-

Posts

25 -

Joined

-

Last visited

About MisterMeester

- Birthday 05/19/1961

Profile Information

-

Gender

Male

-

Location

Warman, SK, Canada

-

Interests

Scale Modeling, Golf, Video Gaming, NFL Fan

Recent Profile Visitors

-

yvesvidal reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

yvesvidal reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

-

yvesvidal reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

yvesvidal reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

-

Canute reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

Canute reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

-

chadwijm6 reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

chadwijm6 reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

-

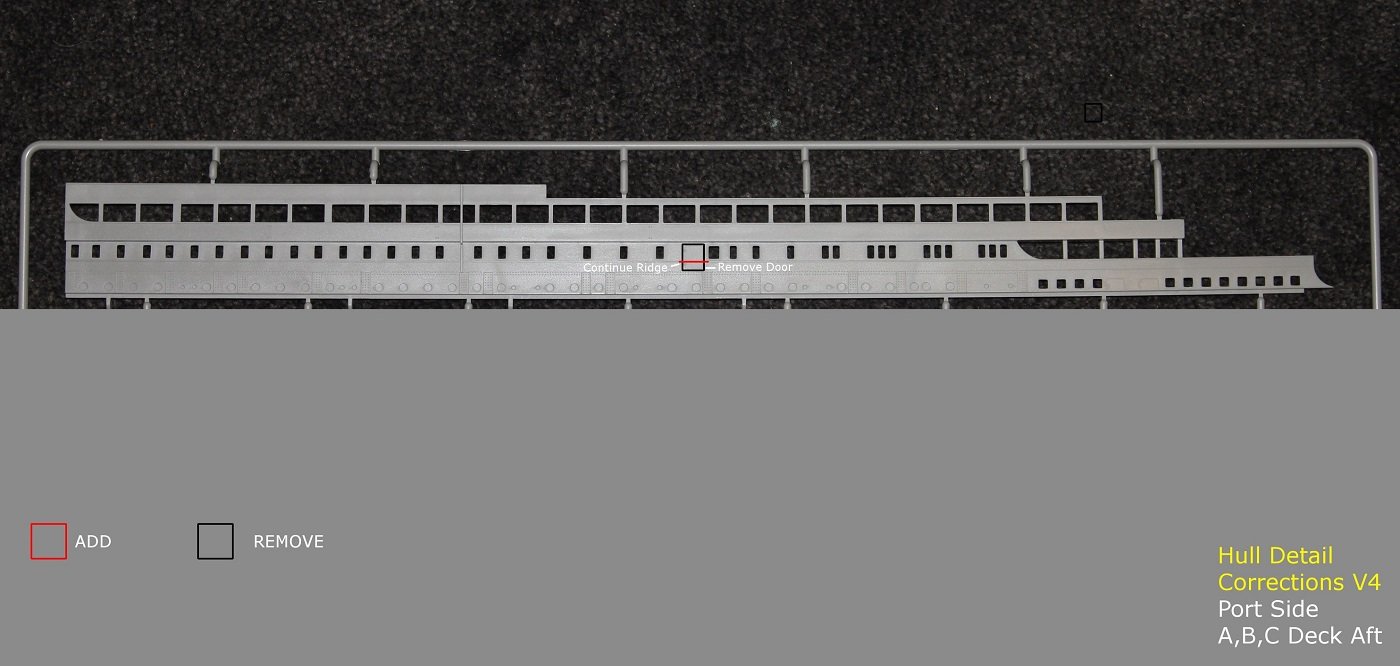

Stern portholes drilled. 1.2mm. Trumpeter did not include the aft hawser leads in the mold. Port Aft hawser leads plotted and drilled here. 1.4mm. Graham's document does not have distances off any references, I assume because his resource materials did not provide any. I'm satisfied that he likely spent many hours researching it, to no avail. I wasn't about to spend many hours myself on it. I plotted my holes by simply eyeballing them based on his document and the Titanic references I have. There's a good picture of these, albeit Olympic, in "Titanic: Icon of an Age", pg 119. Looks like I messed up a bit. I plotted the forwardmost lead a little too far aft. For the starboard aft hawser leads I measured the location of the port aft leads from adjacent plate seams, in millimeters, and transposed. Trumpeter DID include the forward hawser leads in the mold. However, the port forward mold depressions were 1.4mm, while the starboard forward depressions were molded at 2.0mm. I did not discover this until after I'd already drilled the other six leads. Regardless, I drilled these leads 2.0mm. Instead of drilling the other six leads again, at 2.0mm (which would be too large), I decided to plug these with 2.0mm styrene rod and will re-drill at 1.4mm. Still a work in progress, as I need to fill the cavities with putty. Minor hiccup here. The largest bit for the Wowstick is 2.2mm. The next portholes in line to drill were the .094" holes, which require either a 2.4mm bit (which I don't have) or a 3/32" bit. The Wowstick chuck is not big enough to take a 3/32" so I used my Deko drill. Drilling these holes on the starboard side went pretty much hiccup free. However, on the port side, after only two holes drilled, the bit decided to start skating on me resulting in the next two holes to drill out of alignment. Time to stop and regroup. Green arrow shows the first two holes working out fine. Red arrows show the misaligned holes. If the styrene rod in the hawser leads above works out, I have a mind to do the same here, to correct these two holes. New plan required pilot holes for the remaining. I chose to use a pin first, eyeballing as close to center as possible to mark the spot, and then use a push pin to enlarge the mark. Then I used a 0.8mm bit in the Wowstick for the pilot hole before finishing off with the 3/32" with the Deko. Everything went well from here. So, all portholes are now drilled except for the .109" holes. I have an "Utley" portholes aftermarket kit on order from Scale Warships that require a 3.0mm hole. Upon arrival of that kit, I will then drill one 3.0mm hole and do a dry fit with an "Utley" porthole before proceeding with the rest. Another little task required was this...... There are 12 of these deck supports on the inside of the hull that require cleanup for the porthole "glass" inserts. Somewhat surprised that Trumpeter did not position all the supports so as to not conflict with any portholes, but alas, I suppose that's part of model building. Door removals. As per Graham's research as shown, and cross referencing appears to confirm, a number of doors have been incorrectly molded in and, for accuracy sake, need to be removed. Still some cavity filling required for the above. And the door removal I worked on today, on part P2, which also requires "continue ridge". For "continuing the ridge", I used 0.25 x 0.50mm styrene strip, attached with Tamiya Extra Thin cement. A work in progress. Letting it set overnight before sanding it down. And to complete this post, it is a common opinion online among other builders of this model that, for a more accurate model, both the KA as well as the Pontos detail kits are beneficial, as each have their advantages. I recently came into a modest amount of unexpected retro pay from my previous work years so I decided to splurge on the Pontos kit. Quite excited to now have this kit as well as the KA kit. And an additional bonus is that I managed to find it in my home country so, no customs duty. More to come. Thanks for looking. Suggestions are welcome. Cheers, Mark

-

Landlubber Mike reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

Landlubber Mike reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

-

mtaylor reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

mtaylor reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

-

king derelict reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

king derelict reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

-

GrandpaPhil reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

GrandpaPhil reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

-

Canute reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

Canute reacted to a post in a topic:

RMS Titanic by MisterMeester - Trumpeter -1/200 - PLASTIC

-

Canute reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

Canute reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

-

As expected, my local hobby store did not have Mr. Surfacer 500 in stock. Order placed with my go-to online supplier. It will arrive next week. In the meantime, I've masked the lapel off expecting that the procedure will not match the existing texture and will probably have to do the whole lapel. Thanks for looking. Cheers, Mark

-

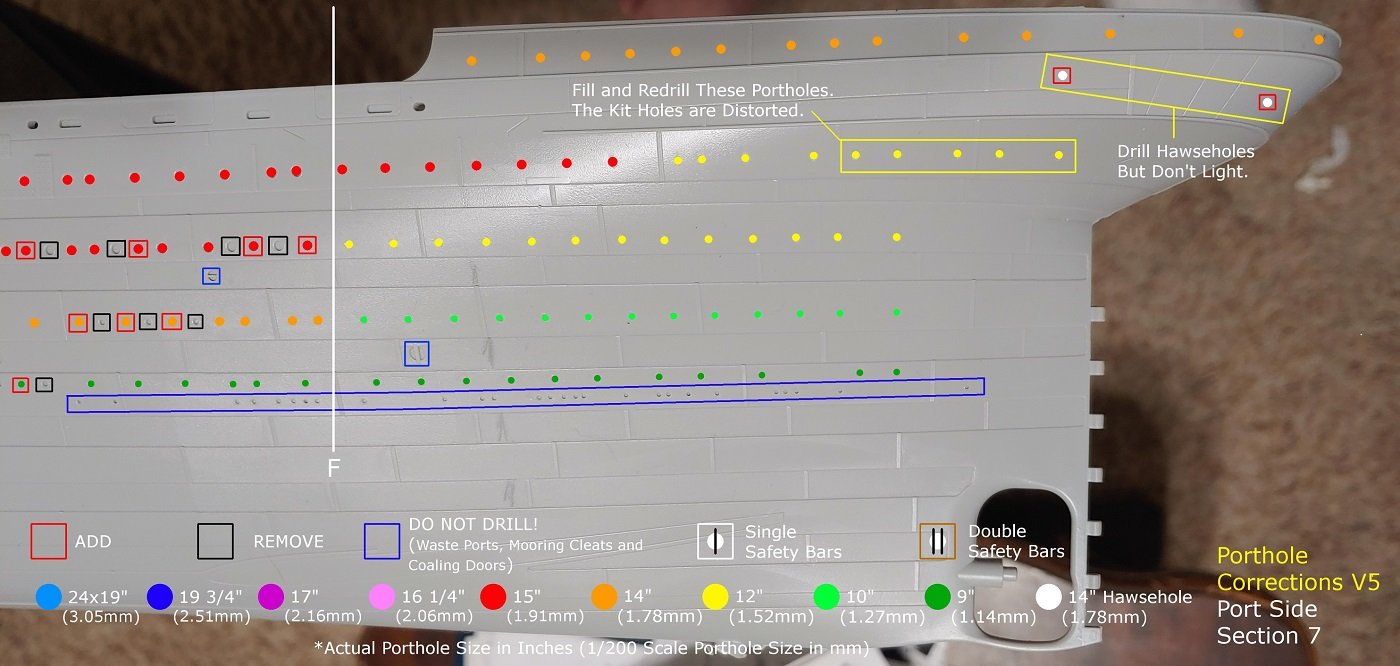

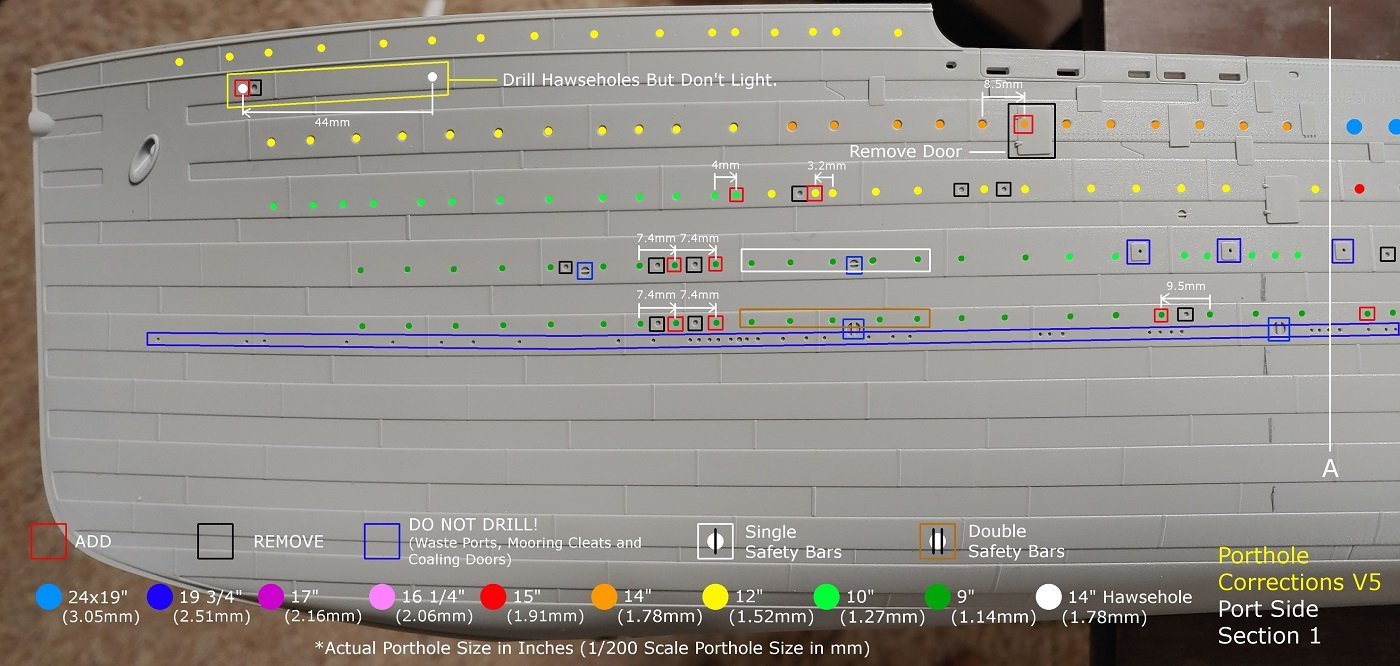

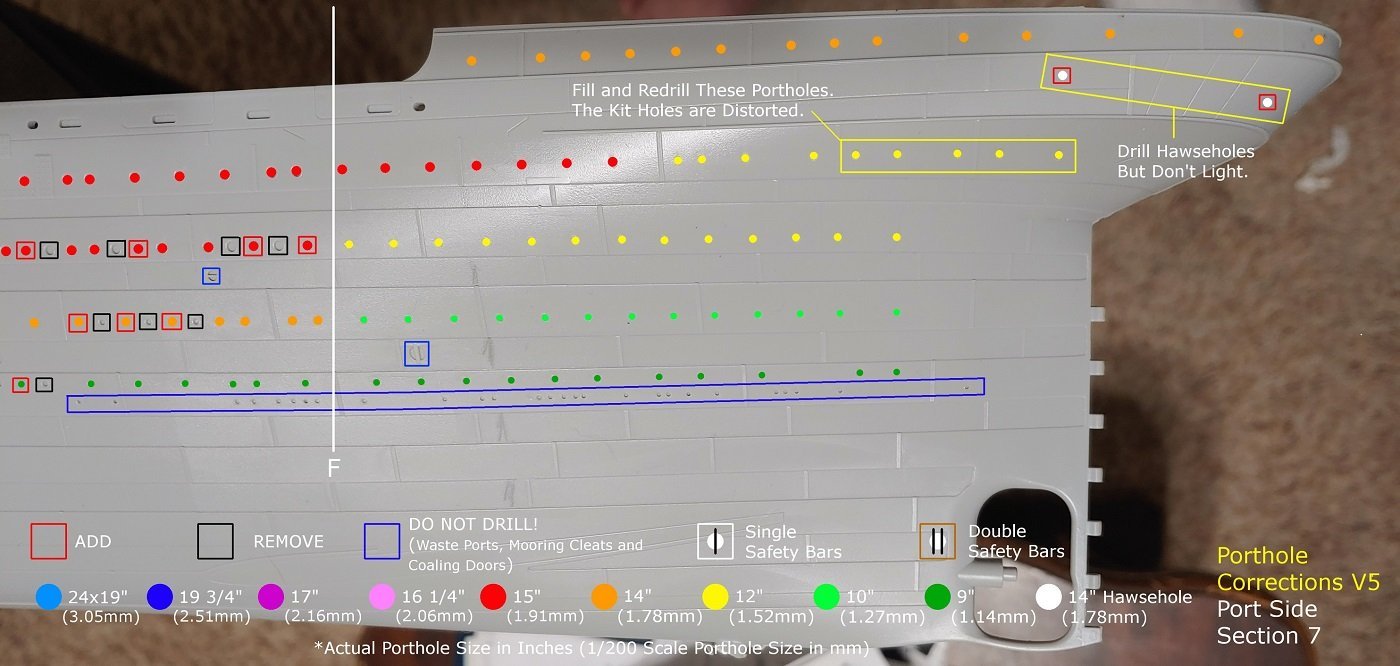

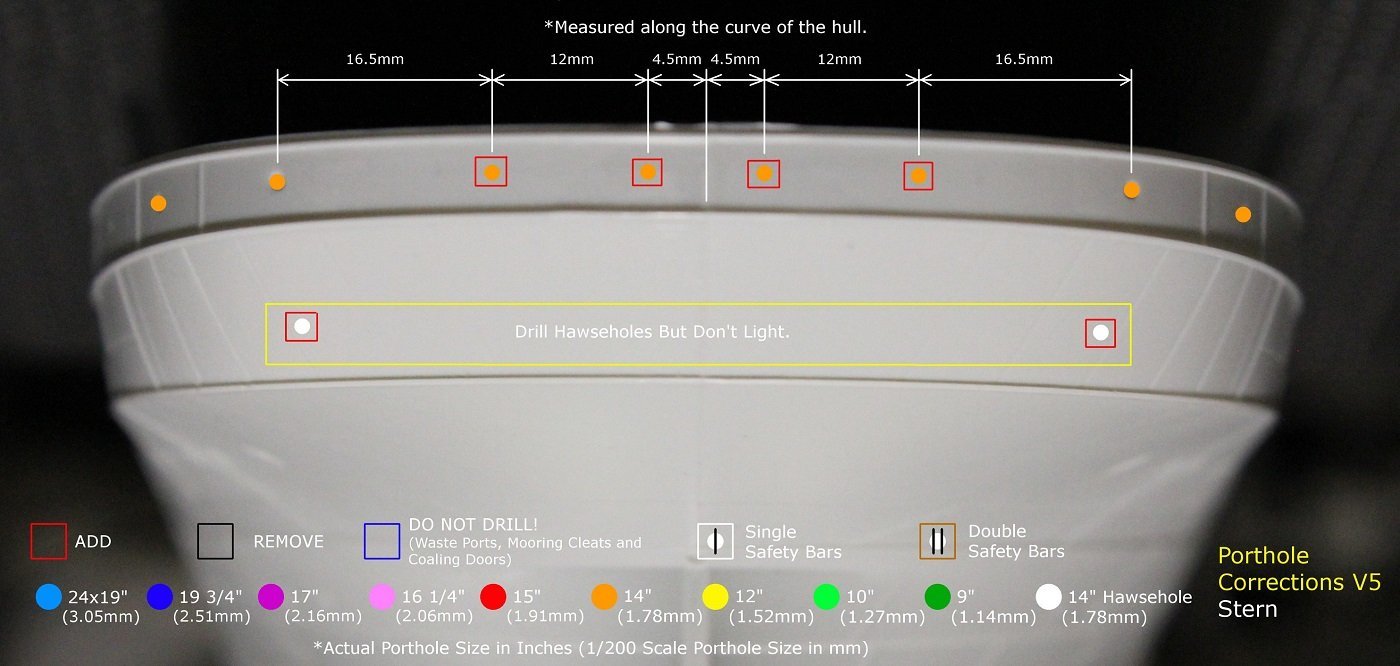

I’ve received permission from Graham Boyd, member participant of the Facebook group “Trumpeter TITANIC 1/200th model ONLY building tips and tricks”, to reference his documents regarding kit inaccuracies to the hull and portholes and the associated corrections. Graham referenced the book “Titanic: The Ship Magnificent” for his detailed work. He created 37 images, for closer detail. Eighteen for the hull corrections and 19 for the porthole corrections. I intend to post only a few in this build log. This will, hopefully, explain what some of my decisions regarding the hull are based on. Porthole Corrections - Port Side, Section 1 Regarding the portholes to “remove”….these portholes never existed. By my count, there are 30 total. Twenty-nine on the Port side and one on the Starboard side. As of this point, I have these all filled (hence, removed) and sanded. Regarding the portholes to “add”….there are a few of these that Trumpeter just missed altogether, but the majority are portholes that are there…just in the wrong place, and need to be moved, so to speak. Considering the scale, I have no idea how Graham determined the precise distance to which a porthole needs to be moved, but I can’t help but think a bit of educated guesswork was involved with that. Regardless, I do not intend to do any of these. By my count there are 55 (+/-) of them. I figure the odds of me getting 55 new scratch portholes drilled perfectly in place are slim. There is bound to be at least one that would stick out like a red dot on a white cashmere sweater. Upon researching this build I’ve learned that building an accurate Titanic model is next to impossible. Apparently even the original builder’s models aren’t accurate. For that reason, I have decided to give myself some leeway in the accuracy department and moving/adding portholes is one of those sacrifices. Further, my skill level is limited. I’m just not willing to risk scarring an expensive kit with a procedure I don’t feel comfortable doing. I intend to make my 1/200 Titanic as accurate as I possibly can, within my skill set. This build is by no means intended to be a show model, or museum piece. It is very much solely for my own satisfaction. But I digress. Back to the reference material… Regarding the “hawseholes” (aka Hawser Port, Mooring Pipe or, as I know them, Fairlead) …. I will not be moving the foremost lead on either side of the bow. I’m fine with where they are. There are four more on the quarters (two either side) that Trumpeter missed. Those four need to be plotted. I do intend to do those. Regarding the single and double “safety bars”…..I will be attempting to apply these using styrene strips. Five single and five double, each side, for a total of 20. Prior to that attempt, however, I’m researching if there is any photo etch available for these portholes. That would be much easier, as the styrene pieces to cut will be quite tiny. Regarding the porthole sizes indicated…..these dimensions are the original sizes, in inches, reduced to 1/200 in millimeters. The mm sizes are not drill bit sizes. In fact, Trumpeter did not mold the portholes to 1/200 scale. They are all slightly smaller. Therefore, determining what size drill bits to use is ongoing. The distorted portholes….. Of the five distorted portholes (each side) to fill and re-drill, I’ve chosen an additional four (each side) that I think are distorted enough to warrant this fix as well. I believe the two aftermost portholes on the top row (bottom row in this pic, both sides) will be covered by the stern plating kit. I’ll hold off drilling those ones until after the plating has been applied. I’ve measured where they should go…. The four missing stern portholes….. I suppose Trumpeter didn’t even bother with these as they likely would not have shown on the mold at all, given their location. Plotted and ready for the drill. I have not decided which drill bit to go with on these yet. The first porthole drilled and first porthole “glass” dry fit. Starting with the lowest row, and consequently, the smallest. With the porthole “glass” aftermarket kit, and using my handy-dandy home made drill bit gauge I can take most of the guesswork out of which size to go with. For these portholes (0.031” aftermarket “glass”) I’ve decided on the 0.8mm Wowstick bit. Note to self: Styrene doesn't drill so well with the larger bits. That's it for now. Got me some drilling to do. Until next time, thanks for looking, and suggestions are welcome. Cheers, Mark

-

MisterMeester reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

MisterMeester reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

-

Guaranteed when I built this model 50+ years ago I did not fill gaps, and sand mold lines and join seams. I would have thrown it together, painted it and that's it. 100% certain, as well, that I used the novelty glow-in-the-dark parts. Not this time. I think I'm beyond that. Going with the conventional head, etc. Who knew a model such as this would have complications? As I am still very early in my scale modeling resurgence, I do not have an extensive repertoire of models worked on to compare this one to, but it would appear that, as models go, it's relatively cheap. And with that, comes lots of fit issues, gaps to fill, and mold lines and join seams to sand. A few pics of some work done so far.... Tamiya White Putty used here. Mr. Surfacer 1000 used here after sanding down the white. Done. Three big gaps were here, right shoe meeting with the right leg. My close up pic has revealed I'm not quite done sanding this down. The right hand comes in two parts. The left hand is all one. As with the torso, Tamiya White and Mr. Surfacer 1000. The Phantom's teeth were less than perfect. Unfortunately, I forgot to take a pic of them before I began chiseling bigger gaps between them. This pic is more or less mid-way through my work. Not a good pic. Out of focus and hard to get a sense of how they started out. Teeth done. I did just the top row. Looking forward to how they'll look when painted. This was inevitable. Sanding the join seam of the head also removed some hair striations. Hair striations chiseled back in. I hope I sanded the seam enough and primer/paint will hide it. My next dilemma is this..... The Phantom's cape covers most of the join seams on the shoulders, but not all. Some of the lapel is exposed toward the collar. The challenge here is, the lapel has an orange peel texture. Sanding the join seams will inevitably smooth a portion of that. Researching what I can do to restore that, I've learned that Mr. Surfacer 500 is a potential solution. Just brush it on and then dab it with the bristles of a brush (or, I'm thinking perhaps foam would work well). I figure if the resultant texture doesn't match, then I would mask the lapel off and do the whole lapel. I'll be checking my local hobby store for Mr. Surfacer 500 tomorrow, but I'm not holding my breath that they'll have it. I expect to have to order it online. Note to self: Do a test of this on a piece of styrene first. In the meantime, I guess I'll get back to sanding. Thanks for looking. Suggestions are welcome. Cheers, Mark

-

MisterMeester reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

MisterMeester reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

MisterMeester reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

MisterMeester reacted to a post in a topic:

The Mayflower by Knocklouder - Amati - 1:60

-

Time for an Update. Things are ramping up. Most items ordered have arrived. Just waiting for four more upgrade kits from two different suppliers, none of which have shipped yet. Not in a rush for those, however. Just a bit never-racking as they were all ordered quite sometime ago. Anyway, a summary on what I have received, thus far.... Bulkhead/Framing kit already mentioned above. I've not gotten any further with that yet than the dry fit. A few more items for reference... Went with the KA detail kit, (vs Pontos). Most reviews favor this kit. "More bang for your buck", I heard a few times. Some suggest both kits, as Pontos has items this kit does not (and vice versa). This kit actually cost me more than the Trumpeter model kit itself, so I think I'll leave the Pontos on the shelf. Interestingly, one review said the KA kit is for advanced modelers and the Pontos is better suited to the newbie. Another reviewer said the exact opposite. I guess I'll never know for sure without the Pontos kit. Purchased the Stern Plating kit from The Midwest Model Shop. A portholes/windows detail kit purchased through "Trumpeter Titanic 1/200th model ONLY building tips and tricks" Facebook group. The distorted portholes at the stern (both sides) identified for filling. Distortion is the result of the mold process. To be drilled out again, later, to make them correct round. Longitudinal view of the port side, with more portholes to be filled. These portholes don't exist. Source of this information is from the aforementioned FB group. I messaged the "author" of that info, for permission to post some of those images here, but never heard back. Anyway, including the distorted portholes, there are 47 to fill and sand. There are another 55 +/- portholes that are out of place and, for accuracy sake, should be filled and moved. I'm not brave enough to go that far. I figure the chances of me drilling 55 new portholes and get all 55 exactly aligned correctly are pretty slim. Unfortunately, the vast majority of the porthole and hull errors and corrections are on the port side. The side of the model I want to display. The starboard side has only a few errors. Fingers crossed that any mistakes I make are few and minor. Just a closer example image of some of the portholes filled. I used Milliput Superfine White. Image showing the distorted portholes, both sides, filled. And so begins the sanding. 240 grit stick. A finished porthole. Followed the 240 stick with a 400 grit stick. It went better than expected. I was concerned with botching up that rivet line. Anyway, 20 more portholes still to sand. Thanks for looking, Suggestions are welcome. Cheers, Mark

-

Haha! Yes! Hague, (The). I called it that too, for the first few years that we lived here. Just 22 minutes to the North (I'm actually in Warman also). Thanks for the offer of help. Two newbies heads are likely better than one! Cheers, Mark

-

MisterMeester reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

MisterMeester reacted to a post in a topic:

Phantom of the Opera by MisterMeester - Atlantis - 1/8

-

I did a dry fit, last night, of an aftermarket frame kit I bought off eBay. It's about 2mm too long, longitudinally. Me thinks it will fit better once I clean it up. If not, will have to modify it a bit. Once that is done, I'll get a better idea of how the fit will be with the midship section of C Deck.

-

Well, with reluctance, I’ve decided to post a build log on this basic kit. For me, the operative word being basic. I purchased this model on impulse two years ago on an opportunistic basis for one reason. Nostalgia. I had it, and a few of the other Aurora Monster Models, 50+ years ago. But since purchasing it, and recently building my Academy 1/400 RMS Titanic, it has taken on a new purpose. That being to help learn entry level scale modeling skills, which will, no doubt, be necessary to improve on for my Trumpeter 1/200 RMS Titanic build. I looked at starting a build log for this kit on another community board, but that board was somewhat frustrating in that the engine that drove it seemed slow and clunky, annoying pop-up ads, 3rd party photo hosting, and it was unclear on exactly what a build thread on that site is. For me, posting a build log is not showing off. I’m fully aware, in the short time I’ve been here, that the talent on this board is immense. How could I possibly be showing off to that talent with such a basic kit? Contrary, this log is about receiving feedback on how I could, and can, do things better. Critique and suggestions are welcome. My wife and I watched the original Lon Chaney silent film a few nights ago, for reference and inspiration. Loved it. I’d seen “The Phantom of the Opera” many many years ago, but that must have been the Claude Rains version, as I know for sure it was not the Chaney film. First time I’ve watched that one. A couple of inaccuracies to point out: The Phantom (Erik) did not have long silver hair, as depicted in the box art. And, if there was any “prisoner”, it was not a guy behind bars. It was Christine, an opera understudy whom the Phantom was obsessed with. And so it begins….. This is as far as I've gotten. I have a bar clamp on order for the right leg. In my, thus far, short scale modeling career, I've become somewhat disappointed in THE hobby store in my locale. It's lacking a fair bit and I've had to resort to ordering online for quite a few items. I don't want to use rubber bands as I don't trust that I will be able to prevent those from coming into contact with the liquid cement. I think I did a pretty good job on sanding the left leg inseam, but..... ....sloppy work on the outer seam of the left leg. Particularly up near the belt line where those trouser folds are. The other pieces are on hold, for now. Awaiting the bar clamp, as mentioned, and also needle sand sticks for the arms on order too. My hobby shop didn't have those either. Me thinks the sleeve folds in the arms are going to make for some tricky sanding. Thanks for looking. Suggestions are welcome. Cheers, Mark

-

Thanks all. Hamilton...haha....yes...born and raised in BC! Moved to Sask in 2016. Wife has family here. To answer your question...seems Rider fans are generally neutral toward Lions fans here. It's more Winnipeg, Calgary and Edmonton they have an aversion to. But mostly Winnipeg. That's been my observation. Side note: the step son-in-law was born and raised here, but he's a Stamps fan. Says he could never cheer for the Riders. I've met a few like that. I think it has to do with them growing up with a team that was generally very bad when they were kids. Anyhoo....build update.....not much to say. I've still be doing a fair bit of research and planning. I can finally say, however, that I have physically actually started as of tonight. Did some scraping of the mold nubs on the bottom of the hull. Very minimal, so far, but it's a start. I've ordered a underhull plating kit from Maritime Models, so I'm going to leave the seam line on the bottom to help assist with getting that aligned right. I also have the stern counter plating kit from Midwest Model Shop. That arrived a few days ago. Still not sure about the seam line for where that gets laid down. I'll probably sand it down. For sure the seam line on the upper aft stern will get sanded, but not until after I plot the four missing portholes that go there. Next up will be marking the hull for the many corrections identified on the Port side, as well as plotting which portholes get filled, which get drilled and which don't. I'm still not planning on using the LED set, but I have decided to drill the portholes anyway and go with a resin portholes/windows aftermarket kit. My original plan was to use a pencil on the portholes. That plan was based on a tip I came across on the "Trumpeter Titanic 1/200th Model Only Building Tips and Tricks" FB group (sheesh, that title is so long I still don't have it memorized). It's a cool way of simulating glass. Anyhoo, what changed my mind is the distorted portholes on the Port and Stbd Quarters. To fix those requires filling, then drilling. If I'd gone the pencil route, I would then need to back those portholes from the inside with styrene to "colour" them in. Problem with that is they would then be more recessed than all the other penciled in portholes that wouldn't have been drilled out. Hence, the decision to just drill them all and fit clear resin in each one, thus making it all uniform. The actual drilling won't happen until the aftermarket kit gets to me. I want to drill some test holes in styrene and then fit each of the different size resins so as to know the correct size drill bit to use for each of the various sizes. So, that's were it's at. More to come soon. Thanks for looking, Mark

-

I thought it's time to get my build log started, even though I haven't actually started the build yet. Soon. I've been quite busy with research, planning and start up. Essentially 50 years since I built scale models, so lots to do in preparing for this build. Start up is still in progress. Before anything else, I first off just want to put out a big thanks to Evan, aka Force9, for his very detailed and resources rich Titanic 1/200 build log. I’ve learned so much from his thread, before I even begin my Titanic, and I would have missed so much without this information. Thanks Evan. Okay. Some preliminary stuff.... This was my work station for my Academy 1/400 Titanic. All building, and the limited painting I did, was here. Not exactly conducive to the Trumpeter 1/200 version. My new workstation for the Trumpeter 1/200 Titanic. The pool table is being sequestered for a few years. That's fine. We didn't play much anyway. The son-in-law helped me carry the 4x8 plywood in yesterday. Originally purchased for the electrician to install the pool table light fixture. Stowed in the garage since. Spidey senses must have known there'd be a use for it again. The task lamp is the same one as with the small table. I just drilled a 1/2" hole in the plywood for it. Now it's interchangeable, as I will still be using the small work station. On the left, I put the binder together just yesterday and today. Some inspiration from Evan, again, on that, but I give myself credit as well for recognizing this need. Throughout my entire working career, I have always been about organization. It's half of it. Even as a Deckhand, organization was key. An organized and clean deck is a good working deck. Same goes for building models, I figure. The book on the right was recently purchased online and just arrived today. I'm optimistic this will be a valuable resource toward my build. A closer view of the "build binder". Not sure what else to call it. I'm an older salt, and thus somewhat old school. Digital pictures and screenshots are fine to a point. But, for the most part, I like the physical copy in my hand. Much (probably most) of what is in this binder are digital screenshots. Anyhow, lots going on with startup. My new Airbrush Station. The new airbrush kit just arrived today! And one more pic for now. One problem with the Spray Booth venting is insulating the gaps at the window. Been pondering this for days now (the Spray Booth arrived last week). Stuffing bubble wrap in the gaps proved to be a Mickey Mouse solution. Got the idea of foam in my head as a solution. Placed an order for some poly foam yesterday. It's coming from the US, however, so a solid resolution here might be awhile. Suggestions are welcome. Anyhoo, that's it for now. Lots more to come. I've ordered five after market kits for the model, none of which have arrived as yet. My first approach to the model itself will be addressing the hull. No brainer there, I suppose, but in particular, how to approach the hull inaccuracies and porthole inaccuracies. Regarding the portholes, I came across a tip on Gene Davis' FB page (the title of which is too lengthy to repeat) that I most likely will go with. I like it. I don't plan on using the LED lighting kit for my model and this tip appears to me to be a great option for the portholes for those modelers not doing the LEDs. Stay tuned. In the meantime....suggestions are welcome. Thanks for looking and cheers, Mark

-

Thanks Peter. Cheers, Mark

-

Dutch. My Grandfather was from The Hague. Not many of us here on this side of the pond. Cheers, Mark

-

Yes, Trumpeter.

-

And how 'bout those Canucks, eh?!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.