onward. Mini Brass Hull Details PE aftermarket kit. This is my first experience with photo etch. Looking forward to it. I think I'll do the Condenser Discharge Ports first. Cheers, Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.